Prestress Self-Equilibrium Force-Finding Method for Cable-Supported Grid Structures Considering Zero-Stress State Form-Finding and the Construction Process

Abstract

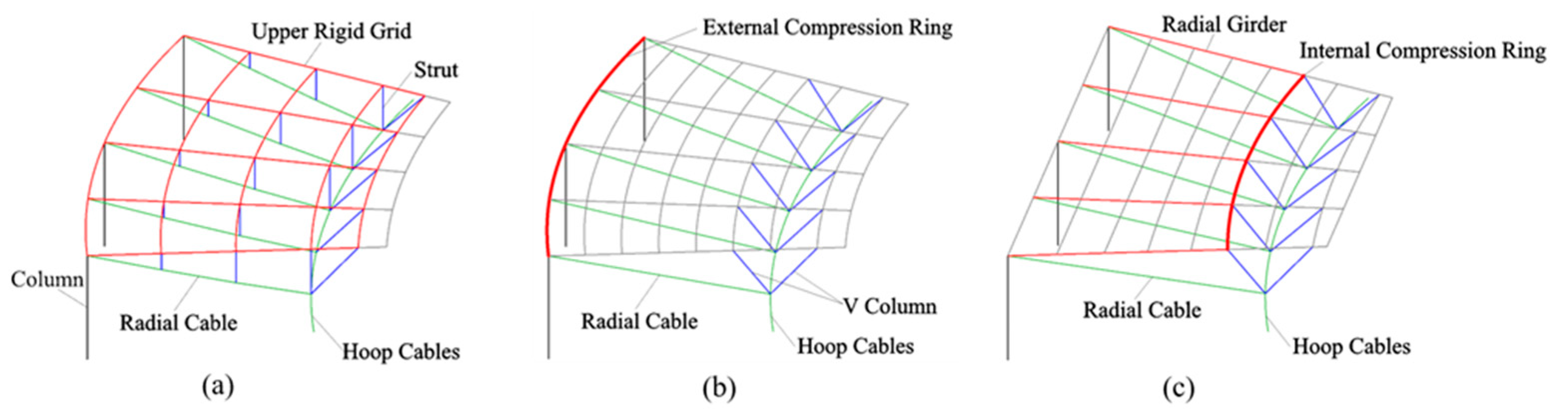

:1. Introduction

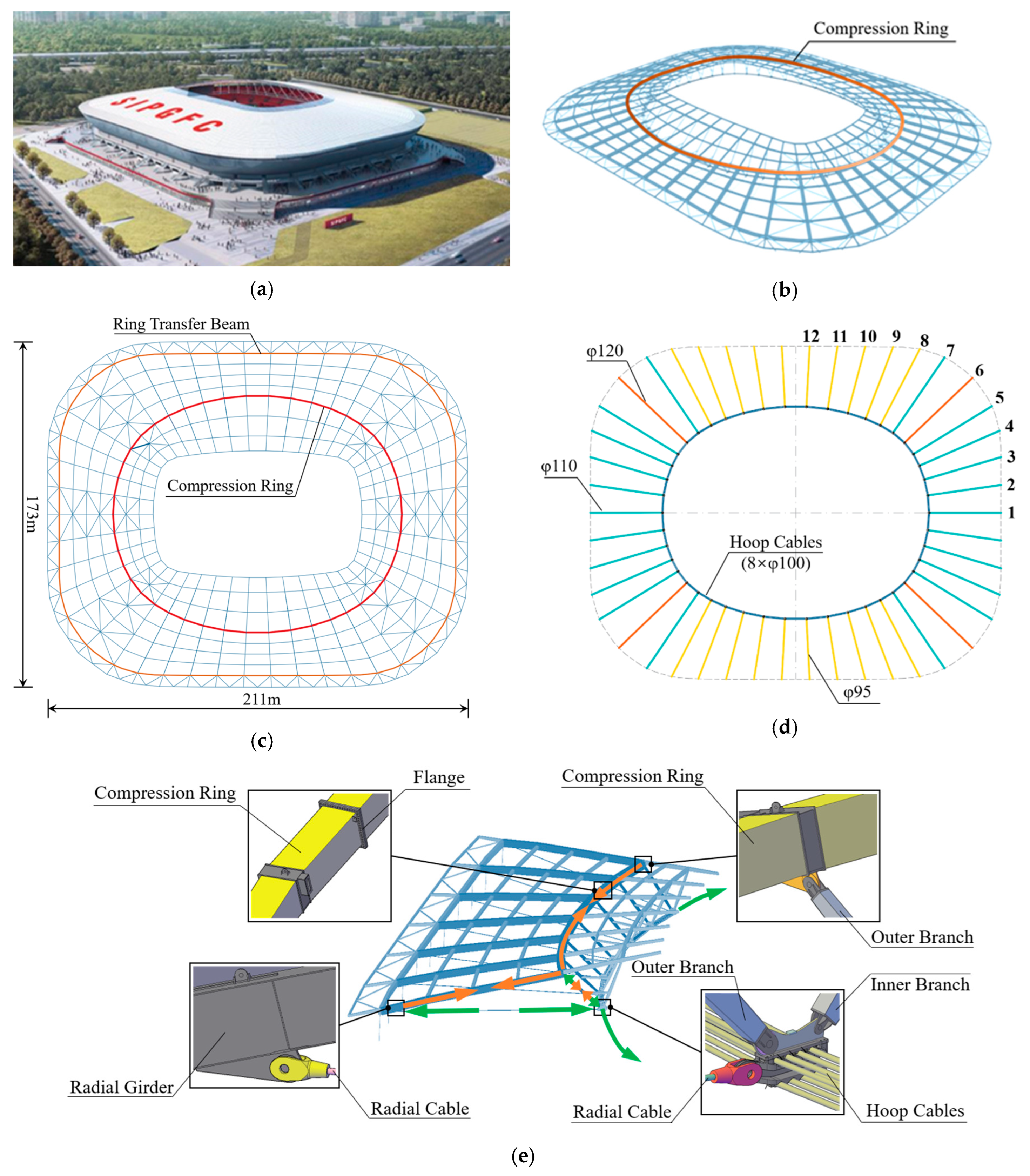

2. Engineering Background

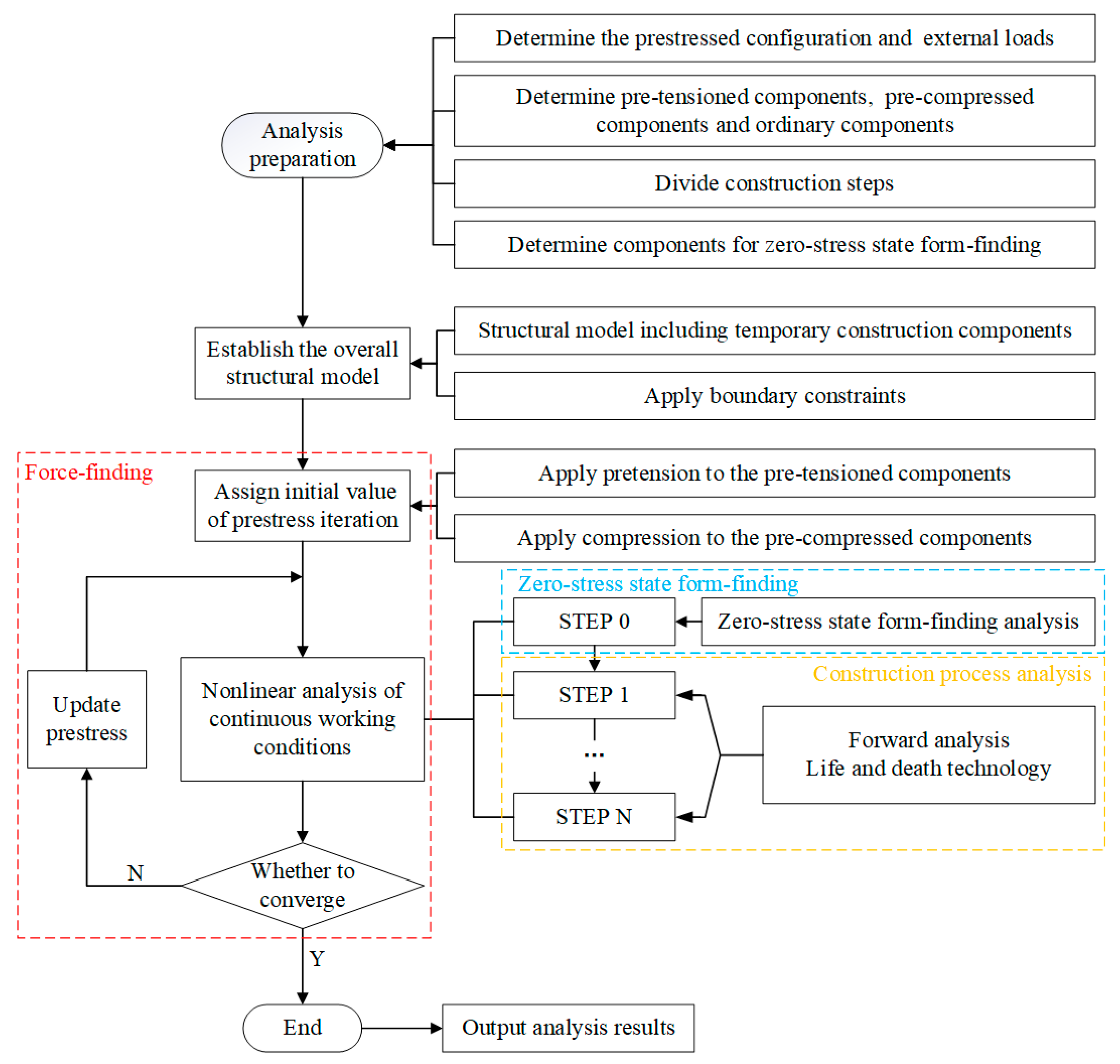

3. Prestress Self-Equilibrium Force-Finding Method (PSEFF) Considering Zero-Stress State Form-Finding and the Construction Process

3.1. Preparatory Work

- Classifying structural components into three categories: pretensioned, precompressed, and ordinary components. Prestress components are not restricted to cables. Considering the prestress self-balance, the pretensioned and precompressed components determined should form a prestress flow closed loop, establishing a self-balancing system. The prestress is not released due to structural deformation, thus providing effective stiffness for the structure. There is no prestress applied in ordinary components.

- Determining the structural components participating in the zero-stress state form-finding. In general, structural components are not all assembled at one time. They are assembled step by step according to the construction scheme. Some components are installed before tensioning and others after tensioning. The structure is in the zero-stress state before tensioning; hence, those components assembled before tensioning are involved in the zero-stress state form-finding. The zero-stress state structure should be statically determined or as close to it as possible.

3.2. Application of Prestress

3.3. Nonlinear Analysis

- Zero-stress state form-finding: Activate the components participating in zero-stress state form-finding and kill other components. In the zero-stress state, the structural stress should be released fully, and the stress level is low. The zero-stress state is regarded as the initial state for subsequent construction analysis.

- Construction process analysis: Adapt direct analysis. According to the construction steps divided in advance, gradually activate the assembled new components in each step until the structure achieves the design configuration. Ordinary components can be activated directly. The prestress in pretensioned and precompressed components is closely related to the unstressed length of the components. To obtain accurate results, it is necessary to ensure that the unstressed lengths of prestress components will not change during calculation. Therefore, the nodal co-ordinates of prestress components should be constrainedly moved to the design position before being activated.

