Abstract

There is widespread enthusiasm toward utilizing mass timber panels (MTP), mainly cross-laminated timber (CLT), in construction, including for the basements of low-rise buildings. CLT is deemed a sustainable alternative to the widely used concrete foundation walls due to significant advantages such as less vulnerability to cracking due to uneven load distribution and presence of concentrated loads, higher thermal resistance, less construction time due to whole-wall prefabrication and installation, and less detrimental environmental effects. This study is part of an extensive research program aimed at developing the structural analysis and design concepts and methodology for constructing house foundation walls using MTPs, focusing on the usage of CLT. After comparison of CLT basements with their equivalent concrete ones from the sustainability point of view, and a brief discussion on geotechnical and hygrothermal considerations, the main theme of the article includes the structural analysis and design methodology, requirements, and the procedure to achieve a reliable and efficient design of a CLT basement. A simplified analysis procedure to design the laminate thicknesses and the number of layers in CLT foundation walls for different scenarios considering various variables such as soil type and backfill height is discussed, and results in the form of pre-engineered design tables are provided. The findings of this study demonstrate that, depending on the soil type and backfill height, 3–7-ply CLT panels would be needed for net wall heights of up to 3 m. Additionally, advanced finite element analyses are performed on sample architypes to validate the simplified analysis procedure used for design. It is shown that the proposed analysis procedure and the pre-engineered tables produce conservative and efficient results.

1. Introduction

Concrete has been the dominant material used in basement construction of low-rise residential light-wood-frame buildings in North America due to its durability and strength (Figure 1a). However, there have been frequent performance problems associated with concrete foundation walls, such as dampness, cracking of the concrete, high thermal loss, and long construction times associated with casting and curing. Although concrete foundation walls are generally lightly reinforced to minimize cracks due to shrinkage and temperature, the formation of a crack is inevitable in most cases due to the inherent material properties of concrete. As a result, water leakage due to cracking in the concrete is highly possible. A comprehensive review of basement wall cracking problems was conducted by the American Society of Home Inspectors [1]. In addition to the issues above, there are other potential problems, such as serious heat loss, uncomfortable below-grade living space with a feeling of dampness, mold and mildew, problems with concrete pouring at low temperatures, difficulty in constructing in remote locations, and difficulty in finishing. Despite these problems, concrete basements have continued to be the dominant type of basement construction for decades.

Figure 1.

(a) Conventional concrete basement construction; (b) alternate low-rise basement solutions: PWF (Courtesy of Canadian Wood Council and Wood Preservation Canada).

Alternative basement systems have been developed and used commercially. Notable examples are insulated concrete form (ICF) [2,3] and permanent wood foundation (PWF) [4,5,6]. These systems are recognized by the building codes if they meet the requirements of standards such as CAN/ULC-S717.1 [3] for ICF and CSA S406-16 [5] for PWF. Despite their inclusion in building codes, these systems have not been widely accepted as a replacement for traditional concrete foundation walls due to various challenges, such as higher cost, lack of resiliency to deal with a wide range of soil conditions, and propensity for defective construction [2,6]. As shown in Figure 1b, PWF is a light-wood-frame foundation system made of lumber framing and sheathing. It is meant to support low-rise buildings [7].

Recent advances in mass timber products have opened the door to rethinking sustainable alternate solutions to replace concrete to overcome all mentioned deficiencies and reduce carbon footprint. Cross-laminated timber (CLT) is a relatively new engineered wood panel product attracting global interest due to its availability in large dimensions, high strength-to-weight ratio, and excellent dimensional stability compared with traditional wood products. CLT is made by cross-laminating layers of dimension lumber into a thick structural panel using a durable adhesive. A comprehensive publication on the production process, applications, and design of CLT was published by FP Innovations [8]. Initially developed in central Europe in the late 1990s as a substitute product for concrete slabs and tilt-up walls, it has now been used to construct tall wood buildings worldwide over the last decade, mainly as load-bearing walls. CLT offers benefits over traditional and more recent basement systems, such as better material insulation properties, ease of prefabrication, structural resiliency, and, more importantly, lower environmental footprints. CLT foundation walls can be categorized as PWF due to similar intended usage and demands, although they are not included in the current PWF guidelines and standards. However, there are similarities in structural demand calculation and construction techniques that have benefited from this research. For instance, to provide a dry and comfortable living space below the grade, similar construction practices for moisture control and insulation can be adopted [9,10]. For CLT as a foundation wall, only a handful of research studies have been conducted [11,12] that can provide insight, reiterating the lack of information and the need for further studies in this area.

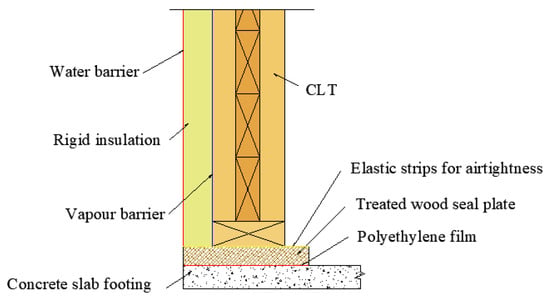

As a result, a research program is currently being conducted at the University of Alberta to develop a new concept for constructing house basements using MTP, including CLT. This project initiated the design process to turn the conceptual idea into tangible new foundation wall construction technologies that eliminate the performance problems associated with the concrete walls and provide house occupants with a warm and healthy basement using wood as a more sustainable material. Technical challenges need to be addressed before CLT can be used with confidence as a material for constructing house basements. One of the main concerns is the long-term durability of CLT foundation walls, given that wood is prone to attack by biological agents under high humidity conditions or in soil contact. In order to develop the required construction technologies that can be accepted by authorities having jurisdiction, building owners, developers, and insurance companies, it is important that a holistic system approach, encompassing structural, thermal, and durability performance attributes, is adopted to ensure that construction details introduced to address one performance issue do not negatively impact another performance attribute. Figure 2 demonstrates a sample solution for using CLT, accompanied by a moisture barrier and thermal insulation, in this application.

