Abstract

The Indonesian roof tile manufacturing industry relies heavily on manual operations, specifically in transportation and inspection processes, which creates multiple issues, such as fatigue, injuries, human error, and reduced productivity. Various industries in the Indonesian industrial landscape have begun embracing a problem-solving approach known as the theory of inventive problem-solving (TRIZ) to mine solutions for industrial issues. Nevertheless, its application in the Indonesian roof tile manufacturing industry remains unaddressed. The study aims to solve manual handling issues in the roof tile manufacturing industry using TRIZ. Three observations were outlined from manual roof tile transportation and inspection, followed by the formulation of engineering contradictions (ECs). The ECs were linked with system parameters, which were used as indicators within the contradiction matrix to extract inventive principles as solution models for conceptual development. The concept included an automated system with a conveyor belt (#15: dynamics) for effective transportation, automated image capture (#28: mechanics substitution) for effective inspection, and a flipping conveyor (#25: self-service) to eliminate manual contact. Although the study addressed several issues stemming from manual operations, mechanical analysis, prototyping, and usability testing still require improvements.

1. Introduction

The Indonesian roof tile transportation industry remains a highly manual process involving operators carrying heavy stacks of tiles over their backs and shoulders [1,2]. If repeated for an extended duration, the action can develop musculoskeletal pain and disorders related to the shoulders, spine, and knees [1,3,4,5].

The manual handling of 350 to 400 pieces of roof tiles for eight hours a day exposes workers to minor and severe injury risks, such as hand and foot accidents [6]. The workers stay in complex postures (squatting or bending) during the process where clay is fed into the press machine for long durations (eight hours a day), specifically during the inspection process that involves sitting crossed-legged [7]. Furthermore, manual roof tile handling can increase the risk of product damage [1].

Rosida, Astuti, Widyaputra, Puspitasari, Seyanto, Hisjam, and Zakaria [1] emphasised the need to increase the roof tile transportation process productivity while reducing reliance on manual labour, such as introducing an automated transportation system. The system reduces manual and material handling activities while lowering the risk of occupational musculoskeletal disorders by minimising employee medical care fees (doctor visits, medication, and hospitalisations) [8,9].

The TRIZ, which is an abbreviation for “Theoria Resheneyva Isobretatelskehuh Zadach” in Russian and “Theory of Inventive Problem-Solving” in English, is a systematic problem-solving approach that could resolve the issues encountered by roof tile manufacturing companies. The TRIZ is a method for innovative problem-solving and forecasting based on logic and information [10]. Altshuller [11] described the method in the subsequent steps: identifying the issue, making comparisons and correlating the issue with general TRIZ issues, identifying a general TRIZ solution that solves the issue, and developing ideal solutions that address the issue.

Every element that has an impact on a system is a parameter in TRIZ. The system’s parameters are interdependent with one another. While some parameters positively influence others, some also negatively influence others. The parameters that negatively affect one another are in disagreement with one another. A 39 × 39 contradiction matrix (engineering parameters, ECs) is the foundation of TRIZ, which involves changing the system to increase ideality. The matrix suggests some principles from among 40 “Inventive Principles” after inserting improving and degrading parameters. The TRIZ method can be used to find a solution after interpreting these principles [12]. A list of 39 “engineering parameters” were identified after the documents were examined, which leads to contention (between improving features and worsening features). Table 1 lists 40 inventive principles for problem-solving that have been defined [11].

Table 1.

Engineering parameters and inventive principles of TRIZ [10].

The TRIZ is currently applied more frequently in Six Sigma processes, project management, risk management, and innovation initiatives. The method solves problems by analysing repeatability, predictability, and reliability through the study of problem and solution patterns [13]. The three underlying hypotheses of TRIZ, “contradictions”, state that any evolving system should resolve several contradictions that arise as a result of evolutionary trends, desires, or opportunities for system development. The TRIZ model of contradictions also adds a structured vision that connects characters and defines contradictions to those applying the model. The process occurs by expressing the contradiction on two levels: the “engineering contradiction”, which represents the opposition between two system evaluation parameters and the “physical contradiction”, which defines two states of the system action parameter that satisfy each conflicting objective [14].

Studies have examined the use of TRIZ in the development of construction techniques and technologies, such as [15] detailing the step-by-step TRIZ analysis of the development of formwork technology. The formwork patent examination is based on the 40 inventive principles where the top 5 that appeared most frequently were culled from an analysis of 176 Taiwanese patents from 1975 to 2005. The guiding principles include prior action, combining, segmentation, cushioning in advance, and mediator. The work provided several examples of each principle to illustrate how formwork technology has advanced. The contradiction matrix was employed to predict future development trends that identified the formwork engineering industry’s future innovation trends, which included the following creative principles: “Inversion, Segmentation, Property Transformation, Mechanical System Replacement, and Extraction”. Observably, TRIZ offers a methodical approach to technology research and analysis of construction technologies.

Figure 1 depicts a method developed by Akay, Demıray, and Kurt [12] for using TRIZ to address manual handling problems. The study emphasised that rather than focusing on a few particular issues, it was important to identify all factors that had an impact on people. In addition, how “Inventive Principles” are interpreted is crucial for applying TRIZ to manual handling issues. The proposed TRIZ methodology may prove to be an effective tool for reducing manual handling issues, according to the authors’ conclusion. Additionally, it can be used by engineers and workers who lack or have not yet acquired a thorough understanding of ergonomics and human factors.

Figure 1.

TRIZ methodology for solving human factors (adopted from [12]).

