Does Metakaoline Replacement Adversely Affect the Cyclic Behavior of Non-Strengthened and Strengthened RC Beams: An Experimental Investigation

Abstract

:1. Introduction

2. Research Significance

- Assess the most environmentally friendly concrete mix through the optimum cement replacement by metakaolin.

- Study the effect of metakaolin as a partial substitute for cement on the cyclic performance of RC beams.

- Explore the applicability of strengthening beams constructed using metakaolin replacement and figure out whether the existence of metakaolin will cause a negative effect on their cyclic performance.

- To perform an experimental investigation utilizing relatively larger-scale specimens to capture closer behavior to real life applications.

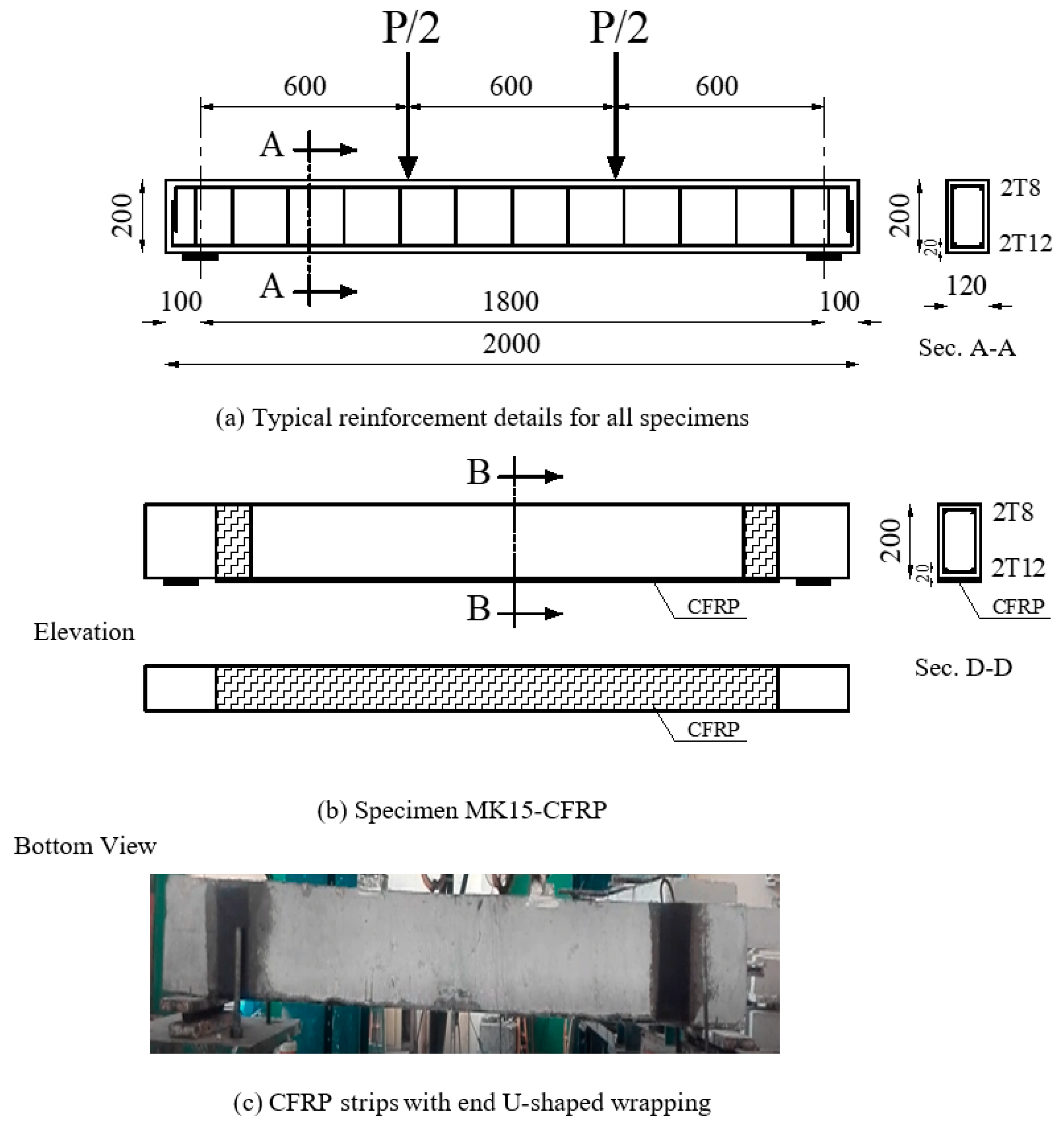

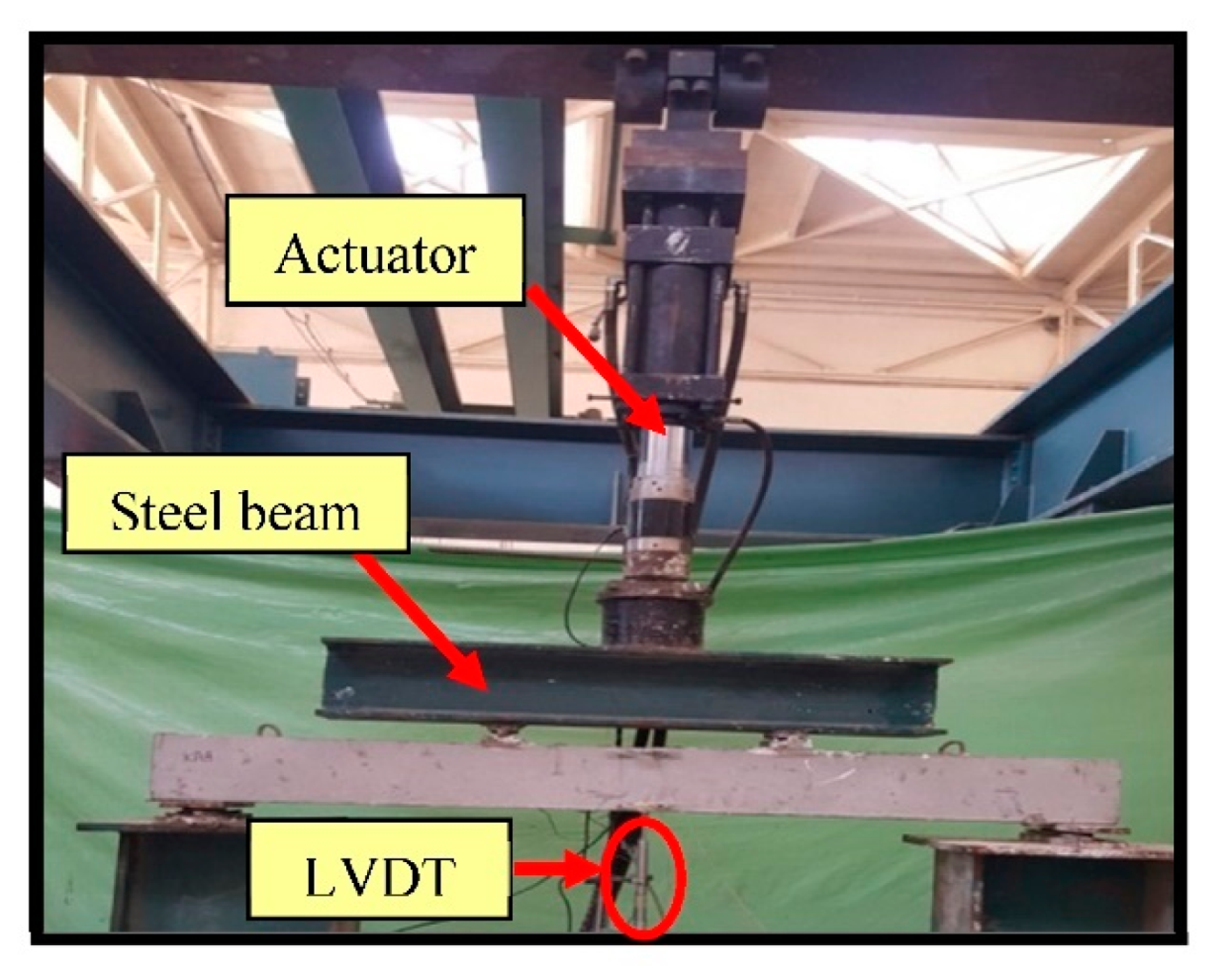

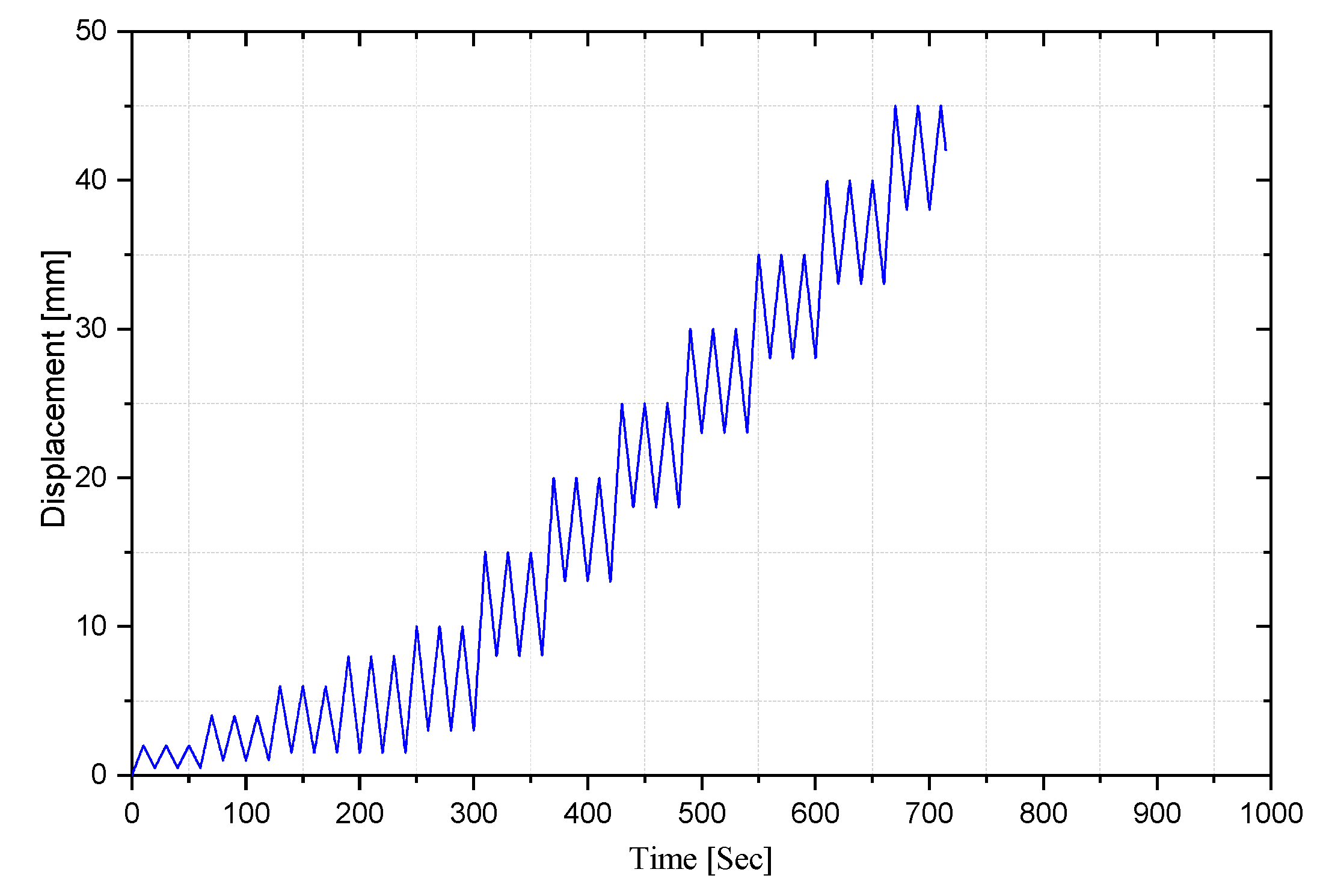

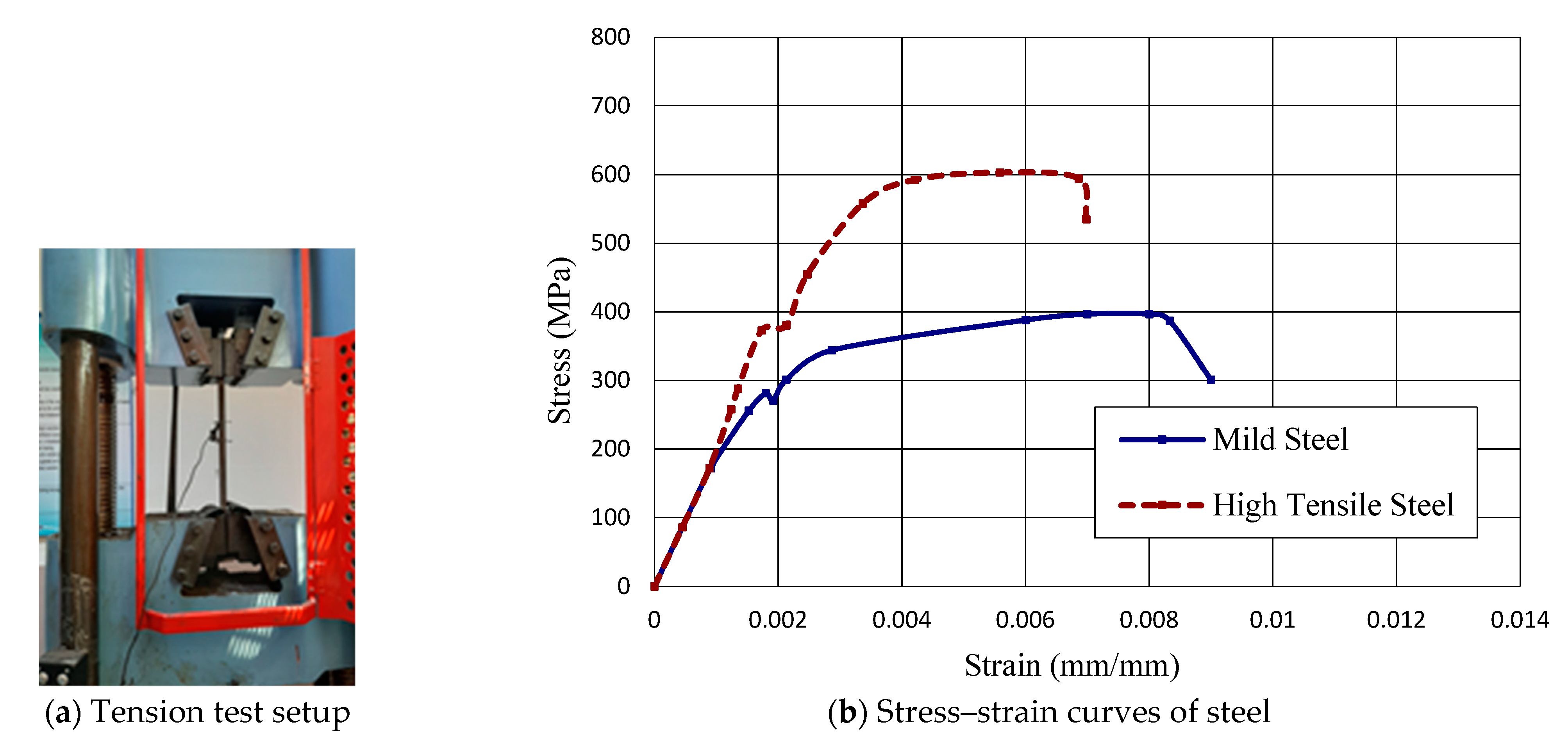

3. Research Program

4. Observations on Non-Strengthened RC Beams