Figure 2.

Proposed detail of the CLT basement wall.

This paper seeks to initiate a multidisciplinary approach to address all the vital issues involved, including the long-term durability, with a focus on structural analysis and design. A brief discussion on the geotechnical and hydrothermal aspects of CLT foundation walls is provided after comparing conventional concrete foundation wall systems with the proposed CLT walls from a sustainability point of view. Then, the structural analysis and design of such CLT foundation walls are discussed. The main objective is to develop a simplified analysis procedure to calculate the laminate thicknesses and the number of layers in CLT basement walls subjected to soil lateral loading to provide an alternate solution to the conventional concrete foundation walls.

2. Sustainability Considerations

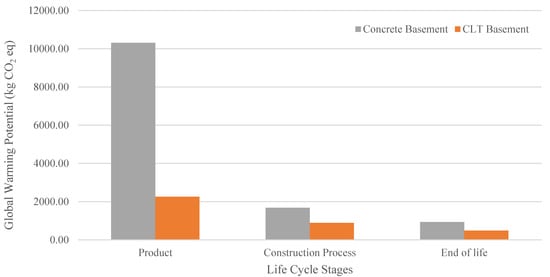

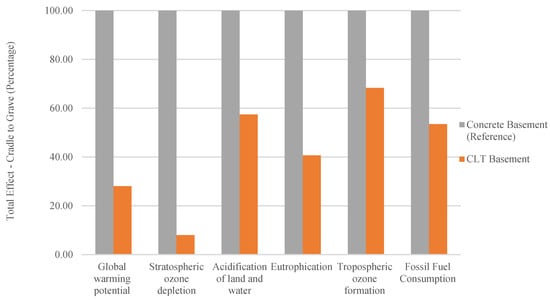

This section compares the environmental effects of CLT foundation walls with the equivalent concrete walls commonly used in low-rise construction. This exercise assumes a 216 m2 basement (12 m × 18 m) with a wall height of 3.0 m. For concrete basement walls, 200 mm thick walls are assumed to be made of 25 MPa concrete and 15 mm diameter reinforcement bars, while five-ply CLT is considered an equivalent timber-based alternative. The Athena Impact Estimator for Buildings, version 5.4 [13], was utilized to run the life-cycle analysis (LCA). Figure 3 compares one of the main life-cycle assessment (LCA) measures, global warming potential (GWP), representing the emission of carbon dioxide, for conventional concrete basements and the one made with CLT. As can be seen, the CLT basement option would significantly reduce the global warming potential measure by almost 80% as a primary structural material. During construction, the reduction in the GWP is noticeable as well. More importantly, contrary to the general belief, it is demonstrated that moving toward the CLT foundation wall would be less detrimental to the environment at the end of the life cycle of the building (50 years of life span assumed). Table 1 compares the main measures based on the Leadership in Energy and Environmental Design (LEED) [14] rating system for concrete and CLT basement systems. As can be seen, there are improvements in all detrimental effects by moving toward CLT as the main material for the basement construction. Figure 4 compares the two systems graphically, using the conventional concrete foundation wall system as the reference. As can be seen, by moving toward a CLT foundation wall, there are significant improvements in all environmental measures based on LEED, which is the dominant rating system for residential buildings in North America. It is noted that, in LEED, there are few categories that provide an opportunity for a building to gain scores to be certified. Due to the nature of the research, the “material and resources” category was considered the target category.

Figure 3.

Global warming potential measure results comparison of concrete basement versus CLT.

Table 1.

LEED LCA measure comparison—cradle to grave (reference: concrete basement; proposal: CLT basement).

Figure 4.

LEED LCA measures comparison—cradle to grave (reference: concrete basement; proposal: CLT basement).

3. Geothermal and Hygrothermal Considerations

In general, the earth pressure acting on a soil-retaining structure, e.g., a foundation wall, depends on the lateral deformation of the soil. Unless the deformation conditions can be estimated precisely, no theoretical solution can accurately predict the lateral earth pressure distribution. For rigid retaining walls, earth pressure and water pressure can be estimated using theoretical solutions from Rankine’s or Coulomb’s earth pressure theories, which assume a linear earth pressure distribution behind the retaining wall. Results from these theories are satisfactory only if the soil deformation is large enough to mobilize the soil shear strength. These methods provide limited information on the distribution and magnitude of lateral earth pressures induced by different wall displacements. In this case, earth pressure distribution becomes more complicated for flexible walls since it depends on wall deflection and soil deformation; in this case, “apparent” earth pressure distribution may be adopted for design [15]. As a result, the precise design of foundation walls requires knowledge of earth pressure theory, soil behavior, and construction methods, an understanding of the limitations of the available theoretical design methods, and experience. Terzaghi’s observation of Coulomb’s retaining wall calculation is still widely applied, particularly in limit equilibrium methods, in calculating earth pressures. Such calculations assume that active and passive zones can be identified on the basis of the movement of the wall; the pressure distribution is triangular and hydrostatic, and it increases linearly with depth. This method is deemed conservative for practical purposes, as it is commonly exercised in practice. Accordingly, triangular soil pressure was assumed in this study, increasing linearly. Depending on the wall movement, soil distribution can diverge from what is commonly assumed, which was neglected in this study. Additionally, the effects of soil placement, creep, and thermal movements were ignored.

