Abstract

Timber construction is considered a main strategy towards a more sustainable built environment. Industrialized manufacturing methods have advanced the realization of multi-storey timber buildings generating enthusiasm about their implementation in urban areas, and the expectation of their further completion. These are still pilot projects, so there is a lack of specific literature and guidelines, including common understanding, standard procedures and holistic considerations. This paper aims to assess the current situation of design and construction processes of timber buildings in Austria, highlighting barriers and opportunities and formulating recommendations for its further adoption. The methodology used is based on an extended literature review and a qualitative analysis from expert interviews. Different disciplines were involved to approach the topic holistically. Interviews were recorded, transcribed and inductive coded within several iterative rounds. Excerpts were organized into codes, sub-codes and categories to identify and classify themes and patterns and build the case. The findings are structured into the categories of Acquisition, Design and Production and Assembly, and further identified as Barriers and Opportunities. Upon the analysis of results, a selective range of recommendations are formulated and summarized in a catalogue, serving as a guide for further research and actions to widespread the adoption of timber.

1. Introduction

The European Green Deal, together with the EU Taxonomy and the New European Bauhaus, is a set of policy initiatives of the European Commission with the overall goal of making Europe climate neutral by 2050 [1,2,3]. Emissions of greenhouse gases (GHG) must be reduced and their atmospheric concentration stabilized [4]. The decarbonisation of the construction sector is a main objective at national and international scale since it accounts for 40% of global energy use and its related emissions [5]. Due to recent building regulations, operational carbon emissions have been reduced. Operational carbon is defined as the emissions of carbon dioxide by heating, lighting, air conditioning and powering the building during its lifetime. Consequently, embodied carbon emissions coming from products manufacturing, transportations and construction phases have become a topic of great concern [6,7]. Three main strategies based on reduction, sequestration and storage can be implemented. Embodied carbon emissions can be significantly reduced by avoiding the production of carbon-intensive building materials such as cement and steel [8]. Its atmospheric removal can be supported by enhancing its natural sequestration in forests. The long-term storage of sequestered carbon is possible by using harvested biomass in large-scale [6,8]. The reduction in CO2 emissions using timber as main structural material can be up to 60%, varying according to different scenarios [9,10,11], since around 45% of the embodied carbon sequestered in a regular office building corresponds to the superstructure [7]. Further, the small climate benefit uses of timber should be avoided by eliminating promotions to burn wood, while supporting markets for products in their second life or those of lower grades [12]. Timber in construction has a long history in German-speaking countries but is largely confined to small-volume buildings, mainly because of highly restrictive ordinances regarding fire. Due to recent changes in Austrian building regulations, the non-combustibility requirement was partially dropped [13]. Through the ease of those regulations, advancements in engineered wood products (EWP) have been rapidly promoted. EWPs are manufactured by binding or fixing derivative wood products together to form composite materials [14]. Some new significant developments are laminated veneer lumber (LVL), glued laminated timber (Glulam), dowel laminated timber (DLT) and cross laminated timber (CLT) [15], the latter being the main material used in the construction of the tallest timber buildings worldwide, including The UBC Brock Commons (53 m) at the University of British Columbia, Canada [16], The HoHo (84 m) in Vienna, Austria [17] and The Mjøstårnet (85 m) in Brumunddal, Norway [18]. Their wide implementation is expected to arise due to their superior physical, environmental and economic properties compared to mineral-based building materials [19]. Its strength-to-weight ratio, lightness and workability allow the production of highly prefabricated elements in efficient and specialized factories away from weather detriments and under controlled conditions. The significant reduction in work on site minimizes the site management, the facilities, the skilled on-site workers, the accidents and the mistakes [20]. However, planning and building large volume timber constructions represents a great challenge for planning offices and construction companies with no previous knowledge and experience. Due to its multi-layer character, key technical requirements such as fire resistance, humidity protection and heat and sound isolation have an impact on the structural performance [21], and specific and in-depth knowledge about material properties and technical performance is necessary. Prefabrication also requires the integration of all disciplines with their required openings to avoid modifications on site later on [22]. Additionally, aspects about production processes, platforms and systems, transport requirements and on-site assembly techniques must be taken into account. This approach varies from traditional mineral constructions to processes and interdependencies not yet specifically defined, which leads to inefficient procedures with enormous impacts in costs, time, quality, and strains in the collaboration in terms of tension, stress and dissatisfaction.

Many studies have been run in order to test the technical properties of timber building elements and systems for multi-storey buildings [15,23,24], others to develop comparative surveys of buildings to investigate structural systems [25] and emerging architectural typologies [26], and others focused on manufacturing or automation [27,28]. Still, there is a research gap and a lack of literature about specific definition of design and construction processes with their enablers and hurdles. This research bridges this gap, focusing on multi-storey timber-based buildings of up to six storeys, according to the building classes stipulated in Austrian fire regulations [13]. The innovative contribution of this study relies on the investigation of their state-of-the art in Austria, analysing their specific design and construction processes, identifying barriers and opportunities to their widespread implementation, and formulating recommendations for their assessment. In the first section, the research design and methodical process are described. The second part examines the state-of-the art and research on design and production processes of multi-storey timber buildings based on the literature review. Next, the methodical approach of the collection and analysis of the data within the expert interviews are presented. Then, the findings are revealed and validated through triangulations. Based on this, recommendations to overcome the barriers identified making advantage of the highlighted opportunities are formulated. Finally, the results and the recommendations are discussed, and in the conclusion section, the content of the paper is summarised.

2. Materials and Methods

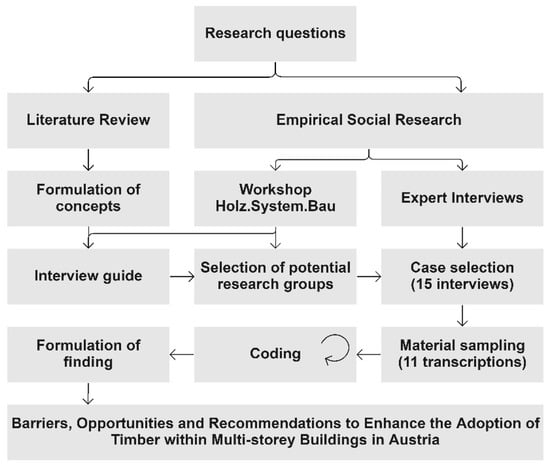

The methodological approach used in this paper builds new theories using multiple cases with emphasis on the relations of constructs supported by theoretical arguments [29]. First, the method addresses relevant research questions. Second, a case selection is performed through a purposeful sampling and expert’s interviews are run, as part of the empirical social research. Third, raw data are iteratively organized and grouped, forming abstract concepts or categories comparing theory and data and finding common patterns [30]. Fourth, relations between constructs are supported by theoretical arguments based on data, logic and prior research bringing validity and coherence, together with credibility and generalizability (Figure 1) [29]. In this way, the design and construction processes of multi-storey timber buildings are analysed and described in depth, filling the identified research gap. This analysis uncovers current constraints and opportunities affecting the implementation of timber in multi-storey buildings, providing new empirical knowledge and unlocking the development of strategies and recommendations.

Figure 1.

Research design and methodical process.

