Exploring the Missing Link between Life Cycle Assessment and Circularity Assessment in the Built Environment

Abstract

1. Introduction

1.1. The European Policy Context

1.2. The State of the Art of Circularity Indicators

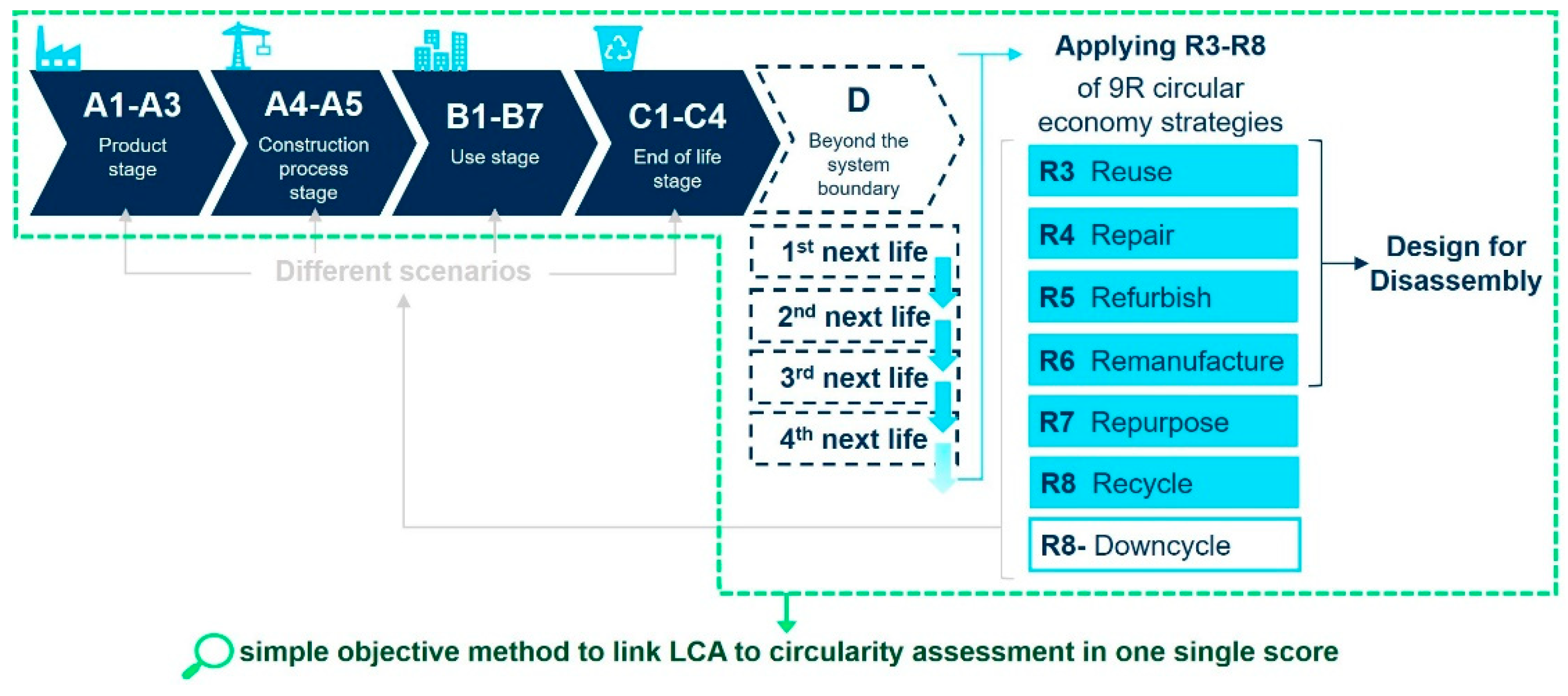

1.3. The State of the Art of Quantifying the Environmental Impact of Circular Buildings

1.4. The Missing Link between LCA and Circularity Assessments

2. Materials and Methods

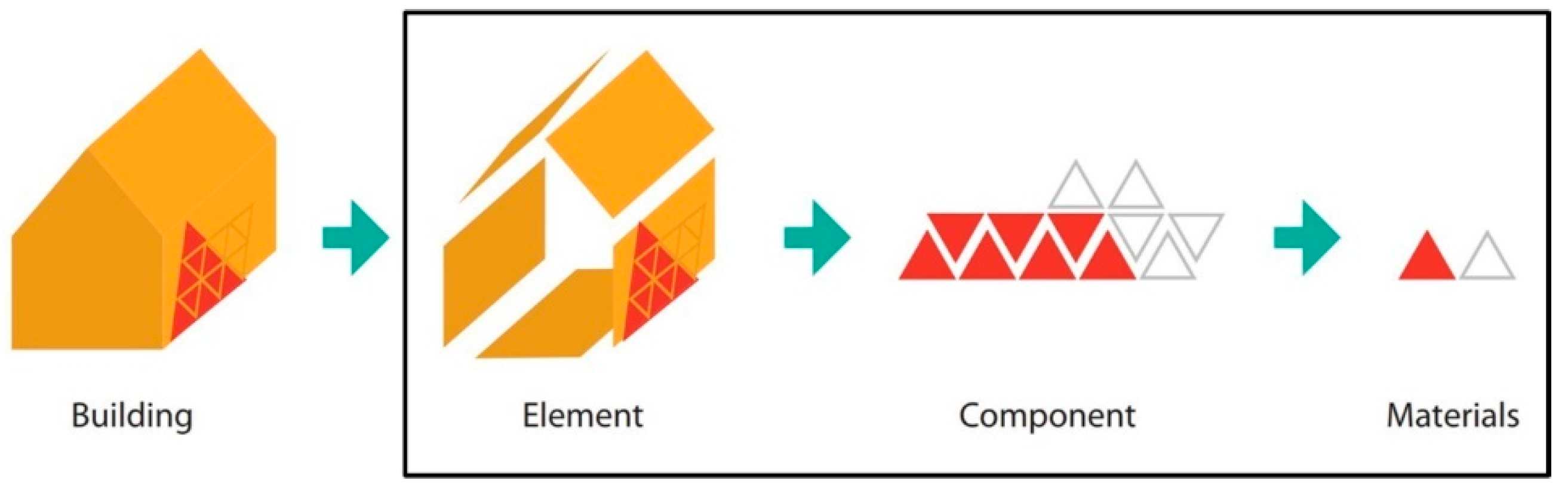

2.1. Methodology

- The mathematical linking of LCA to detachability assessment.

