Shear Strength of Headed Stud Connectors in Self-Compacting Concrete with Recycled Coarse Aggregate

Abstract

:1. Introduction

2. Experimental Work

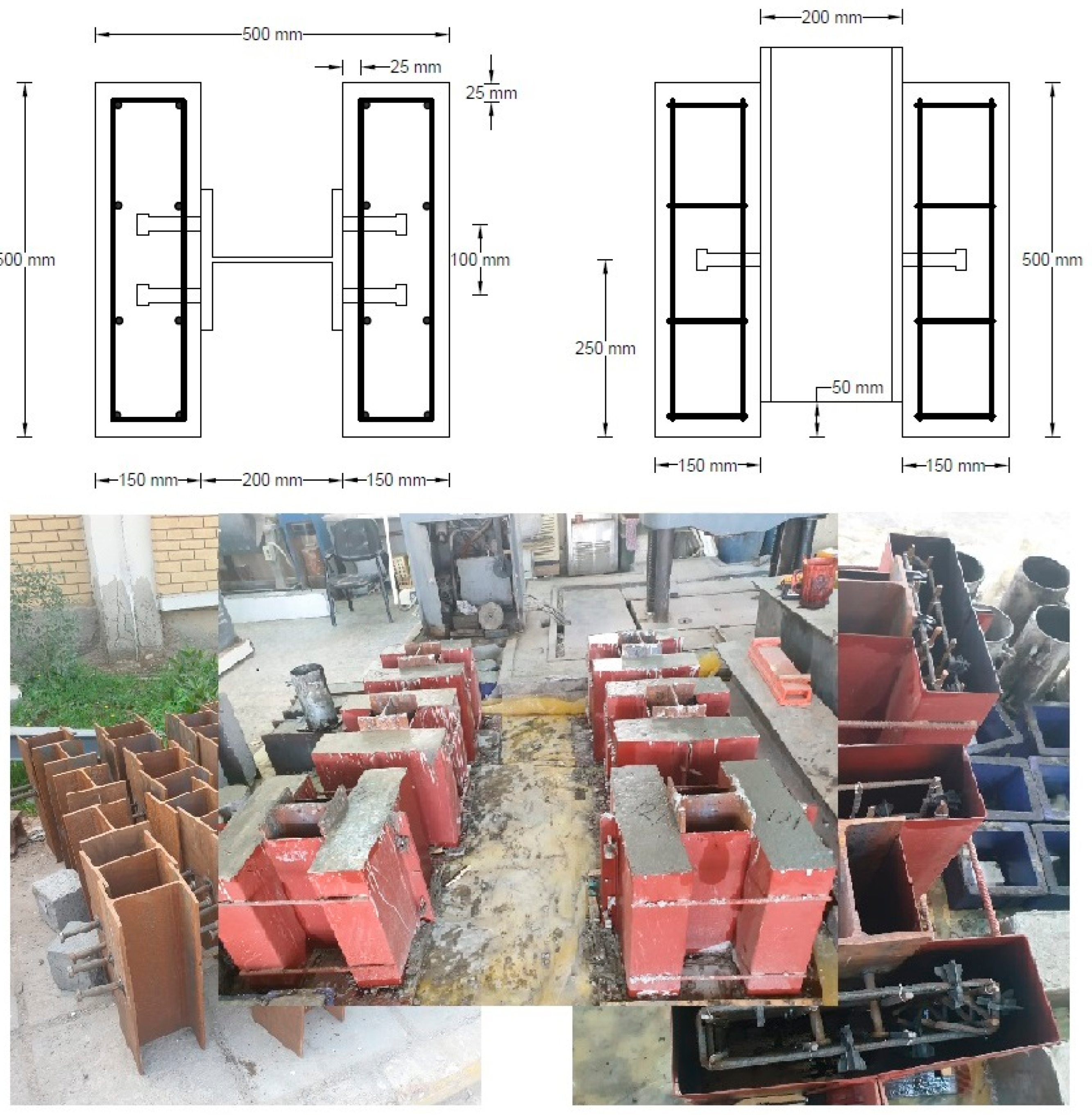

2.1. Test Specimens

