Compressive Strength Estimation and CO2 Reduction Design of Fly Ash Composite Concrete

Abstract

:1. Introduction

2. Strength Evaluation Models

2.1. Hydration-Based Strength (HBS) Model

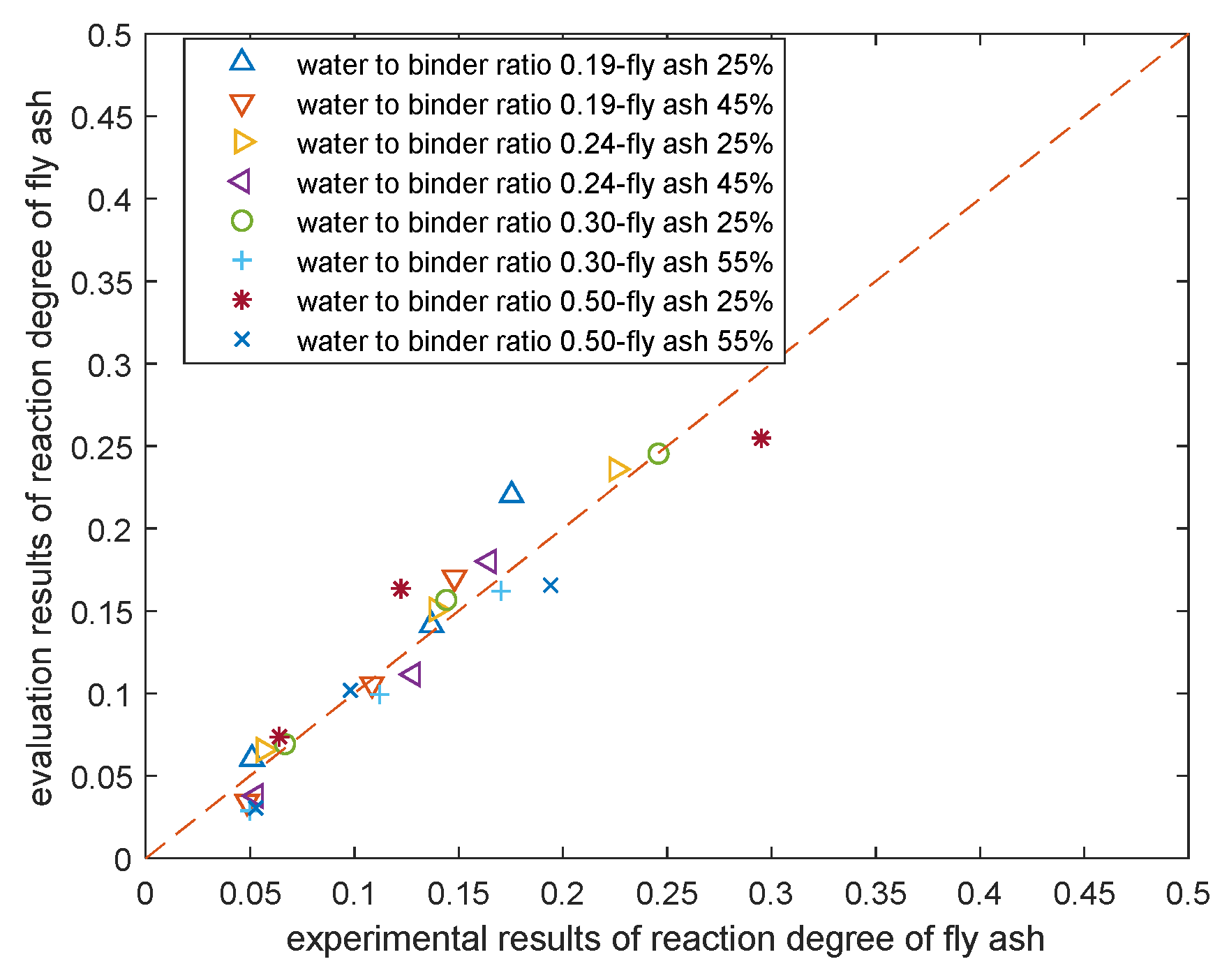

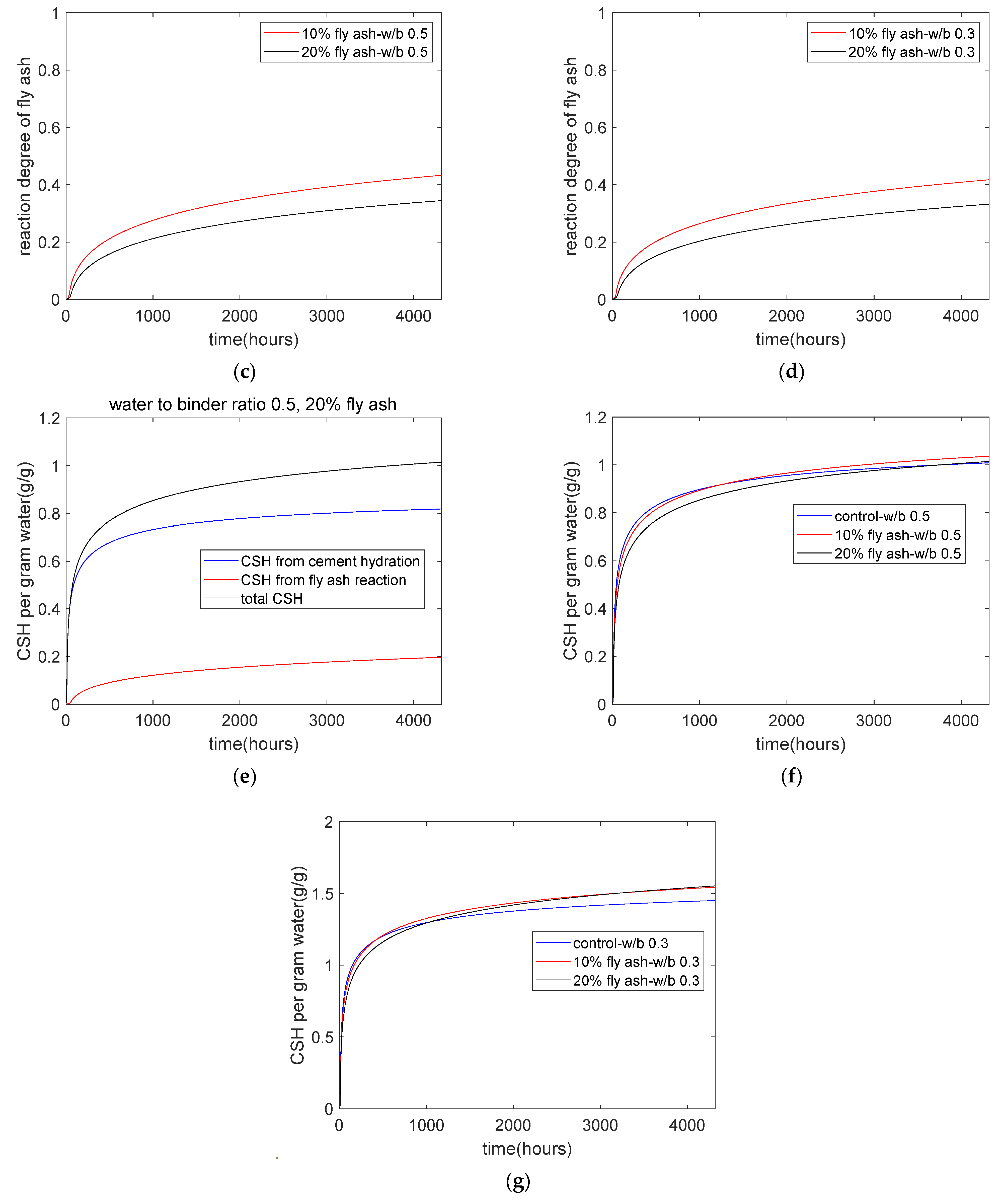

2.2. Verifications and Parameter Study of Hydration Model

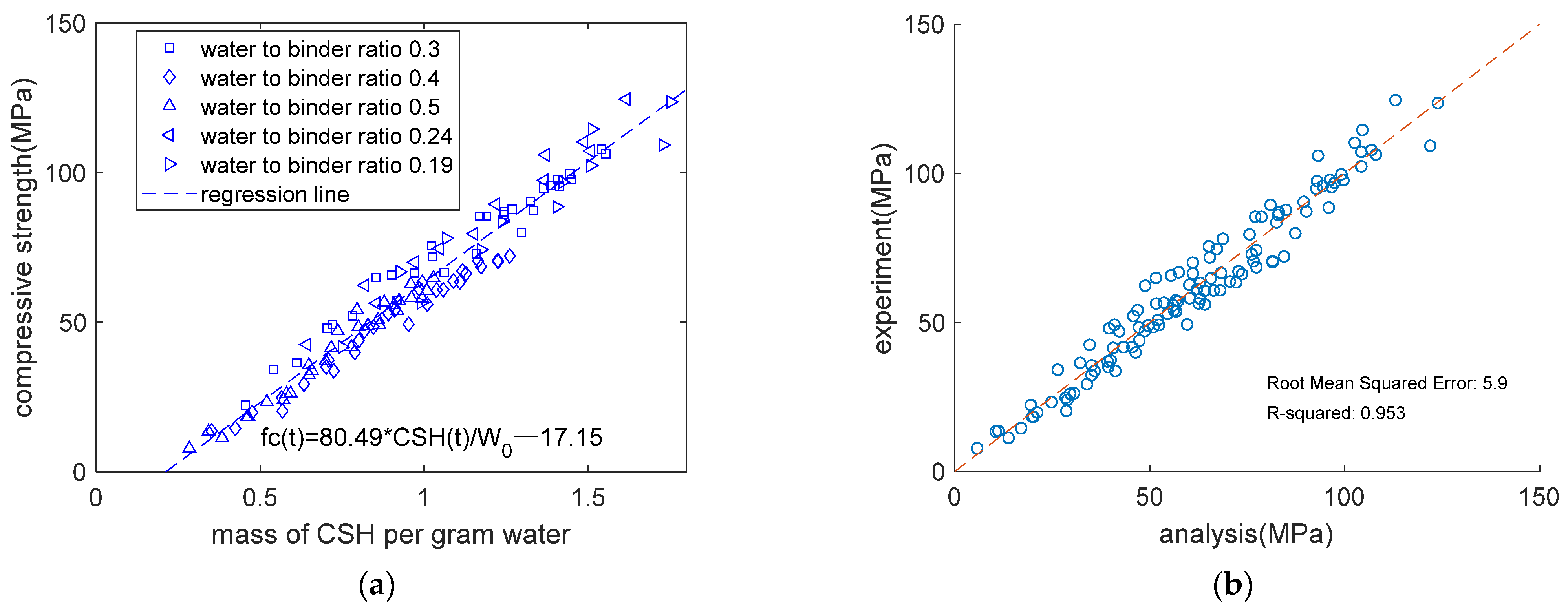

2.3. Verifications and Parameter Study of Strength Model

3. CO2 Emissions and CO2 Reduction Strategy

3.1. CO2 Emission Models

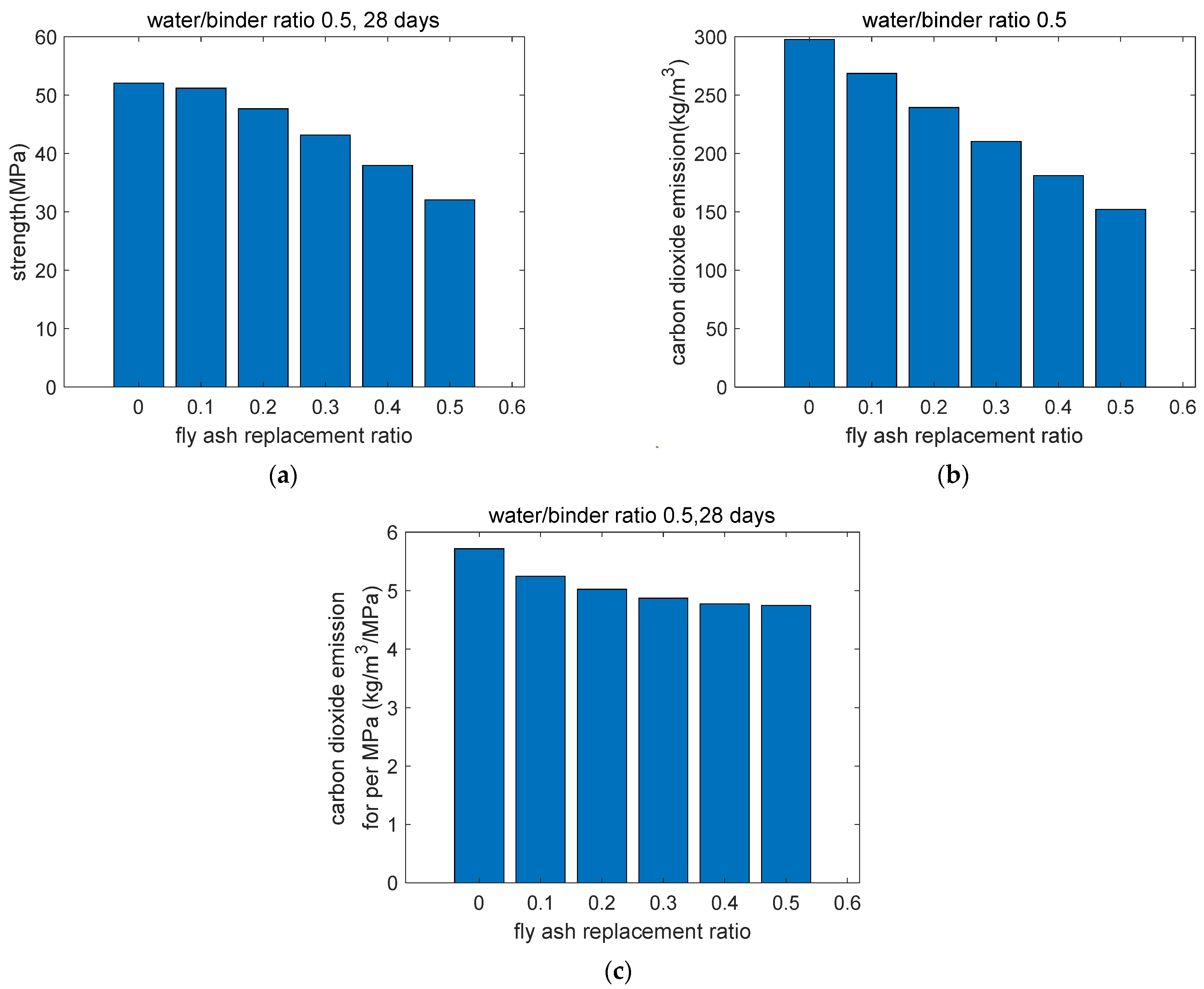

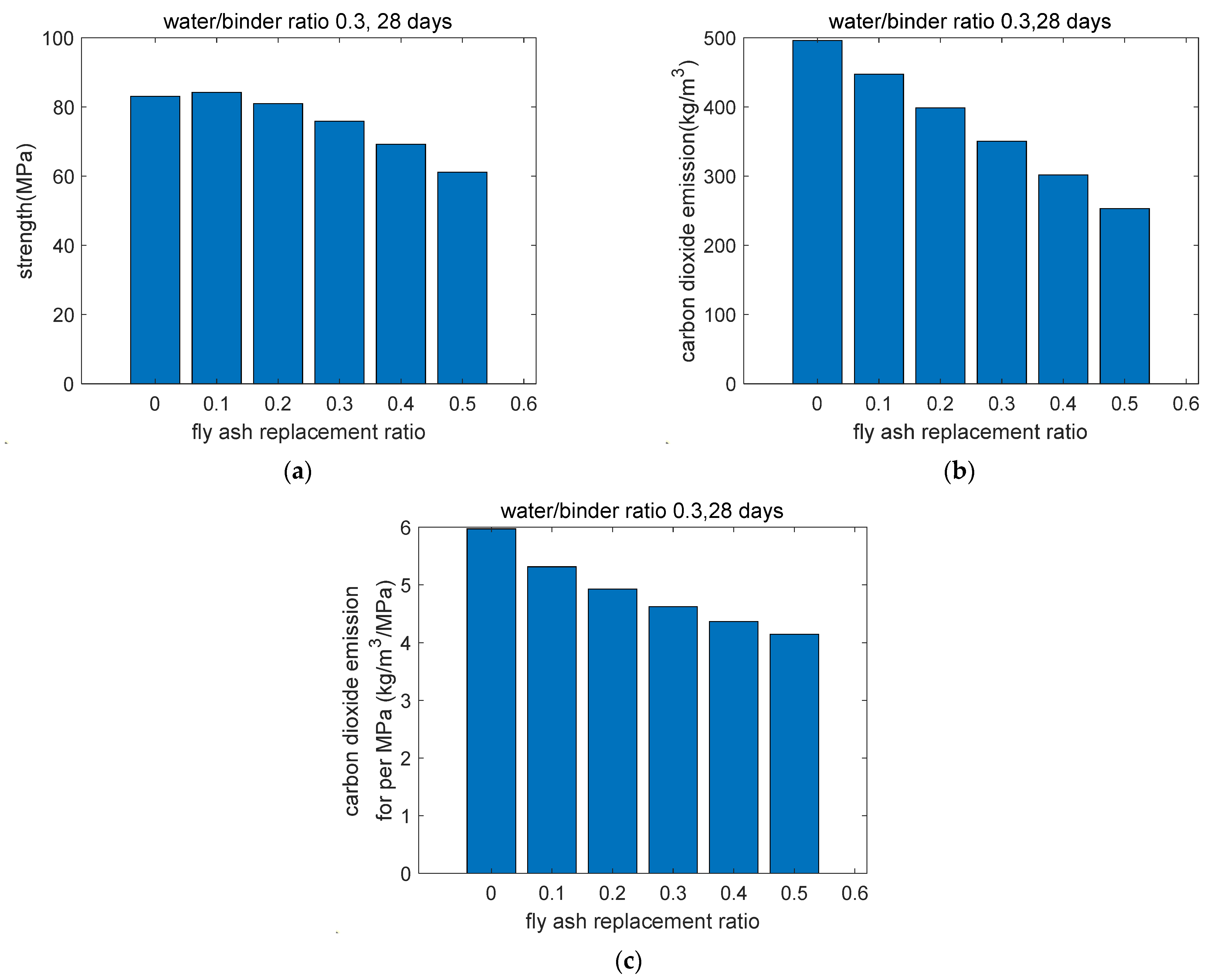

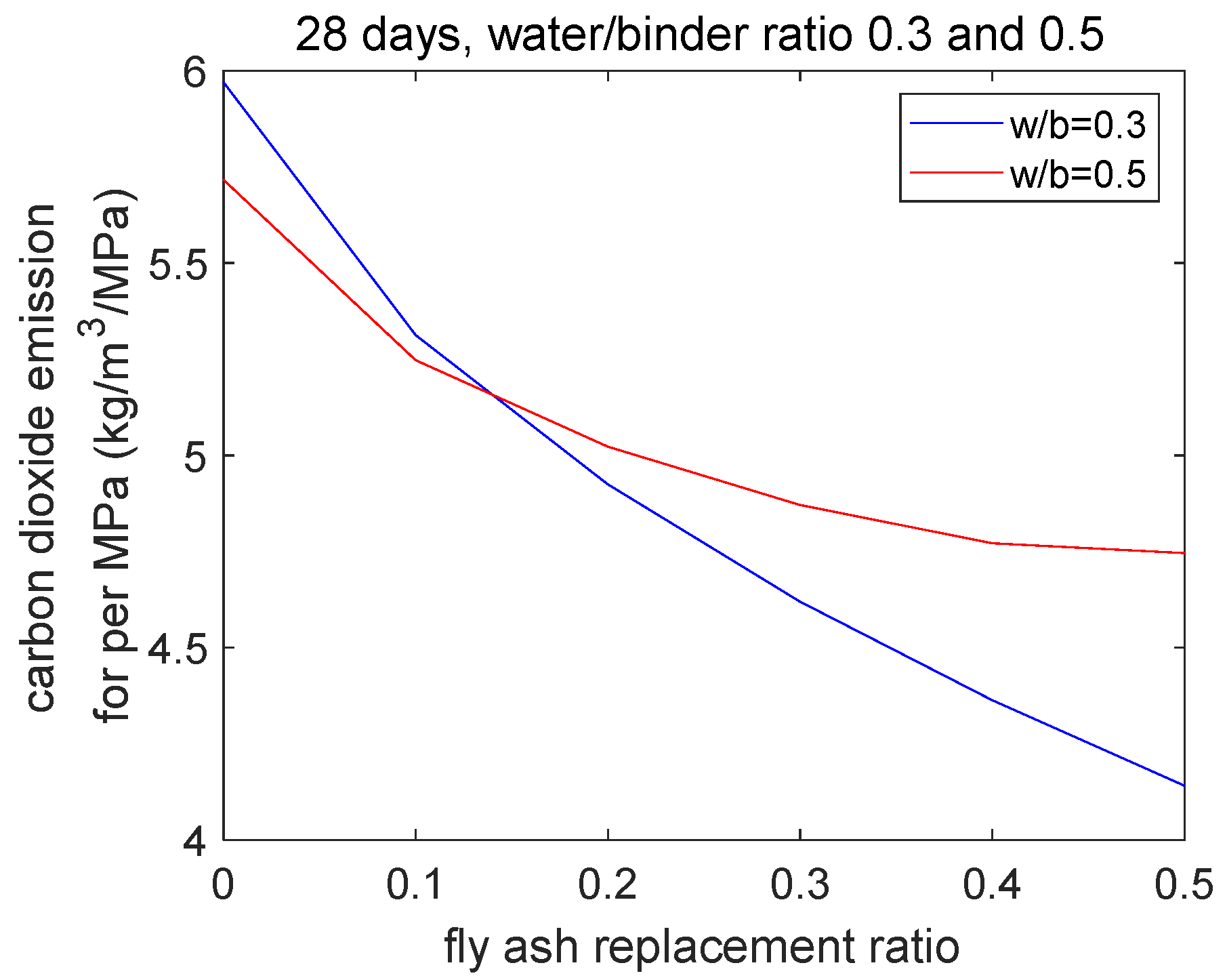

