Gypsum Mortars with Acacia dealbata Biomass Waste Additions: Effect of Different Fractions and Contents

Abstract

:1. Introduction

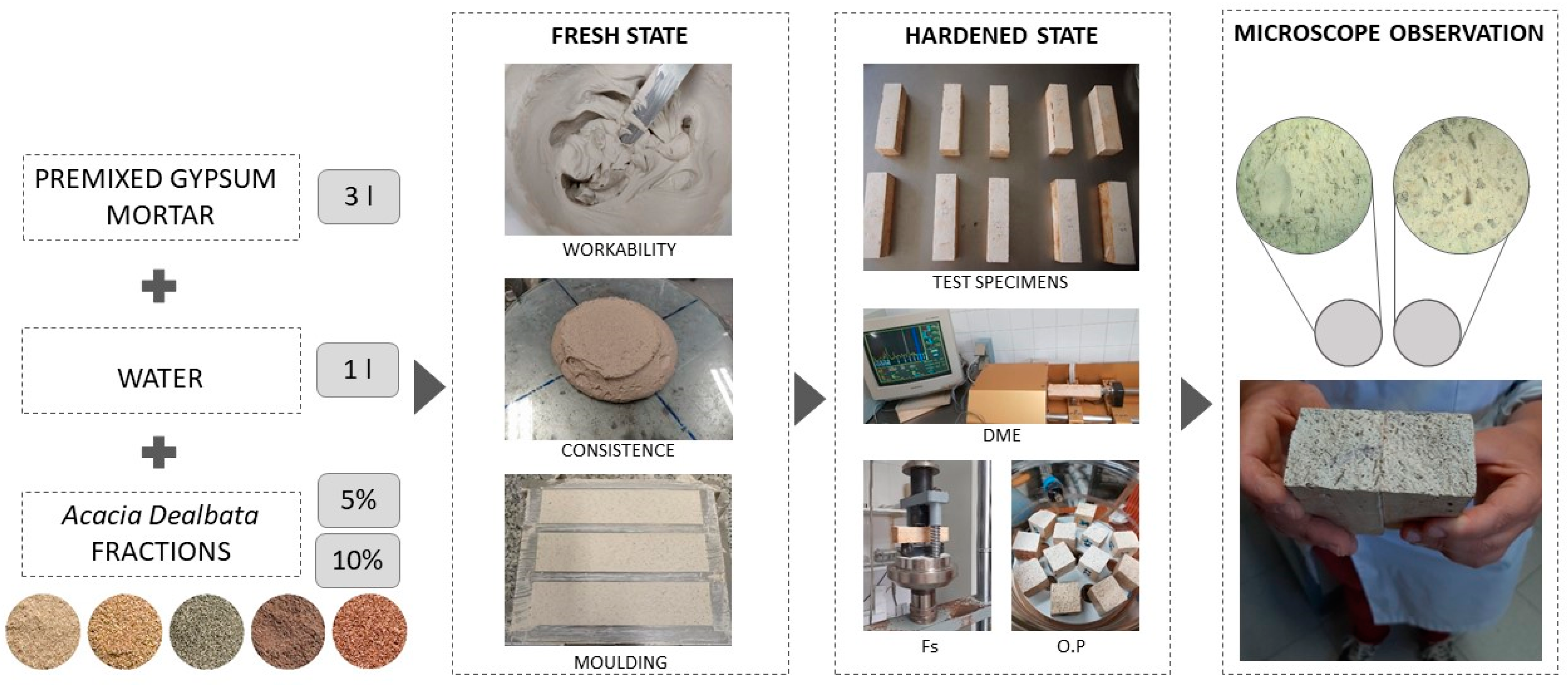

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.3. Specimens and Methods

- Volumetric shrinkage—determined using a digital caliper.

- Apparent bulk density—based on EN 1015-10 [34]—geometrically determined using a digital caliper and a balance with 0.001 g resolution.

