Study on the Constitutive Model of Concrete Confined by Multi-Spiral Composite Stirrups

Abstract

1. Introduction

2. Research Significance

3. Experiment

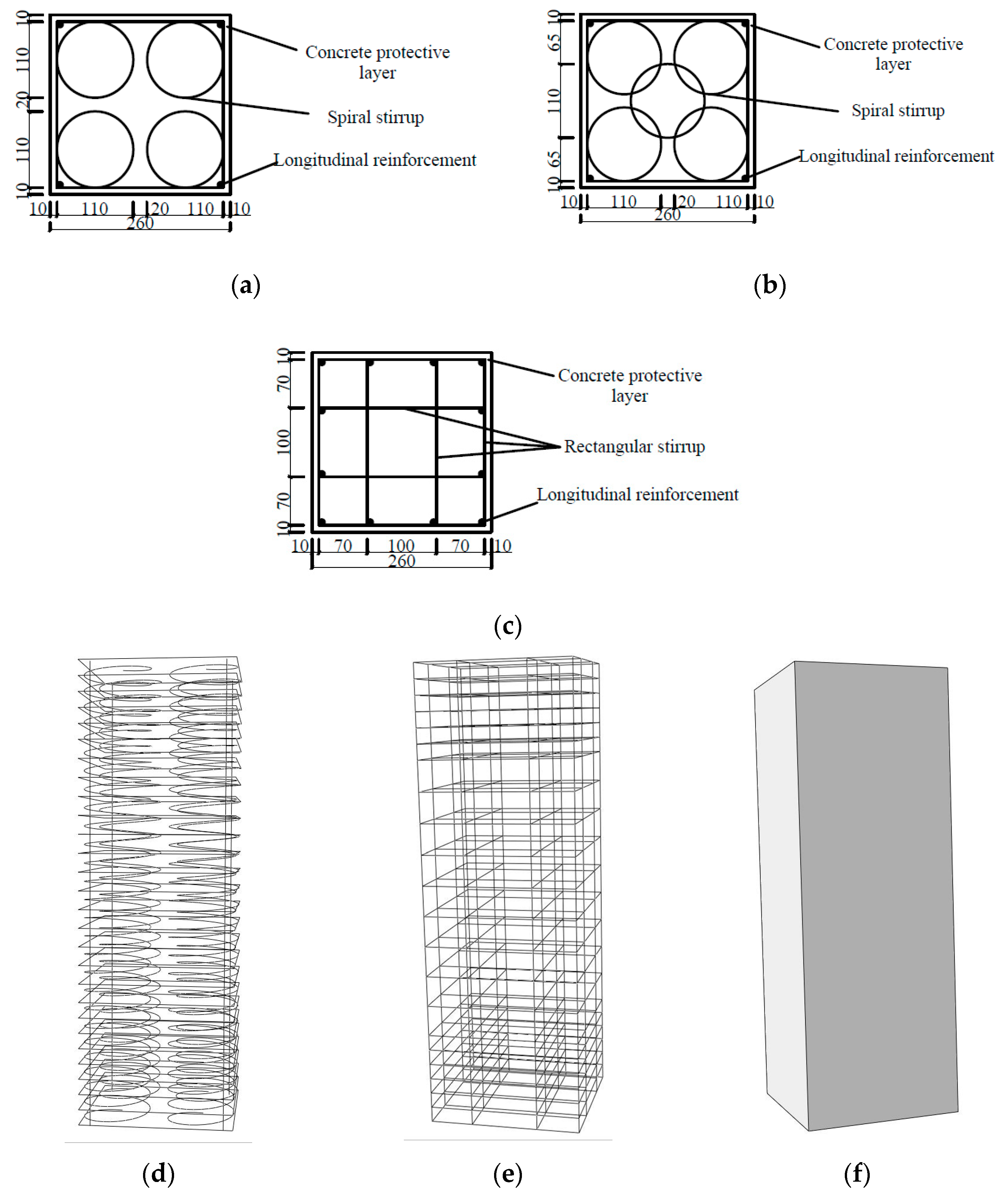

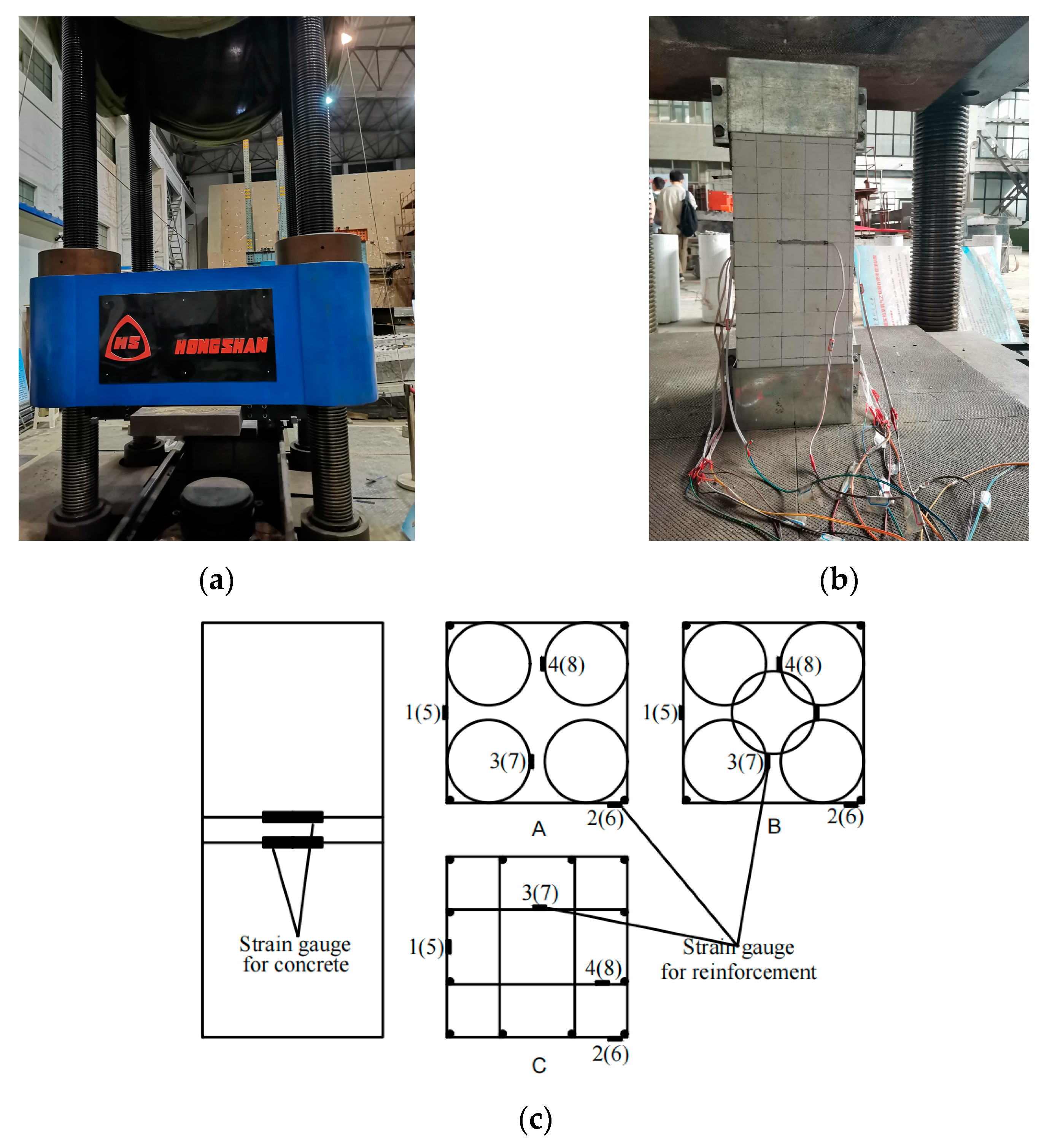

3.1. Test Program

3.2. Analysis of Strength and Ductility

3.3. Analysis of Influencing Factors

