Experimental Study on the Seismic Behavior of Squat SRC Shear Walls with High Axial Load Ratio

Abstract

:1. Introduction

2. Experimental Program

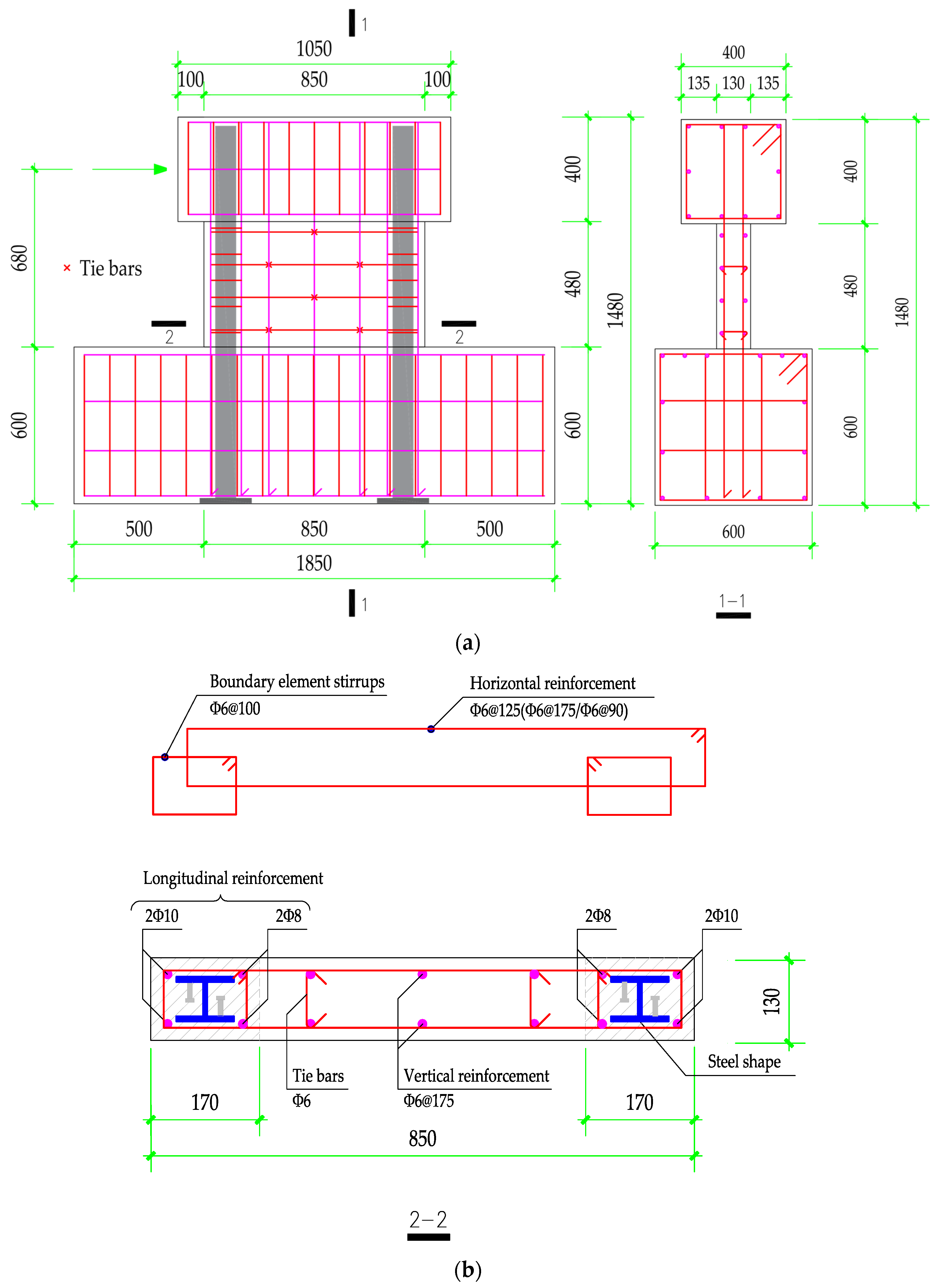

2.1. Details of Specimens

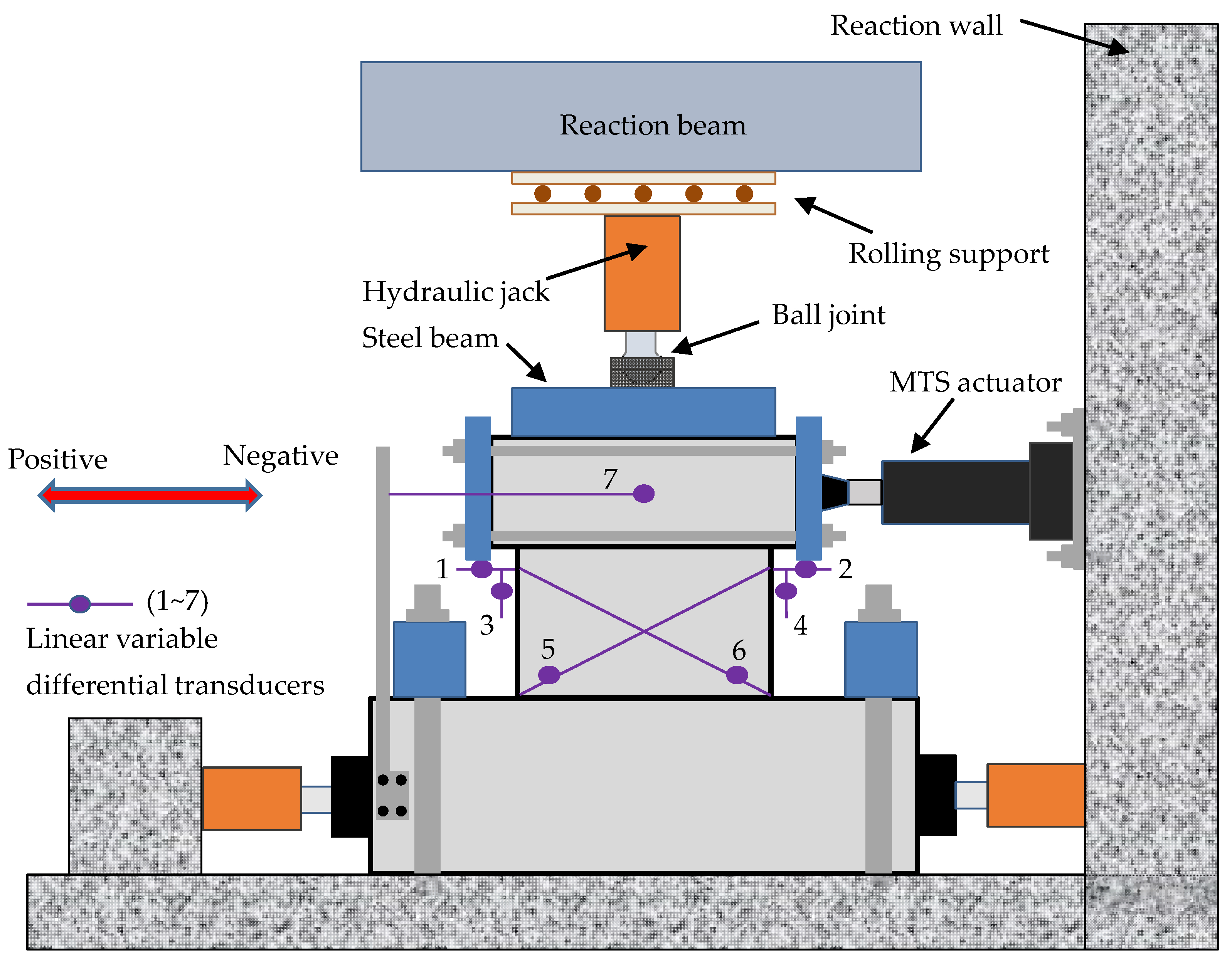

2.2. Test Setup

2.3. Loading Protocol

