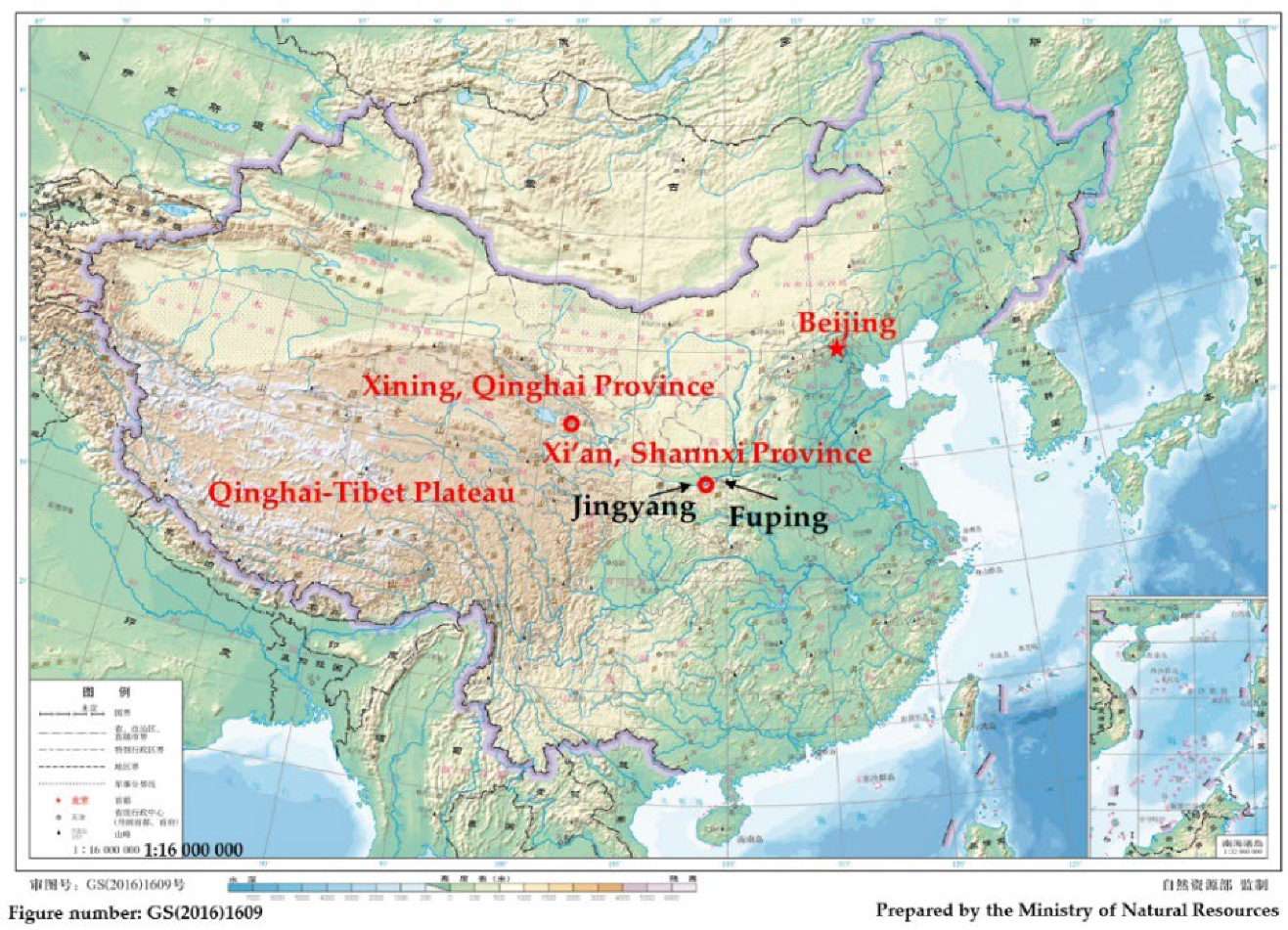

Experimental Study on the Effects of Freeze–Thaw Cycles on Strength and Microstructure of Xining Region Loess in China