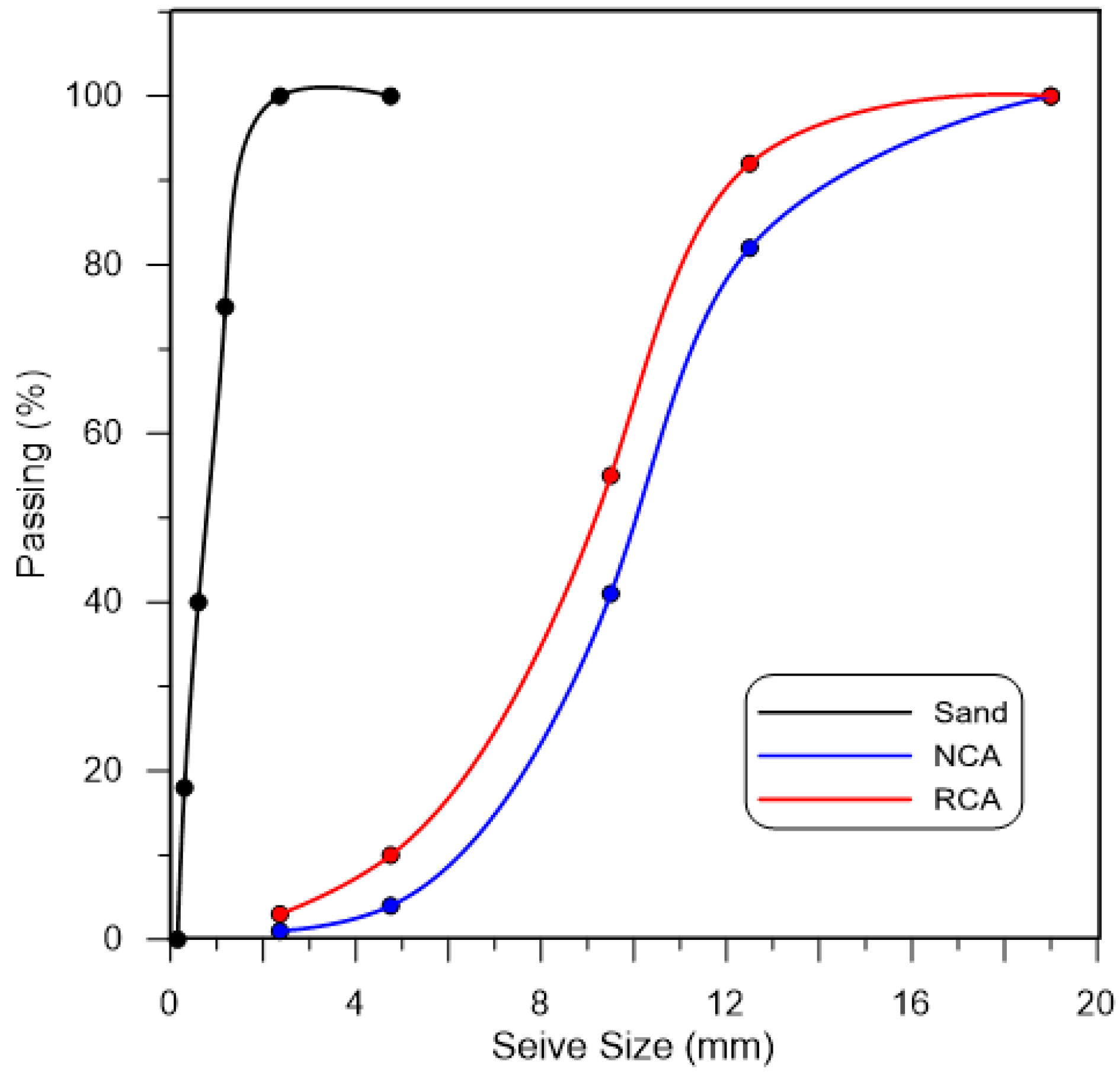

2.2. Material Properties

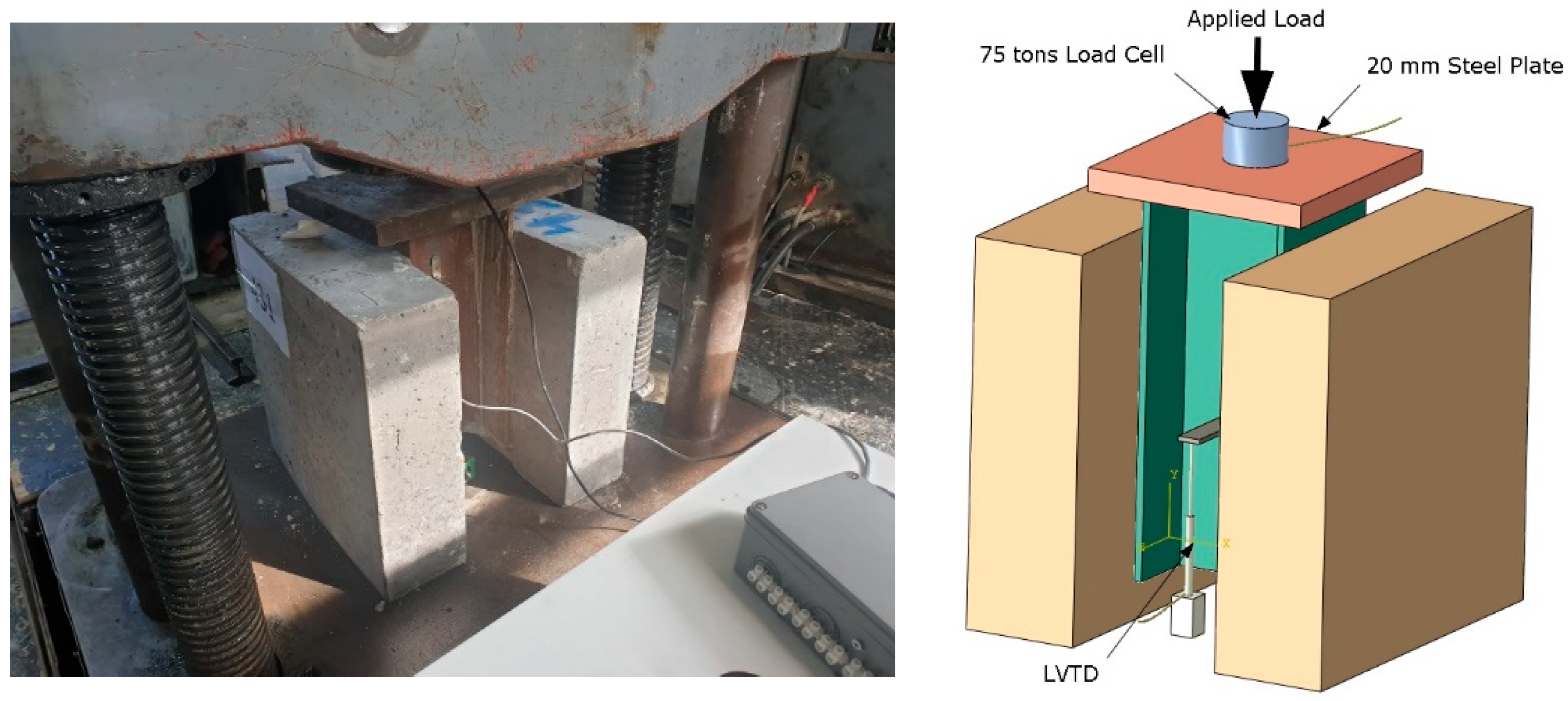

2.3. Push-Out Tests

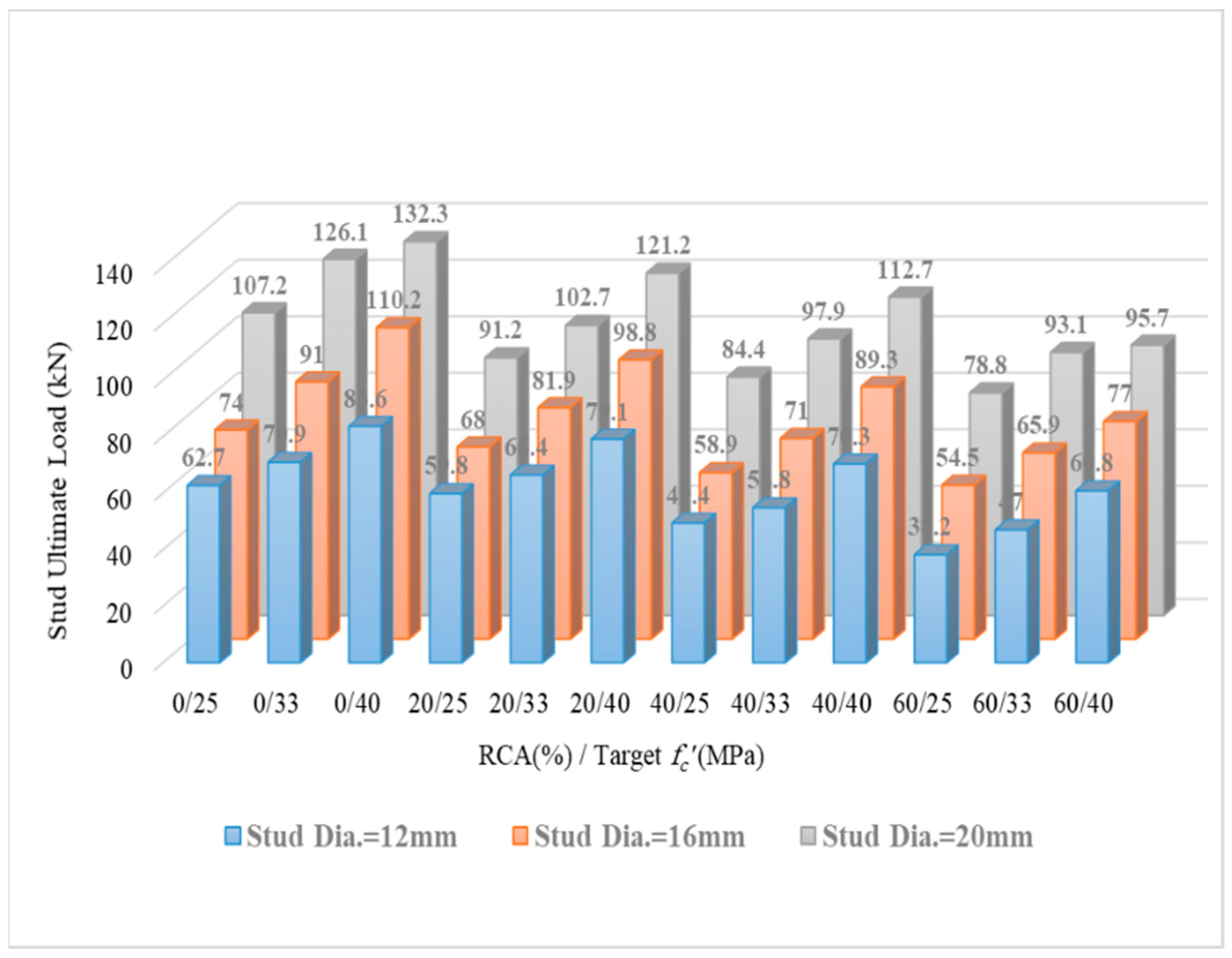

3. Test Results and Discussion

