Abstract

The construction sector in Malaysia has been facing challenges in productivity due to the increase in greenhouse gas (GHG) emissions. This study aims to enhance the usage of low-carbon building materials among construction professionals so that the carbon emission and GHG can be reduced during the early stage of construction. The scope of this research involved main parties in the Malaysian construction industry, represented by fifty professionals including contractors, consultants, and architects with a focus on low-carbon building materials. Procedures in this study involved a literature review on low-carbon building materials in the construction industry followed by a questionnaire survey with analysis using One-way Analysis of Variance (ANOVA). Major study findings indicated that there is a significant need for increasing the awareness of low-carbon building materials, as this is vital to introduce the concept of sustainable development and consequently cutting down carbon emissions to all parties working in construction. The study also suggested that barriers in adoption also prevent alternative material choices as a means of mitigating embodied carbon emissions. Many of these barriers are common across materials with uptake restricted by lack of demonstration projects, regulation, high costs, shortage of skilled labor, lack of design knowledge, time constraints, and lack of knowledge on LCA. The results are significant as the construction industry can seek to overcome these barriers by providing more information on material performance, design training on alternative materials, cost reduction on low-carbon materials, and more demonstration projects as well as case studies. From the work in this study, the industry must also share the knowledge on embodied carbon and implement regulations that will limit embodied carbon. The industry must adopt a business case strategy in encouraging greater value in assessment schemes to adopt low carbon building materials.

1. Introduction

The construction sector is the largest global consumer of materials, and buildings are the sector with the largest single energy use worldwide. Climate change has been said to be the result of global warming due to rapid construction. Global warming and climate are the effects of more than 60% of GHG, especially CO2 emissions [1]. The rise of CO2 emission as a significant GHG is caused by the construction activities of humans [2] and it is a global concern in reducing CO2 emissions [1]. CO2 emissions need to be managed effectively to stabilize the concentrations of GHG and reduce emissions [2].

The global concern for environmental sustainability is apparent in an increasing public mandate, and the development strategy largely depends on whether the enduring economic growth causes environmental degradation or whether such growth is sufficient to compensate for the environmental cost of production or the development process. Nevertheless, exhaustible natural resources serve as inputs into the production or development process [1].

The population and economic growth have affected the carbon dioxide (CO2) emissions and energy consumption in Malaysia due to the development of the construction sector in Malaysia [1]. As of 2017, Malaysia has been reported to have a population growth rate of 1.3% with an estimation of 32.0 million [3]. These growths in population and economy have changed Malaysia’s economic influence from the primary sector (mainly agricultural) to the secondary sector (industrial) and had encouraged additional energy consumption primarily. Malaysia has set a goal to minimize 45% of carbon emission intensity by 2030. Thus, the transformation of low-carbon building materials enhancement in the construction sector can help in reducing carbon emissions [1].

CO2 emissions can be managed by extensive use of renewable energy technologies. Life Cycle Assessment (LCA) can be applied to construction practice and also everyday design to assess the environmental effect of buildings. By applying this assessment method, energy and resource consumption can be quantified over its life cycle. The LCA needs to be applied in the early stages of building design including calculation requirements and other methodological alternatives which comprise LCA-based application and can be useful for assessment of the environmental impact of building [4].

Life cycle thinking is rising in the sector of building construction. There are three critical parts in the life cycle of buildings such as construction, the operational phase, and also demolition. Previous studies also indicated most of the environmental impact in the life cycle of the building is during the operational phase [2]. It is important to understand the degree of awareness in Malaysia to address challenges faced by construction professionals for the implementation of low-carbon building materials. Therefore, this study aims to enhance the adoption of low-carbon building materials by construction professionals and to investigate the barriers preventing construction professionals from selecting low-carbon building materials.

2. Literature Review

The construction sector has been proven to be one of the contributors to the increase in CO2 and other GHG emissions in Malaysia [3]. Carbon emissions accordingly need to be managed by enhancing the use of low-carbon building materials in as many construction projects as possible. To enhance the use of low-carbon building materials in construction projects, every construction professional plays an important role in monitoring and selecting the best materials for the project. Embodied energy has been emphasized as the energy that occurs based on the building materials and the techniques used in construction [5]. Typically, reinforced concrete frame structures are used in constructing a building, while for claddings and openings, glass and aluminum will often be chosen. Materials such as aluminum, steel, concrete, and bricks are considered to be materials that contribute to high embodied energy [6].

2.1. Existing Studies

As we are all aware, the world nowadays is dealing with severe environmental issues which are the thinning of the ozone layer, global warming, etc. From previous studies a few years back, the researchers proved that the climate all over the world is changing drastically and changes with time. Hence, these issues need to be solved quickly to prevent our environment from being destroyed due to human activities [4]. The awareness of these environmental issues among developers and construction companies especially regarding environmental footprints is a vital matter in managing the development of the construction sector [2].

The rapid development of the construction sector has increased GHG emissions in all countries around the world. There are two types of GHG emissions which are: (a) industrial and (b) urban commercial and residential. The GHG which is CO2 emission will arise more with the increase in economic activity [2].

In recent years, the demand for quantifying the environmental impact of human activities is rising to help manage climate change. Nowadays, the carbon footprint can be seen after many environmental certification systems have been established. Thus, it raises awareness of ecological problems. LCA has been standardized for assessing the environmental impact of products and services over their life cycles. The method of LCA has been widely used in the construction industry, and many studies have been done to apprehend the environmental profile of buildings and also to come up with solutions to manage the impact over a building’s life cycle.

Current global market conditions and a superior financial climate have lowered the demand for innovative low-carbon building materials, with construction owners typically prioritizing project value, time, practicality, and aesthetics. This situation creates an obvious dilemma for practitioners and stakeholders, as carbon emissions linked to the use of construction materials should decrease.

In Malaysia, there is a lack of research done so far to find out whether construction companies are using low-carbon building materials and the challenges in the adoption of low-carbon building materials. There is, therefore, a need to fill this gap in knowledge and to avail useful information which can benefit the players in the construction industry, and to ensure continuous increase in low-carbon building material and productivity improvement in the construction industry, it is important to analyze problems in low-carbon building material in construction and develop coping strategies.

2.2. Barriers to the Adoption of Alternative Materials in the Construction Industry

A number of factors prevent the selection of innovative materials [7]. These are lack of short- to medium-term commercial benefits, lack of effective marketing and dissemination of information on new materials to practicing engineers, and lack of supportive material performance data and full-scale demonstration projects. The authors argue that this can be combated through the addition of design guidance alongside effective marketing and stakeholder engagement.

Even in cases where sufficient information and demonstration projects are available, material choices are typically governed by other priorities. An international study of design teams conducted in 2012 by Arup for the World Business Council for Sustainable Development (WBCSD) demonstrated that although many factors influence material choice, the cost was the overarching priority, and material sustainability criteria were often less influential than the personal knowledge and past experiences of the project team [8].

