Effect of Posidonia oceanica Fibers Addition on the Thermal and Acoustic Properties of Cement Paste

Abstract

:1. Introduction

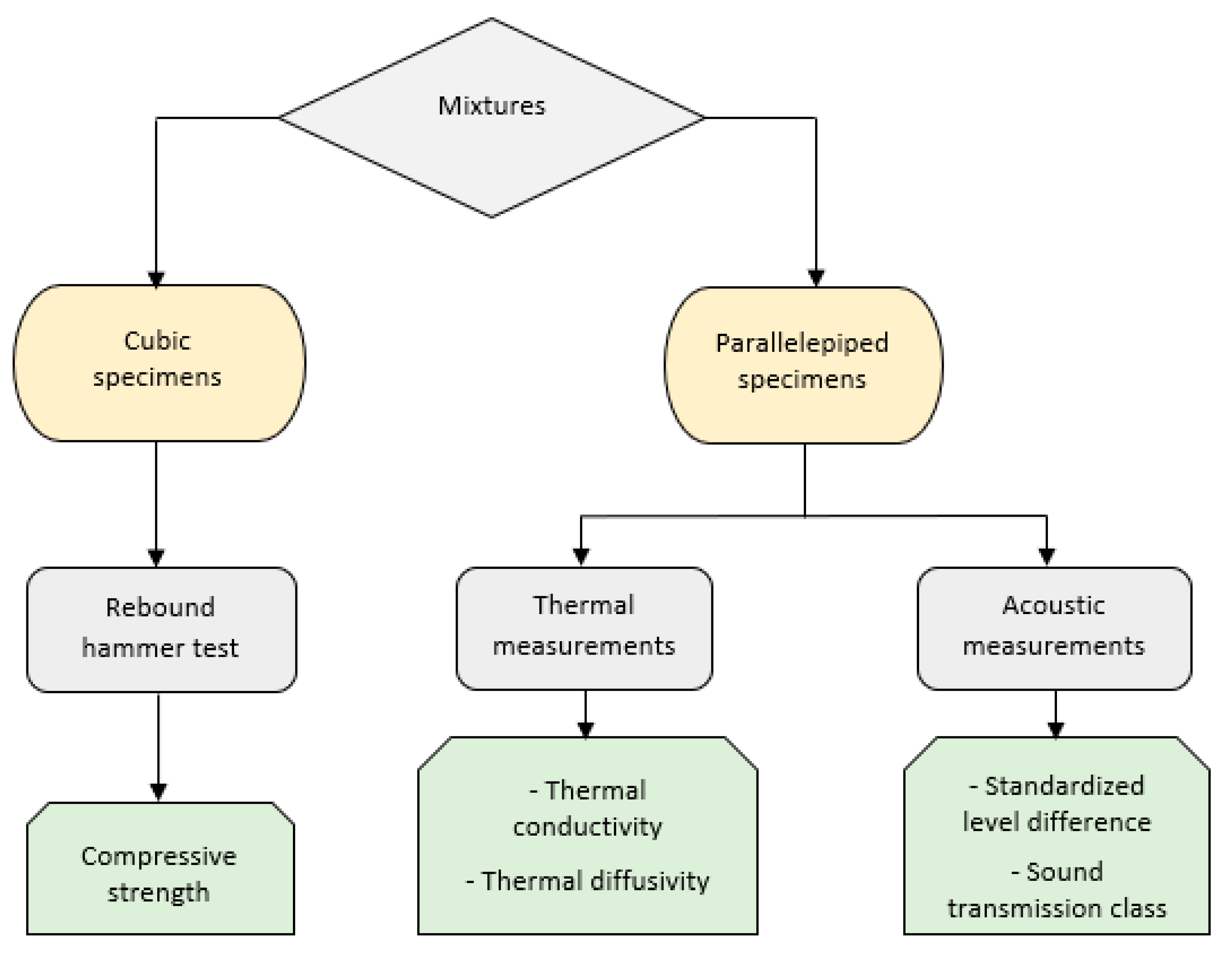

2. Experimental Program

3. Materials and Methods

3.1. Materials

3.1.1. Cement

3.1.2. Posidonia oceanica Fibers

3.2. Experimental Tests

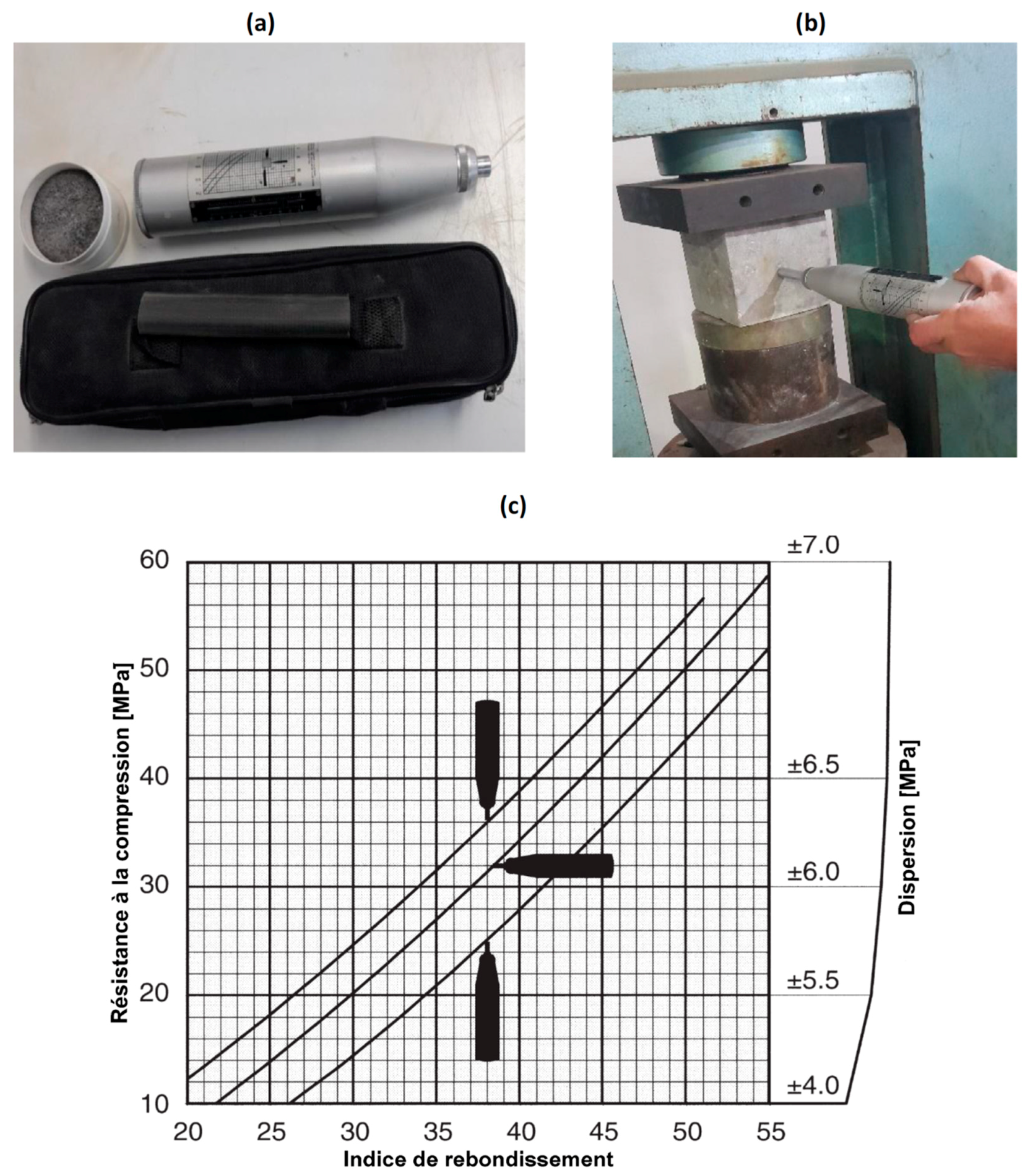

