Compressive Behavior of Interlocking Plastic Blocks Structural Elements Having Slenderness

Abstract

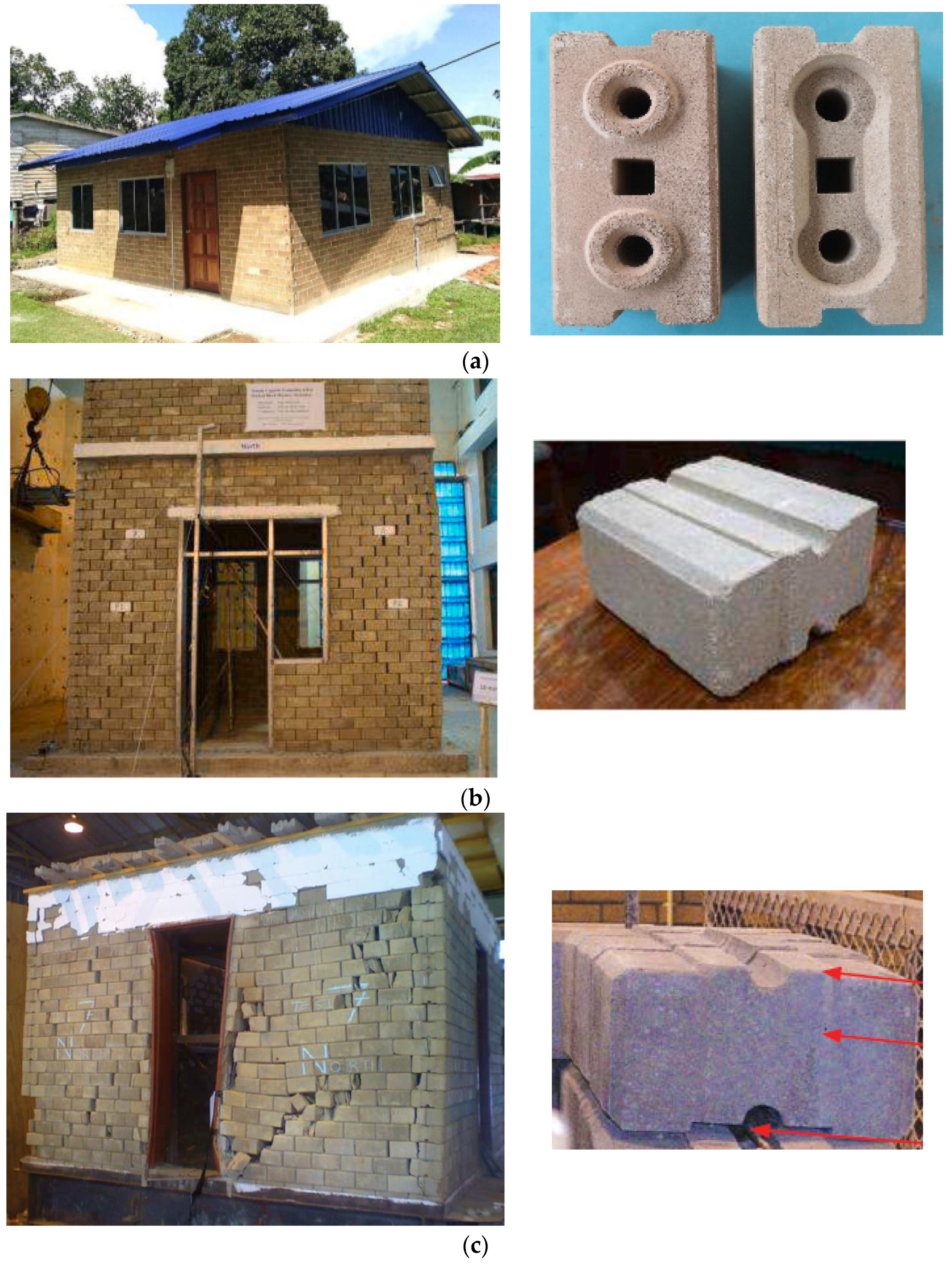

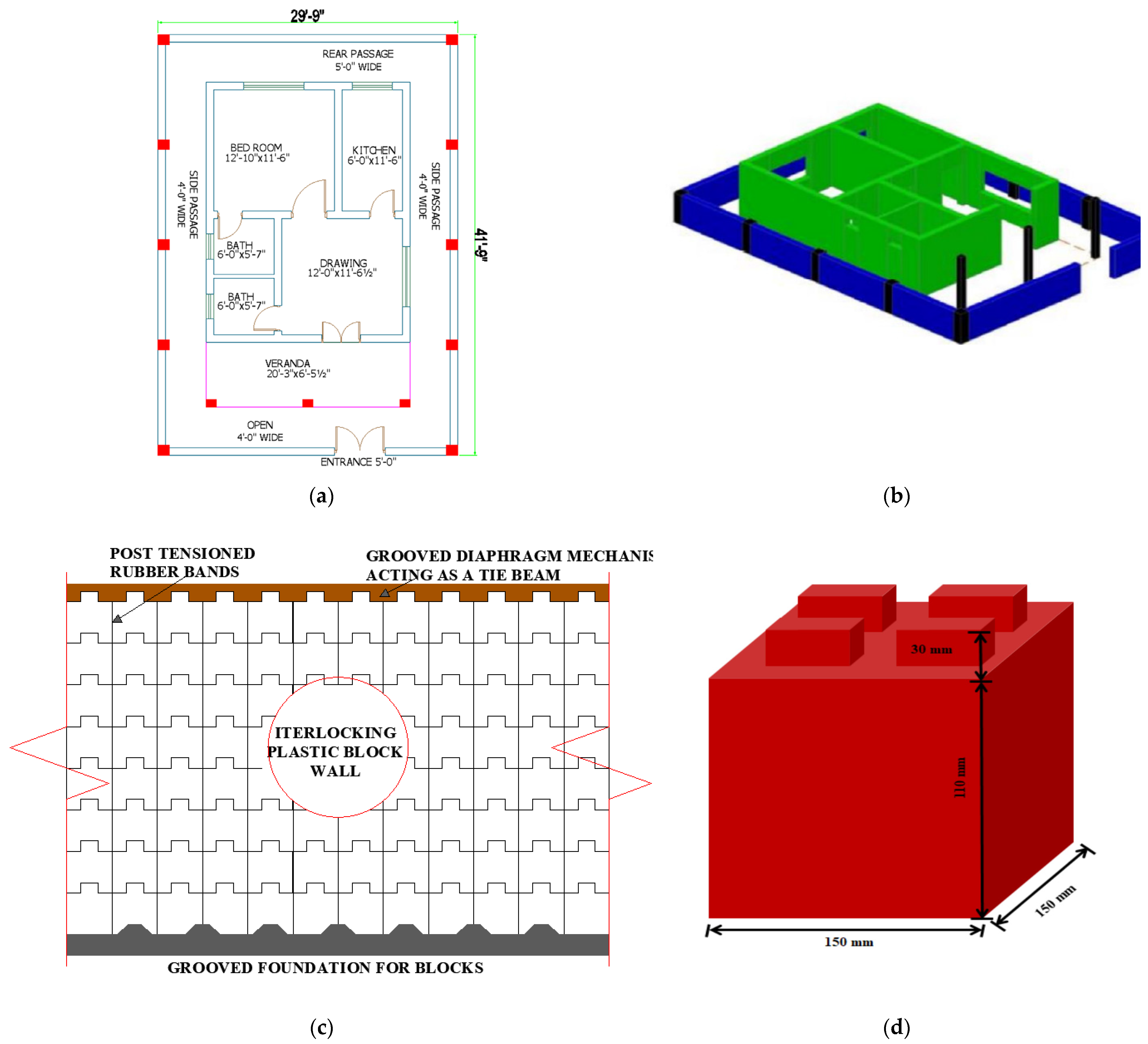

:1. Introduction