3.1. Modes of Failure and Shear Strength

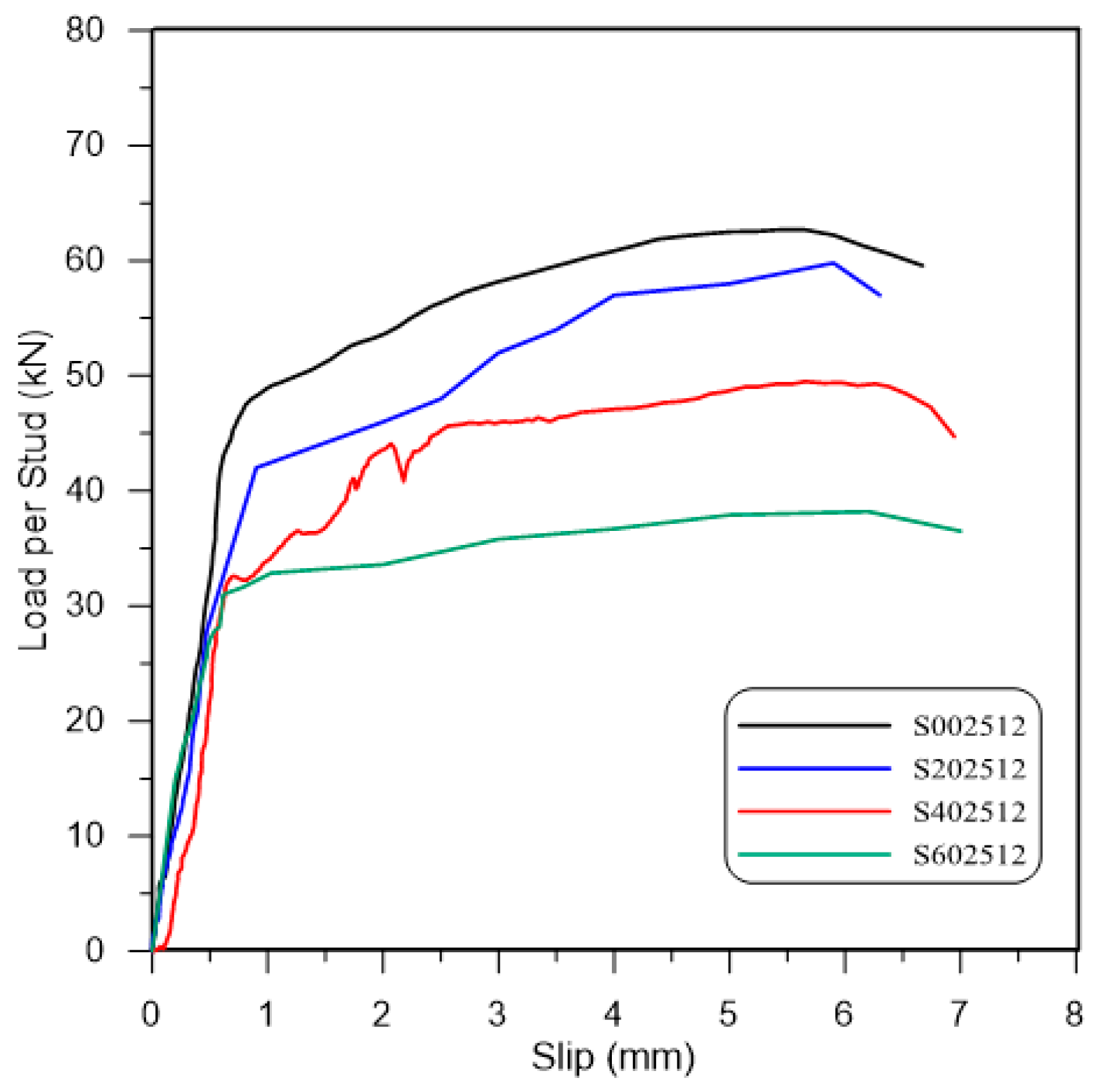

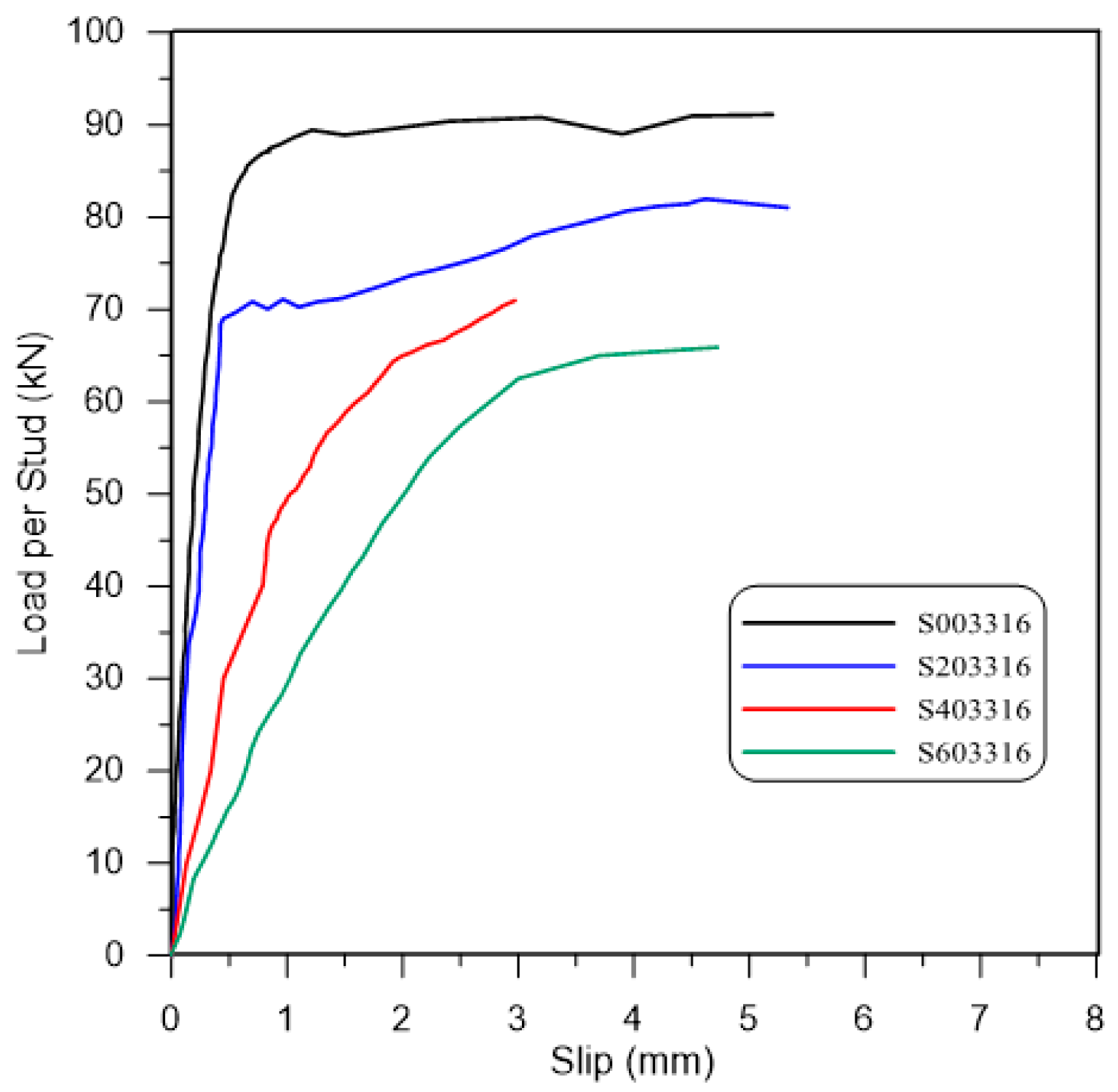

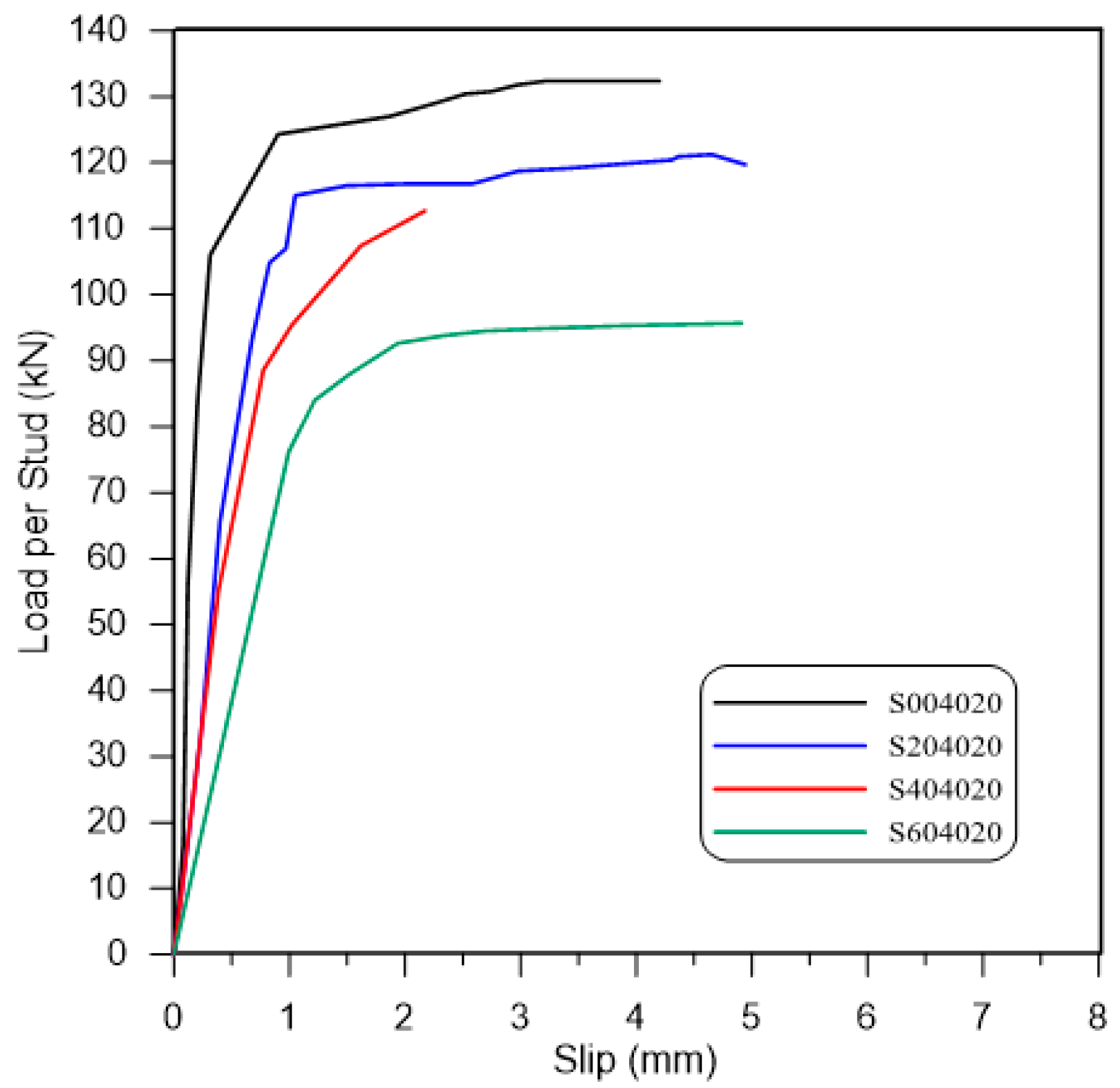

3.2. Load–Slip Relationships

4. Evaluation of the Test Results

5. Conclusions

- The ultimate shear strength of headed stud shear connectors embedded in SCC is directly proportional to the concrete compressive strength and/or the diameter of headed stud connectors, regardless of the RCA ratio used.

- The use of SCC with RCAs has a negative effect on the shear strength of headed stud connectors. This negative effect may be reduced by increasing the concrete compressive strength and/or the stud diameter.

