Strength Design of Ultra-High-Performance Fiber-Reinforced Cementitious Composites Using Local Ecological Admixture

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Mix Proportion

2.2. Mix Procedure

2.3. Test Methods

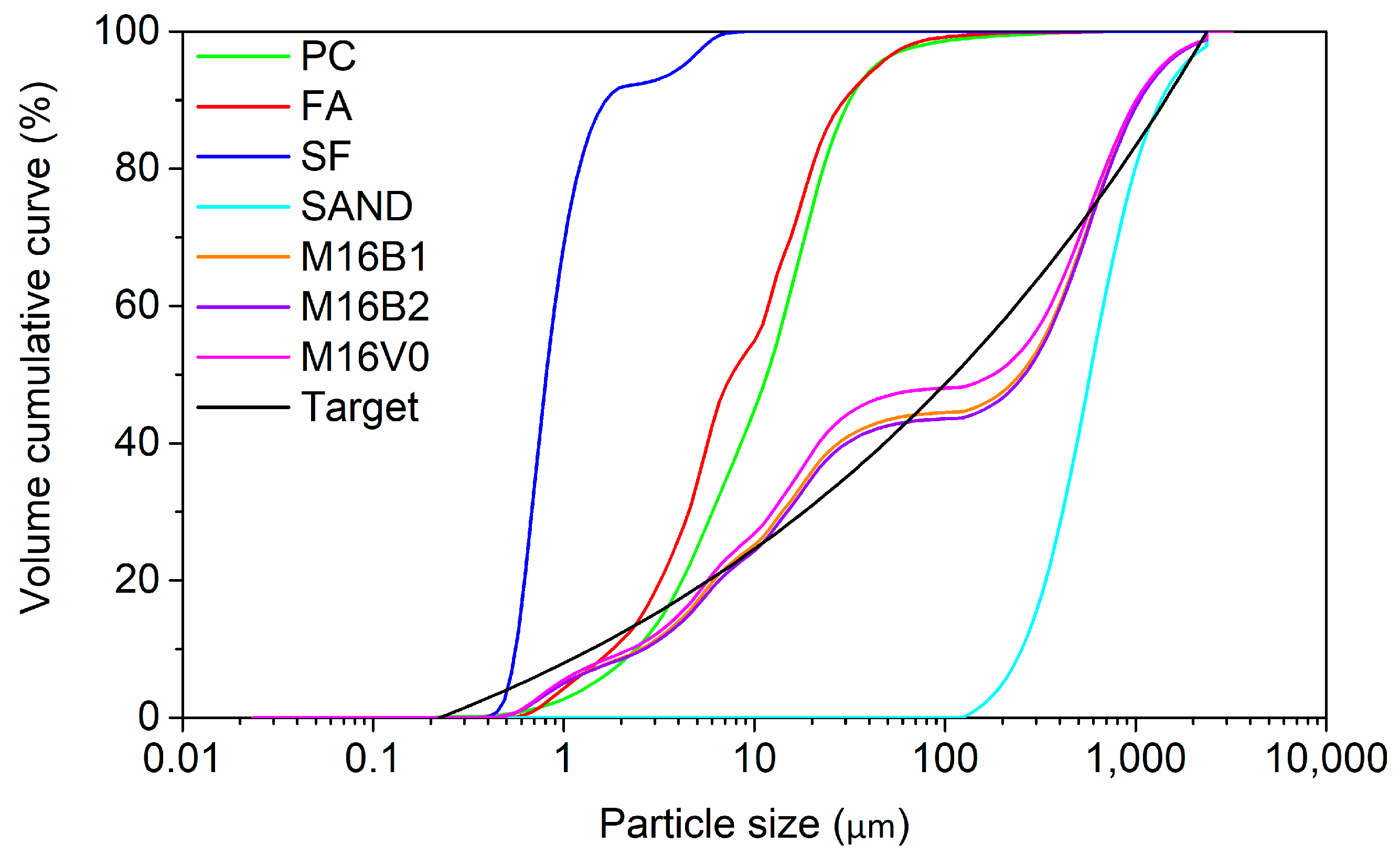

2.3.1. Particle-Size Distribution

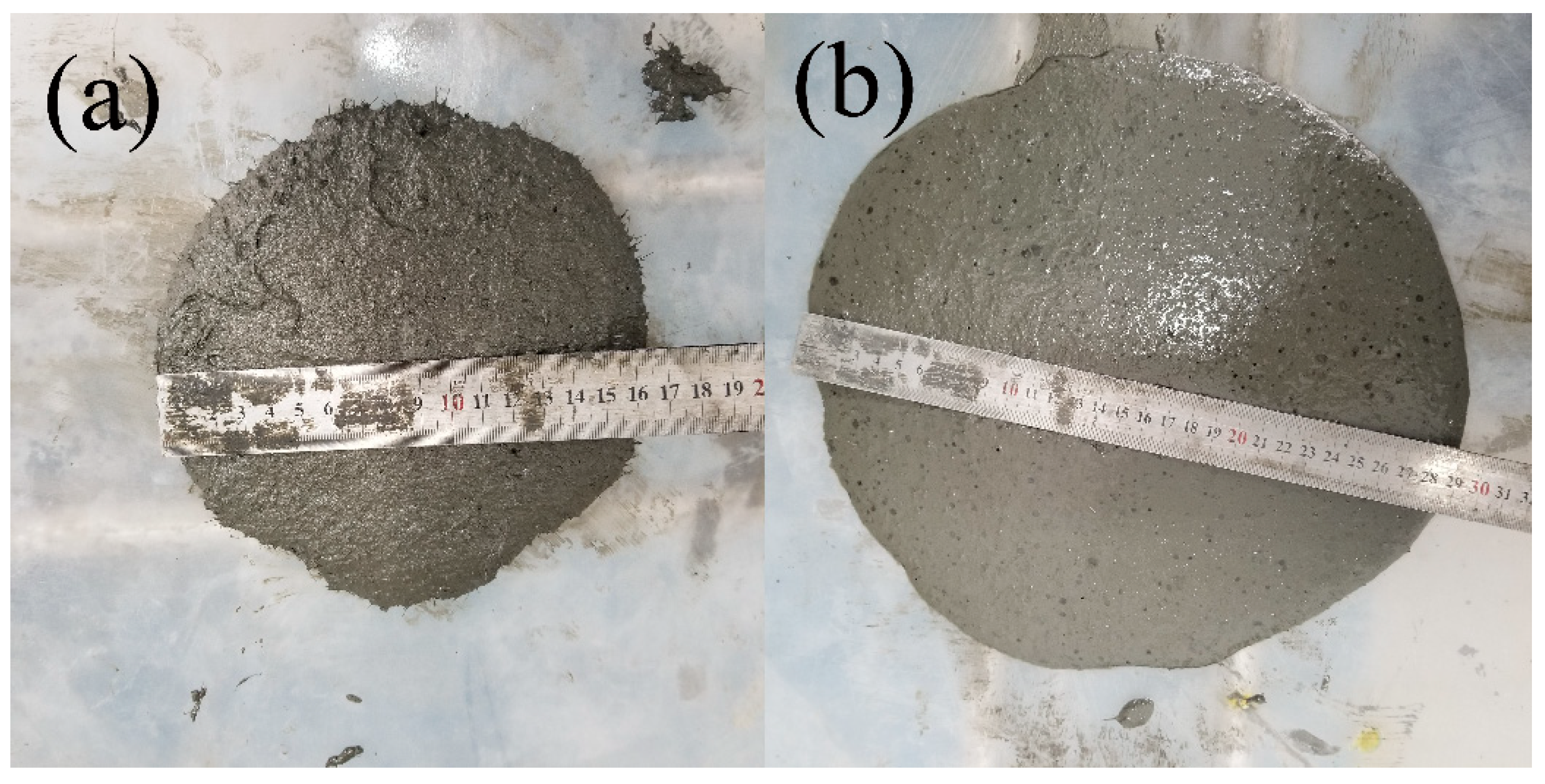

2.3.2. Flowability of Fresh UHPFRC

2.3.3. Mechanical Strength

2.3.4. Hydration Products