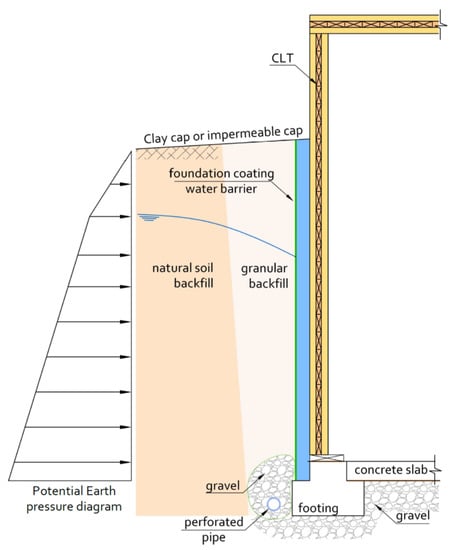

When CLT is exposed to water, high moisture content can result and lead to biodegradation. However, if a water- and vapor-impermeable coating is applied on the exterior side of a CLT, the coating can reduce moisture penetration from the surrounding wet environment. While the investigation regarding the water barrier systems on CLT panels is ongoing, the preliminary results reveal that the selected commercially available water and vapor barrier products can protect the CLT foundation walls. In particular, foundation coatings with water protection and vapor protection functions as a single product, self-adhesive membranes, and high-density polyethylene (HDPE) membranes are promising. The authors propose a drainage system as shown in Figure 5, which includes a granular backfill to replace the native soil in the case of silts and clays prone to frost heave. The granular backfill will prevent water accumulation near the surface of the basement wall, reducing the water pressure. Gravels and a perforated drainpipe are placed around the footing to conduct the excess water out of the foundation. The gravel below the footing will protect against the uplifting forces generated by adfreezing displacement, prevent frost heave, and thaw settlement.

Figure 5.

Drainage system including the recommendation to avoid frost-susceptible soils in contact with footings.

The design of the exterior wall assemblage needs to provide sufficient thermal resistance as required by building codes. In the National Building Code of Canada (NBCC) [16], for climate zone 7A, including Edmonton, Regina, Winnipeg, and Quebec, the required overall thermal resistance is 3.08 K∙m2/W (R-17.5). Furthermore, condensation due to vapor diffusion through the walls must also be avoided. The hygrothermal analysis for a basement wall is not straightforward because the wall is partially exposed to exterior air and partly covered by soil. Due to the temperature and moisture variations in the vertical direction, water vapor could flow inward or outward depending on the depth of the wall, and it can be in a reverse direction in different months. The hygrothermal design proposes a layer of external insulation as a better option for internal insulation only. There is no thermal bridging due to structural components (e.g., studs). A layer of vapor barrier and continuous insulation can reduce the vapor permeability of the wall assemblage. While a precise hygrothermal performance evaluation of the wall assemblage is outside of the scope of the current paper (this will be discussed in a separate publication), the results for three-ply CLT foundation walls show no condensation due to vapor diffusion. In general, using CLT in basement walls in combination with layers of vapor barrier and rigid external insulation (as shown in Figure 3) can satisfy the hygrothermal requirements.

4. Structural Analysis and Design

4.1. Design Objective, Methodology, and Design Loads

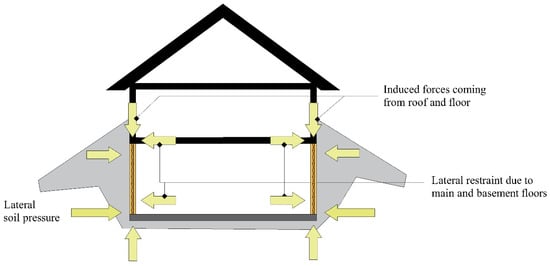

The main objective of the structural design section is to showcase the simplified analysis procedure leading to determining the required thickness of the CLT in this specific application for different scenarios. To achieve the goal, the approach outlined by the American Wood Council (AWC) [4] for designing the PWF was adopted, focusing on lateral soil loads as the main lateral demand, as shown in Figure 5. Obviously, the wind or earthquake loads should be added to the actual building, which was excluded in this study since, according to the reports on basement wall behavior under major earthquakes [17], the performance of basement walls is satisfactory, and the possibility of failure is rare even if the structures are not explicitly designed for earthquake loading. The soil types and loading were determined according to ASCE7-16. [18]. Regarding CLT strength design calculations, the Canadian wood design code, CSA O86-19, was adopted [19]. The structural components of the CLT basement wall system consist of CLT panels, top and bottom plates, and the connections attaching the panels or to the foundation slab. All components should be designed to support all the applied loads as shown in Figure 6, satisfying the ultimate and serviceability limit states as indicated in the NBCC [16] or ASCE7-16 [18]. For soil pressure, a load factor of 1.5 is required when checking the ultimate limit states of the walls per NBCC. This factor is 1.6 for the ASCE 7-16 code.

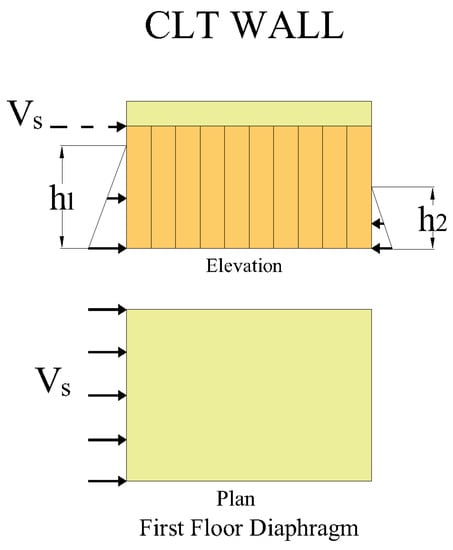

Figure 6.

Loads considered for CLT basement wall design.