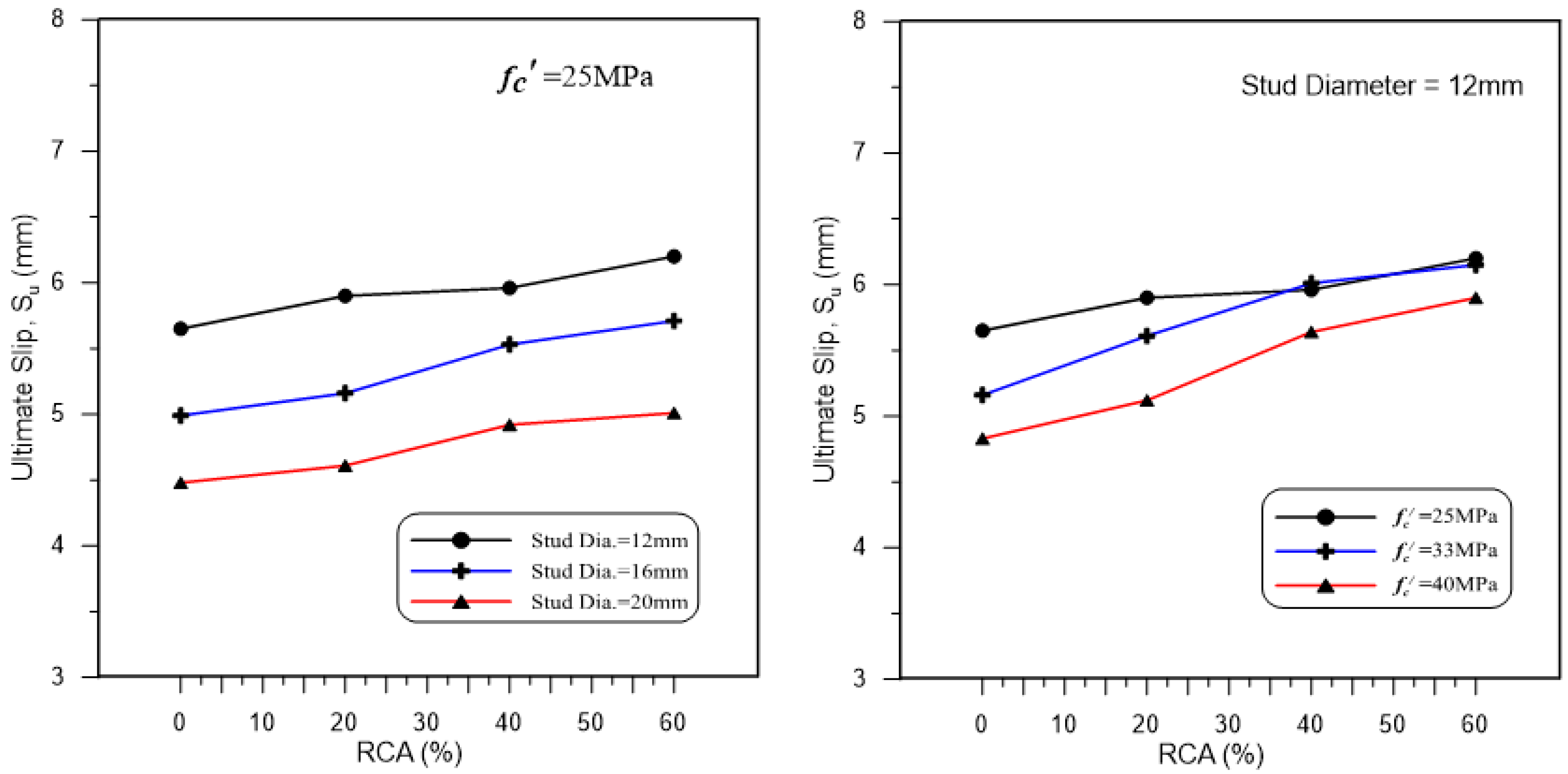

- The shear stiffness and ultimate slip of the tested push-out specimens were inversely proportional to the RCA ratio because of the reduction in the concrete bearing resistance in the region that supported the headed studs, which occurred as a result of the higher aggregate crashing value of RCAs in comparison with NCAs.

- The increase in the ultimate slip due to the RCA ratio may be controlled by increasing the concrete compressive strength.

Author Contributions

Funding

Conflicts of Interest

References

- Ollgaard, J.G.; Slutter, R.G.; Fisher, J.W. Shear strength of stud connectors in lightweight and normal-weight concrete. AISC Eng. 1971, 8, 55–64. [Google Scholar]

- Lam, D.; El-Lobody, E. Behavior of headed stud shear connectors in composite beam. J. Struct. Eng. 2005, 131, 96–107. [Google Scholar] [CrossRef]

- Shim, H.B.; Chung, K.S.; Jang, S.H.; Lee, J.H.; Park, S.T. Pushout tests on shear studs in high strength concrete. In Proceedings of the Fracture Mechanics of Concrete and Concrete Structures, Seoul, Korea, 23–28 May 2010. [Google Scholar]

- Palleres, L.; Hajjar, J. Headed steel studs anchors in composite structures, Part 1: Shear. J. Constr. Steel Res. 2010, 66, 198–212. [Google Scholar] [CrossRef]

- Qi, J.; Wang, J.; Li, M.; Chan, L. Shear capacity of stud shear connectors with initial damage: Experiment, FEM model and theoretical formulation. Steel Compos. Struct. 2017, 25, 79–92. [Google Scholar]

- Yang, F.; Liu, Y.; Li, Y. Push-out tests on large diameter and high strength welded stud connectors. Adv. Civil Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Qi, J.; Hu, Y.; Wand, J.; Li, W. Behavior and strength of headed stud shear connectors in ultra-high performance concrete of composite bridges. Front. Struct. Civil Eng. 2019, 13, 1138–1149. [Google Scholar] [CrossRef]

- He, J.; Lin, Z.; Liu, Y.; Xu, X.; Xin, H.; Wang, S. Shear stiffness of headed studs on structural behaviors of steel-concrete composite girders. Steel Compos. Struct. 2020, 36, 553–568. [Google Scholar]

- Matias, D.; Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregate—Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Tang, W.C.; Ryan, P.C.; Cui, H.Z.; Liao, W. Properties of self-compacting concrete with recycled coarse aggregate. Adv. Mater. Sci. Eng. 2016, 2016, 2761294. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Arora, S.; Sharma, V.; Bhardwaj, B. Workability retention and strength development of self-compacting recycled aggregate concrete using ultrafine recycled powders and silica fume. J. Hazard. Toxic Radioact. Waste 2019, 23, 1–12. [Google Scholar] [CrossRef]

- Tang, W.; Khavarian, M.; Yousefi, A.; Chan, R.W.K.; Cui, H. Influence of surface treatment of recycled aggregate on material properties and bond strength of self-compacting concrete. Sustainability 2019, 11, 4182. [Google Scholar] [CrossRef] [Green Version]

- Garcia, R.M.; Romero, M.I.G.; Pozo, J.M.M. Recycled aggregate for self-compacting concrete production: A feasible option. Materials 2020, 13, 868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dawood, E.T. Behavior of self-compacting concrete produced form recycled aggregate. AIP Conf. Proc. 2020, 2213, 020023. [Google Scholar] [CrossRef]

- Kathirvel, P.; Murali, G.; Vatin, N.I.; Abid, S.R. Experimental study on self- compacting fibrous concrete comprising magnesium sulphate solution treated recycled aggregates. Materials 2022, 15, 340. [Google Scholar] [CrossRef]

- Xue, W.C.; Ding, M.; Wang, H.; Luo, Z.W. Static behavior and theoretical model of stud shear connectors. J. Bridge Eng. 2008, 13, 623–634. [Google Scholar] [CrossRef]

- Badie, S.S.; Tadros, M.K.; Kakish, H.F.; Splittgerber, D.L.; Baishya, M.C. Large shear studs for composite action in steel bridge girders. J. Bridge Eng. 2002, 7, 195–203. [Google Scholar] [CrossRef]

- Lee, P.G.; Shim, C.S.; Chang, S.P. Static and fatigue behavior of large stud shear connectors for steel-concrete composite bridges. J. Constr. Steel Res. 2005, 61, 1270–1285. [Google Scholar] [CrossRef]

- Shim, C.S.; Lee, P.G.; Yoon, T.Y. Static behavior of large stud shear connectors. Eng. Struct. 2004, 26, 1853–1860. [Google Scholar] [CrossRef]