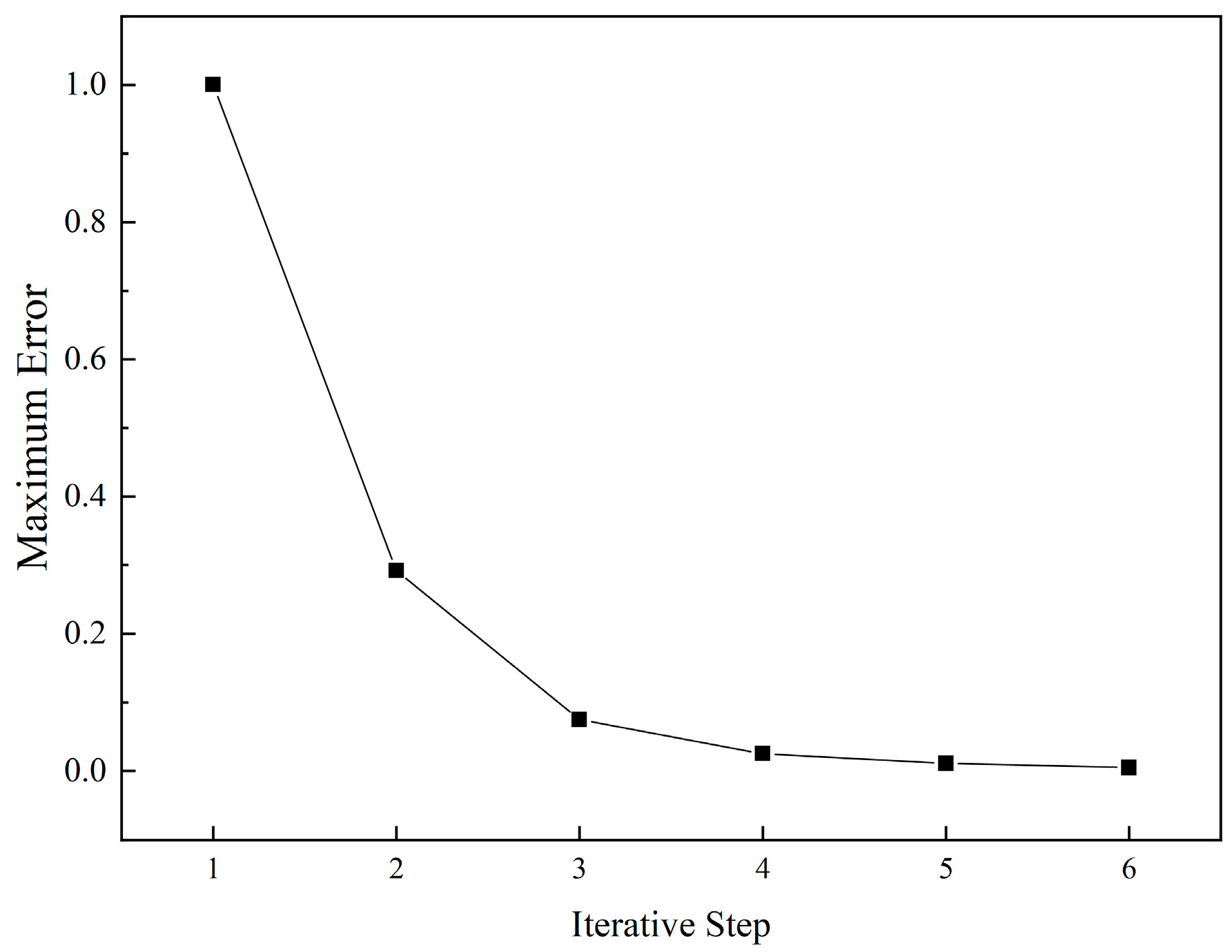

3.4. Convergence Criterion

4. Practical Application

4.1. FEM Model

4.1.1. Element Type

4.1.2. Material Properties

4.1.3. Connection Joint

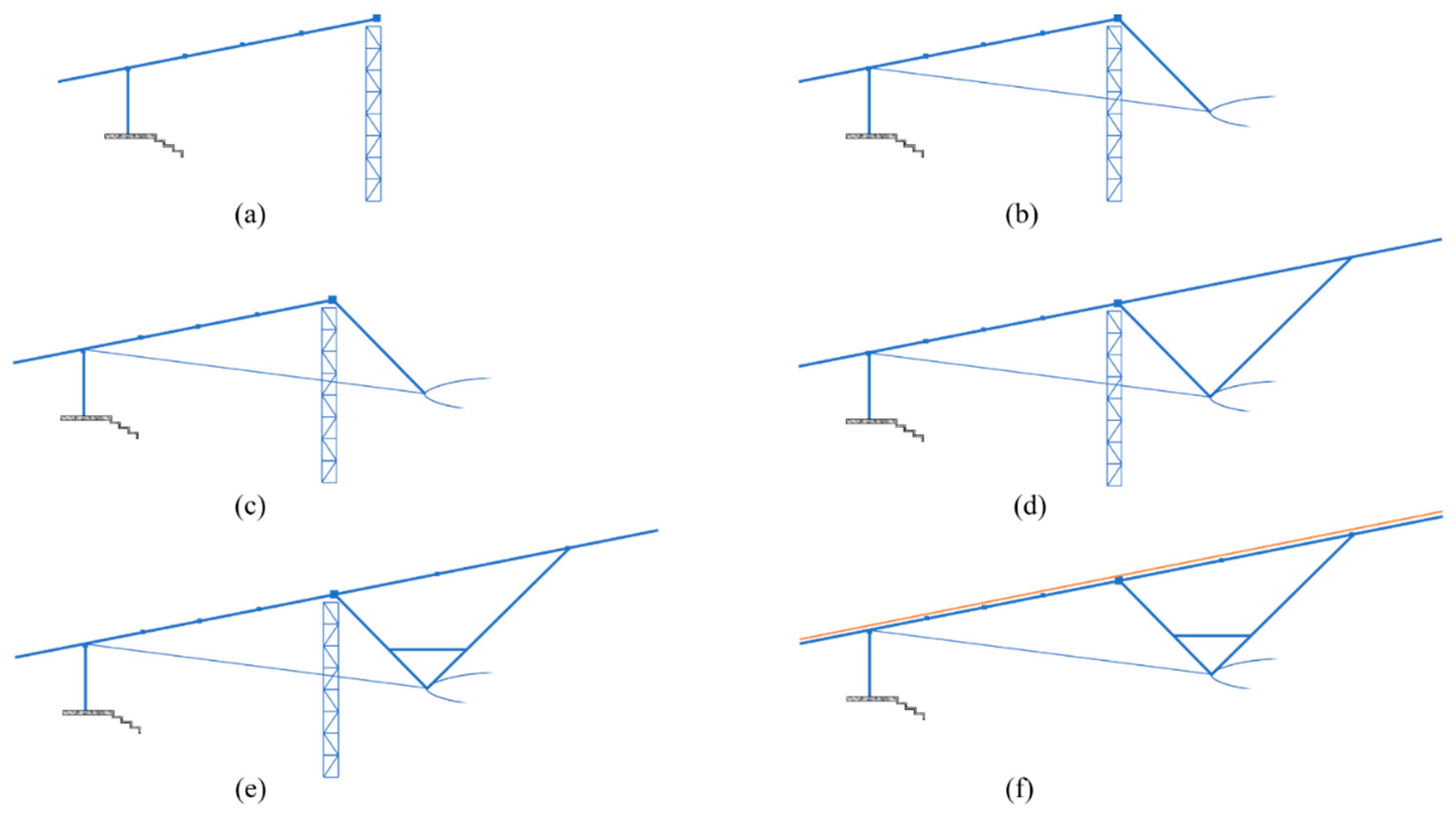

4.2. Construction Steps and Components Division

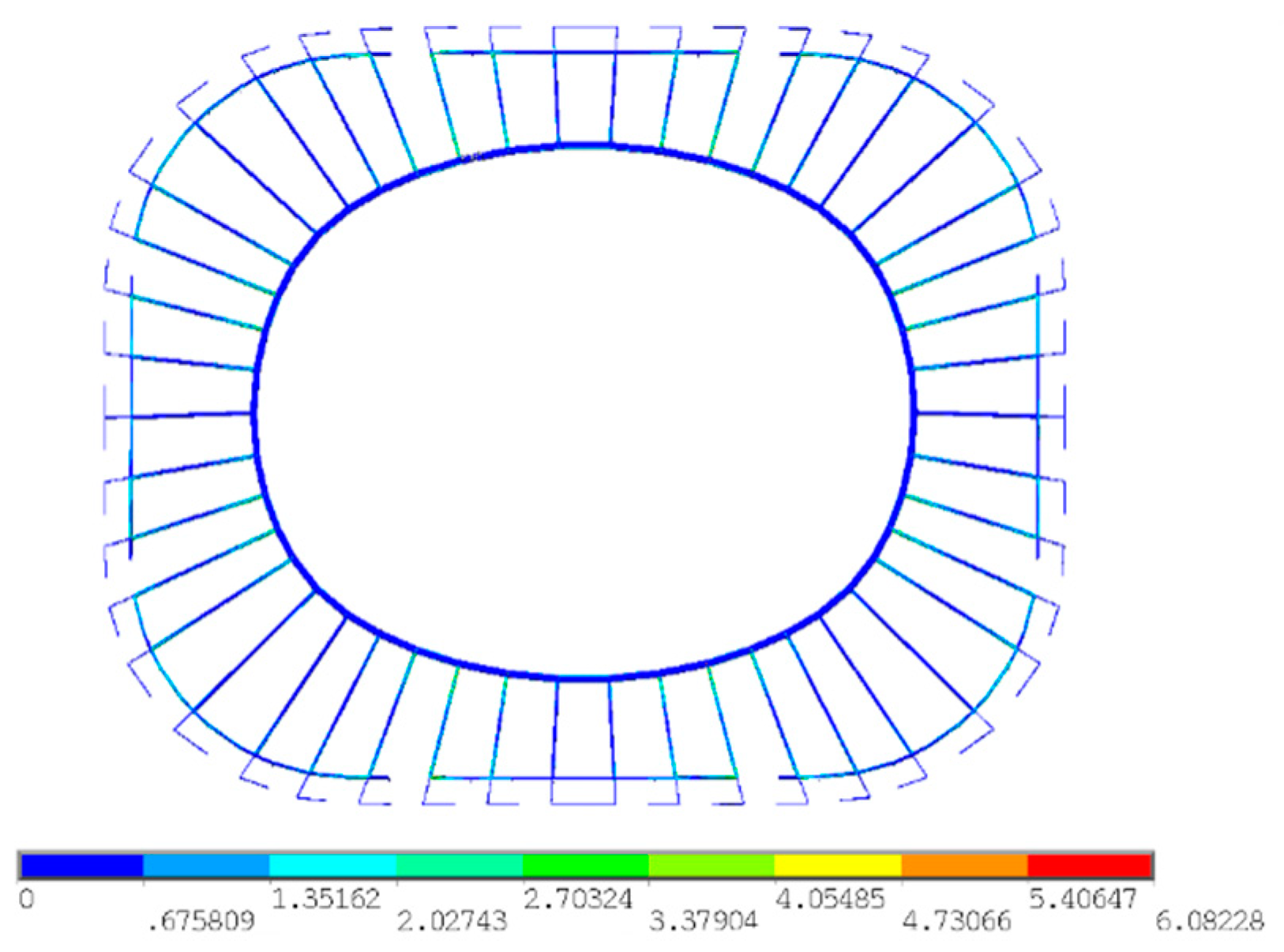

4.3. Zero-Stress State Form-Finding Results

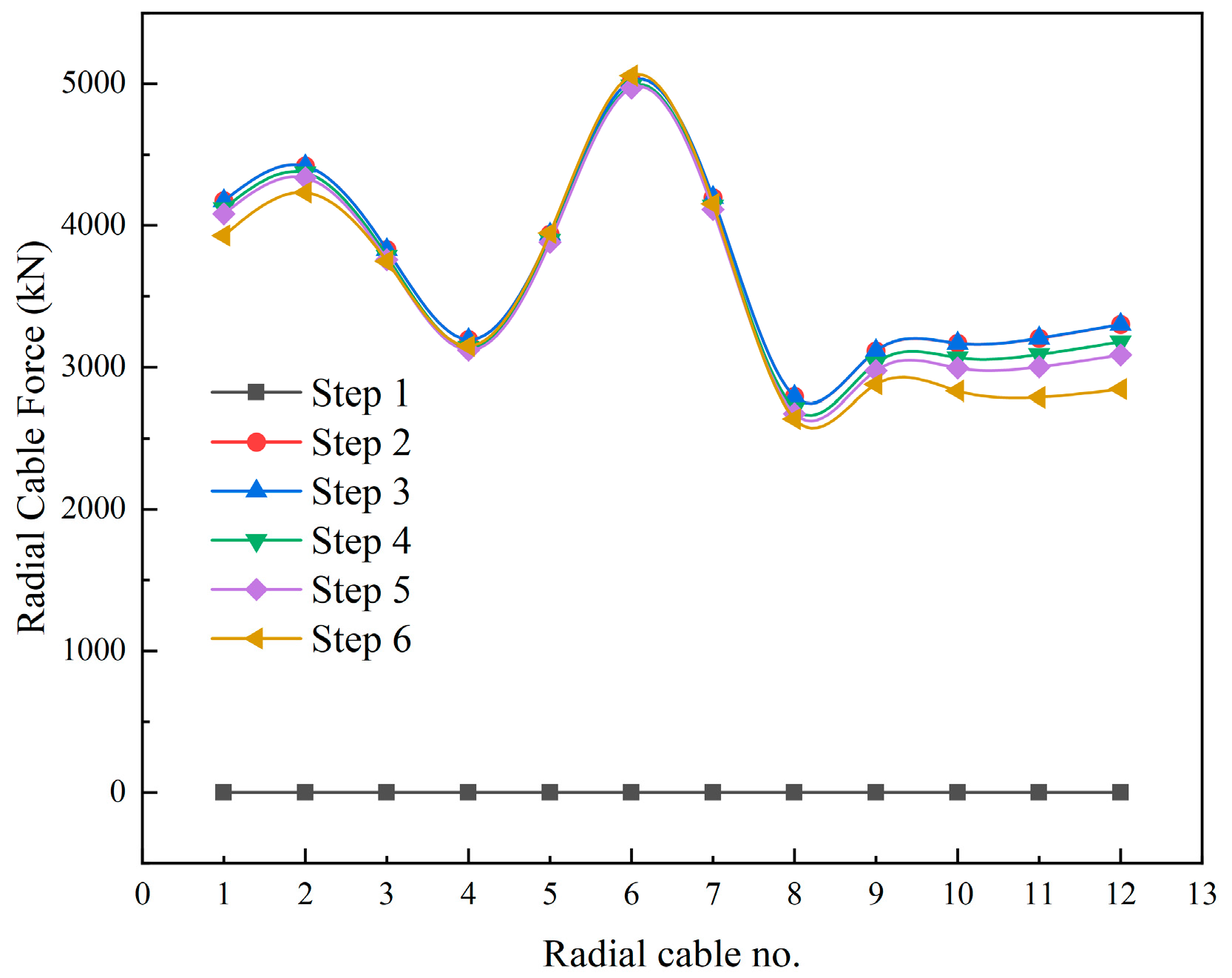

4.4. Force-Finding Results

4.5. Construction Process Analysis

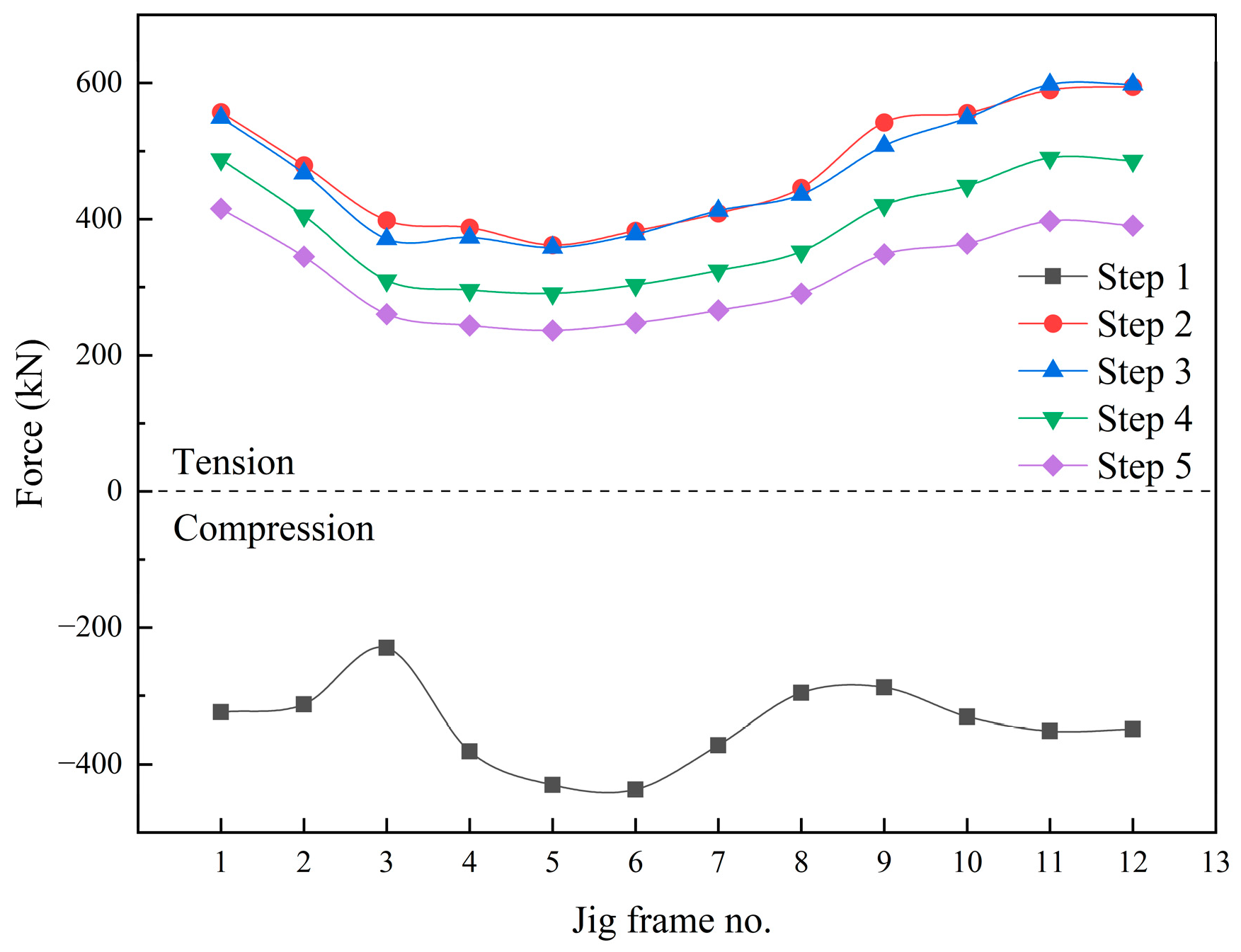

4.5.1. Internal Force

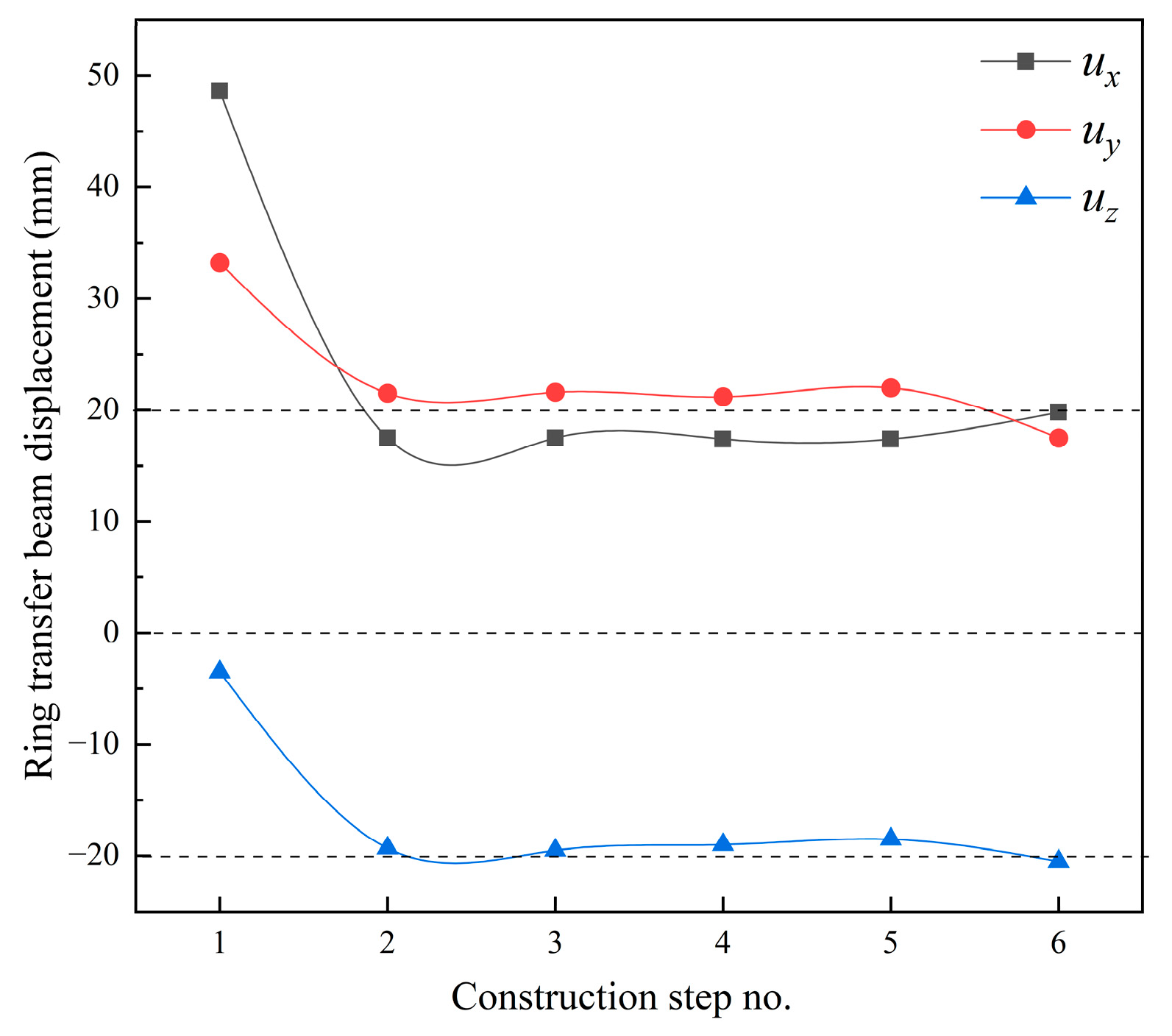

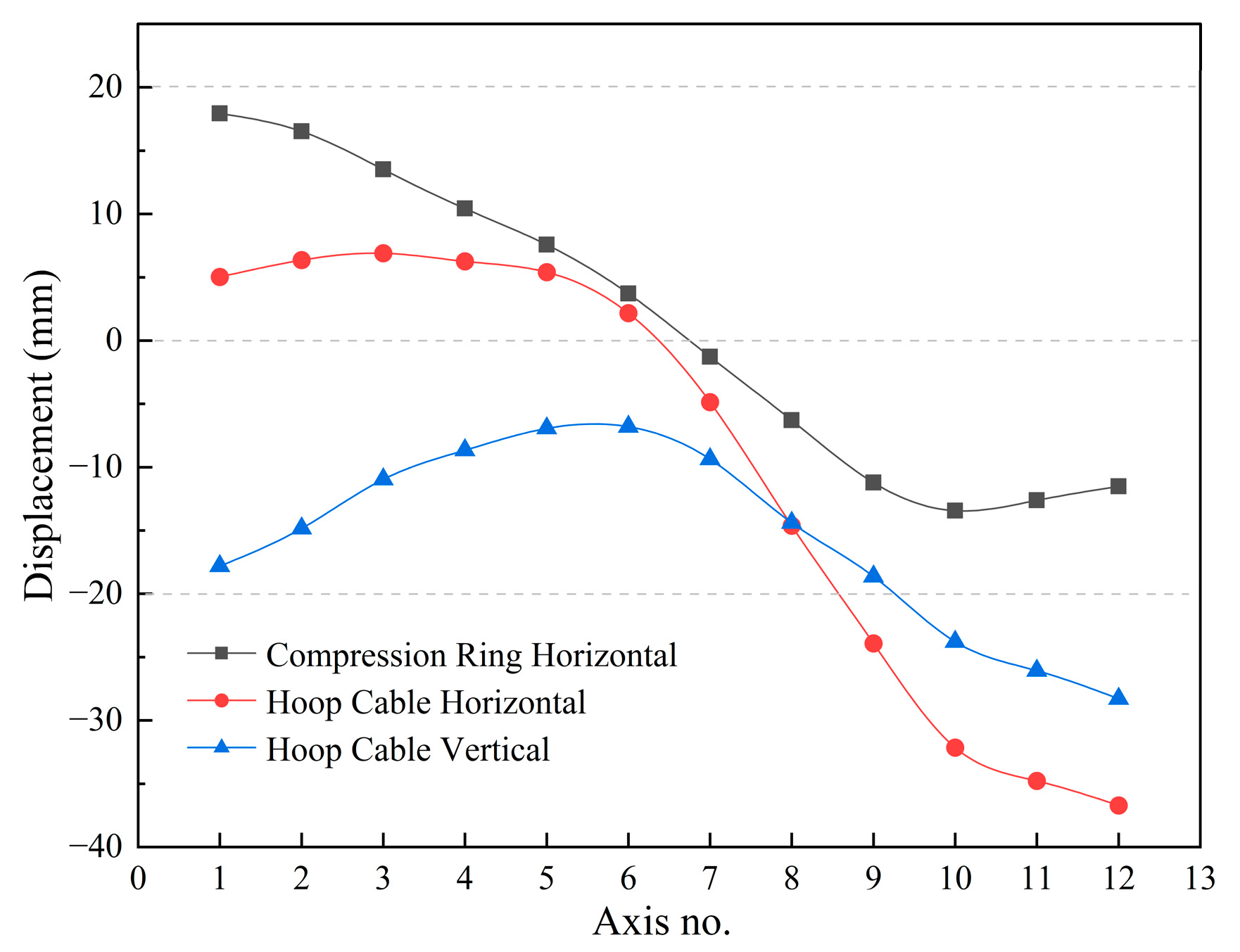

4.5.2. Displacement

5. Discussion

6. Conclusions

- CSGS with an internal compression ring is a new structure combining rigidity and flexibility. The compression ring is located inside the structure and not restricted by the plane shape, which ensures that the internal forces of the compression ring are mainly axial force and which reduces the bending stress.