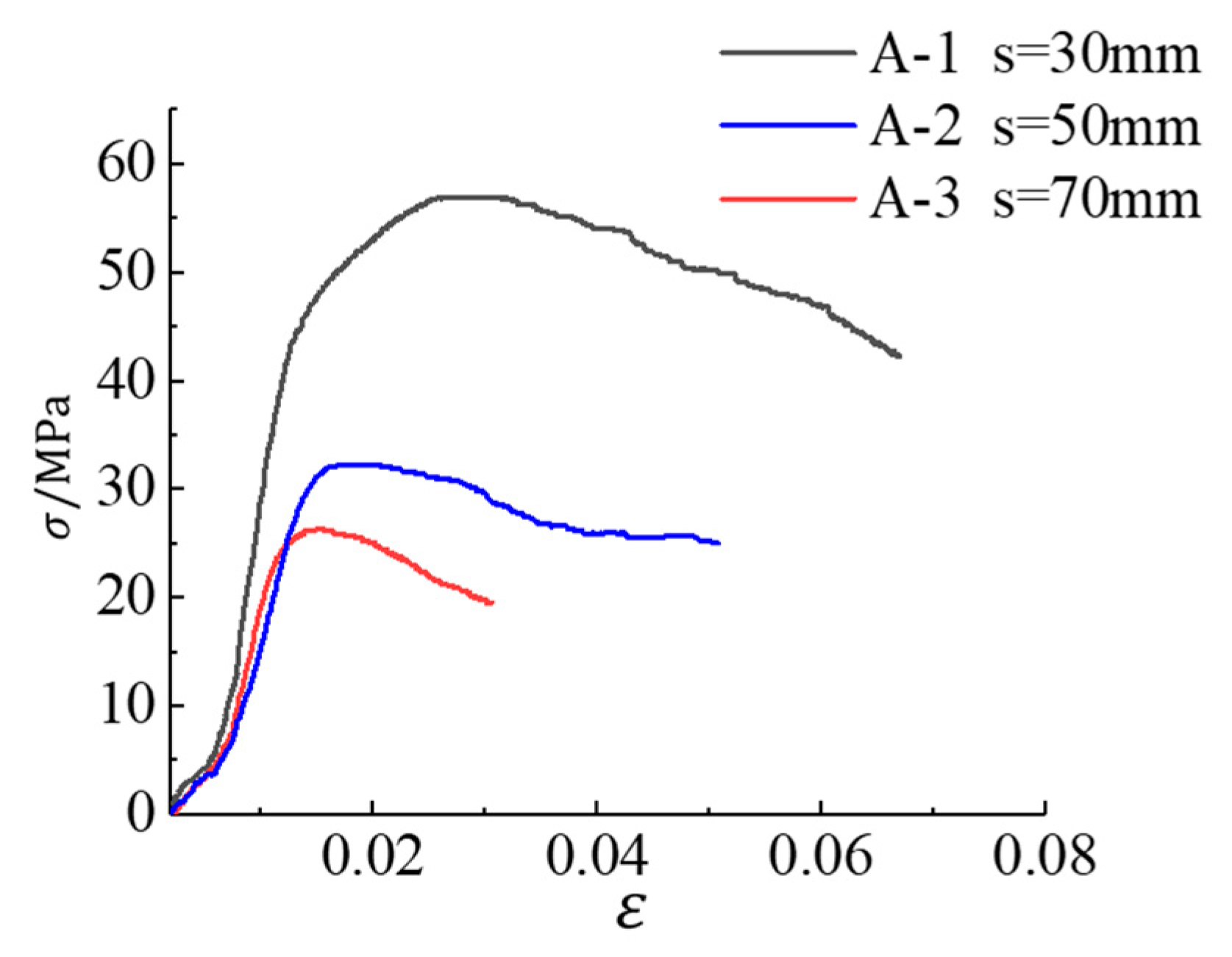

3.3.1. Stirrup Spacing

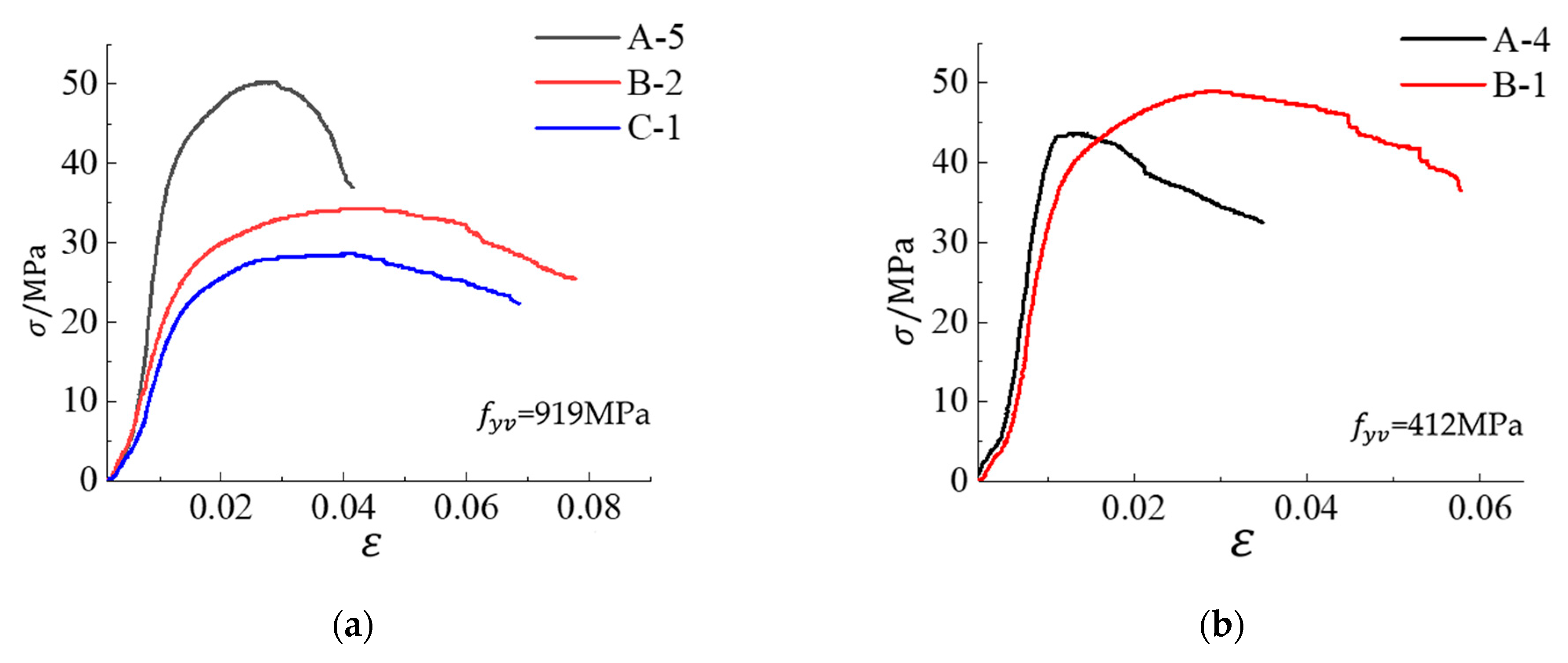

3.3.2. Stirrup Form

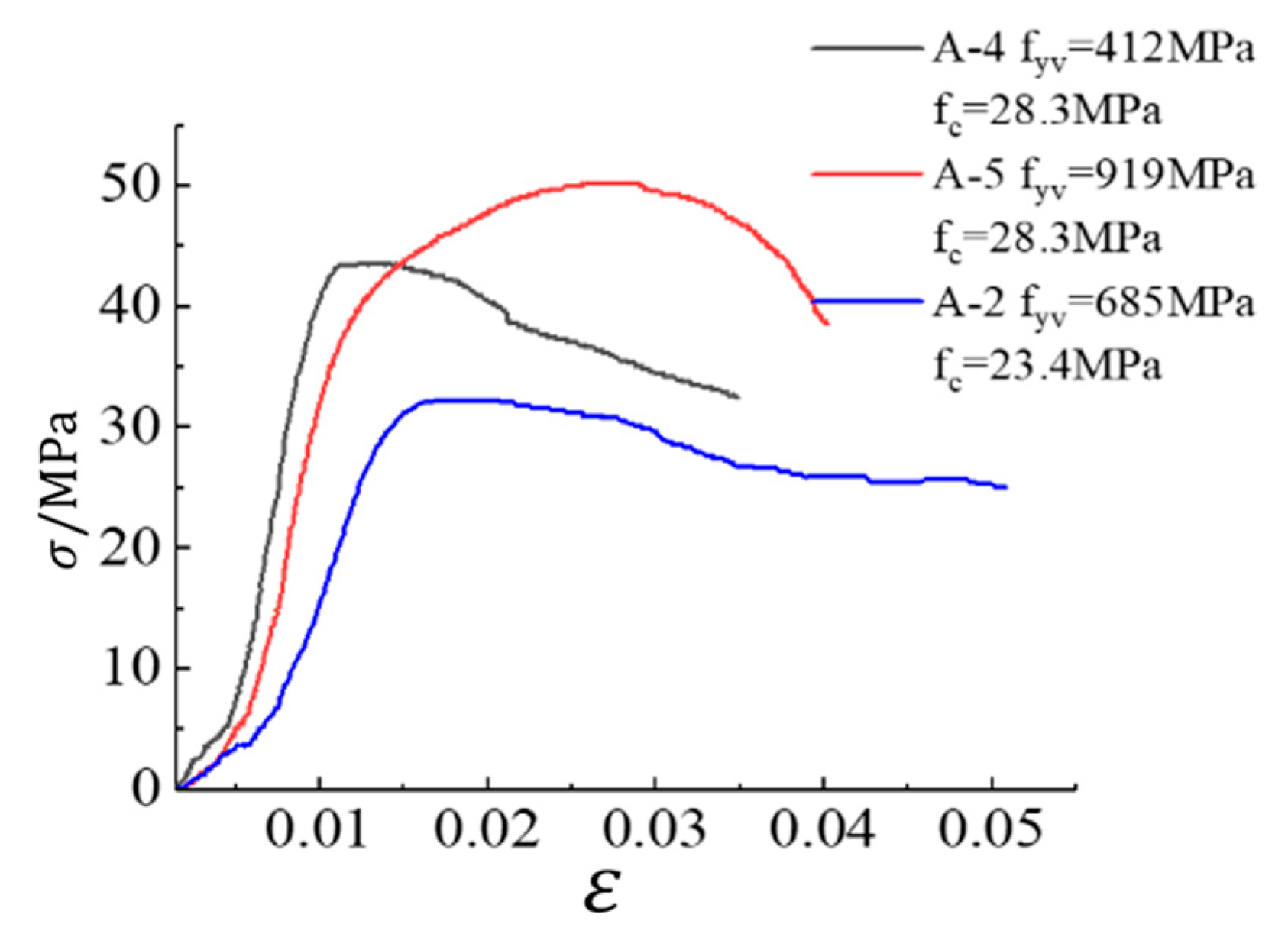

3.3.3. Stirrup Strength

4. Calculation of Stress and Strain

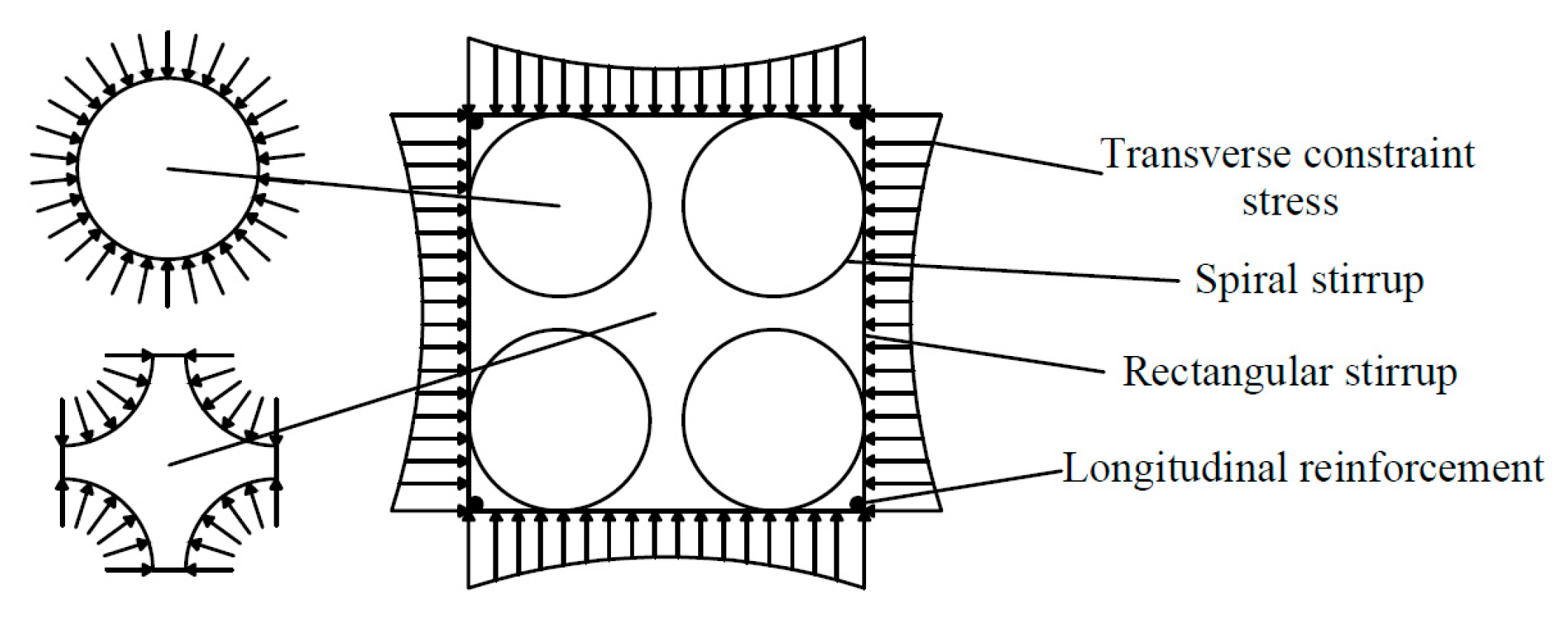

4.1. Analysis of Constraint Mechanism