Abstract

:1. Introduction

2. Materials and Methods

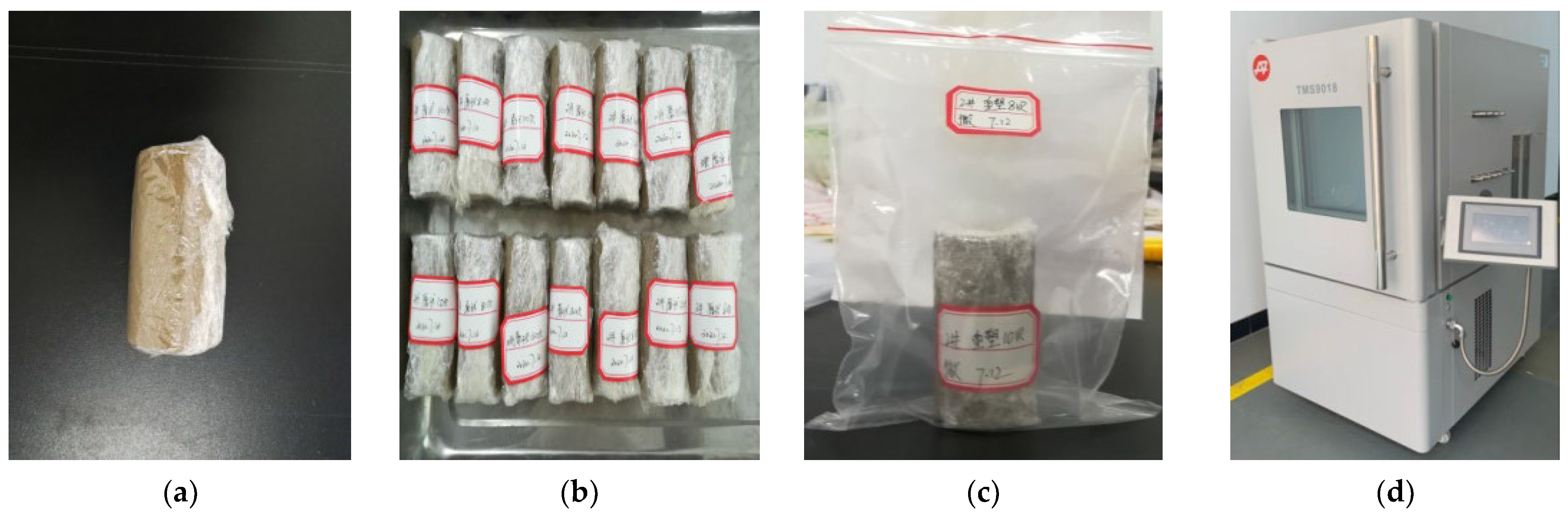

2.1. Sample Preparation

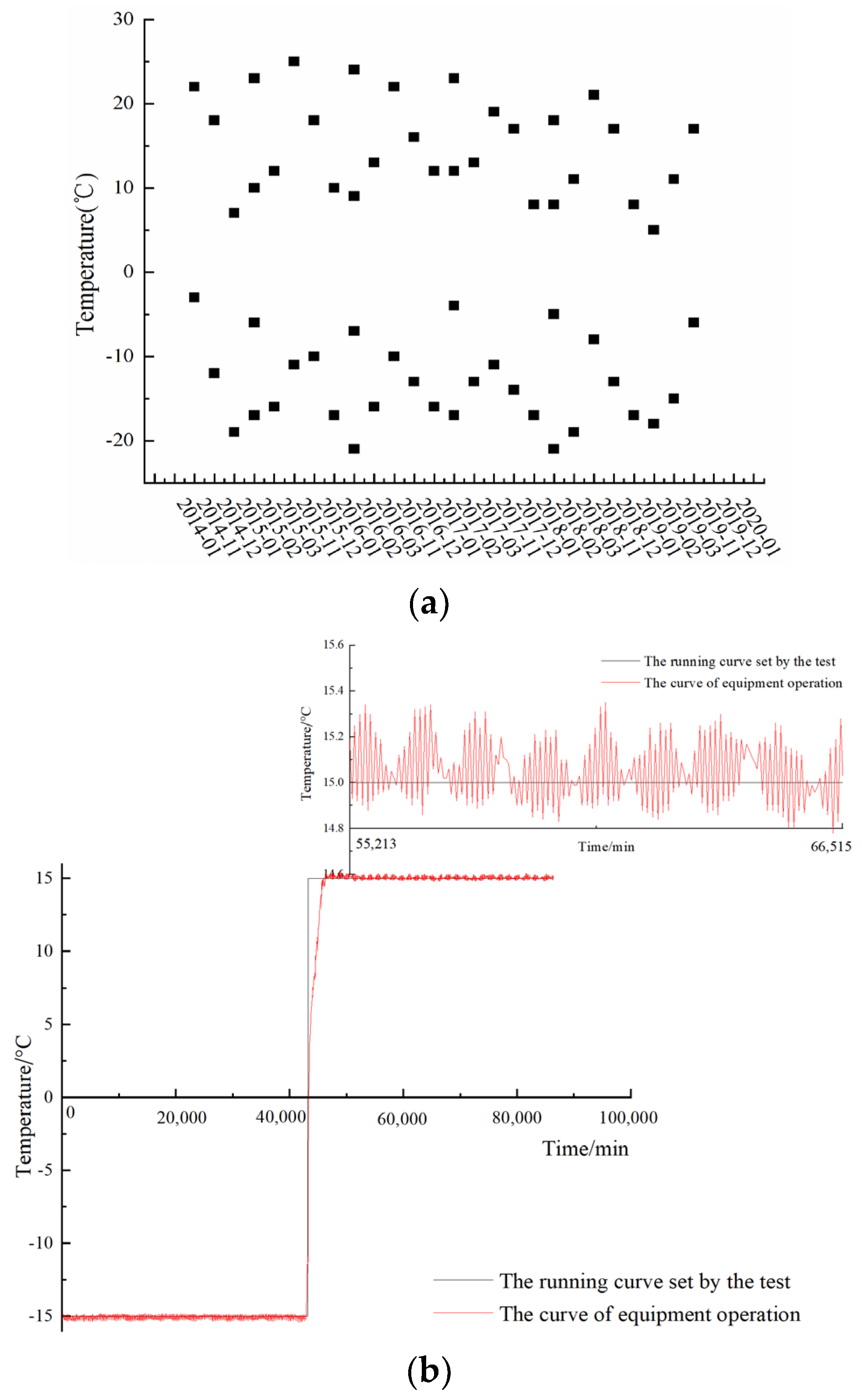

2.2. Experimental Design

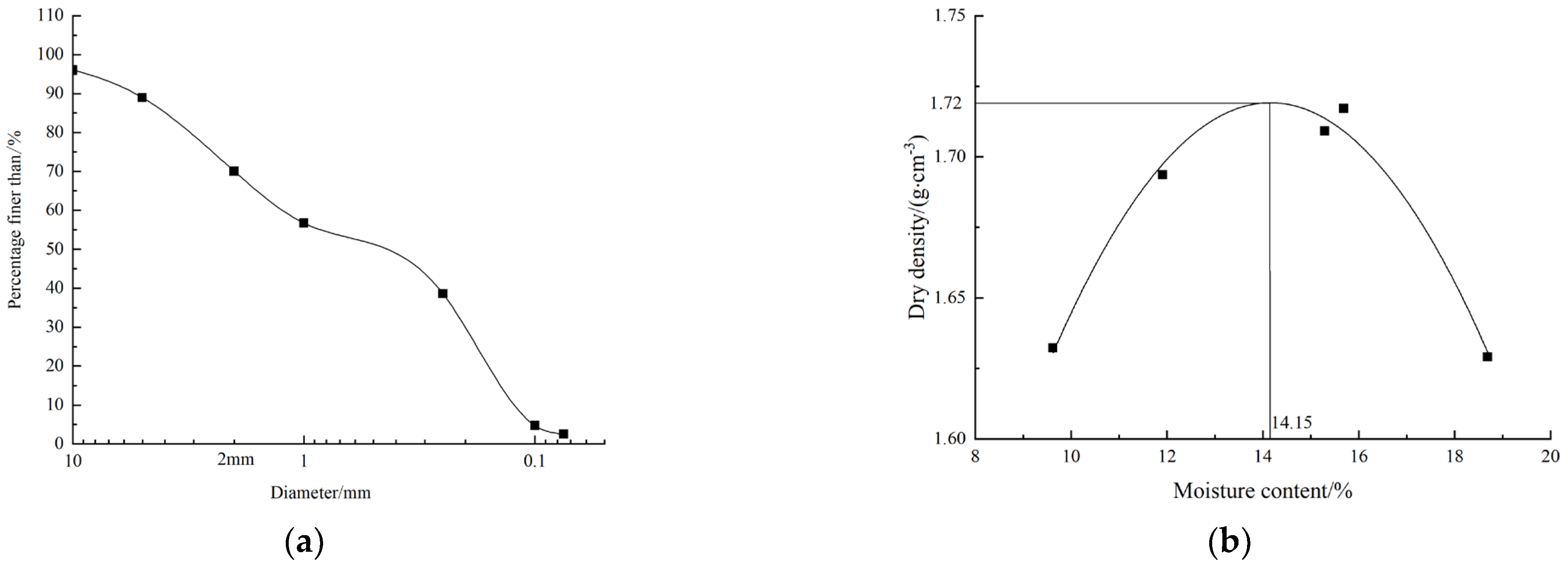

2.3. Basic Physical Properties of Loess