- The equivalent temperature difference is applied to the components as prestress. The Newton–Raphson method is employed to solve nonlinear problems. The structural finite element model is built to implement the analysis. To acquire the accurate structural configuration and prestress distribution, the prestressed components should form a self-balancing system, and their unstressed length ought to be constant during the calculation.

- Compared with the design configuration, the zero-stress state configuration expands horizontally, and the internal forces are completely released. The internal forces and displacements are relatively stable in the construction steps after prestressing. The prestress distribution and displacements of the formed structure are in accordance with the designer’s expectations. The maximum deviation of radial cable force is 8%, and the displacement deviations are within 1/1000. The analysis results demonstrate the effectiveness of the PSEFF method.

- The PSEFF method proposed in this paper has been successfully applied to the forming analysis of CSGS with an internal compression ring. Accurate zero-stress state configuration and feasible prestress actual response during the construction process can be obtained at one time. The versatility of the method for other cable-strut structures and the efficiency improvement compared with other methods should be studied further.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kawaguchi, M.; Abe, M.; Tagemichi, I. Design, tests and realization of “suspen-dome” system. J. Int. Assoc. Shell Spat. Struct. 1999, 40, 179–192. [Google Scholar]

- Kang, W.; Chen, Z.; Lam, H.F.; Zuo, C. Analysis and design of the general and outmost-ring stiffened suspendome structures. Eng. Struct. 2003, 25, 1685–1695. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, W.; Yuan, H.; Zhu, J.; Zheng, J. Modified double-control form-finding analysis for suspendomes considering the construction process and the friction of cable–strut joints. Eng. Struct. 2016, 120, 75–81. [Google Scholar] [CrossRef]

- Krishnan, S. Cable-stayed columns and their applications in building structures. J. Build. Eng. 2020, 27, 100984. [Google Scholar] [CrossRef]

- Feng, Y.; Xiang, X.; Wang, H.; Chen, W. Mechanical behavior and form-finding research on large opening spoke-wheel-type cable supported grid structure. J. Build. Struct. 2019, 40, 69–80. [Google Scholar] [CrossRef]