2.1.1. LCA Method

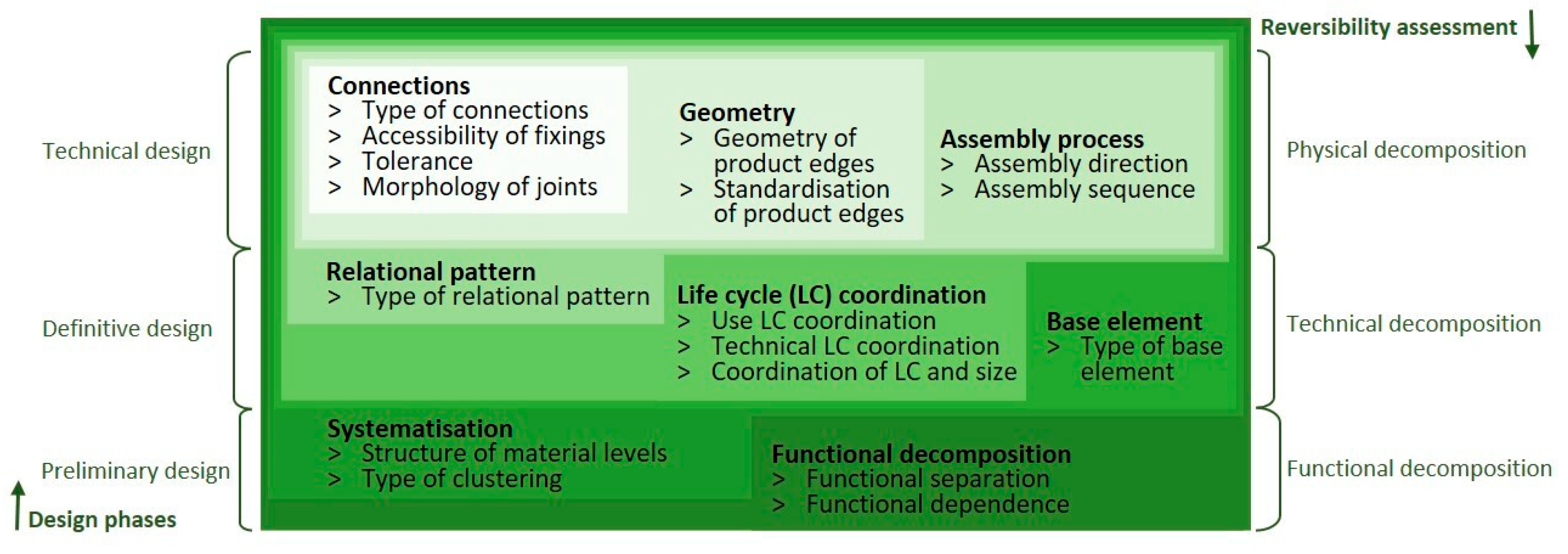

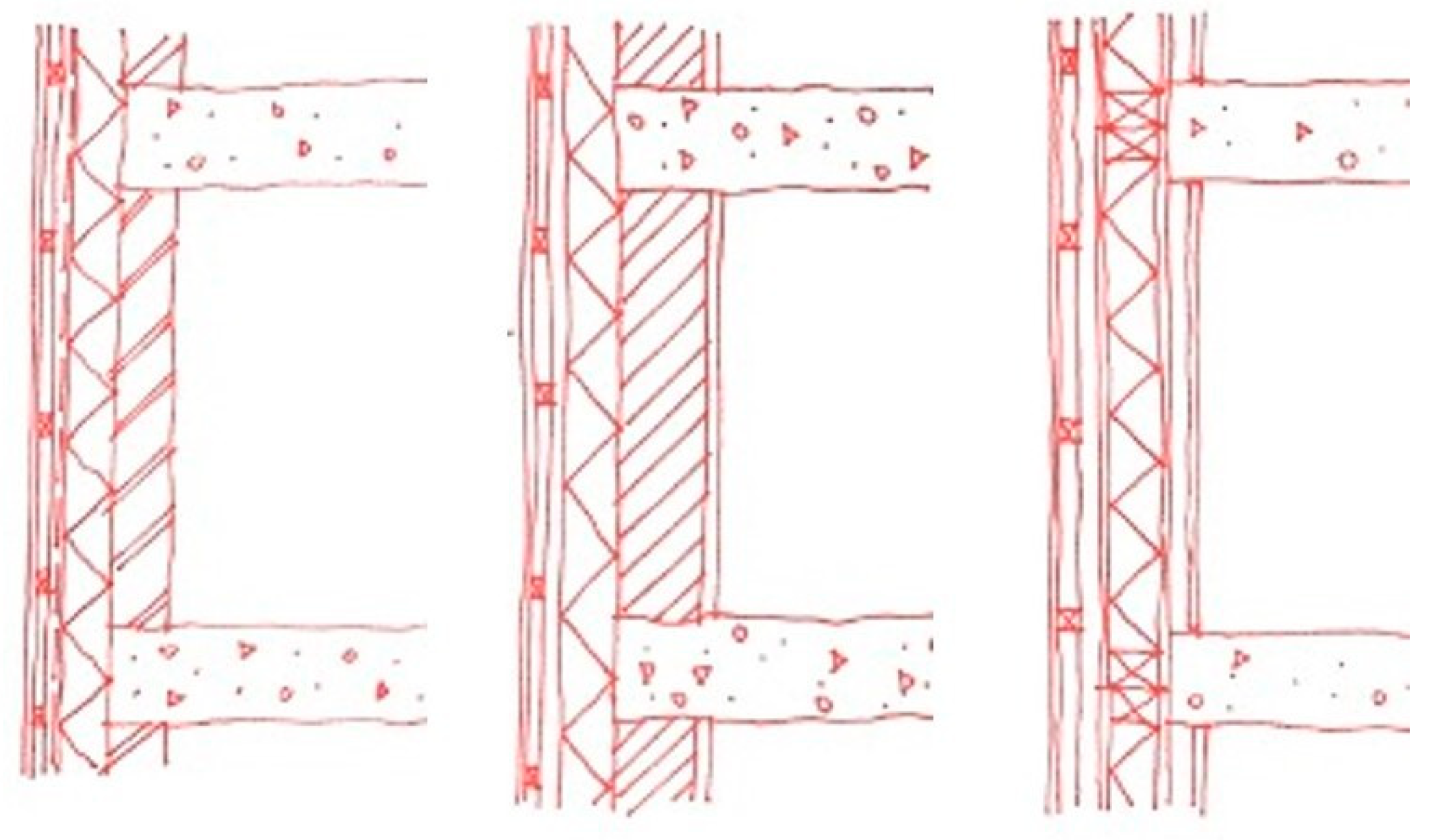

2.1.2. Detachability Assessment Based on Type of Connection

2.1.3. Linking LCA Results to Detachability Assessment Scores

- The first option of linking is done by the multiplication (1-CI) of each material with the EI, GWP or M of each material. The CI is subtracted from one, as the higher the CI, the better. While in the case of the EI, GWP or M, the lower the amount, the better. The subtraction is therefore needed to align the variables. Thus, the following equation is used to calculate the linked EI (EI’) of a building element consisting of n materials:

- 2.

- In the second explored option, an average (AVG) CI per component is calculated first before subtracting it from 1 and subsequently multiplying it with the EI, GWP or M of each material. The average component CI is calculated based on the CIs of the materials within each component. The second equation is:

- 3.

- As a variant on the previous option, in the third option, the smallest (i.e., worst scoring; MIN) CI of a material within a component is taken instead of the AVG of a component:

- 4.

- In the final possibility, the harmonic mean (HM) of CIs per component is applied:

2.2. Case Study Descriptions

2.2.1. Case Study 1: New Built Primary School

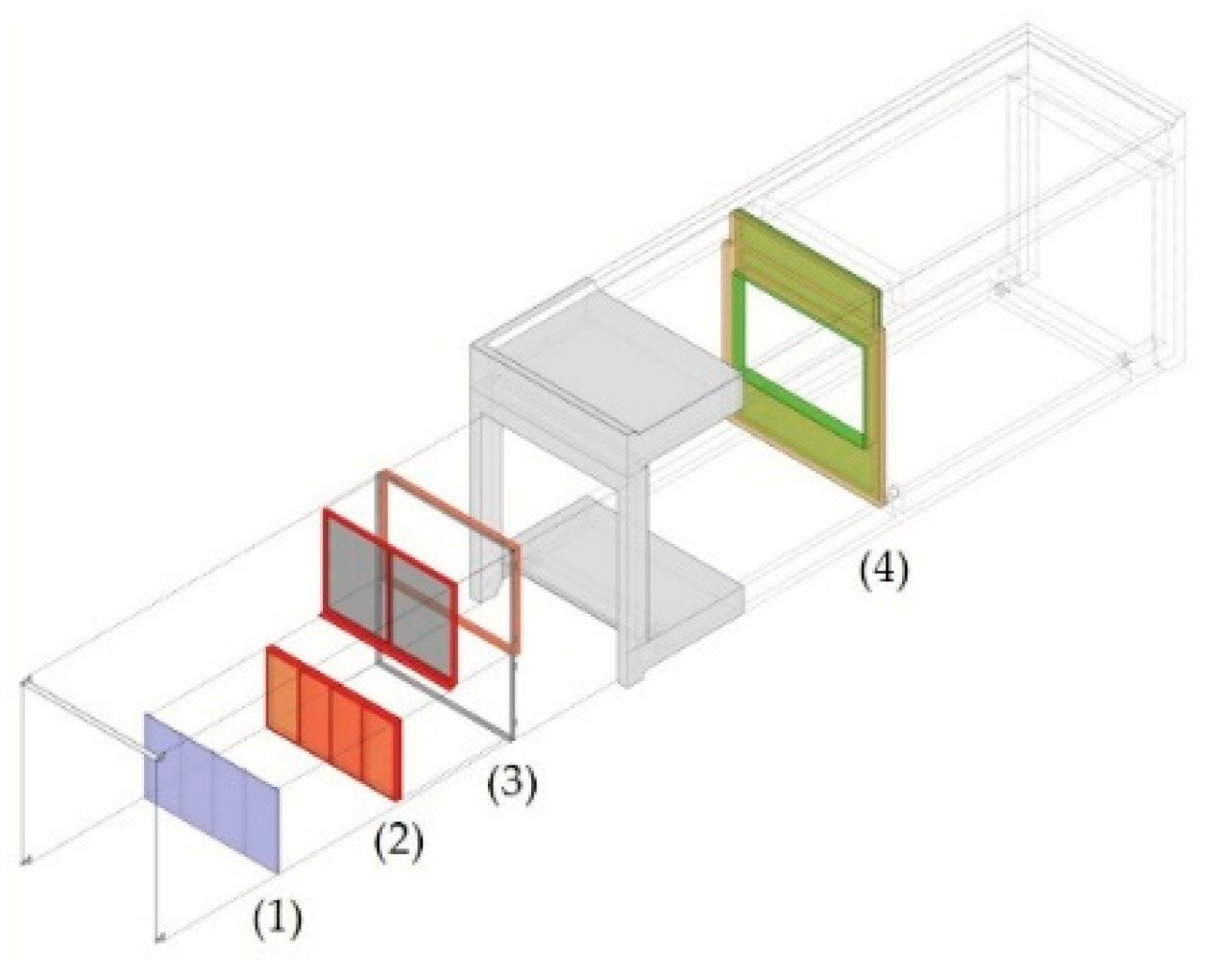

2.2.2. Case Study 2: Renovation of Student Housing Building

3. Results

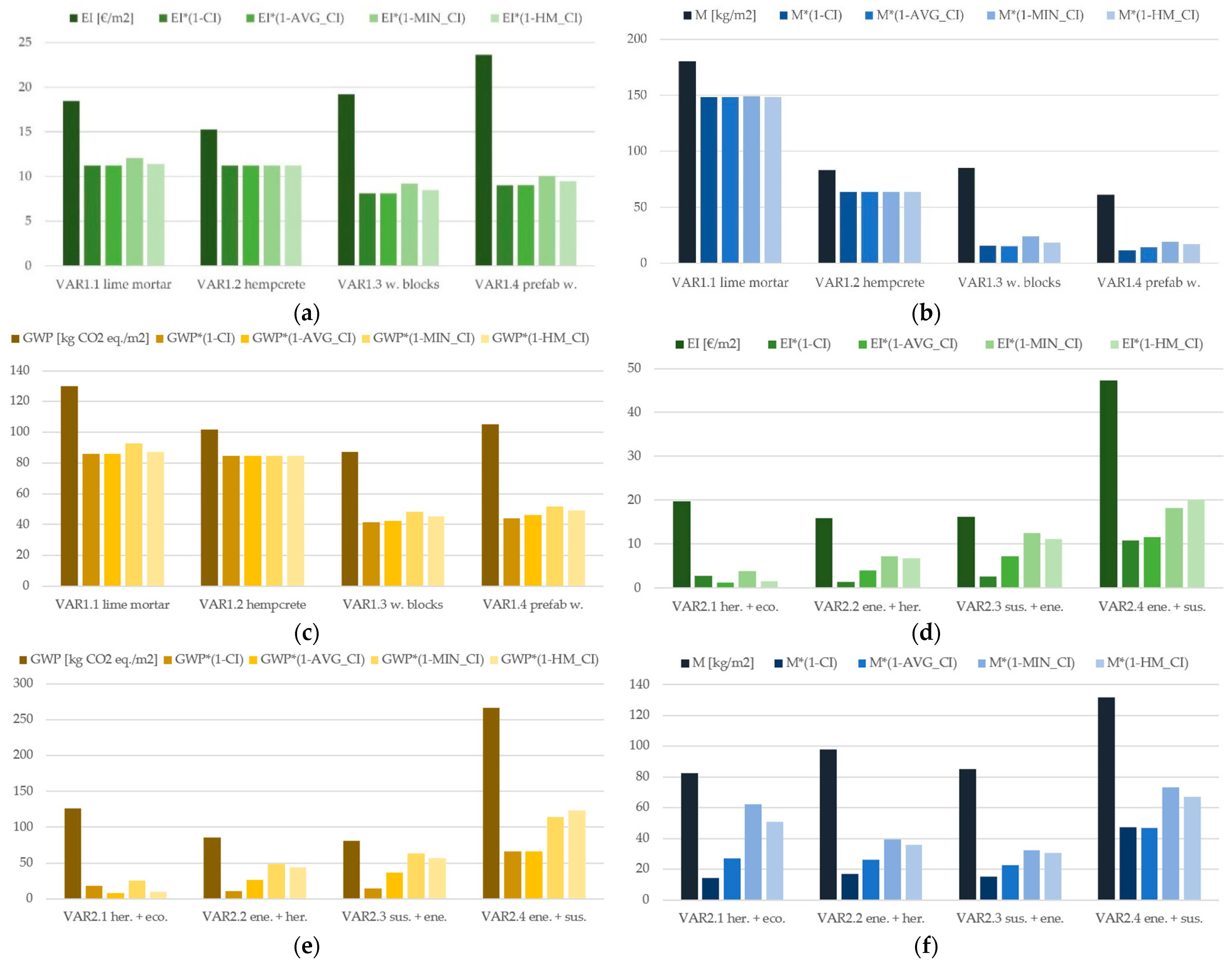

3.1. Unlinked Baseline Results

3.2. Applying the Linking Method

- between 50% and 62% regarding the EI,

- between 45% and 58% regarding the GWP,

- between 69% and 82% regarding the M,

4. Conclusions

5. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Accessibility of the Connection |

| AVG | Average |

| BAU | Business As Usual |

| BCI | Building Circularity Index |

| CI | Connection Index |

| CPR | Construction Products Regulation |

| CTI | Circular Transition Indicators |

| DfD | Design for Disassembly |

| DI | Detachability Index |

| EC | European Commission |

| EEC | Environmental External Costs |

| EI | Environmental Impact |

| EN | European Standard |

| EOL | End-of-Life |

| eq. | equivalents |

| GE | Geometry of building solution Edges |

| GWP | Global Warming Potential |

| HM | Harmonic Mean |

| IP | Interpenetrations |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| M | Mass (input flows) |

| MFA | Material Flow Analysis |

| MIN | Minimum |

| PEF | Product Environmental Footprint |

| RPT | Reuse Potential Tool |

| SPI | Sustainable Products Initiative |

| TC | Type of Connection |

| TCT | Transformation Capacity Tool |

| TOTEM | Tool to Optimise the Environmental impact of Materials |

References

- European Commission. Green Deal: New Proposals to Make Sustainable Products the Norm and Boost Europe’s Resource Independence. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_22_2013 (accessed on 7 April 2022).