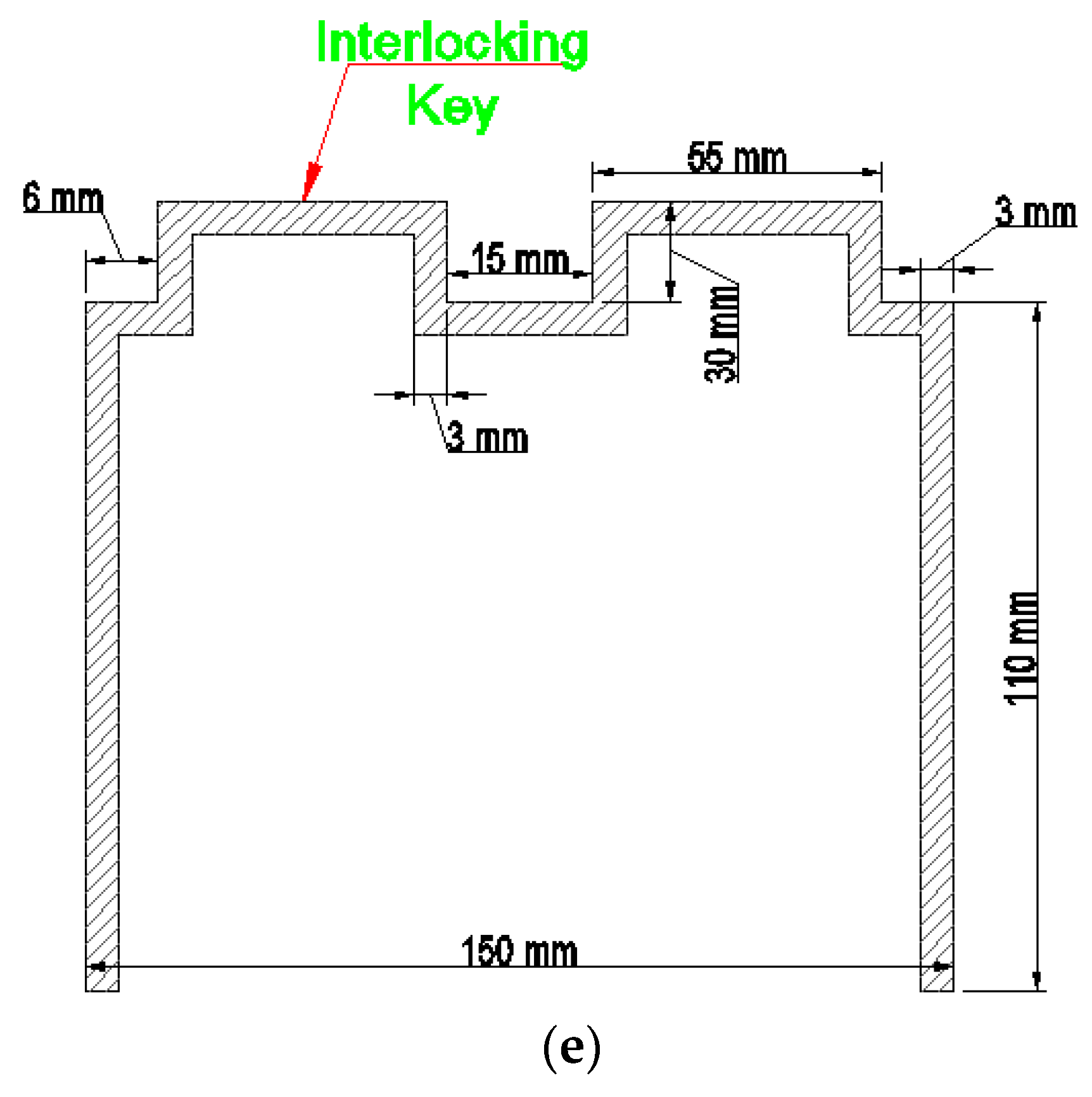

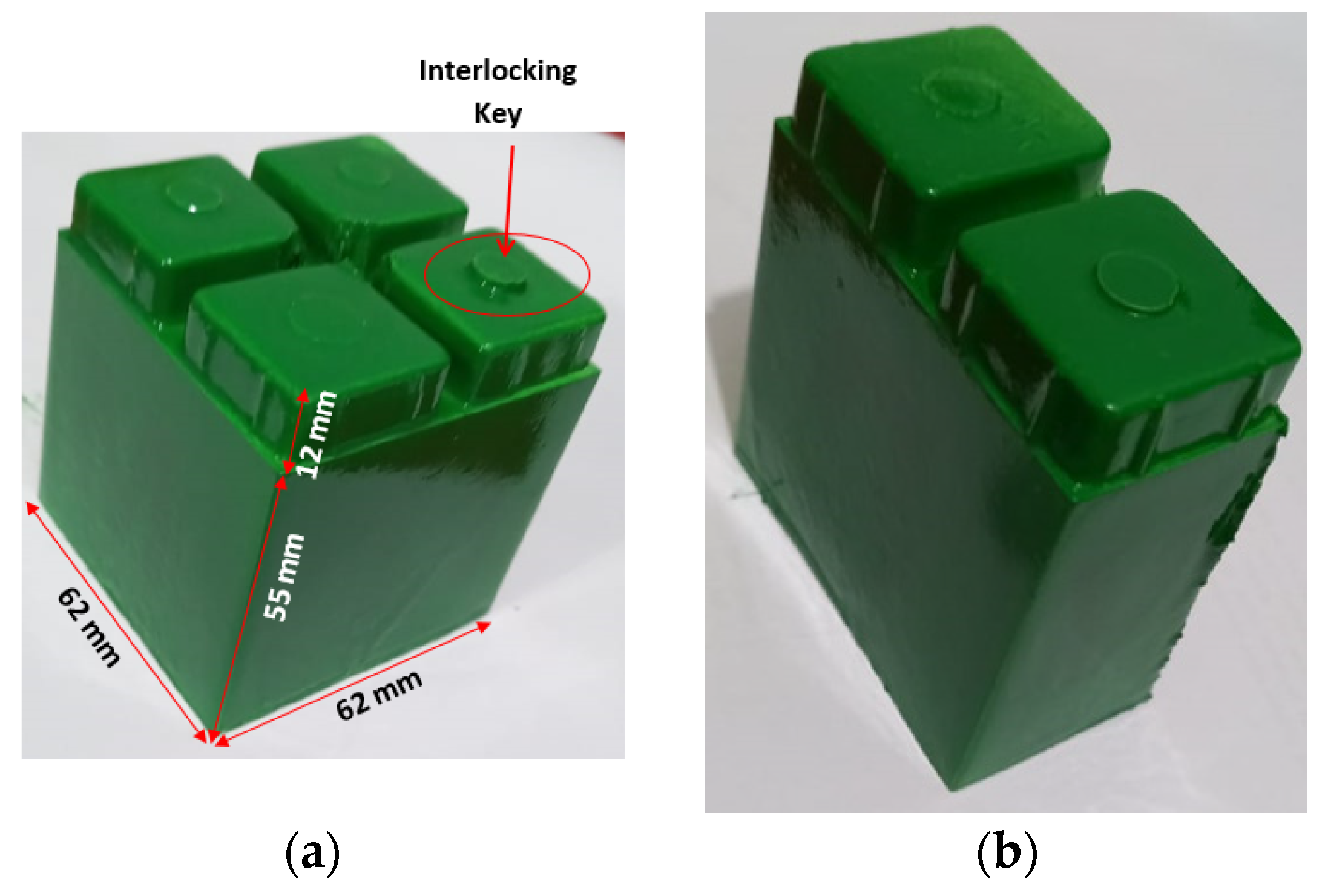

2. Experimental Work

2.1. Construction of Scaled-Down Prototypes of Structural Elements

2.2. Test Setups

2.3. Evaluated Parameters

3. Results

3.1. Compressive Behavior

3.2. Stress–Strain Curves

3.3. Energy Absorption and Toughness Index

4. Correlations for Comparison

4.1. Correlation between Load Carrying Capacities of One and Two-Block-Wide Structural Elements

4.2. Correlation between the Load Carrying Capacities of Solid Walls and Walls with Openings

5. Conclusions

- 1

- The one-block-wide structural elements experience sudden failure, unlike two-block-wide structural elements.