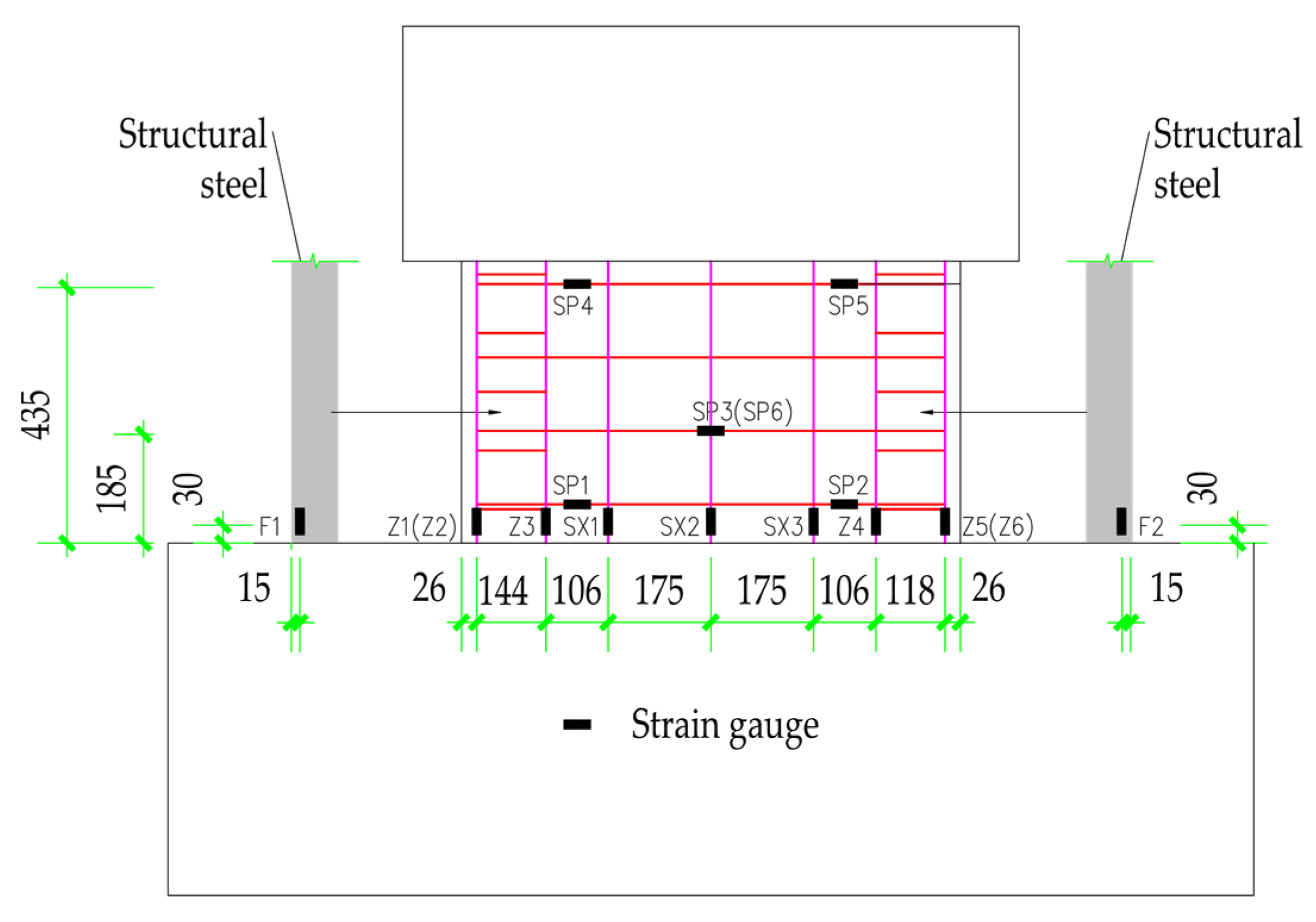

2.4. Instrumentation

3. Experimental Results and Discussion

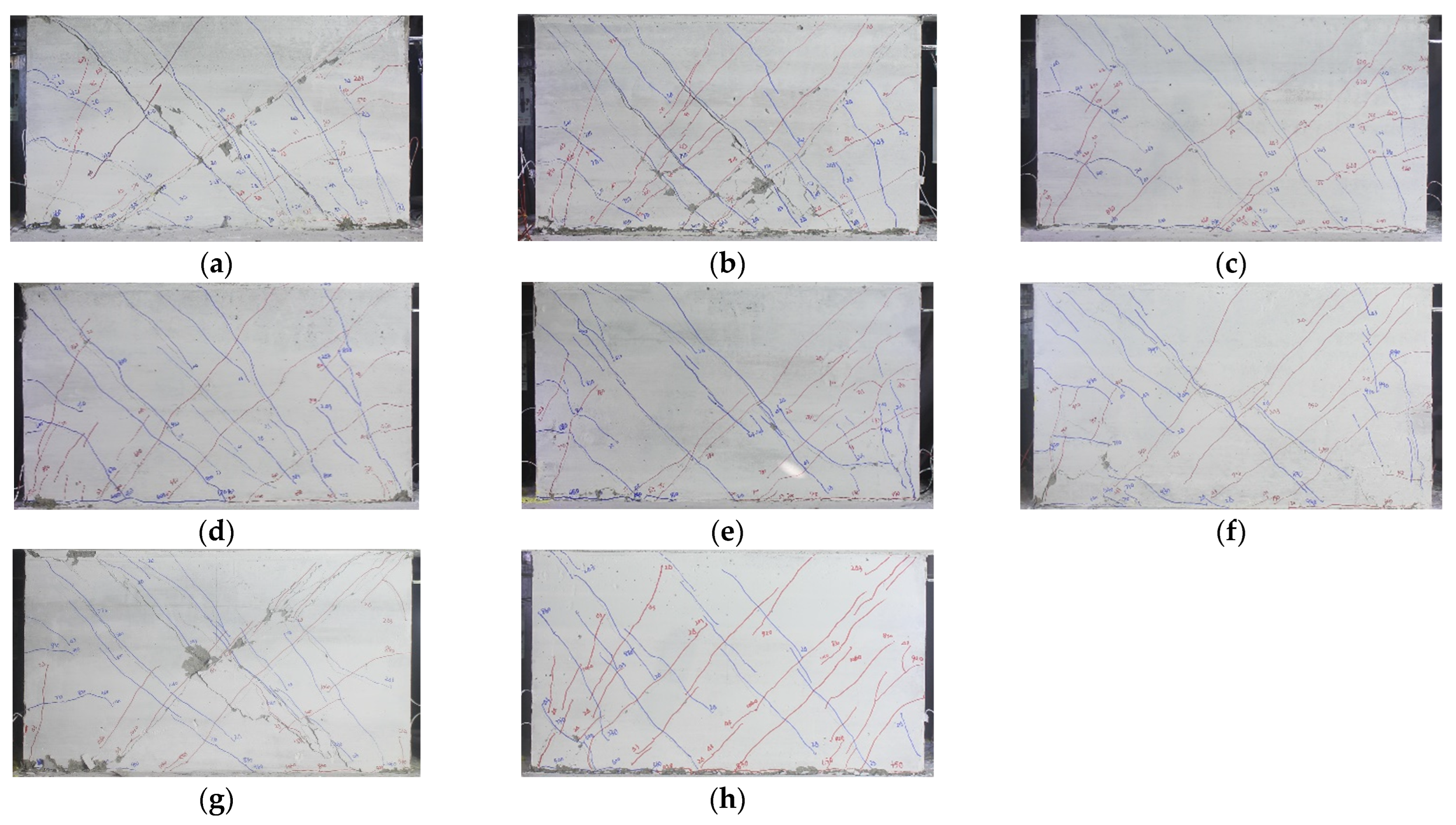

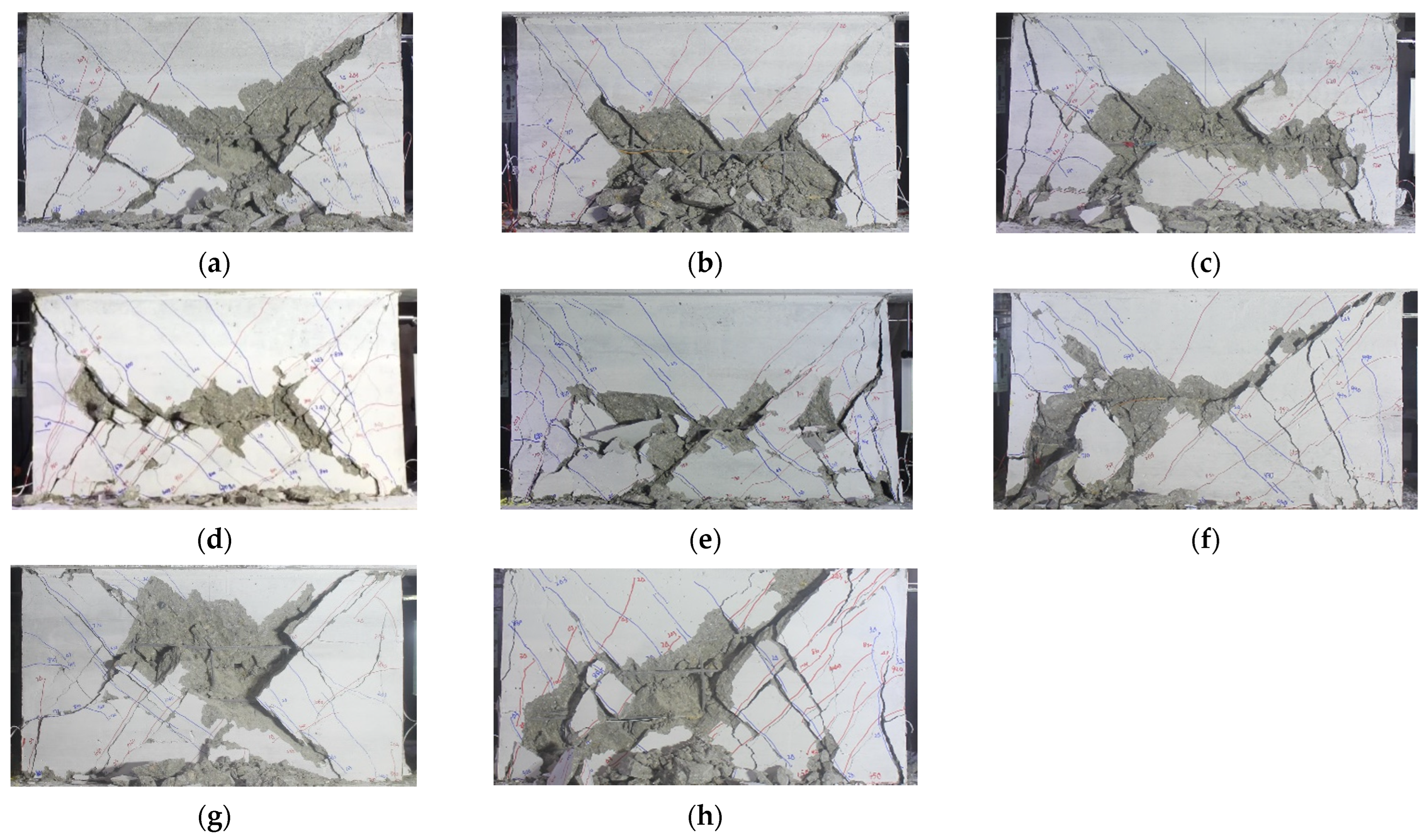

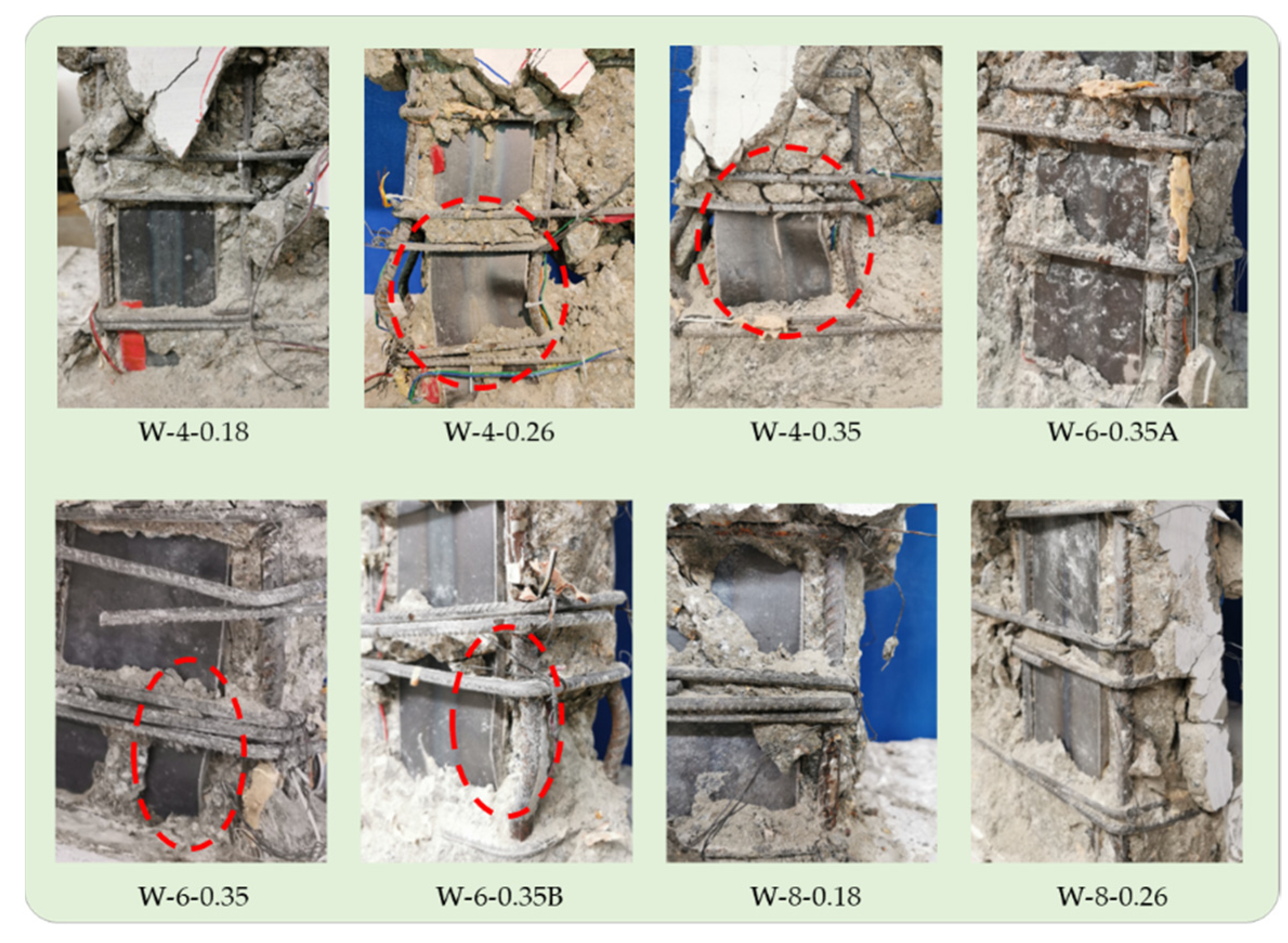

3.1. Failure Process and Failure Modes

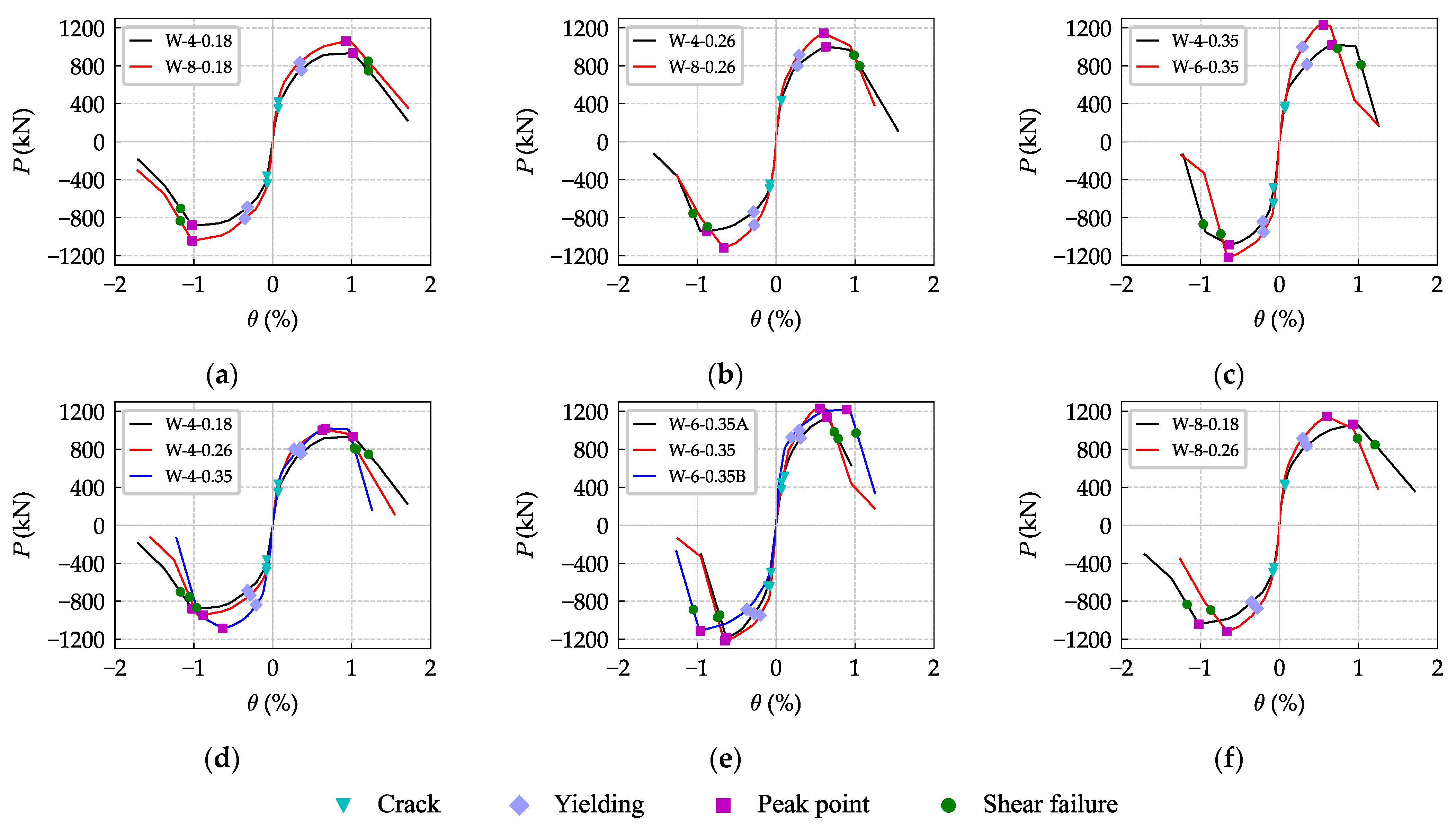