- Feng, Y.; Xiang, X.; Wang, H. Static performance parameter analysis of large opening spoke-wheel-type cable supported grid structure. J. Build. Struct. 2019, 40, 81–91. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, Q.; Dong, S.; Fu, X. Structural design of a practical suspendome. Adv. Steel Constr. 2008, 4, 323–340. [Google Scholar]

- Wang, Y.; Xu, X.; Luo, Y. A unifying framework for form-finding and topology-finding of tensegrity structures. Comput. Struct. 2021, 247, 106486. [Google Scholar] [CrossRef]

- Chen, L.; Dong, S. Optimal Prestress Design and Construction Technique of Cable-Strut Tension Structures with Multi-Overall Selfstress Modes. Adv. Struct. Eng. 2013, 16, 1633–1644. [Google Scholar] [CrossRef]

- Li, X.; Xue, S.; Liu, Y. A novel form finding method for minimum surface of cable net. J. Build. Eng. 2022, 48, 103939. [Google Scholar] [CrossRef]

- Nie, R.; He, B.; Hodges, D.H.; Ma, X. Form finding and design optimization of cable network structures with flexible frames. Comput. Struct. 2019, 220, 81–91. [Google Scholar] [CrossRef]

- Deng, H.; Jiang, Q.; Kwan, A.S.K. Shape finding of incomplete cable-strut assemblies containing slack and prestressed elements. Comput. Struct. 2005, 83, 1767–1779. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, W.; Fu, G.; Li, R. Computation method of zero-stress state of pneumatic stressed membrane structure. Sci. China Technol. Sci. 2012, 55, 717–724. [Google Scholar] [CrossRef]

- Tang, Y.; Li, T.; Ma, X.; Hao, L. Extended Nonlinear Force Density Method for Form-Finding of Cable-Membrane Structures. J. Aerosp. Eng. 2017, 30, 4016101. [Google Scholar] [CrossRef]

- Tang, Y.; Li, T. Equivalent-force density method as a shape-finding tool for cable-membrane structures. Eng. Struct. 2017, 151, 11–19. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, J.; Tsukimoto, S.; Shimoda, M. Design optimization of cable–membrane structures for form-finding and stiffness maximization. Compos. Struct. 2020, 206, 9–22. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, J.; Ohsaki, M.; Wu, Y. Topology optimization and shape design method for large-span tensegrity structures with reciprocal struts. Int. J. Solids Struct. 2018, 192, 528–536. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, S.; Li, S.; Xu, G. Analytical form-finding of tensegrities using determinant of force-density matrix. Compos. Struct. 2018, 189, 87–98. [Google Scholar] [CrossRef]

- Pagitz, M.; Mirats Tur, J.M. Finite element based form-finding algorithm for tensegrity structures. Int. J. Solids Struct. 2009, 46, 3235–3240. [Google Scholar] [CrossRef]

- Yuan, S.; Zhu, W. Optimal self-stress determination of tensegrity structures. Eng. Struct. 2021, 238, 112003. [Google Scholar] [CrossRef]

- Dong, W.; Stafford, P.J.; Ruiz-Teran, A.M. Inverse form-finding for tensegrity structures. Comput. Struct. 2019, 215, 27–42. [Google Scholar] [CrossRef] [Green Version]

- Bagrianski, S.; Halpern, A.B. Form-finding of compressive structures using Prescriptive Dynamic Relaxation. Comput. Struct. 2014, 132, 65–74. [Google Scholar] [CrossRef]

- Domaneschi, M.; Limongelli, M.G.; Martinelli, L. Multi-site damage localization in a suspension bridge via aftershock monitoring. Ing. Sismica 2013, 30, 56–72. [Google Scholar]

- Wang, X.; Wang, H.; Zhang, J.; Sun, Y.; Bai, Y.; Zhang, Y.; Wang, H. Form-finding method for the target configuration under dead load of a new type of spatial self-anchored hybrid cable-stayed suspension bridges. Eng. Struct. 2021, 227, 11407. [Google Scholar] [CrossRef]

- Martinelli, L.; Domaneschi, M.; Shi, C. Submerged Floating Tunnels under Seismic Motion: Vibration Mitigation and Seaquake effects. Procedia Eng. 2016, 166, 229–246. [Google Scholar] [CrossRef]

- Zhang, P.; Zhou, J.; Chen, J. Form-finding of complex tensegrity structures using constrained optimization method. Compos. Struct. 2021, 268, 113971. [Google Scholar] [CrossRef]

- Schek, H.J. The force density method for form finding and computation of general networks. Comput. Methods Appl. Mech. Eng. 1974, 3, 115–134. [Google Scholar] [CrossRef]

- Linkwitz, K.; Schek, H.J. Einige Bemerkungen zur Berechnung von vorgespannten Seilnetzkonstruktionen. Ing. Arch. 1971, 40, 145–158. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Deng, X.; Feng, J. Form-finding method for multi-mode tensegrity structures using extended force density method by grouping elements. Compos. Struct. 2018, 187, 1–9. [Google Scholar] [CrossRef]

- Koohestani, K. Innovative numerical form-finding of tensegrity structures. Int. J. Solids Struct. 2020, 206, 304–313. [Google Scholar] [CrossRef]

- Otter, J.R.H.; Cassell, A.C.; Hobbs, R.E. Poisson, Dynamic relaxation. Proc. Inst. Civ. Eng. 1966, 35, 633–656. [Google Scholar] [CrossRef]

- Day, A.S.; Bunce, J.H. Analysis of cable networks by dynamic relaxation. Civ. Eng. Public Work. Rev. 1970, 4, 383–386. [Google Scholar]

- Barnes, M.R. Form Finding and Analysis of Tension Structures by Dynamic Relaxation. Int. J. Space Struct. 1999, 14, 89–104. [Google Scholar] [CrossRef]

- Argyris, J.H.; Angelopoulos, T.; Bichat, B. A general method for the shape finding of lightweight tension structures. Comput. Methods Appl. Mech. Eng. 1974, 3, 135–149. [Google Scholar] [CrossRef]

- Domaneschi, M. Experimental and numerical study of standard impact tests on polypropylene pipes with brittle behavior. Proc. Inst. Mech. Eng. Part B 2012, 226, 2035–2046. [Google Scholar] [CrossRef]

- Domaneschi, M.; Perego, U.; Borgqvist, E.; Borsari, R. An industry-oriented strategy for the finite element simulation of paperboard creasing and folding. Packag. Technol. Sci. 2017, 30, 269–294. [Google Scholar] [CrossRef]

- Tanarrok, B.; Qin, Z. Nonlinear analysis of tension structures. Comput. Struct. 1992, 45, 973–984. [Google Scholar] [CrossRef]

- Lee, S.; Lee, J. Form-finding of tensegrity structures with arbitrary strut and cable members. Int. J. Mech. Sci. 2014, 85, 55–62. [Google Scholar] [CrossRef]