- 2

- The maximum stress of the two-block-wide structural elements, i.e., the solid wall and wall with an opening, were higher than those of the one-block-wide structural elements by 30% and 50%, respectively. However, in the case of columns, this phenomenon was not repeated.

- 3

- The energy absorption quantities of two-block-wide structural elements, i.e., the column, solid wall, and wall with an opening, were higher as compared to one-block-wide structural elements by 74%, 35%, and 84%, respectively.

- 4

- Due to the slenderness effect, the peak load-carrying capacities of two-block-wide structural elements i.e., the column, solid wall, and wall with a door opening, were higher than the peak load-carrying capacities of one-block-wide structural elements by 53%, 6%, and 70%, respectively.

- 5

- The peak load-carrying capacities of the one and two-block-wide solid walls were higher than the peak load-carrying capacities of the one and two-block-wide walls with openings by 73% and 68%, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Javan, A.R.; Seifi, H.; Xu, S.; Lin, X.; Xie, Y. Impact behaviour of plate-like assemblies made of new and existing interlocking bricks: A comparative study. Int. J. Impact Eng. 2018, 116, 79–93. [Google Scholar] [CrossRef]

- Sohn, H.; Farrar, C.R.; Hemez, F.M.; Czarnecki, J.J. A Review of Structural Health Review of Structural Health Monitoring Literature 1996–2001. In Proceedings of the Third World Conference on Structural Control, Como, Italy, 7–12 April 2002. [Google Scholar]

- Bilgin, H.; Shkodrani, N.; Hysenlliu, M.; Ozmen, H.B.; Isik, E.; Harirchian, E. Damage and performance evaluation of masonry buildings constructed in 1970s during the 2019 Albania earthquakes. Eng. Fail. Anal. 2022, 131, 105824. [Google Scholar] [CrossRef]

- Saretta, Y.; Sbrogio, L.; Valluzzi, M.R. Seismic response of masonry buildings in historical centres struck by the 2016 Central Italy earthquake. Calibration of a vulnerability model for strengthened conditions. Constr. Build. Mater. 2021, 299, 123911. [Google Scholar] [CrossRef]

- Zucconi, M.; Sorrentino, L. Census-Based Typological Damage Fragility Curves and Seismic Risk Scenarios for Unreinforced Masonry Buildings. Geosciences 2022, 12, 45. [Google Scholar] [CrossRef]

- Derakhshan, H.; Walsh, K.Q.; Ingham, J.M.; Griffith, M.C.; Thambiratnam, D.P. Seismic fragility assessment of nonstructural components in unreinforced clay brick masonry buildings. Earthq. Eng. Struct. Dyn. 2020, 49, 285–300. [Google Scholar] [CrossRef]

- Lulić, L.; Ožić, K.; Kišiček, T.; Hafner, I.; Stepinac, M. Post-earthquake damage assessment—Case study of the educational building after the Zagreb earthquake. Sustainability 2021, 13, 6353. [Google Scholar] [CrossRef]

- Gautam, D.; Chettri, N.; Tempa, K.; Rodrigues, H.; Rupakhety, R. Seismic vulnerability of bhutanese vernacular stone masonry buildings: From damage observation to fragility analysis. Soil Dyn. Earthq. Eng. 2022, 160, 107351. [Google Scholar] [CrossRef]

- Edgell, G. The remarkable structures of Paul Cottancin. Struct. Eng. A 1985, 63, 201–207. [Google Scholar]

- Abrams, D.P. Seismic response patterns for URM buildings. TMS J. 2000, 18, 71–78. [Google Scholar]