- EN 1994-1-1; Eurocode 4: Design of Composite Steel and Concrete Structures, Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- AASHTO. AASHTO LFRD Bridge Design Specifications, 4th ed.; American Associate of State Highway and Transportation Officials: Washington, DC, USA, 2007. [Google Scholar]

| Specimen’s Designation | RCA% | Concrete Properties | Stud Diameter (mm) | ||

|---|---|---|---|---|---|

| Compressive Strength (MPa) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | |||

| S002512 | 0 | 26.0 | 3.1 | 24.6 | 12 |

| S002516 | 16 | ||||

| S002520 | 20 | ||||

| S003312 | 33.6 | 3.5 | 29.4 | 12 | |

| S003316 | 16 | ||||

| S003320 | 20 | ||||

| S004012 | 41.7 | 4.2 | 31.4 | 12 | |

| S004016 | 16 | ||||

| S004020 | 20 | ||||

| S202512 | 20 | 25.9 | 3.1 | 23.5 | 12 |

| S202516 | 16 | ||||

| S202520 | 20 | ||||

| S203312 | 33.7 | 3.4 | 27.8 | 12 | |

| S203316 | 16 | ||||

| S203320 | 20 | ||||

| S204012 | 41.2 | 4.1 | 30.6 | 12 | |

| S204016 | 16 | ||||

| S204020 | 20 | ||||

| S402512 | 40 | 25.7 | 3.0 | 20.1 | 12 |

| S402516 | 16 | ||||

| S402520 | 20 | ||||

| S403312 | 33.1 | 3.4 | 26.2 | 12 | |

| S403316 | 16 | ||||

| S403320 | 20 | ||||

| S404012 | 41.0 | 4.0 | 28.5 | 12 | |

| S404016 | 16 | ||||

| S404020 | 20 | ||||

| S602512 | 60 | 25.9 | 3.1 | 19.3 | 12 |

| S602516 | 16 | ||||

| S602520 | 20 | ||||

| S603312 | 34.1 | 3.6 | 25.7 | 12 | |

| S603316 | 16 | ||||

| S603320 | 20 | ||||

| S604012 | 40.8 | 4.0 | 27.9 | 12 | |

| S604016 | 16 | ||||

| S604020 | 20 | ||||

| (MPa) | W/C Ratio | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | NCA (kg/m3) | RCA (kg/m3) | CG (%) | LP (kg/m3) | SP (L/m3) |

|---|---|---|---|---|---|---|---|---|---|

| 25 | 0.39 | 120 | 310 | 1200 | 700 | 0 | 0 | 150 | 6.4 |

| 0.40 | 125 | 310 | 1200 | 560 | 132 | 20 | 150 | 6.2 | |

| 0.42 | 130 | 310 | 1200 | 420 | 264 | 40 | 150 | 6.1 | |

| 0.39 | 120 | 310 | 1200 | 280 | 396 | 60 | 150 | 6.2 | |

| 33 | 0.35 | 125 | 360 | 1120 | 700 | 0 | 0 | 150 | 7.5 |

| 0.36 | 130 | 360 | 1120 | 560 | 132 | 20 | 150 | 7.2 | |

| 0.38 | 135 | 360 | 1120 | 420 | 264 | 40 | 150 | 7.0 | |

| 0.35 | 126 | 360 | 1120 | 280 | 396 | 60 | 150 | 7.2 | |

| 40 | 0.34 | 145 | 430 | 1010 | 700 | 0 | 0 | 150 | 10.0 |

| 0.35 | 150 | 430 | 1010 | 560 | 132 | 20 | 150 | 10.5 | |

| 0.36 | 155 | 430 | 1010 | 420 | 264 | 40 | 150 | 10.5 | |

| 0.34 | 148 | 430 | 1010 | 280 | 396 | 60 | 150 | 10.0 |

| Material | Max. Size (mm) | Specific Gravity | Sulfate Content (%) | Absorption (%) | Loose Bulk Density (kg/m3) | Aggregate Crushed Value * (%) |

|---|---|---|---|---|---|---|

| Sand | 2.36 | 2.64 | 0.110 | 0.98 | 1610 | ---- |

| NCA | 12.5 | 2.60 | 0.061 | 1.11 | 1560 | 19.5 |

| RCA | 12.5 | 2.45 | 0.071 | 6.51 | 1320 | 30.4 |

| (MPa) | RCA Ratio (%) | Slump Flow Value (mm) | Blocking Ratio | Sieve Segregation (%) |

|---|---|---|---|---|

| 25 | 0 | 750 | 0.92 | 10.2 |

| 20 | 730 | 0.93 | 9.1 | |

| 40 | 700 | 0.94 | 8.5 | |

| 60 | 700 | 0.92 | 7.2 | |

| 33 | 0 | 740 | 0.94 | 9.8 |

| 20 | 740 | 0.91 | 8.6 | |

| 40 | 730 | 0.93 | 6.8 | |

| 60 | 730 | 0.92 | 6.1 | |

| 40 | 0 | 740 | 0.94 | 9.5 |

| 20 | 720 | 0.92 | 8.2 | |

| 40 | 730 | 0.94 | 6.1 | |

| 60 | 730 | 0.91 | 5.8 |

| Specimen’s Designation | Stud Ultimate Shear Load, Pu (kN) | Ultimate Slip, Su (mm) | Mode of Failure |