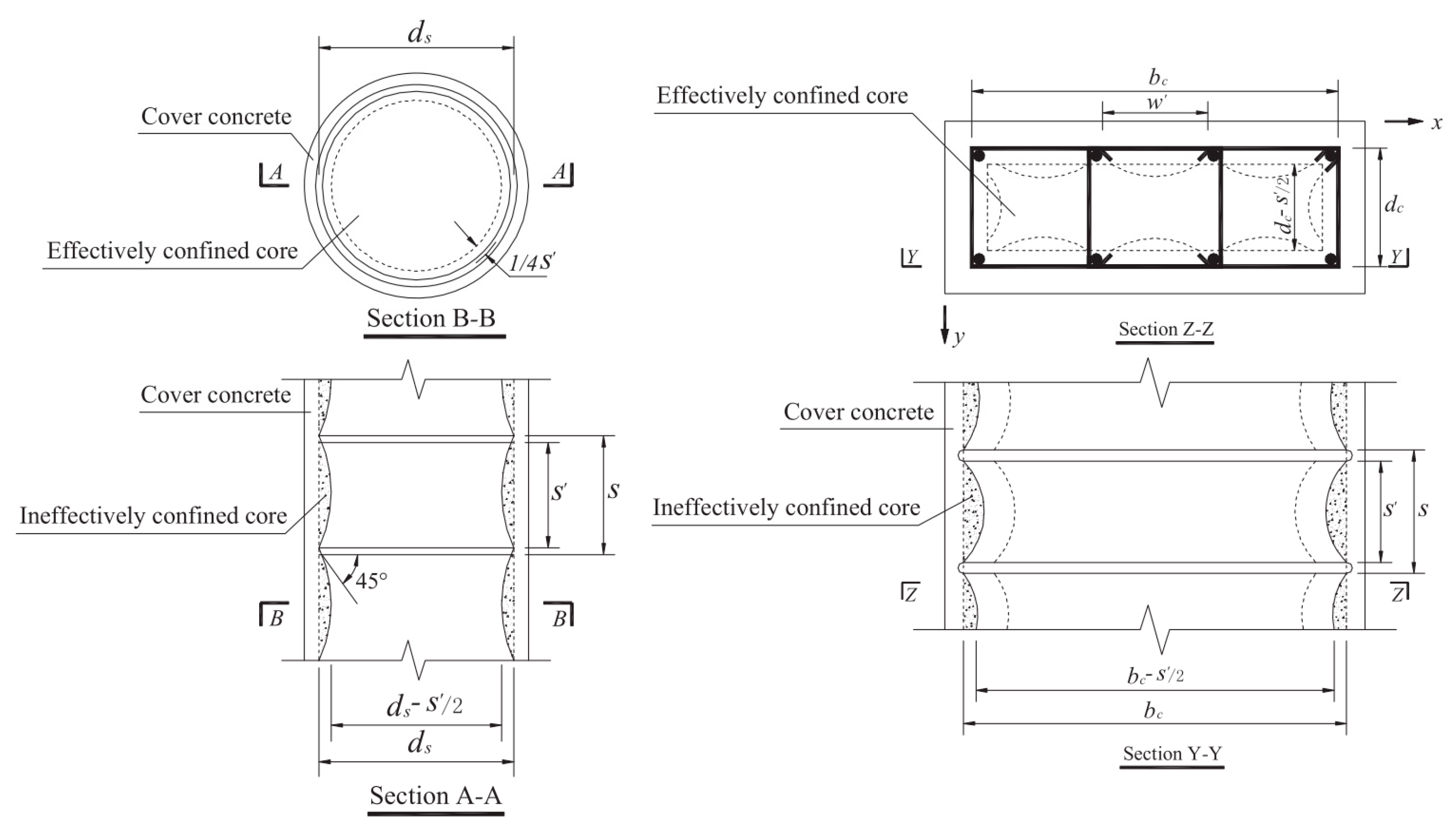

4.2. Effective Lateral Restraint Stress

4.3. Peak Stress

4.4. Peak Strain

4.5. Ultimate Compressive Strain

4.6. Stirrup Stress

- Let and substitute them into Equations (5) and (6) to find the effective lateral constraint stresses and imposed on concrete by inner spiral hoops and outer rectangular hoops;

- Substitute and into Equation (7) to calculate the effective transverse constraint stress of high-strength stirrup on core concrete;

- Substitute into Equations (14) and (15), respectively, to calculate the peak stress and peak strain ;

- By substituting , and into Equation (17), the strain of the high-strength stirrup is obtained;

- The stress of the high-strength stirrup is gained by the stress-strain relation of high-strength stirrup;

- Only when the , the calculated value of is re-substituted into step1 to recalculate the relevant parameters;

- Repeat steps 2 to 6 until convergence.