Based on the following main research questions, the theoretical framework of the research is assessed including theoretical, empirical and methodological literature [31] grounding the argumentations of the study and allowing to contextualize, compare and generalize the collected data (s. Literature Review):

- What are the reasons for the rather low market share of multi-storey timber buildings?

- Which actors can constrain or enable their implementation?

- Which are the weaknesses and strengths within design–production–construction processes?

- Which are the opportunities and strategies to support the further implementation of multi-storey timber buildings?

The next stage comprehends an empirical social research based on an expert workshop and semi-structured expert interviews, which construct subjective theories referred to the amount of knowledge and assumptions of the experts based on their systemized specialist knowledge and their practical and technical process oriented knowledge [29]. After analysing the collected data, findings were validated through a triangulation and the strategies and recommendations are defined.

3. Literature Review

Within this section, the analysis of the theoretical and empirical literature review regarding the state of the art of multi-storey timber constructions is presented. The term “multi-storey timber building” is found in the literature under a wide spectrum of variables. Within this paper, this term is referred to those buildings with more than two storeys where the load bearing structure is made of EWP. Due to humidity protection, the reinforcement of horizontal loads or fire regulations, multi-storey timber buildings often have a concrete basement, slabs or core, which forms a hybrid timber construction, an important variable considered in this study.

3.1. Historical and Technical Development of Multi-Storey Timber Buildings

Despite the known and valuable ecological and technical arguments for timber use in construction, the reasons behind its lack of widespread use can be explained by looking into the historical and technical development of multi-storey timber constructions. In densely forested regions, timber was predominantly used as construction material, and multi-storey timber buildings have been developed since antiquity. In Europe, timber constructions were mainly implemented due to architectural concepts that led to different systems in accordance with geographical conditions. While in the alpine region, a heavyweight system of logs and planks was widely used, in central Europe, timber-frame constructions were preferred [32]. Within the industrial revolution in the 19th century and the technical progresses that came with it, the use of steel started to increase to the detriment of timber. After the world wars, and due to the rising need for security in Europe, timber started to be replaced by mineral-based construction. In addition, extensive damages caused by fires in cities, such as the Great Fire of London in 1666, led the authorities to remove timber from buildings [33]. By the middle of the 20th century, timber as construction material was reduced in Europe to a market of lower and sometimes temporary buildings [34], and for roofs, ceilings or stairs, while concrete and steel became established [35]. It was not until the oil crises and the debate about environmental protection and the consumption of resources that the focus returned to timber due to its renewable and natural character [34,35]. Over the last 30 years, significant improvements have been achieved in terms of mechanical strength, innovative products and fasteners, high-performance materials and machine-supported prefabrication [35], which, together with the proven fire protection [36] and an improving legislative environment, have pushed timber constructions forwards [34].

3.2. Structural Systems, Components and Elements

Timber construction is a high-quality alternative to conventional construction if a good use of their specific properties is implemented. To exploit its ecological advantages with an efficient use of energy and resources, and its fast construction processes, an intelligent selection and combination of different structural systems is crucial what requires deep understanding of material properties, structural performances, and production and constructive processes [37]. Original timber building systems are based on cross-sectioned linear members such as beams, laths or planks [38], wherein the load-bearing axe corresponds to the fibre direction of the individual element [39]. Through the years, their combinations have led to planar elements, either through light construction methods or in solid components [38,39]. The first group consists of linear elements as DLT or logs, planar materials such as panels, and ribbed and box slabs, working structurally as a framework with a linear function. By the second group, the inhomogeneity and anisotropy of wood is minimised, and high-performance and easy calculable surfaces are allowed, englobing CLT and LVL, among others [38].

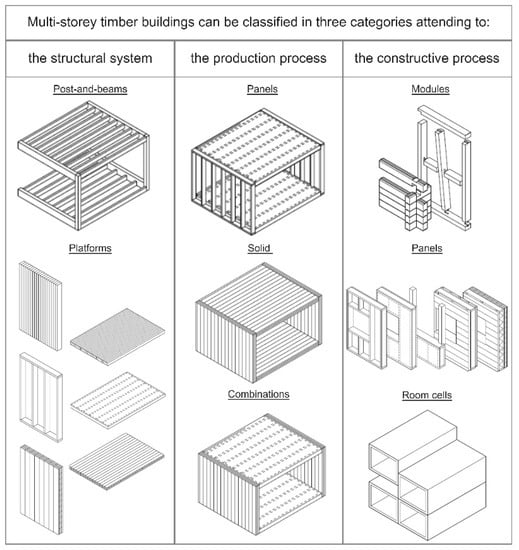

According to the recent literature, there exist three main categories for the definition and classification of multi-storey timber buildings (Figure 2). The first category attends to the structural system and differentiates post-and-beam systems, where their load-bearing structure is based on linear elements and separated of the enclosure, and platforms, with their planar load-bearing elements, including both panels and solid construction [38,40,41]. The second category attends to the production process and differentiates between panels, solid and combined systems. The first group corresponds to a structure formed by cross-sectioned linear members, the second to mass timber solid walls and ceilings, and the third to systems that combine both [38,40,41,42]. The third category corresponds to the constructive process, and differentiates between modules, panels, and room cells, wherein the first group is based on small units piled up together forming enclosing and load-bearing elements, the second on one-storey high elements, and the third on complete room modules [40,41,43]. Current practice combines different systems according to their specific properties what makes such a classification ambiguous [38]. The LifeCycle Tower One is an example of a successful combination of different systems. In this eight-storey office building in Dornbirn, a post-and-beam structural system was implemented with an assembled highly prefabricated non-load-bearing panel for the exterior walls, and a composite timber-concrete slab for the beam ceilings [44]. Ikea has also developed and patented a system for hotels, which combines manufactured and assembled room cells for bathrooms, and mass timber elements for walls and slabs, being efficiently transported and assembled [45].

Figure 2.

Three main categories for the classification of multi-storey timber buildings according to [38,41,43].