2.3.5. Morphology

3. Results and Discussion

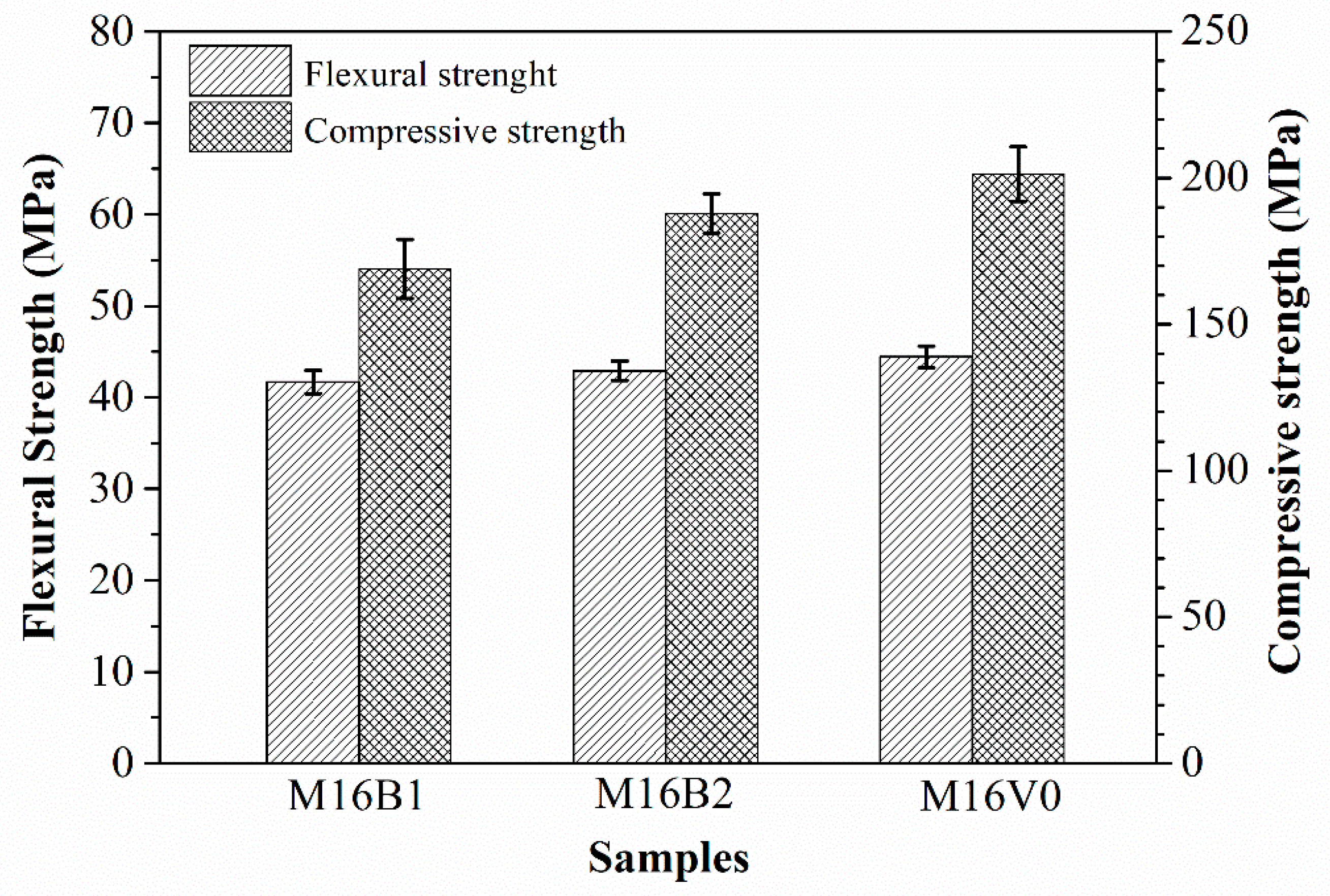

3.1. Raw-Materials Proportion

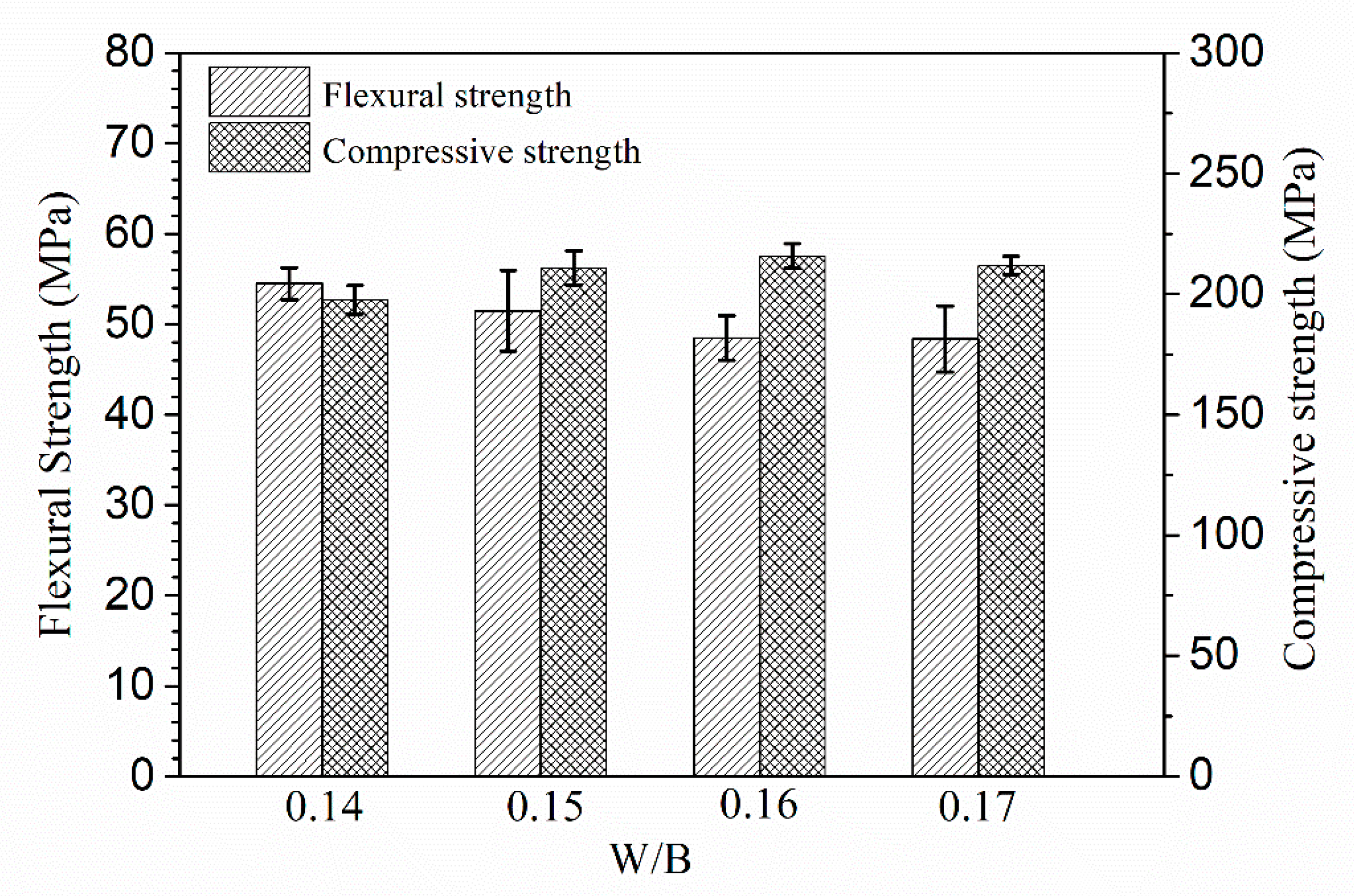

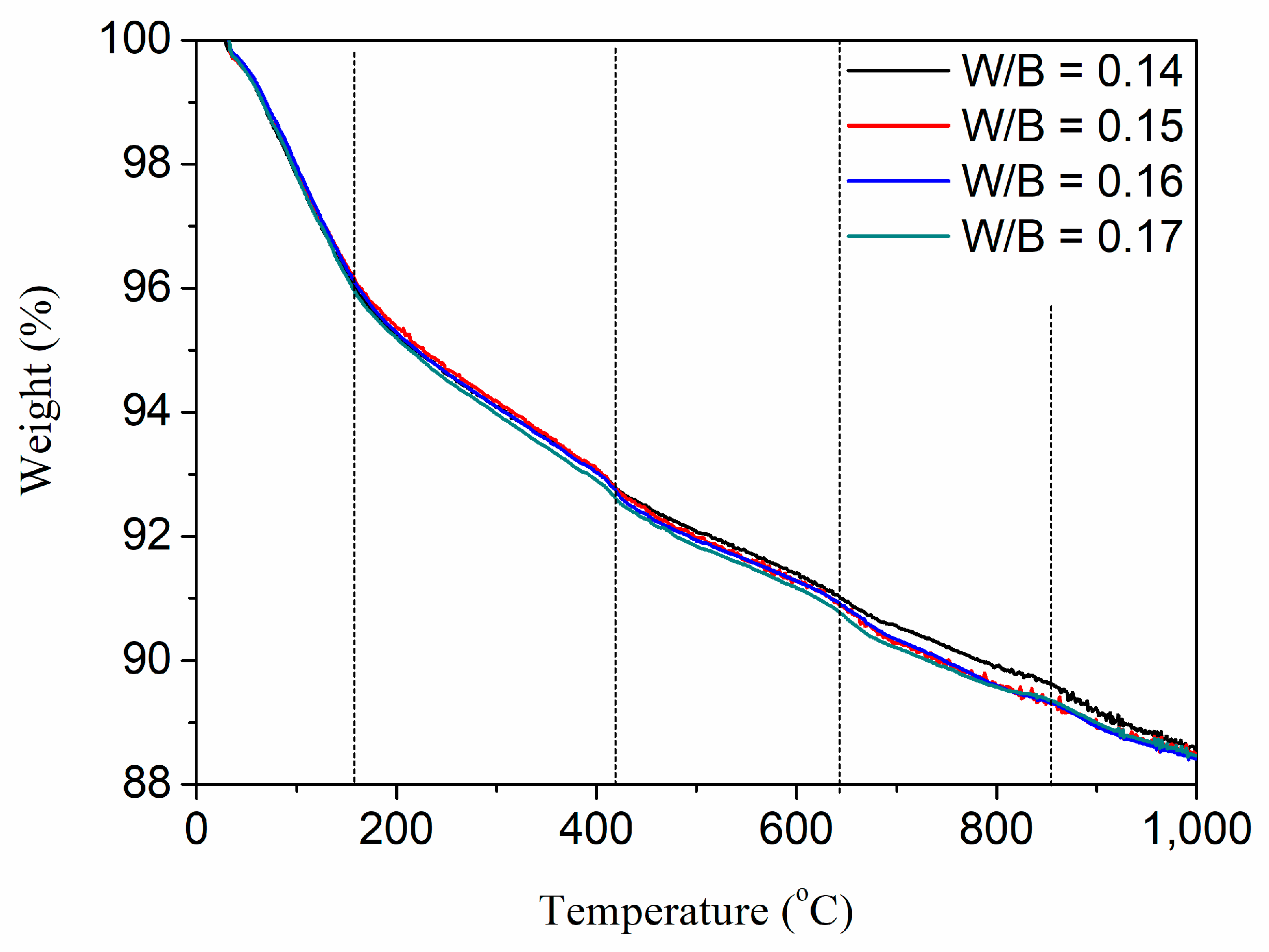