5. Constitutive Model

5.1. Establishment of Constitutive Model

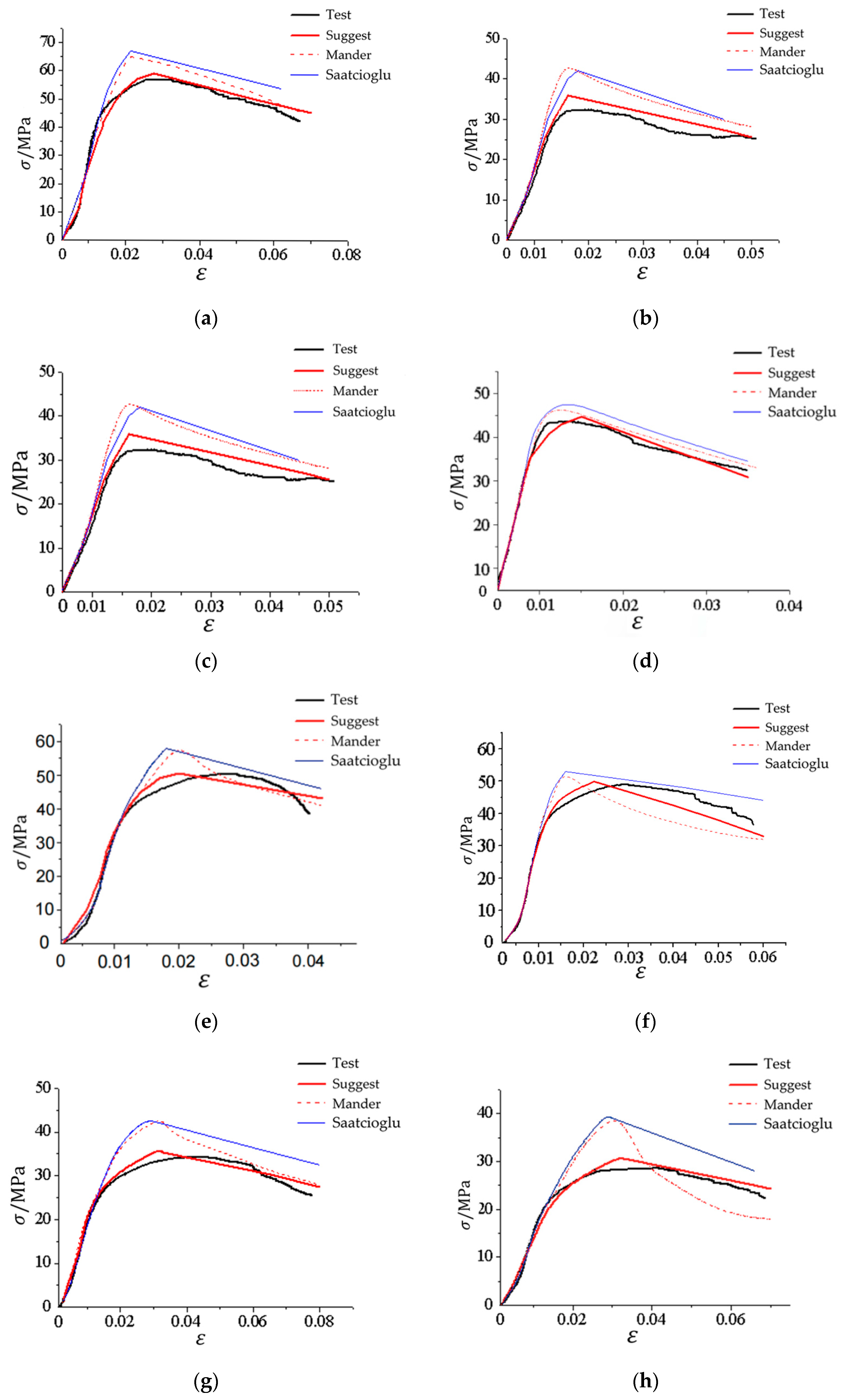

5.2. Comparative Analysis of Constitutive Models

6. Conclusions

- With the decrease of stirrup spacing or the increase of stirrup strength, the carrying capacity and ductility of the specimens are significantly improved, and the deformation ability is also better. The strength and ductility of the square RC column specimen confined by five-spiral composite stirrups are obviously better than those of the corresponding specimens with four-spiral composite stirrups, and slightly better than those of the corresponding specimen with traditional well-shaped composite stirrups.

- The restraint mechanism of multi-spiral composite stirrups was analyzed. According to the different degrees of constraint, the cross-section of the square RC column is divided into three areas: the highly constrained region (the area surrounded by the circular spiral stirrups), the partially constrained region (the area outside the circular spiral stirrups and the area within the rectangular hoop) and the unconstrained region (the protective layer).

- Combined with theoretical analysis and experimental data regression, the formulas of effective confinement stress, peak stress, peak strain, and ultimate strain of concrete confined by multi-spiral composite stirrups are proposed and compared with the experimental results. The results show that the error between the calculated and experimental values is less than 5%, which means the calculation formula presented in this paper has high accuracy.

- A constitutive model of concrete confined by multi-spiral composite stirrups is proposed and compared with several typical constitutive models of constrained concrete. The results indicate that the presented constitutive model fits well with the experimental curve and can predict the axial compression performance of this type of constrained concrete well.

7. Discussion

8. Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, L.P.; Lu, X.Z.; Zhao, S.C. Analysis on seismic damage of buildings in the Wenchuan earthquake. J. Build. Struct. 2008, 29, 1–9. [Google Scholar] [CrossRef]

- Li, H.N.; Xiao, S.Y.; Huo, L.S. Damage investigation and analysis of engineering structures in the Wenchuan earthquake. J. Build. Struct. 2008, 29, 10–19. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, J.; Jiang, X.; Mo, L. Experimental research and finite element analysis on seismic behavior of square reinforced concrete columns with four interlocking spirals. Structures 2022, 39, 1–16. [Google Scholar] [CrossRef]

- Yang, L.G.; Wang, Y.Y.; Liew, J.Y.R. Compression-Bending Strength Model for Corrugated Steel Tube Confined Reinforced Concrete Section. J. Struct. Eng. 2021, 147, 04021187. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.S.S.; Al-Mahaidi, R.; Mohammed, A.S.; Ahmed, H.U.; Zaid, O.; Althoey, F.; Ahmed, J.; Isleem, H.F.; Bennetts, I. Investigation of the effectiveness of CFRP strengthening of concrete made with recycled waste PET fine plastic aggregate. PLoS ONE 2022, 17, e0269664. [Google Scholar] [CrossRef]

- Ahmed, M.; Sheikh, M.N.; Hadi, M.N.S.; Liang, Q.Q. Nonlinear analysis of square spiral-confined reinforced concrete-filled steel tubular short columns incorporating novel confinement model and interaction local buckling. Eng. Struct. 2022, 274, 115168. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, J.; Lu, L.; Liang, H.; Ma, Z. The Strength in Axial Compression of Aluminum Alloy Tube Confined Concrete Columns with a Circular Hollow Section: Experimental Results. Buildings 2022, 12, 699. [Google Scholar] [CrossRef]

- Wei, Y.; Xu, Y.; Wang, G.; Cheng, X.; Li, G. Influence of the Cross-Sectional Shape and Corner Radius on the Compressive Behaviour of Concrete Columns Confined by FRP and Stirrups. Polymers 2022, 14, 341. [Google Scholar] [CrossRef]

- Hao, M.J.; Zheng, W.Z.; Chang, W. Compression behavior of reinforced concrete columns jacketed with multi-spiral transverse reinforcement. Struct. Concr. 2022, 26, 2942–2967. [Google Scholar] [CrossRef]

- Chen, Z.P.; Zhou, J.; Jing, C.G.; Tan, Q.H. Mechanical behavior of spiral stirrup reinforced concrete filled square steel tubular columns under compression. Eng. Struct. 2021, 226, 19. [Google Scholar] [CrossRef]

- Eid, R.; Cohen, A.; Guma, R.; Ifrach, E.; Levi, N.; Zvi, A. High-Strength Concrete Circular Columns with TRC-TSR Dual Internal Confinement. Buildings 2019, 9, 218. [Google Scholar] [CrossRef]

- Wang, Q.X.; Zhao, G.F.; Lin, L.Y. Experimental study on ductility of high strength concrete columns. J. Build. Struct. 1995, 16, 22–31. [Google Scholar] [CrossRef]

- Sheikh, S.A.; Uzumeri, S.M. Analytical model for concrete confinement in tied columns. J. Struct. Eng. 1982, 108, 2703–2722. [Google Scholar] [CrossRef]

- Mander, J.B. Seismic Design of Bridge Piers. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 1983. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Cusson, D.; Paultre, P. High-strength concrete columns confined by rectangular ties. J. Struct. Eng. 1994, 120, 783–804. [Google Scholar] [CrossRef]

