Thermal and Physico-Chemical Characteristics of Plaster Reinforced with Wheat Straw for Use as Insulating Materials in Building

Abstract

:1. Introduction

2. Materials and Experimental Methods

2.1. Materials

2.1.1. Wheat Straw

2.1.2. Plaster

2.2. Samples Preparation

3. Characterization

3.1. Physico-Chemical Characterization of Materials

3.1.1. TGA

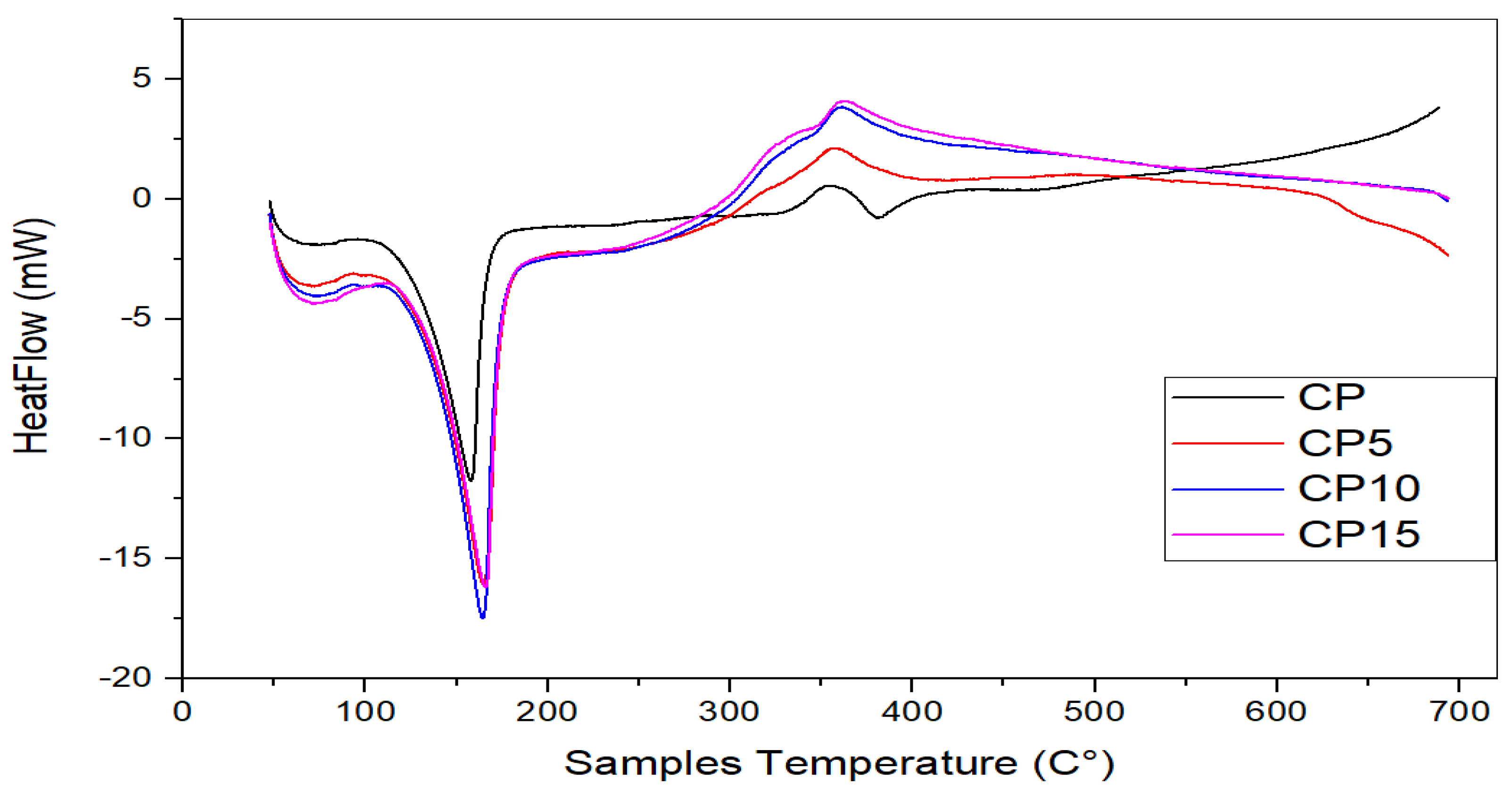

3.1.2. DSC

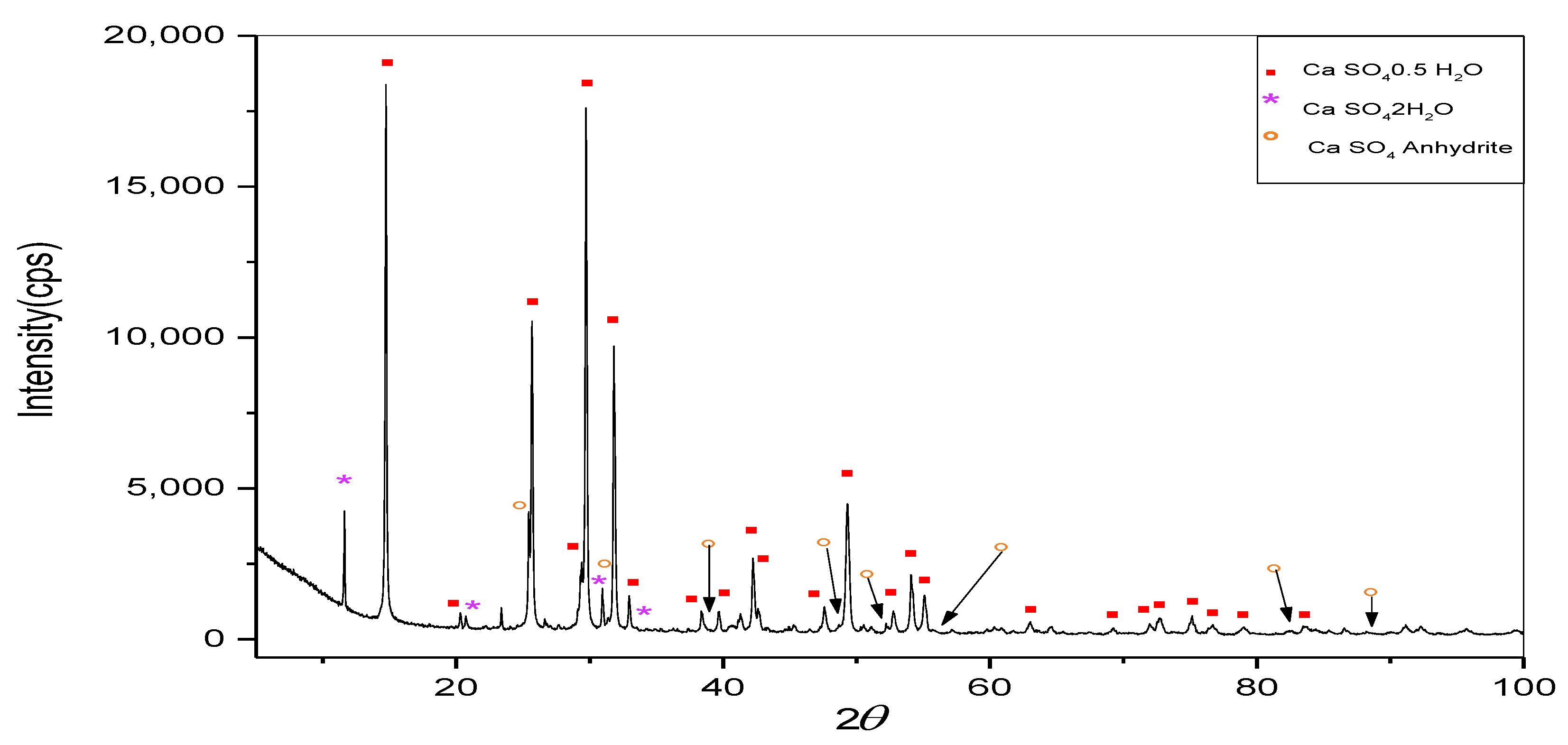

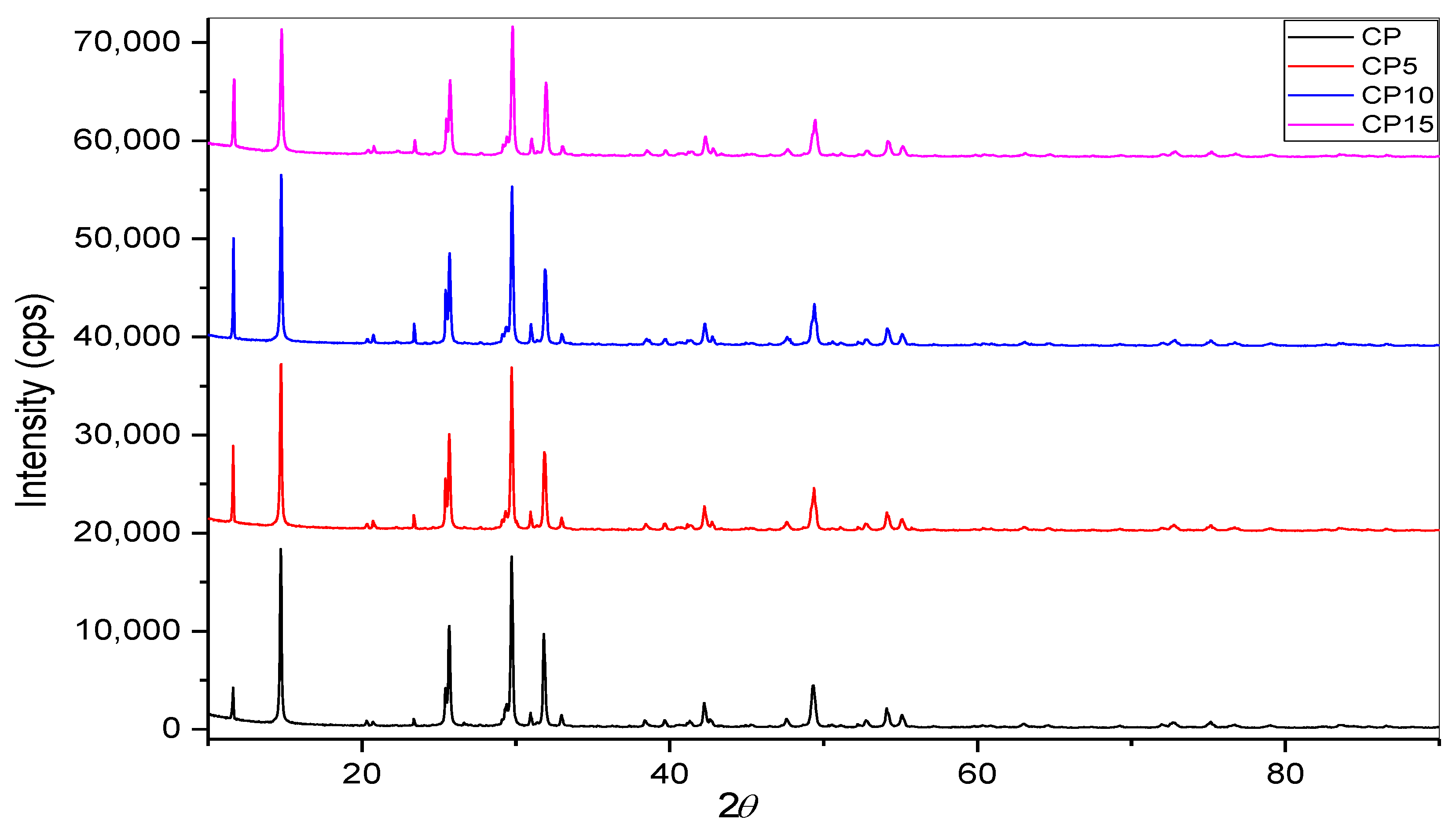

3.1.3. XRD

3.1.4. FTIR

3.1.5. SEM