The TRIZ aids in identifying and codifying universal principles of creativity to make the creative process more predictable [16]. The TRIZ has been employed more frequently in various Indonesian industries and sectors, such as the food industry, healthcare industry, electronics industry, and transportation [17,18,19,20,21]. Several researchers have also successfully integrated the use of TRIZ tools with other methods, such as Kansei engineering, lean approach, environmentally conscious quality function deployment (ECQFD), and design thinking [17,18,20,22]. The TRIZ is a versatile, innovative method that has been used in manufacturing and production for continuous improvement [23] in numerous industries in Korea [24] and in education to enhance students’ and educators’ problem-solving skills [25].

The use of TRIZ has become increasingly popular in solving many industrial problems and has reached a maturity level in the TRIZ evolution stages [26]. The method has been utilised by companies such as Siemens, NASA (National Aeronautics and Space Administration), Procter and Gamble, General Motors, BMW (Bayerische Motoren Werke), Schneider Electric, Apple, Ford Motor Company, Motorola, and Xerox [27,28].

Kim and Cochran [29] addressed the TRIZ method for axiomatic design content. The TRIZ method was framed by Cavallucci and Weill [30] for use during the design process. The TRIZ method was used by Ming Kaan et al. [31] to address the issue of environmental protection during the product development process. The use of TRIZ was mentioned by Cavallucci et al. [32] as a way to incorporate creativity into the design process. The application of QFD and TRIZ together in product development was covered by Yamashina et al. [33]. Mann [34] also covered the application of the TRIZ method in design using various examples. In order to enhance a manufacturing system, Stratton and Mann [35] combined the Theory of Constraints (TOC) and TRIZ. The application of TRIZ in engineering designs was discussed by Ishihama [36]. In order to simplify the product structure, Bariani et al. [37] combined TRIZ methods and “Design for Manufacture and Assembly” (DFMA) to decrease the number of parts. In an effort to replace metal parts with plastic ones, Cascini and Rissone [38] attempted to use product design tools with the TRIZ method; they were successful. The vibration, noise, and energy loss issues in hydraulic disc brake systems were resolved by Mao and Tseng [39] using the TRIZ method. In order to solve the issues that arise because of high pressure and temperature in the plastic materials of valve systems, Tsai et al. [40] used the TRIZ method. A computational design exploration technique called GA+TRIZ was introduced by Khodadadi and von Buelow [41]. It helps designers define the design problem precisely, create a parametric model with the right variables, find a number of workable solutions, and resolve any conflicts between competing design goals. A proposal for eco-innovation in renewable energy was made by Alvarez et al. [42] and is based on knowledge management, TRIZ methodology, and exergy analysis. Mansoor et al. [43] presented the potential TRIZ modelling approaches for issues relating to green roofs and showed how to use the TRIZ database of creative principles and ground-breaking solution approaches.

Even though the TRIZ method has been used by researchers and industry workers for decades, it has only been applied frequently to product development, which is actually insufficient. The TRIZ method is employed as a technique for solving technical issues, as has been observed in all studies conducted to date. However, there has not been any research on using the TRIZ method to address both technical and usability engineering issues in the literature. Moreover, TRIZ usage in the construction and building industry is still quite limited, and further research is needed, as concluded by Renev and Chechurin [44]. TRIZ method can be applied to every industry and every branch of service. Nonetheless, its use in addressing the manual issues in the Indonesian roof tile manufacturing industry, specifically in the transportation and inspection process, remains unknown. The study proposed a solution to the issues in the roof tile manufacturing industry using TRIZ with an emphasis on the roof tile transportation and inspection system.

2. Methods

A typical roof tile manufacturing system comprises multiple processes, including the mixing of raw materials, forming or shaping process, pressing, incineration, and inspection [45]. The study highlighted the transportation and inspection process after the incineration. The qualitative method and direct observations were adopted in the study. The primary observations within the transportation and inspection processes were identified based on relevant past studies, including (a) the entire roof tile transportation system is manual [1]; (b) the entire roof tile inspection system is manual [1,46,47]; (c) the operators can manually handle and touch the tiles during the inspection [7].

Relevant research questions (RQs) were formulated based on the aforementioned observations as follows:

- RQ1: How can TRIZ be used to resolve the manual labour contradictions in the transportation and inspection process of the Indonesian roof tile manufacturing industry?

- RQ2: What are the inventive steps of the solution used to address the manual issues in the roof tile transportation and inspection process?

The methodology chosen to be included first in the newly proposed solution is TRIZ, based on the direct observation and formulation of the study hypothesis. Classical TRIZ involves the systematic analysis of patents and engineering origin [48]. The classical TRIZ tools used in the study were the engineering contradiction, system parameters, matrix of contradiction, and 40 inventive principles (the solution models to the proposed ideas).

Problem formulation, contradictions, and inventive principles are the most critical and useful tools for novel idea development, which direct the search for solutions with the greatest possibility of success in replacement of traditional trial and error methodologies. The Problem Formulation was performed with a cause-and-effect graph to identify contradictions. A crucial aspect of TRIZ is overcoming contradictions without making compromises. The Contradiction Table is a 39 x 39 matrix of engineering parameters that identifies at least one of 40 Inventive Principles to solve an identified contradiction. The engineering contraindications perform best in conjunction with the inventive principles as they are general principles for solving technical issues.

2.1. RQ1: TRIZ in Resolving Manual Labour Contradictions

2.1.1. Engineering Contradictions

Several engineering contradictions (ECs) can be formulated using the “if-then-but” method based on the major observations on the issues in regular roof tile transportation and inspection systems. The technique involves using the observations as the manipulative variable (under “if”), the positive aspect from the observations as the improving variable (under “then”), and the negative aspect from the observations as the worsening variable (under “but”) [49,50]. Three ECs were formulated based on the observations:

- EC1: If the entire roof tile transportation system is done manually, then transporting the tiles becomes straightforward and less complex but human intervention is constantly required.

- EC2: If the entire inspection system is done manually, then inspecting the tiles becomes straightforward and less complex, but it is challenging to detect all defects manually.