3. Analysis of Micro-Test Results

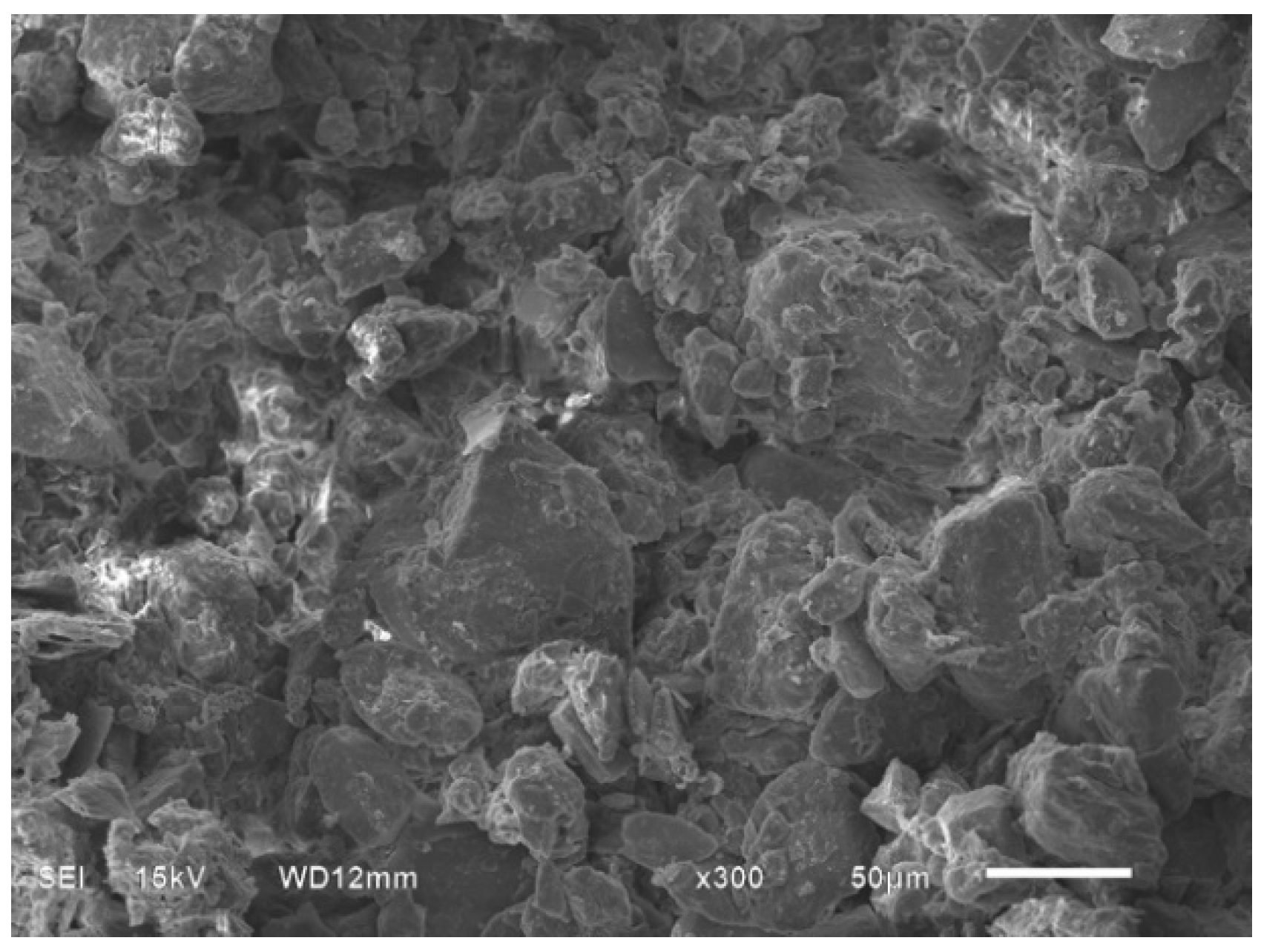

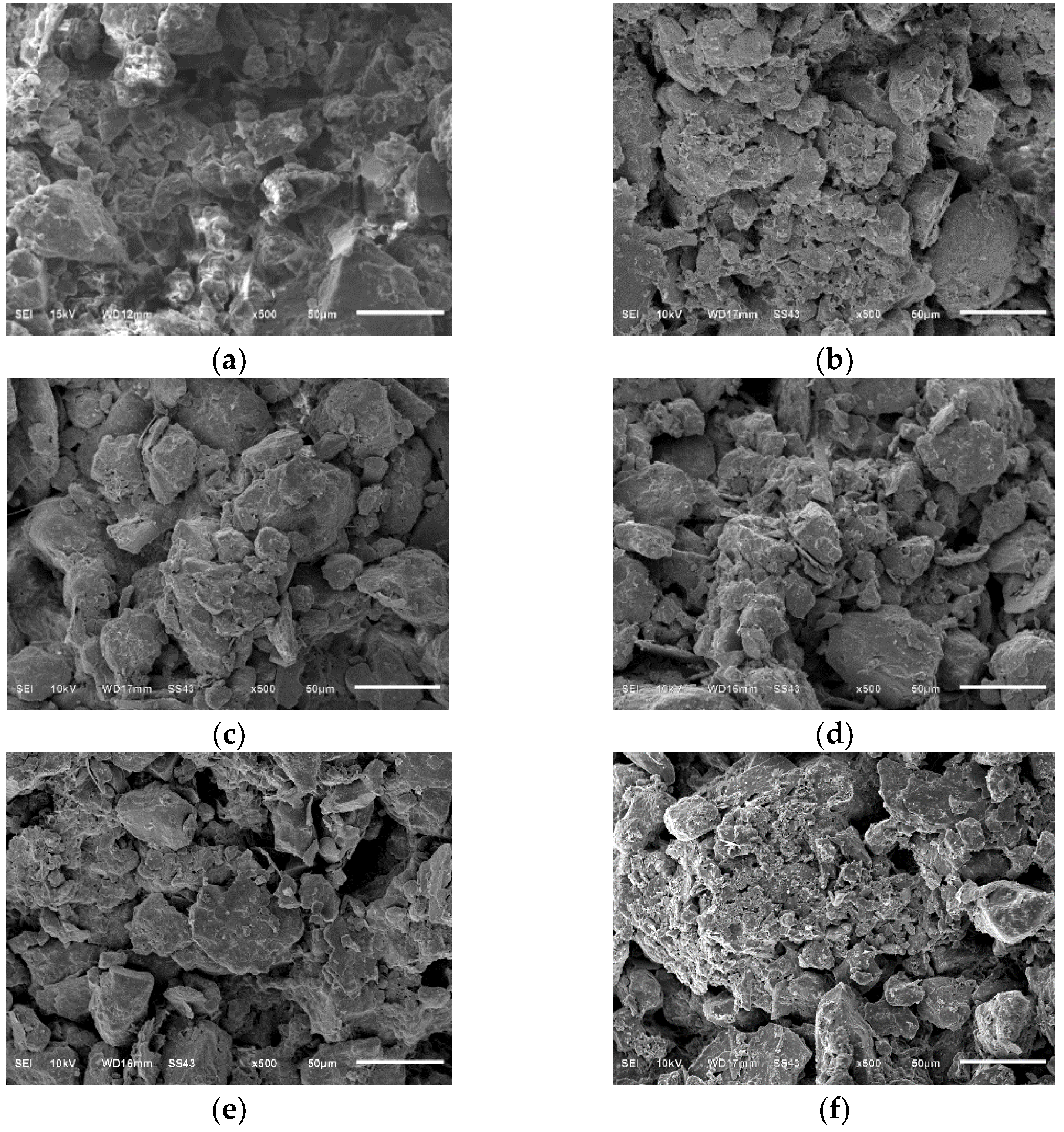

3.1. SEM Test

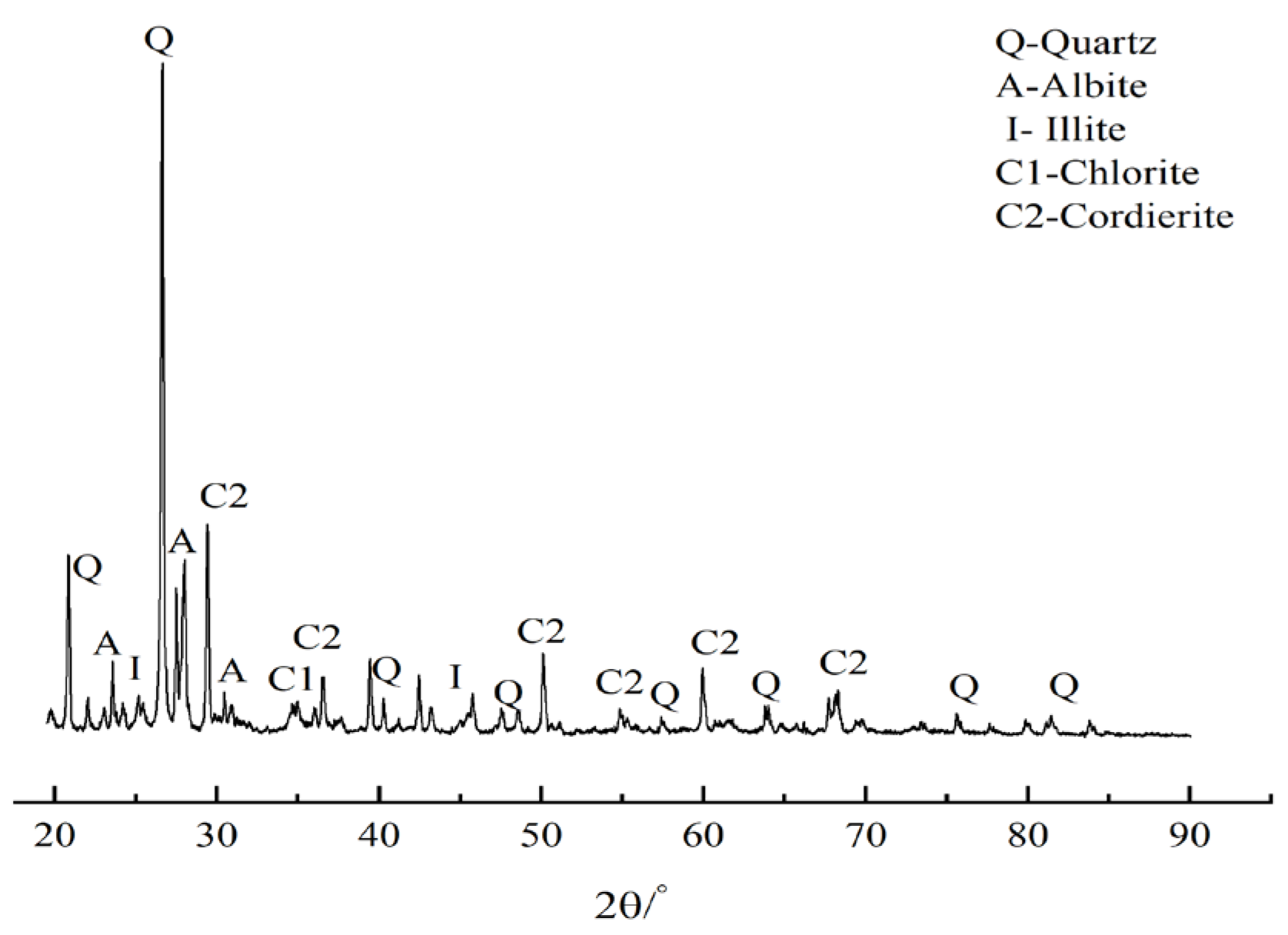

3.2. XRD and XRF Test

4. Analysis of Mechanical Test Results