3.2. Thermophysical Characteristics Measurements

Apparent Density

3.3. Thermal Conductivity

3.4. Time Lag

3.5. Energy Saving

4. Results

4.1. Thermal Property

4.1.1. TGA

4.1.2. DSC

4.2. Microstructure

4.2.1. XRD

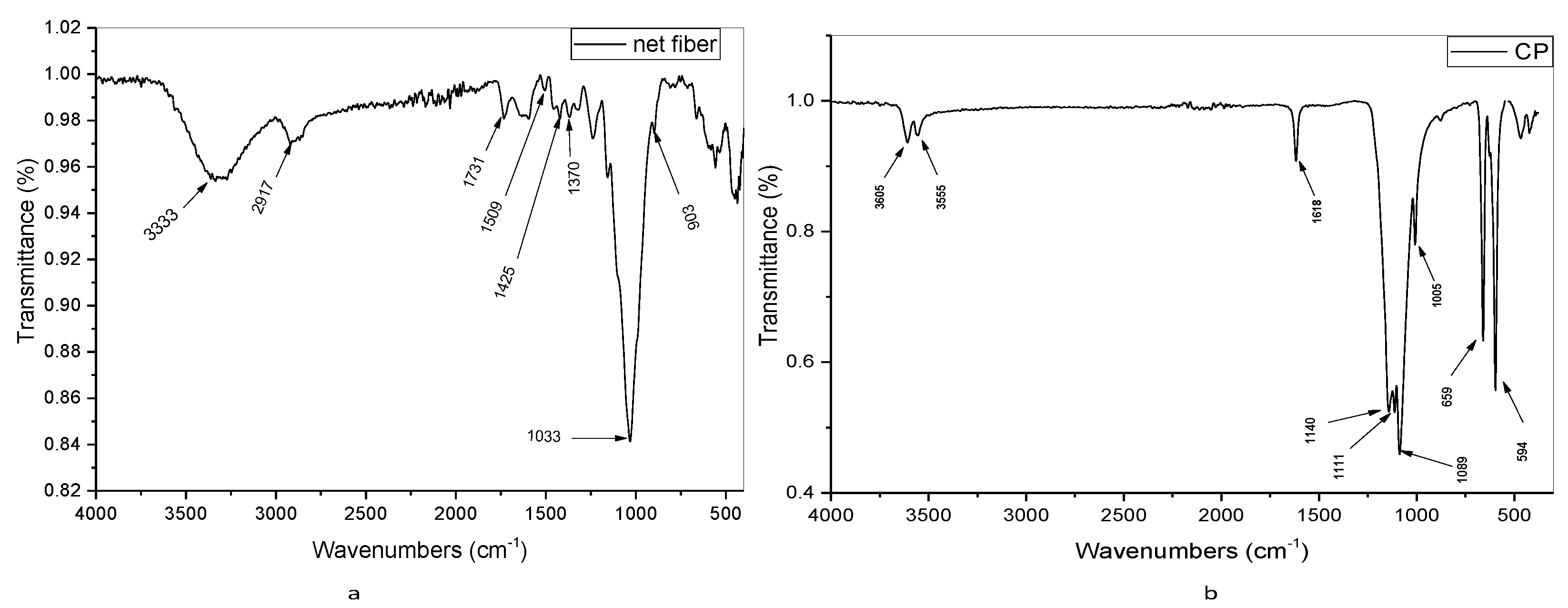

4.2.2. FTIR

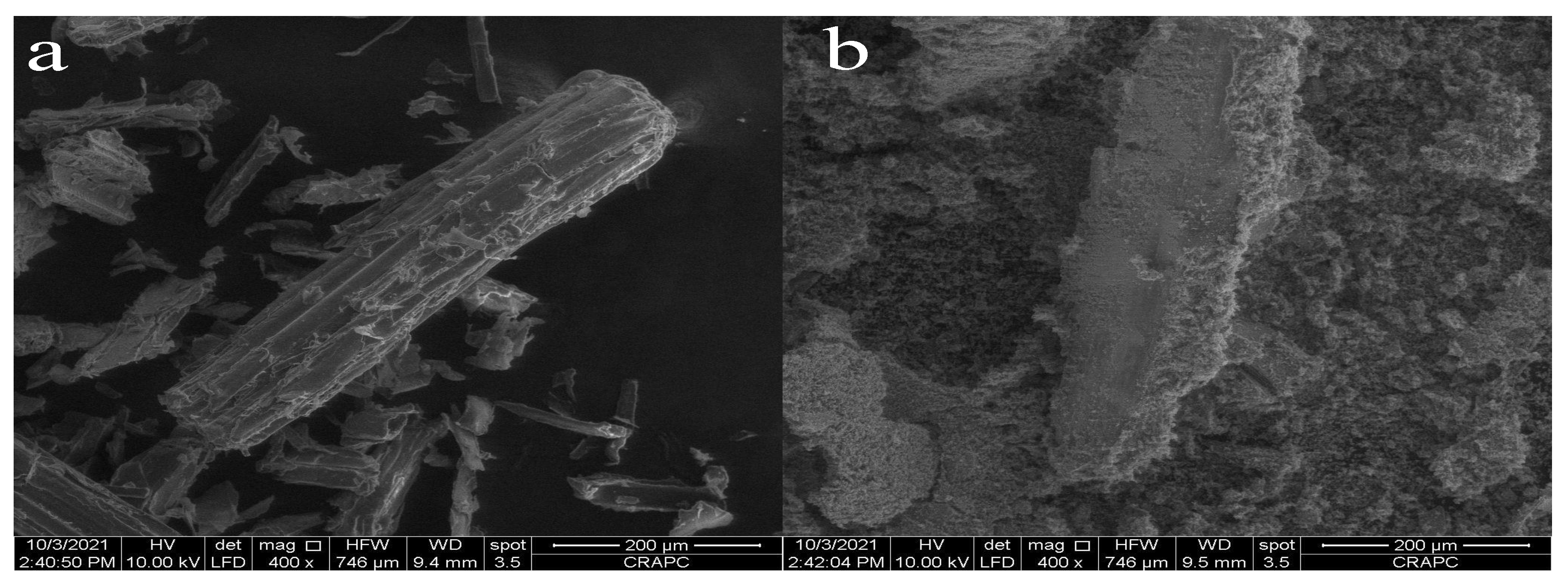

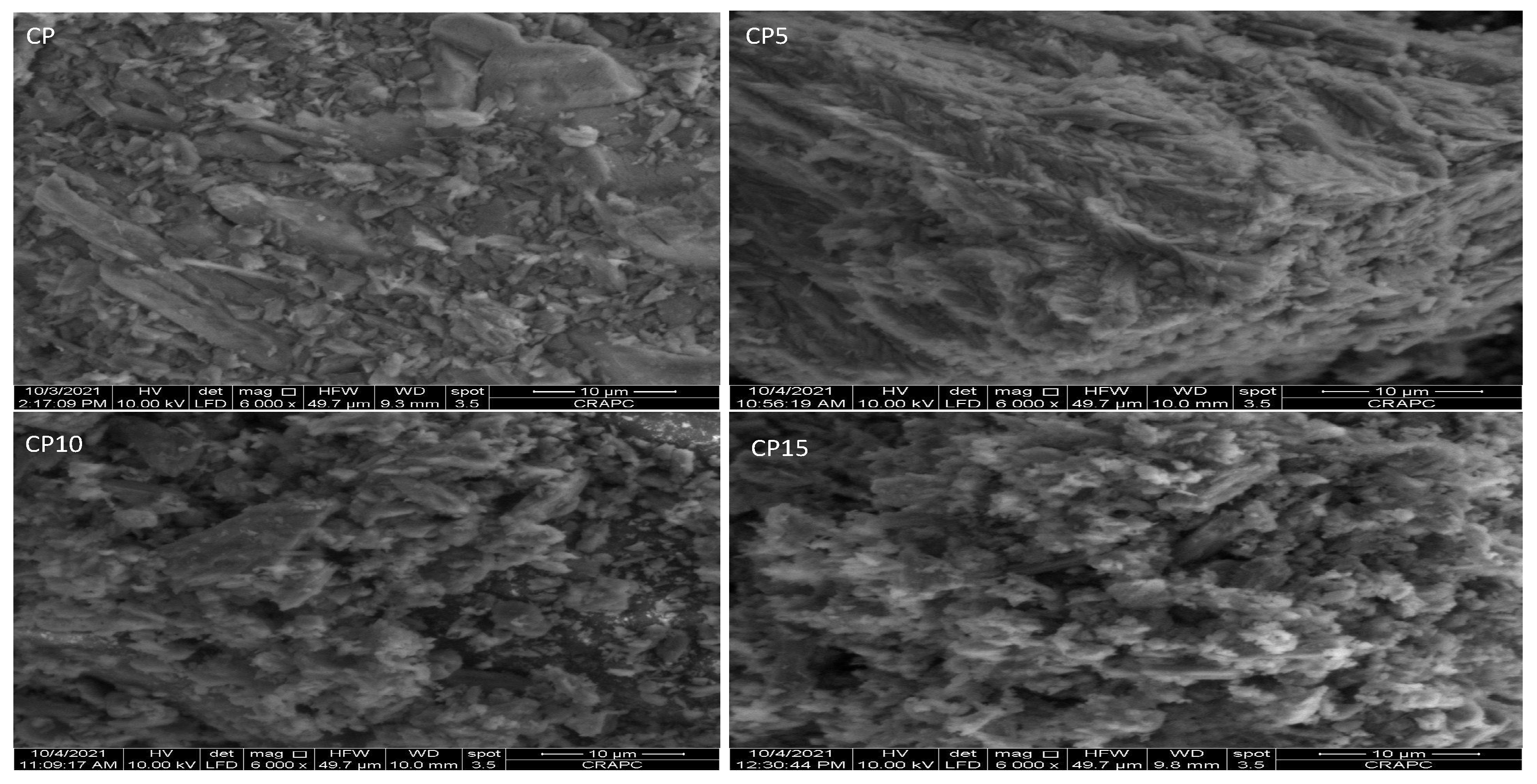

4.2.3. SEM

4.3. Thermophysical Properties

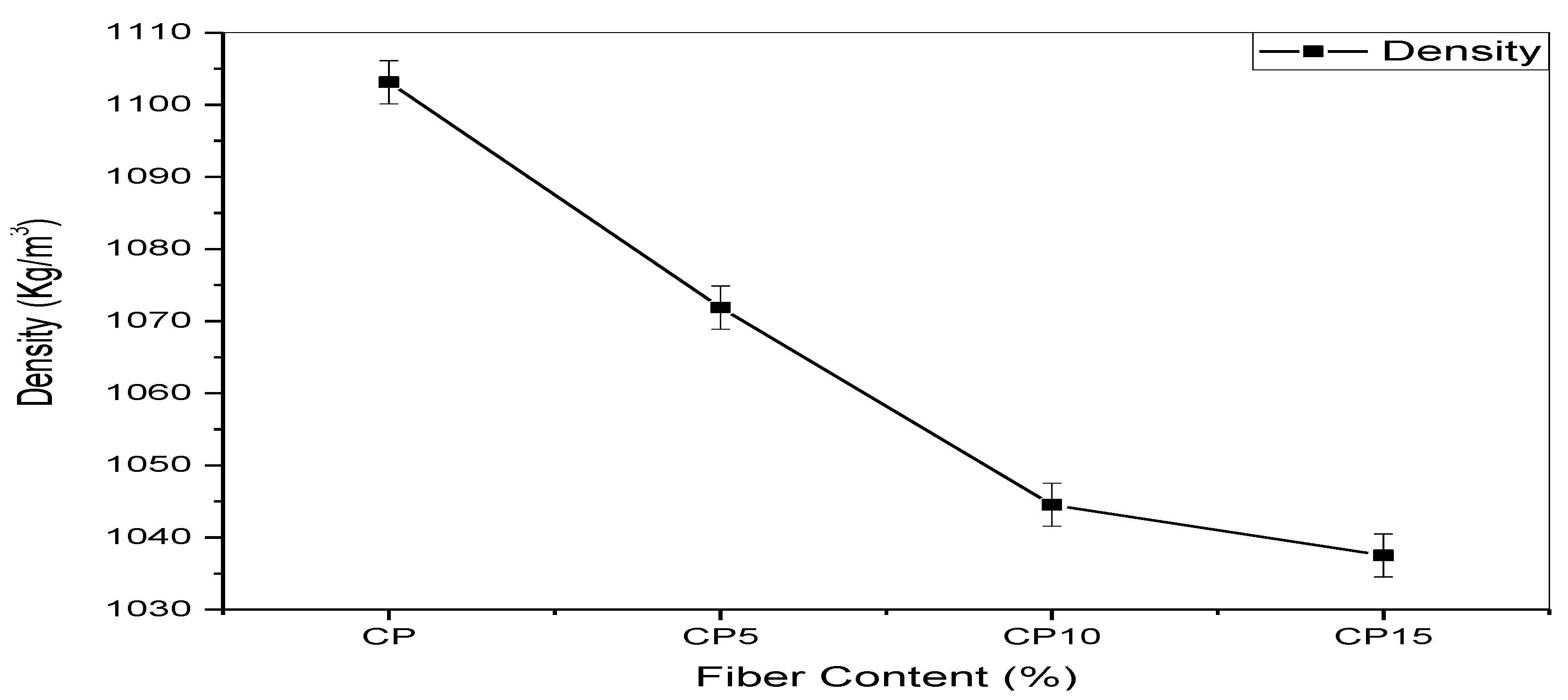

4.3.1. The Apparent Density

4.3.2. Thermal Conductivity

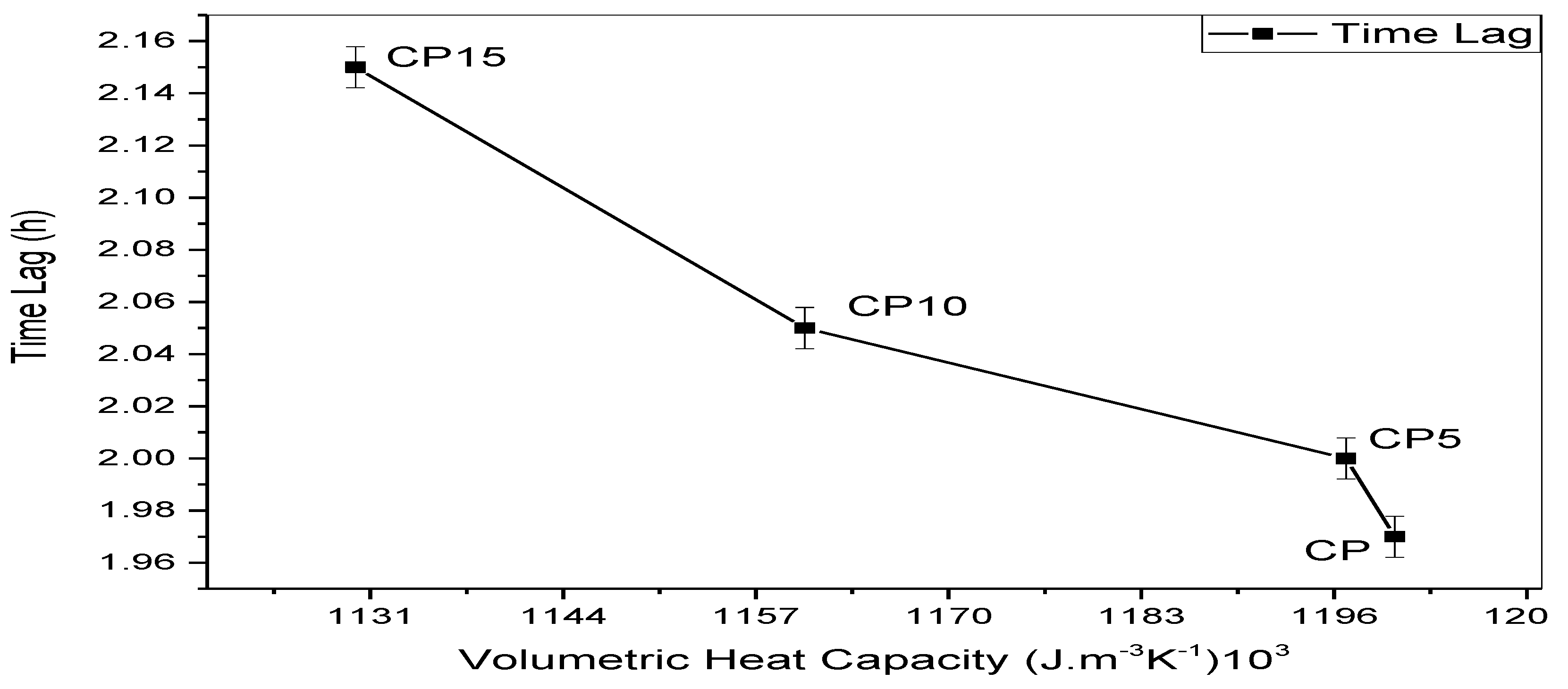