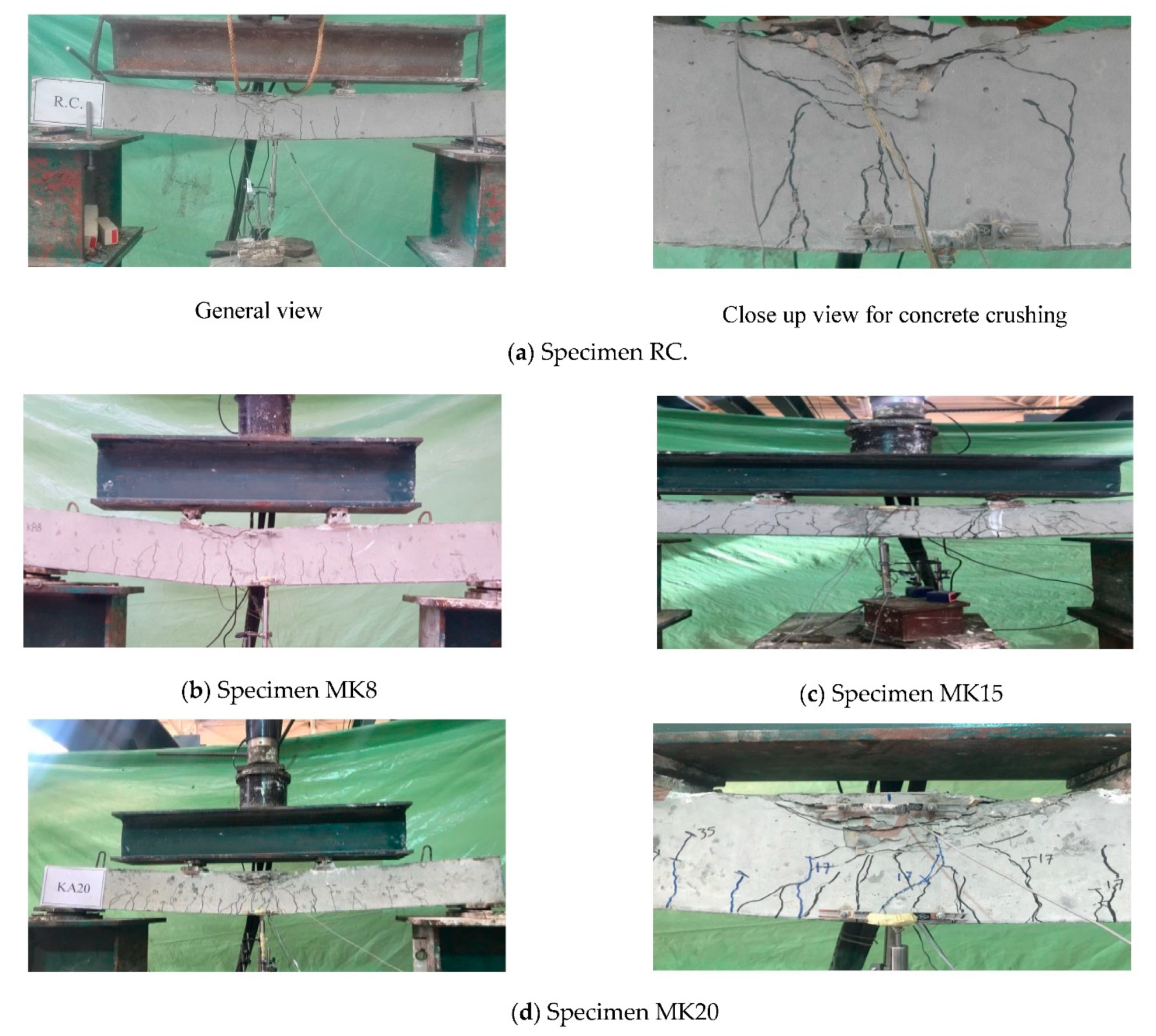

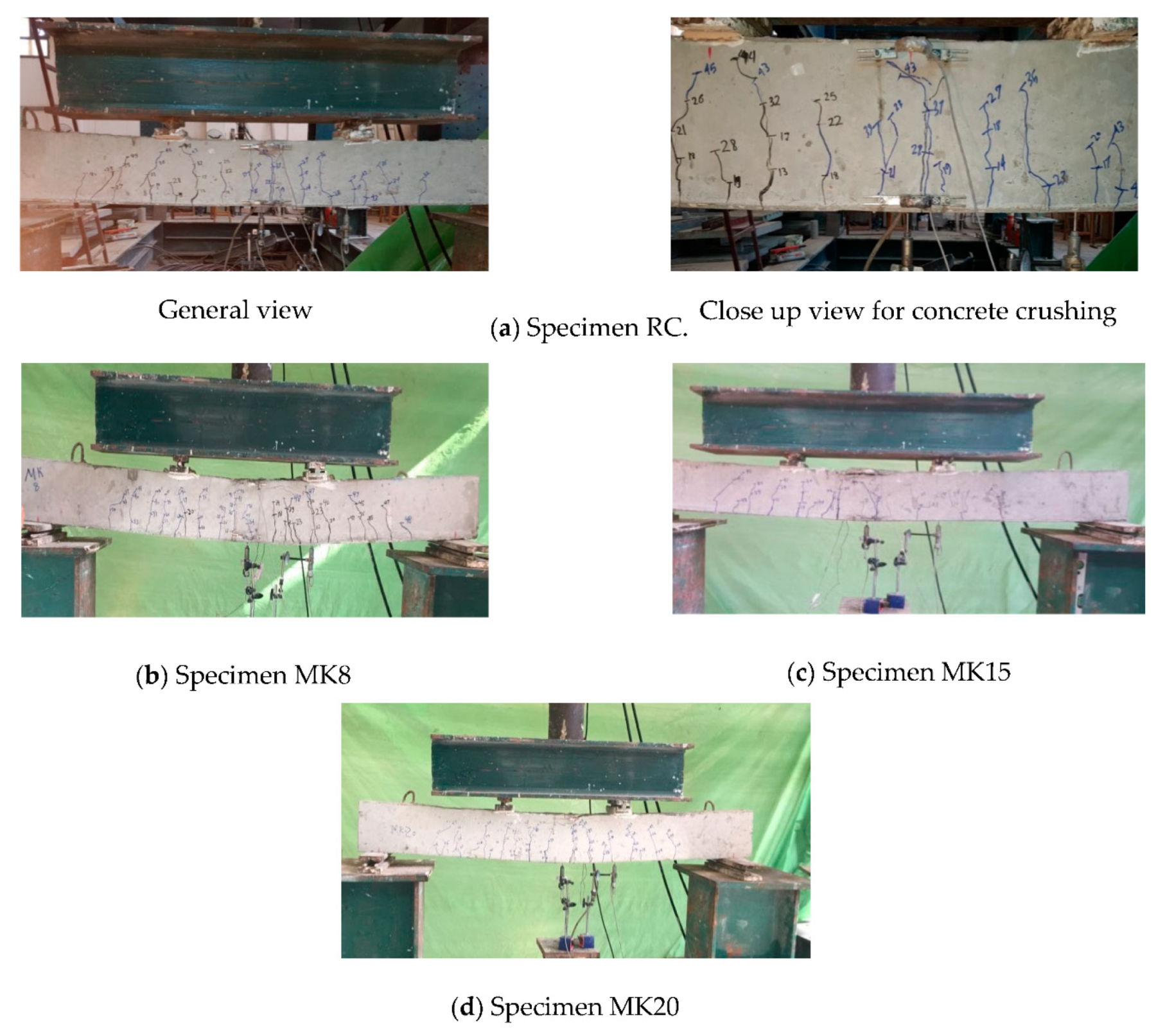

4.1. Shape of Failure and Crack Pattern

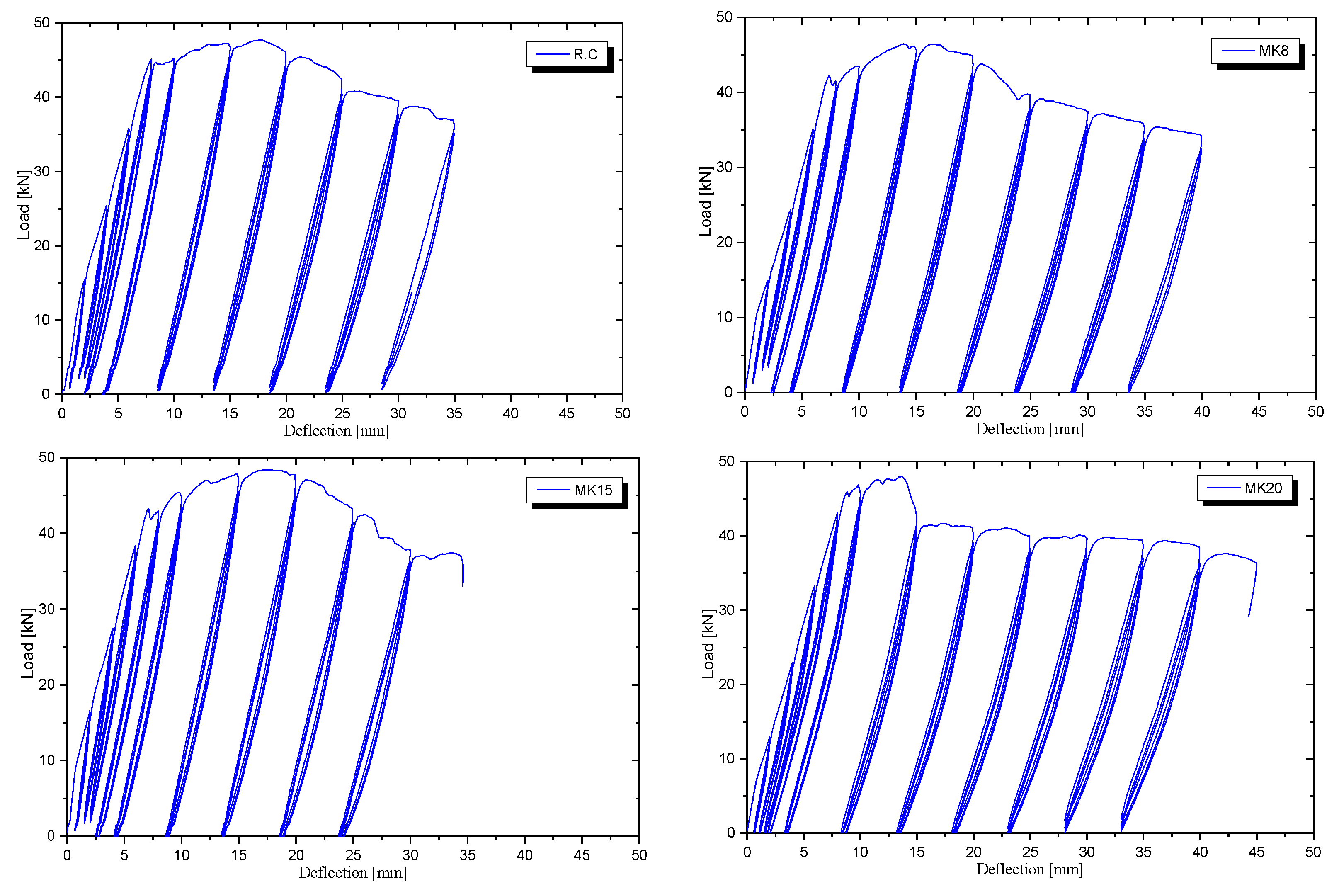

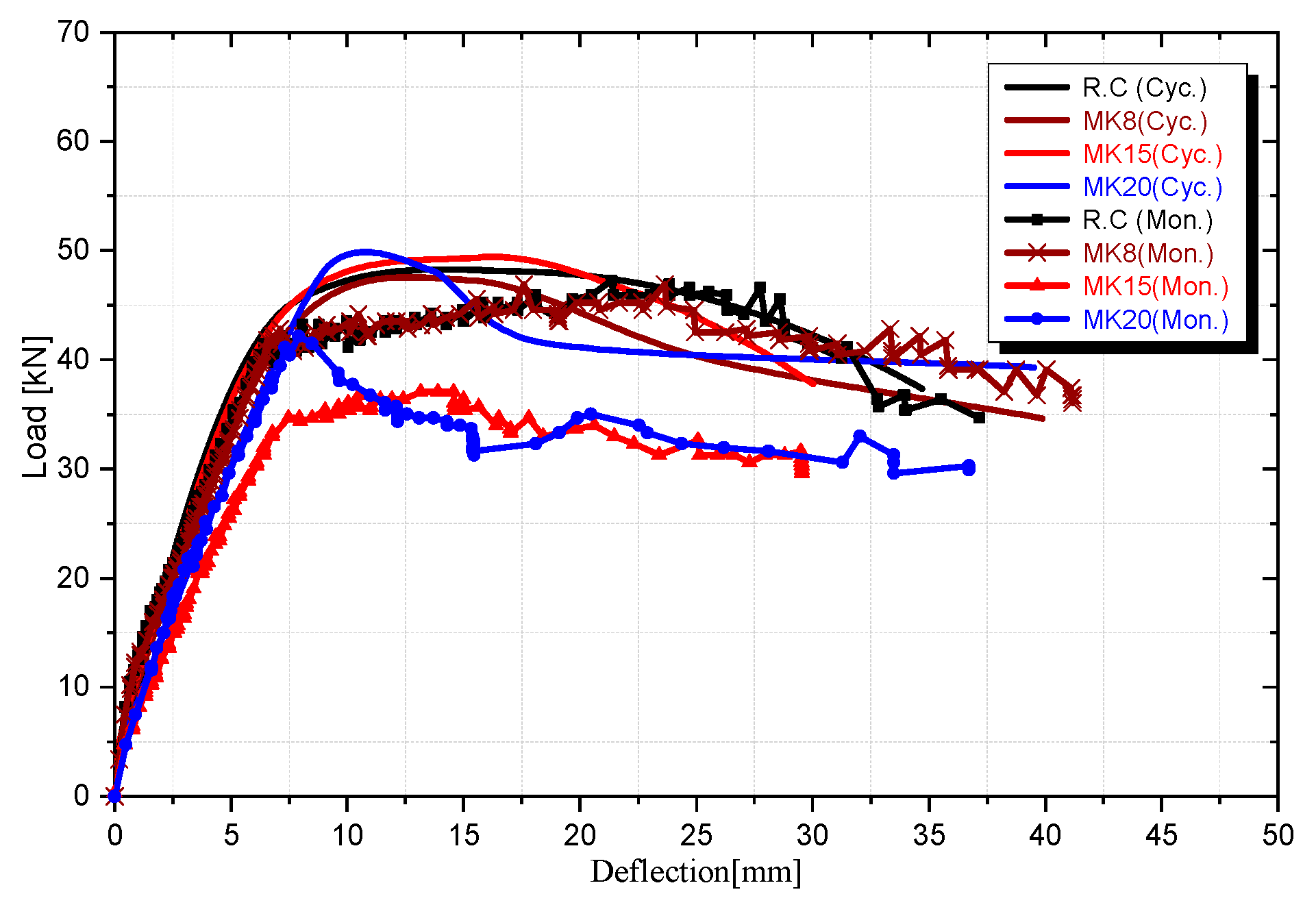

4.2. Load–Deflection Relationship

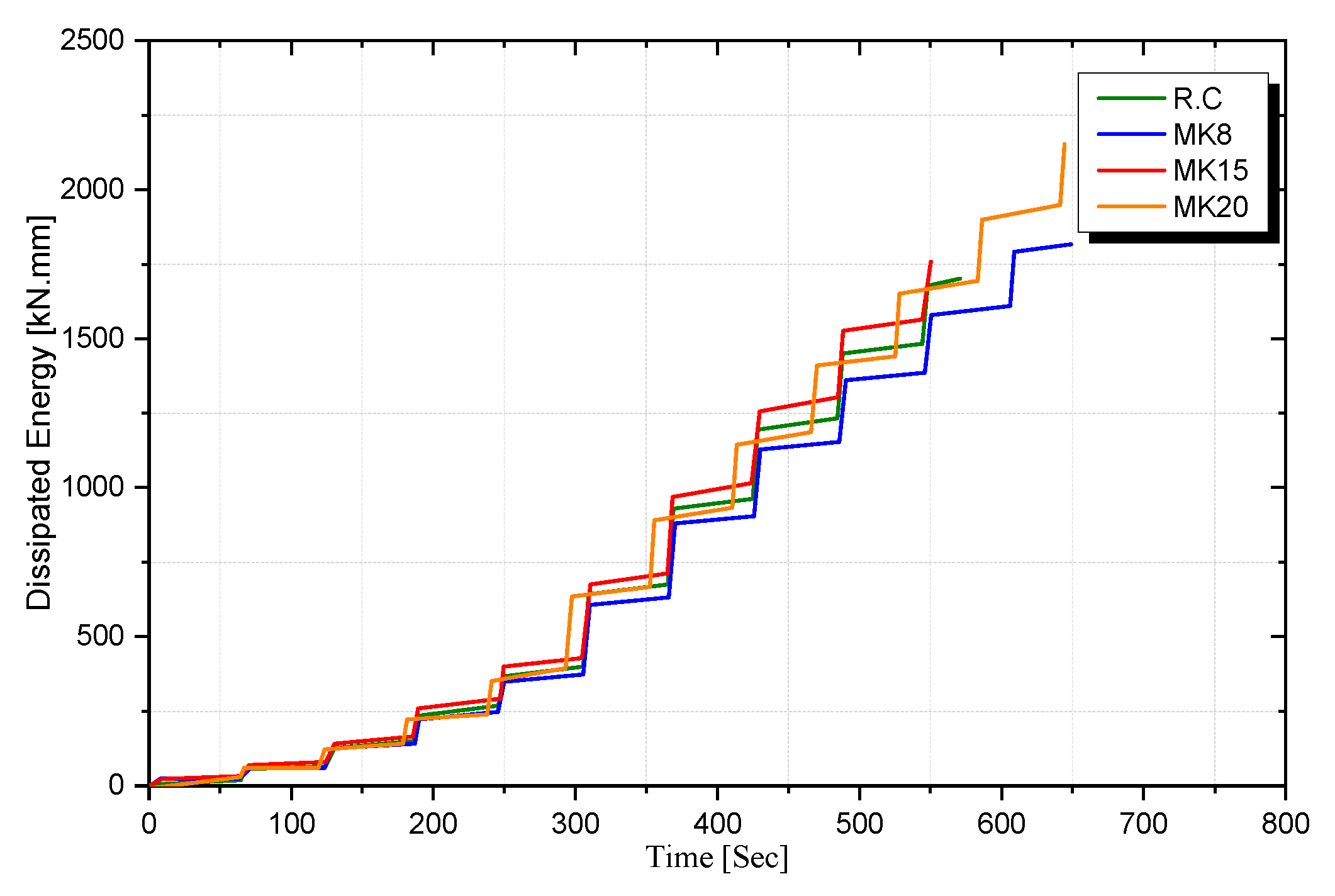

4.3. Effect of the Cement Replacement on Energy Dissipation Capacity

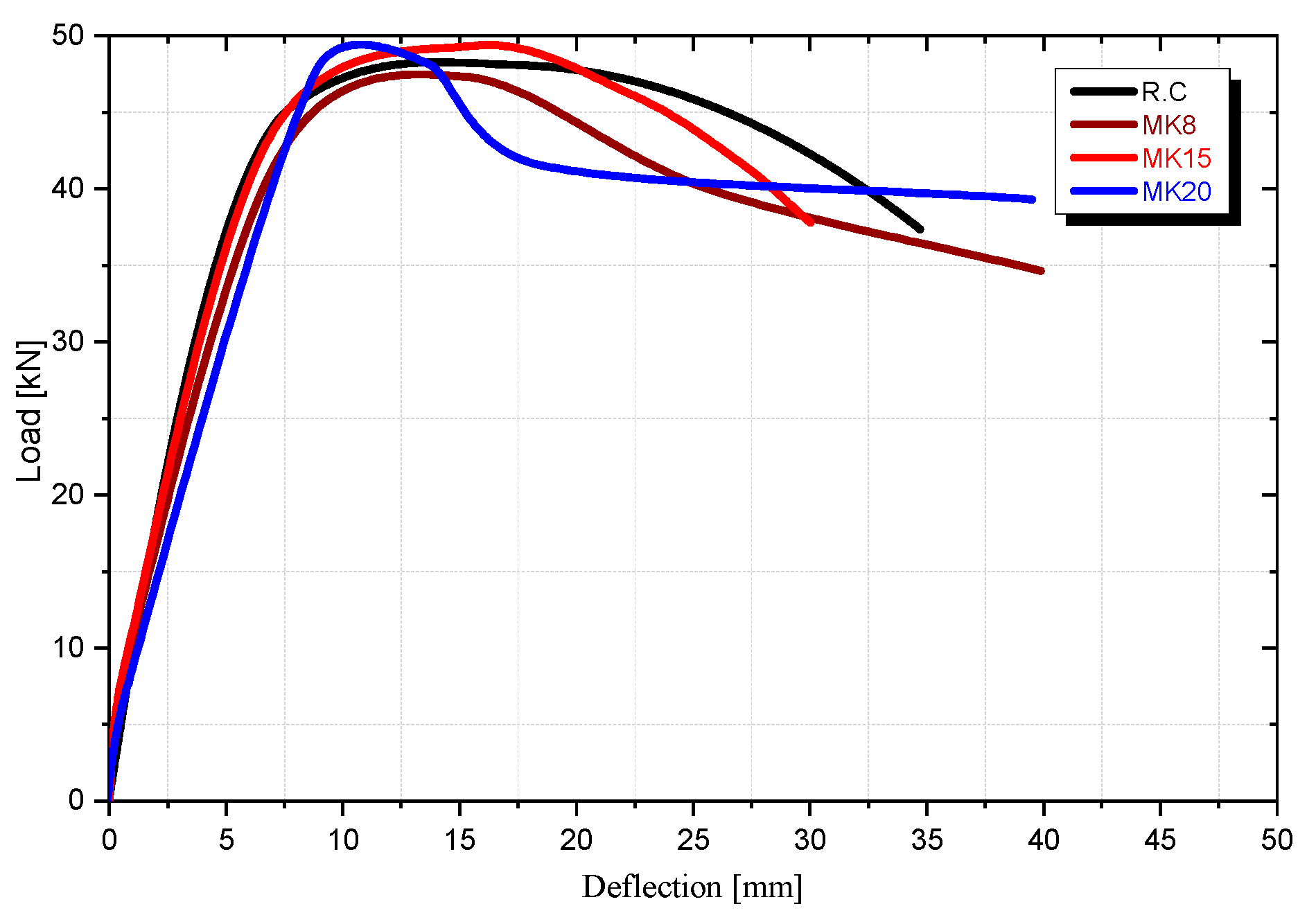

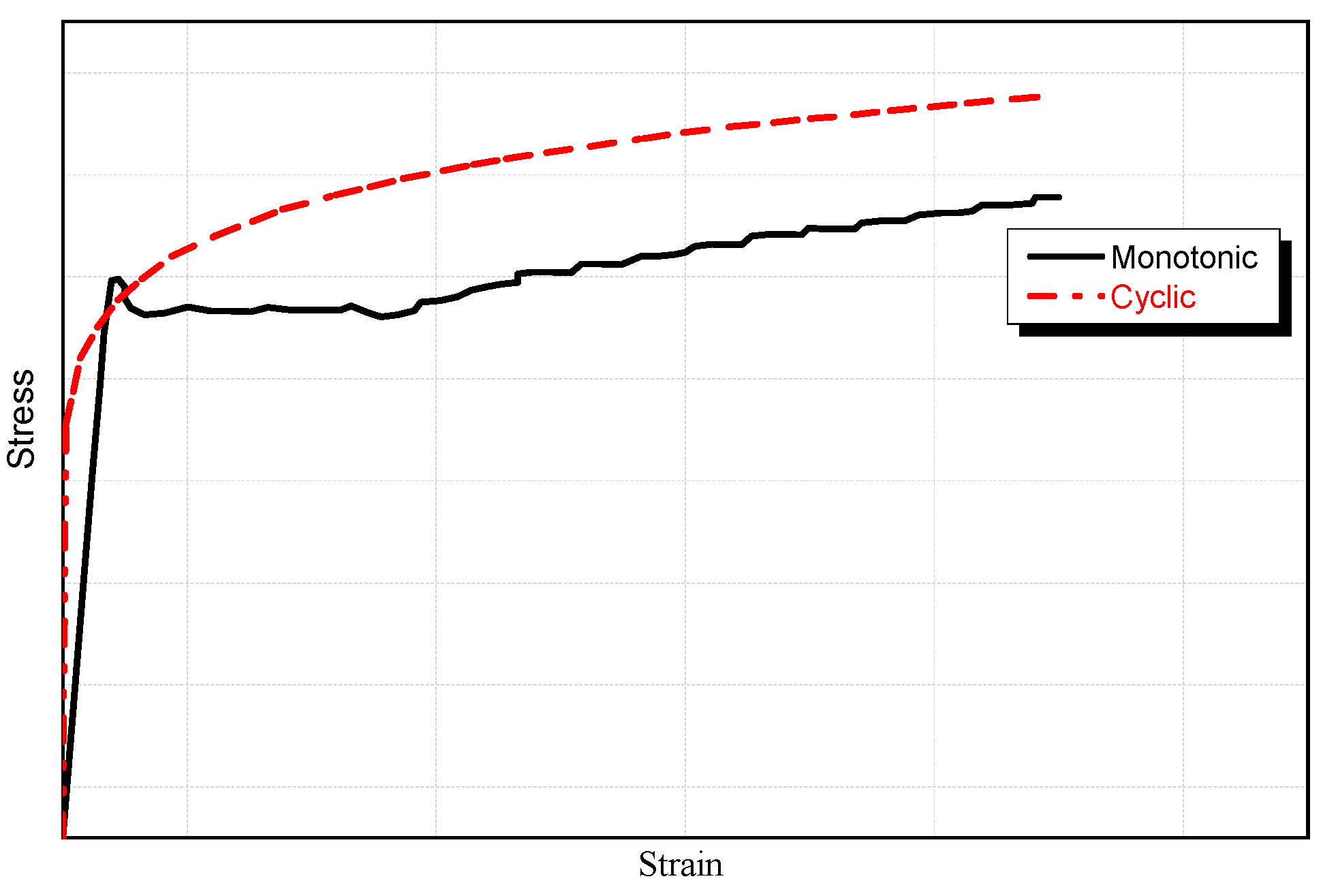

4.4. Comparison between Cyclic and Monotonic Loads for Non-Strengthened Beams

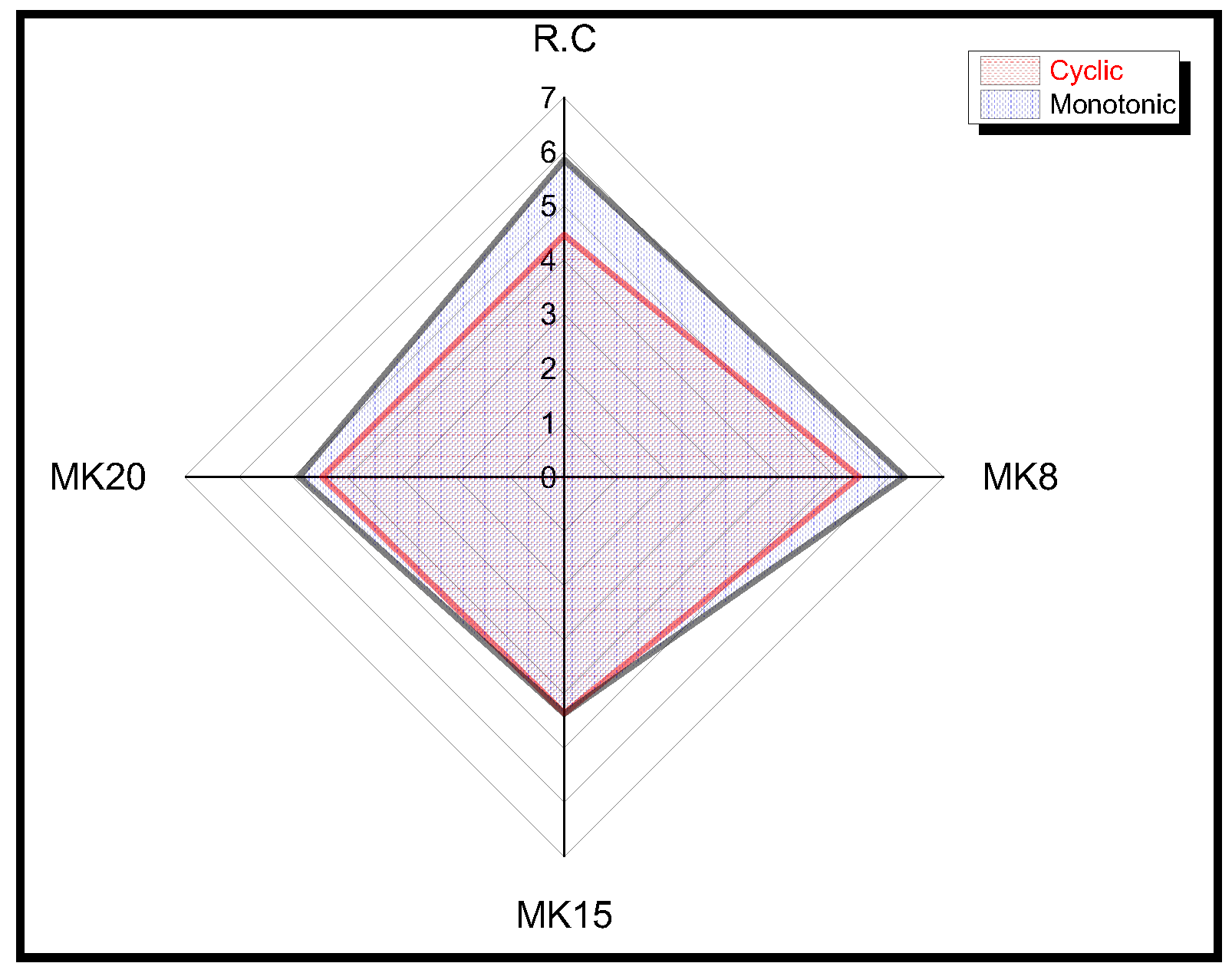

4.5. Ductility

5. Observation on Strengthened Beams

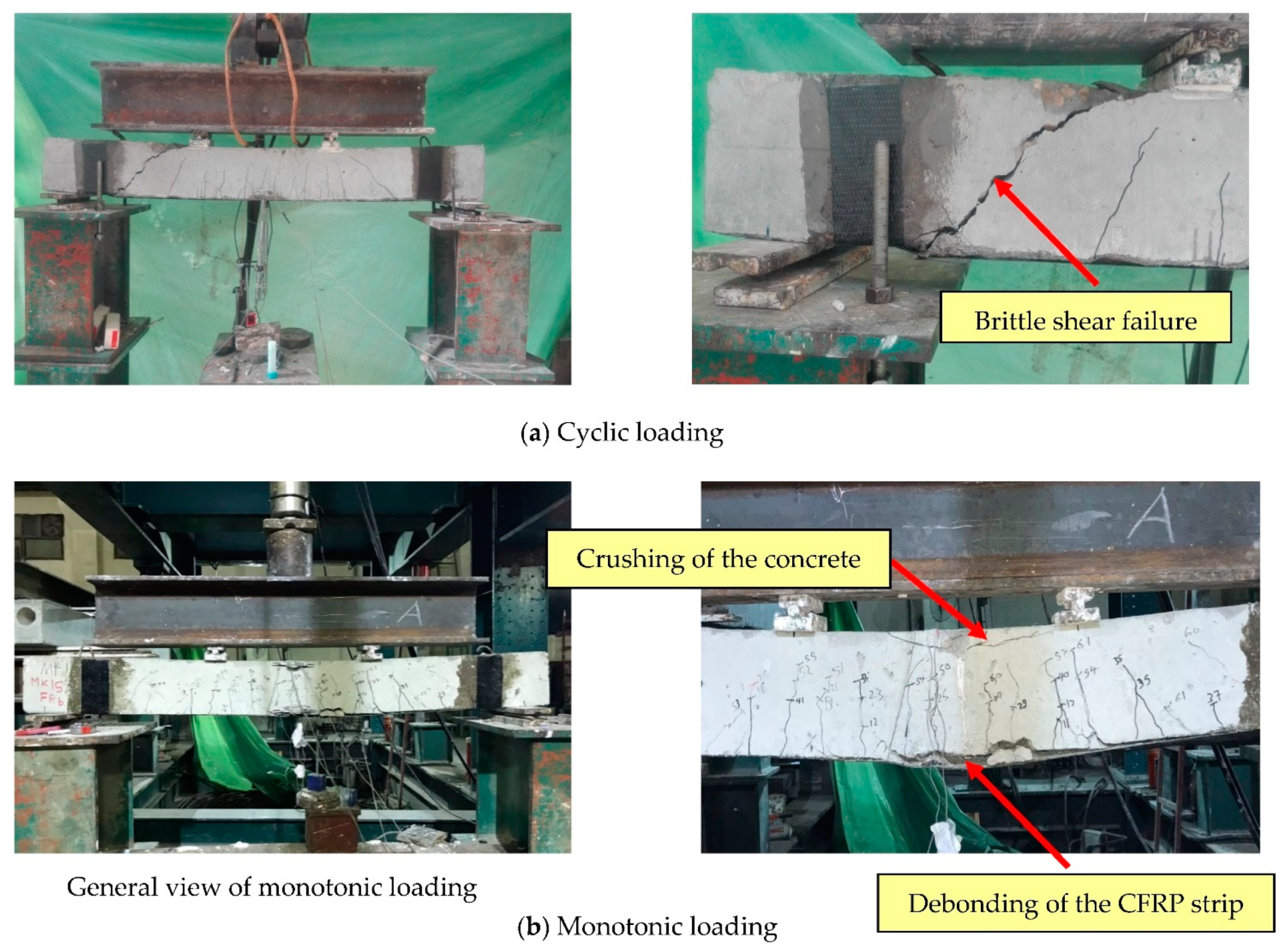

5.1. Mode of Failure and Crack Pattern

5.2. Load–Deflection Relationship

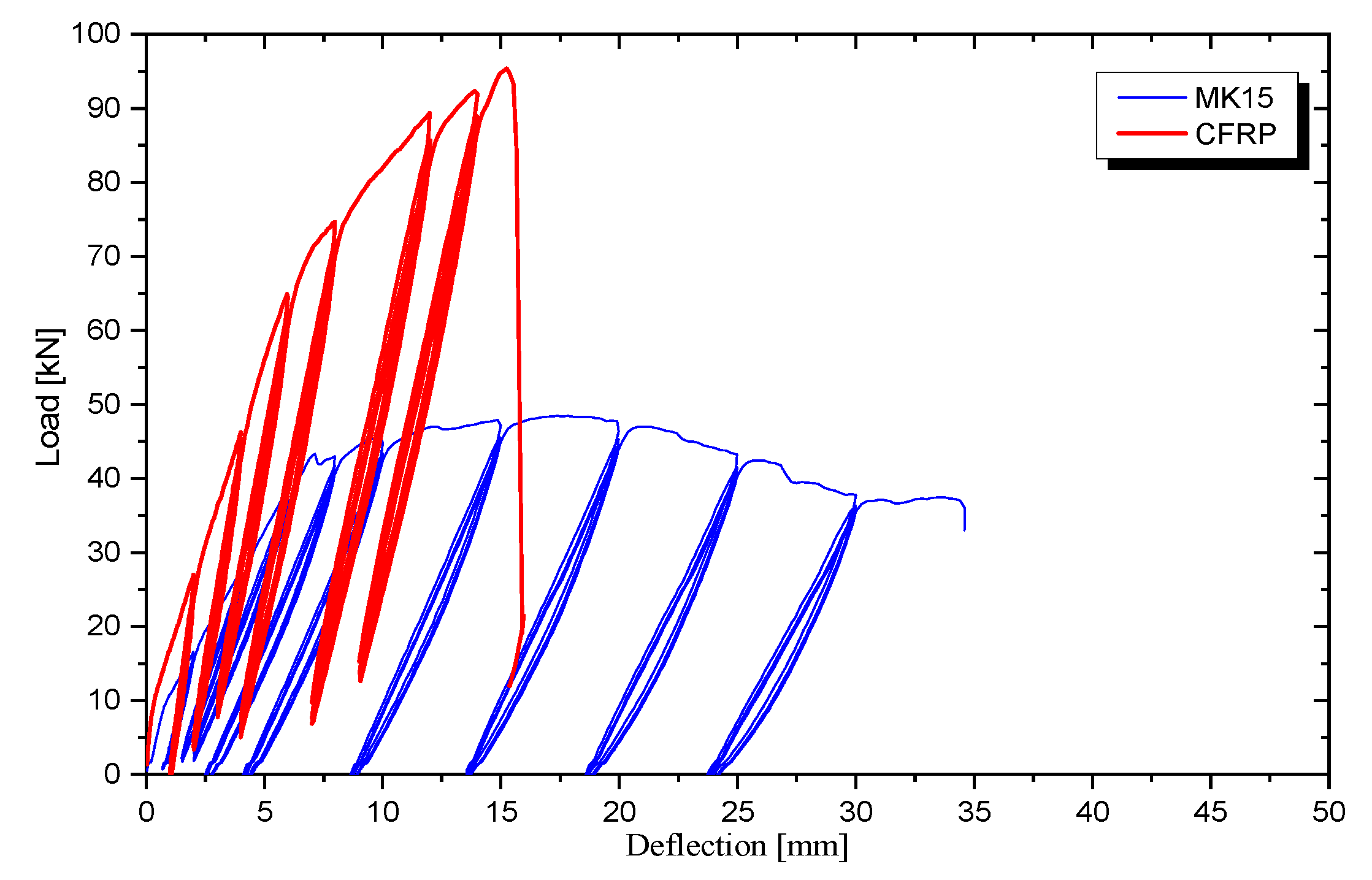

5.2.1. Comparison between Beams (MK15-CFRP) and (MK15) under Cyclic Loading

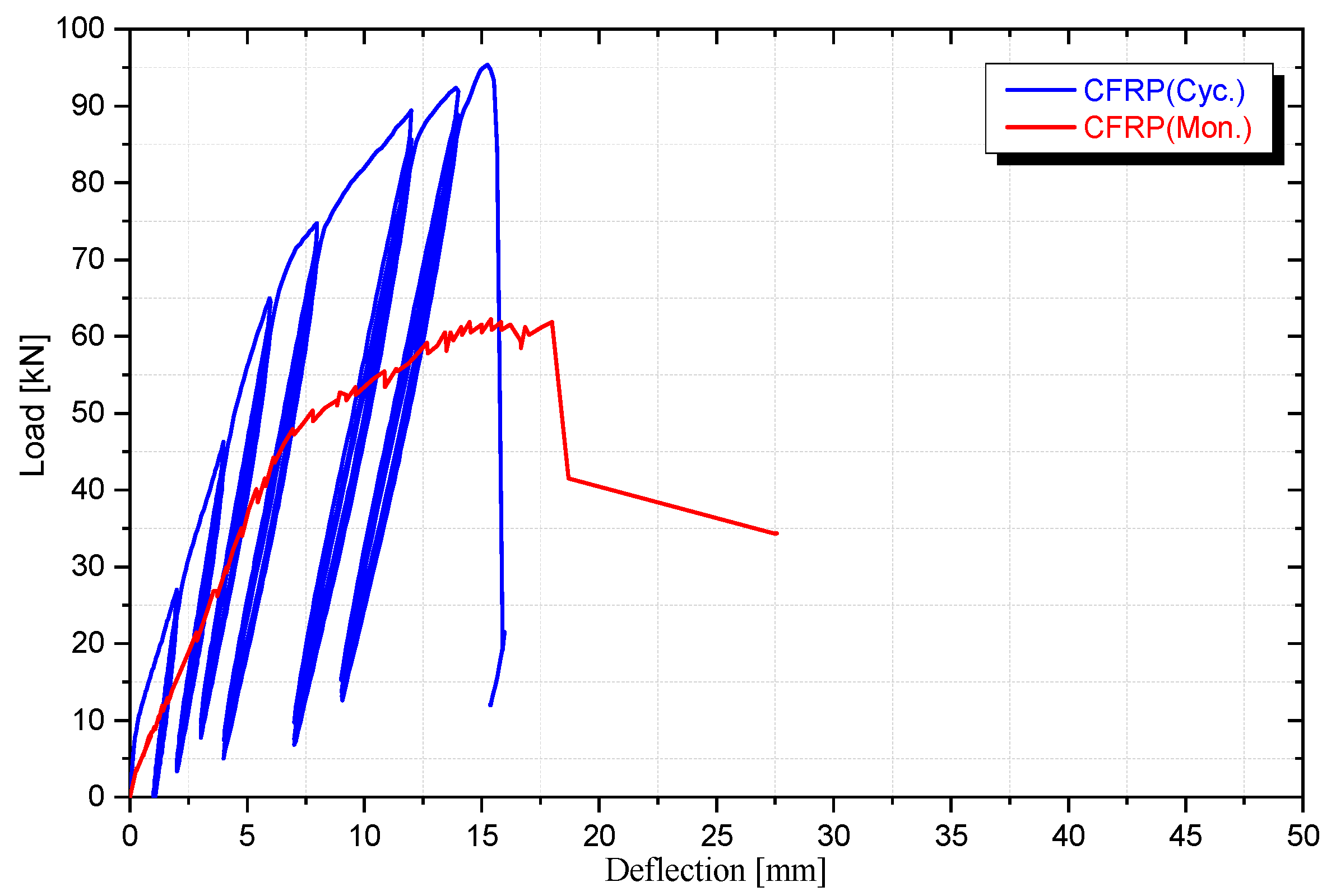

5.2.2. Comparison between Cyclic and Monotonic Loads for the Strengthened Beams