- Flexural and compressive strengths—based on EN 1015-11 [35]—using an electromechanical testing device from Microtest, model EM1/100/FR. The loading rates were adjusted so that failure occurred within a period of 10–25 s for flexural strength and 30–90 s for compressive strength. Load cells of 2 kN and 200 kN were used, depending on the mechanical strength of the material (Figure 4).

- Dynamic modulus of elasticity—based on EN 14146 [36]—by resonance frequency using a Zeus ZRM equipment.

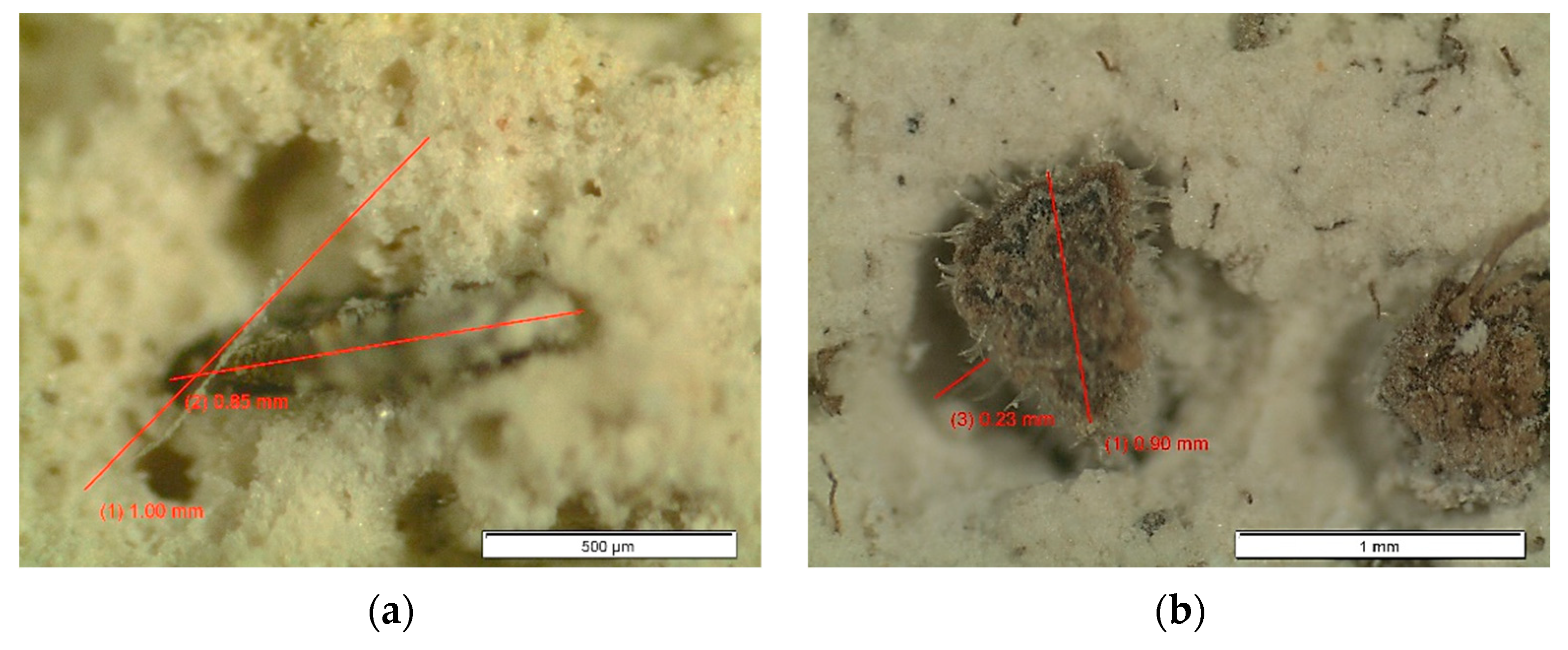

- Optical microscope observation—using an Olympus SZH-10 optical microscope.

- Open porosity—based on EN 1936 [37]—by vacuum and hydrostatic weighing.