3.3. Design and Construction Processes in Timber Building

More planning effort and time is required compared to conventional mineral-based construction, since parameters related to fire safety, prefabrication, technical building equipment, building physics and structural systems have a direct impact on design and planning [37,39,46,47]. Early communication and transparency within the planning process are crucial for a common understanding and an integrated planning approach. This longer planning process is usually compensated with timesaving in the construction phase [48,49]. All timber systems aim for the highest level of prefabrication possible, so the construction process is shifted to the factory, and on-site work is reduced [50], being a prerequisite for economic efficiency and quality in timber construction [46,49,50], where requirements from the production of the components, to their joinery by the manufacturer and to their assembly on-site [39] influence preliminary design [47,48,49]. This higher detailing leads to a shift of services, which were revised and defined within the research project leanWOOD, and served for current adjustments of the building service specifications in Austria with a focus on prefabricated timber construction [51,52]. The traditional award and cooperation model extensively used in German-speaking countries is based on a separation of planning and construction, which makes price comparisons easy for clients, moderates effort in calculations for contracting companies, and ensures the fiduciary role of the architect towards the client [47,48,50]. However, it constrains the integration of specific expertise in early phases to optimize design, and the assessment of specific features of the construction company, which implies re-design phases [47,48,50,51]. Other models such as the general contractor, the so-called bowteams or functional tendering are preferred when designing multi-storey timber buildings [48,50]. A full-service general contractor is only found in large construction companies and englobe both planning and construction easing reliable cost and scheduling planning. However, the client loses their commissioned architect with its consultancy and general administrator function, and architectural aspects are subordinated to economic concerns [48]. Functional tenders award contracts with the construction company at earlier stages easing the development of optimized solutions with the planning team. However, economic optimisations from the execution companies can be made at the expense of the design and quality [48,50]. Bowteam models come from the Netherlands and consist of stating one single contractual relationship between the construction and the planning team, and the client in early phases with performance criteria [48]. Herein, construction companies can be awarded after concluding the planning if they ensure the project’s completion on schedule and budget; otherwise, they are compensated, and the client can obtain alternative tenders [48,50]. This model of including all planners is still in early phases of development, and legal adjustments must be still addressed [48]. Another possibility is found in Switzerland with the role of the consulting timber construction engineer, who can be commissioned by the design team and is responsible for structural, detailed, building physics and implementation planning [49,50,53]. Digital tools and processes ease the cooperation between design and production teams, wherein CAD (computer-aided design) design plans are transferred to construction companies for further optimization, adjustments and final production [46,48]. Herein, CAM (computer aided-manufacturing) planning is used, which eases the use of computer numerical control (CNC) machines. Aspects related to material consumption, structural dimensioning, element system and cuttings are throughout evaluated and optimized [48]. Further, assemble sequences, storage and transports are planned by the timber construction company, considering weather protection measures [46,49]. The close BIM (building information modelling) or lonely BIM is the most common way of transferring the data between design and production using compatible software, since open BIM models and libraries of structural components are not yet sufficiently developed leading to loss of information or unavailability to file exchanges [49,51]. Current developments aim to establish an integrated planning and manufacturing process, from design to machine control, accompanied by a BIM coordinator with extensive expertise in timber structures and the entire planning and production process [48].

3.4. Global Trends

In this section, global trends affecting overall construction industry are explored in order to identify threats and opportunities influencing the timber sector. According to a study from McKinsey, construction is the largest industry in the world and is characterized by intensive manual work, inefficient coordination, low annual productivity growth, insufficient quality and high customer dissatisfaction [54]. That leads to claims, and time and cost overruns, presenting low profitability despite high risks. Further, higher requirements can be predicted, in terms of complexity, affordability, sustainability, stricter work safety regulations, and higher level of customization and flexible structures. On the other hand, new materials, products and technologies will emerge in detriment to skilled labour workers towards digitalization, industrialization and modern methods of construction based on standardization and off-site construction [54,55]. The study from McKinsey [54] suggests that the construction sector is shifting from a project-based approach, where uniquely designed structures are worked out on site, towards a product-based construction process, where standardized sub-elements and building blocks are designed like functions and separately manufactured and combined with customization options and branding characters. Developers, manufactures and contractors will become specialized in end-user segments exploiting repetition and producing efficiently, where aspects related to the reduction in carbon emissions and the implementation of lightweight building materials within large prefabricated elements and modules will become fundamental. Digital technologies will enhance cooperation and provide a better control and integration of the value and supply chain, opening new business models and collaborative contracting. Additionally, automated parametric design with object libraries and automated production processes will align the overall system to other industries like shipbuilding or car manufacturing. This disruption implies great investments in technology and facilities such as manufacturing machinery and equipment, and in human resources [54].

Timber as less-carbon-intensive renewable raw material aligns to these trends attending to the impact of their extraction, production, use and deposit, and to its lightness what reduces the overall construction weight, meaning less foundation and less embodied carbon emissions, and what allows great workability in factories and on-site easing high levels of prefabrication within large elements with integrated functions. Additionally, timber is associated with comfort and confidence, becoming widely popular and appreciated for a more conscious and healthy future, where the branding of modern buildings based on ecological, healthy, natural and regional materials within optimized production processes align with a society that tends to promote more sustainable lifestyles [55]. Few timber companies have already implemented this approach, delivering transferable and customizable branded systems, as seen by LCT-One and by Ikea for hospitality [44,45].

4. Empirical Social Research

The main contribution of the empirical social research was achieved through expert interviews where several representatives from different professional domain were involved [29,56]. These interviews were organized and coordinated based on an expert workshop held previously where the main focus was to discuss the topic of timber use within mid-rise buildings, where some barriers were identified, key wins were explored, and long-term strategies were proposed [57]. The results reported within this expert workshop narrowed the questions for the survey supported by the concepts built through the literature review, leading to an interview guide with seven sections wherein common sections remained constant while specific ones were addressed to the target groups. Table 1 represents the sections of the interview guide and their associated topics. The interviews were conducted in person over a period of six months with an average duration of one hour depending on the time available, interest in the topic, willingness to cooperate and the level of knowledge of the interviewee. Interviews were recorded, transcribed and complemented with field notes. The subjectivity of researcher and participants becomes part of the process, and the validity is assessed by the triangulation with references to the case of study [29,58].

Table 1.

Structure of the interview guide.

4.1. Sampling

The selection of the right interviewees is based on a purposive sampling, wherein meaningful cases with the necessary knowledge and experience are selected. Decisions about the selection of the particular sample were met at two correlated stages, while collecting data and while interpreting data [59]. The interview partners covered all project stages and diverse professional backgrounds, including architectural design, engineering, building, management and consultation. The selection of several cases from each group allows comparison and triangulation and builds a representative sampling. Participants were recruited through a snowballing process, wherein main criteria were a wide experience in large volume timber constructions in Austria and extensive knowledge about design and construction processes. A balanced discipline share was ensured with a total amount of 15 interviewees. At the next stage, decisions about the selection of the interviews to be transcribed and analysed were met based on criteria such as (i) available knowledge and experience, (ii) capacity of reflexion, (iii) articulation, (iv) time availability and (v) willingness to cooperate [60], wherein 11 interviews were selected for an in depth analysis. As result, two main targeted groups were formed, namely design with six participants and production and assembly with five. Architects and timber engineers built the first group, with four and two participants. Constructors, manufacturers and advisors built the second group with two and three representatives. Table 2 represents the professional backgrounds of the selected interview partners.

Table 2.

Interview Partners constellation.

4.2. Coding and Categorizing

The analytical techniques and concrete process model, together with the analytical units, are defined within two successive processes, to firstly uncover and contextualize statements augmenting the material (Coding), and secondly to reduce the data by paraphrasing and summarizing (Categorizing). Coding units are referred to the smallest excerpt of the interviews that can be related to a concept and labelled into a category. Coding is the analytical process by which concepts are identified, iteratively conceptualized, contextualized and put back together, building new theories through a process of abstraction [61]. Categorizing is the summary of similar or related codes into generic concepts reducing the material and producing a uniform schema, which eases triangulation and the presentation of the findings. Codes are further defined through sub-codes that describe their content. Characters define the properties and dimensions of singular sub-codes. Therefore, single codes can be labelled into only one category but involve different characters according to their sub-codes. In the course of this stage of the study, the software MAXQDA was used as a supportive tool for coding and categorizing. A summary of all codes with their embedded sub-codes and their corresponding categories is represented in Table A1 located in the Appendix of this paper and described in detail in the following section.