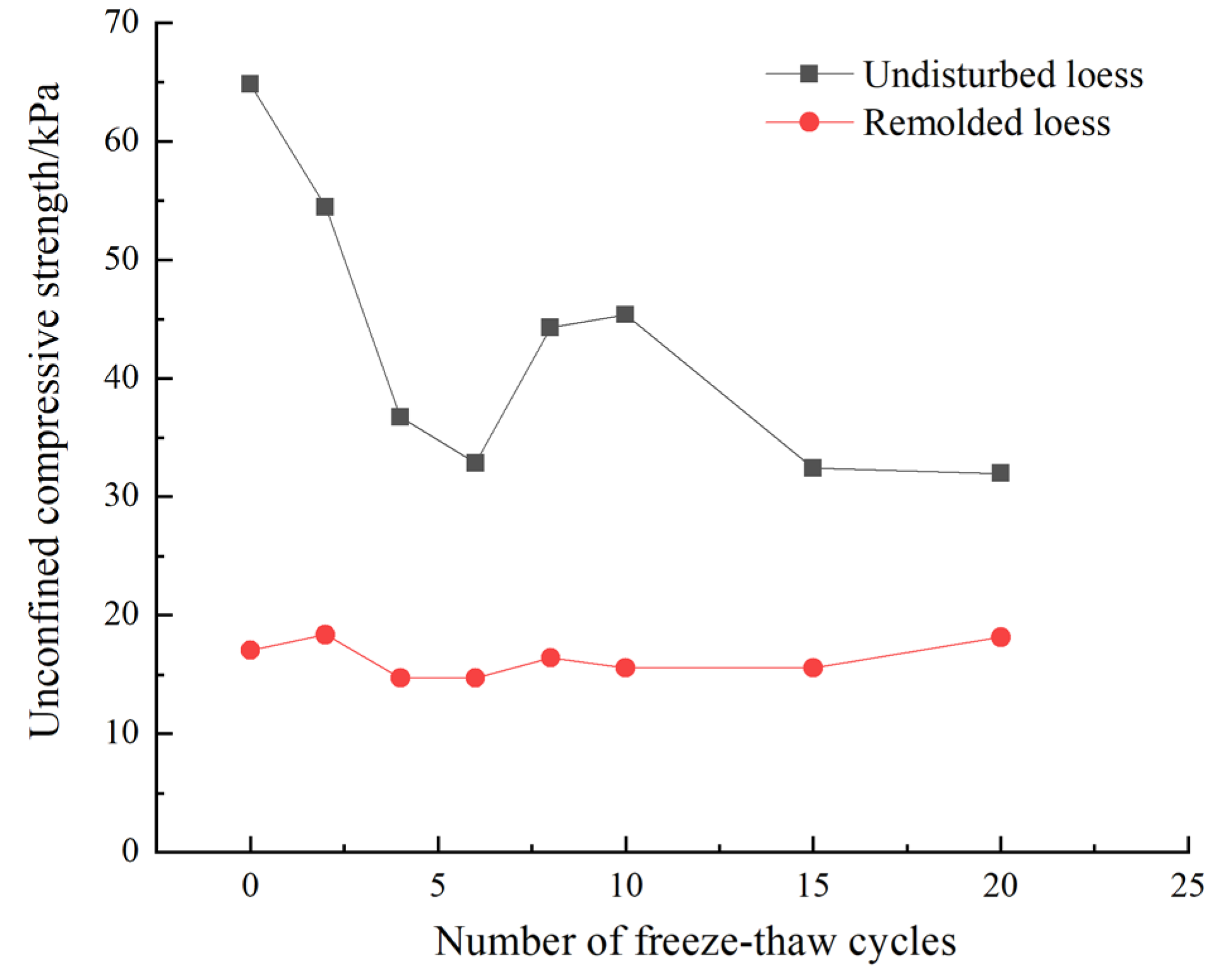

4.1. Unconfined Compressive Strength

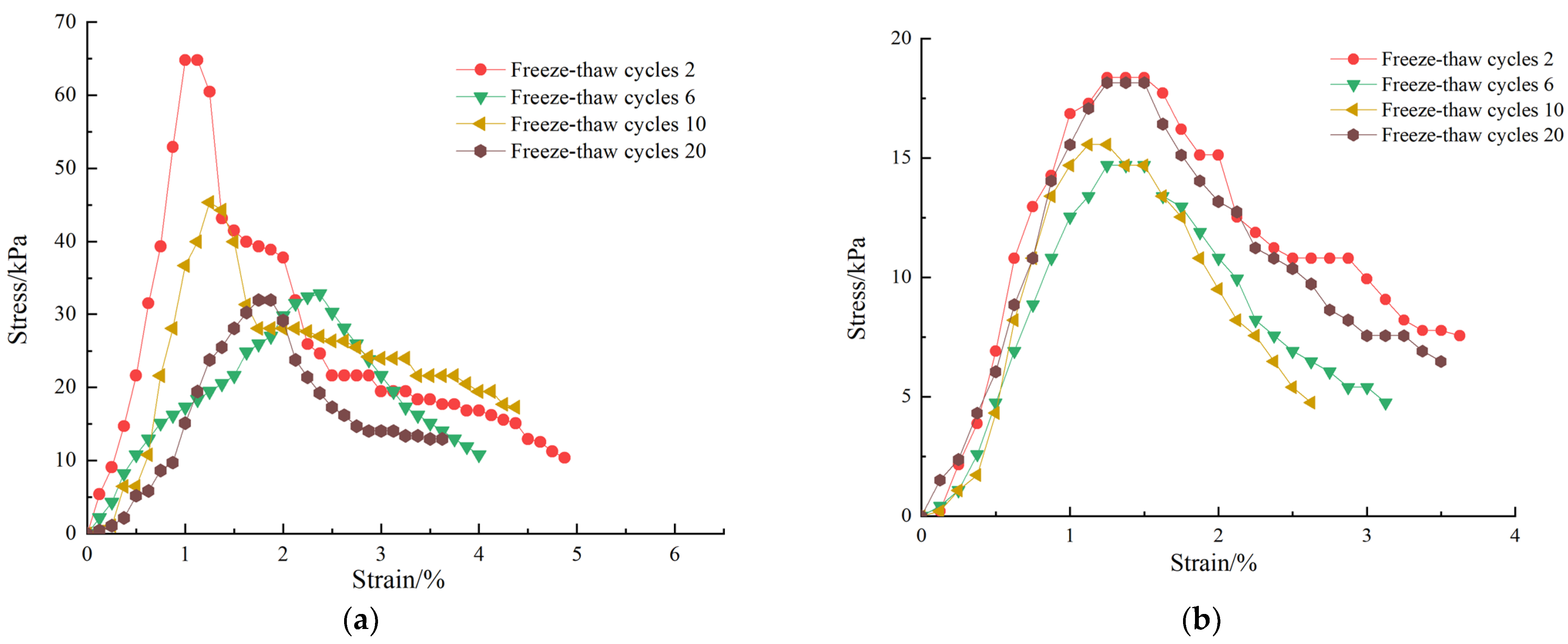

4.2. Stress–Strain Curve

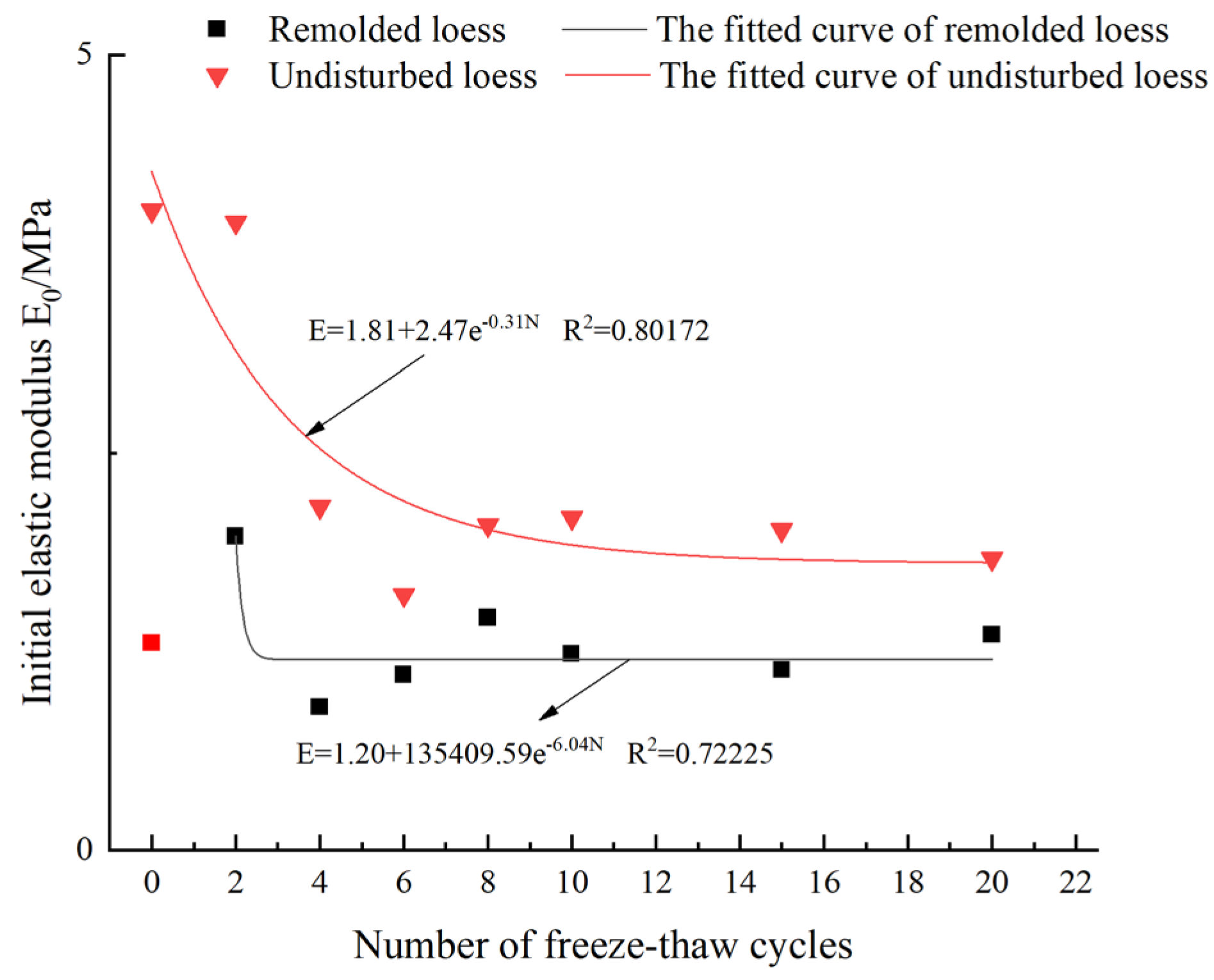

4.3. Elastic Modulus

5. Conclusions

- With an increasing number of freeze–thaw cycles, the unconfined compressive strength of undisturbed loess and remolded loess first increases and then decreases as the strain increases, and the stress–strain curve exhibits strain-softening characteristics. During the freeze–thaw cycle, through the mutual conversion of free water to ice water inside the sample, the structure of the loess is destroyed. At the same time, due to the influence of the primary structure, the unconfined compressive strength of the undisturbed loess is higher than remolded loess.