3.2. Hysteretic Response Curves

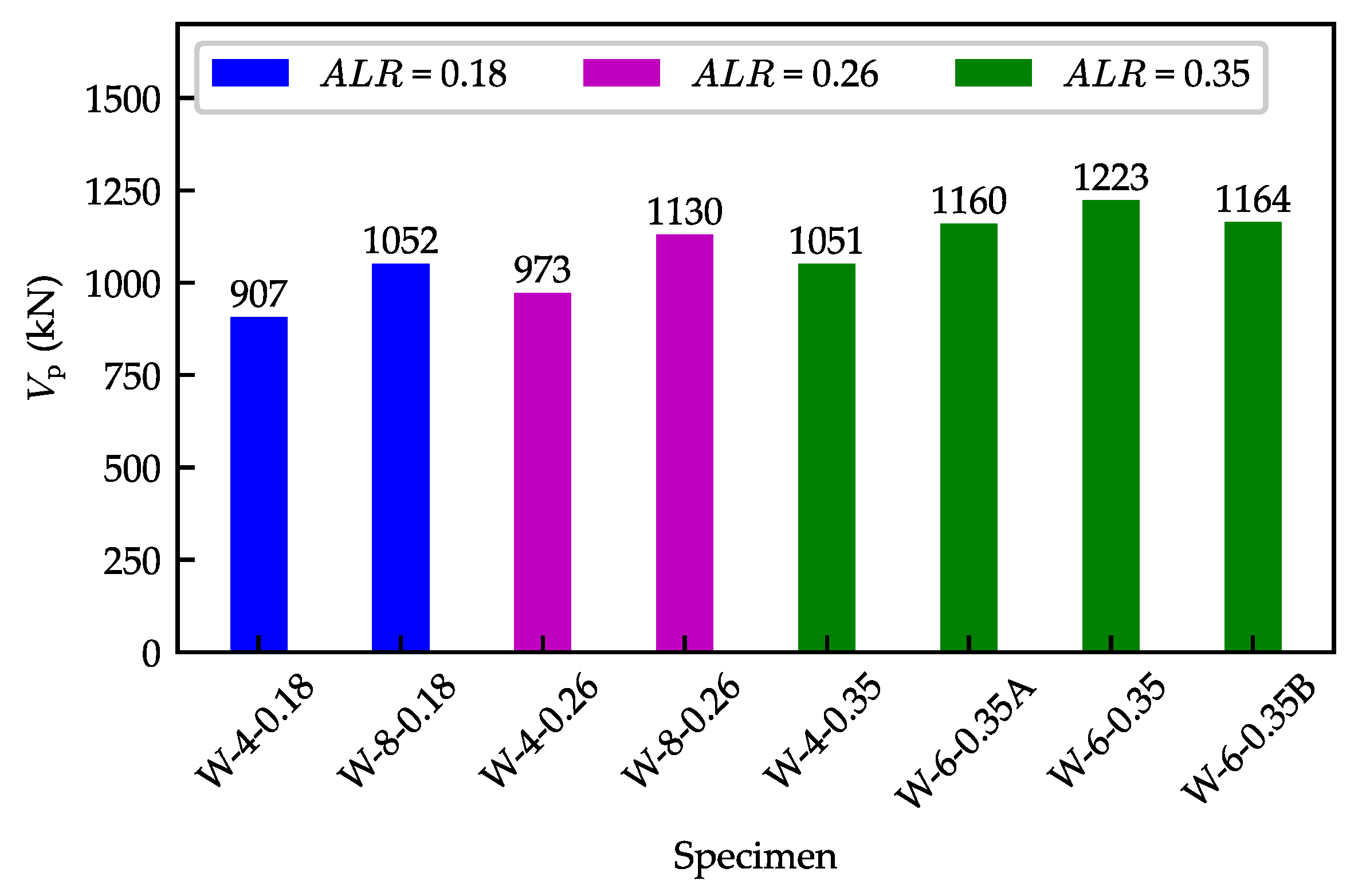

3.3. Strength and Ductility Coefficient

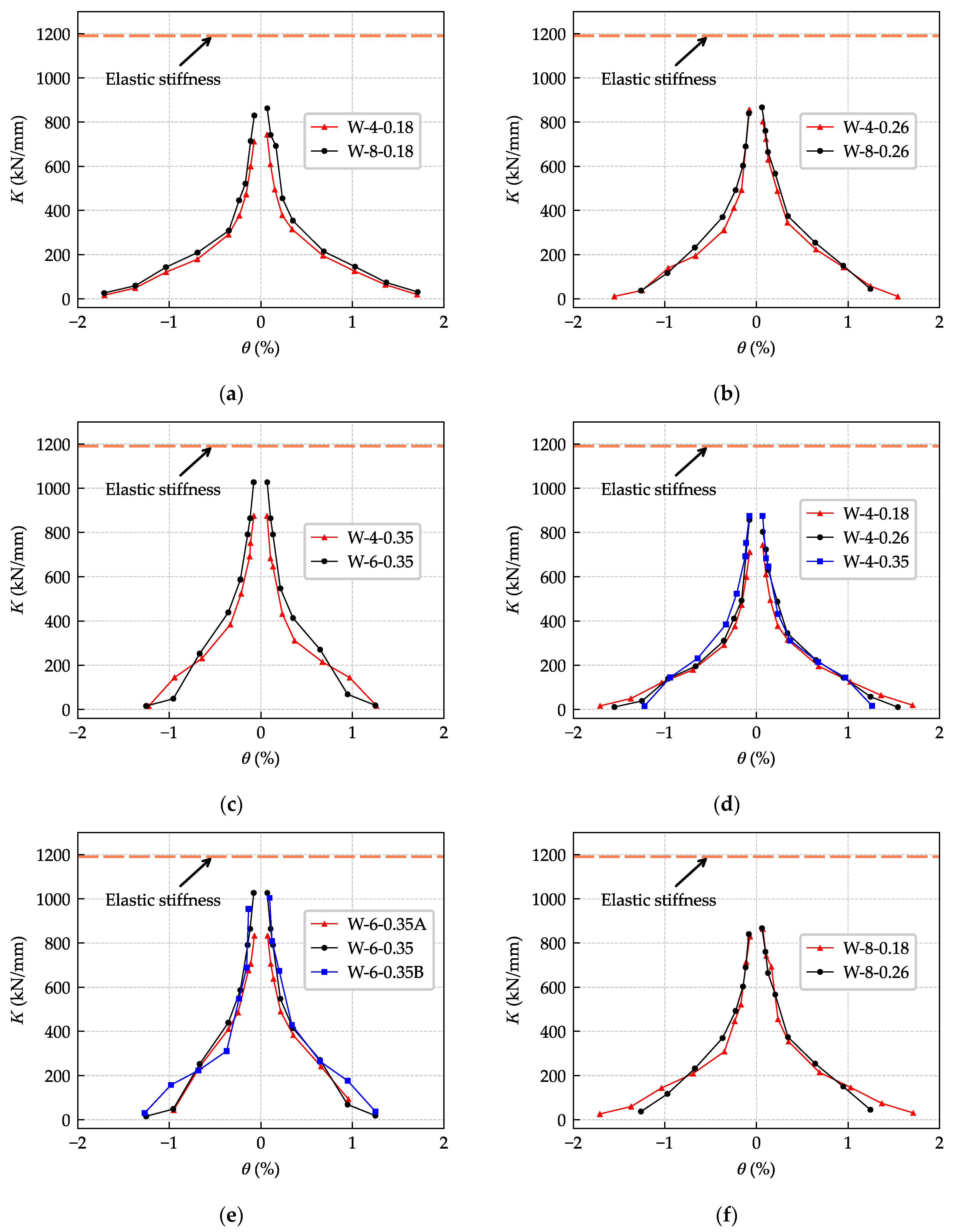

3.4. Stiffness Degradation

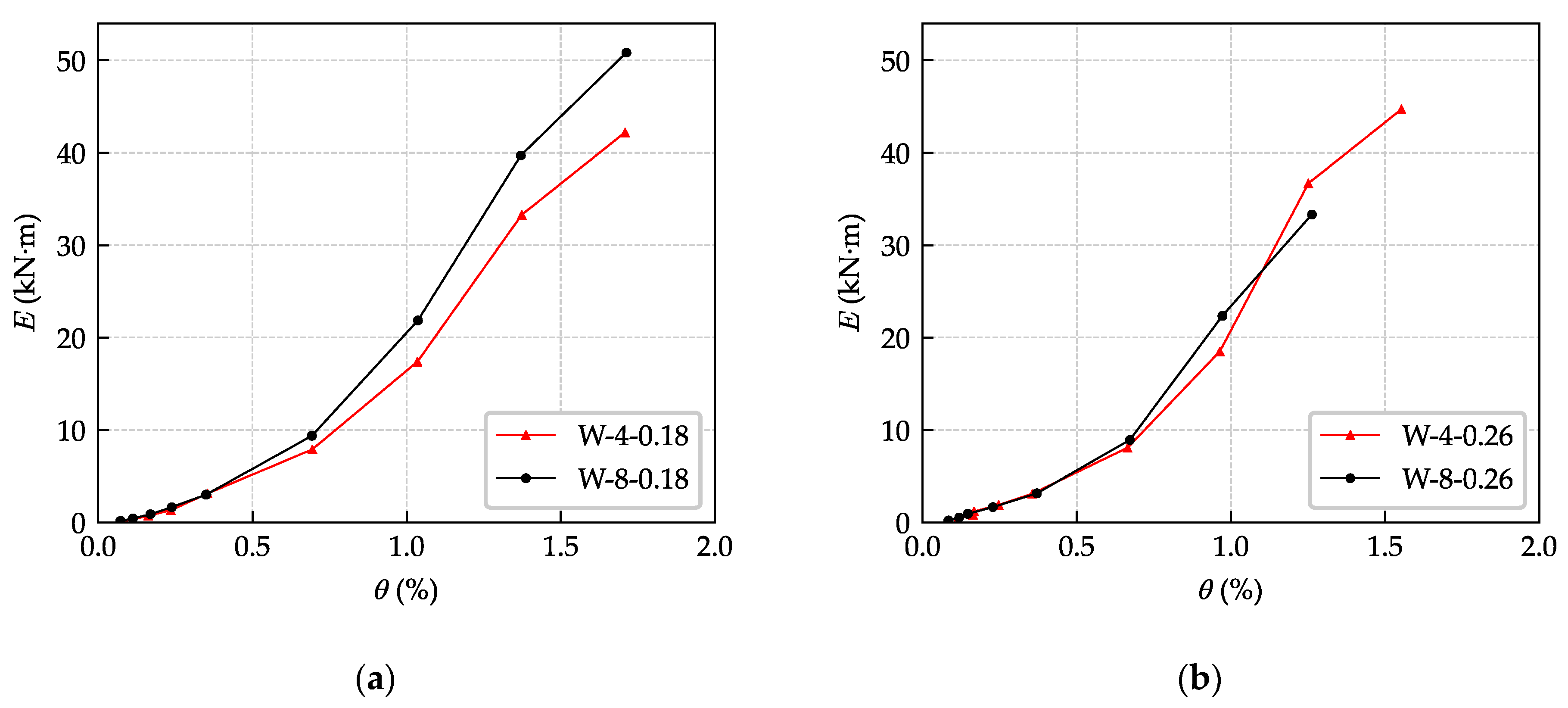

3.5. Energy Dissipation Capacity

3.6. Axial Deformation

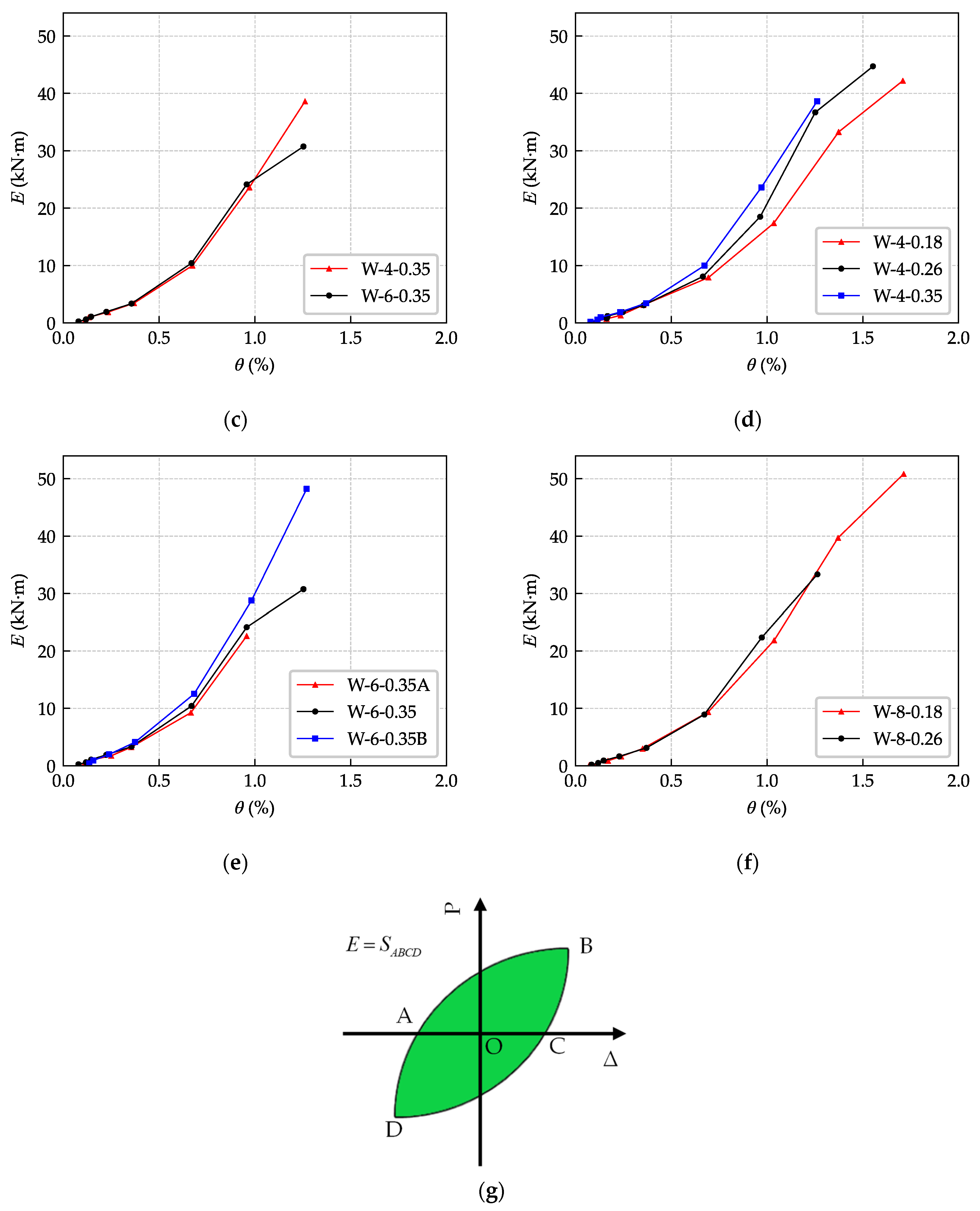