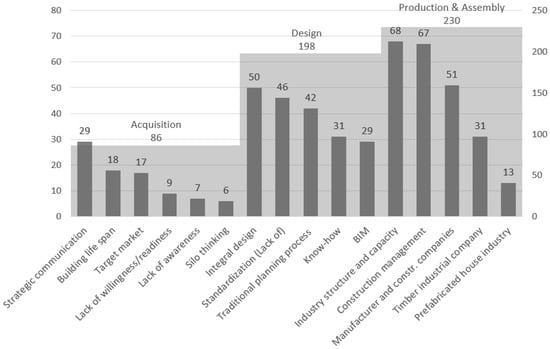

5. Findings

Within five rounds of coding, categorizing and characterizing, a total amount of 65 sub-codes were defined and embedded into 16 codes with 514 nominations and labelled into three categories (Acquisition, Design and Production and assembly) and referenced to two characters (Barriers and Opportunities). In the Acquisition stage, 6 codes were extracted with 22 sub-codes and a total amount of 86 nominations. Within the Design phase, 5 codes were identified with 23 sub-codes, and 198 mentions were accounted for. Finally, 5 codes with 20 sub-codes and 230 references were defined within the Production and assembly category. A summary of the codes are represented in Table 3, organised by categories and frequency of nomination (Nom.). Sub-codes are embedded into the related codes and explained in further sections in order to simplify the table.

Table 3.

Summary of results according to the frequency of nominations.

The frequency of nominations of the three categories (right y-axis) and their embedded codes (left y-axis) are represented in Figure 3, showing higher concerns in the production and assembly stage with almost half of the total nominations, followed by the design Stage, with around one-third of those, and concluding with the acquisition, stage with one-sixth.

Figure 3.

Frequency of nominations of all three categories (right y-axis) with their codes (left y-axis).

5.1. Acquisition Phase

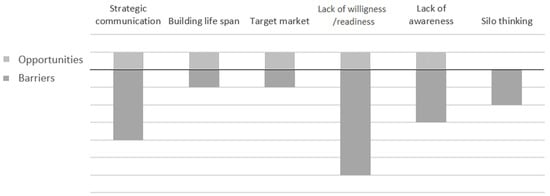

In this section, phenomena occurring within the acquisition or demand phase are presented, implying two main targeted groups, decision makers and society. An adequate strategic communication is urgently needed to overcome the prejudices and preconceptions commonly found in the sector and society, and to promote the use of timber by communicating its hard and soft benefits to decision makers and citizens. Unique high-rise projects gain attention, but more conventional mid-rise projects are needed to become standard. Their public documentation would enhance cooperation and openness, overcoming silo thinking and promoting new construction methods and building materials. The six codes allocated in this category with their embedded 22 sub-codes and their assigned character are represented in Table 4 and described in detail in the following subsections. Figure 4 shows the relation of barriers and opportunities corresponding to the sub-codes allocated in each code; three times more barriers than opportunities were identified. A lack of willingness and readiness englobe the greatest barriers, followed by a lack of strategic communication and a lack of awareness.

Table 4.

Summary of codes in category Acquisition with their embedded sub-codes and character according to their frequency of nomination.

Figure 4.

Relation of opportunities and barriers corresponding to the sub-codes allocated in each code of the category Acquisition.

5.1.1. Strategic Communication

Great concerns regarding the lack of strategic communication were reported, including not only the dissemination of economic long-term benefits of timber buildings, but also those related to systemized construction methods, such as the potential implementation of circular design, the optimization of planning and execution processes and the reduction in time and costs [21]. Quality and costs are key topics when starting a project, and there exist too little experience and knowledge. Although the number of timber buildings has increased in recent years, further reference and standard projects with their corresponding documentation are needed to obtain key data for the calculations and examples for planning. There exists an appreciable awareness about the ecological benefits of timber and about using sustainable and renewable materials within the sector and society that support the realisation of these buildings. Regarding to the costs, the unfeasibility of communicating unmeasurable benefits was identified, such as those related to more net floor area and lower overall building height due to thinner building elements, or long-term health benefits and well-being effects. Another barrier mentioned was the public image of fragile structure of the industry based on its fragmentation, the reduced number of qualified players, the lack of cooperation and the number of possible solutions due to own specific “in-house” developments. This lack of cohesion leads to no representatives in the politics nor association with influence on regulations or in the promotion for standardisation.

5.1.2. Building Life Span

Interviewees stated that there is a wide misconception about timber constructions being too rigid and constraining conversion of use, ground floor flexibility and creativity. Materiality should be in harmony with the construction, and not imposed, so well-thought solutions do not constrain creativity nor freedom. On the other side, the possibilities of deconstruction, dismantling and circular design are currently not sufficiently exploited, and it is an area where timber construction could assume a key position in prolonging carbon storage and saving primary resources.

5.1.3. Target Market

The current trend of realising unique projects in the form of high-rise buildings is a great promotion strategy that demonstrates their feasibility, but traditional heights are needed to meet the requirements of typical urban areas and promote their establishment within this sector. Zurich was mentioned as a role model due its higher concentration of mid-rise timber buildings. According to experts, timber should be implemented as a main structural material within mid-rise buildings with three to seven storeys above ground, based on the assumable level of complexity and the great relation cost/quality. Their right and complete planning was mentioned to be competence of architects and engineers with no specific specialization. In this context, the current training for these professionals was highly criticized by several interviewees.

5.1.4. Lack of Willingness and Readiness

In general, decision makers such as developers, contractors, builders and politicians lack knowledge and experience about building with timber. In contrast, there exists a wealth of experience, standards, knowledge and tradition regarding mineral building materials. Since the common approach is familiar, calculable and profitable, there is no willingness or readiness to shift towards timber construction, which is seen as too complex and too risky. Regarding complexity, concerns about humidity were mentioned as a notable aspect of attention, since it influences the conservation of the material, and the safety and durability of the construction. Although there is great awareness about the benefits of its use for the decarbonisation of the sector, which is seen through European initiatives promoting sustainable construction methods and building materials, a remarkable pressure within users and politics is not yet present, giving construction companies and developers little incentive to rethink their usual processes. Higher costs than in mineral constructions were also reported, together with high cost uncertainty before tendering. Low benefit margins and profitability based on the relation of execution costs and high land prices were reported, highlighting that timber as a raw material is more expensive than concrete, has execution costs that are not rentable, and shows profitability throughout the life cycle costs. Traditional lowest-price rules in tenders also work as barrier constraining the development of quality projects and the promotion of alternative designs with unconventional materials, according to the interviewees, leading to frustration and dissatisfaction.

5.1.5. Lack of Awareness

By society in general, there is a lack of awareness about the robustness of timber and its potential use in large constructions mainly based on prejudices and preconceptions, such as the assumption that timber is not suitable for multi-storey buildings due to a lack of adequate structural performance. Further, there exist concerns regarding its fast combustion and the possible collapse of a construction if timber is used as main structural material. Additionally, building with timber is considered more expensive than building with traditional mineral-based materials, based on the costs of the materials themselves, which, together with the combustion character, are commonly shared between citizens and key players of the sector. On the other side, there is a general trend to get back to nature, to the roots, and implement a logical and reasonable built atmosphere based on natural, renewable and bio-based construction materials.