- Thanoon, W.A.; Jaafar, M.; Noorzaei, J.; Kadir, M.R.A.; Fares, S. Structural behaviour of mortar-less interlocking masonry system under eccentric compressive loads. Adv. Struct. Eng. 2007, 10, 11–24. [Google Scholar] [CrossRef]

- Dias, J.L.M. Cracking due to shear in masonry mortar joints and around the interface between masonry walls and reinforced concrete beams. Constr. Build. Mater. 2007, 21, 446–457. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.; Briet, R.; Chouw, N. Dynamic response of mortar-free interlocking structures. Constr. Build. Mater. 2013, 42, 168–189. [Google Scholar] [CrossRef]

- Fundi, S.I.; Kaluli, J.; Kinuthia, J. Performance of interlocking laterite soil block walls under static loading. Constr. Build. Mater. 2018, 171, 75–82. [Google Scholar] [CrossRef]

- Jaafar, M.S.; Thanoon, W.A.; Najm, A.M.; Abdulkadir, M.R.; Ali, A.A.A. Strength correlation between individual block, prism and basic wall panel for load bearing interlocking mortarless hollow block masonry. Constr. Build. Mater. 2006, 20, 492–498. [Google Scholar] [CrossRef]

- Zahra, T.; Dhanasekar, M. Characterisation and strategies for mitigation of the contact surface unevenness in dry-stack masonry. Constr. Build. Mater. 2018, 169, 612–628. [Google Scholar] [CrossRef]

- Martínez, M.; Atamturktur, S. Experimental and numerical evaluation of reinforced dry-stacked concrete masonry walls. J. Build. Eng. 2019, 22, 181–191. [Google Scholar] [CrossRef]

- Ahmad, S.; Hussain, S.; Awais, M.; Asif, M.; Muzamil, H.; Ahmad, R.; Ahmad, S. To study the behavior of interlocking of masonry units/blocks. IOSR J. Eng. 2014, 4, 39–47. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, X.; Hao, H.; Bi, K.; Lin, Y. Response of reinforced mortar-less interlocking brick wall under seismic loading. Bull. Earthq. Eng. 2022, 20, 6129–6165. [Google Scholar] [CrossRef]

- Leite, J.; Lourenço, P.B.; Mendes, N. Design Proposal for Masonry Infill Walls Subject to Seismic Actions. Appl. Sci. 2022, 12, 503. [Google Scholar] [CrossRef]

- Khan, F.; Ali, M. Behavior of interlocking plastic-block structure under harmonic loading using locally developed low-cost shake table. In Proceedings of the Annual Australian Earthquake Engineering Society Conference, Perth, Western Australia, 16–18 November 2018; p. 51. [Google Scholar]

- Sudheer, M.; Ali, M. Behaviour of interlocking block structures under dynamic loading: A review. In Proceedings of the 2nd International Conference on Sustainable Development in Civil Engineering, MUET, Jamshoro, Pakistan, 5–7 December 2019; p. 231. [Google Scholar]

- Al-Fakih, A.; Wahab, M.A.; Mohammed, B.S.; Liew, M.; Zawawi, N.A.W.A.; As’ad, S. Experimental study on axial compressive behavior of rubberized interlocking masonry walls. J. Build. Eng. 2020, 29, 101107. [Google Scholar] [CrossRef]

- Ali, M.; Gultom, R.J.; Chouw, N. Capacity of innovative interlocking blocks under monotonic loading. Constr. Build. Mater. 2012, 37, 812–821. [Google Scholar] [CrossRef]

- Misir, I.S.; Yucel, G.; Kuran, F.; Eser, C.B.; Aldemir, O.; Topcu, S. Experimental out-of-plane damage limits of historical stone masonry walls. Constr. Build. Mater. 2022, 333, 127098. [Google Scholar] [CrossRef]