- Cusson, D.; Paultre, P. Stress-strain model for confined high-strength concrete. J. Struct. Eng. 1995, 121, 468–477. [Google Scholar] [CrossRef]

- Saatcioglu, M.; Razvi, S.R. Strength and ductility of confined concrete. J. Struct. Eng. 1992, 118, 1590–1607. [Google Scholar] [CrossRef]

- Bing, L.; Park, R.; Tanaka, H. Stress-strain behavior of high-strength concrete confined by ultra-high- and normal-strength transverse reinforcements. J. Struct. Eng. 2001, 98, 395–406. [Google Scholar]

- Rong, C.; Shi, Q. Analysis constitutive models for actively and passively confined concrete. Compos. Struct. 2021, 256, 113009. [Google Scholar] [CrossRef]

- Li, Y.Z.; Cao, S.Y.; Jing, D.H. Axial compressive behaviour of RC columns with high-strength MTS transverse reinforcement. Mag. Concr. Res. 2017, 69, 436–452. [Google Scholar] [CrossRef]

- Li, Y.Z.; Cao, S.Y.; Jing, D.H. Analytical compressive stress-strain model for concrete confined with high-strength multiple-tied-spiral transverse reinforcement. Struct. Des. Tall Spec. Build. 2018, 27, e1416. [Google Scholar] [CrossRef]

- Shi, Q.X.; Yang, K.; Liu, W.Y.; Zhang, X.H.; Jiang, W.S. Experimental study on mechanical behavior of high strength concrete confined by high-strength stirrups under concentric loading. Eng. Mech. 2012, 29, 141–149. [Google Scholar]

- Yang, K.; Shi, Q.X.; Zhao, J.H.; Jiang, W.S.; Meng, H. Study on the constitutive model of high-strength concrete confined by high-strength stirrups. China Civ. Eng. J. 2013, 46, 34–41. [Google Scholar] [CrossRef]

- Ouyang, X.; Wu, Z.M.; Shan, B.; Chen, Q.; Shi, C.J. A critical review on compressive behavior and empirical constitutive models of concrete. Constr. Build. Mater. 2022, 323, 126572. [Google Scholar] [CrossRef]

- Zheng, W.Z.; Zhang, J.; Wang, G.; Wang, Y. Experimental Study on Axial Compression Behavior of High- strength Concrete Columns Confined by Spiral Stirrups. China J. Highw. Transp. 2022, 35, 22–35. [Google Scholar] [CrossRef]

- Jin, L.; Li, P.; Du, X.L. Compressive stress-strain model for stirrup-confined concrete columns considering the effect of structural size. J. Civ. Environ. Eng. 2020, 42, 81–89. [Google Scholar] [CrossRef]

- Li, M.H.; Zhou, W.; Liu, M.J.; Liu, G.Y.; Zhang, S. Experimental investigation of reinforced concrete columns with composite spiral stirrups under eccentric loading. J. Harbin Inst. Technol. 2019, 51, 113–120. [Google Scholar] [CrossRef]

- Yin, Y.L. Researches and developments of alternative confinements for rectangular concrete columns (I). China Civ. Eng. J. 2004, 37, 1–10. [Google Scholar] [CrossRef]

- Yin, Y.L. Researches and developments of alternative confinements for rectangular concrete columns (II). China Civ. Eng. J. 2004, 37, 1–12. [Google Scholar] [CrossRef]

- Yin, Y.L.; Weng, Z.Q.; Wang, R.Z.; Liang, J.Y. Axial compressive behavior of precast SRC columns with multi-spirals. Eng. Sci. 2006, 8, 16–30. [Google Scholar]

- Yin, Y.L.; Wu, T.L.; Liu, T.C.; Sheikh, S.A.; Wang, R. Interlocking spiral confinement for rectangular columns. Concr. Int. 2011, 33, 38–45. [Google Scholar]

- Yin, Y.L.; Wang, J.C.; Wang, P.H. Development of multi-spiral confinements in rectangular columns for construction automation. J. Chin. Inst. Eng. 2012, 35, 309–320. [Google Scholar] [CrossRef]

- Hung, H.H.; Wang, P.H.; Yin, Y.L.; Wang, J.C.; Chang, K.C. Large-scale cyclic loading test on a multi-spiral stirrup bridge pier constructed by automated method. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Chen, Y.; Feng, J.; Yin, S. Compressive behavior of reinforced concrete columns confined by multi-spiral hoops. Comput. Concr. 2012, 9, 359–373. [Google Scholar] [CrossRef]

- Weng, C.C.; Yin, Y.L.; Wang, J.C.; Liang, C.Y. Seismic cyclic loading test of SRC columns confined with 5-spirals. Sci. China Series E-Tech. Sci. 2008, 51, 529–555. [Google Scholar] [CrossRef]

- Shih, T.H.; Chen, C.C.; Weng, C.C.; Yin, Y.L.; Wang, J.C. Axial strength and ductility of square composite columns with two interlocking spirals. J. Constr. Steel Res. 2013, 90, 184–192. [Google Scholar] [CrossRef]

- Wu, T.L.; Ou, Y.C.; Yin, Y.L.; Wang, J.C.; Wang, P.H.; Ngo, S.H. Behavior of oblong and rectangular bridge columns with conventional tie and multi-spiral transverse reinforcement under combined axial and flexural loads. J. Chin. Inst. Eng. 2013, 36, 980–993. [Google Scholar] [CrossRef]

- Tang, Q.; Li, Y.; Lu, X.Z.; Yan, W.M. Study on axial compression capacity of multi-spiral hoops confined concrete columns. Eng. Mech. 2018, 35, 166–171. [Google Scholar] [CrossRef]

- Wang, P.-H.; Chang, K.-C.; Yin, S.Y.-L.; Wang, J.-C.; Ou, Y.-C. Simplified Finite-Element Analysis Method for Axial Compression Behavior of Rectangular Concrete Columns with Interlocking Multispiral Reinforcements. J. Struct. Eng. 2020, 146, 04019176. [Google Scholar] [CrossRef]