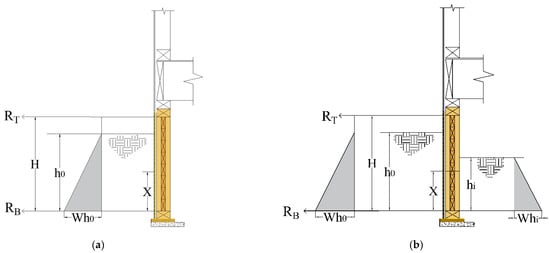

Two cases of basement wall and crawl space were considered as shown in Figure 7a and Figure 8b, both common in low-rise North American construction. In the basement wall scenario, the backfill is available on one side, while the wall is under lateral pressure on both sides in the crawl space. Figure 7 shows the lateral load distribution in both cases and the parameters necessary to quantify the demand and response. These parameters are backfill height (m), CLT wall height (m), location of the maximum moment (m), lateral soil load (kN/m2), backfill height on the outside of crawl space (m), backfill height on the inside of crawl space (m), reaction at the top of the CLT wall (kN), reaction at the bottom of the CLT wall (kN), and CLT wall thickness (m).

Figure 7.

Using CLT panels in (a) basement wall and (b) crawl space.

Figure 8.

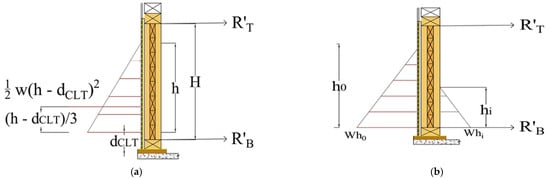

Using CLT panels as basement wall (a) vertically and (b) horizontally.

Furthermore, two cases of vertical and horizontal placement of CLT are considered to investigate the tradeoff between a more structurally robust system and easier constructability, as shown in Figure 8. As seen in Figure 8a, considering five-ply CLT, there are three plies positioned vertically, providing flexural resistance against lateral soil pressure; as shown in Figure 8b, there are just two vertical layers with a smaller lever arm. As a result, the vertical arrangement is favorable structurally, although additional panel-to-panel connections might cause the construction to be more difficult. Considering CLT panels with different ply thicknesses (thicker longitudinal plies and thinner transverse plies) might lead to a more economical design, assuming that the in-plane shear capacity of the walls, as discussed in the following section, is not governing.

4.2. CLT Panel Analysis and Design

4.2.1. Ultimate Limit States

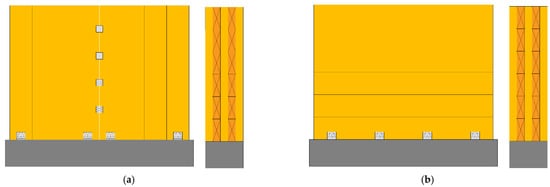

The wall is primarily checked for bending and shear due to lateral soil pressure for the ultimate limit states. For simplicity, it is assumed that the CLT foundation wall is a simply supported panel at the top and bottom. The free-body diagrams of the two cases are shown in Figure 9.

Figure 9.

Free-body diagrams of (a) basement wall and (b) crawl space.

Writing the equilibrium equations for Figure 9a leads to Equation (1) for the determination of the moment at a desired section of x. Equating shear to zero gives the location of the maximum moment, as shown in Equation (2).

Accordingly, the reactions at the top and bottom of the wall can be determined using Equations (3) and (4).

For shear calculations, according to the O86-19 [19] and NDS [20], the effect of loads acting within a distance from a support equal to the depth of the CLT wall need not be taken into account for shear demand calculation. As a result, the maximum shear force can be calculated as shown in Equation (5).

For the crawl space application, Equations (1)–(5) can be rewritten as Equations (6)–(10), respectively.

where .

In addition to out-of-plane moment and shear, the in-plane shear due to differential backfill heights needs to be considered, as shown in Figure 10. In this figure, is the backfill height with the greatest depth (m), is the backfill height on the opposite side of the greatest depth (m), and is the lateral load induced due to differential backfill (kN).

Figure 10.

Resultant in-plane force due to differential backfill (top) elevation (bottom) plan.

can be determined using Equation (11).

As shown in Figure 6, the basement walls are under axial loads due to the dead and live loads of the superstructure above. As a result, the compressive strength of the wall is checked both alone and combined with lateral backfill demand.

4.2.2. Serviceability Limit States

The main serviceability limit state that should be considered is deflection. According to CSA 086-19, the maximum deflection should be determined for the specified load applied perpendicular to the panel, considering both short-term elastic effects and instantaneous elastic long-deflection deformation. There are equations proposed for the panel under uniform and concentrated load but not for triangular load distribution, as shown in Figure 7 and Figure 9. As a result, Equation (12) is derived using the same principles.

where (EI)eff and (GA)eff are effective bending stiffness and effective in-plane shear rigidity. The limit of H/240 can be adopted from available PWF codes until further research is performed [4].

4.2.3. Pre-Engineered Selection Tables

Following the steps discussed above can determine the structural demand necessary to design the CLT basement. Using equations of CSA O86-14 for designing CLT elements subjected to different load scenarios, one can design a CLT basement under individual and/or combined effect moment, shear, and axial force induced. To provide some insight into the final design results, two engineered design tables (Table 2 and Table 3) were developed, similar to what is available for concrete basements. As can be seen, these two tables summarize the approximate thickness required for CLT basements (Grades E1 and E3), considering different soil types and backfill heights, assuming vertical arrangement. For the development of the tables, a 4.5 kN/m vertical load is assumed.

Table 2.

CLT number of plies required for vertical arrangement, E1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 35 mm.

Table 3.

CLT number of plies required for vertical arrangement, E3 grade, longitudinal layer thickness = 35 mm and Transverse layer = 35 mm.