- The unconfined compressive strength of undisturbed loess and remolded loess decreases after 6 freeze–thaw cycles, and the strength increases after 8 to 20 freeze–thaw cycles.

- It can be seen from the SEM images that with increasing freeze–thaw cycles, the large particles inside the sample gradually decompose into small particles, increasing the fine particles inside the sample. At the same time, the larger pores inside the sample gradually reduce in size. With the increase in the number of freeze–thaw cycles, the particles inside the soil become denser, and the strength increases.

- The mineral composition of loess after freeze–thaw cycles are studied, and it is found that the internal composition of loess did not change significantly, and the mineral content is stable. Therefore, the effect of freeze–thaw cycles on the mineral composition of loess can be ignored in engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, J.; Xie, B.L.; Ji, G.; Ji, X.; Zhang, W. Experimental Study on the Permeability of Fly Ash Soil-cement. Sci. Technol. Eng. 2019, 19, 323–329. [Google Scholar]

- Wang, L.; Yuan, Z.X.; Wang, G. Study on method for preliminary and detailed evaluation on liquefaction of loess sites. China Earthq. Eng. J. 2013, 35, 1–8. [Google Scholar]

- Tian, H. Culture-Oriented Research of Residential Building Material and Construction Design Method in the Loess Area. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2013. [Google Scholar]

- Lee, J.; Kim, S.; Hwang, G. Changes in physical properties and its metal removal efficiency for the yellow soils by calcination process. J. Korea Acad. Ind. Coop. Soc. 2017, 18, 584–591. [Google Scholar]

- Wang, T. Study on the Green Experience of Traditional Residential Buildings in the Loess Plateau. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2018. [Google Scholar]

- Yang, S.; Wi, S.; Cho, H.; Park, J.; Yun, B.; Kim, S. Developing energy-efficient temporary houses for sustainable urban regeneration: Manufacturing homes with loess, pearlite, and vermiculite. Sustain. Cities Soc. 2020, 6, 102287. [Google Scholar] [CrossRef]

- Hwang, H.; Lee, J.; Yang, J.; Cheng, L. An experimental study for basic properties of hwangto binder. J. Archit. Inst. Korea 2008, 24, 79–86. [Google Scholar]

- Zheng, X.; Ma, W.; Bing, H. Impact of Freezing and Thawing Cycles on the Structures of Soil and a Quantitative Approach. J. Glaciol. Geocryol. 2017, 37, 132–137. [Google Scholar]

- Tang, L.; Tian, S.; Ling, X.; Li, G.; Zhou, G. Effect of Freeze-Thaw Cycles on the Strength of Base Course Materials Used under China’s High-Speed Railway Line. J. Cold Reg. Eng. 2017, 31, 06017003. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S.; Li, G. Effect of freeze-thaw cycles in mechanical behaviors of frozen loess. Cold Reg. Sci. Technol. 2018, 146, 9–18. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S.; Cai, C. Damage evolution and recrystallization enhancement of frozen loess. Int. J. Damage Mech. 2018, 27, 1135–1155. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, A.; Cheng, L. Effects of Cyclic Freeze and Thaw on Engineering Properties of Compacted Loess and Lime-Stabilized Loess. Mater. Civ. Eng. 2019, 31, 04019205. [Google Scholar] [CrossRef]

- Zhao, J.; Ju, Y. Test Research on Influence of Freezing and Thawing Cycle on Undisturbed Loess in Yonghe. Sci. Technol. Eng. 2016, 16, 269–272. [Google Scholar]

- Ye, W.; Li, C.; Dong, X.; Liu, Z.; Peng, R.; Wang, Y.; Wu, Y.; Sun, R.; Wei, W. Study on Damage Identification of Loess Microstructure and Macromechanical Response under Freezing and Thawing Conditions. J. Glaciol. Geocryol. 2018, 40, 546–555. [Google Scholar]

- Zhou, Y.; Wu, X.; Dong, X.; Liu, H. Experimental Study on Strength Deterioration of Remolded Loess Under Freeze-Thaw Cycles. Railw. Eng. 2018, 58, 78–80. [Google Scholar]

- Li, G.; Wang, F.; Ma, W.; Fortier, R.; Mu, Y.; Hou, X. Variations in Strength and Deformation of Compacted Loess Exposed to Wetting-drying and Freeze-thaw Cycles. Cold Reg. Sci. Technol. 2018, 151, 159–167. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, Z.; Feng, W.J.; Ming, J.; Zhang, Z. Determination of long-term strength of frozen loess after numerous freeze-thaw cycles. Sci. Cold Arid. Reg. 2014, 6, 494–498. [Google Scholar]

- Zhang, S.; Ni, J.; Ma, L.; Li, X.; Li, X. Experimental Study on Mechanical Properties of Cement Soils and Fly Ash Soils after Freeze-thaw Cycling. J. Water Resour. Water Eng. 2018, 29, 196–201. [Google Scholar]

- Liu, C.; Lv, Y.; Wu, X. Effects of Freeze-thaw Cycles on the Unconfined Compressive Strength of Straw Fiber-reinforced Soil. J. Geotext. Geomembr. 2020, 48, 581–590. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; Ren, J.; Yuan, J. Comparative Experimental Study on Permeability of Undisturbed and Remolded Loess under Freezing-thawing condition. J. Eng. Geol. 2017, 25, 292–299. [Google Scholar]

- Wei, Y.; Yang, G.; Ye, W.; Wang, L. Factorial Experiment on Unconfined Compression Strength of Freeze-thawing Loess. J. Xi’an Univ. Sci. Technol. 2019, 39, 103–111. [Google Scholar]

- Zhang, Z.; Zhou, H.; Qin, Q.; Bing, H.; Wu, J.; Zhou, P. Experimental Study on Porosity Characteristics of Loess under Freezing-thawing Cycle. J. Jilin Univ. 2017, 47, 839–847. [Google Scholar]