The suitability and sustainability of a particular material are highly dependent on site- and project-specific factors. The lowest embodied carbon solution will vary across structure types, and from project to project. The end goal of policy-makers and advocates of low-carbon construction must be to promote the most appropriate option for each particular project. Therefore, simultaneous promotion of a wide variety of material options is essential. This requires skills development, and legislation that is sensitive to, and supportive of, this multitude of options. Therefore, while it is crucial for studies to assess the barriers to the adoption of particular materials, it is also essential to identify common leverage points and interventions that support multiple solutions.

This approach was adopted by [9] when conducting an online questionnaire and a series of subsequent interviews assessing the barriers to entry for non-conventional building materials. Watson et al. surveyed 62 UK construction professionals on their opinions and views of alternative materials, how often these materials were used, and what influenced their use. Results demonstrated that awareness of many alternative materials such as rammed earth, cross-laminated timber, and straw bale infill was high, but their use remained low. Over half of the respondents had not considered using non-conventional materials. The principal barriers identified in that study were high costs, lack of technical knowledge, and lack of client knowledge.

3. Low-Carbon Building Materials

Innovative building materials use materials with low-carbon emissions and have the potential for reusing common materials such as stones, soil, and timber/biomass. Such natural materials have impediments, however, especially with regard to quality and strength. Preparing and transporting natural materials includes vitality consumption, which leads to carbon emissions. To limit carbon outflows, it will be essential to make advancements in the creation of building materials and items with lesser measures of vitality usage [4]. Some types of low-carbon building materials are discussed below.

3.1. Precast Hollow Core Slabs

Precast hollow core slabs are usually used in concrete flooring systems in innovative construction projects. They form a self-supporting system with an excellent lower surface finish and can also be constructed quickly at the site. This material has a factory-assured quality that offers numerous benefits for its value-added construction. Precast hollow core slabs can be used widely in projects such as office and education buildings, warehouses and factories, shopping complexes and apartments, and also in wall panels.

3.2. Precast Half Slabs

Precast half slabs are a pre-stressed slab system applied with slab topping concrete. They have high structural performance in terms of deflection control and cracks compared to standard concrete. This is because of the factory-controlled environment during the manufacturing process.

3.3. Steel Framework System

Steel formwork usually consists of panels fabricated out of thin steel plates that are strengthened along the edges by small steel angles. The panel units are held together with the use of proper clamps. The panels may be fabricated in any shape or size. Steel formwork is usually used in high-rise building construction. It is also used for heavy concrete work and should be handled with reasonable care to ensure its longevity, as it has a high initial and handling cost.

3.4. Prefabricated Timber Frame System

Framing systems are often used in modern construction. A skeletal structure is created to support the load and weight of the timber. The primary capacity of these systems is the transfer of loads through large spans. Hence, this system will be used for building warehouses, bridges, and industrial buildings. Timber is classified into four groups: Group A—extremely strong; Group B—very strong; Group C—strong; Group D—weak. Group A and B include timbers from Malaysia such as bakau, chengal, kekatong, mata ulat and bekak; however, timbers from other countries are also included, such as oak, maple, mahogany, and teak.

3.5. Glued Laminated Timber

Glued laminated timber (glulam) is a composite of individual solid laminated woods and produces a broad wood cross-section. The benefit of using glulam is its support for the environment. The material comes from the ground yet does not require mining. Glulam offers flexibility in size and shape and can be custom-made to requirements. Besides its unique appearance, it also lends a comfortable and warm feel to buildings. Furthermore, glulam is suitable for building construction as it has excellent strength, up to one-and-a-half to two times that of steel.

3.6. Ground Granulated Blastfurnace Slag

Ground granulated blastfurnace slag (GGBS) represents a method of preventing wastage because it can substitute for material used in concrete mixtures. Composed of waste material made out of blast furnaces used to produce iron, GGBS can be used in ready-mixed concrete because it has higher workability, making for smooth processes of placing and compaction. The risk of reinforcement corrosion can be reduced with the high defiance to chloride ingress, conferring sustainability. GGBS is good to use with ordinary portland cement (OPC) because its hardening is very slow [10]. So, a composition of 50% GGBS and 50% OPC is a great combination that confers more strength to concrete.

3.7. Pulverized Fuel Ash

Pulverized fuel ash (PFA) is another type of portland cement that is a by-product of coal-powered power stations. It is also an example of a pozzolanic material and can be added to cement throughout the manufacturing process. The advantages of PFA are that it is highly economical, that it is environmentally friendly, as the waste materials from industry are used effectively to create quality building materials, and that it has microscopic particles which make the concrete highly dense and reduce its permeability. It can therefore add greater strength to buildings.

3.8. Unfired Brick

Unfired brick is also known as earth masonry. It is usually constructed with some additives to improve its strength. Unfired brick is used in the development of walls. To cut costs in construction, the preferred wall thickness has been reduced to approximately 100 mm (the standard thickness for concrete blockwork and fired clay bricks). Reduced wall thickness helps to minimize structural loading and increases buildings’ available space. The advantage of this brick is its hygroscopic environmental regulation [11]. It is a commonly used material in construction and is a low-carbon material.

3.9. Ethylene Tetrafluoroethylene

Ethylene tetrafluoroethylene (ETFE) is a material that can be used as cladding for buildings, offering 95% light transmission and flexibility. The evaluation of embodied energy values in ETFE is in the range of 26.5 to 210 MJ/kg. ETFE is a fluorine-based plastic and can be considered a robust high-strength version of Polytetrafluoroethylene (PTFE) [12].

3.10. Geopolymer Concrete

Geopolymer concrete is made from GGBS and fly ash. Thus, it helps to reduce carbon emissions and stock wastage by decreasing the use of portland cement. It has low permeability, making it vulnerable to aggressive environments [13]. It also has low hydration heat compared to cement concrete.

4. Research Methodology

4.1. Design of Study and Respondents

This research adopted a quantitative approach to understanding the awareness level of low-carbon building materials in the construction industry. A questionnaire survey is suitably chosen due to the number of respondents involved in the data collection process. This approach effectively gathers information as it is more specific, result-oriented, and involves the collection of numerical data.

The survey is easy to control with targeted respondents working in the construction industry. The supplementary questionnaire is designed with rating scale questions, as well as some objective multiple-choice questions. The respondents were chosen from ten companies obtained from the Construction Industry Development Board Malaysia [14]. The total number of respondents interviewed was 50, and they fell under three categories of construction professionals including engineers, architects, and contractors.

4.2. Study Instrument

The questionnaire contained three sections, A, B, and C. Section A was multiple-choice questions designed to collect information regarding the respondent’s personal information. Likert scale was used for calculating the average index method to show the priority for sections B and C. In Section B, the respondents were asked to rate influences on their selection of construction materials. This section required respondents to rate their influences on the construction materials selection on a scale of 1 (Least influential) to 5 (Very influential).