- EC3: If the operator is allowed to handle the tiles during the inspection manually, then it is easy for the operator to inspect both sides of the tiles manually, but there will also be a risk of human-induced defects or damages to the tiles.

2.1.2. System Parameters

A parameter or system parameter in TRIZ refers to any factor that defines a system, determines (or limits) a system’s performance, or describes the system’s characteristics. A system parameter takes the perspective of the function instead of the system components [50]. The subsequent step in the TRIZ approach involves parameterising the contradictions before resolving them [51]. The improving and worsening variables (under “then” and “but”) were linked with the 39 standardised system parameters of TRIZ [52].

Table 2 presents the linkage between the ECs and the system parameters. Notably, EC1 was linked with device complexity (#36) for the improving variable and the extent of automation (#38) for the worsening variable. The EC2 was linked with device complexity (#36) for the improving variable and difficulty detecting (#37) for the worsening variable. Finally, EC3 was linked with ease of operation (#33) for the improving variable and object-affected harmful factor (#30) for the worsening variable.

Table 2.

Linkages between engineering contradictions and the system parameters.

2.1.3. Contradiction Matrix

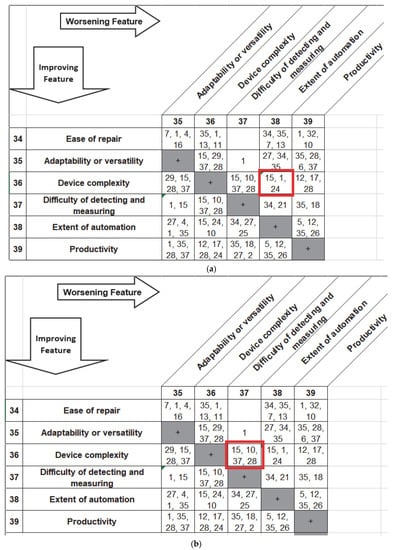

The contradiction matrix is an arrangement of 39 improving parameters and 39 worsening parameters (a 39 by 39 matrix), with every cell entry providing the most frequently applied inventive principles to resolve or eliminate the EC [53]. In this step, the chosen parameters for each EC from the previous section were cross-linked within the matrix to identify a set of inventive principles.

The inventive principles are a set of rules proven to be effective in numerous applications and represent models of powerful, generic solutions [54]. Out of all the inventive principles extracted from the contradiction matrix, the most suitable principle was selected to resolve the EC. Figure 2 illustrates the process of extracting the inventive principles within the contradiction matrix based on the system parameters for all ECs. The intersected cell between the system parameters contains the inventive principles (indicated within the red box within each figure). Table 3 demonstrates the inventive principles extracted from the contradiction matrix for each EC.

Figure 2.

Segments of contradiction matrix where inventive principles are extracted according to identified system parameters. (a) Extracting inventive principles with system parameters #36 and #38; (b) Extracting inventive principles with system parameters #36 and #37; (c) Extracting inventive principles with system parameters #33 and #30.

Table 3.

Inventive principles extracted from the contradiction matrix to potentially resolve contradictions.

The EC1 was resolved by extracting the principles of dynamics (#15), segmentation (#1), and intermediary (#24). The EC2 was resolved by extracting the principles of dynamics (#15), preliminary action (#10), thermal expansion (#37), and mechanics substitution (#28). Lastly, EC3 was resolved by extracting the principles of taking out (#2), self-service (#25), mechanics substitution (#28), and inert atmosphere (#35). The inventive principles function as solution models in proposing the best solution or idea to resolve the ECs.

3. Results and Discussion

Regarding EC1 (Solution—conveyor belt system), the parameter of conflict included the extent of automation. The automation level in the system is considered significantly low due to manual handling when transporting the roof tiles. The dynamics principle (#15) was the most suitable for resolving EC as the principle involves the conversion of an object (or process) from a more rigid or inflexible mode to a more movable or adaptive system [49,50]. One of the ideas proposed in the principle includes the use of a conveyor belt system.

Conveyor belt systems have been employed in multiple production industries for the transportation of goods, including the marble industry, food industry (sushi restaurants), mining industry, and the airport industry (baggage handling systems) [55,56,57,58]. Conveyor belt systems have also been incorporated into roof tile production systems in other countries [59,60]. A conveyor belt system can eliminate or minimise the need for human intervention in the manual handling of roof tiles, thus preventing potential injuries and long-term musculoskeletal disorders.

For EC2 (automated image capture system as the solution), the parameter of conflict included the difficulty in detecting or inspecting a specific condition. Due to the manual inspection process, operators encountered complexity in detecting all defects without mistakes. The manual process could also be tiring and frustrating for the workers. The mechanics’ substitution was the most suited for resolving the EC as it involves replacing a mechanical means with a sensory (optical, acoustic, taste, or smell) means [49,50]. An automated image capture system would be appropriate for resolving this EC based on the principle.

Automated image capture systems have been utilised on different scales in various industries to detect surface defects, including the automotive industry (detecting defects on automotive coatings), the fruit processing industry (detecting defects on apples), and the textile industry (detecting raw silk defects) [61,62,63]. Hence, the use of an automated image capture system in roof tile inspections could potentially minimise the number of defects from human error and reduce worker fatigue and frustration.

For EC3 (flipping conveyor system as the solution), the parameter of conflict included the object-affected harmful factor. The operators are required to manually flip the tile to inspect for defects on both sides during the manual inspection process. The action introduces a risk of defects or damages to the tiles caused by manual handling or contamination. The self-service principle was the most appropriate for resolving EC3 as it requires the system to service itself by performing supplementary and auxiliary operations [49,50].