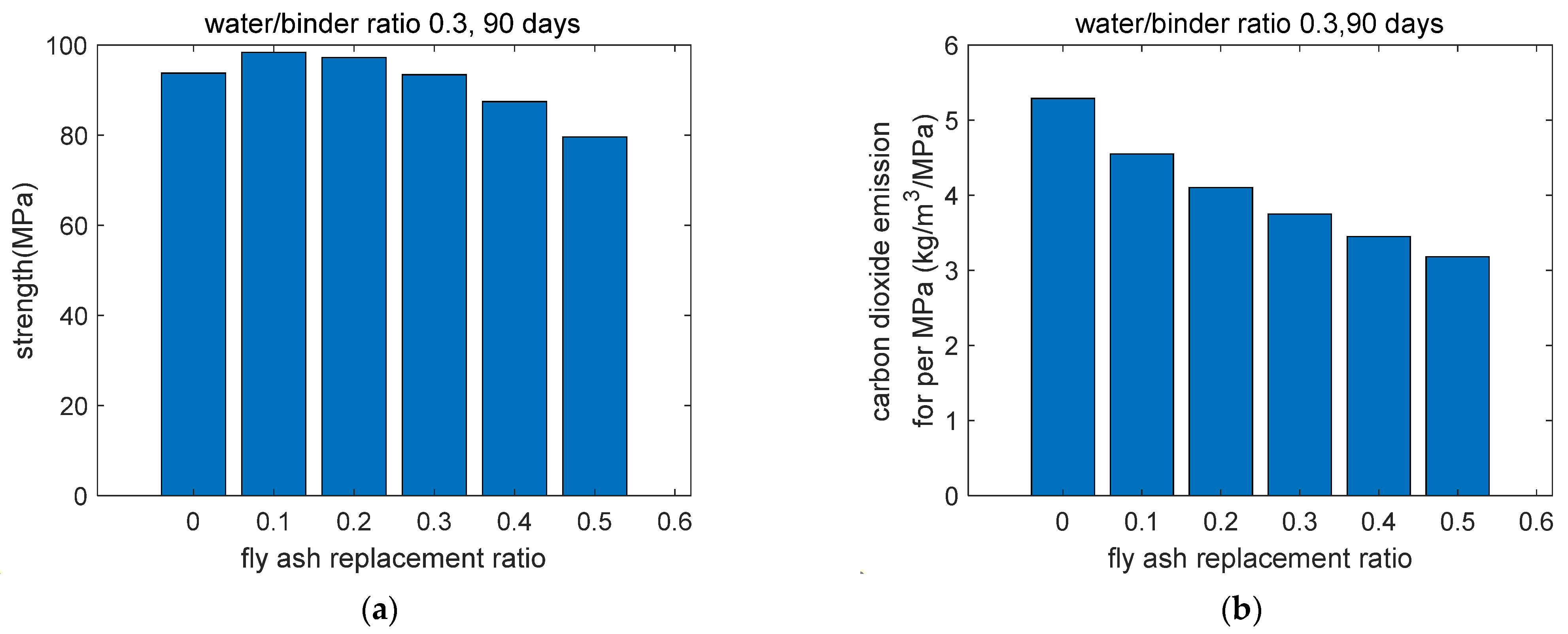

3.2. Parameter Analysis of CO2 Emissions and CO2 Reduction Strategy

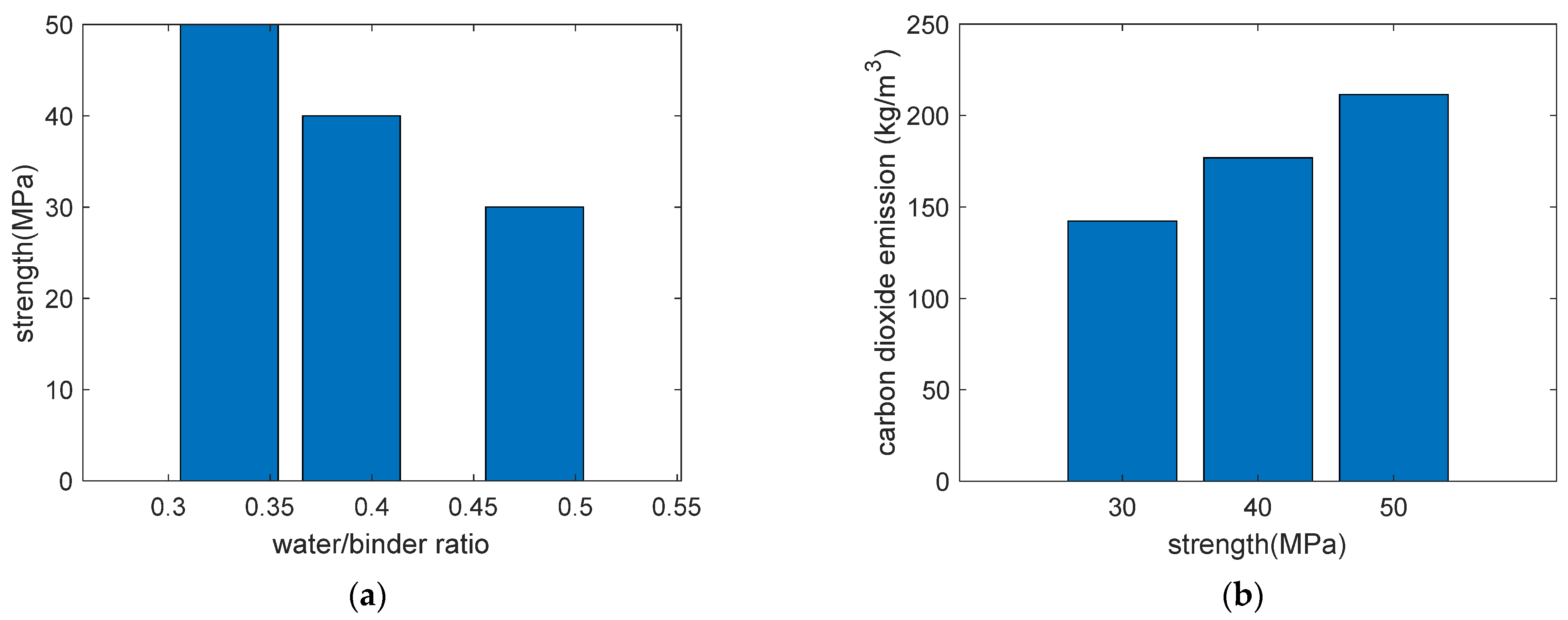

4. Genetic Algorithm-Based-Optimal Design of Low-CO2 Fly Ash Composite Concrete

4.1. Aim Function and Constraint Function of Optimal Design

4.1.1. Aim of Optimal Design of Low-CO2 Concrete

4.1.2. Constraint of Strength

4.1.3. Constraint of Fly Ash/Binder Ratio

4.2. Genetic Algorithm to Determine Optimal Combinations

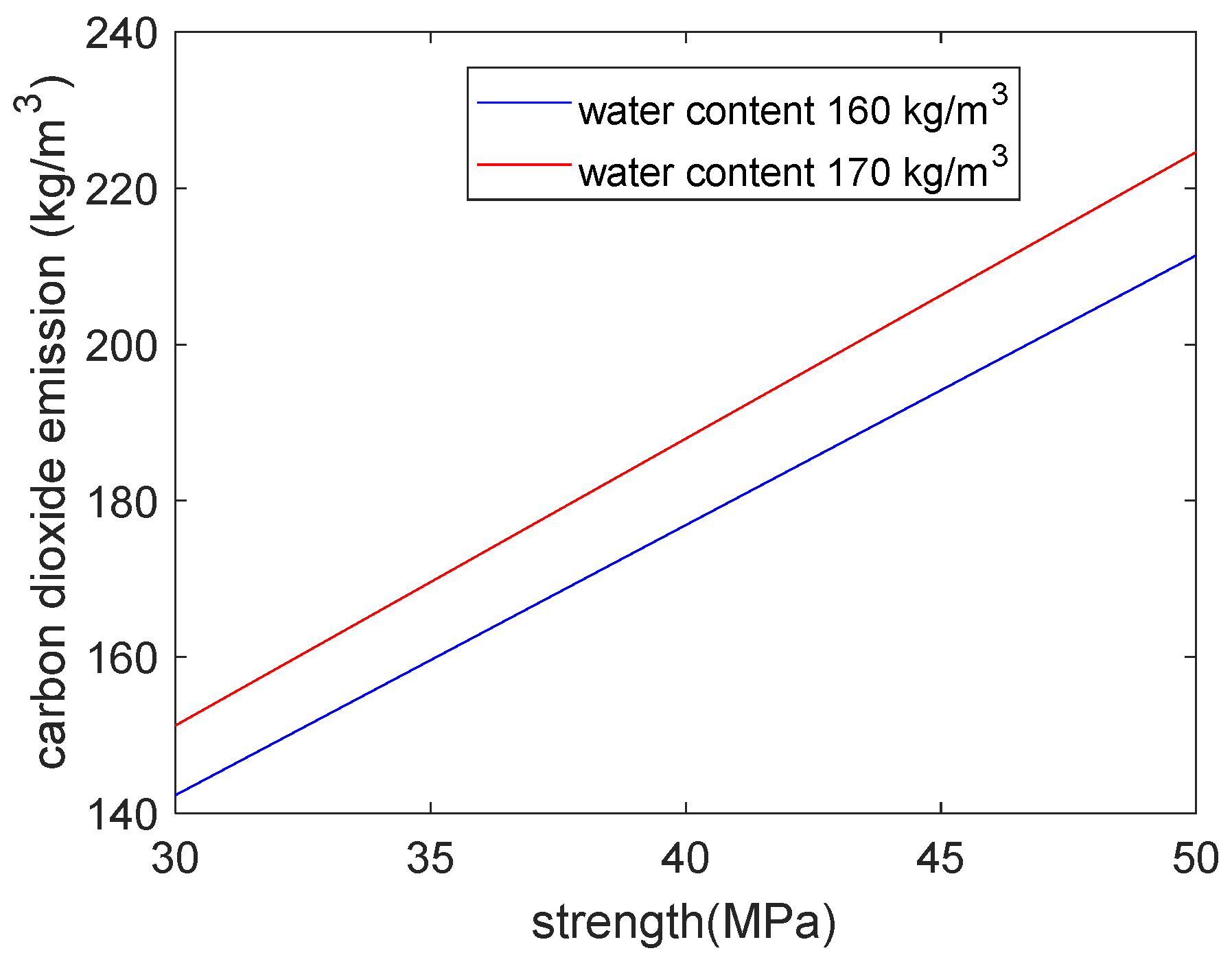

4.2.1. Optimal Combinations of Example 1 (Water Content = 160 kg/m3)

4.2.2. Optimal Combinations of Example 2 (Water Content = 170 kg/m3)