3. Results and Discussion

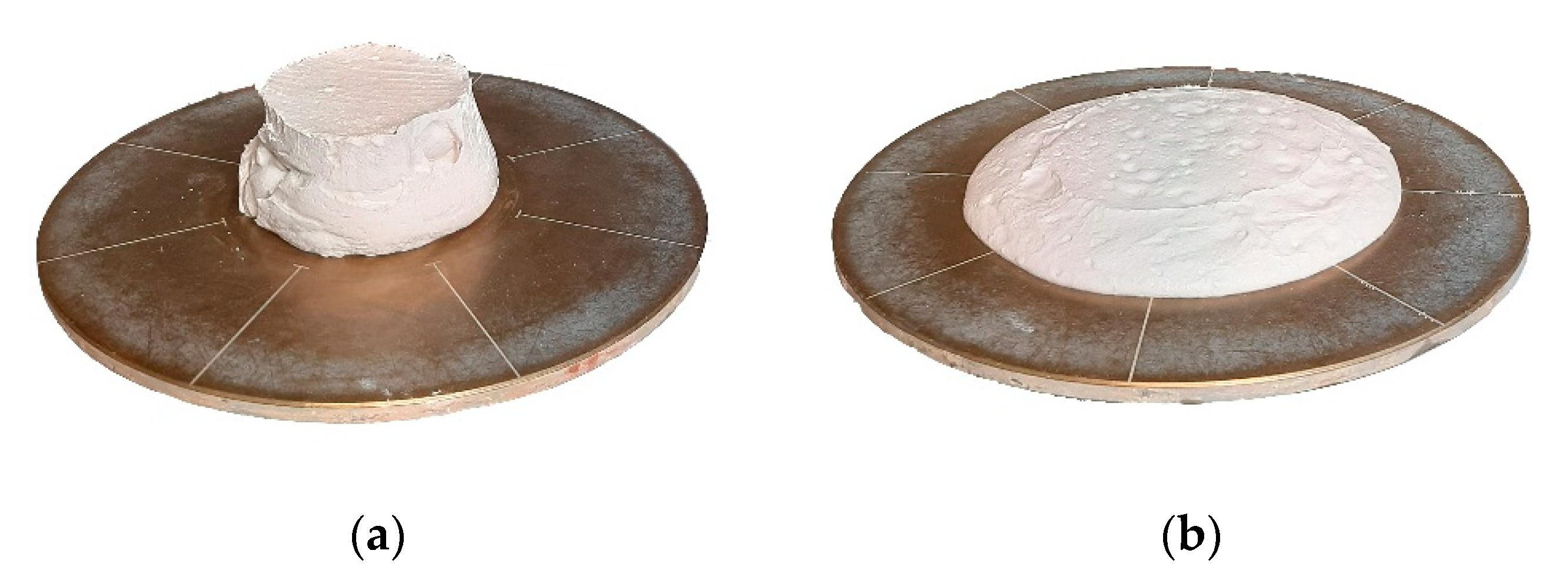

3.1. Flow-Table Consistency, Density, and Drying Shrinkage

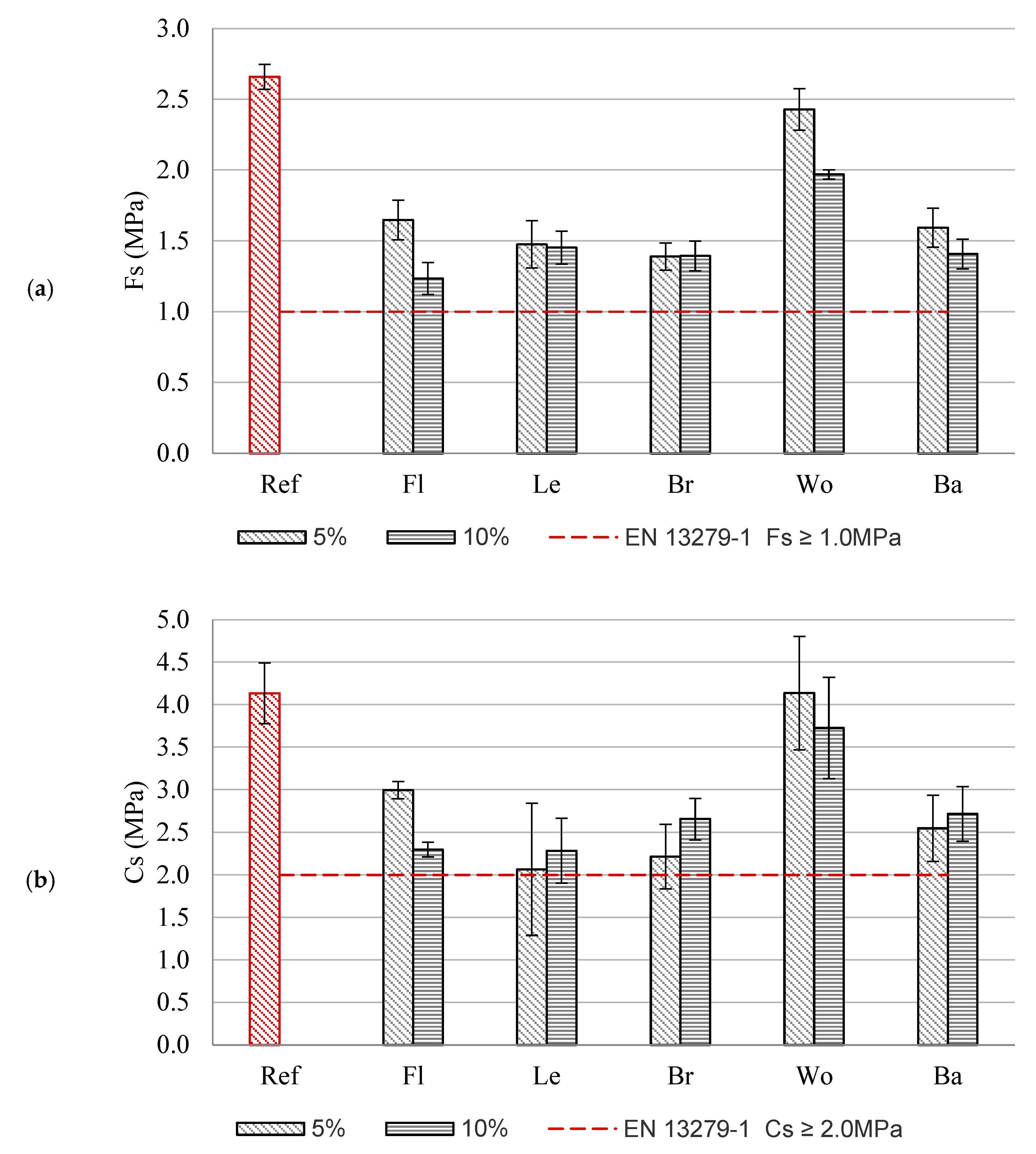

3.2. Flexural and Compressive Strength

3.3. Dynamic Modulus of Elasticity (DME)

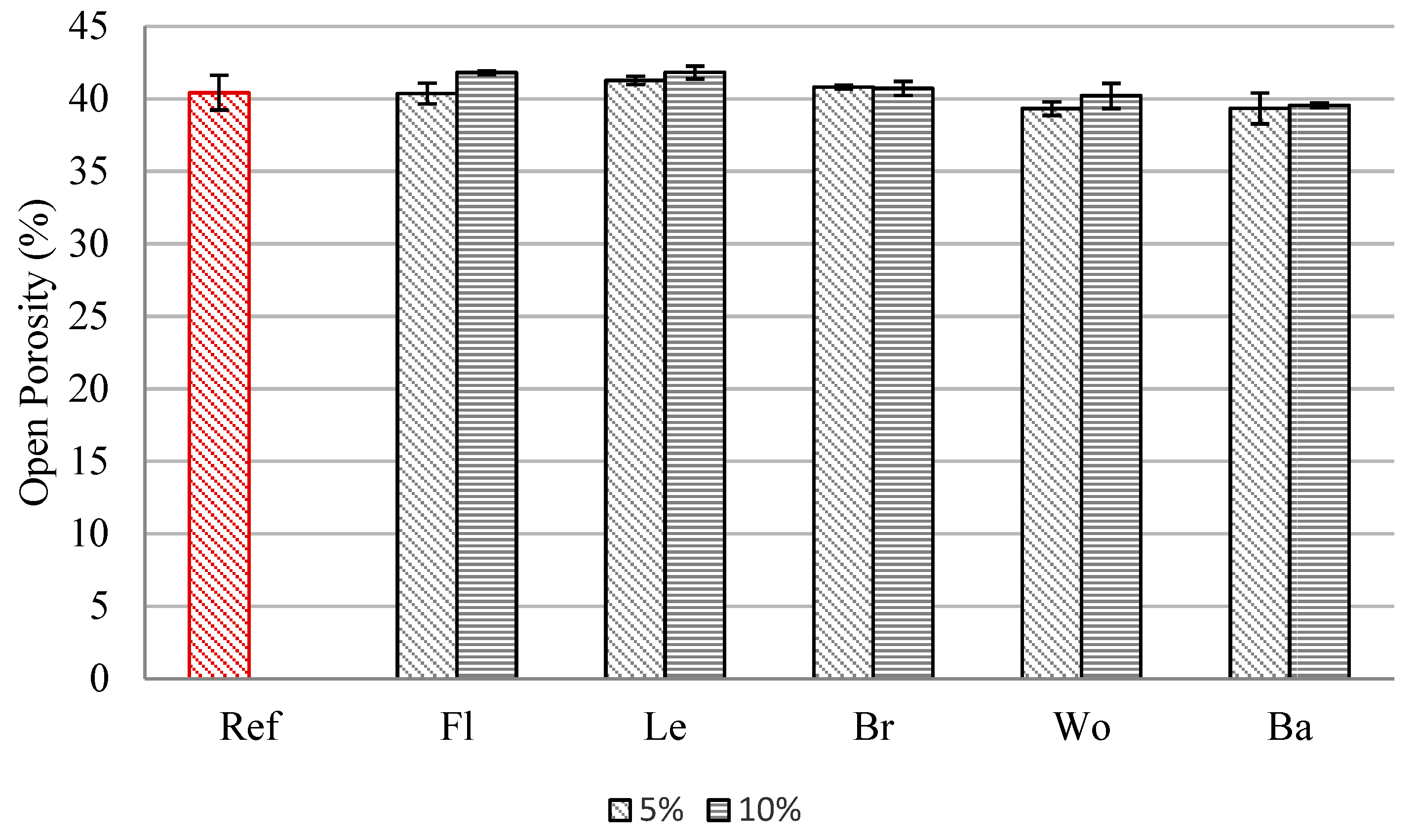

3.4. Open Porosity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Mäkinen, T.M.; Juvonen, R.; Jokelainen, J.; Harju, T.H.; Peitso, A.; Bloigu, A.; Silvennionen-Kassinen, S.; Leinonen, M.; Hassi, J. Cold temperature and low humidity are associated with increased occurrence of respiratory tract infections. Respir. Med. 2009, 103, 456–462. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reinikainen, L.M.; Jaakkola, J.J. Efffects of temperature and humidification in the office environment. Arch. Environ. Health 2001, 56, 365–368. [Google Scholar] [CrossRef]

- Markowicz, P.; Larsson, L. Influence of relative humidity on VOC concentrations in indoor air. Environ. Sci. Pollut. Res. 2015, 22, 5772–5779. [Google Scholar] [CrossRef] [PubMed]