The respondents were asked in Section B to rate the influences of construction professionals on materials selection based on their working experience stated in Section A. In addition, the respondents were also asked to rate their knowledge and understanding of the listed materials on a scale of 1 (used on projects (s)), 2 (aware of but not used), and 3 (no knowledge). Based on the same list of materials, respondents rank frequencies in using the materials on a scale of 1 (least often) to 9 (most often) and also their experiences in using the materials by ranking it with 1 (positive and will use the material again), 2 (somewhat positive), 3 (somewhat negative) and 4 (negative and will not use the material again). This section also asked the respondents to rate factors encouraging them to use low-carbon building materials.

In Section C, the questions emphasize the barriers to materials selection. This section consists of questions that have 1 Likert scale question and 1 open-ended question. The respondents were asked to rate the barriers to materials selection on a scale of 1 (not important), 2 (least important), 3 (important), 4 (very important), and 5 (extremely important). Respondents were also asked to add any other relevant barriers encountered based on experiences in the construction sector.

4.3. Data Analysis

Data were collected and analyzed using analysis of variance (ANOVA), focused on one-way ANOVA. one-way ANOVA is used to compare population means and as a technique for hypothesis testing. It is also known as the ANOVA F-test, which was developed by R. A. Fisher in 1920 [15]. The ANOVA table is shown below in Table 1.

Table 1.

ANOVA Table (Scofield, 2018).

ANOVA results obtained have been analyzed to study the awareness of the construction professionals (engineer, architect, and contractor) on low-carbon building materials selection. Thus, based on the results obtained from the study, the results will then be interpreted in Microsoft Excel using the Data Analysis option which is one-way ANOVA (Single Factor). For the respondent’s background part in the questionnaire, only the scope of work and occupation of the respondents were considered. The scope of work represents the major work of the respondents. Meanwhile, the occupation is to identify the percentage of architects, contractors, and engineers among the respondents.

The purpose of the one-way ANOVA method is to generate a p-value, which determines whether the assumptions made are accepted or rejected. The goal of this procedure is to split the total variation in the data into a portion due to random error and portions due to changes in the values of the independent variable(s). A hypothesis is accepted when the p-value obtained is less than a 0.05 level of significance. Then, the hypothesis is considered significant.

5. Results and Discussion

The results were analyzed to study the awareness of the construction professionals (engineers, architects, and contractors) about selecting low-carbon building materials, and the barriers to their selection. The results were then interpreted in Microsoft Excel using the Data Analysis option, which is one-way ANOVA (Single Factor). For the part of the questionnaire about the respondent’s background, only the scope of work and the respondent’s occupation were considered. Scope of work represents the major work of the respondents. Occupation identified the percentages of architects, contractors, and engineers among the respondents. The one-way ANOVA method generates a p-value which determines whether the assumptions made are accepted or rejected. A hypothesis is accepted when the p-value obtained is less than a 0.05 level of significance. The hypothesis is then considered significant.

5.1. Respondents’ Backgrounds

As above, the respondents were chosen based on three construction professions—architecture, engineering, and contracting. There were 20 engineers, 20 contractors, and 10 architects who participated in the study. The involvement of architects, engineers, and also contractors in this study is important because these positions each play a key role in the approach to green building. Additionally, they are responsible for providing professional qualifications and training to employees [16].

5.2. Selection of Construction Materials

The influence of respondents in the selection of materials plays a vital role in constructing a building because each of them holds a different scope of work and has a different understanding of the materials [17]. Table 2 shows the one-way ANOVA for the influence of respondents on the selection of construction materials.

Table 2.

One-way ANOVA of the influence of respondents over the selection of construction materials.

Table 3 shows the Sum of Square (SS), Degree of freedom (df), Mean Square (MS), F-statistic, p-value, and F critical. To begin with, contractors and engineers have a higher influence over the selection of materials than architects. Thus, the Sum of Square Between groups (SSB) generated is 9.68, while the Sum of Square Within groups (SSW) obtained is 160.9, resulting in the Sum of Square Total (SST), which is 170.58. df is calculated by k − 1, resulting in 2 and 47 for Between groups and Within groups, respectively.

Table 3.

Source of variation ANOVA.

Meanwhile, the MS obtained for Between groups is 4.84, and for Within groups it is 3.4234. Thus, the result of the F-statistic is 1.4138, which is obtained by dividing 4.84 by 3.4234. The p-value obtained is 0.2534, which is a more than 0.05 level of significant difference. To summarize, the influence of respondents is not sufficient to conclude that they are influential in the selection of construction materials.

Construction professionals play an essential role in construction companies. Their decisions determine the safety, workability, and quality of sustainable materials and client satisfaction [18]. Table 4 shows the one-way ANOVA influence of the groups of construction sector professionals over the selection of materials. The client is the most influential person in the selection of materials for construction, and their consent is sought because they are the key stakeholder [17].

Table 4.

One-way ANOVA influence of construction sector professionals over the selection of materials.

Table 5 is the one-way ANOVA influence of the construction sector professionals over the selection of materials. The SSB is 433.15. Meanwhile, the SSW obtained is 1487.64, and this accumulates the SST to 1920.79. Further, df Between groups is 7, while for Within groups it is 392, and 399 is the total df attained. Further, the MS for Between groups is 61.8786, and for Within groups, it is 3.795. Hence, the result of the F-statistic is 16.3053, which is the result of the division between MS for Between groups and Within groups.

Table 5.

Source of variation ANOVA.