4.2.3. Optimal Combinations of Example 3 (Fly Ash CO2 Emission of 0.2 kg/kg)

4.3. Summary of Design Examples

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Moffatt, E.G.; Thomas, M.D.; Fahim, A. Performance of high-volume fly ash concrete in marine environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- Ahmadi-Nedushan, B. Prediction of elastic modulus of normal and high strength concrete using ANFIS and optimal nonlinear regression models. Constr. Build. Mater. 2012, 36, 665–673. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J. Eco-friendly mortar with high-volume diatomite and fly ash: Performance and life-cycle assessment with regional variability. J. Clean. Prod. 2020, 261, 121224. [Google Scholar] [CrossRef]

- Atiş, C.D. Carbonation-porosity-strength model for fly ash concrete. J. Mater. Civ. Eng. 2004, 16, 91–94. [Google Scholar] [CrossRef]

- Babu, K.G.; Rao, G.S.N. Efficiency of fly ash in concrete with age. Cem. Concr. Res. 1996, 26, 465–474. [Google Scholar] [CrossRef]

- Hwang, K.; Noguchi, T.; Tomosawa, F. Prediction model of compressive strength development of fly-ash concrete. Cem. Concr. Res. 2004, 34, 2269–2276. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Antiohos, S.; Tsimas, S. Supplementary cementing materials in concrete. Part II: A fundamental estimation of the efficiency factor. Cem. Concr. Res. 2002, 32, 1533–1538. [Google Scholar] [CrossRef]

- Kang, S.; Lloyd, Z.; Kim, T.; Ley, M.T. Predicting the compressive strength of fly ash concrete with the Particle Model. Cem. Concr. Res. 2020, 137, 106218. [Google Scholar] [CrossRef]

- Wu, M.; Li, C.; Yao, W. Gel/space ratio evolution in ternary composite system consisting of Portland cement, silica fume, and fly ash. Materials 2017, 10, 59. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vargas, J.; Halog, A. Effective carbon