- Jones, A.P. Indoor air quality and health. Atmos. Environ. 1999, 33, 4535–4564. [Google Scholar] [CrossRef]

- Walkoff, P. Indoor air humidity, air quality, and health—An overview. Int. J. Hyg. Environ. Health 2018, 221, 376–390. [Google Scholar] [CrossRef] [PubMed]

- Almeida, R.M.S.F.; Ramon, N.M.M.; Freitas, V.P. Thermal comfort models and pupils’ perception in free-running school buildings of a mild climate country. Energy Build. 2016, 11, 64–75. [Google Scholar] [CrossRef]

- Vellei, M.; Herrera, M.; Fosas, D.; Natarajan, S. The influence of relative humidity on adaptive thermal comfort. Build. Environ. 2017, 124, 171–185. [Google Scholar] [CrossRef]

- Freire, M.T.; Veiga, R.; Santos Silva, A.; de Brito, J. Restoration of ancient gypsum-based plasters: Design of compatible materials. Cem. Concr. Compos. 2021, 120, 104014. [Google Scholar] [CrossRef]

- Lima, J.; Faria, P.; Veiga, R. Comparison of an earth mortar and common binder mortars for indoor plastering. In Proceedings of the ICSEFCM2021—2nd International Conference on Sustainable, Environmentally Friendly Construction Materials, Szczecin, Poland, 31 August–2 September 2021; Horszczaruk, E., Brzozowski, P., Eds.; pp. 71–76, ISBN 978-83-7663-324-4. [Google Scholar]

- Santos, T.; Gomes, M.I.; Santos Silva, A.; Ferraz, E.; Faria, P. Comparison of mineralogical, mechanical and hygroscopic characteristic of earthen, gypsum and cement-based plasters. Constr. Build. Mater. 2020, 254, 119222. [Google Scholar] [CrossRef]

- Ranesi, A.; Faria, P.; Veiga, M.R. Traditional and modern plasters for built heritage: Suitability and contribution for relative humidity passive regulation. Heritage 2021, 4, 132. [Google Scholar] [CrossRef]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life cycle assessment of mortars: A review on technical potential and drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Brazão Farinha, C.; Silvestre, J.D.; de Brito, J.; Veiga, R. Life Cycle Assessment of Mortars with Incorporation of Industrial Wastes. Fibers 2019, 7, 59. [Google Scholar] [CrossRef] [Green Version]

- Cintura, E.; Nunes, L.; Esteves, B.; Faria, P. Agro-industrial wastes as building insulation materials: A review and challenges for Euro-Mediterranean countries. Ind. Crops Prod. 2021, 171, 113833. [Google Scholar] [CrossRef]

- Mazhoud, B.; Collet, F.; Pretot, S.; Chamoin, J. Hygric and thermal properties of hemp-lime plasters. Build. Environ. 2016, 96, 206–216. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fiber. Constr. Build. Mater. J. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Pavlíková, M.; Zemanová, L.; Pokorný, J.; Záleská, M.; Jankovský, O.; Lojka, M.; Pavlík, Z. Influence of wood-based biomass ash admixing on the structural, mechanical, hygric, and thermal properties of air lime mortars. Materials 2019, 12, 2227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maskell, D.; da Silva, C.F.; Mower, K.; Rana, C.; Dengel, A.; Ball, R.J.; Ansell, M.P.; Thomson, A.; Peter, U.; Walker, P.J. Bio-based plasters for improved indoor air quality. In Proceedings of the ICBBM–2nd International Conference on Bio-based Building Materials, Clermont-Ferrand, France, 21–23 June 2017. [Google Scholar]

- Romano, A.; Bras, A.; Grammatikos, S.; Shaw, A.; Riley, M. Bio-based and recycled materials: Characterisation and hygrothermal assessment for passive relative humidity management. In Proceedings of the 3rd International Conference on Bio-based Building Materials, Belfast, UK, 26–28 June 2018. [Google Scholar]