The conveyor system (used to resolve EC1) could be paired with an auxiliary function that flips the tile automatically during the inspection process. The mechanism within the conveyor system (flipping conveyor) can be applied to resolve EC3. Similar concepts have been employed in automatic parcel turning machines and numerous packaging industries [64,65,66]. Allowing the conveyor system to self-service the flipping activity for the inspection process will save more time and reduce risks of contamination, damage, and defects compared to the regular manual handling process.

In order to find the ECs among the design parameters, a designer should carefully examine a design problem to determine which parameters can be improved and which are degrading. In the TRIZ literature, the parameters that need to be improved are referred to as Useful Functions (UF), while the parameters that deteriorate are referred to as Harmful Functions (HF). It is important to note that the term “function” in this field implies an aspect of the intended result that may be desirable (UF) or undesirable (UD) (HF). The designer can then consult the matrix of contradiction, where the 39 parameters that need to be improved are listed along the rows and columns, respectively, and those that are getting worse are listed along the bottom (see Figure 2).

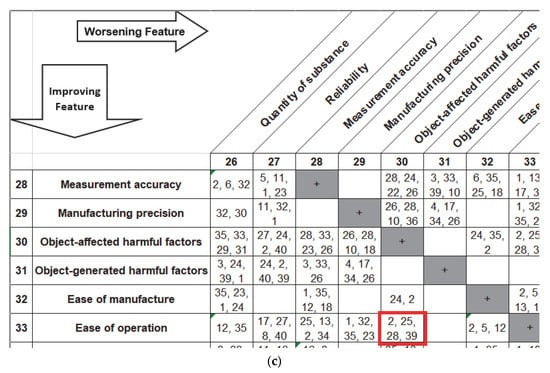

3.1. Proposed Concept

Figure 3 depicts the process flow diagram for the new roof tile transportation and inspection system. The novelty in the proposed system is observed in several processes, namely the transportation, inspection, and flip processes.

Figure 3.

Process flow diagram on new roof tile transportation and inspection system.

3.2. RQ2: Inventive Steps of the Solution

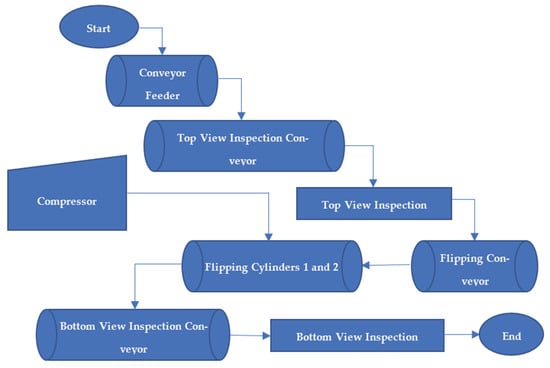

3.2.1. First Inventive Step: Conveyor-Based Transportation and Inspection Process

The critical stage of the transportation process occurs from the incinerator stage (at the start of the process flow diagram) to the stage where the product is ready to be packaged and inspected. Conveyors are needed to transport the tiles, which are divided into four units: conveyor 1 (feeder conveyor), conveyor 2 (top view inspection conveyor), conveyor 3 (flipping conveyor), and conveyor 4 (bottom view inspection conveyor). Conveyor 1 transports the tiles from the incinerator to the top view inspection process (#15: dynamics). Conveyor 2 facilitates the crucial inspections on the top side of the roof tile (#28: mechanics substitution). Conveyor 3 aids the flipping of the roof tile position from top view to bottom view (#25: self-service). Lastly, conveyor 4 assists in the critical inspections on the bottom side of the roof tile (#28: mechanics substitution). The lists below include the instruments needed for the conveyor design:

Conveyor 1 (feeder conveyor) is connected with:

- A three-phase motor as a means of driving the feeder conveyor;

- An inverter as a tool to change the direction of motor motion;

- A reverse button as a manual sensor to turn on the reverse motor conveyor with auto manual mode;

- A forward button as a manual sensor to turn on the forward motor conveyor with auto manual mode;

- A stop button as a manual sensor to turn off the conveyor;

- A Programmable Logic Controller (PLC) as an instrument to store the automation system.

Conveyor 2 (top view inspection conveyor) is linked with:

- A three-phase motor as a means of driving the top view inspection conveyor;

- An inverter as a tool to change the direction of motor motion;

- A reverse button as a manual sensor to turn on the reverse motor conveyor with auto manual mode;

- A forward button as a manual sensor to turn on the forward motor conveyor with auto manual mode;

- A stop button as a manual sensor to turn off the conveyor;

- A photoelectric sensor as a device that provides a signal to stop the conveyor at a critical time to take photos;

- A PLC as an instrument to store the automation system.

Conveyor 3 (flipping conveyor) is connected with:

- A three-phase motor as the flipping conveyor driving tool;

- An inverter as a tool to change the direction of motor motion;

- A reverse button as a manual sensor to turn on the reverse motor conveyor with auto manual mode;

- A forward button as a manual sensor to turn on the forward motor conveyor with auto manual mode;

- A stop button as a manual sensor to turn off the conveyor;

- A photoelectric sensor as a device that provides a signal to stop the conveyor at a critical time to take photos;

- A PLC as an instrument to store the automation system.

Conveyor 4 (bottom view inspection conveyor) is linked with:

- A three-phase motor as a driving tool for the bottom view inspection conveyor;

- An inverter as a tool to change the direction of motor motion;

- A reverse button as a manual sensor to turn on the reverse motor conveyor with auto manual mode;

- A forward button as a manual sensor to turn on the forward motor conveyor with auto manual mode;

- A stop button as a manual sensor to turn off the conveyor;

- A photoelectric sensor as a device that provides a signal to stop the conveyor at a critical time when photos are taken;

- A PLC as an instrument to store the automation system.