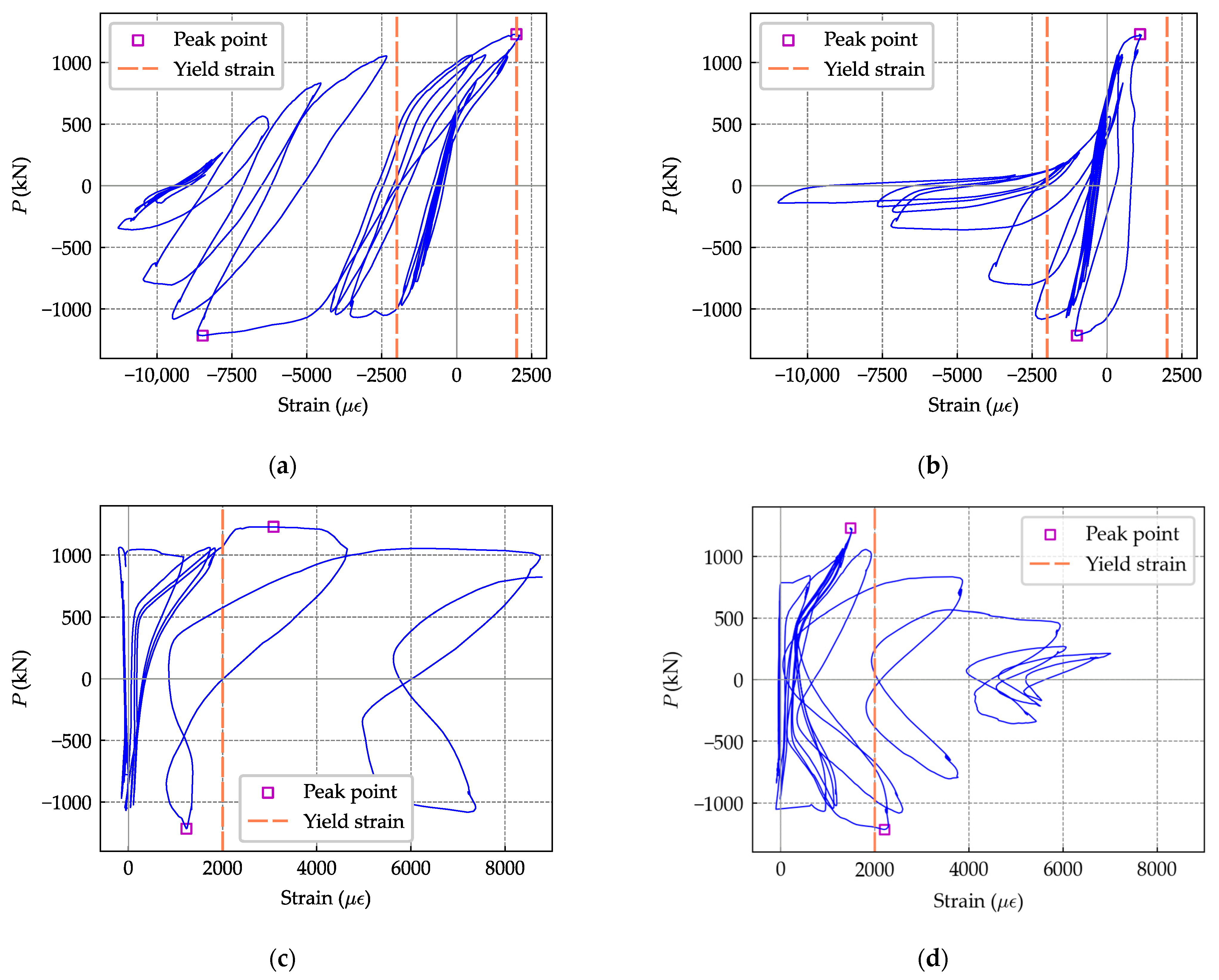

3.7. Strains

4. Strength and Deformation Evaluation

4.1. Shear Strength Evaluation

4.2. Deformation Capacity Evaluation

5. Conclusions

- All the squat SRC shear walls failed in shear. After peak strength, the concrete of the web was crushed, causing the degradation of the lateral strength, the buckling of vertical reinforcement bars, and the redistribution of the axial load to the boundary elements. Axial shortening deformation increased rapidly after the peak strength for specimens with ALRs of 0.26 and 0.35. Although the maximum axial shortening deformation was larger than 5 mm, no axial failure occurred since the wall boundary elements encased with structural steel were capable of maintaining the axial bearing capacity after the web concrete was crushed. Additionally, a steel ratio of at least 6% prevented the steel sections from serious local buckling;