3.2.1. Schmidt Rebound Hammer Test

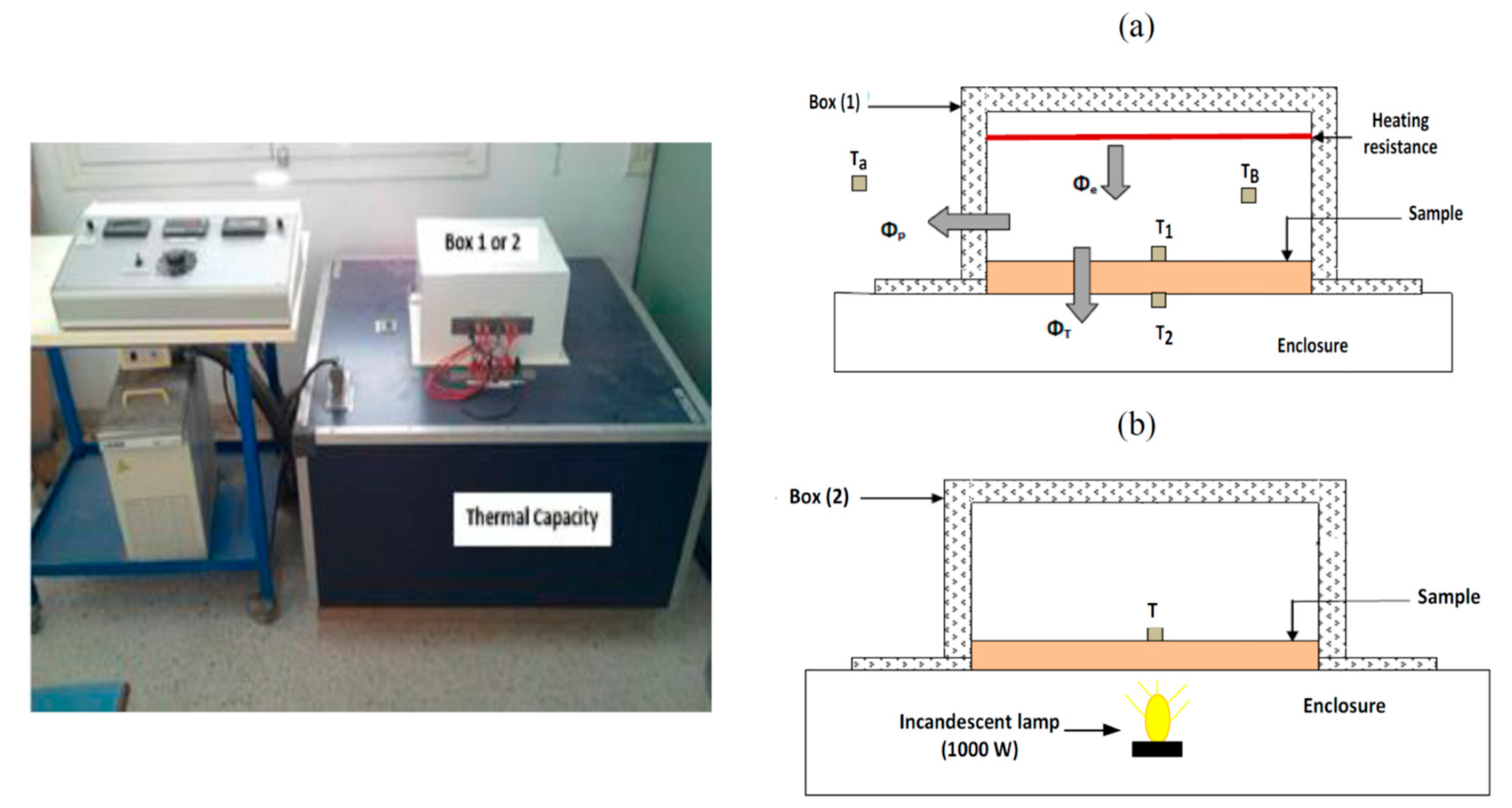

3.2.2. Thermal Conductivity Test

3.2.3. Thermal Diffusivity Measurement

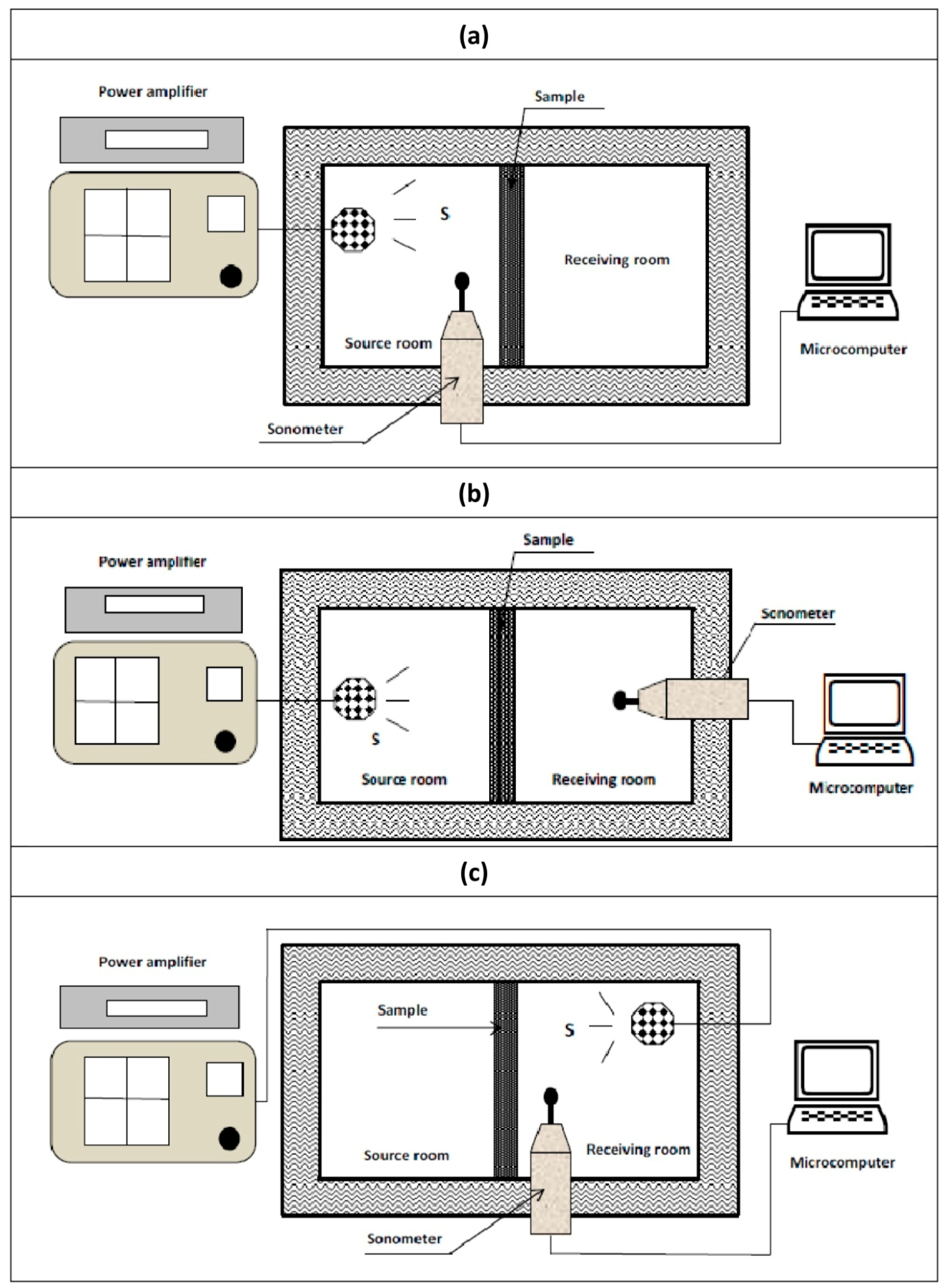

3.2.4. Measurement of Acoustic Properties

Level Difference

Standardized Level Difference

- An acoustic enclosure in which the sample was placed to separate between the source room and the reception room.

- A sound source (S) placed in the source room and connected to a power amplifier.

- A sonometer installed in the receiving room to measure the sound pressure levels inside the box. The values were displayed directly on a microcomputer connected to the sound level meter.