- Kunchariyakun, K.; Sinyoung, S.; Kajitvichyanukul, P. Comparative microstructures and mechanical properties of mortar incorporating wood fiber waste from various curing conditions. Case Stud. Constr. Mater. 2022, 16, e00855. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; de Lima, T.E.S.; Fediuk, R.; Olisov, A. Investigation of the potential use of Curauá fiber for reinforcing mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Maia Pederneira, C.; Veiga, R.; de Brito, J. Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars. Materials 2020, 14, 823. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Rodrigues, A.M.; Loureiro, L.M.E.F.; Sá, L.C.R.; Matias, J.C.O. Energy recovery from invasive species: Creation of value chains to promote control and eradication. Recycling 2021, 6, 21. [Google Scholar] [CrossRef]

- Raposo, M.A.M.; Pinto-Gomes, C.J.; Nunes, L.J.R. Selective shrub management to preserve Mediterranean forests and reduce the risk of fire: The case of mainland Portugal. Fire 2020, 3, 65. [Google Scholar] [CrossRef]

- Lorenzo, P.; González, L.; Reigosa, M.J. The Genus Acacia as Invader: The characteristic case of acacia dealbata link in Europe. Ann. For. Sci. 2010, 67, 101. [Google Scholar] [CrossRef] [Green Version]

- Dawit, J.B.; Lemu, H.G.; Regassa, Y.; Akessa, A.D. Investigation of the mechanical properties of Acacia tortilis fiber reinforced natural composite. Mater. Today Proc. 2021, 38, 2953–2958. [Google Scholar] [CrossRef]

- Sakthi Vadivel, K.; Govindasamy, P. Mechanical and water absorption properties of Acacia Arabica bark fiber/polyester composites: Effect of alkali treatment and fiber volume fraction. Mater. Today Proc. 2021, 46, 2281–2287. [Google Scholar] [CrossRef]

- Ogawa, S.; Yazaki, Y. Tannins from Acacia mearnsii De Wild. Bark: Tannin determination and biological activities. Molecules 2018, 23, 837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perriot, R.; Breme, K.; Uwe, J.M.; Carenini, E.; Ferrando, G.; Baldovini, N. Chemical composition of french mimosa absolute oil. J. Agric. Food Chem. 2010, 58, 1844–1849. [Google Scholar] [CrossRef]

- Sowndhararajan, K.; Joseph, J.M.; Manian, S. Antioxidant and Free Radical Scavenging Activities of Indian Acacias: Acacia Leucophloea (Roxb.) Willd., Acacia Ferruginea Dc., Acacia Dealbata Link. and Acacia Pennata (l.) Willd. Int. J. Food Prop. 2013, 16, 1717–1729. [Google Scholar] [CrossRef]

- EN 13279-1; Gypsum Binders and Gypsum Plasters—Part 1: Definitions and Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2008.

- EN 13279-2; Gypsum Binders and Gypsum Plasters—Part 2: Test methods. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- EN 1015-6; Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 1015-10; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 14146; Natural Stone Test Methods. Determination of the Dynamic Modulus of Elasticity (by Measuring the Fundamental Resonance Frequency). European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- EN 1936; Determination of Real Density and Apparent Density and Total and Partial Open Porosity. European Committee for Standardization (CEN): Brussels, Belgium, 2007.

- Tan, K.; Qin, Y.; Du, T.; Li, L.; Zhang, L.; Wang, J. Biochar from waste biomass as hygroscopic filler for pervious concrete to improve evaporative cooling performance. Constr. Build. Mater. 2021, 287, 123078. [Google Scholar] [CrossRef]

- Pachón-Morales, J.; Colin, J.; Pierre, F.; Puel, F.; Perré, P. Effect of torrefaction intensity on the flow properties of lignocellulosic biomass powders. Biomass Bioenergy 2019, 120, 301–312. [Google Scholar] [CrossRef]