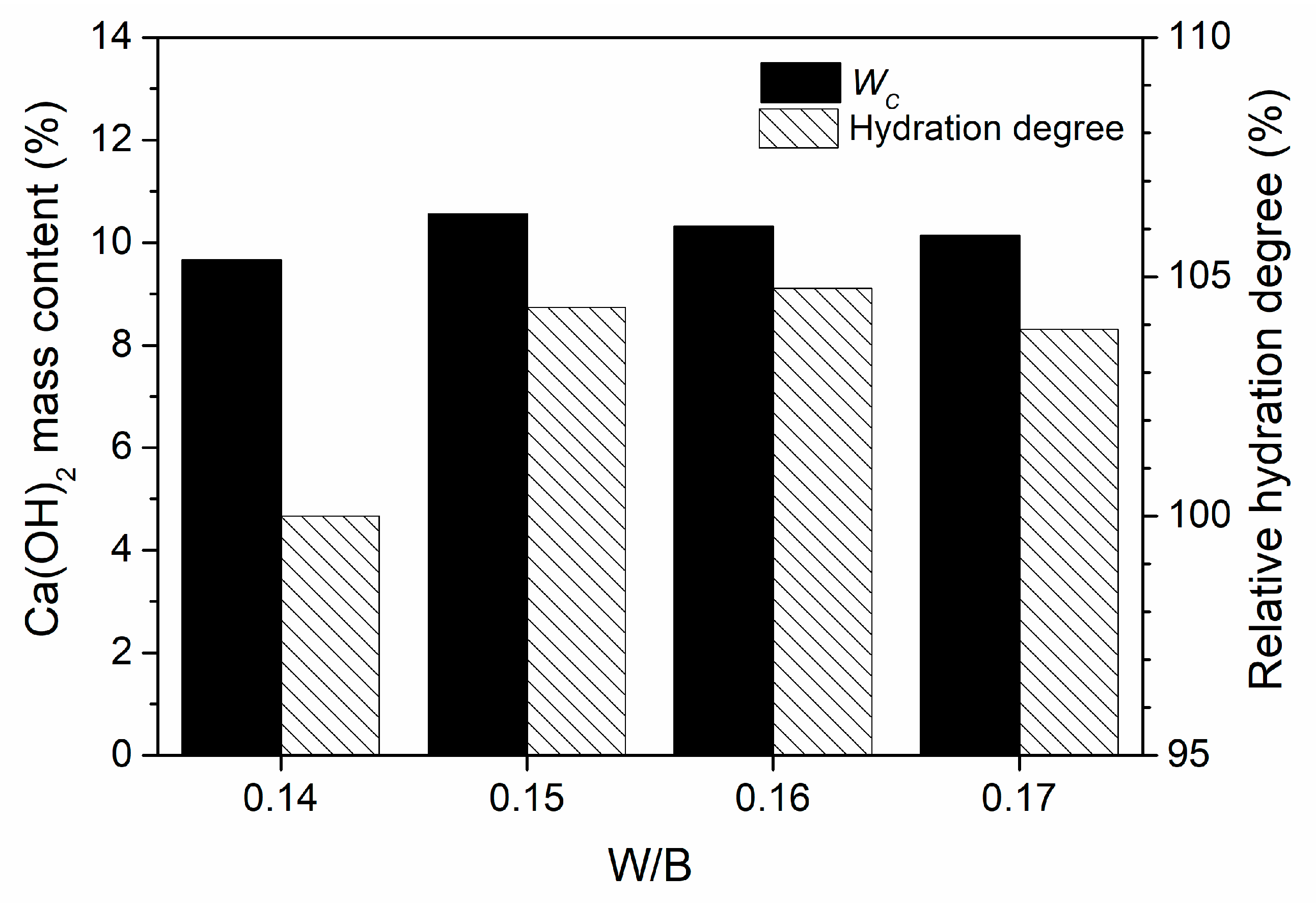

3.2. Water-to-Binder Ratio

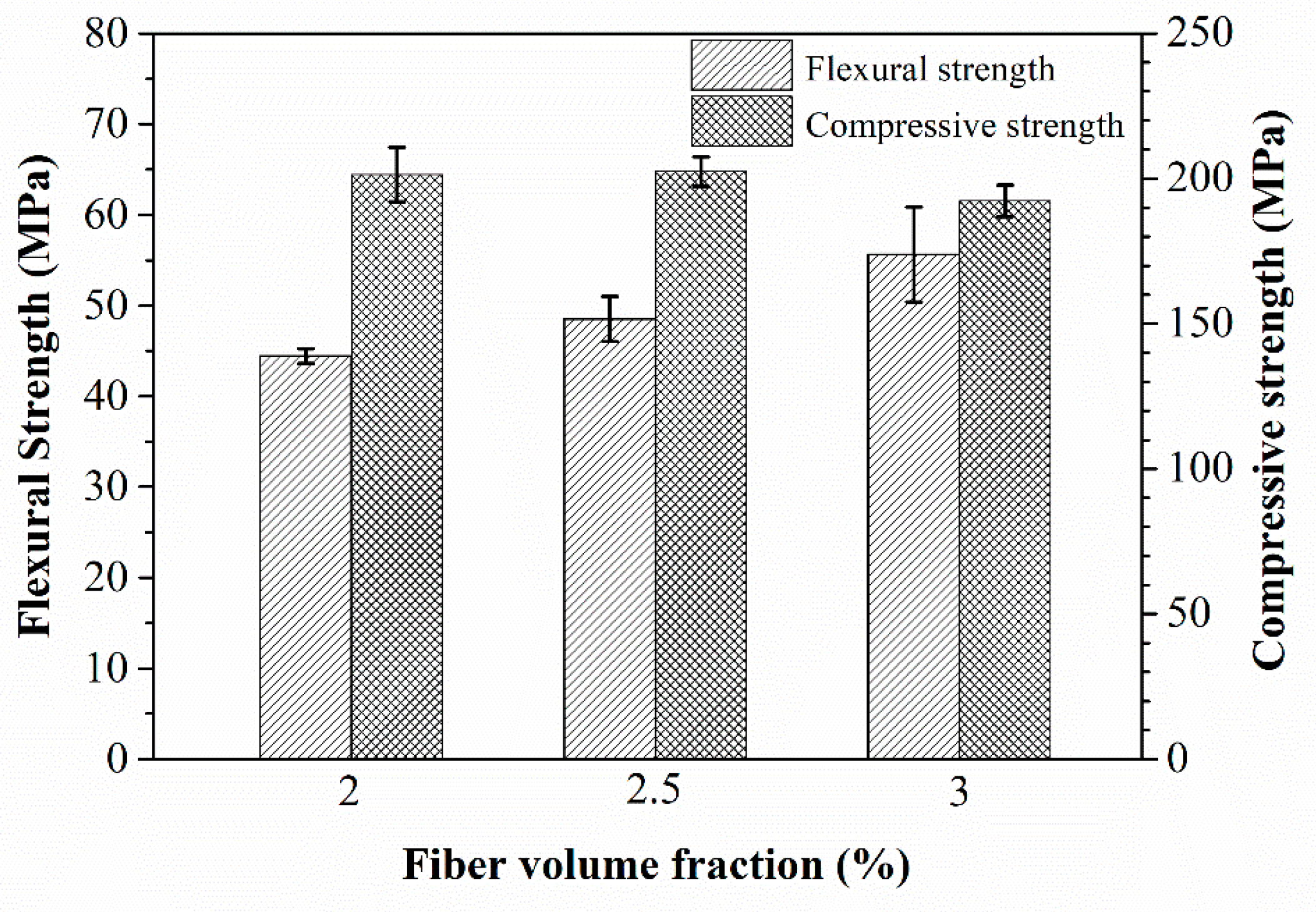

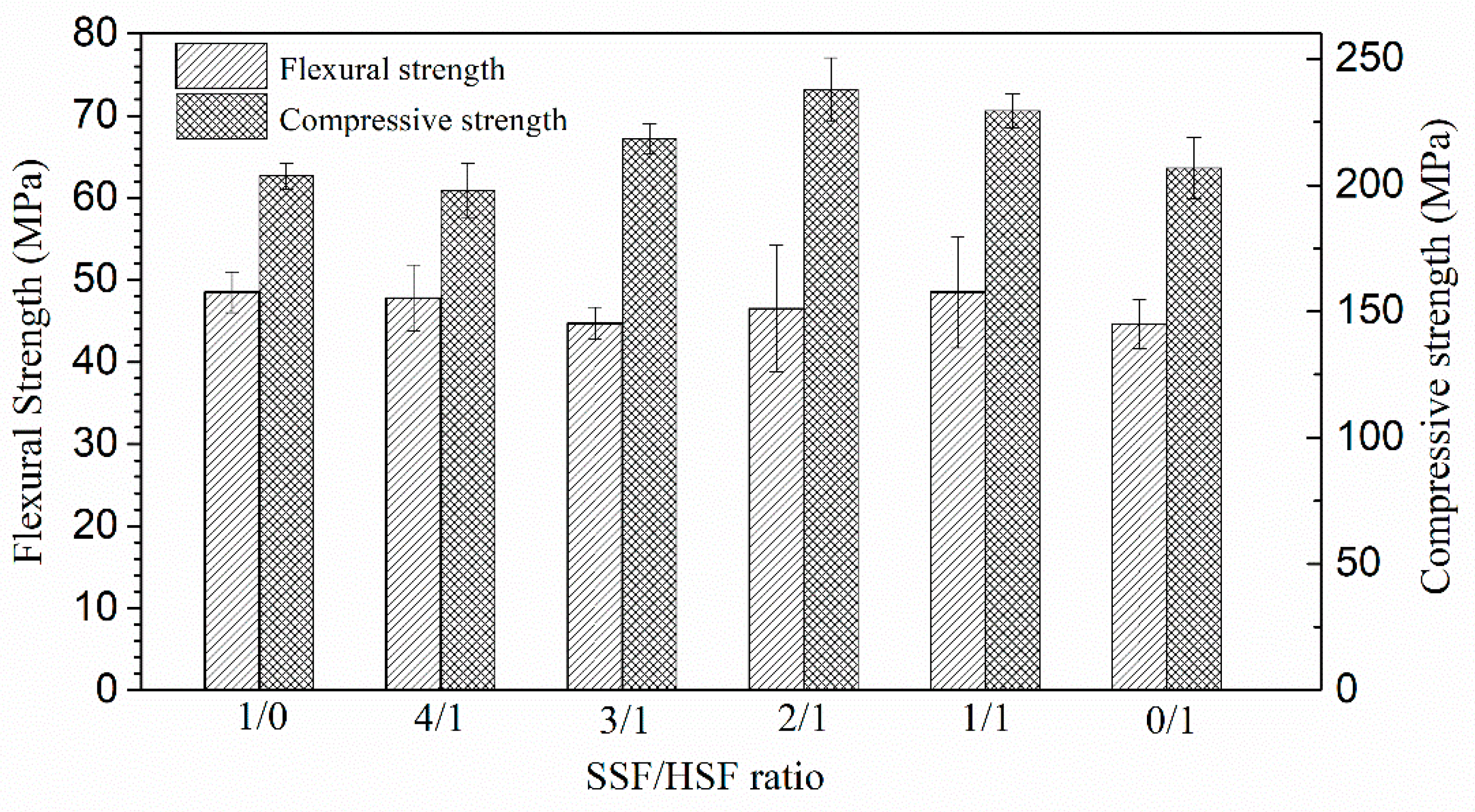

3.3. Fiber Content and Fiber Geometry

3.4. The Effect Efficiency Index F

4. Conclusions

- (1)

- With a high range of substitution materials, the compressive strength of UHPFRC was beyond 180 MPa, and the maximum strength reached 237.8 MPa after 7 days of steam curing.