- Sturm, T.; Ramos, L.F.; Lourenço, P.B. Characterization of dry-stack interlocking compressed earth blocks. Mater. Struct. 2015, 48, 3059–3074. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Li, Y.; Zheng, N.; Ingham, J.M. Testing and modelling the in-plane seismic response of clay brick masonry walls with boundary columns made of precast concrete interlocking blocks. Eng. Struct. 2017, 131, 513–529. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Kunhanandan Nambiar, E. Accelerated masonry construction review and future prospects. Prog. Struct. Eng. Mater. 2004, 6, 1–9. [Google Scholar] [CrossRef]

- Casapulla, C.; Mousavian, E.; Argiento, L.; Ceraldi, C.; Bagi, K. Torsion-shear behaviour at the interfaces of rigid interlocking blocks in masonry assemblages: Experimental investigation and analytical approaches. Mater. Struct. 2021, 54, 134. [Google Scholar] [CrossRef]

- Asman, N.; Bolong, N.; Mirasa, A.; Asrah, H.; Saad, I. Interlocking compressed earth bricks as low carbon footprint building material. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012086. [Google Scholar] [CrossRef]

- Gul, A.; Alam, B.; Shahzada, K. Seismic performance evaluation of unconfined dry stacked block masonry structure. Eng. Struct. 2022, 265, 114529. [Google Scholar] [CrossRef]

- Elvin, A.; Uzoegbo, H. Response of a full-scale dry-stack masonry structure subject to experimentally applied earthquake loading. J. South Afr. Inst. Civ. Eng. J. Van Die Suid-Afrik. Inst. Van Siviele Ing. 2011, 53, 22–32. [Google Scholar]

- Sarhosis, V.; Garrity, S.; Sheng, Y. Influence of brick–mortar interface on the mechanical behaviour of low bond strength masonry brickwork lintels. Eng. Struct. 2015, 88, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Tang, Z.; Ali, M.; Chouw, N. Residual compressive and shear strengths of novel coconut-fibre-reinforced-concrete interlocking blocks. Constr. Build. Mater. 2014, 66, 533–540. [Google Scholar] [CrossRef]

- Müller, D.; Bujotzek, L.; Proske, T.; Graubner, C.-A. Influence of spatially variable material properties on the resistance of masonry walls under compression. Mater. Struct. 2022, 55, 84. [Google Scholar] [CrossRef]

- Fu, G.; Fu, G.; Yu, C.; Li, S.; Wang, F.; Yang, J. Behaviour of rectangular concrete-filled steel tubular slender column with unequal wall thickness. Eng. Struct. 2021, 236, 112100. [Google Scholar] [CrossRef]

- Hube, M.; Marihuén, A.; de la Llera, J.C.; Stojadinovic, B. Seismic behavior of slender reinforced concrete walls. Eng. Struct. 2014, 80, 377–388. [Google Scholar] [CrossRef]

- Zahra, T.; Asad, M.; Thamboo, J. Effect of geometry on the compression characteristics of bonded brickwork. Structures 2021, 32, 1408–1419. [Google Scholar] [CrossRef]

- Qamar, F.; Qin, S. Development of Nonlinear Finite Element Models of Mortar-Free Interlocked Single Block Column Subjected to Lateral Loading. Arab. J. Sci. Eng. 2021, 46, 11047–11062. [Google Scholar] [CrossRef]

- Aslam, M.S. Compressive Behavior of Interlocking Plastic Block Structural Elements. Master’s Thesis, Department of Civil Engineering, Capital University of Science & Technology, Islamabad, Pakistan, 2021. [Google Scholar]

- Keivan, A.; Zhang, R.; Keivan, D.; Phillips, B.M.; Ikenaga, M.; Ikago, K. Rate-independent linear damping for the improved seismic performance of inter-story isolated structures. J. Earthq. Eng. 2022, 26, 793–816. [Google Scholar] [CrossRef]

- Khan, F. Dynamic Behavior of Prototype Interlocking Plastic-Block Structure Using Locally Developed Low-Cost Shake Table. Master’s Thesis, Department of Civil Engineering, Capital University of Science & Technology,, Islamabad, Pakistan, 2019. [Google Scholar]