- Larger steel ratios increased the lateral shear strength of the squat SRC shear walls. The improvements were 15.99% and 16.10% when increased from 4% to 8% for specimens with ALRs of 0.18 and 0.26, respectively. For specimens with an ALR of 0.35, the lateral strength increased by 16.37% when increased from 4% to 6%;

- The increase in ALR enhanced the shear strength yet reduced the deformation ability of the squat SRC shear walls. The lateral strength increased by 15.88% when ALR increased from 0.18 to 0.35 for specimens with = 4%. The increment was 7.41% when ALR increased from 0.18 to 0.26 for specimens with = 8%;

- Larger horizontal reinforcement ratios improved the energy dissipation capacity and the ductility of the specimens. To achieve a ductility larger than 3.0, should be at least 0.35% for squat SRC shear walls. However, had no significant effect on the shear strength;

- A reduction factor of 0.74 is recommended for the initial lateral stiffness of squat SRC shear walls when calculated by Equations (4)–(6);

- The formula proposed in the Chinese code JGJ 138-2016 extremely underestimated the shear strength of the squat SRC shear walls, with a mean calculated-experimental strength ratio of 0.42 and a standard deviation of 0.03. Liu’s formula provided a better but also conservative estimation of the shear strength for the squat SRC shear wall specimens. The mean calculated-experimental strength ratio was 0.74 and the standard deviation was 0.06. This improvement was achieved mainly by the modification of shear resistance provided by the concrete and the structural steel;

- The results from this research can be used to establish deformation acceptance criteria for performance levels of squat SRC shear walls in the future, since there are no reasonable drift limits for SRC shear walls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paulay, T.; Priestly, M.J.N. Seismic Design of Reinforced Concrete and Masonry Buildings; Wiley: New York, NY, USA, 1992. [Google Scholar]

- Pilakoutas, K.; Elnashai, A.S. Cyclic Behavior of RC Cantilever Walls, Part I: Experimental Results. ACI Struct. J. 1995, 92, 271–281. [Google Scholar] [CrossRef]

- Salonikios, T.N.; Kappos, A.J.; Tegos, I.A.; Penelis, G.G. Cyclic Load Behavior of Low-Slenderness Reinforced Concrete Walls: Design Basis and Test Results. ACI Struct. J. 1999, 96, 649–660. [Google Scholar] [CrossRef]

- Hidalgo, P.A.; Ledezma, C.A.; Jordan, R.M. Seismic Behavior of Squat Reinforced Concrete Shear Walls. Earthq. Spectra 2002, 18, 287–308. [Google Scholar] [CrossRef]

- Salonikios, T.N. Shear strength and deformation patterns of R/C walls with aspect ratio 1.0 and 1.5 designed to Eurocode 8 (EC8). Eng. Struct. 2002, 24, 39–49. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Wibowo, L.S.B.; Giduquio, M.B.; Lequesne, R.D. Strength and Deformation of Reinforced Concrete Squat Walls with High-Strength Materials. ACI Struct. J. 2021, 118, 125–137. [Google Scholar] [CrossRef]

- Looi, D.T.W.; Su, R.K.L.; Cheng, B.; Tsang, H.H. Effects of axial load on seismic performance of reinforced concrete walls with short shear span. Eng. Struct. 2017, 151, 312–326. [Google Scholar] [CrossRef]

- Qian, J.R.; Lu, W.; Fang, E.H. Displacement Ductility-Based Aseismic Design for Shear Walls. J. Build. Struct. 1999, 20, 42–49. (In Chinese) [Google Scholar] [CrossRef]

- Telleen, K.; Maffei, J.; Heintz, J.A. Practical lessons for concrete wall design, based on studies of the 2010 Chile earthquake. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Wei, Y.; Qian, J.R.; Zhao, Z.Z.; Cai, Y.Y.; Yu, Y.Q.; Shen, L. Lateral Loading Experiment of SRC Low Shear Walls with High Axial Force Ratio. Ind. Constr. 2007, 37, 76–79. (In Chinese) [Google Scholar]

- Qian, J.R.; Wei, Y.; Zhao, Z.Z.; Cai, Y.Y.; Yu, Y.Q.; Shen, L. Experimental study on seismic behavior of SRC shear walls with high axial force ratio. J. Build. Struct. 2008, 29, 43–50. (In Chinese) [Google Scholar] [CrossRef]

- Ji, X.D.; Sun, Y.; Qian, J.R.; Lu, X.Z. Seismic behavior and modeling of steel reinforced concrete (SRC) walls. Earthq. Eng. Struct. Dyn. 2015, 44, 955–972. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, X.L.; Dong, Y.G. Seismic behaviour of composite shear walls with multi-embedded steel sections. Part I: Experiment. Struct. Des. Tall Speéc. Build. 2010, 19, 618–636. [Google Scholar] [CrossRef]

- Dan, D.; Fabian, A.; Stoian, V. Nonlinear behavior of composite shear walls with vertical steel encased profiles. Eng. Struct. 2011, 33, 2794–2804. [Google Scholar] [CrossRef]

- Dan, D.; Fabian, A.; Stoian, V. Theoretical and experimental study on composite steel–concrete shear walls with vertical steel encased profiles. J. Constr. Steel Res. 2011, 67, 800–813. [Google Scholar] [CrossRef]

- Massone, L.M.; Sayre, B.L.; Wallace, J.W. Load–Deformation responses of slender structural steel reinforced concrete walls. Eng. Struct. 2017, 140, 77–88. [Google Scholar] [CrossRef]

- Ma, K.-Z.; Ma, Y.-D.; Liang, X.-W. Seismic Behavior of Steel Reinforced High-Strength Concrete Composite Walls. J. Earthq. Eng. 2020, 24, 1290–1310. [Google Scholar] [CrossRef]

- Liao, F.-Y.; Han, L.-H.; Tao, Z. Performance of reinforced concrete shear walls with steel reinforced concrete boundary columns. Eng. Struct. 2012, 44, 186–209. [Google Scholar] [CrossRef]

- Todea, V.; Dan, D.; Stoian, V.; Florut, S.-C.; Popescu, D.-A. Seismic behaviour of composite steel-concrete shear walls with central openings. ce/papers 2021, 4, 1844–1848. [Google Scholar] [CrossRef]

- Wu, Y.; Kang, D.; Gao, L.; Su, Y.; Yang, Y. Seismic Behavior of Bolted Endplate Connection Between Steel Reinforced Concrete (SRC) Wall and SRC Beam for Use in High-Rise Buildings. Int. J. Civ. Eng. 2018, 16, 1561–1572. [Google Scholar] [CrossRef]

- JGJ 138-2016; Code for Design of Composite Structures. China Architecture & Building Press: Beijing, China, 2016.