|---|---|---|---|

| S002512 | 62.7 | 5.65 | Combined failure |

| S002516 | 74.0 | 4.99 | Combined failure |

| S002520 | 107.2 | 4.48 | Combined failure |

| S003312 | 70.9 | 5.16 | Combined failure |

| S003316 | 91.0 | 4.50 | Combined failure |

| S003320 | 126.1 | 4.31 | Combined failure |

| S004012 | 83.6 | 4.83 | Combined failure |

| S004016 | 110.2 | 3.78 | Combined failure |

| S004020 | 132.3 | 4.20 | Combined failure |

| S202512 | 59.8 | 5.90 | Combined failure |

| S202516 | 68.0 | 5.16 | Combined failure |

| S202520 | 91.2 | 4.61 | Combined failure |

| S203312 | 66.4 | 5.61 | Combined failure |

| S203316 | 81.9 | 4.62 | Combined failure |

| S203320 | 102.7 | 1.99 | Stud failure (root) |

| S204012 | 79.1 | 5.12 | Combined failure |

| S204016 | 98.8 | 3.91 | Combined failure |

| S204020 | 121.2 | 4.65 | Combined failure |

| S402512 | 49.4 | 5.96 | Combined failure |

| S402516 | 58.9 | 5.53 | Combined failure |

| S402520 | 84.4 | 4.92 | Combined failure |

| S403312 | 54.8 | 6.01 | Combined failure |

| S403316 | 71.0 | 2.97 | Stud failure (root) |

| S403320 | 97.9 | 4.66 | Combined failure |

| S404012 | 70.3 | 5.64 | Combined failure |

| S404016 | 89.3 | 4.26 | Combined failure |

| S404020 | 112.7 | 2.17 | Stud failure (root) |

| S602512 | 38.2 | 6.20 | Combined failure |

| S602516 | 54.5 | 5.71 | Combined failure |

| S602520 | 78.8 | 5.01 | Combined failure |

| S603312 | 47.0 | 6.15 | Combined failure |

| S603316 | 65.9 | 4.72 | Combined failure |

| S603320 | 93.1 | 4.82 | Combined failure |

| S604012 | 60.8 | 5.90 | Combined failure |

| S604016 | 77.0 | 4.81 | Combined failure |

| S604020 | 95.7 | 4.91 | Combined failure |

| Specimen’s Designation | Ultimate Shear Capacity (kN) | PEN/Pu | PAA/Pu | ||

|---|---|---|---|---|---|

| Test, Pu | Eurocode 4, PEN | AASHTO, PAA | |||

| S002512 | 62.7 | 33.3 | 45.1 | 0.53 | 0.72 |

| S002516 | 74.0 | 59.3 | 80.2 | 0.8 | 1.08 |

| S002520 | 107.2 | 92.6 | 125.4 | 0.86 | 1.17 |

| S003312 | 70.9 | 39.8 | 49.8 | 0.56 | 0.7 |

| S003316 | 91.0 | 70.8 | 88.5 | 0.78 | 0.97 |

| S003320 | 126.1 | 110.6 | 138.2 | 0.88 | 1.1 |

| S004012 | 83.6 | 39.8 | 49.8 | 0.48 | 0.6 |

| S004016 | 110.2 | 70.8 | 88.5 | 0.64 | 0.8 |

| S004020 | 132.3 | 110.6 | 138.2 | 0.84 | 1.04 |

| S202512 | 59.8 | 32.6 | 44.1 | 0.55 | 0.74 |

| S202516 | 68.0 | 57.9 | 78.4 | 0.85 | 1.15 |

| S202520 | 91.2 | 90.5 | 122.5 | 0.99 | 1.34 |

| S203312 | 66.4 | 39.8 | 49.8 | 0.6 | 0.75 |

| S203316 | 81.9 | 70.8 | 88.5 | 0.86 | 1.08 |

| S203320 | 102.7 | 110.6 | 138.2 | 1.08 | 1.35 |

| S204012 | 79.1 | 39.8 | 49.8 | 0.5 | 0.63 |

| S204016 | 98.8 | 70.8 | 88.5 | 0.72 | 0.9 |

| S204020 | 121.2 | 110.6 | 138.2 | 0.91 | 1.14 |

| S402512 | 49.4 | 30.0 | 40.6 | 0.61 | 0.82 |

| S402516 | 58.9 | 53.4 | 72.3 | 0.91 | 1.23 |

| S402520 | 84.4 | 83.4 | 112.9 | 0.99 | 1.34 |

| S403312 | 54.8 | 38.9 | 49.8 | 0.71 | 0.91 |

| S403316 | 71.0 | 69.1 | 88.5 | 0.97 | 1.25 |

| S403320 | 97.9 | 108.0 | 138.2 | 1.1 | 1.41 |

| S404012 | 70.3 | 39.8 | 49.8 | 0.57 | 0.71 |

| S404016 | 89.3 | 70.8 | 88.5 | 0.79 | 0.99 |

| S404020 | 112.7 | 110.6 | 138.2 | 0.98 | 1.23 |

| S602512 | 38.2 | 29.5 | 40 | 0.77 | 1.05 |

| S602516 | 54.5 | 52.5 | 71.1 | 0.96 | 1.3 |

| S602520 | 78.8 | 82.0 | 111.1 | 1.04 | 1.41 |

| S603312 | 47.0 | 39.1 | 49.8 | 0.83 | 1.06 |

| S603316 | 65.9 | 69.5 | 88.5 | 1.05 | 1.34 |

| S603320 | 93.1 | 108.6 | 138.2 | 1.17 | 1.48 |

| S604012 | 60.8 | 39.8 | 49.8 | 0.65 | 0.82 |

| S604016 | 77.0 | 70.8 | 88.5 | 0.92 | 1.15 |

| S604020 | 95.7 | 110.6 | 138.2 | 1.16 | 1.44 |

| Mean | 0.82 | 1.06 | |||

| Standard Deviation | 0.19 | 0.25 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleh, S.M.; Majeed, F.H. Shear Strength of Headed Stud Connectors in Self-Compacting Concrete with Recycled Coarse Aggregate. Buildings 2022, 12, 505. https://doi.org/10.3390/buildings12050505

Saleh SM, Majeed FH. Shear Strength of Headed Stud Connectors in Self-Compacting Concrete with Recycled Coarse Aggregate. Buildings. 2022; 12(5):505. https://doi.org/10.3390/buildings12050505

Chicago/Turabian StyleSaleh, Samoel Mahdi, and Fareed Hameed Majeed. 2022. "Shear Strength of Headed Stud Connectors in Self-Compacting Concrete with Recycled Coarse Aggregate" Buildings 12, no. 5: 505. https://doi.org/10.3390/buildings12050505

APA StyleSaleh, S. M., & Majeed, F. H. (2022). Shear Strength of Headed Stud Connectors in Self-Compacting Concrete with Recycled Coarse Aggregate. Buildings, 12(5), 505. https://doi.org/10.3390/buildings12050505