emission reductions from using upgraded fly ash in the cement industry. J. Clean. Prod. 2015, 103, 948–959. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, J.; Luo, W.; Wang, J.; Shi, J.; Zhuang, H.; Wang, Y. Effect of compressive strength and chloride diffusion on life cycle CO2 assessment of concrete containing supplementary cementitious materials. J. Clean. Prod. 2019, 218, 450–458. [Google Scholar] [CrossRef]

- Yang, K.-H.; Seo, E.-A.; Tae, S.-H. Carbonation and CO2 uptake of concrete. Environ. Impact Assess. Rev. 2014, 46, 43–52. [Google Scholar] [CrossRef]

- Kim, T.; Tae, S.; Roh, S. Assessment of the CO2 emission and cost reduction performance of a low-carbon-emission concrete mix design using an optimal mix design system. Renew. Sustain. Energy Rev. 2013, 25, 729–741. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Lu, C.; Leung, C.K.Y.; Li, G. Mechanical properties of green structural concrete with ultrahigh-volume fly ash. Constr. Build. Mater. 2017, 147, 510–518. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Lee, H.-S.; Lim, S.-M.; Wang, X.-Y. Optimal mixture design of low-CO2 high-volume slag concrete considering climate change and CO2 uptake. Int. J. Concr. Struct. Mater. 2019, 13, 56. [Google Scholar] [CrossRef]