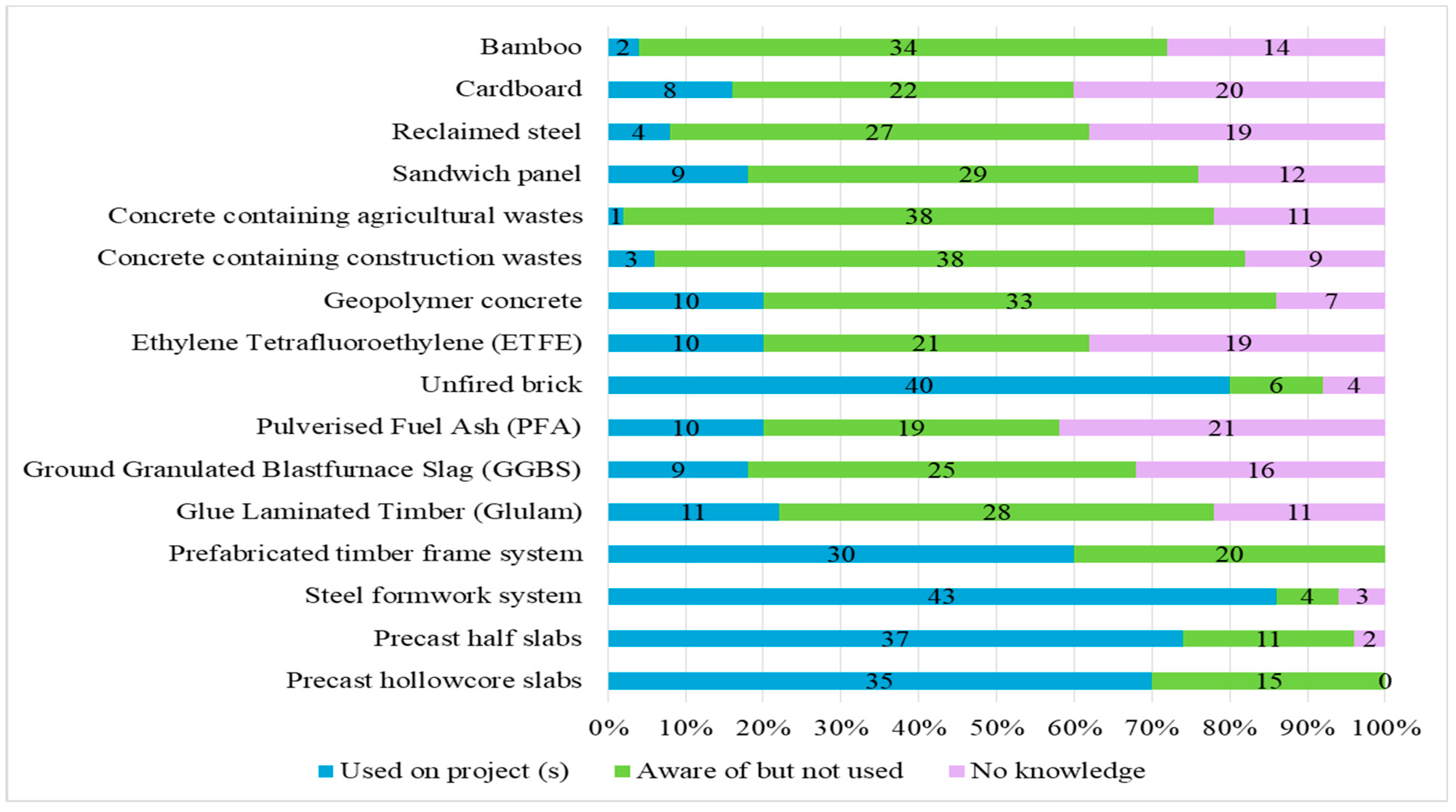

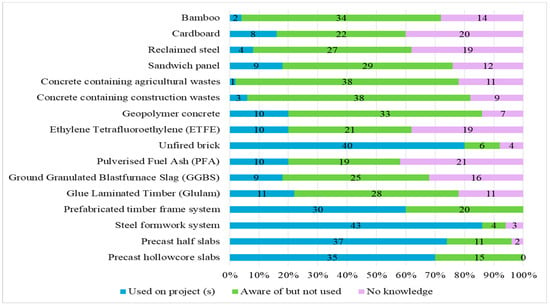

Based on the ANOVA table in Table 5, the p-value is 7.38 × 10−19, and it is less than 0.05. So, it can be concluded that construction professionals are influential in the selection of construction materials. The client appeared to be the most influential professional role in selecting construction materials, with a total of 380 sum of rank, which is 15.7%. Figure 1 shows the result for respondents’ knowledge of the alternative materials listed in the questionnaire. Sixteen materials were listed that are in use in Malaysia.

Figure 1.

Respondents’ knowledge of alternative materials.

The respondents rated the materials by whether they have actually used them on projects, whether they are aware of them but have not used them, or whether they have no knowledge of them. Eighty-six percent of the respondents agreed that they have used steel formwork systems in construction, while 76% said that they are aware of concrete containing agricultural and construction wastes but are not using it in construction. However, 42% of the respondents have no knowledge of PFA. Hence, it is vital to increase awareness about low-carbon building materials to introduce to the construction professionals an idea of the concepts of sustainable development and cutting down carbon emissions [19].

In fact, the respondents stated that the use of low-carbon building materials depends on the type of project, design intention, installation cost, and future maintenance because the uncertain practicality of the materials affects future outcomes [20]. Similarly, there are no specialists to specify a product’s carbon information, and fewer materials are being offered in the market due to high costs. Additionally, as low-carbon building materials are not commonly used, they are not being requested by clients. The regulatory department must confirm the utility and sustainability of the materials and overcome the shortage of knowledge, understanding, and skills about low-carbon building materials among construction professionals by conducting a compulsory program that can offer guidance through demonstration projects and product testing.

Likewise, the selection of materials depends on decisions by the operation team. Thus, social, economic, and environmental risk factors in the selection of materials need to be taken into account. To reduce risks that might be arising from materials selection, construction professionals are preferring to use materials that are easy to find in the market. In addition, it is necessary to consider the impacts of selecting each material for construction works, namely their performance for the longevity and workability of the whole building. The materials must be certified by the responsible authority, as the materials’ specifications need to follow clients’ requirements.

The most worrying finding is that construction professionals are not aware of how risky, costly, and challenging green materials are to use in construction. For instance, a material may not be practical, and may only be suitable for high-rise building construction. It is necessary to take into account the source of a material; it must come from a well-managed, legal source. This is because most green materials are more expensive than general materials.

The frequency of use of low-carbon building materials determines the likelihood of construction professionals using them in construction. Low-carbon building materials should be used in every construction to reduce carbon emissions and support better environments for communities. Table 6 shows the frequency of use of materials, based on the construction professionals’ experiences.

Table 6.

Frequency of use of low-carbon building materials.

Table 7 shows the one-way ANOVA of the frequency of use of materials. The SSB is 1753.5988. Meanwhile, the SSW obtained is 3525.62, and this accumulates the SST to 5279.2188. Further, the df for Between groups is 15, while for Within groups it is 784, and 799 is the total df obtained. Additionally, the MS for Between groups is 116.9066, and for Within groups, it is 4.4970. Hence, the result of the F-statistic generated is 25.9968.

Table 7.

Source of variation ANOVA.

Based on the ANOVA table in Table 7 the p-value is 6.07 × 10−59, and it is less than 0.05. This result demonstrates that each of the construction professionals plays an important role in the use of materials as they can essentially promote the utilization of alternative materials in construction projects. Hence, the frequency of use of alternative materials may contribute to developing green environments and reducing carbon emissions. Most of the respondents are from G7 contractors, which is the highest contractor grade in Malaysia with the capacity to undertake building construction and civil engineering construction projects of any size and unlimited project value. Therefore, a figure of 11.7% of the responses proves that the steel formwork system has been the most frequently used material in construction.