5.1.6. Silo Thinking

The structure of Austrian timber construction companies is small, fragmented, scattered, and locally organized, and there exists no standardization within the planning or manufacturing of timber buildings. Each timber construction company has developed its own specific components and services for partial and detailed problems, remaining as their own “in-house” systems and solutions. There exists no willingness to cooperate and no trust about sharing the developments to foreign companies, and their fair use of their own specific details and platforms, which makes collaboration complicated. These specific systems imply different levels of prefabrication, interfaces, and suitable supply chains, production lines and platforms, with only a limited number of changes allowed, and making their adaptation to alien solutions impracticable. These “in-house” solutions and the lack of standardisation reinforce the perception of complexity of timber buildings and is a source of dismay for many players in the industry, which, for the sake of simplicity, decide to return to the mineral building method.

5.2. Design Phase

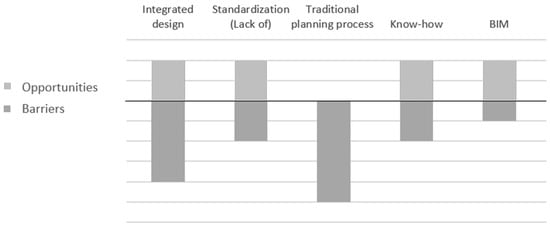

In this section, circumstances highlighted in the design phase are exposed within their five codes and the embedded 23 sub-codes that are represented in Table 5 and in Figure 5 and described in the following subsections. Within the design stage, the number of barriers represents twice the number of opportunities. The traditional planning process based on the structure of the Honorarordnung für Architekten und Ingenieure (HOAI)—Fee structures for Architects and Engineers is an enormous barrier that constrains the right design and definition of multi-storey timber buildings. Its material neutrality and linearity provoke negative iterations at the interface between design and production leading to mistakes, redesign and time and cost overruns. Earlier decisions and higher levels of definition are needed to succeed with prefabrication, wherein a design freeze must be settled with no execution-accompanying planning and no modifications on site that may lead to major delays or damages. This requires an integrated design approach, which still needs to be described in depth, is time-intensive and requires extended expertise that is rarely found in the sector due to a lack of specific academic and professional training. Further, the wide quantity of building elements and the lack of standardisation make the realisation of timber buildings complex and unattractive.

Table 5.

Summary of codes in category Design with their embedded sub-codes and character according to their frequency of nomination.

Figure 5.

Relation of opportunities and barriers corresponding to the sub-codes allocated in each code of the category Design.

5.2.1. Integrated Design

Several timber-specific parameters regarding structure, fire, acoustics, humidity, energy and prefabrication must be coordinated in the early design stages to enhance efficiency and prevent damages and unforeseen problems. Key decisions are to be taken sooner than in traditional mineral constructions, including technical building equipment and their interfaces, where a general lack of common understanding between involved players and their specific requirements is found leading to poor cooperation, misunderstanding and disruptions. A description of the design process and the roles of the team and their coordination is urgently needed, including work packages, internal and external communication, interfaces, interdependencies, responsibilities, input, output and resources in a context of time according to each project and team. Not working on updated documents, information loss, parallel and overlapping processes or an unneeded level of detail are common inefficient issues caused by this lack of coordination, wherein BIM was proposed as a supportive tool to overcome this (s. BIM). The model of the general planner was mentioned as suitable, together with the so-called developer competition, where timber construction companies and planners work together optimizing solutions. Further, the integration of the client is necessary to state goals, requirements and estimated budget, supporting a design to fixed costs. The inherent complexity of multi-storey timber buildings implies an effort- and time-intensive design process, with elevated resources that are not rewarded. Since early decisions imply lower costs but great influences, shortening the overall process, more effort should be invested in the planning. Due to prefabrication, a design freeze must be settled with no late key decisions, as it is within mineral-based buildings through a parallel planning during construction. Changes or late decisions mean great adjustments and reschedules with large impacts on overall logistics, costs and time through the supply chain with their delivery times and providers. Eventually, this also means higher risks of damages if modifications are executed on the field. Traditional tendering processes also work as a barrier for industrially produced constructions constraining the interaction between construction and design, wherein two types were described. A detailed and itemized list of execution specifications leads to a fair market but constrains the freedom of the companies to develop optimized solutions. A functional list of specifications with performance programmes and no detailed description of individual parts allows the early involvement of timber contractors and the chance to optimize solutions, being considered better for prefabricated buildings, but only recommended for less complex constructions. In this context, the experts highlighted the need of redefining tendering processes for industrially produced constructions, assessing the degree of freedom and responsibility for planners and contractors, providing concrete plans without defining all the details to avoid too much unneeded detail forward and too many adjustments backward.

5.2.2. Standardisation (Lack of)

The wide variety of different building elements and joints constrains comparisons and makes the sector less competitive. It is also impractical for planners who must reinvent details, which later on may not match the producible elements of the involved construction company. Due to this lack of standards, most building elements need to run technical proofs before and after tendering, regarding fire, acoustics and humidity along production, assembly and use, which makes the process inefficient and uneconomic. A systemized design and construction has been proposed to overcome these barriers, wherein standardized elements are adjusted and combined, allowing unconventional shapes and creativity under cost and time certainty, requiring no special joints or specific expertise on-site. Additionally, it could be a reactive system that responds to different categories regarding loads, building physics, and cladding, and allows customization related to solar shading, balconies and facades. By doing so, processes would be precisely described ensuring enough resources for the production of both standard system and customizable element. Ideally, building components would be produced by different companies, as in the prefabricated house and automotive industry or marketable–patented products. The intelligent mix of different systems would be advantageous by taking advantage of the specific properties of each one, which still needs to be explored and exploited within the sector.

5.2.3. Traditional Planning Process

The linearly structured planning process based on the awarded practices of the HOAI do not fit with systemized and prefabricated constructions. The separation of planning and execution restricts the inclusion of expertise of timber companies and specialists in the design process. If key parameters and data for an optimal use of resources are not considered or not accurately applied, it leads to re-design processes, which are not rewarded, accompanied by time and cost overruns. Herein, two types of re-design stages are discussed. On the one hand, there are usually a lack of timber-construction-oriented parameters in design regarding material properties and prefabrication requirements. The same occurs within the conversion of concrete oriented designed projects to timber constructions. Ideally, the decision of building with timber is defined at the beginning to conceive an optimized configuration. However, tender processes are material neutral with the purpose to ease fair market, wherein timber has a disadvantage. Due to this lack of knowledge about prefabricated timber construction processes, the execution plans at the interface between planners and timber contractors or experts are usually incomplete or inaccurate and need to be revised, adjusted and exchanged in cycles. On the other hand, at the interface between design and production, and based on the different “in-house”-developed solutions of the companies, there exists a re-design phase where all details need to be adjusted to the specific systems, platforms and supply chain of the involved companies, provoking time and cost overruns and great dissatisfaction and frustration. An earlier integration of timber expertise in the design stage was stated as solution based on three strategies, an experienced design team, which is rarely found in the sector, the acquisition of an independent timber specialist who supports the team through the processes, and the anticipated involvement of the timber construction company, either contractual or as advisor. Specific timber companies already offer consulting services to planners and developers to grow awareness and expand the use of timber, but often for the legitimate purpose of selling their own products. As role model, Switzerland was highlighted, where planners and construction companies plan together the solution, developing an optimal project, but with no fairness in the market.