- Quagliaroli, M.; Albertin, A.; Pollini, N. The role of prestress and its optimization in cable domes design. Comput. Struct. 2015, 161, 17–30. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, X.; Cai, J.; Yang, R.; Feng, J. Prestress design for cable-strut structures by grouping elements. Eng. Struct. 2021, 244, 112010. [Google Scholar] [CrossRef]

- Sun, F.; Zhu, D.; Liang, M.; Zhang, D. Study on Form-Finding of Cable-Membrane Structures Based on Particle Swarm Optimization Algorithm. Math. Probl. Eng. 2020, 2020, 1281982. [Google Scholar] [CrossRef]

- Chen, Y.; Yan, J.; Feng, J.; Sareh, P. A hybrid symmetry–PSO approach to finding the self-equilibrium configurations of prestressable pin-jointed assemblies. Acta Mech. 2020, 231, 1485–1501. [Google Scholar] [CrossRef]

- Li, Y.; Feng, X.; Cao, Y.; Gao, H. A Monte Carlo form-finding method for large scale regular and irregular tensegrity structures. Int. J. Solids Struct. 2010, 47, 1888–1898. [Google Scholar] [CrossRef] [Green Version]

- Ye, J.; Feng, R.; Zhao, X.; Liu, B. A form-finding method of beam string structures-Offload by steps method. Int. J. Steel Struct. 2012, 12, 267–283. [Google Scholar] [CrossRef]

- Fan, L.; Sun, Y.; Fan, W.; Chen, Y.; Feng, J. Determination of active members and zero-stress states for symmetric prestressed cable–strut structures. Acta Mech. 2020, 231, 3607–3620. [Google Scholar] [CrossRef]

- Pellegrino, S. Analysis of prestressed mechanisms. Int. J. Solids Struct. 1990, 26, 1329–2350. [Google Scholar] [CrossRef]

- Pellegrino, S. Structural computations with the singular value decomposition of the equilibrium matrix. Int. J. Solids Struct. 1993, 30, 3025–3035. [Google Scholar] [CrossRef]

- Pellegrino, S.; Calladine, C.R. Matrix analysis of statically and kinematically indeterminate frameworks. J. Solids Struct. 1986, 22, 409–428. [Google Scholar] [CrossRef]

- Yuan, X.; Dong, S. Integral feasible prestress of cable domes. Comput. Struct. 2003, 81, 2111–2119. [Google Scholar] [CrossRef]

- Yuan, X.; Chen, L.; Dong, S. Prestress design of cable domes with new forms. Int. J. Solids Struct. 2007, 44, 2773–2782. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Jiang, J. An algorithm for calculating the feasible pre-stress of cable-struts structure. Eng. Struct. 2016, 118, 228–239. [Google Scholar] [CrossRef]

- Chen, L.; Hu, D.; Deng, H.; Cui, Y.; Zhou, Y. Optimization of the construction scheme of the cable-strut tensile structure based on error sensitivity analysis. Steel Compos. Struct. 2016, 21, 1031–1043. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, G.; Yang, Q. Determination of cable forces during construction for cable-supported lattice shells. J. Build. Struct. 2004, 24, 76–81. [Google Scholar] [CrossRef]

- Yuan, X.; Dong, S. Inverse Analysis of Construction Process of Cable Dome. J. Build. Struct. 2001, 22, 75–80. [Google Scholar] [CrossRef]

- Luo, B.; Guo, Z.; Chen, X.; Gao, F.; Wang, K. Static equilibrium form-finding analysis of cable-strut system based on nonlinear dynamic finite element method. Adv. Steel Constr. 2005, 11, 452–468. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method for Solid and Structural Mechanics, 6th ed.; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Pica, A.; Wood, R.D.; Hinton, E. Finite element analysis of geometrically nonlinear plate behaviour using a mindlin formulation. Comput. Struct. 1980, 11, 203–215. [Google Scholar] [CrossRef]

- Surana, K.S. Geometrically non-linear formulation for two dimensional curved beam elements. Comput. Struct. 1983, 17, 105–114. [Google Scholar] [CrossRef]

| Section Type | Component | Sectional Dimension (mm) |

|---|---|---|

| Rectangular tube | Internal compression ring | 1500 × 1500 × 50 × 50 |

| Radial girder | 650 × 650 × 14 × 22 | |

| Ring beam | 1400 × 700 × 10 × 48 | |

| V column | 600 × 350 × 12 × 12 | |

| Circular tube | Column | 400 × 10 |

| Component Type | Density (kg/m3) | Young’s Elastic Modulus (MPa) | Linear Expansion Coefficient (1/°C) | Poisson’s Ratio |

|---|---|---|---|---|

| Radial & Hoop cables | 7850 | 1.60 × 105 | 1.2 × 10−5 | 0.3 |

| Steel Components | 8635 1 | 2.06 × 105 | 1.2 × 10−5 | 0.3 |

| Component | Displacement (mm) | ||

|---|---|---|---|

| In the Long Axis Direction ux | In the Short Axis Direction uy | Vertical Displacement uz | |

| Internal compression ring | 34.6 | 23.9 | 3.2 |

| Ring transfer beam | 46.5 | 32.7 | −0.1 |

| Component | Hoop Cable No. | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Force (kN) | 3398.4 | 3165.7 | 3493.3 | 3282.7 | 3604.9 | 3403.7 | 3733.9 | 3527.6 |

| Internal Forces | Construction Step No. | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Hoop cables average force (kN) | 0 | 3276.3 | 3276.4 | 3317.9 | 3341.5 | 3451.3 |

| Compression ring axial force (kN) | 9.51 | −26,100 | −26,100 | −26,500 | −26,600 | −27,200 |

| Upper rigid grid stress (MPa) | 42.5 | 112.6 | 115.1 | 111.4 | 110.9 | 130.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Luo, B.; Liu, H.; Zhang, M. Prestress Self-Equilibrium Force-Finding Method for Cable-Supported Grid Structures Considering Zero-Stress State Form-Finding and the Construction Process. Buildings 2022, 12, 749. https://doi.org/10.3390/buildings12060749

Zhang N, Luo B, Liu H, Zhang M. Prestress Self-Equilibrium Force-Finding Method for Cable-Supported Grid Structures Considering Zero-Stress State Form-Finding and the Construction Process. Buildings. 2022; 12(6):749. https://doi.org/10.3390/buildings12060749

Chicago/Turabian StyleZhang, Ningyuan, Bin Luo, Haixia Liu, and Minquan Zhang. 2022. "Prestress Self-Equilibrium Force-Finding Method for Cable-Supported Grid Structures Considering Zero-Stress State Form-Finding and the Construction Process" Buildings 12, no. 6: 749. https://doi.org/10.3390/buildings12060749

APA StyleZhang, N., Luo, B., Liu, H., & Zhang, M. (2022). Prestress Self-Equilibrium Force-Finding Method for Cable-Supported Grid Structures Considering Zero-Stress State Form-Finding and the Construction Process. Buildings, 12(6), 749. https://doi.org/10.3390/buildings12060749