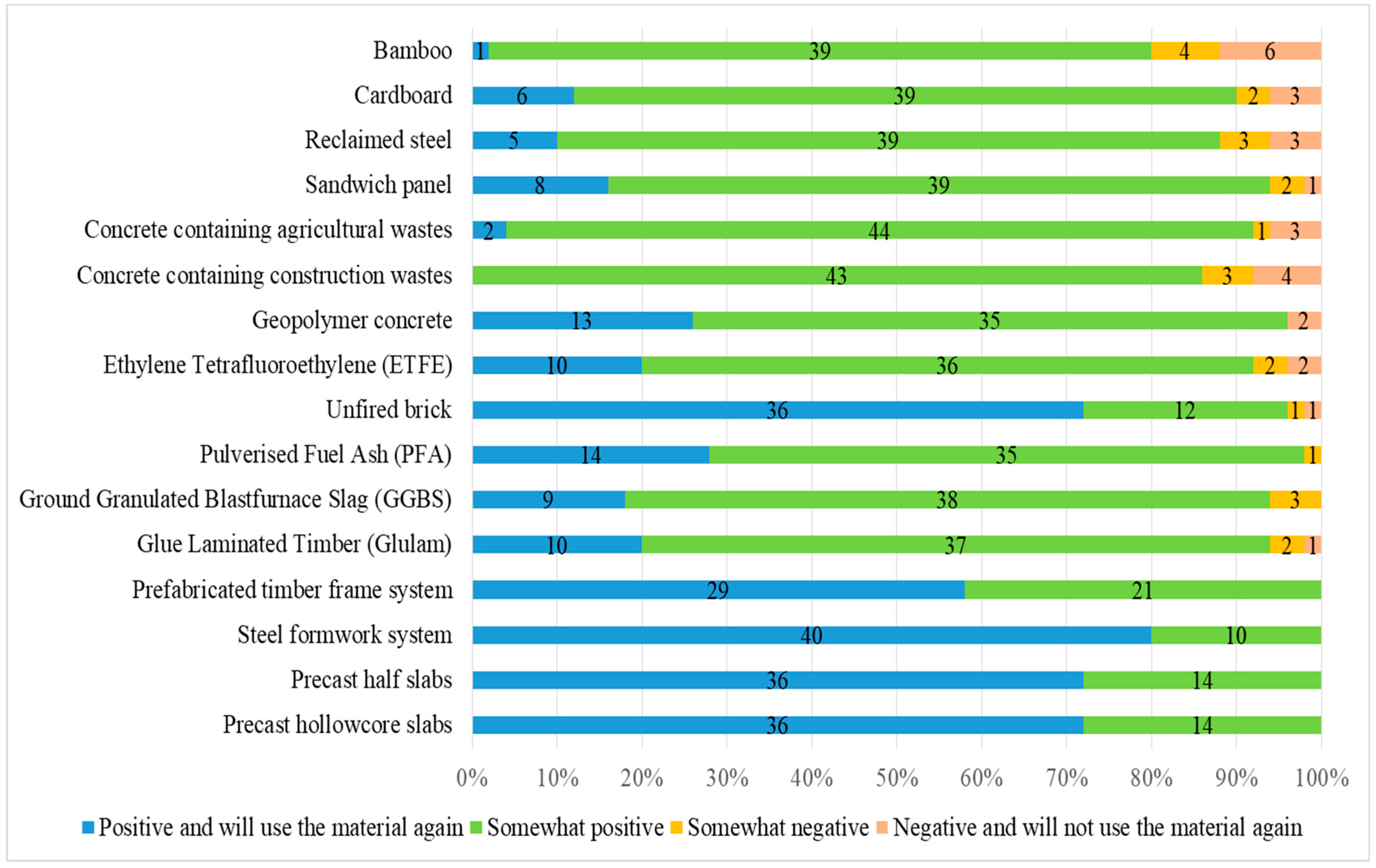

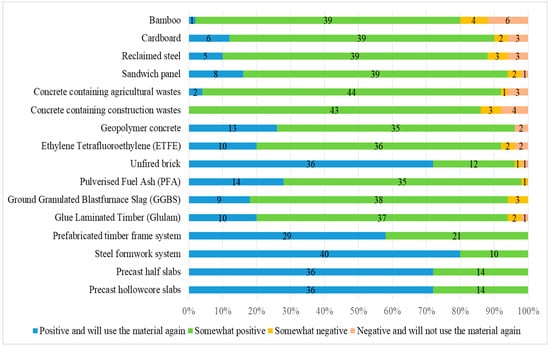

5.3. Experience in Using Alternative Materials

Past experience in using materials is very important to construction professionals, as this will influence the materials that they will choose in the future. Low-carbon building materials are those that can help reduce GHG emissions, and construction professionals should be targeting an 80% carbon emission reduction [21]. The construction professionals’ responses regarding their experience in using materials are shown in Figure 2.

Figure 2.

Experience in using alternative materials.

The findings regarding the experience of construction professionals in using alternative materials are based on the positive and negative feedback they gave about their experience in using the materials. Eighty percent of the respondents rated positive feelings about steel formwork systems and indicated that they would use them again in the future. However, 88% of respondents are only somewhat positive about using concrete containing agricultural wastes, while 8% of the respondents are somewhat negative about using bamboo as an alternative material in construction. Further, 8% are totally negative about, and will not use, concrete containing construction waste.

The use of low-carbon building materials can be driven by factors that should be practiced by every construction professional in the sector. As such, the use of low-carbon building materials should be made compulsory. Table 8 shows the one-way ANOVA of the current factors encouraging the use of alternative materials in construction.

Table 8.

One-way ANOVA of the current factors encouraging the use of alternative materials.

Clients play an important role in the use of low-carbon building materials because the client’s permission is necessary for the choice of materials [22]. Based on the ANOVA table in Table 9 the SSB is 254.76 while for SSW is 1403.24. So, the SST is 1658. The df for Between groups and Within groups is 12 and 637, respectively, which results in a total of 649 for the total df. Meanwhile, the MSSB and MSSW are 21.23 and 2.2029. So, the F-statistic generated is 9.6373. In other words, the p-value is 2.24745 × 10−17, which is less than 0.05. In short, the current factors listed are the factors encouraging the use of alternative materials in construction.

Table 9.

Source of variation ANOVA.

