When fluid damping is insufficient for reducing sloshing, as the viscosity of fluid is near resonance, baffles can be effective as tools for reducing the impact of dynamic loads [

2]. Preventing the creation of an oscillating fluid mode using baffles dates back to the studies on fuel tanks in the National American Space and Aviation Center in the 1960s by Silveria et al. [

3] and Abrahamson et al. [

4]. Since then, valuable experimental and analytical studies about sloshing liquid have been published, including Miles [

5], Welt and Modi [

6], and Faltinsen [

7,

8]. Today, most researchers focus on using numerical methods such as finite element and boundary element analysis of sloshing events. In recent years, Biswal et al. investigated nonlinear sloshing in cylindrical and rectangular tanks with a baffle in the two-dimensional case using the finite element method [

9]. Pal and Bhattacharya examined the numerical scheme for the analysis of liquids sloshing in a tank partially filled with liquid under earthquake excitation and validated the results using experimental data [

10]. The study showed that utilizing a baffle considerably reduces the sloshing pressure. Curadelli et al. examined the dynamic response of an elastic spherical tank partially filled with liquid and subjected to a horizontal ground motion [

11]. In their study, the baffle was used for liquid sloshing damping. They showed that the blade damper could effectively reduce liquid and tank hydrodynamic load fluctuations, and the blade could hardly improve the tank simultaneously. Askari and Daneshmand [

12] and Askari et al. [

13] studied the effect of baffles on the dynamic properties of a cylindrical tank partially filled with liquid. Xue and Lin developed a 3D numerical model to examine the liquid sloshing in a prismatic tank under conditions close to resonant frequency excitation [

14]. The numerical experiments proved that the developed 3D numerical model was robust in handling fluid–structure interaction and the ring baffle was an effective tool in reducing violent sloshing amplitude. Wang et al. obtained the liquid sloshing’s natural frequencies and mode shapes in a rigid cylindrical container with multiple baffles of the same inner radius using a semi-analytical approach [

15]. They observed that the natural frequencies increased with the rise in the inner radius of the baffles. The uppermost baffle effects on natural frequencies and modes were much more significant than the other baffles. Goudarzi and Sabbagh-Yazdi conducted an experimental and analytical investigation of hydrodynamic damping resulting from lower and upper mounted vertical baffles and horizontal baffles in partially filled rectangular tanks [