As can be seen, three-ply CLT walls are deemed sufficient for most anticipated cases. Generally, it is required to move toward five- or seven-ply CLT panels for walls taller than 2.4 m on soils with high lateral pressure to achieve an acceptable design. The governing limit states for such an increase in thickness are also demonstrated. To achieve a more economical design, CLT panels with unequal longitudinal and transverse layers (reduced thickness of transverse layers) were also considered, and the associated pre-engineered tables were produced (see Appendix A: Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9 and Table A10). It was observed that using CLT panels horizontally requires a minimum thickness of five-ply CLT in all cases, which might not be economical.

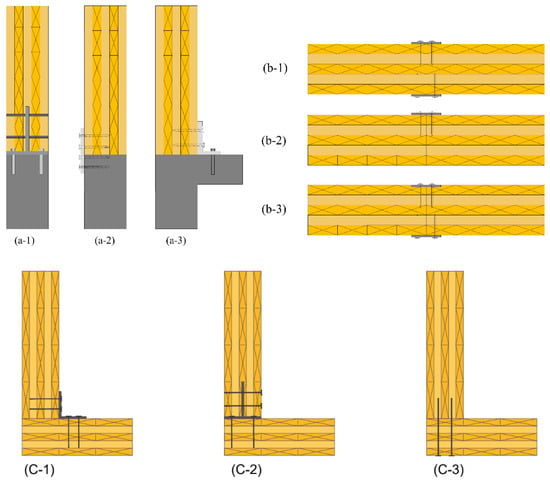

4.3. Connections

The top and bottom connections of the CLT wall should be designed to resist the induced reactions at the top and bottom, as determined in Equations (3), (4), (8), and (9), as well as the in-plane shear force due to differential backfill, as calculated in Equation (11). The top reaction is transferred to the adjacent floor system, while the bottom reaction is transferred to the concrete floor via base shear connections. Figure 11 showcases some typical examples of the base shear connections. It can be noted that the base shear is deemed sufficient to take the induced uplift due to soil lateral force. However, in scenarios with high uplift due to transient effects of wind or seismic activity, hold-down connections should be utilized as required. Among all the options in Figure 11a, Figure 11(a-3) provides a stiff connection that can prevent water penetration in basement applications and can be used as the base shear connection case. The other type of connection that might be needed in the vertical arrangement of CLT panels is the panel-to-panel connection. Examples of such connections are shown in Figure 11. It is suggested to use detail Figure 11(b-3), such that there is interference with the water barrier on the outside. It is recommended that the fasteners and the connectors be made of stainless steel. Hot-dipped galvanized steel fasteners can be used in the case of well-covered connections with no exposure to water. It should be noted that stainless-steel fasteners and galvanized steel parts should not be in contact [4]. In the current literature on the behavior of both base shear and panel-to-panel connections, the connections were largely investigated under in-plane loading, not out-of-plane loading, which is the dominant case herein. As a result, until further experimental investigation into these connections is available, it is suggested to be conservative and provide very stiff connections by increasing the number of connections to ensure the integrity of the systems, mainly in terms of water barrier. This also applies to the corner connections showcased in Figure 11c.

Figure 11.

Feasible options for connections: (a) base shear connections; (b) panel-to-panel connections; (c) corner connections [8].

4.4. Design Verification

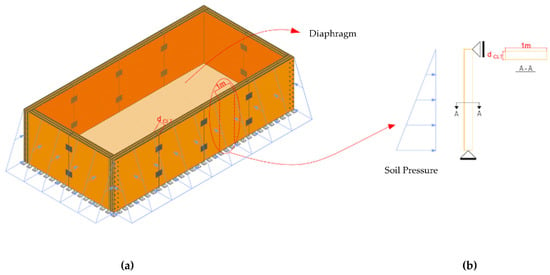

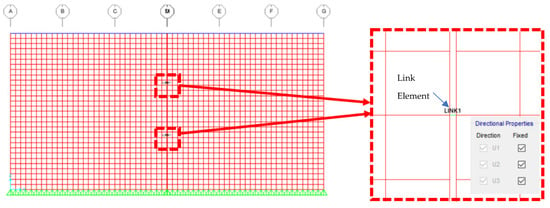

To verify the simplified analysis and design procedure, finite element analysis software, Sap 2000 (version 21) [21], was employed to provide a more realistic model for CLT foundation walls under soil pressure. Three architype models were selected, 6 m × 12 m (A) and 12 m × 12 m (B) models with continuous panels (panel-to-panel connections not modelled), and a 6 m × 12 m (C) model with connections, as summarized in Table 4, to compare with the simplified analysis model, discussed in Section 4.2 (model S). Figure 12 schematically showcases the difference between the developed FE models (A to C) and the simplified analysis model (model S). For each architype, three-ply, five-ply, and seven-ply CLT were considered and modeled as layered shell elements, with different characteristics in longitudinal and transverse layers (see Table 5), resulting in nine FE models. Each model consisted of rectangular foundation wall systems with a mesh size of 100 mm × 100 mm, obtained by a mesh sensitivity study. The backfill height was assumed to be equal to the wall height (3 m). The bottoms of the walls were pinned, while the tops of the walls were defined as diaphragms. As shown in Figure 13, in model C, a small gap was considered between the panels, and panel-to-panel connections were defined using rigid link elements with 1 m spacing along with the height of the panels.

Table 4.

Architype models considered for FE verification of analysis.

Figure 12.

(a) Three-dimensional FE model of CLT basements under lateral soil pressure versus (b) simplified one-dimensional analysis model used in design.

Table 5.

Layered shell elements with different characteristics in longitudinal and transverse layers to define CLT material in the software.