5.4. Barriers to Selection of Alternative Materials

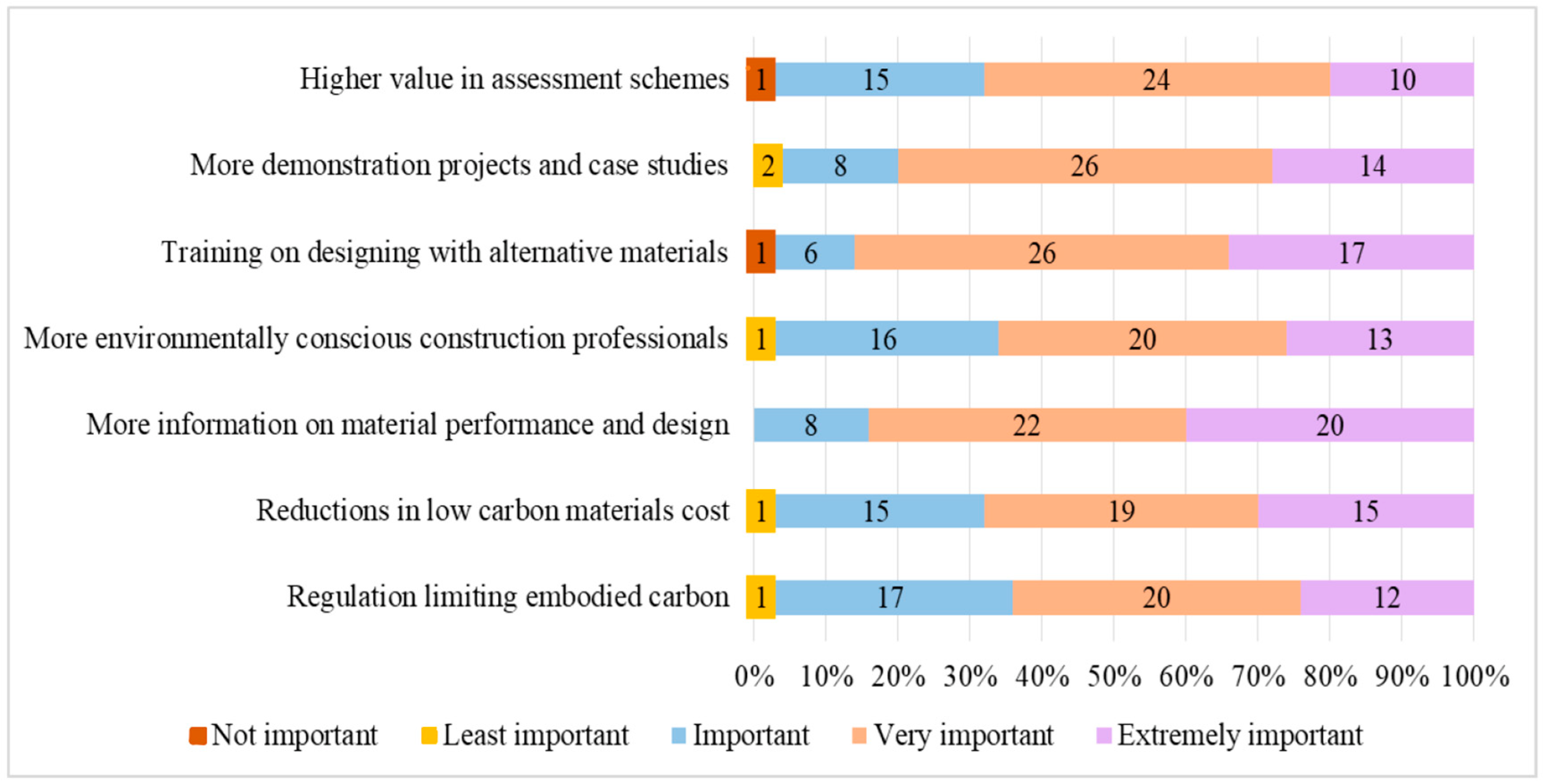

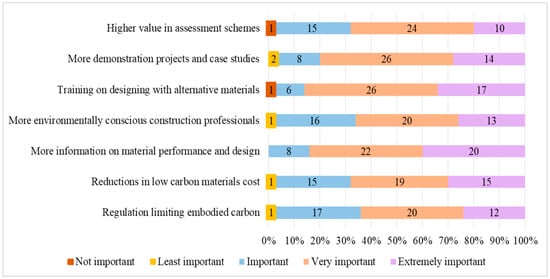

The use of low-carbon building materials may not have been fully accepted in Malaysia due to the complaints of most construction professionals about the complications they face as barriers, as shown in Figure 3.

Figure 3.

Future factors encouraging the use of alternative materials.

Thirty-four percent of the respondents agreed that the regulation limiting embodied carbon is the most important factor encouraging the use of alternative materials, while 52% said that very important factors are more demonstration projects and case studies, and training on designing with alternative materials. Further, 20% of respondents said that the most extremely important factor encouraging the use of alternative materials is more information on materials’ performance and design.

However, some respondents also noted barriers that restricted them from implementing the use of low-carbon building materials in construction. These were difficulties in obtaining government-certified materials, and accessing manufacturers or suppliers certified by government authorities. More research and development are needed about such materials, which should be attached with Building Modelling Information (BIM) and coordination before construction to ensure the success and longevity of the methods.

Respondents also complained about the cost and availability of alternative materials due to the low number of suppliers. The users of low-carbon building materials are thus taking risks and need higher levels of confidence to consistently use them. For example, one respondent claimed that materials made from timber are problematic to use, as they are known to have a low resistance to fire. Further, using low-carbon building materials presents difficulties due to the typical mindset of industry participants, who are reluctant to experiment with innovation.