3.2.2. Second Inventive Step: Flip Process

The flipping process is conducted to reverse the roof tile from the top view to the bottom view. The process is performed at the conveyor for the bottom view inspection, where a tool within the conveyor automatically pushes the tiles to engage the flipping process, which comprises the following instruments:

- Flipping cylinder 1 to push the roof tile;

- Flipping cylinder 2 to push the roof tile;

- A PLC as an instrument to save the program of the flipping conveyor automation system.

The instrument utilised for the process requires a compressor as an air supply to provide pressure to each flipping cylinder. Based on the preceding explanations, Figure 4 illustrates the complete process flow of the main functions and instruments employed for the new roof tile transportation and inspection process.

Figure 4.

Process flow of roof tile transportation and inspection system. (a) Process from start to A; (b) Process from A to end.

3.3. Potential Green and Carbon Consequences

The improvement in the roof tile transportation and inspection process mainly includes the use of automation. The use of automation positively and indirectly impacts minimising climate change. Automation enables a more flexible work model with reduced manual labour and working hours. Although a slight trade-off in productivity could occur, reducing working hours can lower greenhouse gas (GHG) emissions [67].

The industry could adopt a remote working model as the processes are automated. Given that the transport sector is a considerable emitter of carbon dioxide, a better strategy is needed to mitigate the impact of transportation emissions [68]. Remote working saves energy and minimises GHG emissions [69]. The automated system enables an IT-enabled remote working environment to deliver commuter GHG abatement [70].

The TRIZ component of the proposed methodology contributed to the design exploration process in different capacities. In the case of roof tile transportation and inspection systems, the TRIZ component assists in minimising climate change and enables a more flexible work model with reduced manual labour and working hours. It also helped to check and mitigate the impact of transportation emissions. The TRIZ matrix of ECs and Inventive Principles assisted in determining the appropriate inspection system with a better understanding of parameter dependencies and resolving tile transportation issues.

4. Conclusions

The study proposed a solution to the manual-related issues encountered by the Indonesian roof tile manufacturing industry using TRIZ with an emphasis on roof tile transportation and inspection system. Three ECs were formulated and linked with the system parameters of TRIZ based on major observations within the roof tile manufacturing industry. Several inventive principles were extracted to resolve each EC using the contradiction matrix.

The study was based on two RQs highlighting the roof tile transportation and inspection system using TRIZ. The RQ1 addressed how TRIZ can be used to resolve the manual labour contradictions in the transportation and inspection process of the Indonesian roof tile manufacturing industry, while RQ2 addressed the inventive steps of the solution used to overcome the manual issues in the roof tile transportation and inspection process. RQ1 was resolved by identifying the engineering contradictions using the “if-then-but” method, which linked the contradictions with system parameters and extracted the inventive principles from the contradiction matrix based on the system parameters. The RQ2 was resolved by applying the reasoning from the selected inventive principles to conceptualise solutions to each contradiction such that the solutions are novel and unobvious in technical effects.

The solutions included a conveyor belt system to resolve EC1 (#15: dynamics), an automated image capture system to resolve EC2 (#28: mechanics substitution), and a flipping conveyor system to resolve EC3 (#25: self-service). The study demonstrated and discussed the proposed concept of the automated system and its instruments. Apart from reducing human errors, fatigue, and frustrations among workers, the improved system exhibits the potential to enhance the productivity of the roof tile manufacturing process.

Directions for Future Research

Although the prototyping and usability testing of the concept was not included, the current study will extend and explore the phase in another study, considering the importance of pursuing the transition of the proposed concept to the mechanical design analysis, prototyping, and testing stages. In the mechanical design analysis stage, performing the finalised detailed design, stress analysis, and simulations is vital. The prototyping stage should include decisions on the methods used to prototype the design. For instance, future studies should determine the appropriateness of traditional manufacturing, additive manufacturing, or rapid prototyping methods for the project. Finally, future research should opt to administer the design of experiments to test the effectiveness of the prototype compared to the manual method.

Author Contributions

Conceptualisation, P.K.N., M.D.P., K.W.L., B.K.L., A.O., S.A.S. and Y.N.S.; Data curation, M.D.P.; Formal analysis, P.K.N. and M.D.P.; Funding acquisition, P.K.N., M.D.P. and K.W.L.; Investigation, P.K.N., M.D.P., K.W.L., B.K.L., A.O., S.A.S. and Y.N.S.; Methodology, P.K.N., M.D.P., K.W.L., B.K.L., A.O., S.A.S. and Y.N.S.; Project administration, P.K.N., M.D.P., K.W.L. and B.K.L.; Resources, P.K.N.; Visualization, P.K.N., M.D.P., K.W.L. and B.K.L.; Writing—original draft, P.K.N., K.W.L. and B.K.L.; Writing—review & editing, P.K.N., M.D.P., K.W.L. and B.K.L. All authors have read and agreed to the published version of the manuscript.

Funding

The research project and APC were funded by the MMU-Tel U Joint Research Grant (grant number MMU/RMC-PL/TELKOM/AL2021/037 and Project SAP ID MMUE/210069).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The study was part of a collaborative project between researchers from Multimedia University (MMU) Malaysia and Telkom University Indonesia. The researchers would like to thank relevant members of the Faculty of Engineering and Technology, MMU, and Telkom University for their assistance in the study. Special thanks go to the Research Management Centres of both MMU and Telkom University for introducing this collaborative opportunity to the researchers and assisting in the facilitation of the project and funding. Lastly, the authors are exceptionally grateful to Chiew Fen Ng for providing constructive criticism on the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rosida, A.W.; Astuti, D.P.; Widyaputra, F.A.A.; Puspitasari, W.; Seyanto, R.H.; Hisjam, M.; Zakaria, R. Proposed Design of Ergonomic Roof Tile Transportation Equipments in Bekonang Roof Tile Company. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management, Singapore, 7–11 March 2021; pp. 6827–6837. [Google Scholar]