4. Results and Discussion

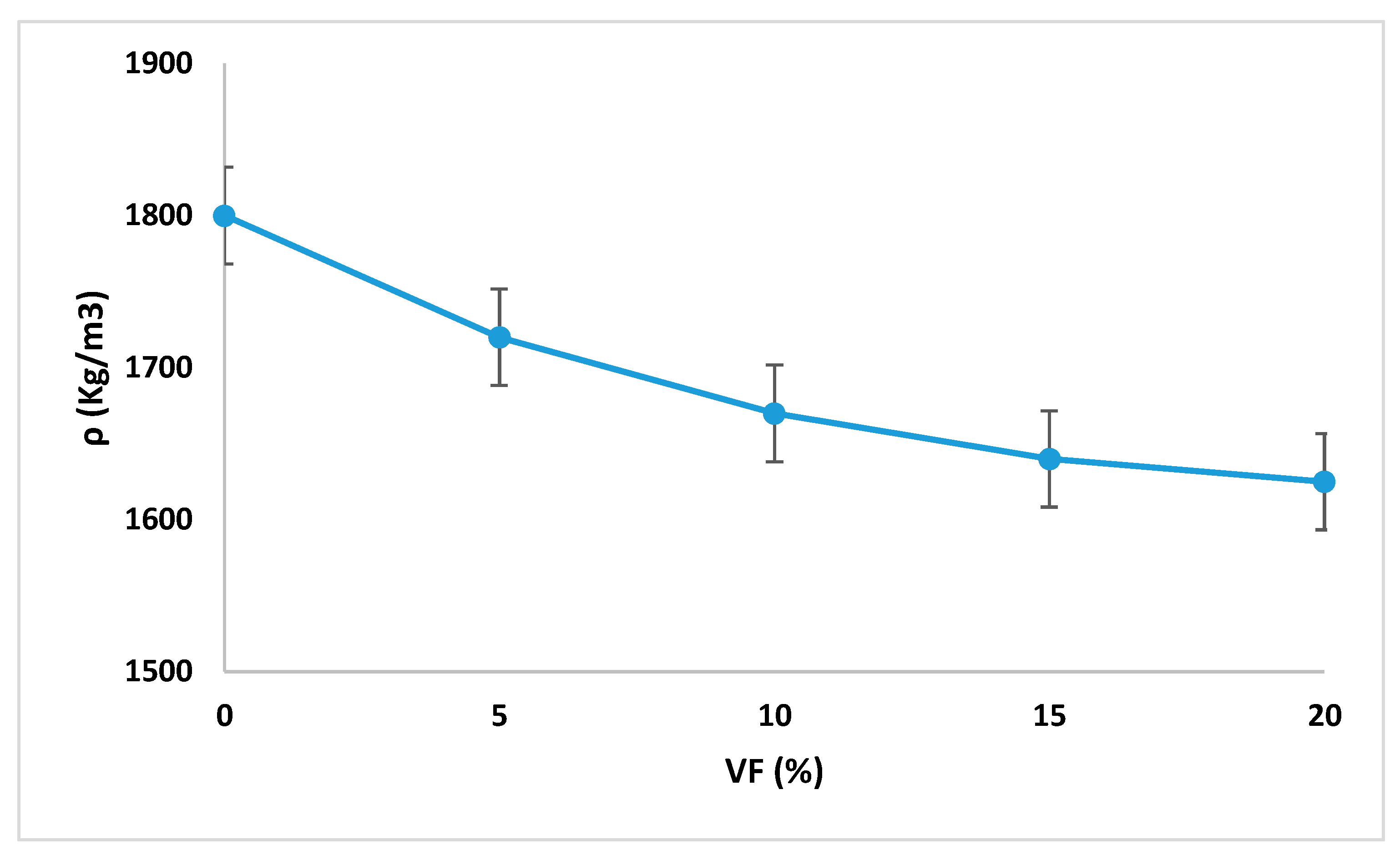

4.1. Density

4.2. Schmidt Rebound Hammer Test

4.3. Thermal Conductivity

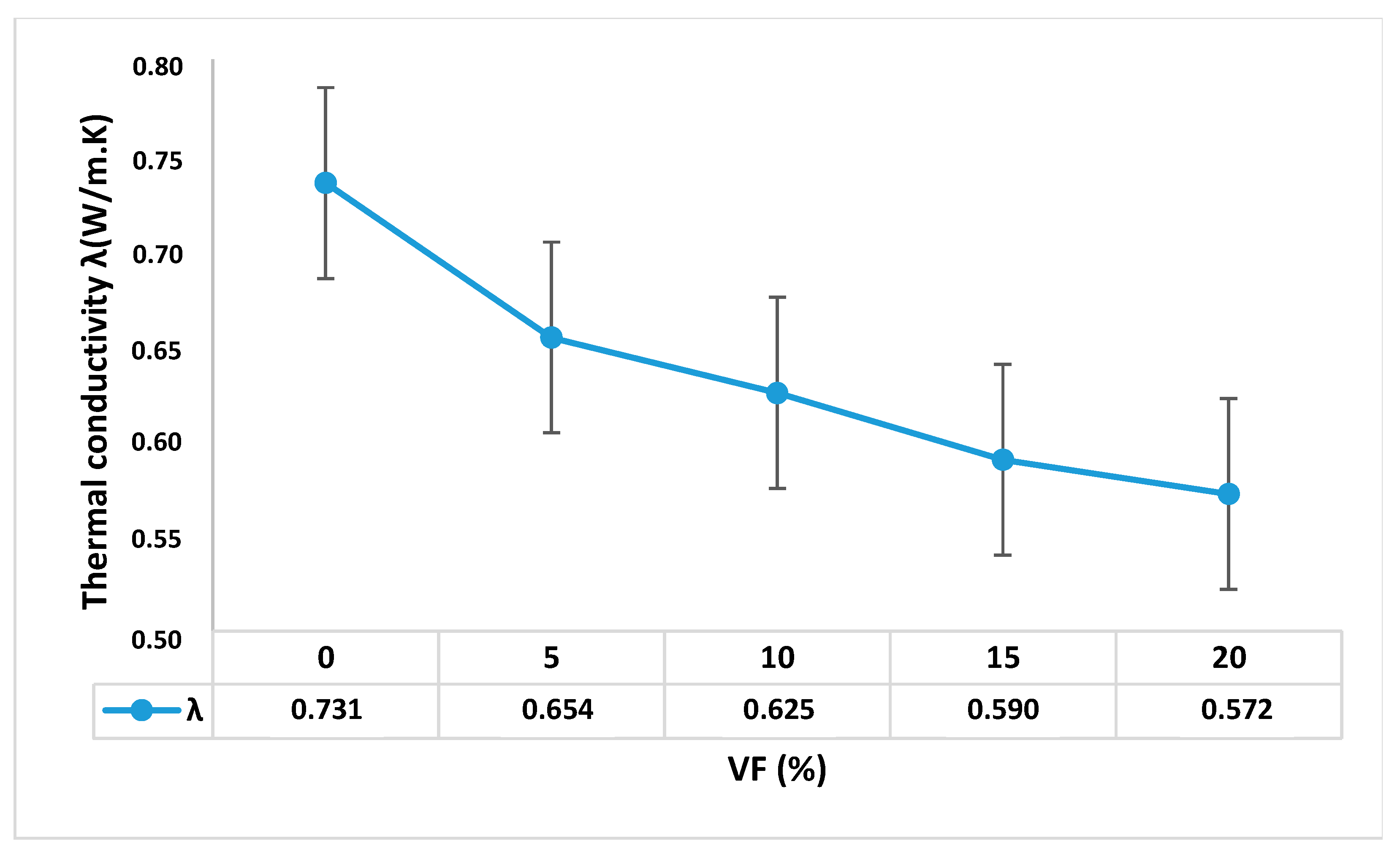

4.4. Thermal Diffusivity

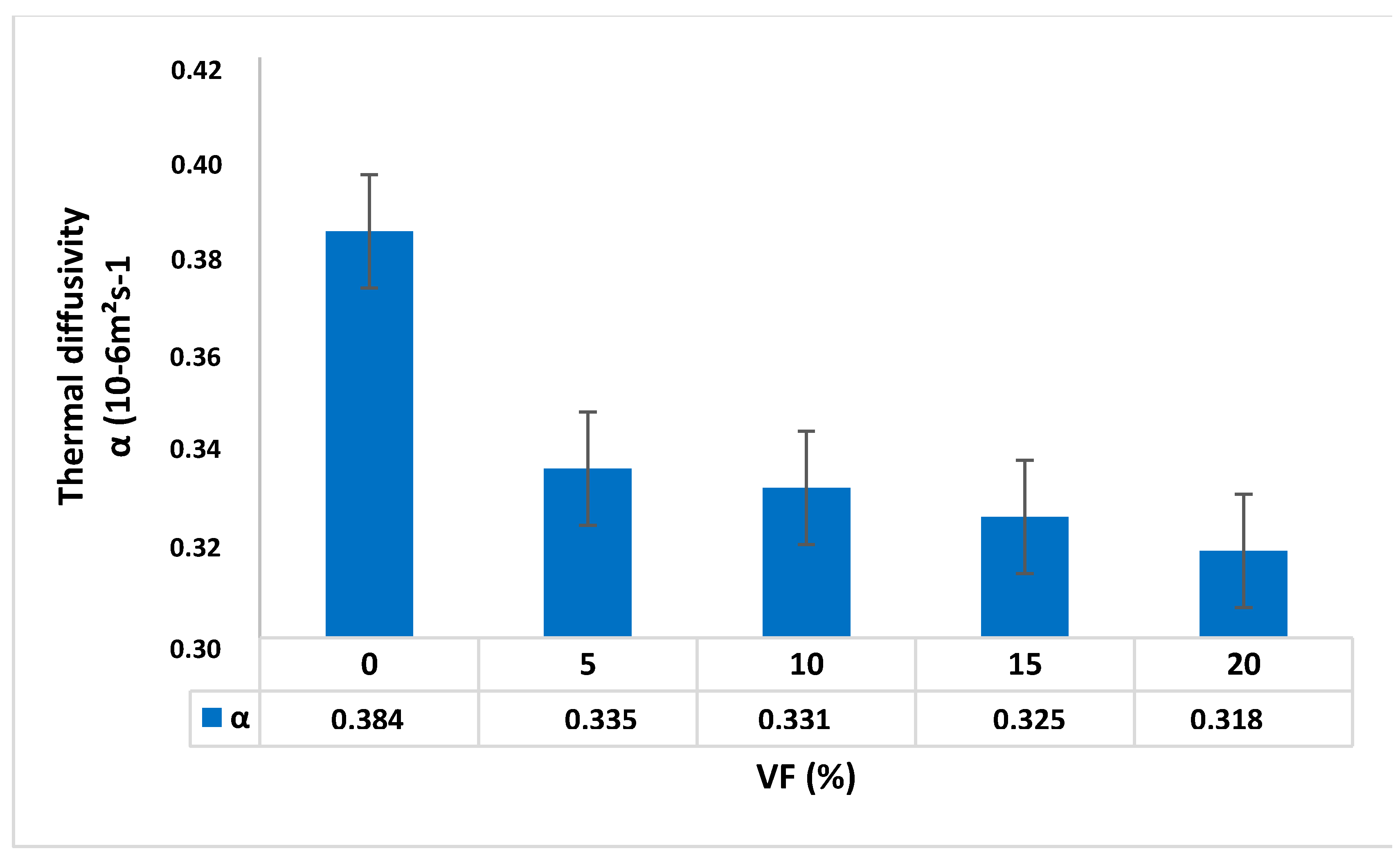

4.5. Standardized Level Difference

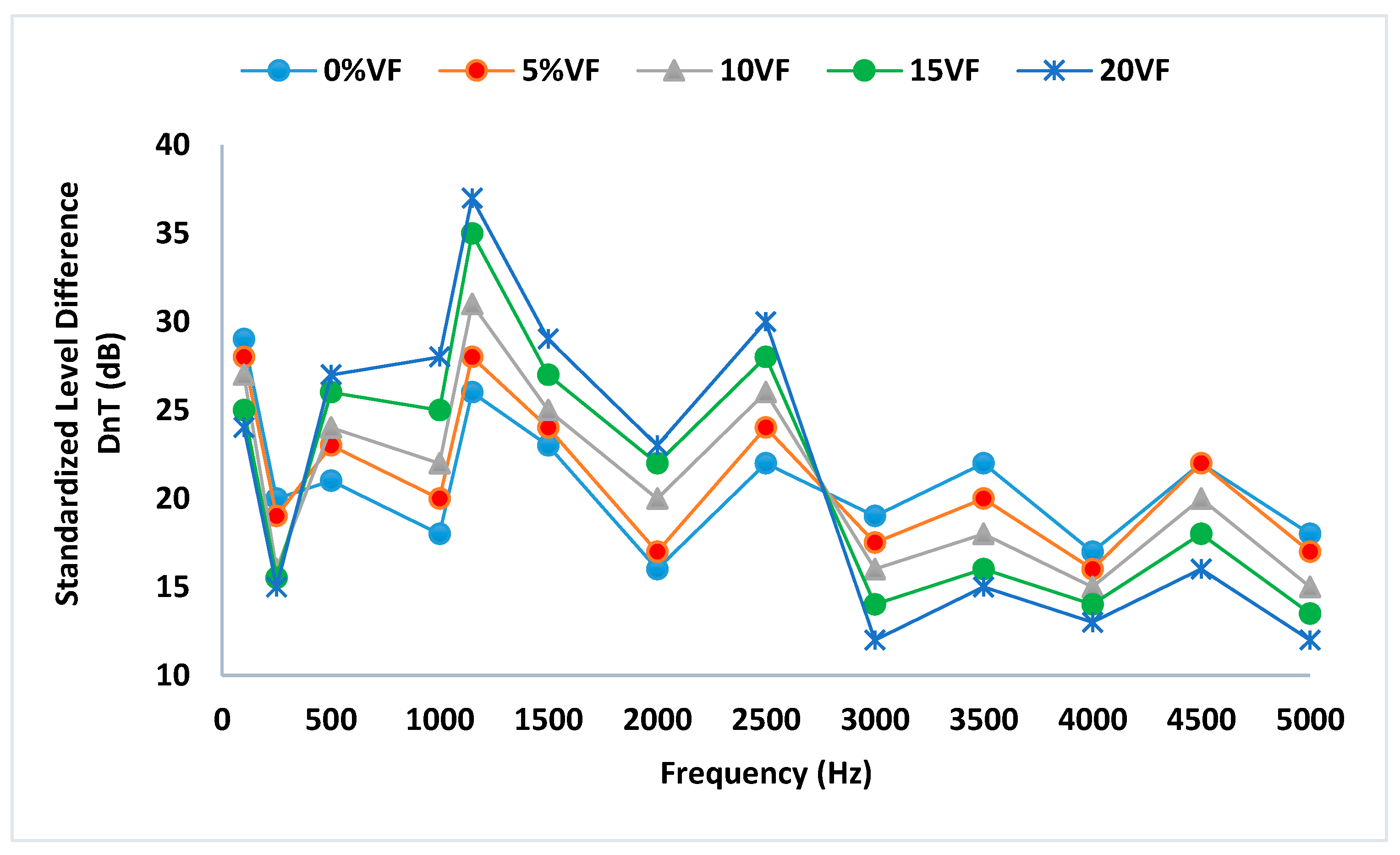

4.6. Sound Transmission Class

5. Conclusions

- ✓

- Posidonia fibers could be used as a reinforcement material in cementitious composites for a W/C ratio = 0.5.

- ✓

- The incorporation of Posidonia fibers decreased the density of mixtures from 1800 kg/m3 to 1625 kg/m3 for the volume fractions of fibers ranging from 0% to 20%, which corresponded to a reduction of about 10%.

- ✓

- The optimal mechanical properties of mixtures were found when a 5–10% volume fraction of Posidonia fibers was used.

- ✓

- The addition of Posidonia fibers in the cement matrix decreased the thermal conductivity and the thermal diffusivity of mixtures. This reduction improved the thermal insulation of the material.