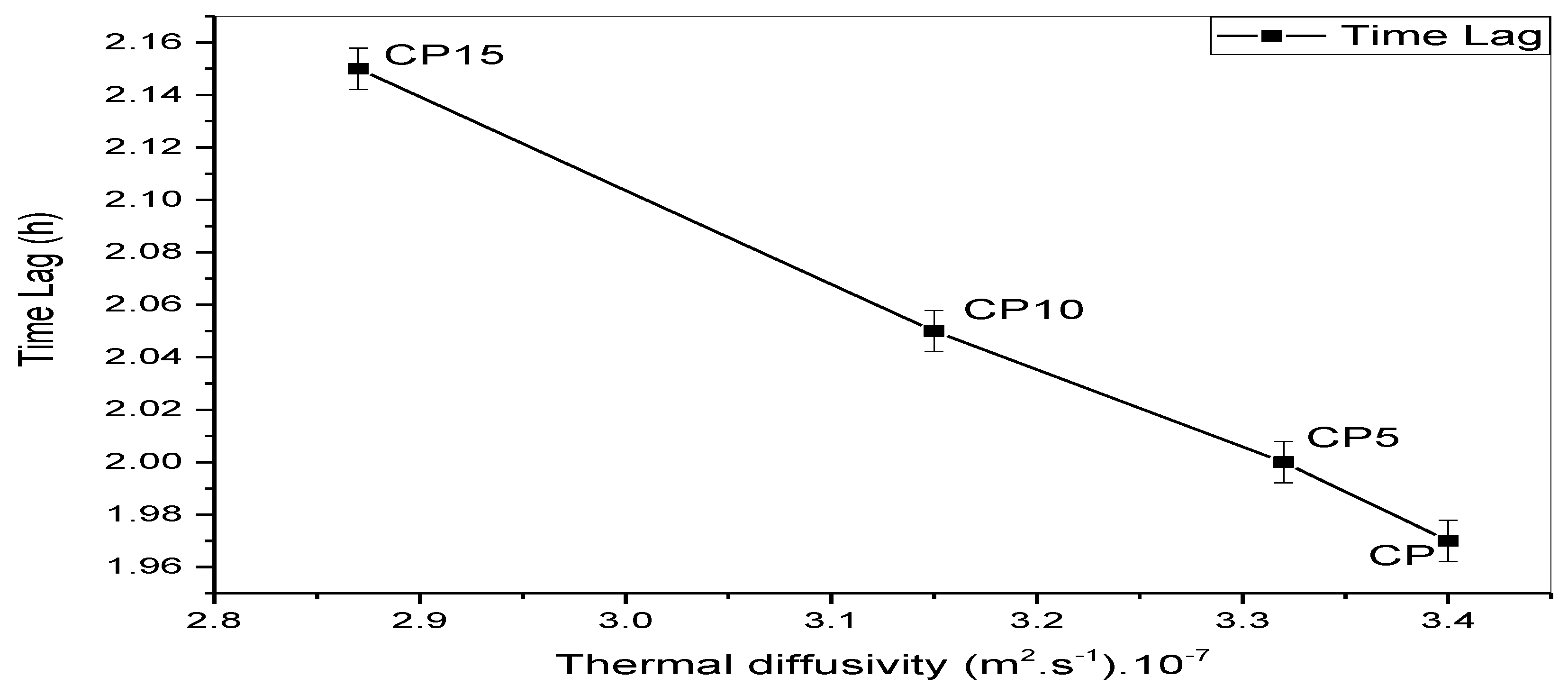

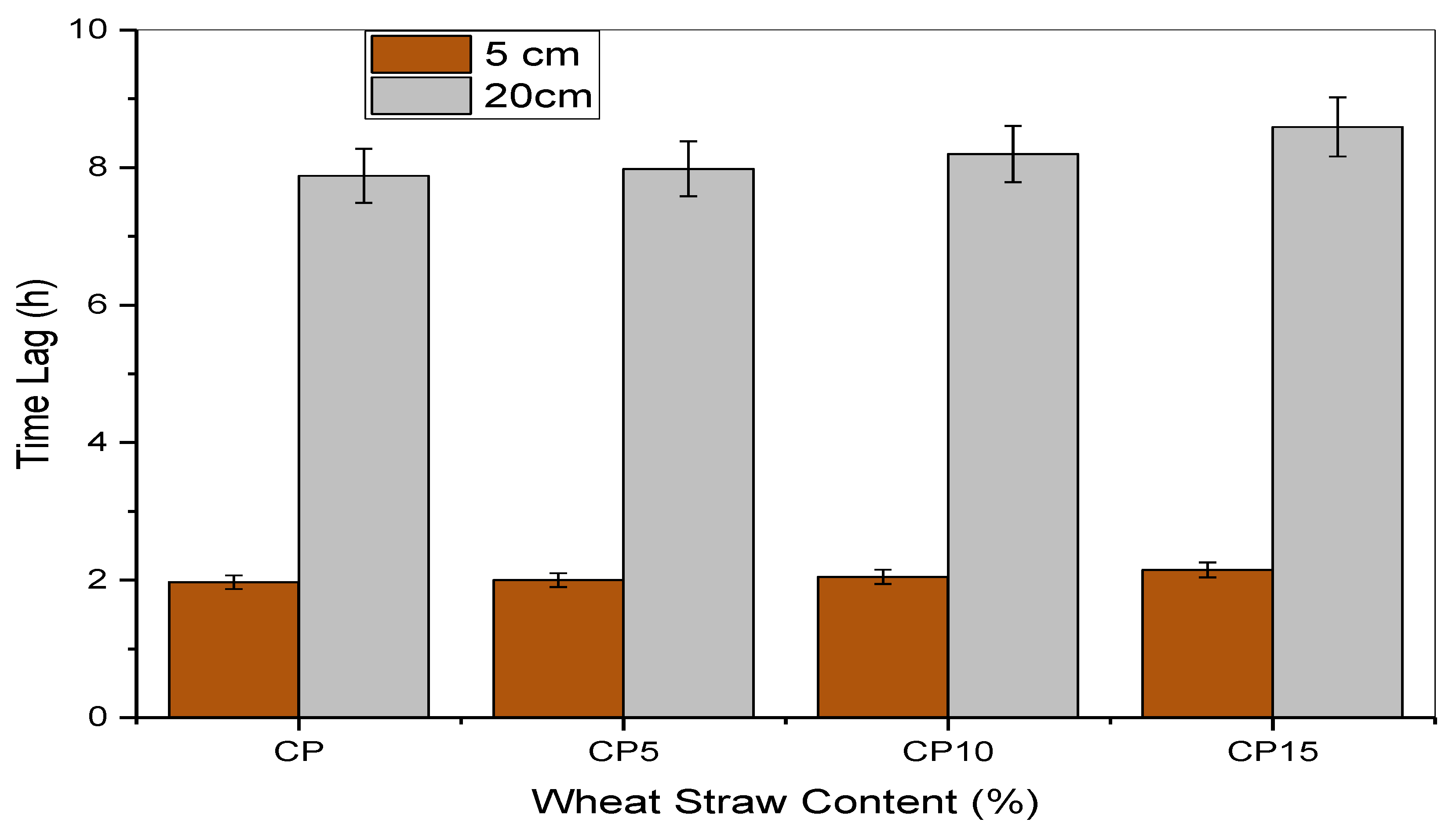

4.3.3. Time Lag

4.3.4. Energy Saving

5. Conclusions

- The FTIR and DRX results revealed that after incorporating varying amounts of wheat straw into the plaster, there was no influence on the level of chemical characteristics and that it was chemically stable, as well as no changes at the level of the matrix’s microstructure. On the other hand, TGA results showed strong thermal stability with an acceptable drop in mass after wheat straw integration, whereas