Figure 13.

Panel-to-panel connection definition in model C.

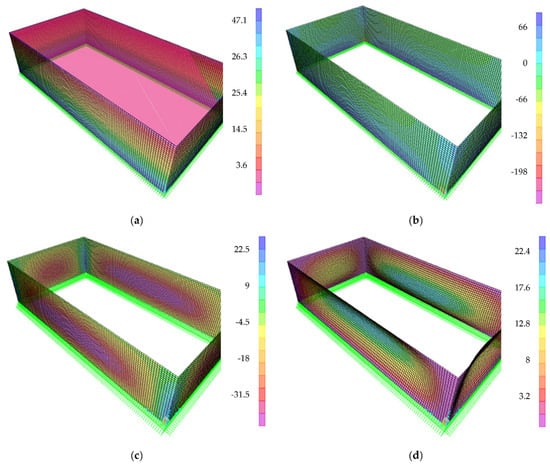

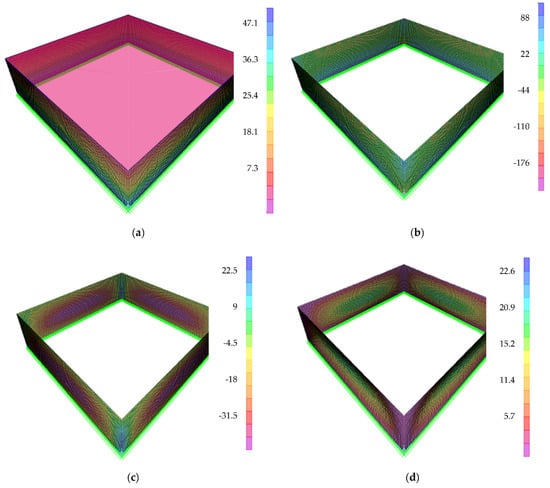

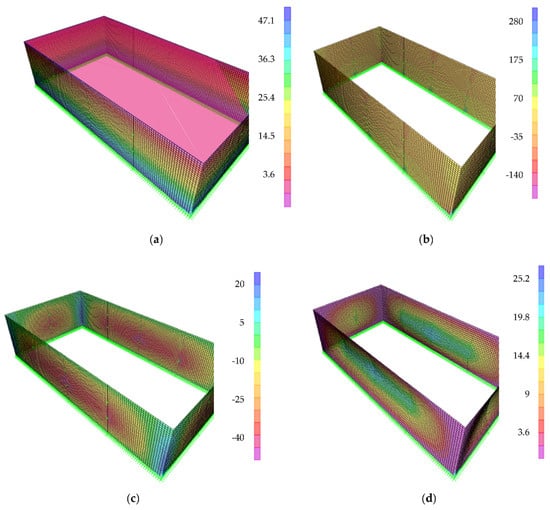

Figure 14, Figure 15 and Figure 16 show the factored shear, factored moment, and unfactored induced displacements for the walls subjected to lateral soil pressure. The maximum results are summarized in Table 6. As can be seen, the results of the three FE models (A, B, and C) are similar to each other and comparable with the results of the simplified analysis model (model S), which was used to produce the pre-engineered tables (with minor deviation in displacement results). While the scope of architype models is limited, it is believed that they are representative of a reasonable range of foundation walls of low-rise houses in practice. As a result, Table 6 demonstrates the validity of the analysis and design procedures used to produce the pre-engineered tables. In general, it is shown that the results of the simplified analysis method (model S) are conservative, as they are the upper bound of FE model results (models A to C). Nevertheless, the simplified analysis was deemed sufficiently efficient because of the small margin between the results of detailed models A to C compared to the simplified model S. Model C demonstrates that using very stiff (almost rigid) connections in such applications ensures that all vertical panels attached will act monolithically. Therefore, it might not be necessary to model connections for panel design purposes. However, a more detailed analysis of the system will depend on more experimental research on the behavior of both base shear connections and panel-to-panel connections under such out-of-plane loading.

Figure 14.

Model A (three-ply CLT) external and internal force diagrams: (a) soil pressure; (b) shear; (c) moment; (d) displacement.

Figure 15.

Model B (three-ply CLT) external and internal force diagrams: (a) soil pressure; (b) shear; (c) moment; (d) displacement.

Figure 16.

Model C (three-ply CLT) external and internal force diagrams: (a) soil pressure; (b) shear; (c) moment; (d) displacement.

Table 6.

FE architype models results versus simplified analysis results used for design.

5. Summary and Conclusions

The following conclusions can be drawn from this research:

- Cross-laminated timber (CLT) can be used as an alternative solution for concrete foundation walls, commonly used in low-rise residential buildings. This solution may overcome the issues that inherently exist when using concrete for such applications, such as cracking and possibility of water penetration, high thermal loss, long construction time, feeling of dampness, mold and mildew growth, problems with construction at low temperatures, difficulty of construction in remote locations, and difficulty of finishing within the construction time.

- When compared to equivalent concrete systems, CLT foundation walls can significantly improve all environmental measures, such as acidification potential and global warming potential.

- For various scenarios, including soil type and backfill height, a simplified analysis procedure for designing laminate thicknesses and the standardized number of layers in CLT basement walls was discussed. The results were presented in the form of pre-engineered design tables. These tables are provided to replace existing reinforced concrete foundation walls commonly used in low-rise construction. Advanced finite element analysis was performed on sample architypes to validate the simplified analysis procedure used for design. It was shown that the proposed analysis procedure and the calculated pre-engineered tables produce conservative and efficient results.

- Depending on the soil type and backfill height, 3–7-ply CLT panels are sufficient for net wall heights of up to 3 m in the vertical arrangement. In general, three-ply CLT was deemed sufficient for most anticipated cases. However, using a horizontal arrangement, five-ply CLT is required as a minimum. As a result, for economic reasons, it is suggested to use CLT in the vertical arrangement.