5.2.4. Know-How

Architects and engineers do not usually have the required knowledge about timber constructions and their processes. Mineral-based rules lead to inefficient morphological configurations, not producible building elements or uneconomic transportations. Due to low demand, there are too few engineers specialized in timber, who are mainly booked by architects, but also plan mineral-based construction on a regular basis. Within this topic, the role of the Swiss timber engineer from Zurich was discussed as an example for integrated design, who covers several disciplines under a holistic view, namely building physics, structural design, fire resistance, construction properties and production processes. These were proposed for highly complex projects, and not for timber buildings between three and seven storeys, which should competent architects and engineers. To solve this discrepancy between existing and desired competence, several supportive tools and catalogues have been developed to help planners with the overwhelming repertoire of multi-layered solutions, offering a summary of proven building elements and realized projects [62,63,64,65]. Most of them have been produced by construction companies with the legitimate goal to promote their own products, being, therefore, not objective. Other independent and non-profit catalogues such as dataholz [66] have also been proposed, wherein their unfeasible amount of building elements and combinations was criticized. Recent developments allow solutions to be narrowed by selecting specific desired parameters regarding fire, acoustics and thermal behaviour. According to experts, further parameters related to structural dimensions and cost estimation, or desired quality and level of expertise of the designer, could be highly advantageous. This criticized lack of expertise within architects and engineers is caused by the missing specific academic and professional training, which is a result of the low demand of timber buildings according to the experts.

5.2.5. Building Information Modelling (BIM)

BIM was proposed as a support tool for the integrated design (s. integrated design), wherein several planning offices currently implement BIM processes reporting higher working hours and criticizing that the benefits mainly rely by construction companies and facility managers. As it occurs by integrated design, there is a need to describe BIM processes and define standards including boundaries and interfaces together with BIM levels and standards, level of detail, level of information and level of definition. The roles of BIM Managers and BIM Coordinators were discussed regarding their required expertise on multi-storey timber buildings to successfully assess the workflow, being rarely found in the sector. Further, discipline-specific software needs to be described, as it involves several interfaces and problems of compatibility and transferability. Above IFC (industry foundation classes) and open BIM, closed BIM was recommended to avoid information loss. Timber construction companies are BIM-capable, since CAD/CAM tools such as Cadwork [67], SEMA [68], Dietrich’s [69] and hsbcad [70] have been used for over 30 years, encompassing all the building information and delivering machine data for industrial production through CNC machines. Their interface to design is not yet solved though, working mainly through plans and models exchanges, where construction companies often have to rebuild the model. Additionally, the interfaces to building services were highlighted as especially complicated, since there exists a lack of BIM implementation and demand in the sector due to a lack of demand.

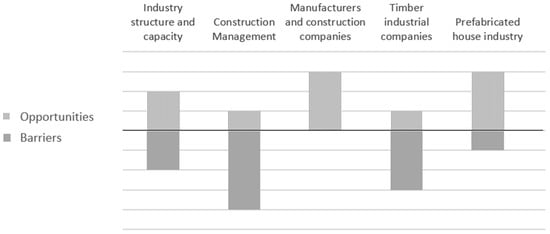

5.3. Production and Assembly Phase

Within their 5 codes and 20 sub-codes represented in Table 6, the phenomena occurring at the production and assembly stage are described in this section and visualized in Figure 6, where the number of barriers and opportunities identified are equal. Due to its lightness and workability, timber eases great levels of prefabrication, which, together with its ecological properties, makes its implementation remarkably attractive. The main goal of the sector is to shift all complex tasks to the factory, making the trades better coordinated, tasks efficiently monitored and elements highly prefabricated. However, with supplementary trades, the interface with concrete and the production of ceilings still need to be assessed. The expected and desired increase in demand in the upcoming years cannot be covered under current circumstances. Great investments in infrastructure and the development of innovative collaborative business models are required. Regarding players, on the one side, manufacturers and construction companies have great skills in production and construction processes, with remarkable expertise in digitalization, logistics and material properties. On the other side, CLT-industrial companies present low levels of standardization and prefabrication, creating conflicts in the interface to manufacturers, construction companies and design. On the contrary, the prefabricated house industry has highly standardized production processes, including logistics and a supply network delivering extensively prefabricated elements with high time and cost certainty.

Table 6.

Summary of codes in category Production and assembly with their embedded sub-codes and character according to their frequency of nomination.

Figure 6.

Relation of opportunities and barriers corresponding to the sub-codes allocated in each code of the category Production and Assembly.

5.3.1. Industry Structure and Capacity

Off-site construction may be one of the major advantages of timber construction, especially in urban areas where the disturbances to the neighbourhood are higher, in terms of noise, dust, space and traffic. The main goal of the sector is to shift the conventional, resource-intensive construction site towards an assembly field, leading to higher quality and efficiency, and lower rates of accidents and mistakes. Building without scaffolding and using just mobile cranes was highlighted as an enormous advantage, implying great savings. The size of the prefabricated elements is a parameter of concern, aiming to reduce journeys and special transport with their additional costs and complex logistics. The issue of adequate weather protection of the elements and the construction to avoid damages was discussed, including puffer time, an envelope or a tight surface. Parallel to production, work can be undertaken onsite, optimizing the overall process, where finishing work on the inside can be performed once the envelope is tight. Still, the time spent on site was criticized, suggesting an urgent acceleration of fitting work and the inclusion of building services. Although a growing trend towards multi-storey timber buildings can be observed, only a few large corporations have the capacity to realize them, monopolizing the market and constraining fair markets. Therefore, and despite the desire to raise the number of multi-storey timber buildings, the industry with its small-scale structure and its capacity with its current infrastructure and procedures, will not be able to cover the expected demand pressure. Manufacturers would need additional infrastructure to increase their capacity meaning great investments and the required guarantee of enough requests for their amortisation, which is currently not possible due to the lack of constant and regular requests. Creating a network of suppliers or a bidding community was suggested in order to ensure deliveries and a successful workflow, where several small and flexible companies would produce different building elements, organizing one of them the work on site, in accordance with industrial companies, as seen in the automotive or in the prefabricated house industry. Otherwise, large construction companies will absorb manufacturers. For a functioning production network, the sector should overcome mentioned barriers such as the lack of willingness and predisposition to cooperate, the exchange of own knowledge and systems, the differences between the production platforms and structure of the companies, and the lack of standardization.