- European Commission. DG GROW Proposal for a Regulation Laying Down Harmonised Conditions for the Marketing of Construction Products, Amending Regulation (EU) 2019/1020 and Repealing Regulation (EU) 305/2011. Available online: https://ec.europa.eu/docsroom/documents/49315 (accessed on 7 April 2022).

- European Commission. Sustainable Products Initiative. Available online: https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/12567-Sustainable-products-initiative_en (accessed on 7 April 2022).

- European Commission. DG ENV Proposal for Ecodesign for Sustainable Products Regulation. Available online: https://ec.europa.eu/environment/publications/proposal-ecodesign-sustainable-products-regulation_en (accessed on 7 April 2022).

- Galle, W.; Debacker, W.; De Weerdt, Y. Co-creating systemic changes for a circular economy in/under construction, preliminary lessons from the Flemish living lab on circular construction. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012012. [Google Scholar] [CrossRef]

- Cottafava, D.; Ritzen, M. Circularity indicator for residential buildings: Addressing the gap between embodied impacts and design aspects. Resour. Conserv. Recycl. 2021, 164, 105120. [Google Scholar] [CrossRef]

- Antonini, E.; Boeri, A.; Lauria, M.; Giglio, F. Reversibility and Durability as Potential Indicators for Circular Building Technologies. Sustainability 2020, 12, 7659. [Google Scholar] [CrossRef]

- Cambier, C.; Galle, W.; De Temmerman, N. Research and Development Directions for Design Support Tools for Circular Building. Buildings 2020, 10, 142. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Alba Concepts Building Circularity Index. Available online: https://albaconcepts.nl/building-circularity-index/#slide-1-wat-is-bci (accessed on 7 April 2022).

- OVAM. 24 Ontwerprichtlijnen Veranderingsgericht Bouwen; OVAM: Mechelen, Belgium, 2016. [Google Scholar]

- VUB Architectural Engineering. Building a Circular Economy: Design Qualities to Guide and Inspire Building Designers and Clients; VUB Architectural Engineering: Brussels, Belgium, 2019. [Google Scholar]

- Durmisevic, E. Reuse Potential Tool, Deliverable 8 Reversible Building Design, BAMB H2020 Project. 2019.

- Durmisevic, E. Transformation Capacity Tool, Deliverable 12.2, BAMB H2020 Project. 2019.

- Ellen MacArthur Foundation. Measure Business Circularity: Circulytics. Available online: https://ellenmacarthurfoundation.org/resources/circulytics/overview (accessed on 7 April 2022).

- WBCSD. Circular Transition Indicators V2.0, Metrics for Business, by Business; WBCSD: Geneva, Switzerland, 2021. [Google Scholar]

- ISO 20887:2020-01; Sustainability in Buildings and Civil Engineering Works—Design for Disassembly and Adaptability—Principles, Requirements and Guidance. International Organization for Standardization: Geneva, Switzerland, 2020.

- European Commission. Level(s) in Action. Available online: https://ec.europa.eu/environment/levels/lets-meet-levels/levels-action_en (accessed on 7 April 2022).

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Malabi Eberhardt, L.C.; van Stijn, A.; Nygaard Rasmussen, F.; Birkved, M.; Birgisdottir, H. Development of a Life Cycle Assessment Allocation Approach for Circular Economy in the Built Environment. Sustainability 2020, 12, 9579. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of environmental assessment methods when reusing building components: A case study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- CEN/TC. 350 EN 15804:2012+A2:2019; Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Products. CEN-CENELEC: Brussels, Belgium, 2019; p. 72.

- CEN/TC. 350 EN 15978:2011; Sustainability of Construction Works-Assessment of Environmental Performance of Buildings-Calculation Method. CEN-CENELEC: Brussels, Belgium, 2011; p. 60.

- Vandervaeren, C.; Galle, W.; Stephan, A.; De Temmerman, N. More than the sum of its parts: Considering interdependencies in the life cycle material flow and environmental assessment of demountable buildings. Resour. Conserv. Recycl. 2022, 177, 106001. [Google Scholar] [CrossRef]

- Malabi Eberhardt, L.C.; van Stijn, A.; Kristensen Stranddorf, L.; Birkved, M.; Birgisdottir, H. Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure. Sustainability 2021, 13, 5621. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; JRC Technical Reports; Publications Office of the European Union: Luxembourg, 2019.

- Rajagopalan, N.; Brancart, S.; De Regel, S.; Paduart, A.; De Temmerman, N.; Debacker, W. Multi-criteria decision analysis using life cycle assessment and life cycle costing in circular building design: A case study for wall partitioning systems in the circular retrofit lab. Sustainability 2021, 13, 5124. [Google Scholar] [CrossRef]

- van Stijn, A.; Malabi Eberhardt, L.C.; Wouterszoon Jansen, B.; Meijer, A. A Circular Economy Life Cycle Assessment (CE-LCA) model for building components. Resour. Conserv. Recycl. 2021, 174, 105683. [Google Scholar] [CrossRef]

- González, A.; Sendra, C.; Herena, A.; Rosquillas, M.; Vaz, D. Methodology to assess the circularity in building construction and refurbishment activities. Resour. Conserv. Recycl. Adv. 2021, 12, 200051. [Google Scholar] [CrossRef] [PubMed]

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C.-Q. An analytical review on application of life cycle assessment in circular economy for built environment. J. Build. Eng. 2021, 44, 103374. [Google Scholar] [CrossRef]

- Saidani, M.; Kreuder, A.; Babilonia, G.; Benavides, P.T.; Blume, N.; Jackson, S.; Koffler, C.; Kumar, M.; Minke, C.; Richkus, J.; et al. Clarify the nexus between life cycle assessment and circularity indicators: A SETAC/ACLCA interest group. Int. J. Life Cycle Assess. 2022, 27, 916–925. [Google Scholar] [CrossRef]

- Durmisevic, E. Reversible Building Design Guidelines, WP3 Report, BAMB H2020 Project. 2018.

- Debacker, W.; Allacker, K.; De Troyer, F.; Janssen, A.; Delem, L.; Peeters, K.; De Nocker, L.; Spirinckx, C.; Van Dessel, J. Milieugerelateerde Materiaalprestatie Van Gebouwelementen; OVAM: Mechelen, Belgium, 2012. [Google Scholar]

- Allacker, K.; Debacker, W.; Delem, L.; De Nocker, L.; De Troyer, F.; Janssen, A.; Peeters, K.; Van Dessel, J.; Servaes, R.; Rossi, E.; et al. Environmental Profile of Building Elements [Update 2020]; OVAM: Mechelen, Belgium, 2020. [Google Scholar]

- Lam, W.C.; Trigaux, D.; Serveas, R.; Allacker, K.; Debacker, W.; Delem, L.; De Nocker, L.; De Troyer, F.; Janssen, A.; Peeters, K.; et al. Environmental Profile of Buildings [Update 2021]; OVAM: Mechelen, Belgium, 2021. [Google Scholar]

- Durmisevic, E. Transformable Building Structures, Design for Disassembly as a Way to Introduce Sustainable Engineering to Building Design and Construction. Ph.D. Thesis, Technische Universiteit Delft, Delft, The Netherlands, 2006. [Google Scholar]

- Van Vliet, M.M. Disassembling the Steps towards Building Circularity, Redeveloping the Building Disassembly Assessment Method in the Building Circularity Indicator. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2018. [Google Scholar]

- Van Vliet, M.M.; van Grinsven, J.; Teunizen, J. Circular Buildings, Meetmethodiek Losmaakbaarheid Versie 2.0; Dutch Green Building Council: The Hague, The Netherlands, 2021. [Google Scholar]

- OVAM; SPW. Brussels Environment TOTEM. Available online: https://www.totem-building.be/ (accessed on 7 April 2022).