- (2)

- The powder proportion played the key role in strength development. The strength increased with the synergetic effect of compact packing and high activity of binders.

- (3)

- The fiber content was more efficient for flexural strength. Additionally, the compressive strength was more sensitively with the ratio of HSF, which performed well with high adhesion strength. However, the massive usage of fiber and HSF brought distribution problems that decreased the compressive strength.

- (4)

- The W/B ratio ranged from 0.14 to 0.17 and was hesitated for use with compressive strength in practical applications. High W/B ratio was preferred to improve the flowability and increase the hydration degree but also induced more pores and cracks when water was consumed.

- (5)

- The significance of different materials’ aspects on compressive strength was evaluated by the F-value with the ANOVA method, and powder proportion was most important in the strength design of UHPFRC.

Author Contributions

Funding

Conflicts of Interest

References

- Al Nuaimi, N.; Sohail, M.G.; Hawileh, R.A.; Abdalla, J.A.; Douier, K. Durability of reinforced concrete beams strengthened by galvanized steel mesh-epoxy systems under harsh environmental conditions. Compos. Struct. 2020, 249, 112547. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Shi, C.; Zhu, D.; Li, N.; Deng, Y. Development of ultra-high performance geopolymer concrete (UHPGC): Influence of steel fiber on mechanical properties. Cem. Concr. Compos. 2020, 112, 103670. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Huseien, G.F.; Abidin, A.R.Z.; Ismail, M. Long-term mechanical and durable properties of waste tires rubber crumbs replaced GBFS modified concretes. Constr. Build. Mater. 2020, 256, 119505. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Castel, A. Reinforcement corrosion in limestone flash calcined clay cement-based concrete. Cem. Concr. Res. 2020, 132, 106051. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Shin, W.; Chun, B.; Banthia, N. Assessment of steel fiber corrosion in self-healed ultra-high-performance fiber-reinforced concrete and its effect on tensile performance. Cem. Concr. Res. 2020, 133, 106091. [Google Scholar] [CrossRef]

- Li, P.; Sluijsmans, M.; Brouwers, H.; Yu, Q. Functionally graded ultra-high performance cementitious composite with enhanced impact properties. Compos. Part B Eng. 2020, 183, 107680. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Yuan, T.; Shin, H.-O.; Yoon, Y.-S. Strategic use of steel fibers and stirrups on enhancing impact resistance of ultra-high-performance fiber-reinforced concrete beams. Cem. Concr. Compos. 2020, 107, 103499. [Google Scholar] [CrossRef]

- Sharif, A.M.; Assi, N.A.; Al-Osta, M.A. Use of UHPC slab for continuous composite steel-concrete girders. Steel Compos. Struct. 2020, 34, 321–332. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B Eng. 2019, 174, 107021. [Google Scholar] [CrossRef]

- Zhou, Z.; Qiao, P. Durability of ultra-high performance concrete in tension under cold weather conditions. Cem. Concr. Compos. 2018, 94, 94–106. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and preparation of ultra-high performance concrete with low environmental impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

- Ganesh, P.; Murthy, A.R. Tensile behaviour and durability aspects of sustainable ultra-high performance concrete incorporated with GGBS as cementitious material. Constr. Build. Mater. 2019, 197, 667–680. [Google Scholar] [CrossRef]

- Vincler, J.P.; Sanchez, T.; Turgeon, V.; Conciatori, D.; Sorelli, L. A modified accelerated chloride migration tests for UHPC and UHPFRC with PVA and steel fibers. Cem. Concr. Res. 2019, 117, 38–44. [Google Scholar] [CrossRef]

- Zhu, J.-S.; Wang, Y.; Yan, J.-B.; Guo, X.-Y. Shear behaviour of steel-UHPC composite beams in waffle bridge deck. Compos. Struct. 2020, 234, 111678. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Liu, R.; Hao, C.; Cao, Z. Dynamic properties of a steel–UHPC composite deck with large U-ribs: Experimental measurement and numerical analysis. Eng. Struct. 2020, 213, 110569. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Chen, G. Flexural strengthening of reinforced concrete beams or slabs using ultra-high performance concrete (UHPC): A state of the art review. Eng. Struct. 2020, 205, 110035. [Google Scholar] [CrossRef]

- Farzad, M.; Sadeghnejad, A.; Rastkar, S.; Moshkforoush, A.; Azizinamini, A. A theoretical analysis of mechanical and durability enhancement of circular reinforced concrete columns repaired with UHPC. Eng. Struct. 2020, 209, 109928. [Google Scholar] [CrossRef]

- Ragalwar, K.; Heard, W.F.; Williams, B.A.; Ranade, R. Significance of the particle size distribution modulus for strain-hardening-ultra-high performance concrete (SH-UHPC) matrix design. Constr. Build. Mater. 2020, 234, 117423. [Google Scholar] [CrossRef]

- Norhasri, M.M.; Hamidah, M.; Fadzil, A.M. Inclusion of nano metaclayed as additive in ultra high performance concrete (UHPC). Constr. Build. Mater. 2019, 201, 590–598. [Google Scholar] [CrossRef]