DSC plots show an increase in peak temperature as well as enthalpy, which increases the thermal capacity of the compounds in which wheat straw was integrated. Wheat straw fibers induced an increase in pores and an acceptable distribution in the plaster matrix, resulting in excellent adhesion between the two compounds, according to SEM pictures.

- As for the thermophysical analytics, the samples were prepared, with different percentages of wheat straw, were prepared and tested to investigate their hygrothermal behavior. The results achieved from the test measurements show that the addition of wheat straw in the plaster matrix resulted in a linear reduction in the density and an increase in porosity. This means a reduction in thermal conductivity and therefore a more insulating behavior of the material. Furthermore, The time lag of a wall with varied configurations is impacted by the thermophysical parameters of the wall’s material, thickness, and orientation. So there is an inverse connection between the time lag and that of thermal energy and thermal diffusion. This is because as the wall thickness gets thicker, its heat storage capacity increases. Plaster containing 15% wheat straw has good energy saving, i.e., a small thermal conductivity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, S.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

- Shoubi, M.V.; Shoubi, M.V.; Bagchi, A.; Barough, A.S. Reducing the operational energy demand in buildings using building information modeling tools and sustainability approaches. Ain Shams Eng. J. 2015, 6, 41–55. [Google Scholar] [CrossRef] [Green Version]