- NBN. NBN/DTD B 08-001:2017; Sustainability of Construction Works-Environmental Product Declarations—Core Rules for the Product Category of Construction Products—National Supplement to NBN EN 15804+A1:2014. NBN: Brussels, Belgium, 2017.

- CEN/TC. 350 EN 15804:2012+A1:2013; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN-CENELEC: Brussels, Belgium, 2013; p. 65.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: Roadmap to a Resource Efficient Europe; COM(2011) 571; European Commission: Brussels, Belgium, 2011.

- Wolf, M.-A.; Pant, R.; Chomkhamsri, K.; Sala, S.; Pennington, D. The International Reference Life Cycle Data System (ILCD) Handbook; Publications Office of the European Union: Ispra, Italy, 2012. [Google Scholar]

- Ecoinvent. Ecoinvent 3.3. Available online: https://ecoinvent.org/the-ecoinvent-database/data-releases/ecoinvent-3-3/ (accessed on 7 April 2022).

- De Nocker, L.; Debacker, W. Annex: Monetisation of the MMG Method (Update 2017); OVAM: Mechelen, Belgium, 2018. [Google Scholar]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—the UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Rabl, A.; Spadaro, J.V. The RiskPoll Software, Version 1.051. 20 August 2004.

- Frischknecht, R.; Steiner, R.; Jungbluth, N. The Ecological Scarcity Method–Eco-Factors 2006. A method for Impact Assessment in LCA; Environmental Studies No. 0906; Federal Office for the Environment (FOEN): Bern, Switzerland, 2008.

- Milà i Canals, L.; Romanyà, J.; Cowell, S.J. Method for assessing impacts on life support functions (LSF) related to the use of ‘fertile land’ in Life Cycle Assessment (LCA). J. Clean. Prod. 2007, 15, 1426–1440. [Google Scholar] [CrossRef]

- Köllner, T. Species-pool effect potentials (SPEP) as a yardstick to evaluate land-use impacts on biodiversity. J. Clean. Prod. 2000, 8, 293–311. [Google Scholar] [CrossRef]

- EC-DG GROW. Circular Economy—Principles for Building Design; European Commission: Brussels, Belgium, 2020.

- European Commission. Level(s) European Framework for Sustainable Buildings. Available online: https://ec.europa.eu/environment/levels_en (accessed on 7 April 2022).

- Allacker, K. Sustainable Building: The Development of an Evaluation Method. Ph.D. Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2010. [Google Scholar]

- World Bank Group. Belgium-Climatology|Climate Change Knowlegde Portal. Available online: https://climateknowledgeportal.worldbank.org/country/belgium/climate-data-historical#:~:text=Belgium%20has%20a%20temperate%20maritime,winters%20relatively%20mild%20and%20rainy (accessed on 12 July 2022).

- Michiels, J.; Lam, W.C.; Claes, S.; Elsen, S.; Galle, W.; Vergauwen, A.; Buyle, M. Circulaire School Voor De Toekomst, Eindverslag; Open Call Circulaire Stad en Ondernemen-Vlaanderen Circulair; Vrije Universiteit Brussel: Brussels, Belgium, 2021. [Google Scholar]

- MAKER Architecten; Origin Architecture & Engineering; VK Architects & Engineers; Beneens; JUUNOO; VITO. Het ontwerpen, ontwikkelen en uitvoeren van renovatiestrategieën van na-oorlogse architectuur’ Werkpakket 3, presentatie 15-07-2021. 2021; 129.

| # | Impact Category | Unit | LCIA Model | Monetary Value [€/Unit] |

|---|---|---|---|---|

| 1 | Global warming | kg CO2 eq. | EN 15804+A1 [42] (as used in CML version October 2012) | 0.05 |

| 2 | Ozone depletion | kg CFC 11 eq. | EN 15804+A1 [42] (as used in CML version October 2012) | 49.10 |

| 3 | Acidification for soil and water | kg SO2 eq. | EN 15804+A1 [42] (as used in CML version October 2012) | 0.43 |

| 4 | Eutrophication | kg (PO4)3-eq. | EN 15804+A1 [42] (as used in CML version October 2012) | 20 |

| 5 | Photochemical ozone creation | kg Ethene eq. | EN 15804+A1 [42] (as used in CML version October 2012) | 0.48 |

| 6 | Depletion of abiotic resources—elements | kg Sb eq. | EN 15804+A1 [42] (as used in CML version October 2012) | 1.56 |

| 7 | Depletion of abiotic resources—fossil fuels | MJ, net calorific value | EN 15804+A1 [42] (as used in CML version October 2012) | 0 |

| 8a | Human toxicity—cancer effects | CTUh | Rosenbaum et al., 2008 [47] (as used in USEtox) | 665,109 |

| 8b | Human toxicity—non-cancer effects | CTUh | Rosenbaum et al., 2008 [47] (as used in USEtox) | 144,081 |

| 9 | Particulate matter | kg PM2.5 eq. | Rabl & Spandaro, 2004 [48] (RiskPoll) | 34 |

| 10 | Ionising radiation-human health effects | kg U235 eq. | Frischknecht et al., 2000 [49] (as used in ReCiPe midpoint) | 9.7 × 10−4 |

| 11 | Ecotoxicity: freshwater | CTUe | Rosenbaum et al., 2008 [47] (as used in USEtox) | 3.7 × 10−5 |

| 12 | Water resource depletion | m3 water eq. | Frischknecht et al., 2008 [49] (as used in Swiss Ecoscarcity 2006) | 0.067 |

| 13a | Land use: occupation, soil organic matter | kg C deficit | Milà i Canals et al., 2007 [50] (Soil Organic Matter) | 1.4 × 10−6 |

| 13b | Land use: occupation, biodiversity-all * | PDF·m2yr | Köllner, 2000 [51] (as used in Eco-Indicator 99) | * |

| 13m1 | -urban | m2yr | Köllner, 2000 [51]; characterisation factors set on (−)1 | 0.30 |

| 13m2 | -agricultural | m2yr | Köllner, 2000 [51]; characterisation factors set on (−)1 | 0.006 |

| 13m3 | -forest | m2yr | Köllner, 2000 [51]; characterisation factors set on (−)1 | 2.2 × 10−4 |

| 14a | Land use: transformation, soil organic matter | kg C deficit | Milà i Canals et al., 2007 [50] (Soil Organic Matter) | 1.4 × 10−6 |

| 14b | Land use: transformation, biodiversity-all ** | PDF·m2 | Köllner, 2000 [51] (as used in Eco-Indicator 99) | ** |

| 14m1 | -urban | m2 | not available | not available |

| 14m2 | -agricultural | m2 | not available | not available |

| 14m3 | -forest | m2 | not available | not available |

| 14m4 | -tropical forest | m2 | Köllner, 2000 [51]; characterisation factors set on (−)1 | 27 |