- López-Hortas, L.; Rodríguez-González, I.; Díaz-Reinoso, B.; Torres, M.D.; Moure, A.; Domínguez, H. Tools for a multiproduct biorefinery of Acacia dealbata biomass. Ind. Crops Prod. 2021, 169, 113655. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Condes, M.J.; Rubio-de-Hita, P.; Pérez-Gálvez, F. Impact of wetting–drying cycles on the mechanical properties and microstructure of wood waste–gypsum composites. Materials 2019, 12, 1829. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fatma, N.; Allègue, L.; Salem, M.; Zitoune, R.; Zidi, M. The effect of doum palm fibers on the mechanical and thermal properties of gypsum mortar. J. Compos. Mater. 2019, 53, 2641–2659. [Google Scholar] [CrossRef]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Pedreño-Rojas, M.A. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- Chicki, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental investigation of new biocomposite with low cost forthermal insulation. Energy Build. 2013, 66, 267–273. [Google Scholar] [CrossRef]

- Panesar, D.K.; Shindman, B. The mechanical, transport and thermal properties of mortar and concrete containing waste cork. Cem. Concr. Compos. 2012, 34, 982–992. [Google Scholar] [CrossRef]

- Dai, D.; Fan, M. Preparation of bio-composite from wood sawdust and gypsum. Ind. Crops Products 2015, 74, 417–424. [Google Scholar] [CrossRef]

| A. dealbata Fraction | Loose Bulk Density (g/cm3) | Color (CIELB Coordinates) | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Wood | 0.211 | 65.58 | 0.68 | 18.94 |

| Branchlets | 0.378 | 59.11 | 1.31 | 17.51 |

| Leaves | 0.415 | 34.97 | 0.59 | 11.04 |

| Flowers | 0.217 | 35.33 | 8.50 | 11.39 |

| Bark | 0.435 | 43.19 | 7.58 | 12.85 |

| Mortar | Acacia Fraction | Addition (vol, %) | Addition (Mass, g) | Flow (mm) |

|---|---|---|---|---|

| REF | – | – | – | 163.0 |

| Fl5 | Flowers | 5 | 32.6 | 163.0 |

| Le5 | Leaves | 5 | 62.2 | 168.5 |

| Br5 | Branchlets | 5 | 56.7 | 171.3 |

| Wo5 | Wood | 5 | 31.7 | 160.3 |

| Ba5 | Bark | 5 | 65.2 | 175.5 |

| Fl10 | Flowers | 10 | 65.3 | 165.5 |

| Le10 | Leaves | 10 | 124.4 | 156.5 |

| Br10 | Branchlets | 10 | 113.5 | 171.0 |

| Wo10 | Wood | 10 | 63.3 | 165.3 |

| Ba10 | Bark | 10 | 130.4 | 165.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranesi, A.; Faria, P.; Correia, R.; Freire, M.T.; Veiga, R.; Gonçalves, M. Gypsum Mortars with Acacia dealbata Biomass Waste Additions: Effect of Different Fractions and Contents. Buildings 2022, 12, 339. https://doi.org/10.3390/buildings12030339

Ranesi A, Faria P, Correia R, Freire MT, Veiga R, Gonçalves M. Gypsum Mortars with Acacia dealbata Biomass Waste Additions: Effect of Different Fractions and Contents. Buildings. 2022; 12(3):339. https://doi.org/10.3390/buildings12030339

Chicago/Turabian StyleRanesi, Alessandra, Paulina Faria, Ricardo Correia, Maria Teresa Freire, Rosário Veiga, and Margarida Gonçalves. 2022. "Gypsum Mortars with Acacia dealbata Biomass Waste Additions: Effect of Different Fractions and Contents" Buildings 12, no. 3: 339. https://doi.org/10.3390/buildings12030339

APA StyleRanesi, A., Faria, P., Correia, R., Freire, M. T., Veiga, R., & Gonçalves, M. (2022). Gypsum Mortars with Acacia dealbata Biomass Waste Additions: Effect of Different Fractions and Contents. Buildings, 12(3), 339. https://doi.org/10.3390/buildings12030339