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lehne, J.; Preston, F. Making Concrete Change Innovation in Low-carbon Cement and Concrete. In Energy, Environment and Resources Department, Chatham House Report; The Royal Institute of International Affairs: Cambridge, UK, 2018. [Google Scholar]

- Patil, B.B.; Kumbhar, P.D. Strength and durability properties of High Performance Concrete incorporating high reactivity Metakaolin. Int. J. Mod. Eng. Res. 2012, 3, 1099–1104. [Google Scholar]

- Issac, S.; Paul, A. A Literature Review on the Effect of Metakaolin and Fly Ash on Strength Characteristics of Concrete. Int. J. Adv. Res. Innov. Ideas Educ. 2018, 2, 55–60. [Google Scholar]

- Aiswarya, S.; Prince Arulraj, G.; Dilip, C. A Review on use of Metakaolin in concrete. Eng. Sci. Technol. Int. J. 2013, 3, 592–597. [Google Scholar]

- Sreenivasalu, A.; Srinivasa Rao, K. Design of M100 grade concrete (ACI method). Glob. J. Eng. Appl. Sci. 2012, 2, 183–185. [Google Scholar]

- Dubey, S.; Chandak, R.; Yadav, R.K. Effect of Metakaolin on Compressive Strength of Concrete. Int. J. Eng. Res. Appl. 2015, 5, 80–82. [Google Scholar]

- Alharbi, Y.R.; Abadel, A.A.; Mayhoub, O.A.; Kohail, M. Effect of using available metakaoline and nano materials on the behavior of reactive powder concrete. Constr. Build. Mater. 2021, 269, 121344. [Google Scholar] [CrossRef]

- Weise, K.; Ukrainczyk, N.; Duncan, A.; Koenders, E. Enhanced Metakaolin Reactivity in Blended Cement with Additional Calcium Hydroxide. Materials 2022, 15, 367. [Google Scholar] [CrossRef]

- Srivastava, V.; Kumar, R.; Agarwal, V.C.; Mehta, P.K. Vikas Effect of Silica Fume and Metakaolin combination on concrete. Int. J. Civ. Struct. Eng. 2012, 893–900. [Google Scholar] [CrossRef] [Green Version]

- Muralinathan, P.; Daniel, A.J.; Sivakamasundari, S. Study of High Strength Concrete Using Metakaolinat Elevated Temperatures. Int. J. Pure Appl. Math. 2018, 119, 1267–1273. [Google