5.3.2. Construction Management

According to the interviewees, an optimized construction management for industrialized and systemized timber buildings is still missing, regarding both expertise and experts. Regarding the organization of deliveries, the coordination of complementary trades working on site is a great topic of concern, since they rarely have experience in timber, as well as their execution requirements regarding humidity, structure and visual exposure. The working site must be under constant monitoring, including collaborative meetings to coordinate assembly sequences and interdependencies. The amount of work accomplished on site is a result of the low inclusion and level of prefabrication of complementary trades, which is highly time-intensive and degrades the advantages of prefabrication, according to the experts. The model of the general constructor is the favourite for owners and developers, due to the guaranteed quality and costs, and little effort on extra negotiations with different trades, but this is not yet a standard procedure, and too few companies assume this role. The low prefabrication level of ceilings is also a topic of concern, which is mainly used as an installation layer with wet screed requiring a certain curing time. It was proposed to execute the slabs in the factory as floor construction elements with the connections ready for a plug and play, or to pre-assemble the installations in the wall. A further issue to be assessed is the interface with concrete, including constructive tolerances, execution speed, methods of erection and manager role. According to the experts, due to their specific expertise and experience, timber construction companies should take the management lead, organize the overall logistic and implement prefabricated concrete elements. For in situ concrete, agreements between timber and concrete builders must be met to ensure a successful execution. The timber industry has often been compared to the automotive industry and their processes based on Lean principles, wherein several synergies have been recognised, such as the exploitation of technology or digital platforms, the prefabrication and preassembly of an asset’s components, upfront knowledge of implementation, and collaboration models within the design phase. Lean principles and tools have already been implemented, especially in the factory, while on site, timber elements are delivered just in time, and assembly sequences are planned in-depth. Still, there is a need to implement leaner logistics regarding complementary trades and the coordination of different manufacturers if a decentralized production is implemented.

5.3.3. Timber Manufacturer and Construction Companies

Experts have stated that timber manufacturers and construction companies have recognisable levels of expertise and experience in manufacturing and construction processes, technical and constructive details and logistics, making them capable of raising the level of prefabrication and encompassing 10 trades into one if contracted as a general constructor, but too few existing companies are able to assume this challenge. Timber manufacturers are small companies that produce mainly panel constructions and cover additional fields such as stairs and roofing, within more or less industrialized processes as a subcontractor. Most timber construction companies also produce prefabricated elements in their factories and organize the delivery on site of their elements, and other wooden products such as CLT in accordance with industrial companies. They used to have design members specialized in structural design, building physics and fire resistance, technical members focused on production and assembly, and developers and a research and development department. According to experts, both have achieved highly efficient production and assembly processes, with aligned tasks, direct linkage between factory and worksite, and no negative iterations. The fact that production processes are not yet industrial is seen by the experts as an enormous potential for improvements, where adjustments of the production line, halls, robots and software are needed for a higher level of industrialization.

5.3.4. Timber Industrial Companies

The development of the CLT has pushed the timber industry forward and, consequently, industrial companies. Although it is produced, cut, joint, trimmed, milled and drilled on both sides, the prefabrication level of CLT is remarkably lower than within other timber elements, like panels. This fact is seen as a great barrier by the experts, and as a great potential if the interface to construction companies and manufactures is assessed. Industrial companies are mainly focused on mass production, where the integration of building processes into production is missing. This inclusion and the consequent increase in prefabrication is a great aspiration of companies, but they lack knowledge of structural design and construction processes. Entering the market of prefabrication, industrial companies would compete with their higher purchasers, construction companies, who would stop buying their products. On the other side, if the expertise of manufacturers is exploited and the prefabrication takes place within their factories, CLT is to be delivered from industrial companies to construction companies and then to the site, being inefficient due to higher transportations. Due to its weight, the further processing of CLT requires specific infrastructure, which is rarely found within construction companies. Due to the lack of standardization within CLT, several dimensions and number of layers are produced, meaning higher bi-directional exchange of documents and data between industrial companies and construction companies with adjustments and corrections, and the corresponding additional time for the production plans and the production itself. These different production widths and parameters further influence the architectural design and the configuration of the project. Additionally, the production tolerances need to be standardized in order to perform optimally at the interface with other elements such as timber panels, or materials such as concrete. Since CLT is delivered directly to the site by the industrial companies, lower profit margins for construction companies have been reported, as they merely organise the deliveries without producing their own elements.

5.3.5. Prefabricated House Industry

The main goal of the prefabricated house industry is to make the leap to the market of multi-storey timber buildings, but they lack the required infrastructure. Completely new production lines would be needed in order to further deliver housing and ensure their market moves at a steady pace. They work with specific building units based on high standardization with time and cost certainty, where the elements and components can be adjusted within a raster, remaining joints and details the same. That leads to a remarkable reduction in effort in design and production planning, since submission and execution plans are not needed. In this sense, they implement BIM and integrated design, successfully solving the interface between design and production, but in a closed environment. Production processes are not yet industrial, and it is expected to stay manual due to lower labour costs of workers in relation to robots and improved infrastructure according to the experts. Their highly optimized and digitally controlled manufacturing process is based on software from the automotive industry, to which participants have access to check deliveries and tasks, according to their defined role and rights. Involved companies work like an organized production network covering more than one country, and, together with their constant requests, ease the definition of production and assembly data, ensuring timely delivery below estimated costs. Large savings are achieved in the procurement of materials and components due to bulk purchasing, which, together with the reduction in work in design and production planning, increases the efficiency and profitability of industry, where investments in sales decrease the overall cost reduction.

6. Discussion of Results

According to the frequency of nominations accounted within the three categories and their embedded codes, the Production and Assembly stage represents the most discussed one, with almost half of the total nominations, whereby the proportion of barriers and opportunities are equal, showing great concerns but also strengths and relevant potentials. Further, the Design stage accounts around one-third of all nominations, with a ratio of opportunities to barriers of 1:2. The design stage has huge impacts both in the production and assembly stage due to the prefabrication and its higher detail definition, and in the acquisition stage due to the higher complexity and lack of expertise. Therefore, the limitations and opportunities here identified require great attention, having the potential to heavily influence their correlated stages. Finally, the Acquisition stage englobes one-sixth of the nominations, where the number of limitations is three times the number of opportunities. Although this stage represents the least-discussed stage, it also accounts for the worst proportion of limitations to opportunities, with barriers creating enormous repercussions on the whole process and affecting the entire industry. Therefore, it is a crucial stage demanding great awareness.

By the Acquisition stage, a general lack of awareness was highlighted as a great barrier both by the side of the developers and contractors, as well as by society. There exists an image of high complexity with risks and uncertainty. Society also lacks awareness in terms of fire protection and structural performances. This disinformation is mainly caused by the lack of examples and public documentation. An adequate strategic communication, more reference projects and higher transparency could overcome the prejudices and preconceptions commonly found in the sector and society and promote the use of timber by transmitting its hard and soft benefits. Further, it could enhance cooperation and openness to try new methods of construction and building materials.

In the Design phase, the traditional planning process based on the HOAI structure represents a great barrier, constraining the correct definition of multi-storey timber buildings by separating design and construction. Its material neutrality and linearity lead to negative iterations due to errors and re-designs, meaning time and cost overruns. Higher levels of definition and a design freeze are needed due to prefabrication, which implies an in-depth defined integrated design approach. Planning a timber building is time-intensive and requires extensive expertise, which is rarely found in the sector, due to the lack of specific training. In addition, the large number of constructive solutions and the lack of standardisation increase the complexity of design. In this context, the use of standardised highly prefabricated elements could help to overcome these barriers, where details, joints and complex components are already defined, and their combination allows architectural freedom and customization.

In the Production and assembly phase, prefabrication presents a great opportunity thanks to the lightness and workability of timber, which facilitates high levels of prefabrication in large elements, which, together with its ecological properties, makes its implementation remarkably attractive. However, the local and fragmented structure of the industry constrains eventual increases in demand, where large investments in infrastructure and the development of innovative and collaborative business models would be necessary. In addition, complementary trades, interfaces with concrete, the production of ceilings and the lack of standardization and a low level of prefabrication of CLT still need to be assessed. Manufacturers and construction companies have high levels of competence in production and construction process, with considerable expertise in digitisation, logistics and specific material properties. Additionally, the prefabricated house industry has highly standardised production processes, including logistics and a supply network, delivering largely prefabricated elements with time and cost certainty. Herein, the combination of higher standardization and prefabrication level, together with remarkable expertise, would create a great disruption.