- Arora, A.; Almujaddidi, A.; Kianmofrad, F.; Mobasher, B.; Neithalath, N. Material design of economical ultra-high performance concrete (UHPC) and evaluation of their properties. Cem. Concr. Compos. 2019, 104, 103346. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Tajasosi, S.; Tahmouresi, B. Effect of materials proportion on rheology and mechanical strength and microstructure of ultra-high performance concrete (UHPC). Constr. Build. Mater. 2018, 187, 1103–1112. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Sohail, M.G.; Wang, B.; Jain, A.; Kahraman, R.; Ozerkan, N.G.; Gencturk, B.; Dawood, M.; Belarbi, A. Advancements in Concrete Mix Designs: High-Performance and Ultrahigh-Performance Concretes from 1970 to 2016. J. Mater. Civ. Eng. 2018, 30, 04017310. [Google Scholar] [CrossRef]

- Chen, X.; Wan, D.-W.; Jin, L.-Z.; Qian, K.; Fu, F. Experimental studies and microstructure analysis for ultra high-performance reactive powder concrete. Constr. Build. Mater. 2019, 229, 116924. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Han, J.; Lin, G.; Qian, D.; Liu, Z.; He, Y. Environmental and economical friendly ultra-high performance-concrete incorporating appropriate quarry-stone powders. J. Clean. Prod. 2020, 260, 121112. [Google Scholar] [CrossRef]

- Dong, Y. Performance assessment and design of ultra-high performance concrete (UHPC) structures incorporating life-cycle cost and environmental impacts. Constr. Build. Mater. 2018, 167, 414–425. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.; Wang, F. Autogenous shrinkage behavior of ultra-high performance concrete. Constr. Build. Mater. 2019, 226, 459–468. [Google Scholar] [CrossRef]

- Qian, D.; Yu, R.; Shui, Z.; Sun, Y.; Jiang, C.; Zhou, F.; Ding, M.; Tong, X.; He, Y. A novel development of green ultra-high performance concrete (UHPC) based on appropriate application of recycled cementitious material. J. Clean. Prod. 2020, 261, 121231. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, S.; Liu, Z.; Wang, F. Utilization of steel slag in ultra-high performance concrete with enhanced eco-friendliness. Constr. Build. Mater. 2019, 214, 28–36. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; He, B.; He, L. Performance of ultra-high performance concrete (UHPC) with cement partially replaced by ground granite powder (GGP) under different curing conditions. Constr. Build. Mater. 2019, 213, 469–482. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Guo, C.; Wu, S.; Gao, X.; Peng, S. The physical and chemical impact of manufactured sand as a partial replacement material in Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2019, 99, 203–213. [Google Scholar] [CrossRef]

- Visage, E.T.; Weldon, B.D.; Jauregui, D.V.; Newtson, C.M. Flexural Performance of Ultrahigh-Performance Concrete Developed Using Local Materials. J. Mater. Civ. Eng. 2019, 31, 04019050. [Google Scholar] [CrossRef]

- Ma, R.; Guo, L.; Sun, W.; Liu, J.; Zong, J. Strength-enhanced ecological ultra-high performance fibre-reinforced cementitious composites with nano-silica. Mater. Struct. 2017, 50, 166. [Google Scholar] [CrossRef]

- Ma, R.; Guo, L.; Ye, S.; Sun, W.; Liu, J. Influence of Hybrid Fiber Reinforcement on Mechanical Properties and Autogenous Shrinkage of an Ecological UHPFRCC. J. Mater. Civ. Eng. 2019, 31, 04019032. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Xiao, X.; Zhang, X.; Wang, Y.; He, Y. Low carbon design of an Ultra-High Performance Concrete (UHPC) incorporating phosphorous slag. J. Clean. Prod. 2019, 240, 118157. [Google Scholar] [CrossRef]

- Li, P.; Cao, Y.; Brouwers, H.; Chen, W.; Yu, Q. Development and properties evaluation of sustainable ultra-high performance pastes with quaternary blends. J. Clean. Prod. 2019, 240, 118124. [Google Scholar] [CrossRef]

- Bae, Y.; Pyo, S. Ultra high performance concrete (UHPC) sleeper: Structural design and performance. Eng. Struct. 2020, 210, 110374. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Song, J.; Lee, G.C. Application of Ultra-High Performance Concrete in bridge engineering. Constr. Build. Mater. 2018, 186, 1256–1267. [Google Scholar] [CrossRef]

- Abdelbaset, H.; Cheng, B.; Tian, L.; Li, H.-T.; Zhang, Q.-H. Reduce hot spot stresses in welded connections of orthotropic steel bridge decks by using UHPC layer: Experimental and numerical investigation. Eng. Struct. 2020, 220, 110988. [Google Scholar] [CrossRef]

- Shao, X.; Deng, L.; Cao, J. Innovative steel-UHPC composite bridge girders for long-span bridges. Front. Struct. Civ. Eng. 2019, 13, 981–989. [Google Scholar] [CrossRef]

- Zhou, Z.; Qiao, P. Tensile behavior of ultra-high performance concrete: Analytical model and experimental validation. Constr. Build. Mater. 2019, 201, 842–851. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive Powder Concretes with High Ductility and 200–800 Mpa Compressive Strength. Special Publication-R. Soc. Chem. 1994, 144, 507–518. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Yu, Q.; Brouwers, H. Effect of coarse basalt aggregates on the properties of Ultra-high Performance Concrete (UHPC). Constr. Build. Mater. 2018, 170, 649–659. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. Changes in rheology and mechanical properties of ultra-high performance concrete with silica fume content. Cem. Concr. Res. 2019, 123, 105786. [Google Scholar] [CrossRef]

- Žurauskienė, R.; Valentukevičienė, M. Experimental Research on Quality Parameters of Recycled Concrete. Materials 2020, 13, 2538. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K.; Viegas, R. Material efficiency in the design of UHPC paste from a life cycle point of view. Constr. Build. Mater. 2018, 160, 505–513. [Google Scholar] [CrossRef]

- Sbia, L.A.; Peyvandi, A.; Lu, J.; Abideen, S.; Weerasiri, R.R.; Balachandra, A.M.; Soroushian, P. Production methods for reliable construction of ultra-high-performance concrete (UHPC) structures. Mater. Struct. 2017, 50, 7. [Google Scholar] [CrossRef]