Scholar]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of Fly Ash and Metakaolin on Pervious Concrete Properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Pandei, R.W. Effects of metakaolin on compressive strength and permeability properties of pervious cement concrete. J. Teknol. 2019, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, A.; Aqil, T. Effect on Flexural Strength by using Glass Fibre and Metakaolin in Concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 322–326. [Google Scholar]

- Jagtap, S.A.; Shirsath, M.N.; Karpe, S.L. Effect of Metakaolin on the Properties of Concrete. Int. Res. J. Eng. Technol. 2017, 4, 643–645. [Google Scholar]

- Rashwan, M.M.; Megahed, A.R.; Essa, M.S. Effect of local metakaolin on properties of concrete and its sulphuric acid resistance. JES J. Eng. Sci. 2015, 43, 183–199. [Google Scholar] [CrossRef]

- Sarangi, P.; Panda, K.C.; Jena, S. Effect of Metakaolin on the Enhancement of Concrete Strength. Indian J. Sci. Res. 2017, 14, 121–127. [Google Scholar]

- Patil, S.P.; Sangle, K.K. Flexural Strength Evaluation of Prestressed Concrete Beams with Partial Replacement of Cement by Metakaolin and Flyash. Am. Int. J. Res. Sci. Technol. Eng. Math. 2013, 3, 187–194. [Google Scholar]

- Dennison, D.; Simon, J.M. Effect of Metakaolin on the Structural Behavior of Normal and Steel Fiber Reinforced Concrete Beams. Int. J. Sci. Eng. Res. 2014, 5, 1684–2278. [Google Scholar]

- Sherif, M.A. Utilization of Metakaolin on Sustainable Concrete Properties. IOSR J. Mech. Civ. Eng. 2017, 61–71. [Google Scholar]

- Ding, J.T.; Li, Z. Effects of Metakaolin and Silica Fume on Properties of Concrete. ACI Mater. J. 2002, 99, 393–398. [Google Scholar]

- Bashir, I.A.; Rasool, M.A.; Rashid, M.; Singh, P. Experimental Investigation of Compressive Behaviour of Pier by Partial Replacement of Metakaolin. Glob. J. Technol. Optim. 2017, 8, 22–28. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.-M.K.; Karayannis, C.G. Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study. Materials 2019, 12, 1398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, H.; Li, C.; Cheng, S.; Yuan, J. Flexural Performance of Concrete Beams Reinforced with Continuous FRP Bars and Discrete Steel Fibers under Cyclic Loads. Polymers 2022, 14, 1399. [Google Scholar] [CrossRef]

- Hyun, J.-H.; Bang, J.-W.; Lee, B.-Y.; Kim, Y.-Y. Effects of the Replacement Length of Concrete with ECC on the Cyclic Behavior of Reinforced Concrete Columns. Materials 2021, 14, 3542. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Wei, M.; Wang, L.; Cheng, B. Hysteretic Behavior of Geopolymer Concrete with Active Confinement Subjected to Monotonic and Cyclic Axial Compression: An Experimental Study. Materials 2020, 13, 3997. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.; Li, J.; Mo, Y. Effect of loading rate on cyclic behavior of reinforced concrete beams. Adv. Struct. Eng. 2018, 21, 990–1001. [Google Scholar] [CrossRef]