- Prasetio, M.D.; Rifai, M.H.; Xavierullah, R.Y. Design of Defect Classification on Clay Tiles using Support Vector Machine (SVM). In Proceedings of the 6th International Conference on Interactive Digital Media, Bandung, Indonesia, 14–15 December 2020; pp. 1–6. [Google Scholar]

- Adarsh, K.; Anilendu, P.; Singh, J.K.; Ravindra Kumar, T.; Swagatika, J. An ergonomic intervention for manual load carrying on Indian farms. Int. J. Ind. Ergon. 2021, 83, 103126. [Google Scholar] [CrossRef]

- Dave, B.R.; Krishnan, A.; Rai, R.R.; Degulmadi, D.; Mayi, S. The Effect of Head Loading on Cervical Spine in Manual Laborers. Asian Spine J. 2021, 15, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Moradi, B.; Barakat, S. The Association of Manual Load Lifting Tasks with the Ergonomic Risk Factors of Musculoskeletal Disorders. J. Hum. Environ. Health Promot. 2020, 6, 183–187. [Google Scholar] [CrossRef]

- Sutjana, I.D.P. Working Accidents among Mill Operators in Small-sized Factories Manufacturing Home Roof Tiles in Pejaten and Nyitdah Villages, Tabanan Regency Indonesia. J. Occup. Health 2000, 42, 91–95. [Google Scholar] [CrossRef]

- Sutalaksana, I.Z.; Widyanti, A. Anthropometry approach in workplace redesign in Indonesian Sundanese roof tile industries. Int. J. Ind. Ergon. 2016, 53, 299–305. [Google Scholar] [CrossRef]

- Anasua, B. Costs of occupational musculoskeletal disorders (MSDs) in the United States. Int. J. Ind. Ergon. 2014, 44, 448–454. [Google Scholar] [CrossRef]

- Jongprasithporn, M.; Yodpijit, N.; Phaisanthanaphark, C.; Buranasing, Y.; Sittiwanchai, T. Effects of Industry 4.0 on Human Factors/Ergonomics Design in 21st Century. In Advances in Industrial Design; Di Bucchianico, G., Shin, C.S., Shim, S., Fukuda, S., Montagna, G., Carvalho, C., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 437–443. [Google Scholar]

- Coşkun, K.; Altun, C. Applicability of TRIZ to In-Situ Construction Techniques. In Proceedings of the 2nd International Conference on Construction and Project Management IPEDR, Singapore, 16–18 September 2011. [Google Scholar]

- Altshuller, G.S. Creativity as an Exact Science: The Theory of the Solution of Inventive Problems; Gordon and Breach Science Publishers: Amsterdam, The Netherlands, 1984. [Google Scholar]

- Akay, D.; Demıray, A.; Kurt, M. Collaborative tool for solving human factors problems in the manufacturing environment: The Theory of Inventive Problem Solving Technique (TRIZ) method. Int. J. Prod. Res. 2008, 46, 2913–2925. [Google Scholar] [CrossRef]

- Jeeradist, T.; Thawesaengskulthai, N.; Sangsuwan, T. Using TRIZ to enhance passengers’ perceptions of an airline’s image through service quality and safety. J. Air Transp. Manag. 2016, 53, 131–139. [Google Scholar] [CrossRef]

- Ben Moussa, F.Z.; Rasovska, I.; Dubois, S.; De Guio, R.; Benmoussa, R. Reviewing the use of the theory of inventive problem solving (TRIZ) in green supply chain problems. J. Clean. Prod. 2017, 142, 2677–2692. [Google Scholar] [CrossRef]

- Cheng, S.; Yu, W.; Wu, C.; Chiu, R. Analysis of construction inventive patents based on TRIZ. In Proceedings of the International Symposium on Automation and Robotics in Construction, ISARC, Tokyo, Japan, 3–5 October 2006; pp. 134–139. [Google Scholar]

- Mind Tools. TRIZ: A Powerful Methodology for Creative Problem Solving. Available online: https://www.mindtools.com/pages/article/newCT_92.htm (accessed on 9 April 2022).

- Indrawati, S.; Azzam, A.; Adrianto, E.; Miranda, S.; Prabaswari, A.D. Lean Concept Development in Fast Food Industry Using Integration of Six Sigma and TRIZ Method. IOP Conf. Ser. Mater. Sci. Eng. 2020, 722, 012044. [Google Scholar] [CrossRef]

- Kusumo, A.H.; Hartono, M.; Wahyudi, R.D. Product design with integration of Kansei engineering and TRIZ to promote sustainable tourism. AIP Conf. Proc. 2019, 2114, 060018. [Google Scholar] [CrossRef]

- Lestari, N.T.; Susmartini, S.; Herdiman, L. Redesign paediatric walker for children with spastic cerebral palsy using TRIZ Method. J. Phys. Conf. Ser. 2020, 1450, 012117. [Google Scholar] [CrossRef]

- Pradhila, M.F.; Suzianti, A.; Adinda, P.P. Designing Universitas Indonesia Molina EV Bus Dashboard Using ECQFD and TRIZ. IOP Conf. Ser. Earth Environ. Sci. 2018, 114, 012020. [Google Scholar] [CrossRef]

- Purnomo, H.; Kurnia, F. Ergonomic Student Laptop Desk Design Using the TRIZ Method. In Proceedings of the 2018 4th International Conference on Science and Technology (ICST), Yogyakarta, Indonesia, 7–8 August 2018; pp. 1–4. [Google Scholar]

- Da Silva, R.H.; Kaminski, P.C.; Armellini, F. Improving new product development innovation effectiveness by using problem solving tools during the conceptual development phase: Integrating Design Thinking and TRIZ. Creat. Innov. Manag. 2020, 29, 685–700. [Google Scholar] [CrossRef]