- Yang, G.; You, Z.; Wu, D.; Zhao, L. Experimental Study on the Relation of Undisturbed Loess’Pore Size Distribution and Mechanical Property under Freezing-thawing Environment. Coal Eng. 2019, 51, 107–112. [Google Scholar]

- Zhao, L.; Yang, G.; Wu, D. Micro Structure and Fractal Characteristics Loess under Freeze-thaw Cycles. Chin. J. Undergr. Space Eng. 2019, 15, 1680–1690. [Google Scholar]

- Ning, J.; Wang, Y.; Zhang, C. Influence of Initial Water Content and Freeze-thaw Cycles on Microstructure of Loess. Sci. Technol. Eng. 2018, 18, 285–290. [Google Scholar]

- Zhang, Y.; Bing, H. Experimental Study of the Effect of Freezing-thawing Cycles on Porosity Characters of Silty Clay by Using Mercury Intrusion Porosimetry. J. Glaciol. Geocryol. 2015, 37, 169–174. [Google Scholar]

- Chen, W.; Zhang, W.; Ma, Y.; Chang, L.; Wang, M. Mechanism of Changes in Microstructure of Compacted Loess Based on Triaxial Test. J. China Earthq. Eng. 2014, 36, 753–758. [Google Scholar]

- Wu, W.; Zhang, W.; Ma, Y.; Liu, L.; Sui, Y. Experimental study on microstructure change of intact loess based on GDS dynamic triaxial test. J. Qinghai Univ. 2018, 36, 54–60. [Google Scholar]

- Gao, Y.; Ma, Y.; Zhang, W.; Guo, J. Analysis of humidifying deformation characteristics and microstructure of loess in Xining Area. J. Eng. Geol. 2019, 27, 803–810. [Google Scholar]

- GB/T50123-2019; China Planning Press, Standard for Soil Test Method. The Professional Standards Compilation Group of People’s Republic of China: Beijing, China, 2019.

- Long, J.; Zhang, L.; Xing, X.; Guo, X. Study on the strength and microstructure of loess under freeze thaw based on temperature path. J. Coal Geol. Explor. 2021, 49, 242–249. [Google Scholar]

- Fu, X.; Zhang, Z.; Yang, C.; Yun, Q.; Min, J. Study on geometric type changes of Fuping loess microstructure under freeze-thaw cycles. J. Glaciol. Geocryol. 2021, 43, 484–496. [Google Scholar]

- Zhang, L. Study on Shear Strength and Microstructure of Loess under Freeze-thaw Cycles. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar]

- Li, W. Comparative Study on Pure Shear Creep Mechanical Properties of Jingyang Q2 Original and Remolded Loess. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2017. [Google Scholar]

- Chen, T.; Bi, G.; Chen, G.; Yang, H.; Niu, F.; Mu, Y.; Luo, J. Laboratory Study on Effect of Cyclic Freeze-Thaw on the Uniaxial Compressive Properties of Clayey Coarse-Grained Soils. J. Glaciol. Geocryol. 2019, 41, 587–594. [Google Scholar]

- Xie, B.; Zhang, W.; Sun, X.; Liu, L.; Liu, C. Study on the influence of lime-improved loess strength based on different temperature control curves. J. Glaciol. Geocryol. 2021, 44, 263–274. [Google Scholar]

| Type of Soil | Freeze–Thaw Cycle Test | UCS Test | SEM Test | XRD and XRF Test |

|---|---|---|---|---|

| Undisturbed loess | (1) Freeze–thaw cycles were 0, 2, 4, 6, 8, 10, 15, 20 | Each group has 3 samples, a totalof 48 samples | Each group has 2 samples, a totalof 32 samples | Each group has 2 samples, a totalof 32 samples |

| Remolded loess | (2) The freezing and thawing temperature was set as ±15 °C | |||

| (3) 12 h for freezing and 12 h for thawing as a cycle |

| Specific Gravity of Soil Solids (Gs) | Natural Water Content (%) | Dry Density (g/cm3) | Liquid Limit (%) | Plastic Limit (%) |

|---|---|---|---|---|

| 2.71 | 13.40 | 1.72 | 25.30 | 13.95 |

| Chemical Constituent (Mass%) Freeze–Thaw Cycles | SiO2 | Al2O3 | CaCO3 | MgO | K2O | Na2O | Fe2O3 | Others |

|---|---|---|---|---|---|---|---|---|

| 0 times | 48.0 | 13.5 | 25.9 | 3.15 | 2.74 | 1.26 | 4.17 | 1.28 |

| 2 times | 48.8 | 14.0 | 24.4 | 3.25 | 2.84 | 1.32 | 4.28 | 1.11 |

| 6 times | 49.4 | 13.7 | 24.1 | 3.27 | 2.82 | 1.35 | 4.28 | 1.08 |

| 10 times | 49.1 | 13.5 | 24.8 | 3.13 | 2.70 | 1.30 | 4.28 | 1.19 |

| 20 times | 48.8 | 13.5 | 24.4 | 3.06 | 2.85 | 1.29 | 4.80 | 1.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, B.; Zhang, W.; Sun, X.; Huang, Y.; Liu, L. Experimental Study on the Effects of Freeze–Thaw Cycles on Strength and Microstructure of Xining Region Loess in China. Buildings 2022, 12, 795. https://doi.org/10.3390/buildings12060795

Xie B, Zhang W, Sun X, Huang Y, Liu L. Experimental Study on the Effects of Freeze–Thaw Cycles on Strength and Microstructure of Xining Region Loess in China. Buildings. 2022; 12(6):795. https://doi.org/10.3390/buildings12060795

Chicago/Turabian StyleXie, Banglong, Wuyu Zhang, Xianglong Sun, Yuling Huang, and Leqing Liu. 2022. "Experimental Study on the Effects of Freeze–Thaw Cycles on Strength and Microstructure of Xining Region Loess in China" Buildings 12, no. 6: 795. https://doi.org/10.3390/buildings12060795

APA StyleXie, B., Zhang, W., Sun, X., Huang, Y., & Liu, L. (2022). Experimental Study on the Effects of Freeze–Thaw Cycles on Strength and Microstructure of Xining Region Loess in China. Buildings, 12(6), 795. https://doi.org/10.3390/buildings12060795