- Designing very stiff panel-to-panel connections in the vertical arrangement will assure the designers of the panels’ structural integrity and prevent potential water penetration problems at the connection locations. Detailed modeling of panel-to-panel connections did not seem to change the results significantly.

Along with structural requirements and design, solutions for hydrothermal challenges, efficient barriers, and insulation were discussed. However, thorough discussions of these subjects will be addressed in future publications.

Author Contributions

Conceptualization, H.D. and Y.H.C.; Data curation, H.D.; Formal analysis, H.D. and M.F.; Funding acquisition, Y.C., L.D. and Y.H.C.; Investigation, H.D.; Methodology, H.D. and Y.H.C.; Project administration, H.D. and Y.H.C.; Software, H.D. and M.F.; Supervision, H.D. and Y.H.C.; Validation, H.D. and M.F.; Visualization, H.D. and M.F.; Writing—original draft, H.D., Fernanda Imamura and Y.C.; Writing—review & editing, H.D., F.I., Y.C., L.D. and Y.H.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Alberta Innovates, Landmark Group of Companies and Natural Sciences and Engineering Research Council of Canada (NSERC) through the Industrial Research Chair program.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all data, models, or code generated or used during the study are available from the corresponding author by request.

Acknowledgments

The authors would like to thank Alberta Innovates and Landmark Group of Companies for the financial and technical support. Thoughtful insights from Reza Naseri and Haitao Yu, from Landmark Group of Companies, were also greatly appreciated. Additionally, the authors would like to acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC) through the Industrial Research Chair program.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

CLT number of plies required for vertical arrangement, E1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A1.

CLT number of plies required for vertical arrangement, E1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| Number | Thickness | Number | Thickness | Number | Thickness | Number | Thickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2 | 1.2–2 | 0.5–1.8 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2.2 | 1.2–1.8 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2–2.2 | 0.5–2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 0.5- 1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2 | 0.5–2 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2.2–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.5–2 | 0.5–1.8 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.2–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 2.7 | 2.7 | 0.5–2.4 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 3 | 2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2.7 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Basement Wall Design | ||||||||||

| 2.7 | 2.7 | 0 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 2.7 | 0 | 3 | 87 | 5 | 139 | 5 | 139 | 7 | 191 |

| 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 | |

Table A2.

CLT number of plies required for vertical arrangement, E2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A2.

CLT number of plies required for vertical arrangement, E2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2 | 1.2–2 | 0.5–1.8 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2.2 | 1.2–1.8 | 0.5- 1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2–2.2 | 0.5–2 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 0.5–2.4 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4–2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

Table A3.

CLT number of plies required for vertical arrangement, E3 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A3.

CLT number of plies required for vertical arrangement, E3 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2 | 1.2–2 | 0.5–1.8 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2.2 | 1.2–1.5 | 0.5- 1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2–2.2 | 0.5–2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2 | 0.5–1 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.5–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.4 | 0.5–1.2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2 | 0.5–1 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 1.5–1.8 | 0.5–1.5 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 2.7 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

| 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

| Basement Wall Design | ||||||||||

| 2.7 | 2.7 | 0 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 3 | 2.4 | 0 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 2.7 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 | |

| 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 | |

Table A4.

CLT number of plies required for vertical arrangement, V1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A4.

CLT number of plies required for vertical arrangement, V1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2 | 1.2–2 | 0.5–1.8 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2.2 | 1.2–1.8 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2–2.2 | 0.5–2 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 0.5–2.4 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4–2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 3 | 3 | 0.5–1 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

| 1–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | ||

| Basement Wall Design | ||||||||||

| 3 | 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

Table A5.

CLT number of plies required for vertical arrangement, V2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A5.

CLT number of plies required for vertical arrangement, V2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | No. Layers | Thickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2 | 1.2–2 | 0.5–1.8 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2.2 | 1.2–1.8 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 2–2.2 | 0.5–2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 3 | 87 | 3 | 87 | 3 | 87 | 3 | 87 |

| 1.8 | 0.5- 1.5 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 | |

| 2–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 3 | 87 | 3 | 87 | 3 | 87 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 | |

| 2.7 | 0.5–2.4 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4–2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 3 | 3 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 1–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | ||

| Basement Wall Design | ||||||||||

| 3 | 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

Table A6.

CLT number of plies required for horizontal arrangement, E1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A6.

CLT number of plies required for horizontal arrangement, E1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2 | 1.2–2 | 0.5–1.8 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2.2 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 2.7 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 2.7 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Basement Wall Design | ||||||||||

| 2.7 | 2.7 | 0 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 3 | 2.7 | 0 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 | |

Table A7.

CLT number of plies required for horizontal arrangement, E2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A7.

CLT number of plies required for horizontal arrangement, E2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2 | 1.2–2 | 0.5–1.8 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2.2 | 1.2–1.8 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4–2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

| Crawl Space Design | ||||||||||

| 3 | 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| Basement Wall Design | ||||||||||

| 3 | 3 | 0 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

Table A8.

CLT number of plies required for horizontal arrangement, E3 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A8.

CLT number of plies required for horizontal arrangement, E3 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2 | 1.2–2 | 0.5–1.8 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2.2 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.4 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.5–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 2.7 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

| 3 | 0.5–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

| Basement Wall Design | ||||||||||

| 2.7 | 2.7 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

| 3 | 2.4 | 0 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 2.7 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 | |

| 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 | |

Table A9.

CLT number of plies required for horizontal arrangement, V1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A9.