- Sojka, V.; Lepšík, P. Use of TRIZ, and TRIZ with Other Tools for Process Improvement: A Literature Review. Emerg. Sci. J. 2020, 4, 319–335. [Google Scholar] [CrossRef]

- Oh, D.-S.; Song, Y.-W.; Joo, J.-M.; Park, W.-B. How SK Hynix applies TRIZ to Industry Field Problems. Acta Tech. Napoc. 2020, 63, 117–124. [Google Scholar]

- Cahyono, E.A.B.; Artanto, D.; Arbiyanti, P.; Heliarko, G. Development of TRIZ based competency test material and its influence on improving problem solving skills. J. Phys. Conf. Ser. 2020, 1516, 012054. [Google Scholar] [CrossRef]

- Abramov, O.; Sobolev, S. Current Stage of TRIZ Evolution and Its Popularity. In Advances in Systematic Creativity: Creating and Managing Innovations; Chechurin, L., Collan, M., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–15. [Google Scholar]

- Integrated Consulting Group. Discover TRIZ—Inventive Problem Solving. Available online: https://www.integratedconsulting.eu/discover-triz-inventive-problem-solving/ (accessed on 9 April 2022).

- Souchkov, V. TRIZ in the World: History, Current Status, and Issues of Concern. Available online: http://www.xtriz.com/publications/ValeriSouchkov-TRIZ-in-the-World.htm (accessed on 9 April 2022).

- Kim, Y.S.; Cochran, D.S. Reviewing TRIZ from the perspective of Axiomatic Design. J. Eng. Des. 2000, 11, 79–94. [Google Scholar] [CrossRef]

- Cavallucci, D.; Weill, R.D. Integrating Altshuller’s development laws for technical systems into the design process. CIRP Ann. 2001, 50, 115–120. [Google Scholar] [CrossRef]

- Ming Kaan, L.; Lamvik, T.; Walsh, K.; Myklebust, O. Manufacturing a green service: Engaging the TRIZ model of innovation. IEEE Trans. Electron. Packag. Manuf. 2001, 24, 10–17. [Google Scholar] [CrossRef]

- Cavallucci, D.; Lutz, P.; Thiébaud, F. Methodology for bringing the intuitive design method’s framework into design activities. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 1303–1307. [Google Scholar] [CrossRef]

- Yamashina, H.; Ito, T.; Kawada, H. Innovative product development process by integrating QFD and TRIZ. Int. J. Prod. Res. 2002, 40, 1031–1050. [Google Scholar] [CrossRef]

- Mann, D.L. Better technology forecasting using systematic innovation methods. Technol. Forecast. Soc. Chang. 2003, 70, 779–795. [Google Scholar] [CrossRef]

- Stratton, R.; Mann, D. Systematic innovation and the underlying principles behind TRIZ and TOC. J. Mater. Process. Technol. 2003, 139, 120–126. [Google Scholar] [CrossRef]

- Ishihama, M. Training students on the TRIZ method using a patent database. Int. J. Technol. Manag. 2003, 25, 568–578. [Google Scholar] [CrossRef]

- Bariani, P.F.; Berti, G.A.; Lucchetta, G. A Combined DFMA and TRIZ approach to the simplification of product structure. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1023–1027. [Google Scholar] [CrossRef]

- Cascini, G.; Rissone, P. Plastics design: Integrating TRIZ creativity and semantic knowledge portals. J. Eng. Des. 2004, 15, 405–424. [Google Scholar] [CrossRef]

- Mao, Y.J.; Tseng, C.H. An innovative piston retractor for bicycle hydraulic disc braking systems. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 295–303. [Google Scholar] [CrossRef]

- Tsai, C.C.; Chang, C.Y.; Tseng, C.H. Optimal design of metal seated ball valve mechanism. Struct. Multidiscip. Optim. 2004, 26, 249–255. [Google Scholar] [CrossRef]

- Khodadadi, A.; von Buelow, P. Design exploration by using a genetic algorithm and the Theory of Inventive Problem Solving (TRIZ). Autom. Constr. 2022, 141, 104354. [Google Scholar] [CrossRef]

- Alvarez, J.C.; Hatakeyama, K.; Carvalho, M.; Marçal, R.C.; Inche, J.; de Melo, N. A model for renewable energy-based product innovation based on TRIZ methodology, exergy analysis and knowledge management: Case study. Energy Rep. 2022, 8, 1107–1114. [Google Scholar] [CrossRef]

- Mansoor, M.; Mariun, N.; AbdulWahab, N.I. Innovating problem solving for sustainable green roofs: Potential usage of TRIZ—Theory of inventive problem solving. Ecol. Eng. 2017, 99, 209–221. [Google Scholar] [CrossRef]

- Renev, I.A.; Chechurin, L.S. Application of TRIZ in Building Industry: Study of Current Situation. Procedia CIRP 2016, 39, 209–215. [Google Scholar] [CrossRef]

- Fragassa, C. Limits in Application of International Standards to Innovative Ceramic Solutions. Int. J. Qual. Res. 2015, 9, 279–298. [Google Scholar]

- Syafariani, R.F.; Hayati, E.N.; Muttasir, F.A. Information System of Roof Tiles Production and Distribution. IOP Conf. Ser. Mater. Sci. Eng. 2020, 879, 012025. [Google Scholar] [CrossRef]

- Prasetio, M.D.; Xavierullah, R.Y. An Approaching Machine Learning Model: Tile Inspection Case Study. Int. J. Innov. Enterp. Syst. 2020, 4, 12–22. [Google Scholar] [CrossRef]

- Terninko, J.; Zusman, A.; Zlotin, B. Systematic Innovation: An Introduction to TRIZ (Theory of Inventive Problem Solving); CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Yeoh, T.S. TRIZ: Systematic Innovation in Business and Management, 1st ed.; Firstfruits Publishing: Selangor, Malaysia, 2014. [Google Scholar]