- ✓

- The addition of PO fibers seemed to have a positive effect on the standardized level difference of the mixtures, especially when a 20% volume fraction of Posidonia fibers was used.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| PO | Posidonia oceanica |

| R | Water/cement ratio |

| Vf | Fractions of fibers |

| RC | Compression strength, MPa |

| D | Level difference, dB |

| CP | Mass heat capacity, J·kg−1·K−1 |

| DnT | Standardized level difference, dB |

| λ | Thermal conductivity, W·m−1·K−1 |

| Tr | Reverberation time, s |

| α | Thermal diffusivity, m2·s−1 |

| STC | Sound transmission class |

| ρ | Density, g·cm−3 |

References

- Borum, J.; Duarte, C.M.; Krause-Jensen, D.; Greve, T.M. Europeans Seagrasses: An Introduction to Monitoring and Management; The M&MS Project; The University of California: Los Angeles, CA, USA, 2004. [Google Scholar]

- Boudouresque, C.F.; Bernard, G.; Bonhomme, P.; Rogeau, E.; de Saint Martin, T.; Boudouresque, C.F. Protection and Conservation of Posidonia oceanica Meadows; RAMOGE & RAC/SPA: Tunis, Tunisia, 2012; pp. 1–202. [Google Scholar]

- Ofori, G.; Briffett, C.; Gang, G.; Ranasinghe, M. Impact of ISO 14,000 on construction enterprises in Singapore. Constr. Manag. Econ. 2000, 18, 935–947. [Google Scholar] [CrossRef]

- Aditya, L.; Indra Mahlia, T.M.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- VarunTeja, K.; Meena, T. Performance of Ternary Blended Concrete and Binary Concrete Made with Perlite Powder at Elevated Temperatures. JordanJ. Civ. Eng. 2020, 14, 198–209. [Google Scholar]

- Chafei, C.; Khadraoui, F.; Boutouil, M.; Gomnia, M. Effect of flax fiber streatments on the rheological and the machanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar]

- Fantilli, A.; Chiaia, B.; Gorino, A. Fiber volume fraction and ductility index of concrete beams. Cem. Concr. Compos. 2016, 65, 139–149. [Google Scholar] [CrossRef]

- Korjenic, A.; Petranek, V.; Zach, J.; Hroudova, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Reis, J.M.L. Fracture and flexural characterization of natural fiber-reinforced polymer concrete. Constr. Build. Mater. 2006, 20, 673–678. [Google Scholar] [CrossRef]

- Comak, B.; Bideci, A.; Bideci, O.S. Effects of hempfibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Allegue, L.; Zidi, M.; Sghaier, S. Mechanical properties of Posidonia oceanica fibersre in forced cement. J. Compos. Mater. 2015, 49, 1–9. [Google Scholar] [CrossRef]

- Hamdaoui, O.; Ibos, L.; Mazioud, A.; Safi, M.; Limam, O. Thermophysi calcharacterization of Posidonia oceanica marine fibers intended to beused as an insulation material in Mediterranean buildings. Constr. Build. Mater. 2018, 180, 68–76. [Google Scholar] [CrossRef]