- Sandoval, C.; Roca, P.; Bernat, E.; Gil, L. Testing and numerical modelling of buckling failure of masonry walls. Constr. Build. Mater. 2011, 25, 4394–4402. [Google Scholar] [CrossRef]

| Sr. No. | Interlocking Plastic Block Structural Elements | Label |

|---|---|---|

| 1 | One-Block-Wide Column | Psc |

| 2 | Two-Block-Wide Column | Pdc |

| 3 | One-Block-Wide Solid Wall | Pssw |

| 4 | Two-Block-Wide Solid Wall | Pdsw |

| 5 | One-Block-Wide Wall With Door Opening | Pswo |

| 6 | Two-Block-Wide Wall With Door Opening | Pdwo |

| Sr. No | Structural Element | Peak Load kN | Stress σ MPa | Strain ε (10−3) | Modulus of Elasticity GPa | Energy Absorbed Upto Peak Load (E1) (10−3 Nm) | Energy Absorbed after Peak Load (E2) (10−3 Nm) | Total Energy Absorbed (ET) (10−3 Nm) | Toughness Index (TI) (ET/E1) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | One-Block-Wide Column | 1.3 | 3.85 | 1.7 | 176.674 | 4.81 | 0.24 | 5.06 | 1.05 |

| 2 | Two-Block-Wide Column | 2.8 | 2.28 | 32.1 | 120.694 | 13.71 | 42.35 | 56.07 | 4.09 |

| 3 | One-Block-Wide Solid Wall | 4.1 | 0.94 | 57 | 22.279 | 6.18 | 23.42 | 29.61 | 4.79 |

| 4 | Two-Block-Wide Solid Wall | 11.7 | 1.36 | 68.3 | 13.552 | 26.32 | 19.22 | 45.55 | 1.73 |

| 5 | One-Block-Wide Wall With Opening | 1.1 | 0.39 | 20.1 | 37.675 | 1.26 | 3.83 | 5.11 | 4.02 |

| 6 | Two-Block-Wide Wall With Opening | 3.7 | 0.68 | 2.4 | 18.837 | 7.54 | 24.12 | 31.67 | 4.20 |

| Sr. No. | Structural Element | Correlation | In Terms of |

|---|---|---|---|

| 1 | Two-Block-Wide Column | One-Block-Wide Column | Pdc = 2.2 Psc |

| 2 | One-Block-Wide Solid Wall | One-Block-Wide Solid Wall | Pdsw = 2.9 Pssw |

| 3 | Two-Block-Wide Wall with Opening | One-Block-Wide Wall with Opening | Pdwo = 3.5 Pswo |

| Sr. No. | Structural Element | Correlation | In Terms of |

|---|---|---|---|

| 1 | One-Block-Wide Solid Wall | One-Block-Wide Wall with Opening | Pssw = 3.8 Pswo |

| 2 | Two-Block-Wide Solid Wall | Two-Block-Wide Wall with Opening | Pdsw = 3.2 Pdwo |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adnan, M.; Khalid, F.; Ali, M. Compressive Behavior of Interlocking Plastic Blocks Structural Elements Having Slenderness. Buildings 2022, 12, 2257. https://doi.org/10.3390/buildings12122257

Adnan M, Khalid F, Ali M. Compressive Behavior of Interlocking Plastic Blocks Structural Elements Having Slenderness. Buildings. 2022; 12(12):2257. https://doi.org/10.3390/buildings12122257

Chicago/Turabian StyleAdnan, Muhammad, Faiza Khalid, and Majid Ali. 2022. "Compressive Behavior of Interlocking Plastic Blocks Structural Elements Having Slenderness" Buildings 12, no. 12: 2257. https://doi.org/10.3390/buildings12122257

APA StyleAdnan, M., Khalid, F., & Ali, M. (2022). Compressive Behavior of Interlocking Plastic Blocks Structural Elements Having Slenderness. Buildings, 12(12), 2257. https://doi.org/10.3390/buildings12122257