- Lee, H.-S.; Wang, X.-Y. Hydration model and evaluation of the properties of calcined hwangtoh binary blends. Int. J. Concr. Struct. Mater. 2021, 15, 11. [Google Scholar] [CrossRef]

- Wang, X.-Y. Evaluation of the phase assemblage and strength progress of hybrid blends of cement and fly ash using kinetic and thermodynamic hydration model. Ceram.-Silik. 2021, 65, 56–68. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Lee, H.-S. Modeling the hydration of concrete incorporating fly ash or slag. Cem. Concr. Res. 2010, 40, 984–996. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Influence of type of binder on high-performance sintered fly ash lightweight aggregate concrete. Constr. Build. Mater. 2018, 176, 665–675. [Google Scholar] [CrossRef]

- Xu, G.; Tian, Q.; Miao, J.; Liu, J. Early-age hydration and mechanical properties of high volume slag and fly ash concrete at different curing temperatures. Constr. Build. Mater. 2017, 149, 367–377. [Google Scholar] [CrossRef]

- Li, C.; Zhu, H.; Wu, M.; Wu, K.; Jiang, Z. Pozzolanic reaction of fly ash modified by fluidized bed reactor-vapor deposition. Cem. Concr. Res. 2017, 92, 98–109. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Effect of fly ash and silica fume on compressive and fracture behaviors of concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Wang, X.-Y. Impact of climate change on proportional design of fly-ash-blended low-CO2 concrete. ACI Mater. J. 2019, 116, 141–151. [Google Scholar]

- Park, J.; Tae, S.; Kim, T. Life cycle CO2 assessment of concrete by compressive strength on construction site in Korea. Renew. Sustain. Energy Rev. 2012, 16, 2940–2946. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Ren, M.; Wen, X.; Gao, X.; Liu, Y. Thermal and mechanical properties of ultra-high performance concrete incorporated with microencapsulated phase change material. Constr. Build. Mater. 2021, 273, 121714. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Gao, X. Incorporation of self-ignited coal gangue in steam cured precast concrete. J. Clean. Prod. 2021, 292, 126004. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Gan, Y.; Chang, Z.; Schlangen, E.; Šavija, B. Combined experimental and numerical study of uniaxial compression failure of hardened cement paste at micrometre length scale. Cem. Concr. Res. 2019, 126, 105925. [Google Scholar] [CrossRef]

- Ge, Z.; Tawfek, A.M.; Zhang, H.; Yang, Y.; Yuan, H.; Sun, R.; Wang, Z. Influence of an extrusion approach on the fiber orientation and mechanical properties of engineering cementitious composite. Constr. Build. Mater. 2021, 306, 124876. [Google Scholar] [CrossRef]

| 28-Day Strength (MPa) | Water (kg/m3) | Cement (kg/m3) | Fly Ash (kg/m3) | Water/Binder Ratio | Fly Ash/Binder Ratio | CO2 Emissions (kg/m3) |

|---|---|---|---|---|---|---|

| 30 | 160 | 149.12 | 182.25 | 0.48 | 0.55 | 142.32 |

| 40 | 185.32 | 226.51 | 0.39 | 0.55 | 176.88 | |

| 50 | 221.53 | 270.76 | 0.33 | 0.55 | 211.44 |

| 28-Day Strength (MPa) | Water (kg/m3) | Cement (kg/m3) | Fly Ash (kg/m3) | Water/Binder Ratio | Fly Ash/Binder Ratio | CO2 Emissions (kg/m3) |

|---|---|---|---|---|---|---|

| 30 | 170 | 158.44 | 193.64 | 0.48 | 0.55 | 151.22 |

| 40 | 196.91 | 240.66 | 0.39 | 0.55 | 187.94 | |

| 50 | 235.38 | 287.68 | 0.33 | 0.55 | 224.65 |

| 28-Day Strength (MPa) | Water (kg/m3) | Cement (kg/m3) | Fly Ash (kg/m3) | Fly Ash/Binder Ratio | Water/Binder Ratio | CO2 Emissions (kg/m3) |

|---|---|---|---|---|---|---|

| 55 | 160 | 269.81 | 12.53 | 0.044 | 0.566 | 253.43 |

| 170 | 286.67 | 13.31 | 0.044 | 0.566 | 269.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Lin, R.-S.; Wang, X.-Y. Compressive Strength Estimation and CO2 Reduction Design of Fly Ash Composite Concrete. Buildings 2022, 12, 139. https://doi.org/10.3390/buildings12020139

Han Y, Lin R-S, Wang X-Y. Compressive Strength Estimation and CO2 Reduction Design of Fly Ash Composite Concrete. Buildings. 2022; 12(2):139. https://doi.org/10.3390/buildings12020139

Chicago/Turabian StyleHan, Yi, Run-Sheng Lin, and Xiao-Yong Wang. 2022. "Compressive Strength Estimation and CO2 Reduction Design of Fly Ash Composite Concrete" Buildings 12, no. 2: 139. https://doi.org/10.3390/buildings12020139

APA StyleHan, Y., Lin, R.-S., & Wang, X.-Y. (2022). Compressive Strength Estimation and CO2 Reduction Design of Fly Ash Composite Concrete. Buildings, 12(2), 139. https://doi.org/10.3390/buildings12020139