CLT number of plies required for horizontal arrangement, V1 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2 | 1.2–2 | 0.5–1.8 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2.2 | 1.2–1.8 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 3 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 3 | 0.5–1 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

| 1–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | ||

| Basement Wall Design | ||||||||||

| 3 | 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

Table A10.

CLT number of plies required for horizontal arrangement, V2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

Table A10.

CLT number of plies required for horizontal arrangement, V2 grade, longitudinal layer thickness = 35 mm, and transverse layer = 17 mm.

| Maximum Wall Height (m) | Maximum Backfill Height (m) | Maximum Inside Backfill Height (m) | Soil Classes | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GW, GP, GM, SW, SP | GC, SM | SM-SC, SC, ML, ML-CL | CL | |||||||

| No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | No. Layers | Tickness | |||

| 1.5 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 1.2–1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2 | 1.2–2 | 0.5–1.8 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2.2 | 1.2–1.8 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4 | 1.2–1.5 | 0.5–1.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.8 | 0.5–1.5 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.7 | 1.2 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 1.5–2.4 | 0.5–2.2 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 3 | 1.2–1.8 | 0.5–1.5 | 3 | 87 | 3 | 87 | 5 | 139 | 5 | 139 |

| 2–2.2 | 0.5–2 | 3 | 87 | 5 | 139 | 5 | 139 | 5 | 139 | |

| 2.4–2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | |

| Crawl Space Design | ||||||||||

| 2.7 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 |

| 3 | 0.5–1 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 | |

| 1–2.7 | 5 | 139 | 5 | 139 | 5 | 139 | 5 | 139 | ||

| Basement Wall Design | ||||||||||

| 2.7 | 2.7 | 0.5–2.4 | 5 | 139 | 5 | 139 | 5 | 139 | 7 | 191 |

| 3 | 3 | 0 | 5 | 139 | 5 | 139 | 7 | 191 | 7 | 191 |

References

- ASHI; Basement Cracks and Leaks. ASHI Reporter; ASHI: Fenton, MI, USA, March 2007; Available online: https://www.homeinspector.org/Newsroom/AuthorDetails/131 (accessed on 8 July 2022).

- CMHC. Monitored Thermal Performance of ICF Walls in MURBs; Research Highlights 65863; Canada Mortgage and Housing Corporation: Ottawa, ON, USA, 2007. [Google Scholar]

- CAN/ULC-S717.1; Standard for Flat Wall Insulating Concrete Form (ICF) Units Materials Properties. Underwriter Laboratory: Ottawa, ON, USA, 2017.

- ANSI/AWC. Permanent Wood Foundation Design Specification with Commentary; ANSI/AWC: Leesburg, VA, USA, 2015. [Google Scholar]

- CSA S406-16; Specification of Permanent Wood Foundations for Housing and Small Buildings. Canadian Standards Association: Toronto, ON, Canada, 2016.

- CMHC. Preserved Wood as a Potential Source of Arsenic and Fungi in the Foundation Walls of Homes; Research Highlights 65891; Canada Mortgage and Housing Corporation: Ottawa, ON, Canada, 2007. [Google Scholar]

- Wood Preservation Canada. Permanent Wood Foundation. 2021. Available online: https://woodpreservation.ca/wp-content/uploads/2021/09/PWF-Publication-2021.pdf (accessed on 8 July 2022).

- Karacabeyli, E.; Gagnon, S. CLT Handbook; Special Publication SP-532E FPInnovations; CLT: Pointe Claire, QC, Canada, 2019. [Google Scholar]

- Gibson, G.J. Permanent Wood Foundations—The Illustrated Practical Applications Manual; Craftsman Book Company of America Inc.: Carlsbad, CA, USA, 1990. [Google Scholar]

- Canadian Wood Council. Permanent Wood Foundations; Canadian Wood Council: Ottawa, ON, Canada, 2016. [Google Scholar]

- Buxbaum, C.; Seiler, A.; Pankratz, O. Study on the Hygrothermal Performance of Wooden Basement Systems of Floating Houses in “Passive House Technology”; Building Simulation: Beijing, China, 2007. [Google Scholar]

- Buxbaum, C.; Pankratz, O.; Schorer, M.; Thalhammer, W. Habitable Basement Concepts Made in Timber Construction—Assessment on the Durability of Walls and Floor Slabs Made of Solid Cross-Laminated Timber Boards. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Athena Sustainable Materials Institute. Athena Impact Estimator for Buildings v5.4 Software and Database; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2019. [Google Scholar]

- USGBC. LEED Reference Guide for Building Design and Construction; Version 4; USGBC: Washington, DC, USA, 2020. [Google Scholar]

- CFEM. Canadian Foundation Engineering Manual, 4th ed.; Canadian Geotechnical Society: Calgary, AB, Canada, 2006. [Google Scholar]

- National Research Council of Canada. National Building Code; NRC: Ottawa, ON, Canada, 2015. [Google Scholar]

- Sitar, N.; Mikola, R.G.; Candia, G. Seismically induced lateral earth pressures on retaining structures and basement walls. In Geotechnical Engineering State of the Art and Practice: Keynote Lectures from GeoCongress 2012; ASCE: Reston, VA, USA, 2012; pp. 335–358. [Google Scholar]

- ASCE7; Minimum Design Loads for Buildings and Other Structures. American Society of Civil Engineers: Reston, VA, USA, 2016.

- CSA O86-19; Engineering Design in Wood. Canadian Standards Association: Toronto, ON, Canada, 2019.

- ANSI/AWC. NDS National Design Specification (NDS) for Wood Construction; ANSI/AWC: Leesburg, VA, USA, 2015. [Google Scholar]

- Computers & Structures. Sap2000: Integrated Solution for Structural Analysis and Design; Computers & Structures: Berkeley, CA, USA, 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).