- Missoum, M.; Hamidat, A.; Loukarfi, L.; Abdeladim, K. Impact of rural housing energy performance improvement on the energy balance in the north-west of algeria. Energy Build. 2014, 85, 374–388. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Thermal performance of a selection of insulation materials suitable for historic buildings. Build. Environ. 2015, 94, 155–165. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Ouakarrouch, M.; Garoum, M.; Laaroussi, N. Experimental study of thermophysical proprieties of wooden materials used in building construction. In Proceedings of the 2019 7th International Renewable and Sustainable Energy Conference (IRSEC), Agadir, Morocco, 27–30 November 2019; pp. 1–5. [Google Scholar]

- Martias, C.; Joliff, Y.; Favotto, C. Effects of the addition of glass fibers, mica and vermiculite on the mechanical properties of a gypsum-based composite at room temperature and during a fire test. Compos. Part B Eng. 2014, 62, 37–53. [Google Scholar] [CrossRef]

- Liang, J.Z. Predictions of Young’s modulus of short inorganic fiber reinforced polymer composites. Compos. Part B Eng. 2012, 43, 1763–1766. [Google Scholar] [CrossRef]

- Pellegrino, C.; D’Antino, T. Experimental behaviour of existing precast prestressed reinforced concrete elements strengthened with cementitious composites. Compos. Part B Eng. 2013, 55, 31–40. [Google Scholar] [CrossRef]

- Ashour, T.; Wiel, H.; Georg, H.; Bockisch, F.-J.; Wu, W. The influence of natural reinforcement fibres on insulation values of earth plaster for straw bale buildings. Mater. Design 2010, 31, 4676–4685. [Google Scholar] [CrossRef]

- Braiek, A.; Karkri, M.; Adili, A.; Ibos, L.; Ben Nasrallah, S. Estimation of the thermophysical properties of date palm fibers/gypsum composite for use as insulating materials in building. Energy Build. 2017, 140, 268–279. [Google Scholar] [CrossRef]

- Lamrani, M.; Laaroussi, N.; Khabbazi, A.; Khalfaoui, M.; Garoum, M.; Feiz, A. Experimental study of thermal properties of a new ecological building material based on peanut shells and plaster. Case Stud. Constr. Mater. 2017, 7, 294–304. [Google Scholar] [CrossRef]

- Azzouzi, D.; Rabahi, W.; Seddiri, F.; Hemis, M. Experimental study of the fibres content effect on the heat insulation capacity of new vegetable composite plaster-pea pod fibres. Sustain. Mater. Technol. 2020, 23, e00144. [Google Scholar] [CrossRef]

- Chikhi, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental investigation of new biocomposite with low cost for thermal insulation. Energy Build. 2013, 66, 267–273. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Sair, S.; Mandili, B.; Taqi, M.; El Bouari, A. Development of a new eco-friendly composite material based on gypsum reinforced with a mixture of cork fibre and cardboard waste for building thermal insulation. Compos. Commun. 2019, 16, 20–24. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Asan, H.; Sancaktar, Y. Effects of wall’s thermophysical properties on time lag and decrement factor. Energy Build. 1998, 28, 159–166. [Google Scholar] [CrossRef]

- Chikhi, M. Young’s modulus and thermophysical performances of bio-sourced materials based on date palm fibers. Energy Build. 2016, 129, 589–597. [Google Scholar] [CrossRef]

- Mounir, S.; Maaloufa, Y.; Cherki, A.; Khabbazi, A. Thermal properties of the composite material clay/granular cork. Constr. Build. Mater. 2014, 70, 183–190. [Google Scholar] [CrossRef]

- Lateef, H.U.; Kazmi, M.; Tabish, A.N.; Cheema, I.I.; Rashid, M.I. Effect of demineralization on physiochemical and thermal characteristics of wheat straw. Energy Sources Part Recover. Util. Environ. Eff. 2020, 1–10. [Google Scholar] [CrossRef]

- Bakolas, A.; Biscontin, G.; Contardi, V.; Franceschi, E.; Moropoulou, A.; Palazzi, D.; Zendri, E. Thermoanalytical research on traditional mortars in Venice. Thermochim. Acta 1995, 269–270, 817–828. [Google Scholar] [CrossRef]

- Siddiqi, M.H.; Liu, X.M.; Lateef, H.U.; Rafique, U.; Nawaz, S. Physiochemical and thermal analysis of diverse leaching reagents by demineralising raw wheat straw for clean energy production: Tga-ftir. Chem. Eng. Trans. 2020, 81, 379–384. [Google Scholar]

- Abidi, S.; Nait-Ali, B.; Joliff, Y.; Favotto, C. Impact of perlite, vermiculite and cement on the thermal conductivity of a plaster composite material: Experimental and numerical approaches. Compos. Part B Eng. 2015, 68, 392–400. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Mansour, M.B.; Soukaina, C.A.; Benhamou, B.; Jabrallah, S.B. Thermal characterization of a tunisian gypsum plaster as construction material. Energy Procedia 2013, 42, 680–688. [Google Scholar] [CrossRef] [Green Version]

- Kontogeorgos, D.; Founti, M. Gypsum board reaction kinetics at elevated temperatures. Thermochim. Acta 2012, 529, 6–13. [Google Scholar] [CrossRef]

- Li, Z.; Xu, K.; Wang, J.; Zhang, J.; Ma, X.; Niu, J. Mechanism of Degradation of the Properties of Recycled Plaster Mixed Aluminate Cement. Adv. Mater. Sci. Eng. 2020, 2020. [Google Scholar] [CrossRef] [Green Version]

- Bartolomei, S.S.; Wiebeck, H. Characterization of Gypsum Waste from Civil Construction to Obtain Polymer Composites. In Materials Science Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2019; Volume 958, pp. 47–51. [Google Scholar]

- Ismail, B.; Belayachi, N.; Hoxha, D. Optimizing performance of insulation materials based on wheat straw, lime and gypsum plaster composites using natural additives. Constr. Build. Mater. 2020, 254, 118959. [Google Scholar] [CrossRef]

- Kaushik, A.; Singh, M. Isolation and characterization of cellulose nanofibrils from wheat straw using steam explosion coupled with high shear homogenization. Carbohydr. Res. 2011, 346, 76–85. [Google Scholar] [CrossRef]

- Sain, M.; Panthapulakkal, S. Bioprocess preparation of wheat straw fibers and their characterization. Ind. Crop. Prod. 2006, 23, 1–8. [Google Scholar] [CrossRef]