- Park, R. Evaluation of ductility of structures and structural assemblages from laboratory testing. Bull. N. Z. Soc. Earthq. Eng. 1989, 22, 155–166. [Google Scholar] [CrossRef]

- Paulay, T.; Priestley, M.J.N.; Synge, A.J. Ductility in Earthquake Resisting Squat Shearwalls. ACI J. Proc. 1982, 79, 257–269. [Google Scholar] [CrossRef]

- Lopes, M.S. Experimental shear-dominated response of RC walls. Part II: Discussion of results and design implications. Eng. Struct. 2001, 23, 564–574. [Google Scholar] [CrossRef]

- Pan, G.-B.; Cai, J.; He, A.; Chen, Q.-J.; Zuo, Z.-L.; He, B.-Q.; Tang, X.-L.; Wu, H.-W. An experimental study of the seismic behaviour of precast concrete shear walls with bolted-plate connections. Eng. Struct. 2021, 248, 113203. [Google Scholar] [CrossRef]

- ANSI/AISC 360-16; Specification for Structural Steel Building. American Institute of Steel Construction: Chicago, IL, USA, 2016.

- Liu, H.; Lan, Z.J.; Pang, T.H.; Meng, Z.P.; Liu, A.L.; Wen, F. Test and Analysis on Seismic Behavior of Low-Rise Steel-Encased Reinforced Concrete Shear Walls. Ind. Constr. 1997, 27, 32–36+47. (In Chinese) [Google Scholar]

- Barda, F.; Hanson, J.M.; Corley, W. Shear strength of low-rise walls with boundary elements. Int. Concr. Abstr. Portal 2011, 21, 149–202. [Google Scholar]

- ASCE/SEI 41-17; Seismic Evaluation and Retrofit of Existing Buildings. American Society of Civil Engineers: Reston, VI, USA, 2017. [CrossRef]

| No. | Name | SSR | N (kN) | ALR | Steel Shape | (cm2) | (%) | Horizontal Reinforcement | (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | W-4-0.18 | 0.8 | 732 | 0.18 | Cross-section 1 | 17.76 | 4 | C6@125 | 0.35 |

| 2 | W-8-0.18 | 0.8 | 825 | 0.18 | Cross-section 3 | 35.28 | 8 | C6@125 | 0.35 |

| 3 | W-4-0.26 | 0.8 | 1092 | 0.26 | Cross-section 1 | 17.76 | 4 | C6@125 | 0.35 |

| 4 | W-8-0.26 | 0.8 | 1237 | 0.26 | Cross-section 3 | 35.28 | 8 | C6@125 | 0.35 |

| 5 | W-4-0.35 | 0.8 | 1452 | 0.35 | Cross-section 1 | 17.76 | 4 | C6@125 | 0.35 |

| 6 | W-6-0.35A | 0.8 | 1523 | 0.35 | Cross-section 2 | 26.64 | 6 | C6@175 | 0.25 |

| 7 | W-6-0.35 | 0.8 | 1523 | 0.35 | Cross-section 2 | 26.64 | 6 | C6@125 | 0.35 |

| 8 | W-6-0.35B | 0.8 | 1523 | 0.35 | Cross-section 2 | 26.64 | 6 | C6@90 | 0.50 |

| 9 | W-8-0.35 | 0.8 | 1650 | 0.35 | Cross-section 3 | 35.28 | 8 | C6@125 | 0.35 |

| Diameter (mm) | Grade | ||

|---|---|---|---|

| 6 | HRB400 | 440.0 | 697.0 |

| 8 | HRB400 | 413.4 | 618.1 |

| 10 | HRB400 | 458.0 | 698.0 |

| Thickness (mm) | Grade | ||

|---|---|---|---|

| 4 | Q345 | 411.8 | 545.6 |

| 6 | Q345 | 381.0 | 526.8 |

| 8 | Q345 | 367.7 | 509.5 |

| No. | Name | Loading Direction | (kN) | (kN) | (kN) | (kN) | (%) | (%) | (%) | (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | W-4-0.18 | + | 343 | 754 | 934 | 747 | 0.12 | 0.36 | 1.02 | 1.21 |

| − | 366 | 688 | 880 | 703 | 0.13 | 0.32 | 1.02 | 1.17 | ||

| 2 | W-8-0.18 | + | 415 | 837 | 1061 | 848 | 0.12 | 0.34 | 0.93 | 1.21 |

| − | 445 | 809 | 1044 | 834 | 0.13 | 0.35 | 1.02 | 1.17 | ||

| 3 | W-4-0.26 | + | 434 | 802 | 1001 | 799 | 0.12 | 0.27 | 0.63 | 1.06 |

| − | 449 | 737 | 947 | 755 | 0.14 | 0.29 | 0.88 | 1.05 | ||

| 4 | W-8-0.26 | + | 433 | 915 | 1143 | 913 | 0.11 | 0.29 | 0.60 | 0.99 |

| − | 497 | 877 | 1118 | 894 | 0.15 | 0.28 | 0.67 | 0.87 | ||

| 5 | W-4-0.35 | + | 348 | 815 | 1018 | 811 | 0.12 | 0.35 | 0.67 | 1.03 |

| − | 489 | 840 | 1085 | 867 | 0.14 | 0.21 | 0.63 | 0.97 | ||

| 6 | W-6-0.35A | + | 513 | 918 | 1138 | 910 | 0.19 | 0.31 | 0.64 | 0.79 |

| − | 642 | 929 | 1183 | 946 | 0.20 | 0.28 | 0.64 | 0.72 | ||

| 7 | W-6-0.35 | + | 373 | 1000 | 1230 | 983 | 0.12 | 0.29 | 0.55 | 0.74 |

| − | 650 | 950 | 1216 | 970 | 0.14 | 0.20 | 0.65 | 0.74 | ||

| 8 | W-6-0.35B | + | 450 | 923 | 1215 | 972 | 0.12 | 0.19 | 0.89 | 1.01 |

| − | 500 | 887 | 1113 | 890 | 0.12 | 0.37 | 0.96 | 1.05 |

| Name | JGJ 138-2016 [21] | Liu [27] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W-4-0.18 | 907 | 132 | 123 | 73 | 78 | 406 | 383 | 119 | 24 | 91 | 118 | 735 |

| W-8-0.18 | 1052 | 132 | 123 | 84 | 138 | 477 | 383 | 119 | 24 | 105 | 208 | 840 |

| W-4-0.26 | 974 | 132 | 123 | 84 | 78 | 417 | 383 | 119 | 24 | 105 | 118 | 749 |

| W-8-0.26 | 1130 | 132 | 123 | 84 | 138 | 477 | 383 | 119 | 24 | 105 | 208 | 840 |

| W-4-0.35 | 1051 | 132 | 123 | 84 | 78 | 417 | 383 | 119 | 24 | 105 | 118 | 749 |

| W-6-0.35A | 1161 | 132 | 88 | 84 | 108 | 412 | 383 | 85 | 24 | 105 | 163 | 760 |

| W-6-0.35 | 1223 | 132 | 123 | 84 | 108 | 447 | 383 | 119 | 24 | 105 | 163 | 794 |

| W-6-0.35B | 1164 | 132 | 170 | 84 | 108 | 494 | 383 | 171 | 24 | 105 | 163 | 846 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Han, X.; Chen, X.; Ji, J. Experimental Study on the Seismic Behavior of Squat SRC Shear Walls with High Axial Load Ratio. Buildings 2022, 12, 1238. https://doi.org/10.3390/buildings12081238

Zhang L, Han X, Chen X, Ji J. Experimental Study on the Seismic Behavior of Squat SRC Shear Walls with High Axial Load Ratio. Buildings. 2022; 12(8):1238. https://doi.org/10.3390/buildings12081238

Chicago/Turabian StyleZhang, Lei, Xiaolei Han, Xijun Chen, and Jing Ji. 2022. "Experimental Study on the Seismic Behavior of Squat SRC Shear Walls with High Axial Load Ratio" Buildings 12, no. 8: 1238. https://doi.org/10.3390/buildings12081238

APA StyleZhang, L., Han, X., Chen, X., & Ji, J. (2022). Experimental Study on the Seismic Behavior of Squat SRC Shear Walls with High Axial Load Ratio. Buildings, 12(8), 1238. https://doi.org/10.3390/buildings12081238