| Type of Connection | Score | |

|---|---|---|

| Dry connection | Loose (no fixings) | 1.00 |

| Click connection | ||

| Velcro connection | ||

| Magnetic connection | ||

| Connection with added elements | Bolt and nut connection | 0.80 |

| Spring connection | ||

| Corner connection | ||

| Screw connection | ||

| Connection with added elements (e.g., a façade suspension system) | ||

| Direct integral connection | Pin connection (e.g., staples) | 0.60 |

| Nail connection | ||

| Soft chemical connection | Sealant connection | 0.20 |

| Foam connection | ||

| Hard chemical connection | Adhesive bond | 0.10 |

| Cast bond | ||

| Weld joint | ||

| Cement bond | ||

| Chemical anchors | ||

| Hard chemical bond |

| Wall Variant | External Finish | Insulation | Load-Bearing Structure | Internal Finish |

|---|---|---|---|---|

| Variant 1.1 lime mortar | Varnish | PUR board | Clay brick with lime mortar | Gypsum plaster |

| Softwood cladding | Paint | |||

| Variant 1.2 hempcrete | Varnish | Hempcrete blocks with adhesive mortar | Lime plaster | |

| Softwood cladding | Paint | |||

| Variant 1.3 wooden blocks | Varnish | Wooden building blocks filled w/cellulose flakes | Gypsum plaster board | |

| Softwood cladding | PUR board | Paint | ||

| Variant 1.4 prefab timber | Varnish | Prefab timber components filled with stone wool blankets | Gypsum plaster board | |

| Softwood cladding | Paint | |||

| Wall Variant | External Finish (1) | Insulation (2) | External Window (3) | Internal Finish (4) |

|---|---|---|---|---|

| Variant 2.1 Heritage + Economy | Concrete panel * | Polystyrene (above + under window) * | Aluminium frame * | Hollow wood fibreboard * |

| Single glazing * | Hermetic, aluminium frame with single glazing | |||

| Variant 2.2 Energy + Heritage | 3D printed panels | Stone wool in timber frame | Steel frame | Detachable steel frame with resol and stone wool filling and MDF finish |

| Concrete panel * | Double glazing | |||

| Variant 2.3 Sustainability + Energy | Ceramic fibre-reinforced panels | Stone wool in timber frame | Hardwood frame | Detachable steel frame stone wool filling and MDF finish |

| Concrete panel * | Double glazing | |||

| Variant 2.4 Energy + Sustainability | BIPV panels | Hemp lime between timber laths | Hardwood frame | Lime plaster |

| Concrete panel * | Stone wool in wood-aluminium curtain wall | Double glazing |

| Wall Variant Material | Component # | EI [€/m2] | GWP [kg. CO2 eq./m2] | M [€/m2] | mat_CI [-] | AVR_CI [-] | MIN_CI [-] | HM_CI [-] |

|---|---|---|---|---|---|---|---|---|

| VAR1.1 lime mortar masonry | ||||||||

| Varnish | 1 | 2.65 | 17.25 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| Softwood cladding, screwed | 2 | 3.27 | 8.88 | 13.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Timber substructure, screwed | 2 | 0.29 | 0.79 | 2.7 | 0.80 | 0.80 | 0.80 | 0.80 |

| PUR insulation board | 3 | 4.06 | 33.90 | 3.8 | 0.80 | 0.80 | 0.60 | 0.77 |

| Nylon fixings insulation board | 3 | 0.05 | 0.60 | 0.0 | 1.00 | 0.80 | 0.60 | 0.77 |

| Steel fixings insulation board | 3 | 0.02 | 0.08 | 0.0 | 0.60 | 0.80 | 0.60 | 0.77 |

| Clay brick | 4 | 2.67 | 31.66 | 124.6 | 0.10 | 0.10 | 0.10 | 0.10 |

| Lime mortar | 4 | 1.32 | 15.24 | 24.5 | 0.10 | 0.10 | 0.10 | 0.10 |

| Gypsum plaster | 5 | 0.40 | 3.66 | 10.8 | 0.10 | 0.10 | 0.10 | 0.10 |

| Softwood cladding, screwed | 6 | 3.74 | 17.98 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| VAR1.1 TOTAL | 18.46 | 130.04 | 180.2 | |||||

| VAR1.2 hempcrete blocks | ||||||||

| Varnish | 1 | 2.65 | 17.25 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| Softwood cladding, screwed | 2 | 3.27 | 8.88 | 13.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Timber substructure, screwed | 2 | 0.29 | 0.79 | 2.7 | 0.80 | 0.80 | 0.80 | 0.80 |

| Hempcrete blocks | 3 | 3.60 | 38.31 | 46.9 | 0.10 | 0.10 | 0.10 | 0.10 |

| Adhesive mortar | 3 | 0.07 | 0.81 | 3.8 | 0.10 | 0.10 | 0.10 | 0.10 |

| Lime plaster | 4 | 1.65 | 17.56 | 16.2 | 0.10 | 0.10 | 0.10 | 0.10 |

| Paint | 5 | 3.74 | 17.98 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| VAR1.2 TOTAL | 15.26 | 101.58 | 83.3 | |||||

| VAR1.3 wooden blocks | ||||||||

| Varnish | 1 | 2.65 | 17.25 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| Softwood cladding, screwed | 2 | 3.27 | 8.88 | 13.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Timber substructure, screwed | 2 | 0.29 | 0.79 | 2.7 | 0.80 | 0.80 | 0.80 | 0.80 |

| PUR insulation board, screwed | 3 | 1.04 | 5.18 | 2.6 | 0.80 | 0.80 | 0.80 | 0.80 |

| Wooden building blocks | 4 | 5.62 | 22.36 | 44.8 | 0.80 | 0.90 | 0.80 | 0.89 |

| Cellulose insulation flakes, loose | 4 | 1.04 | 5.18 | 9.3 | 1.00 | 0.90 | 0.80 | 0.89 |

| Timber substructure, screwed | 5 | 0.30 | 0.80 | 2.7 | 0.80 | 0.80 | 0.80 | 0.80 |

| Gypsum plaster board, screwed | 6 | 1.22 | 8.66 | 9.1 | 0.80 | 0.45 | 0.10 | 0.18 |

| Gypsum jointing compound | 6 | 0.04 | 0.25 | 0.2 | 0.10 | 0.45 | 0.10 | 0.18 |

| Paint | 7 | 3.74 | 17.98 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| VAR1.3 TOTAL | 19.20 | 87.35 | 84.9 | |||||

| VAR1.4 prefab wooden components | ||||||||

| Varnish | 1 | 2.65 | 17.25 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| Softwood cladding, screwed | 2 | 3.27 | 8.88 | 13.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Timber substructure, screwed | 2 | 0.29 | 0.79 | 2.7 | 0.80 | 0.80 | 0.80 | 0.80 |

| Bituminised fibreboard, prefab component | 3 | 8.41 | 31.54 | 5.9 | 0.80 | 0.85 | 0.80 | 0.84 |

| Timber frame, prefab component, screwed | 3 | 1.31 | 3.56 | 12.2 | 0.80 | 0.85 | 0.80 | 0.84 |

| Stone wool insulation, prefab component | 3 | 1.02 | 8.27 | 5.8 | 1.00 | 0.85 | 0.80 | 0.84 |

| OSB board of prefab component, screwed | 3 | 1.37 | 7.25 | 9.0 | 0.80 | 0.85 | 0.80 | 0.84 |

| Timber substructure, screwed | 4 | 0.30 | 0.80 | 2.7 | 0.80 | 0.80 | 0.80 | 0.80 |

| Gypsum plaster board, screwed | 5 | 1.22 | 8.66 | 9.1 | 0.80 | 0.45 | 0.10 | 0.18 |