- Shankar, G.R.V.; Suji, D. Static and cyclic behaviour of high performance concrete beams using Metakaoline and partial replacement with quarry dust. J. Ind. Pollut. Control. 2014, 30, 153–162. [Google Scholar]

- Lotfy, E.M. Flexural strengthening of R.C. Beams. Int. J. Eng. Tech. Res. 2016, 6, 83–86. [Google Scholar]

- Mashrei, M.A.; Makki, J.S.; Sultan, A.A. Flexural Strengthening of Reinforced Concrete Beams Using Carbon Fiber Reinforced Polymer (CFRP) Sheets with Grooves. Lat. Am. J. Solids Struct. 2019, 16, e176. [Google Scholar] [CrossRef]

- Mobin, M.N.; Hoque, M.M. Flexural Strengthening of RC Beams with Near Surface Mounted Reinforcing Steel Bars. DUET J. Dhaka Univ. Eng. Technol. 2018, 1–10. [Google Scholar]

- Moubarak, A.; Elwardany, H.; Abu Elhassan, K.; Taher, S. Optimizing metakaolin and Silica-fume in RC beams with/without strengthening. Innov. Infrastruct. Solut. 2021, 6, 117. [Google Scholar] [CrossRef]

- Tarigan, J.; Patra, F.M.; Sitorus, T. Flexural strength using Steel Plate, Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) on reinforced concrete beam in building technology. IOP Conf. Ser. Earth Environ. Sci. 2018, 126, 012025. [Google Scholar] [CrossRef]

- Salih, R.; Zhou, F.; Abbas, N.; Mastoi, A.K. Experimental Investigation of Reinforced Concrete Beam with Openings Strengthened Using FRP Sheets under Cyclic Load. Materials 2020, 13, 3127. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Nehdi, M.L. Experimental and Analytical Investigation on Flexural Retrofitting of RC T-Section Beams Using CFRP Sheets. Appl. Sci. 2020, 10, 1233. [Google Scholar] [CrossRef] [Green Version]

- Shrivastava, R.; Gupta, U.; Choubey, U.B. Effect of cyclic loading on flexural behavior of FRP strengthened RC beams: A Stability Point Approach. Int. J. Adv. Res. Eng. Appl. Sci. 2013, 9–26. [Google Scholar]

- Sagar, R.V. Acoustic emission characteristics of reinforced concrete beams with varying percentage of tension steel reinforcement under flexural loading. Case Stud. Constr. Mater. 2017, 6, 162–176. [Google Scholar] [CrossRef]

- NEHRP. Recommended Seismic Provisions for New Buildings and Other Structures. FEMA P-1050-1, 2015 Ed.; NEHRP, Building Seismic Safety Council, A Council of the National Institute of Building Sciences: Washington, DC, USA, 2015; Volume I: Part 1 Provisions, Chapter 14. [Google Scholar]

- ASTM C33/C33M-13; Standard Specification for Concrete Aggregates. Annual Book of American Society for Testing and Materials ASTM: West Conshohocken, PA, USA, 2018.

- Sika, Technical Data Sheet, Sikament 163 M, April 2018, Sika Egypt for Construction Chemicals, El Abour City, 1st Industrial Zone (A) Section # 10 Block 13035, Egypt. Available online: https://egy.sika.com/content/dam/dms/eg01/e/Sikament%C2%AE%20-163.pdf (accessed on 20 May 2022).

- Kaufmann, E.J.; Metrovich, B.R.; Pense, A.W. Characterization of Cyclic Inelastic Strain Behavior on Properties of A572 Gr. 50 and A913 Gr. 50 Rolled Sections; ATLSS Report No. 01–13; Lehigh University: Bethlehem, PA, USA; American Institute of Steel Construction: Chicago, IL, USA, 2001. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Pearson Education Limited: Edinburgh Gate, UK, 2009; ISBN 978-0-582-23070-5. [Google Scholar]

- Lee, B.J.; Kee, S.-H.; Oh, T.; Kim, Y.-Y. Evaluating the Dynamic Elastic Modulus of Concrete Using Shear-Wave Velocity Measurements. Adv. Mater. Sci. Eng. 2017, 2017, 1651753. [Google Scholar] [CrossRef] [Green Version]

- Afefy, H.; Fawzy, T.M. Strengthening of RC one-way slabs including cut-out using different techniques. Eng. Struct. 2013, 57, 23–36. [Google Scholar] [CrossRef]

| Cement Replacement % | Specimens | Loading Criteria |

|---|---|---|

| 0 | RC | Monotonic |

| 8 | MK8 | |

| 15 | MK15 | |

| 20 | MK20 | |

| 15 | MK15-CFRP * | |

| 0 | RC | Cyclic |

| 8 | MK8 | |

| 15 | MK15 | |

| 20 | MK20 | |

| 15 | MK15-CFRP * |

| Slump (cm) | EC (GPa) | fct +++ (MPa) | fcu ++ (MPa) | Super Plast. (Lit.) | Water (kg) | w/c (%) | Fine Aggregate (kg) | Coarse Aggregate (kg) | Metakaolin Replacement | Cement (kg) | Cement Replacement % | Mix | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| %Volume + | Weight (kg) | ||||||||||||

| 10.50 | 26.60 | 2.70 | 36 | - | 168 | 0.42 | 630 | 1145 | 0 | 0 | 400 | 0 | RC |

| 11 | 26.10 | 2.80 | 35 | 3.2 | 168 | 0.42 | 630 | 1145 | 10.24 | 32 | 368 | 8 | MK8 |

| 10 | 27.50 | 2.90 | 37 | 6 | 168 | 0.42 | 630 | 1145 | 18.80 | 60 | 340 | 15 | MK15 |

| 11 | 27.90 | 3.10 | 40 | 8 | 168 | 0.42 | 630 | 1145 | 24.70 | 80 | 320 | 20 | MK20 |

| Portland Cement (CEM I 42.5) | Aggregate | MK | |||||

|---|---|---|---|---|---|---|---|

| Physical | Coarse | Fine | |||||

| Specific surface area (m2/kg) | 362 | Specific weight | 2.77 | 2.66 | Specific gravity | 2.40 | |

| Specific weight | 3.15 | Bulk density (t/m3) | 1.75 | 1.68 | Color | Light pink | |

| Soundness (mm) | 1.0 | Water absorption % | 2.28 | 0.80 | Chemical composition (%) | SiO2 | 59.70 |

| Initial setting time (min) | 88 | Crushing value % | 21 | ---- | Al2O3 | 30.90 | |

| Fe2O3 | 2.60 | ||||||

| Final setting time (min) | 165 | Coefficient of abrasion % | 18.5 | ---- | CaO | 1.20 | |

| MgO | 0.15 | ||||||

| Compressive strength of standard mortar after 28 days (MPa) | 43.0 | Fineness modulus | ---- | 2.54 | SO3 | 0.03 | |

| K2O | 0.60 | ||||||

| TiO2 | 1.90 | ||||||

| Na2O | 0.50 | ||||||

| ID | Load at Yield, Py(kN) | Maximum Load, Pmax (kN) | Ultimate Load, Pu (kN) | Ductility (μ) + |

|---|---|---|---|---|

| RC | 45.34 | 48.07 | 37.35 | 4.46 |

| MK8 | 42.26 | 47.28 | 34.61 | 5.44 |

| MK15 | 43.40 | 49.33 | 37.79 | 4.36 |

| MK20 | 47.62 | 48.19 | 39.29 | 4.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elwardany, H.; Moubarak, A.M.R.; Abu el-hassan, K.; Seleemah, A. Does Metakaoline Replacement Adversely Affect the Cyclic Behavior of Non-Strengthened and Strengthened RC Beams: An Experimental Investigation. Buildings 2022, 12, 719. https://doi.org/10.3390/buildings12060719

Elwardany H, Moubarak AMR, Abu el-hassan K, Seleemah A. Does Metakaoline Replacement Adversely Affect the Cyclic Behavior of Non-Strengthened and Strengthened RC Beams: An Experimental Investigation. Buildings. 2022; 12(6):719. https://doi.org/10.3390/buildings12060719

Chicago/Turabian StyleElwardany, Hytham, Ahmed M. R. Moubarak, Khaled Abu el-hassan, and Ayman Seleemah. 2022. "Does Metakaoline Replacement Adversely Affect the Cyclic Behavior of Non-Strengthened and Strengthened RC Beams: An Experimental Investigation" Buildings 12, no. 6: 719. https://doi.org/10.3390/buildings12060719

APA StyleElwardany, H., Moubarak, A. M. R., Abu el-hassan, K., & Seleemah, A. (2022). Does Metakaoline Replacement Adversely Affect the Cyclic Behavior of Non-Strengthened and Strengthened RC Beams: An Experimental Investigation. Buildings, 12(6), 719. https://doi.org/10.3390/buildings12060719