7. Recommendations to Enhance Timber Construction

In this section, a number of strategies in the form of a catalogue (Table A1) are proposed serving as a framework of a guideline to support the implementation of multi-storey timber overcoming the barriers by taking advantage of the opportunities highlighted by the experts.

- A criteria catalogue with dependencies based on built examples and their documentation;

- Association or coordination office for timber construction;

- Network of partners or bidding community with aligned contractual incentives;

- Implementation of timber and timber construction related knowledge in academic curriculum;

- Integration of timber expertise in early design stages;

- Increase products standardisation through specialisation in multi-storey buildings;

- Increase prefabrication level;

- Promotion of research and development;

- Establishment of a brand image.

7.1. A Criteria Catalogue with Dependencies Based on Built Examples and Their Documentation

The exchange of documents of already realised projects would be of great help as examples, both technically and for preliminary cost calculation, ensuring a valuable knowledge transfer and an increase in awareness about the feasibility of timber buildings. The special requirements and benefits about building with timber need to be translated in a way that different disciplines and players, especially clients and developers, can recognize dependencies and meet correct decisions. The criteria catalogue developed By Geier [71] within her doctoral thesis is a strategic project-support tool that visually permits the description of projects in early stages of development, allowing a common understanding, transparency and traceability within interdisciplinary communications. Within its 35 criteria, functionality aspects, legal framework, wishes of the client, technical and design-related decisions and aspects related to production, logistic and assembly are summarized, wherein their interdependencies are identified and defined. By specifying the level of complexity related to each criteria, projects are systematically defined, allowing comparison. Taking reference projects as a basis, potential challenges and deviations are uncovered, allowing further assessments in early stages if needed. Transparent communication between the design team and the client or developer is ensured, wherein also different design approaches with their cost estimations can be supported, and uncertainties in the decision-making process can be handled. Criteria can be added or deleted according to the specific requirements of the project, and the target group. A similar system was followed by the German Sustainable Building Council within the initiative “Phase Sustainability”, where a questionnaire was developed serving as a guide for the communication between planning offices and decision makers early in the process about relevant objectives regarding sustainability [72]. Such a catalogue could help developers or clients to understand and exploit the advantages of timber construction, while ensuring quality and ecological impact in accordance with all disciplines. The more projects included in the tool as best practice, the more accurate and useful it will become. In addition, architectural and technical plans could be embedded, serving as a guide for the procurement of new projects delivering comparative values for calculations and plans, and supporting the implementation of more mid-rise timber building.

7.2. Association or Coordination Office for Timber Construction

A few online platforms, such as meta_wissen_holzbau [73], have attempted to provide a summary of information, links and documents to significantly reduce the effort required to fulfil legal and normative obligations. On the other side, regional clusters serve as platforms where small timber construction companies and planners offer their services with the purpose of working collaboratively. One national overarching association or network of construction companies, builders, planners, researchers and those interested in timber construction is still missing. The coordination of an interest group for timber construction, as is done for other building materials, could help the sector to unite different professionals and gain strength and representation in the construction sector, in politics, business and society. A voice within regulatory decisions would be enhanced, which would promote homogeneity to shape the heterogeneous legal framework. Further, it could monitor, standardize and simplify national standards related to fire protection, thermal insulation or sustainable assessment with the aim to harmonise them within Europe, where Austria could take the lead, acting as an enabler. This new level of standardization would ease the cooperation between companies and SMEs even internationally. Standardizing the regulatory framework, products and technology would ease the further standardization of prefabrication and in the planning details, which could help planners within the design phase and at their interface to production. In addition, outreach to laypeople and society would be eased leading to a change in public awareness and to an increase in demand. This coordination office would analyse the state of the art in practice and in research and development, and adapt old standards to innovative timber products and technologies, while identifying trends and contributing to further developments by organizing, coordinating and monitoring research studies.

7.3. Network of Partners or Bidding Community with Aligned Contractual Incentives

The Austrian timber construction sector is characterized by a local organized, small and scattered structure, where 83% of timber construction companies have less than nine employees [74]. These SMEs are largely limited to the segment of small-volume construction projects, wherein efficiently prefabricated standardised wall and ceilings structures are common offered. The establishment of a network of partners or bidding community, supported by an integrated planning, higher standardisation of components, and the digitalisation of processes, could ease the collaborative production of modular components in a decentralised manner. Similar business models are already being successfully implemented in industries such as the furniture industry, car manufacturing and other design-oriented branches [75,76,77,78]. The model of the decentralised production network is characterised by diversified industrial manufacturing processes, centrally controlled logistics and a focus on customer needs. SMEs could jointly take the role of general contractor, increasing their involvement in the value chain of multi-storey and systemised construction methods, being competitive and keeping the value chain at regional level as well as optimizing transport distances, and supporting a growing, inclusive and sustainable industrialisation. By involving local actors and using regional raw materials, diversification is increased, supply chain is ensured, and productive jobs are secured. Relevant trades and services would be included in the production process raising the prefabrication degree of the elements and optimizing the overall construction process. This high degree of division of labour leads to a drastic improvement in quality and competitiveness for SMEs by being focused on their own production, optimizing their conditions and processes, avoiding waste and implementing recycling and reuse. Holzunion is an existing bidding community of four medium-sized timber construction companies in Germany with multi-layered competences and individual expertise into a full-service package, from project planning, design and static calculations to production, transport logistics and assembly [79]. Another example is Lukas-Lang Building Technologies, which has developed a specific construction system with standardized structures, components and modules that are manufactured by their decentralized large system of suppliers and companies within their local factories [80]. The association or coordination office for timber construction before mentioned could have a digital platform, where different companies and players with their specific expertise and products offer their services giving the chance to join competences and capacities for the realisation of large-volume constructions.

7.4. Implementation of Timber and Timber Construction Related Knowledge in Academic Curriculum

To overcome the general prejudices about building with timber and to create awareness about its properties, a wide dissemination of knowledge is needed within the primary, secondary and tertiary education sector, including cross-thematic activities and different subjects, applications and didactic methods. Within the primary educational level, the analysis and understanding of the different applications of timber as raw, working and building material would be promoted. At secondary educational sector, concrete practical applications and insights in the business sector could be performed through internships in companies and research institutions. At universities, specialised departments thematically focused on timber construction need to be established, as it occurs with other building materials, which would train future architects and engineers in the area, including research and practice, and covering doctoral schools and cooperation projects with scientific and industrial partners. By doing so, more and better research competencies and capacities in science and practice, as well as highly qualified young researchers, planners and practitioners would arise and be retained in national companies, becoming an internationally recognised location for innovation, where highly demanded and innovative research topics and cutting-edge-oriented curricula can be carried out. For practice, an extended range of independent and intensive modules for practitioners could also be offered, covering specific topics related to the required skills to enter the market.

7.5. Integration of Timber Expertise in Early Design Stages