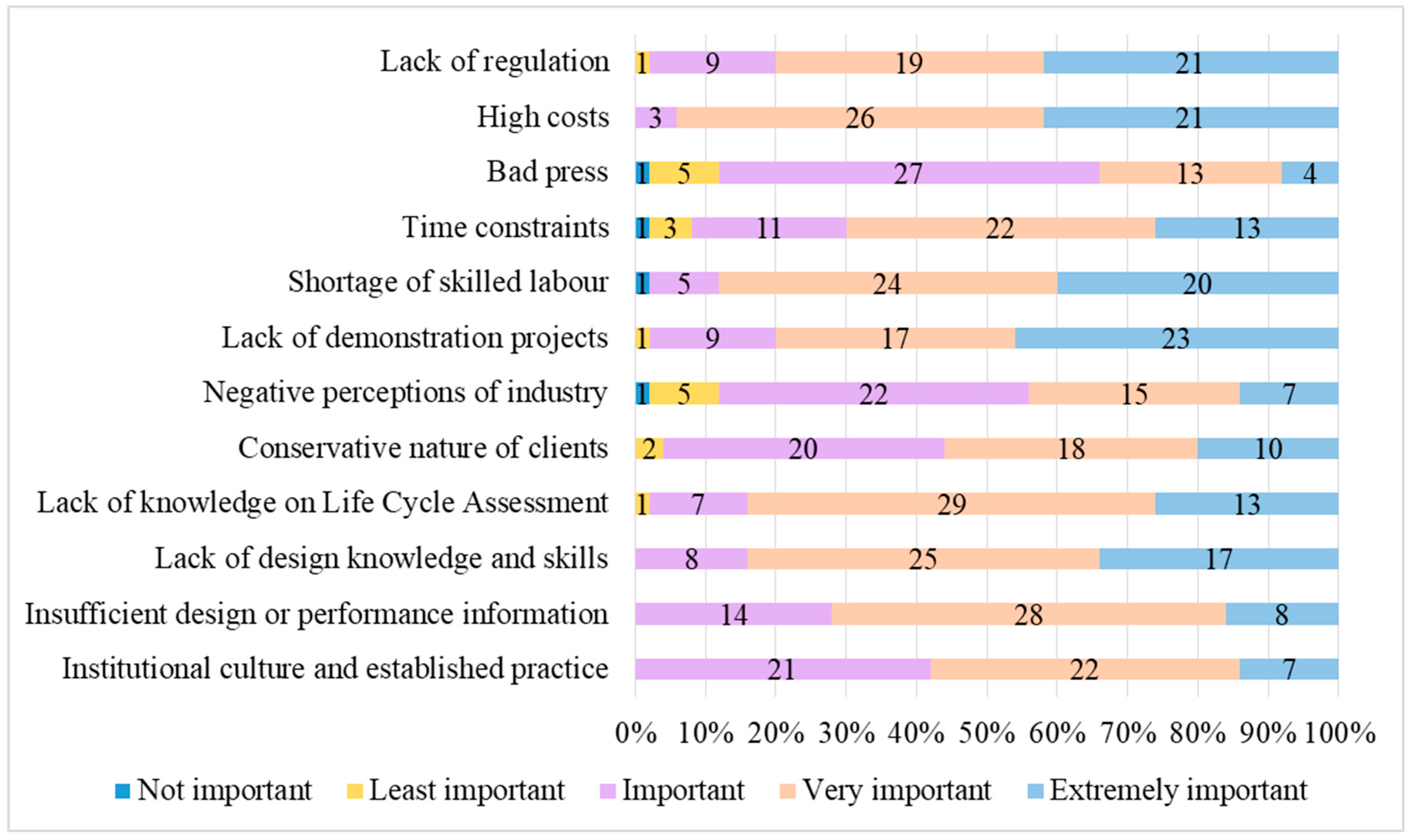

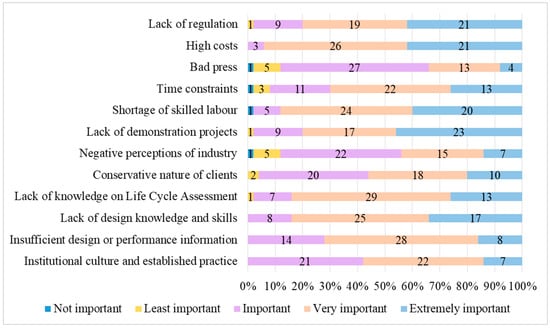

Some of the barriers to selecting alternative materials are institutional culture and established practice, insufficient design or performance information, lack of design knowledge and skills, lack of knowledge about LCA, conservative nature of clients, negative perceptions of the industry, lack of demonstration projects, shortage of skilled labor, time constraints, bad press, high costs, and lack of regulation [23].

The restrictions to using low-carbon building materials center around quality and end-user satisfaction. So, the use of low-carbon building materials in construction will help to develop a sustainable performance for the environment and for end users [24]. Figure 4 shows the barriers to the selection of alternative materials in construction projects.

Figure 4.

Barriers to the selection of alternative materials.

Fifty-four percent of the respondents indicated that the highest important barrier is bad press about the use of alternative materials. However, 58% agreed that lack of knowledge about LCA was very important barrier. In addition, 46% said that the highest extremely important barrier to using alternative materials is the lack of demonstration projects. A demonstration is important to compare the workability of each material; that is, whether it is suitable to be used in construction or not.

5.5. Summary of Findings

This study aimed to enhance the usage of low-carbon building materials among construction professionals so that the carbon emission and GHG can be reduced during the early stage of construction. The main findings are as follows:

- (a)

- Influence of construction professionals

Construction professionals play an essential role in a construction company. Their decision determines the safety, workability, and quality of the sustainable material with satisfaction by the client. Based on the ANOVA results, the client is the most influential person in the selection of materials for construction and should have the consent of the client because they are the stakeholder.

- (b)

- Knowledge of alternative materials

The need of increasing awareness of low-carbon building materials is vital to introduce construction professionals to the concept of sustainable development and cutting down carbon emissions. The results are worrying, with respondents indicating that they have no knowledge of low-carbon building materials and it is not commonly used as it is not required by the client.

- (c)

- Frequency of use of materials

The frequency of use of materials determines the likeness of construction professionals in using low-carbon building materials in construction. The low-carbon building materials should have been used in every construction to enhance the reduction of carbon emissions and to provide a better environment for the community. The results show that each of the construction professionals plays an important role in the usage of materials since they can promote the utilization of alternative materials in construction projects. Hence, the frequency of usage of alternative materials contributes to developing green environment and reducing carbon emissions.

- (d)

- Experience in using material

Experience in using materials is very important for construction professionals to have a better view of the materials that they should use for future improvement. The results for the experience of construction professionals in using alternative materials are somewhat mixed. Eighty percent of the respondents provided a positive experience and will use the steel formwork system again in the future, while 88% of them also provided positive feedback about using concrete containing agricultural wastes. However, 8% of the respondents provided negative experience in using bamboo as an alternative material in construction and will not use concrete containing construction wastes in construction.

- (e)

- Current factors encouraging the use of alternative materials

Low-carbon building materials can be driven by factors that should be practiced by every construction professional in the construction sector. The usage of low-carbon building materials should be made mandatory. ANOVA results indicated that encouraging usage of alternative materials was due to the client’s requirement during construction.

- (f)

- Future factors encouraging the use of alternative materials.

The usage of low-carbon building materials may not have been fully accepted in the central region states of Malaysia because most construction professionals emphasized the barriers restricting them from implementing the usage of low-carbon building materials in construction. It is difficult to obtain material certification by the government authority. It was also highlighted that using low-carbon building materials is challenging due to the typical minds of different parties being reluctant to try innovative approaches in construction.

- (g)

- Barriers to Material Selection

Restriction on using low-carbon materials in a building is about quality and end user satisfaction. Results suggested that the perception of the high cost may be an important barrier but the most important factor for barriers to alternative materials usage is the lack of project demonstrations. This will allow construction professionals to compare the workability of each material and whether it is suitable to be used in construction.

6. Conclusions

The first objective of this study was to study the awareness of the three groups of construction professionals (engineers, architects, and contractors) about low-carbon building materials selection. Fifty respondents among construction professionals participated in contributing suggestions and ideas to move forward in sustainability. Eighty-six percent of the study respondents indicated experience in using steel formwork systems in construction. Seventy-six percent of the respondents are aware of but have not used concrete containing agricultural and construction wastes.