- Xu, Y.; Jin, R.; Hu, L.; Li, B.; Chen, W.; Shen, J.; Wu, P.; Fang, J. Studying the mix design and investigating the photocatalytic performance of pervious concrete containing TiO2-Soaked recycled aggregates. J. Clean. Prod. 2019, 248, 119281. [Google Scholar] [CrossRef]

- Guo, L.; Wu, J.; Wang, H. Mechanical and perceptual characterization of ultra-high-performance cement-based composites with silane-treated graphene nano-platelets. Constr. Build. Mater. 2020, 240, 117926. [Google Scholar] [CrossRef]

- Wu, J.-D.; Guo, L.-P.; Cao, Y.-Z.; Lyu, B.-C. Mechanical and fiber/matrix interfacial behavior of ultra-high-strength and high-ductility cementitious composites incorporating waste glass powder. Cem. Concr. Compos. 2022, 126, 104371. [Google Scholar] [CrossRef]

- Deboucha, W.; Leklou, N.; Khelidj, A.; Oudjit, M.N. Hydration development of mineral additives blended cement using thermogravimetric analysis (TGA): Methodology of calculating the degree of hydration. Constr. Build. Mater. 2017, 146, 687–701. [Google Scholar] [CrossRef]

| PC | FA | SF | ||

|---|---|---|---|---|

| Chemical composition (%) | ||||

| CaO | 64.47 | 7.68 | 1.68 | |

| Al2O3 | 4.87 | 26.88 | 0.32 | |

| Fe2O3 | 3.59 | 5.19 | 0.05 | |

| SiO2 | 20.87 | 53.25 | 95.06 | |

| MgO | 2.13 | 2.26 | 0.39 | |

| SO3 | 2.52 | 0.92 | 0.55 | |

| N2O | 0.11 | 0.70 | 0.11 | |

| K2O | 0.65 | 1.14 | 0.38 | |

| L.O.L | 0.77 | 1.02 | 0.68 | |

| Physical properties | ||||

| Specific gravity | 3.3 | 2.3 | 2.3 | |

| Specific surface area (m2/kg) | 369 | -- | 20,000 | |

| Standard consistency (%) | 27.4 | -- | -- | |

| Initial setting time (min) | 127 | -- | -- | |

| Final setting time (min) | 182 | -- | -- | |

| Flexural strength (MPa) | 3 d | 7.3 | -- | -- |

| 28 d | 10.6 | -- | -- | |

| Compressive strength (MPa) | 3 d | 38.0 | ||

| 28 d | 65.8 | |||

| Type | Length (L)/mm | Equivalent Diameter (D)/mm | L/D Radio | Tensile Strength/MPa |

|---|---|---|---|---|

| Straight steel fiber | 13 | 0.2 | 65 | 2000 |

| End-hooked steel fiber | 14 | 0.2 | 70 | 2000 |

| PC | FA | SF | Sand | Water | SSF | HSF | SP | |

|---|---|---|---|---|---|---|---|---|

| M16B1 | 480 | 384 | 96 | 1150 | 153.6 | 158 | -- | 16.9 |

| M16B2 | 583 | 291 | 97 | 1166 | 155.4 | 158 | -- | 17.1 |

| M16V0 | 632 | 316 | 105 | 1053 | 168.5 | 158 | -- | 17.6 |

| M14V1 | 643 | 322 | 107 | 1072 | 150 | 198 | -- | 17.1 |

| M15V1 | 636 | 318 | 106 | 1060 | 158.9 | 198 | -- | 17.0 |

| M16V1 | 629 | 324 | 105 | 1048 | 167.6 | 198 | -- | 16.8 |

| M17V1 | 622 | 311 | 104 | 1036 | 176.1 | 198 | -- | 16.6 |

| M16V2 | 625 | 313 | 104 | 1042 | 166.7 | 237 | -- | 16.7 |

| M16H1 | 629 | 324 | 105 | 1048 | 167.6 | 158 | 40 | 16.8 |

| M16H2 | 629 | 324 | 105 | 1048 | 167.6 | 149 | 49 | 16.8 |

| M16H3 | 629 | 324 | 105 | 1048 | 167.6 | 132 | 66 | 16.8 |

| M16H4 | 629 | 324 | 105 | 1048 | 167.6 | 99 | 99 | 16.8 |

| M16H5 | 629 | 324 | 105 | 1048 | 167.6 | -- | 198 | 16.8 |

| Determination Coefficient (R2) | |

|---|---|

| M16B1 | 0.9762 |

| M16B2 | 0.9772 |

| M16V0 | 0.9688 |

| Independent Variable | SSa | Fa | SSe | Fe | F Value | Evaluation of Significance |

|---|---|---|---|---|---|---|

| Powder proportion | 2850.7 | 2 | 759.0 | 15 | 28.2 | Most significant |

| W/B | 876.8 | 3 | 2198.8 | 20 | 2.7 | Least significant |

| Fiber content | 1369.1 | 2 | 689.9 | 14 | 13.9 | Less significant |

| Fiber geometry | 6445.6 | 5 | 2133.4 | 29 | 17.5 | Significant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, R.; Hu, X.; Hu, H.; Tian, Z.; Chen, L.; Zong, J. Strength Design of Ultra-High-Performance Fiber-Reinforced Cementitious Composites Using Local Ecological Admixture. Buildings 2022, 12, 2230. https://doi.org/10.3390/buildings12122230

Ma R, Hu X, Hu H, Tian Z, Chen L, Zong J. Strength Design of Ultra-High-Performance Fiber-Reinforced Cementitious Composites Using Local Ecological Admixture. Buildings. 2022; 12(12):2230. https://doi.org/10.3390/buildings12122230

Chicago/Turabian StyleMa, Rui, Xun Hu, Huiying Hu, Ziyang Tian, Lei Chen, and Jinyu Zong. 2022. "Strength Design of Ultra-High-Performance Fiber-Reinforced Cementitious Composites Using Local Ecological Admixture" Buildings 12, no. 12: 2230. https://doi.org/10.3390/buildings12122230

APA StyleMa, R., Hu, X., Hu, H., Tian, Z., Chen, L., & Zong, J. (2022). Strength Design of Ultra-High-Performance Fiber-Reinforced Cementitious Composites Using Local Ecological Admixture. Buildings, 12(12), 2230. https://doi.org/10.3390/buildings12122230