- Cherian, B.M.; Pothan, L.A.; Nguyen-Chung, T.; Mennig, G.; Kottaisamy, M.; Thomas, S. A novel method for the synthesis of cellulose nanofibril whiskers from banana fibers and characterization. J. Agric. Food Chem. 2008, 56, 5617–5627. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Xu, F.; Sun, R.; Fowler, P.; Baird, M. Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr. Res. 2005, 340, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Alemdar, A.; Sain, M. Isolation and characterization of nanofibers from agricultural residues—Wheat straw and soy hulls. Bioresour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef] [PubMed]

- Cordeiro, N.; Neto, C.P.; Rocha, J.; Belgacem, M.N.; Gandini, A. The Organosolv Fractionation of Cork Components; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2002; Volume 56, pp. 135–142. [Google Scholar]

- Kaushik, A.; Singh, M.; Verma, G. Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr. Polym. 2010, 82, 337–345. [Google Scholar] [CrossRef]

- El-Zawawy, W.K. Blended graft copolymer of carboxymethyl cellulose and poly(vinyl alcohol) with banana fiber. J. Appl. Polym. Sci. 2006, 100, 1842–1848. [Google Scholar] [CrossRef]

- Xiao, B.; Sun, X.; Sun, R. Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw. Polym. Degrad. Stab. 2001, 74, 307–319. [Google Scholar] [CrossRef]

- Sun, R.; Tomkinson, J.; Wang, Y.; Xiao, B. Physico-chemical and structural characterization of hemicelluloses from wheat straw by alkaline peroxide extraction. Polymer 2000, 41, 2647–2656. [Google Scholar] [CrossRef]

- Mandal, P.K.; Mandal, T.K. Anion water in gypsum (CaSO4·2H2O) and hemihydrate (CaSO4·1/2H2O). Cem. Concr. Res. 2002, 32, 313–316. [Google Scholar] [CrossRef]

- Putnis, A.; Winkler, B.; Ferndez-Diaz, L. In situ ir spectroscopic and thermogravimetric study of the dehydration of gypsum. Mineral. Mag. 1990, 54, 123–128. [Google Scholar] [CrossRef] [Green Version]

- Prasad, P.; Chaitanya, V.K.; Prasad, K.S.; Rao, D.N. Direct formation of the γ-CaSO4 phase in dehydration process of gypsum: In situ FTIR study. Am. Mineral. 2005, 90, 672–678. [Google Scholar] [CrossRef]

- Liu, Y. Raman, Mid-IR, and NIR spectroscopic study of calcium sulfates and mapping gypsum abundances in Columbus Crater, Mars. Planet. Space Sci. 2018, 163, 35–41. [Google Scholar] [CrossRef]

- Morales-Conde, M.; Rodríguez-Liñán, C.; Pedreño-Rojas, M. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- Charai, M.; Sghiouri, H.; Mezrhab, A.; Karkri, M. Thermal insulation potential of non-industrial hemp (moroccan cannabis sativa l.) fibers for green plaster-based building materials. J. Clean. Prod. 2021, 292, 126064. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M. Improving thermal performance of building walls by optimizing insulation layer distribution and thickness for same thermal mass. Appl. Energy 2011, 88, 3113–3124. [Google Scholar] [CrossRef]

- Kontoleon, K.; Theodosiou, T.; Tsikaloudaki, K. The influence of concrete density and conductivity on walls’ thermal inertia parameters under a variety of masonry and insulation placements. Appl. Energy 2013, 112, 325–337. [Google Scholar] [CrossRef]

- Asan, H. Numerical computation of time lags and decrement factors for different building materials. Build. Environ. 2006, 41, 615–620. [Google Scholar] [CrossRef]

- Alavez-Ramirez, R.; Chiñas-Castillo, F.; Morales-Dominguez, V.; Ortiz-Guzman, M.; Lara-Romero, J. Thermal lag and decrement factor of a coconut-ferrocement roofing system. Constr. Build. Mater. 2014, 55, 246–256. [Google Scholar] [CrossRef]

| Refrences | Sample Composite |

|---|---|

| CP | Comerciale plaster |

| CP5 | Comerciale plaster + 5% of Wheat straw |

| CP10 | Comerciale plaster + 10% of Wheat straw |

| CP15 | Comerciale plaster + 15% of Wheat straw |

| Samples | W m | (W m K) | (Jm K) | a (m s) | Time Lag (h) |

|---|---|---|---|---|---|

| CP | 0.408 | 0.123 | 1200.1 | 3.4 | 1.97 |

| CP5 | 0.385 | 0.13 | 1160.3 | 3.32 | 2 |

| CP10 | 0.377 | 0.133 | 1196.8 | 3.15 | 2.05 |

| CP15 | 0.324 | 0.154 | 1130.0 | 2.87 | 2.15 |

| Energy Saving | |||

|---|---|---|---|

| Materials | (Wm K) | % | References |

| Net plaster | 0.408 | 0 | This work |

| Wheat straw /Plaster (15%) | 0.324 | 20.6 | This work |

| Wood shavings gypsum (40%) | 0.2 | 18.8 | [46] |

| Wheat fiber/plaster (25%) (dry basis) | 0.33 | 4.3 | [10] |

| Barley fiber/plaster (25%) (dry basis) | 0.29 | 18.8 | [10] |

| Wood shavings / plaster (25%) (dry basis) | 0.28 | 19.5 | [10] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saad Azzem, L.; Bellel, N. Thermal and Physico-Chemical Characteristics of Plaster Reinforced with Wheat Straw for Use as Insulating Materials in Building. Buildings 2022, 12, 1119. https://doi.org/10.3390/buildings12081119

Saad Azzem L, Bellel N. Thermal and Physico-Chemical Characteristics of Plaster Reinforced with Wheat Straw for Use as Insulating Materials in Building. Buildings. 2022; 12(8):1119. https://doi.org/10.3390/buildings12081119

Chicago/Turabian StyleSaad Azzem, Lokmane, and Nadir Bellel. 2022. "Thermal and Physico-Chemical Characteristics of Plaster Reinforced with Wheat Straw for Use as Insulating Materials in Building" Buildings 12, no. 8: 1119. https://doi.org/10.3390/buildings12081119

APA StyleSaad Azzem, L., & Bellel, N. (2022). Thermal and Physico-Chemical Characteristics of Plaster Reinforced with Wheat Straw for Use as Insulating Materials in Building. Buildings, 12(8), 1119. https://doi.org/10.3390/buildings12081119