Awareness of construction professionals about low-carbon building materials was identified by the significant relationship between construction professionals and knowledge of materials. Since the materials listed are not commonly used in Malaysia, the awareness of construction professionals of low-carbon building materials depends on the general knowledge of those professionals about low-carbon building materials. It is important for construction professionals to be alert to the carbon content of materials used in construction, as this will help minimize carbon emissions to the environment.

The second objective was to identify the barriers preventing construction professionals from selecting a variety of low-carbon building materials. The One Way ANOVA method for hypothesis testing was used in this study. Forty-six percent of respondents agreed that an extremely important barrier in materials selection is the lack of example studies. Therefore, the results have shown more demonstration projects are required with alternative materials to be practiced in the future to enhance the usage of low-carbon building materials in construction. The barrier that most prevents construction professionals from using low-carbon building materials in construction is the need to have more information on material performance and design. Such information about materials is crucial to selecting relevant materials for construction projects because the practicality and workability of the materials are vital to ensuring that construction projects can help the future of the building.

The results presented in this paper suggest that barriers also prevent alternative material choices as a means of mitigating embodied carbon emissions. Many of these barriers are common across materials with uptake restricted by lack of demonstration projects, regulation, high costs, shortage of skilled labor, lack of design knowledge, time constraints, and lack of knowledge on LCA. The construction industry can seek to overcome these barriers by providing more information on material performance, design training on alternative materials, cost reduction on low-carbon materials, and more demonstration projects as well as case studies. From the work in this study, the industry must also share the knowledge on embodied carbon and implement regulations that will limit embodied carbon. The industry must adopt a business case strategy in encouraging greater value in assessment schemes to adopt low-carbon building materials.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/buildings12040486/s1, the supplementary questionnaire completed by participants.

Author Contributions

Conceptualization, M.C., M.A.N.M. and S.S.Y.; methodology, M.C., M.A.N.M. and S.S.Y.; formal analysis, S.S.Y.; writing—original draft preparation, M.C., M.A.N.M. and S.S.Y.; validation, M.C. and M.A.N.M.; writing—review and editing, M.C., M.A.N.M. and S.S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ara, R.; Sohag, K.; Mastura, S.; Abdullah, S.; Jaafar, M. CO2 emissions, energy consumption, economic and population growth in Malaysia. Renew. Sustain. Energy Rev. 2015, 41, 594–601. [Google Scholar]

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Mahidin, M.U. Current Population Estimates, Malaysia, 2016–2017; Department of Statistics Malaysia: Kuala Lumpur, Malaysia, 2017; pp. 1–4.

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V. Sustainable materials for low carbon buildings. Int. J. Low Carbon Technol. 2009, 4, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Omar, W.M.S. A hybrid life cycle assessment of embodied energy and carbon emissions from conventional and industrialised building systems in Malaysia. Energy Build. 2018, 167, 253–268. [Google Scholar] [CrossRef]

- Zhang, N.; Yu, K.; Chen, Z. How does urbanization affect carbon dioxide emissions? A cross-country panel data analysis. Energy Policy 2017, 10, 678–687. [Google Scholar]

- Arup & World Business Council for Sustainable Development (WBCSD). Material Choice for Green Buildings. 2012. Available online: https://docs.wbcsd.org/2012/01/WBCSD_Material_choice_for_green_buildings.pdf (accessed on 25 October 2021).

- Watson, N.; Walker, P.; Wylie, A.; Way, C. Evaluating the barriers to entry for non-conventional building materials. In Proceedings of the International Association for Bridge and Structural Engineering (IABSE) 2012 Spring Conference on Global Thinking in Structural Engineering: Recent Achievements, Sharm El Sheikh, Egypt, 7–9 May 2012. [Google Scholar]

- Saranya, P.; Nagarajan, P.; Shashikala, A.P. Eco-friendly GBBS Concrete: A state-of-the-art-review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012057. [Google Scholar] [CrossRef] [Green Version]

- Sutton, A.; Black, D.; Walker, P. Unfired clay masonry: An introduction to low-impact building materials. Inf. Pap. BRE Publ. 2011, 15, 1–6. [Google Scholar]

- Lamnatou, C.; Moreno, A.; Chemisana, D.; Reitsma, F.; Clariá, F. Ethylene tetrafluoroethylene (ETFE) material: Critical issues and applications with emphasis on buildings. Renew. Sustain. Energy Rev. 2018, 82, 2186–2201. [Google Scholar] [CrossRef] [Green Version]

- Neupane, K. High-strength geopolymer concrete: Properties, advantages and challenges. Adv. Mater. 2019, 7, 15. [Google Scholar] [CrossRef]

- Construction Industry Development Board (CIDB). Contractor Registration Requirements and Procedures Handbook: Requirements and Procedures for Contractor Registration with the Construction Industry Development Board. 2016. Available online: https://pdfcoffee.com/cidb-catogeries-english-translation-14112016-pdf-free.html (accessed on 20 December 2021).

- Tweney, R.D. History of analysis of variance. In Wiley StatsRef: Statistics Reference Online; Bowling Green State University: Pauling Green, OH, USA, 2014; pp. 1–4. [Google Scholar]

- Hartmann, A. The role of organizational culture in motivating innovative behaviour in construction firms. Constr. Innov. 2006, 6, 159–172. [Google Scholar] [CrossRef]

- Oluwole Akadiri, P. Investigating factors influencing building materials selection in Nigerian construction industry. Am. J. Civ. Eng. Archit. 2018, 6, 154–157. [Google Scholar] [CrossRef] [Green Version]

- Scofield, T.L. Math 143-ANOVA. 2018. Available online: https://sites.calvin.edu/scofield/courses/m143/materials/handouts/anova1And2.pdf (accessed on 27 December 2021).

- Ho, C.S.; Adeyemi, A. Low Carbon Cities: The way forward in real estate development in Malaysia. Int. J. Real Estate Stud. 2013, 8, 50–59. [Google Scholar]

- Ogunkah, I.; Yang, J. Investigating factors affecting material selection: The impacts on green vernacular building materials in the design-decision making process. Buildings 2012, 2, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Giesekam, J.; Barrett, J.R.; Taylor, P. Construction sector views on low carbon building materials. Build. Res. Inf. 2016, 44, 423–444. [Google Scholar] [CrossRef]

- Pedgley, O. Influence of stakeholders on industrial design materials and manufacturing selection. Int. J. Des. 2009, 3, 1–15. [Google Scholar]

- Zhang, S.; Xiang, X.; Ma, Z.; Ma, M.; Zou, C. Carbon neutral roadmap of commercial building operations by mid-century: Lessons from China. Buildings 2021, 11, 510. [Google Scholar] [CrossRef]

- Aghdam, K.A.; Rad, A.F.; Shakeri, H.; Sardroud, J.M. Approaching green buildings using eco-efficient construction materials: A review of the state-of-the-art. J. Constr. Eng. Proj. Manag. 2018, 8, 1–23. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).