| Gypsum jointing compound | 5 | 0.04 | 0.25 | 0.2 | 0.10 | 0.45 | 0.10 | 0.18 |

| Paint | 6 | 3.74 | 17.98 | 0.3 | 0.10 | 0.10 | 0.10 | 0.10 |

| VAR1.4 TOTAL | 23.62 | 105.23 | 61.2 |

| Wall Variant Material | Component # | EI [€/m2] | GWP [kg. CO2 eq./m2] | M [€/m2] | mat_CI [-] | AVR_CI [-] | MIN_CI [-] | HM_CI [-] |

|---|---|---|---|---|---|---|---|---|

| VAR2.1 heritage + economy | ||||||||

| Existing concrete panel | 1 | 0.00 | 0.00 | 51.2 | 0.80 | 0.60 | 0.10 | 0.24 |

| Existing polystyrene strips | 1 | 0.00 | 0.00 | 0.2 | 1.00 | 0.60 | 0.10 | 0.24 |

| Existing PE vapour barrier, glued | 1 | 0.00 | 0.00 | 0.0 | 0.10 | 0.60 | 0.10 | 0.24 |

| Existing waterproof foam tape + sealant | 1 | 0.00 | 0.00 | 0.0 | 0.10 | 0.60 | 0.10 | 0.24 |

| Existing hollow wood fibre board | 1 | 0.00 | 0.00 | 5.1 | 0.80 | 0.60 | 0.10 | 0.24 |

| Existing aluminium sliding window | 1 | 0.00 | 0.00 | 8.7 | 0.80 | 0.60 | 0.10 | 0.24 |

| Aluminium frame | 2 | 14.20 | 88.94 | 7.2 | 0.80 | 0.93 | 0.80 | 0.92 |

| Single glazing | 2 | 5.02 | 33.23 | 1.1 | 1.00 | 0.93 | 0.80 | 0.92 |

| Demountable rubbers and tape | 2 | 0.55 | 4.31 | 9.1 | 1.00 | 0.93 | 0.80 | 0.92 |

| VAR2.1 TOTAL | 19.77 | 126.48 | 82.6 | |||||

| VAR2.2 energy + heritage | ||||||||

| 3D printed panels | 1 | 5.60 | 18.10 | 5.8 | 1.00 | 0.90 | 0.80 | 0.89 |

| Vertical therm. modified wood laths | 1 | 0.10 | 0.27 | 0.2 | 0.80 | 0.90 | 0.80 | 0.89 |

| Existing concrete panel | 2 | 0.00 | 0.00 | 51.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Prefab steel structural frame | 3 | 1.41 | 8.44 | 4.0 | 1.00 | 0.55 | 0.10 | 0.18 |

| Waterproofing | 3 | 0.09 | 0.76 | 0.1 | 0.10 | 0.55 | 0.10 | 0.18 |

| Prefab hardwood timber frame | 4 | 0.02 | 0.05 | 1.3 | 0.80 | 0.45 | 0.10 | 0.18 |

| Air sealing tape | 4 | 0.00 | 0.02 | 0.0 | 0.10 | 0.45 | 0.10 | 0.18 |

| Timber frame | 5 | 0.09 | 0.30 | 0.7 | 0.60 | 0.57 | 0.10 | 0.24 |

| Stone wool insulation, timber frame | 5 | 0.17 | 1.40 | 1.1 | 1.00 | 0.57 | 0.10 | 0.24 |

| OSB board, internal finish | 5 | 0.36 | 2.17 | 2.9 | 0.80 | 0.57 | 0.10 | 0.24 |

| Woodfibre board, external finish | 5 | 0.31 | 1.30 | 1.5 | 0.80 | 0.57 | 0.10 | 0.24 |

| Waterproofing | 5 | 0.09 | 0.76 | 0.1 | 0.10 | 0.57 | 0.10 | 0.24 |

| Air sealing tape | 5 | 0.00 | 0.02 | 0.0 | 0.10 | 0.57 | 0.10 | 0.24 |

| Steel window frame with double glazing | 6 | 4.84 | 33.90 | 18.1 | 0.80 | 0.45 | 0.10 | 0.18 |

| Waterproofing | 6 | 0.07 | 0.56 | 0.1 | 0.10 | 0.45 | 0.10 | 0.18 |

| Steel T-shaped anchor | 7 | 0.06 | 0.36 | 0.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Sunblind, roller | 7 | 0.26 | 1.72 | 1.5 | 0.80 | 0.80 | 0.80 | 0.80 |

| Reusable modular interior wall system | 8 | 1.70 | 5.05 | 1.9 | 1.00 | 0.95 | 0.80 | 0.94 |

| Stone wool insulation, timber frame | 8 | 0.16 | 1.30 | 1.1 | 1.00 | 0.95 | 0.80 | 0.94 |

| Resol insulation | 8 | 0.50 | 7.03 | 1.1 | 1.00 | 0.95 | 0.80 | 0.94 |

| MDF board, internal finish | 8 | 0.07 | 2.14 | 5.0 | 0.80 | 0.95 | 0.80 | 0.94 |

| VAR2.2 TOTAL | 15.89 | 85.64 | 97.9 | |||||

| VAR2.3 sustainability + energy | ||||||||

| Ceramic fibre-reinforced panels | 1 | 0.20 | 1.63 | 6.3 | 1.00 | 0.90 | 0.80 | 0.89 |

| Vertical therm. modified wood laths | 1 | 0.10 | 0.27 | 0.2 | 0.80 | 0.90 | 0.80 | 0.89 |

| Existing concrete panel | 2 | 0.00 | 0.00 | 51.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Prefab steel structural frame | 3 | 1.41 | 8.44 | 4.0 | 1.00 | 0.55 | 0.10 | 0.18 |

| Waterproofing | 3 | 0.09 | 0.76 | 0.1 | 0.10 | 0.55 | 0.10 | 0.18 |

| Prefab hardwood timber frame | 4 | 0.02 | 0.05 | 1.3 | 0.80 | 0.45 | 0.10 | 0.18 |

| Air sealing tape | 4 | 0.00 | 0.02 | 0.0 | 0.10 | 0.45 | 0.10 | 0.18 |

| Timber frame | 5 | 0.09 | 0.30 | 0.7 | 0.60 | 0.57 | 0.10 | 0.24 |

| Stone wool insulation, timber frame | 5 | 0.17 | 1.40 | 1.1 | 1.00 | 0.57 | 0.10 | 0.24 |

| OSB board, internal finish | 5 | 0.36 | 2.17 | 2.9 | 0.80 | 0.57 | 0.10 | 0.24 |

| Woodfibre board, external finish | 5 | 0.31 | 1.30 | 1.5 | 0.80 | 0.57 | 0.10 | 0.24 |

| Waterproofing | 5 | 0.09 | 0.76 | 0.1 | 0.10 | 0.57 | 0.10 | 0.24 |

| Air sealing tape | 5 | 0.00 | 0.02 | 0.0 | 0.10 | 0.57 | 0.10 | 0.24 |

| Hardwood window frame with double glazing | 6 | 10.70 | 52.56 | 11.9 | 0.80 | 0.45 | 0.10 | 0.18 |

| Waterproofing | 6 | 0.07 | 0.56 | 0.1 | 0.10 | 0.45 | 0.10 | 0.18 |

| Steel T-shaped anchor | 7 | 0.06 | 0.36 | 0.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Sunblind, roller | 7 | 0.26 | 1.72 | 1.5 | 0.80 | 0.80 | 0.80 | 0.80 |

| Reusable modular interior wall system | 8 | 1.70 | 5.05 | 0.4 | 1.00 | 0.93 | 0.80 | 0.92 |