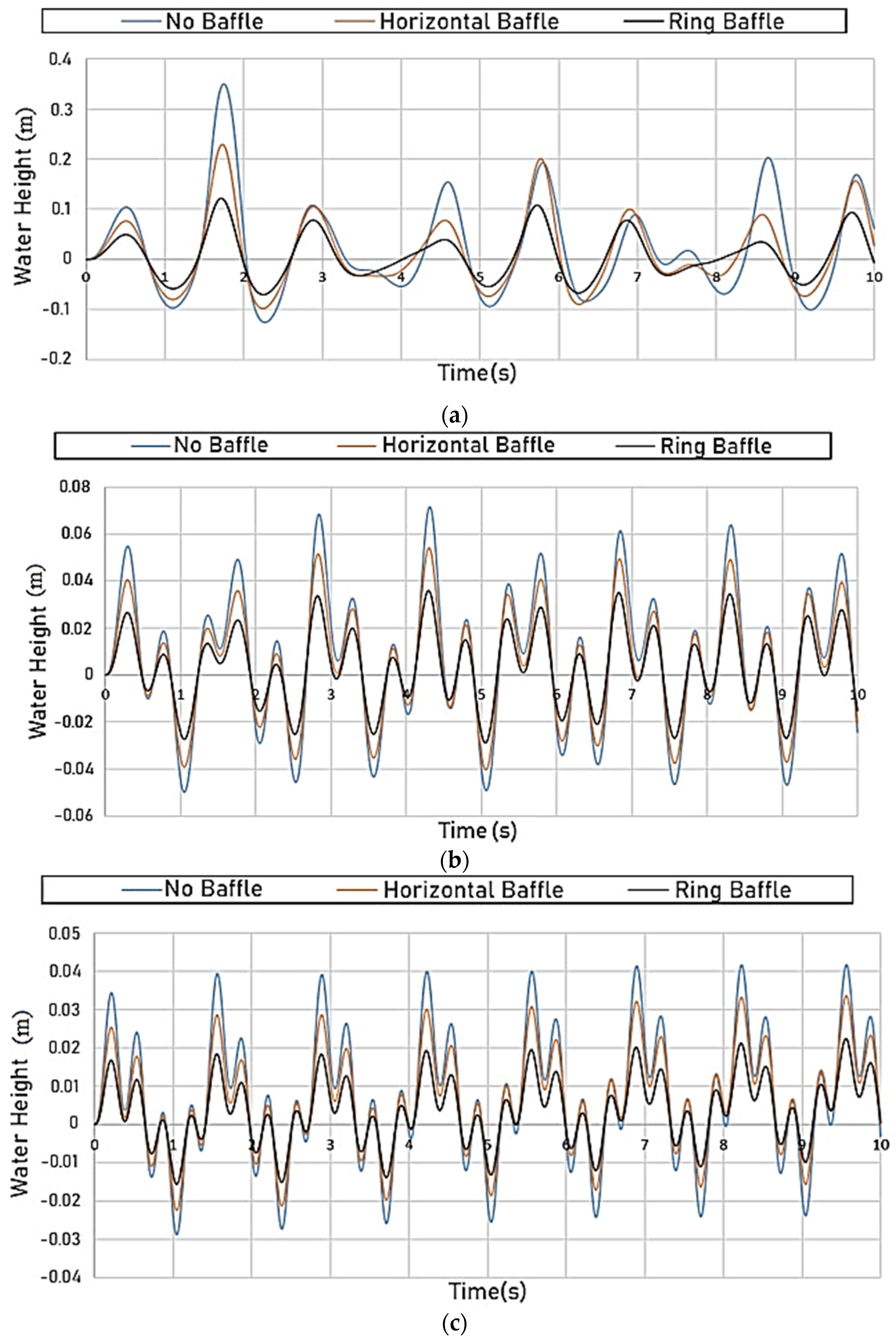

16]. According to the experimental results, horizontal baffles were most effective in all aspect ratios of the tanks. However, the horizontal baffles’ efficiency decreased as the liquid depths declined; but this is not the case in vertical baffles. Hasheminejad and Aghabeigi investigated the effects of surface-piercing or bottom-mounted vertical baffles on two-dimensional liquid sloshing characteristics in a half-full nondeformable horizontal cylindrical container with an elliptical cross-section [

17]. The surface-piercing vertical baffle effectively reduced the antisymmetric sloshing frequencies, especially for lower-aspect-ratio tanks and higher modes. On the other hand, the bottom-mounted baffle greatly influenced the higher antisymmetric slosh modes only when its tip approached the liquid’s free surface. Increasing the vertical baffle extensions did not affect the symmetric modes, while it decreased the antisymmetric natural sloshing frequencies for both surface-piercing and bottom-mounted baffles. The result was in contrast with the horizontal side baffles, for which a boundless increase was observed in all the natural sloshing frequencies with the increasing baffle length. In addition, increasing the tank aspect ratio led to an overall decrease in natural frequencies for all three baffle configurations. Hasheminejad et al. examined a two-dimensional semi-analytic model based on the linear potential theory for transient sloshing in laterally excited horizontal annular containers for three common baffle configurations, a pair of liquid-surface-touching horizontal side baffles, a central surface-piercing vertical baffle, and a bottom-mounted vertical baffle [

18]. The study showed that an increase in the baffle length for the tank with a pair of surface-touching side baffles led to a notable decrease in the upper bounds of the lateral force and moment coefficients. Goudarzi and Danesh established a finite volume-based estimate of hydrodynamic damping caused by vertical baffles in a rectangular tank subjected to seismic excitation [

19]. Nayak and Biswal studied the influence of a submerged block on the impulsive and convective sloshing liquid response in a tank [

20]. They systematically quantified the ground motion’s frequency content on the liquid tank’s nonlinear dynamic response. Shamsoddini et al. applied the incompressible SPH method, particle shifting algorithms, turbulence viscosity calculations, and free surface particle detectors for free surface flow modeling [

21]. The results showed that the used algorithm effectively specifies free surface problems to simulate liquid sloshing phenomena with the aim of vertical and horizontal baffle effects on the control and damping of liquid sloshing. They showed that the horizontal and vertical baffle size and the horizontal baffle base position played a major role in sloshing fluctuation damping. Shamsoddini and Abolpur studied the effects of baffles on water sloshing at the time of liquid tank transportation [

22]. They used the Incompressible Smoothed Particle Hydrodynamics (ISPH) numerical method to model the phenomenon. They approved the ability of the present algorithm for simulating shallow water sloshing by comparing it with experimental data. The results showed that the number of baffles has a major role in sloshing fluctuation damping. Wang et al. studied the effects of multiple porous baffles on the liquid sloshing problem in the horizontal rectangular, annular, or elliptical annular tanks by using the isogeometric boundary element (IGABEM), which coupled the Boundary Element Method (BEM) with the isogeometric boundary based on Non-Uniform Rational B Splines (NURBS). In this research, the effects of the tank’s geometry, liquid filling level, and the baffle’s parameters with various lengths, submergence depths, number of baffles, and porosities on the sloshing characteristics were discussed [

23]. Guan et al. used the nonlinear Boundary Element Method (BEM) with Green’s theorem based on the potential in a three-dimensional tank under horizontal excitation and roll excitation to investigate the effect of different baffles on the sloshing phenomenon [

24]. Their research showed that the horizontal baffle is more effective when the tank is under a roll excitation, while the vertical baffle is more effective in reducing the sloshing amplitude when the tank is under a horizontal harmonic excitation. Hajimehrabi et al. [

25] investigated the effects of baffles on the seismic behavior of concrete cylindrical tanks. Three types of tanks with different aspect ratios, including short, medium, and tall structures, were examined under nine earthquake ground motions. Seismic fragility curves and the bending moment of the tank wall at the base were calculated. They concluded that although using baffles decreases the sloshing wave height, it results in a minor increase in the base bending moment of the tank wall. Cho et al. [

26] investigated the dynamic response characteristics of the cylindrical-baffled liquid storage tank, which was subjected to a vertical acceleration at boosting concerning the number of baffles. They concluded that introducing baffles to the partially filled liquid tank remarkably decreases the maximum values of displacement and effective stress at both the bottom plate and baffles. Hosseinzadeh et al. [

27] studied the annular baffle effects as anti-sloshing damping devices to reduce fluid wave sloshing height in steel storage tanks typically used in oil and petrochemical complexes during an earthquake. They confirmed significant effects of the annular baffles in reducing the fluid wave sloshing height as sloshing-dependent variable dampers.