- Hamdaoui, O.; Limam, O.; Ibos, L.; Mazioud, A. Thermal and mechanical properties of hardened cement paste reinforced with Posidonia oceanica natural fibers. Constr. Build. Mater. 2021, 269, 121339. [Google Scholar] [CrossRef]

- Sridhar, J.; Gobinath, R.; Kırgız, M.S. Comparative study for efficacy of chemically treated jute fiber and bamboo fiber on the properties of reinforced concrete beams. J. Nat. Fibers 2022, 19, 1–12. [Google Scholar] [CrossRef]

- Jedidi, M.; Abroug, A. Valorization of Posidonia oceanica Balls for the Manufacture of an Insulating and Ecological Material. Jordan J. Civ. Eng. 2020, 14, 417–430. [Google Scholar]

- EN 196-1; Methods of Testingcement—Part 1: Determination of Strength. iTeh Standards: Etobicoke, ON, Canada, 2016.

- Taoukil, D.; Sick, F.; Mimet, A.; Ezbakhe, H.; Ajzoul, T. Moisture content influence on the thermal conductivity and diffusivity of wood-concrete composite. Constr. Build. Mater. 2013, 48, 104–115. [Google Scholar] [CrossRef]

- Kuqo, A.; Boci, I.; Vito, S.; Vishkulli, S. Mechanical properties of lightweight concrete composed with Posidonia oceanica fibres. Zast. Mater. 2018, 59, 519–523. [Google Scholar] [CrossRef]

- British Standards Institution EN 12504-2; Testing concrete in Structures, Non-Destructive Testing. Determination of Reboundnumber. BSI: London, UK, 2012.

- British Standards Institution EN 12309-3; Testing hardning concrete-Part 3: Compression Strength of Test Specimens. BSI: London, UK, 2003.

- European Standard EN ISO 8990; Thermal Insulation-Determination of Steady-State Thermal Transmission Properties-Calibrated and Guarded Hot Box. BSI: London, UK, 1996.

- Kellati, N.; El Bouardi, A.; Ajzoul, T.; Ezbakhe, H. Etude de Propriétés Thermophysiques et Acoustiques du Liège Compact et Granulaire; Revue des Energies Renouvelables CER’07: Oujda, Maroc, 2000; pp. 241–244. [Google Scholar]

- Degiovanni, A. Thermal conduction in multilayer slab withinternal sources using a quadripolar method. Int. J. Heat Mass Transf. 1988, 31, 553–557. [Google Scholar] [CrossRef]

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.M.; Bali, A.; Queneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimantalstudy and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- ASTM E413 2016 Edition; Classification for Rating Sound Insulation. ASTM: West Conshohocken, PA, USA, 1 April 2016.

| Chemical Compounds | ||

| Insoluble residue (IR) | ≤5% | |

| Sulfur trioxide (SO3) | ≤3.5% | |

| Magnesium oxide (MgO) | ≤5% | |

| Chloride (Cl) | ≤0.1% | |

| Soundness (mm) | ≤10 | |

| Initial setting time (mn) | ≥60 | |

| Physical Properties | ||

| Absolute density (g/cm3) | 3.13 | Absolute density (g/cm3) |

| Blaine specific surface (cm2/g) | 3100 | Blaine specific surface (cm2/g) |

| Mechanical Property | ||

| True class (MPa) | 44 | True class (MPa) |

| Properties | Values |

|---|---|

| Thermal conductivity λ (W·m−1·K−1) | 0.04–0.07 |

| Mass heat capacity CP (J·kg−1·K−1) | 2500 |

| Density ρ (g·cm−3) | 0.35 |

| STC Rating | Speech Heard through Wall or Floor | Noise Control Level |

|---|---|---|

| 25 | Normal speech understandable | Poor |

| 30 | Loud speech understandable | Marginal |

| 40 | Loud speech audible as a murmur but unintelligible | Good |

| 50 | Loud speech barely audible | Very good |

| >55 | Loud speech not heard | Excellent |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benjeddou, O.; Jedidi, M.; Khadimallah, M.A.; Ravindran, G.; Sridhar, J. Effect of Posidonia oceanica Fibers Addition on the Thermal and Acoustic Properties of Cement Paste. Buildings 2022, 12, 909. https://doi.org/10.3390/buildings12070909

Benjeddou O, Jedidi M, Khadimallah MA, Ravindran G, Sridhar J. Effect of Posidonia oceanica Fibers Addition on the Thermal and Acoustic Properties of Cement Paste. Buildings. 2022; 12(7):909. https://doi.org/10.3390/buildings12070909

Chicago/Turabian StyleBenjeddou, Omrane, Malek Jedidi, Mohamed Amine Khadimallah, Gobinath Ravindran, and Jayaprakash Sridhar. 2022. "Effect of Posidonia oceanica Fibers Addition on the Thermal and Acoustic Properties of Cement Paste" Buildings 12, no. 7: 909. https://doi.org/10.3390/buildings12070909

APA StyleBenjeddou, O., Jedidi, M., Khadimallah, M. A., Ravindran, G., & Sridhar, J. (2022). Effect of Posidonia oceanica Fibers Addition on the Thermal and Acoustic Properties of Cement Paste. Buildings, 12(7), 909. https://doi.org/10.3390/buildings12070909