| Stone wool insulation, timber frame | 8 | 0.17 | 1.40 | 0.4 | 1.00 | 0.93 | 0.80 | 0.92 |

| Resol insulation | 8 | 0.35 | 2.14 | 1.0 | 0.80 | 0.93 | 0.80 | 0.92 |

| MDF board, internal finish | 8 | 0.00 | 0.00 | 0.0 | 0.00 | 0.00 | 0.00 | 0.00 |

| VAR2.3 TOTAL | 16.16 | 80.89 | 85.0 | |||||

| VAR2.4 energy + sustainability | ||||||||

| BIPV panels | 1 | 17.96 | 110.73 | 8.0 | 0.80 | 0.80 | 0.80 | 0.80 |

| Existing concrete panel | 2 | 0.00 | 0.00 | 51.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Timber laths, hemp lime | 3 | 0.34 | 0.94 | 2.9 | 0.60 | 0.50 | 0.10 | 0.23 |

| Hemp lime | 3 | 1.48 | 16.64 | 23.4 | 0.10 | 0.50 | 0.10 | 0.23 |

| Gypsum fibreboard | 3 | 0.73 | 4.70 | 9.4 | 0.80 | 0.50 | 0.10 | 0.23 |

| Wood-aluminium curtain wall profiles | 4 | 1.70 | 28.68 | 10.5 | 0.80 | 0.63 | 0.10 | 0.24 |

| Stone wool panels, curtain wall | 4 | 0.41 | 3.34 | 2.9 | 1.00 | 0.63 | 0.10 | 0.24 |

| Waterproofing | 4 | 0.09 | 0.76 | 0.1 | 0.10 | 0.63 | 0.10 | 0.24 |

| Hardwood window frame with double glazing | 5 | 12.43 | 60.70 | 13.5 | 0.80 | 0.45 | 0.10 | 0.18 |

| Waterproofing | 5 | 0.07 | 0.61 | 0.1 | 0.10 | 0.45 | 0.10 | 0.18 |

| Steel T-shaped anchor | 6 | 0.06 | 0.36 | 0.2 | 0.80 | 0.80 | 0.80 | 0.80 |

| Venetian blind, aluminium slats | 6 | 11.68 | 37.80 | 3.3 | 0.80 | 0.80 | 0.80 | 0.80 |

| Lime plaster, on hemp lime | 7 | 0.30 | 1.60 | 6.4 | 0.10 | 0.10 | 0.10 | 0.10 |

| VAR2.4 TOTAL | 47.25 | 266.88 | 132.0 |

| Linked with HM_CI | M*(1-HM_CI) | −18% | −23% | −78% | −72% | −39% | −63% | −64% | −49% |

| 148.5 | 63.9 | 18.3 | 17 | 50.8 | 36 | 30.7 | 67.2 | ||

| GWP*(1-HM_CI) | −33% | −17% | −48% | −53% | −92% | −49% | −29% | −54% | |

| 87.24 | 84.66 | 45.21 | 49.1 | 9.73 | 43.81 | 57.07 | 123.5 | ||

| EI*(1-HM_CI) | −38% | −26% | −56% | −60% | −92% | −57% | −31% | −57% | |

| 11.38 | 11.25 | 8.5 | 9.47 | 1.52 | 6.89 | 11.14 | 20.11 | ||

| Linked with MIN_CI | M*(1-MIN_CI) | −17% | −23% | −72% | −69% | −25% | −60% | −62% | −44% |

| 149.1 | 63.9 | 23.8 | 19.1 | 62.2 | 39.4 | 32.4 | 73.3 | ||

| GWP*(1-MIN_CI) | −28% | −17% | −45% | −51% | −80% | −44% | −21% | −57% | |

| 92.98 | 84.66 | 48.35 | 51.92 | 25.3 | 48.22 | 63.63 | 113.8 | ||

| EI*(1-MIN_CI) | −35% | −26% | −52% | −57% | −80% | −54% | −23% | −62% | |

| 12.06 | 11.25 | 9.19 | 10.07 | 3.95 | 7.25 | 12.49 | 18.15 | ||

| Linked with AVG_CI | M*(1-AVG_CI) | −18% | −23% | −82% | −77% | −67% | −73% | −73% | −64% |

| 148.3 | 63.9 | 15.2 | 14.2 | 27.3 | 26.4 | 22.7 | 47.0 | ||

| GWP*(1-AVG_CI) | −34% | −17% | −51% | −56% | −93% | −69% | −54% | −75% | |

| 86.07 | 84.66 | 42.49 | 46.29 | 8.43 | 26.9 | 36.96 | 65.96 | ||

| EI*(1-AVG_CI) | −39% | −26% | −58% | −62% | −93% | −75% | −55% | −75% | |

| 11.24 | 11.25 | 8.08 | 9.03 | 1.32 | 4.01 | 7.26 | 11.58 | ||

| Linked with mat_CI | M*(1-CI) | −18% | −23% | −82% | −81% | −82% | −83% | −82% | −64% |

| 148.3 | 63.9 | 15.6 | 11.6 | 14.5 | 17 | 15 | 47.5 | ||

| GWP*(1-CI) | −34% | −17% | −53% | −58% | −86% | −88% | −83% | −75% | |

| 85.96 | 84.66 | 41.27 | 44.23 | 17.79 | 10.41 | 14.14 | 66.62 | ||

| EI*(1-CI) | −39% | −26% | −58% | −62% | −86% | −91% | −83% | −77% | |

| 11.23 | 11.25 | 8.13 | 9.02 | 2.84 | 1.46 | 2.69 | 10.8 | ||

| VAR1.1 | VAR1.2 | VAR1.3 | VAR1.4 | VAR2.1 | VAR2.2 | VAR2.3 | VAR2.4 |

| Case Study 1 | Case Study 2 | |||||

|---|---|---|---|---|---|---|

| ∆ EI [€/m2] | ∆ GWP [kg CO2 eq./m2] | ∆ M [kg/m2] | ∆ EI [€/m2] | ∆ GWP [kg CO2 eq./m2] | ∆ M [kg/m2] | |

| Baseline unlinked results | 8.36 | 42.69 | 118.9 | 31.36 | 185.99 | 49.4 |

| Linked with mat_CI | 3.11 | 44.69 | 136.7 | 9.34 | 56.22 | 33.0 |

| Linked with AVR_CI | 3.16 | 43.58 | 134.1 | 10.26 | 57.52 | 24.3 |

| Linked with MIN_CI | 2.87 | 44.63 | 130.0 | 14.19 | 88.52 | 40.9 |

| Linked with HM_CI | 2.88 | 42.03 | 131.5 | 18.59 | 113.76 | 36.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lam, W.C.; Claes, S.; Ritzen, M. Exploring the Missing Link between Life Cycle Assessment and Circularity Assessment in the Built Environment. Buildings 2022, 12, 2152. https://doi.org/10.3390/buildings12122152

Lam WC, Claes S, Ritzen M. Exploring the Missing Link between Life Cycle Assessment and Circularity Assessment in the Built Environment. Buildings. 2022; 12(12):2152. https://doi.org/10.3390/buildings12122152

Chicago/Turabian StyleLam, Wai Chung, Steven Claes, and Michiel Ritzen. 2022. "Exploring the Missing Link between Life Cycle Assessment and Circularity Assessment in the Built Environment" Buildings 12, no. 12: 2152. https://doi.org/10.3390/buildings12122152

APA StyleLam, W. C., Claes, S., & Ritzen, M. (2022). Exploring the Missing Link between Life Cycle Assessment and Circularity Assessment in the Built Environment. Buildings, 12(12), 2152. https://doi.org/10.3390/buildings12122152