- Yang, K.; Guo, S.H.; Wang, Y.K.; Liu, R.; Hu, Y.Y. Experimental study on axial compression performance of square concrete column confined with new multi-spiral composite stirrup. J. Archit. Civ. Eng. 2021. [Google Scholar]

- Kim, J.K.; Park, C.K. The behaviour of concrete columns with interlocking spirals. Eng. Struct. 1999, 21, 945–953. [Google Scholar] [CrossRef]

- Willam, K.J. Constitutive model for the triaxial behaviour of concrete. Proc. Intl. Assoc. Bridge Structl. Engrs. 1975, 19, 1–30. [Google Scholar]

| Specimen No. | Stirrup Form | Stirrup Yield Strength /MPa | Stirrup Spacing /mm | Ratio of Volume Hoop /% | /MPa | /MPa |

|---|---|---|---|---|---|---|

| A-1 | A | 685 | 30 | 6.31 | 37.3 | 24.9 |

| A-2 | A | 685 | 50 | 3.96 | 30.8 | 20.6 |

| A-3 | A | 685 | 70 | 2.79 | 30.8 | 20.6 |

| A-4 | A | 412 | 50 | 3.96 | 37.3 | 24.9 |

| A-5 | A | 919 | 50 | 3.96 | 37.3 | 24.9 |

| B-1 | B | 412 | 50 | 4.53 | 37.3 | 24.9 |

| B-2 | B | 919 | 50 | 4.53 | 30.8 | 20.6 |

| C-1 | C | 919 | 50 | 3.96 | 30.8 | 20.6 |

| Type | Diameter /mm | Yield Strength /MPa | Elastic Modulus E/105 |

|---|---|---|---|

| HRB400 | 8 | 412 | 2.0 |

| HTRB630 | 8 | 685 | 2.0 |

| 1000 MPa | 8 | 919 | 2.0 |

| Specimen No. | /MPa | |||||

|---|---|---|---|---|---|---|

| A-1 | 56.9 | 0.02803 | 0.05473 | 1.95 | 2.29 | 14.02 |

| A-2 | 33.4 | 0.01921 | 0.03343 | 1.74 | 1.62 | 9.61 |

| A-3 | 26.3 | 0.01686 | 0.02472 | 1.47 | 1.28 | 8.43 |

| A-4 | 43.6 | 0.01408 | 0.02270 | 1.61 | 1.75 | 7.04 |

| A-5 | 50.2 | 0.02340 | 0.03841 | 1.64 | 2.02 | 11.7 |

| B-1 | 50.0 | 0.02471 | 0.04892 | 1.98 | 2.01 | 12.36 |

| B-2 | 34.3 | 0.03508 | 0.06894 | 1.97 | 1.67 | 17.54 |

| C-1 | 28.4 | 0.03521 | 0.06105 | 1.73 | 1.38 | 17.61 |

| Specimen No. | Tested Value/MPa | Calculated Value/MPa | /% |

|---|---|---|---|

| A-1 | 56.9 | 58.9 | 3.515 |

| A-2 | 33.4 | 36.0 | 7.784 |

| A-3 | 26.3 | 28.1 | 6.844 |

| A-4 | 43.6 | 44.7 | 2.523 |

| A-5 | 50.2 | 50.6 | 0.797 |

| B-1 | 50.0 | 49.8 | −4.000 |

| B-2 | 34.3 | 35.9 | 4.665 |

| C-1 | 28.4 | 31.0 | 9.155 |

| Average value of ω | 3.910 |

| Specimen No. | Tested Value/MPa | Calculated Value/MPa | ω /% |

|---|---|---|---|

| A-1 | 0.02803 | 0.02760 | −1.534 |

| A-2 | 0.01921 | 0.01926 | 0.260 |

| A-3 | 0.01686 | 0.01529 | −9.312 |

| A-4 | 0.01408 | 0.01503 | 6.747 |

| A-5 | 0.02340 | 0.02280 | −2.564 |

| B-1 | 0.02471 | 0.02236 | −9.510 |

| B-2 | 0.03508 | 0.03185 | −9.208 |

| C-1 | 0.03521 | 0.03201 | −9.088 |

| Average value of ω | 5.621 |

| Specimen No. | Tested Value/MPa | Calculated Value/MPa | ω /% |

|---|---|---|---|

| A-1 | 0.05473 | 0.05410 | −1.151 |

| A-2 | 0.03343 | 0.03389 | 1.376 |

| A-3 | 0.02472 | 0.02522 | 2.023 |

| A-4 | 0.02270 | 0.02468 | 8.722 |

| A-5 | 0.03841 | 0.04216 | 9.763 |

| B-1 | 0.04892 | 0.04024 | −17.743 |

| B-2 | 0.06894 | 0.06530 | −5.280 |

| C-1 | 0.06105 | 0.06570 | 7.617 |

| Average value of ω | 8.484 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Yu, T.; Ma, G.; Zhao, J.; Sun, S. Study on the Constitutive Model of Concrete Confined by Multi-Spiral Composite Stirrups. Buildings 2022, 12, 2179. https://doi.org/10.3390/buildings12122179

Yang K, Yu T, Ma G, Zhao J, Sun S. Study on the Constitutive Model of Concrete Confined by Multi-Spiral Composite Stirrups. Buildings. 2022; 12(12):2179. https://doi.org/10.3390/buildings12122179

Chicago/Turabian StyleYang, Kun, Tao Yu, Guiliang Ma, Jiaxiang Zhao, and Shanshan Sun. 2022. "Study on the Constitutive Model of Concrete Confined by Multi-Spiral Composite Stirrups" Buildings 12, no. 12: 2179. https://doi.org/10.3390/buildings12122179

APA StyleYang, K., Yu, T., Ma, G., Zhao, J., & Sun, S. (2022). Study on the Constitutive Model of Concrete Confined by Multi-Spiral Composite Stirrups. Buildings, 12(12), 2179. https://doi.org/10.3390/buildings12122179