- Yeoh, T.S.; Yeoh, T.J.; Song, C.L. TRIZ: Systematic Innovation in Manufacturing, 1st ed.; Firstfruits Publishing: Selangor, Malaysia, 2015. [Google Scholar]

- Ullah, A.M.M.S.; Sato, M.; Watanabe, M.; Rashid, M.M. Integrating CAD, TRIZ, and Customer Needs. Int. J. Autom. Technol. 2016, 10, 132–143. [Google Scholar] [CrossRef]

- Shahrin, S.; Rahman, K.A.A.A.; Kamarudin, K.M.; Me, R.C. Matching TRIZ 39 parameters to universal design principles (UDP). AIP Conf. Proc. 2021, 2339, 020020. [Google Scholar] [CrossRef]

- Childs, P.R.N. 3—Ideation. In Mechanical Design Engineering Handbook, 2nd ed.; Childs, P.R.N., Ed.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 75–144. [Google Scholar]

- Chrząszcz, J. TRIZ inventive principles and computer design. In Proceedings of the 21st Conference on Reconfigurable Ubiquitous Computing: Measurement Automation Monitoring, Szczecin, Poland, 12 October 2018; Volume 64, pp. 34–36. [Google Scholar]

- Alper Selver, M.; Akay, O.; Alim, F.; Bardakçı, S.; Ölmez, M. An automated industrial conveyor belt system using image processing and hierarchical clustering for classifying marble slabs. Robot. Comput.-Integr. Manuf. 2011, 27, 164–176. [Google Scholar] [CrossRef]

- Marx, D.J.L.; Calmeyer, J.E. A case study of an integrated conveyor belt model for the mining industry. In Proceedings of the 2004 IEEE AFRICON: 7th Africon Conference in Africa, Gaborone, Botswana, 15–17 September 2004; Volume 2, pp. 661–666. [Google Scholar]

- Ngai, E.W.T.; Suk, F.F.C.; Lo, S.Y.Y. Development of an RFID-based sushi management system: The case of a conveyor-belt sushi restaurant. Int. J. Prod. Econ. 2008, 112, 630–645. [Google Scholar] [CrossRef]

- Shehieb, W.; Sayed, H.A.; Akil, M.M.; Turkman, M.; Sarraj, M.A.; Mir, M. A smart system to minimize mishandled luggage at airports. In Proceedings of the 2016 International Conference on Progress in Informatics and Computing (PIC), Shanghai, China, 23–25 December 2016; pp. 154–158. [Google Scholar]

- Kolb, H.-J.; Wagner, J. Automatic Quality Control of Roofing Tiles. In Neural Networks: Artificial Intelligence and Industrial Applications; Kappen, B., Gielen, S., Eds.; Springer: London, UK, 1995; pp. 303–313. [Google Scholar]

- Okoronkwo, C.A.; Ezurike, O.B.; Igbokwe, J.O.; Oguoma, O.N. The Design, Construction and Computer–Aided Simulation of a Prototype Roofing Tile Machine. Int. Res. J. Eng. Technol. 2016, 3, 1–10. [Google Scholar]

- Lee, F.; Pourdeyhimi, B.; Adamsons, K. Analysis of Coatings Appearance and Surface Defects Using Digital Image Capture-Processing-Analysis System. In Service Life Prediction of Organic Coatings; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1999; Volume 722, pp. 207–232. [Google Scholar]

- Throop, J.A.; Aneshansley, D.J.; Anger, W.C.; Peterson, D.L. Quality evaluation of apples based on surface defects: Development of an automated inspection system. Postharvest Biol. Technol. 2005, 36, 281–290. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Chen, M.; He, Z.; Zuo, B. The obtainment and recognition of raw silk defects based on machine vision and image analysis. J. Text. Inst. 2016, 107, 316–326. [Google Scholar] [CrossRef]

- Aggarwal, I.; Faujdar, N.; Verma, S.; Khanna, P. Development of a smart flipping system. Int. Res. J. Eng. Technol. 2019, 6, 7669–7672. [Google Scholar]

- Mofidul, R.B.; Sabbir, M.S.H.; Podder, A.K.; Rahman, M.S. Design and Implementation of Remote Controlling and Monitoring System for Automatic PLC Based Packaging Industry. In Proceedings of the 2019 1st International Conference on Advances in Science, Engineering and Robotics Technology (ICASERT), Dhaka, Bangladesh, 3–5 May 2019; pp. 1–5. [Google Scholar]

- Tieyi, Z.; Zhenliang, H.; Xue, H. Automatic Postal Parcel Turning Machine Experimental System Design. In Proceedings of the 2nd International Conference on Electronic & Mechanical Engineering and Information Technology (EMEIT 2012), Shenyang, China, 7 September 2012; pp. 2313–2316. [Google Scholar]

- Rosnick, D. Reduced Work Hours as a Means of Slowing Climate Change, 1st ed.; Center for Economic and Policy Research: Washington, DC, USA, 2013. [Google Scholar]

- Nocera, S.; Tonin, S. A Joint Probability Density Function for Reducing the Uncertainty of Marginal Social Cost of Carbon Evaluation in Transport Planning. In Computer-Based Modelling and Optimization in Transportation; de Sousa, J.F., Rossi, R., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 113–126. [Google Scholar]

- Crow, D.; Millot, A. Working from Home Can Save Energy and Reduce Emissions. But How Much? Available online: https://www.iea.org/commentaries/working-from-home-can-save-energy-and-reduce-emissions-but-how-much (accessed on 6 June 2022).

- Sutton-Parker, J. Determining commuting greenhouse gas emissions abatement achieved by information technology enabled remote working. Procedia Comput. Sci. 2021, 191, 296–303. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).