Life-Cycle Assessment of Contemporary and Classical Seismic Retrofitting Approaches Applied to a Reinforced Concrete Building in Israel

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Framework

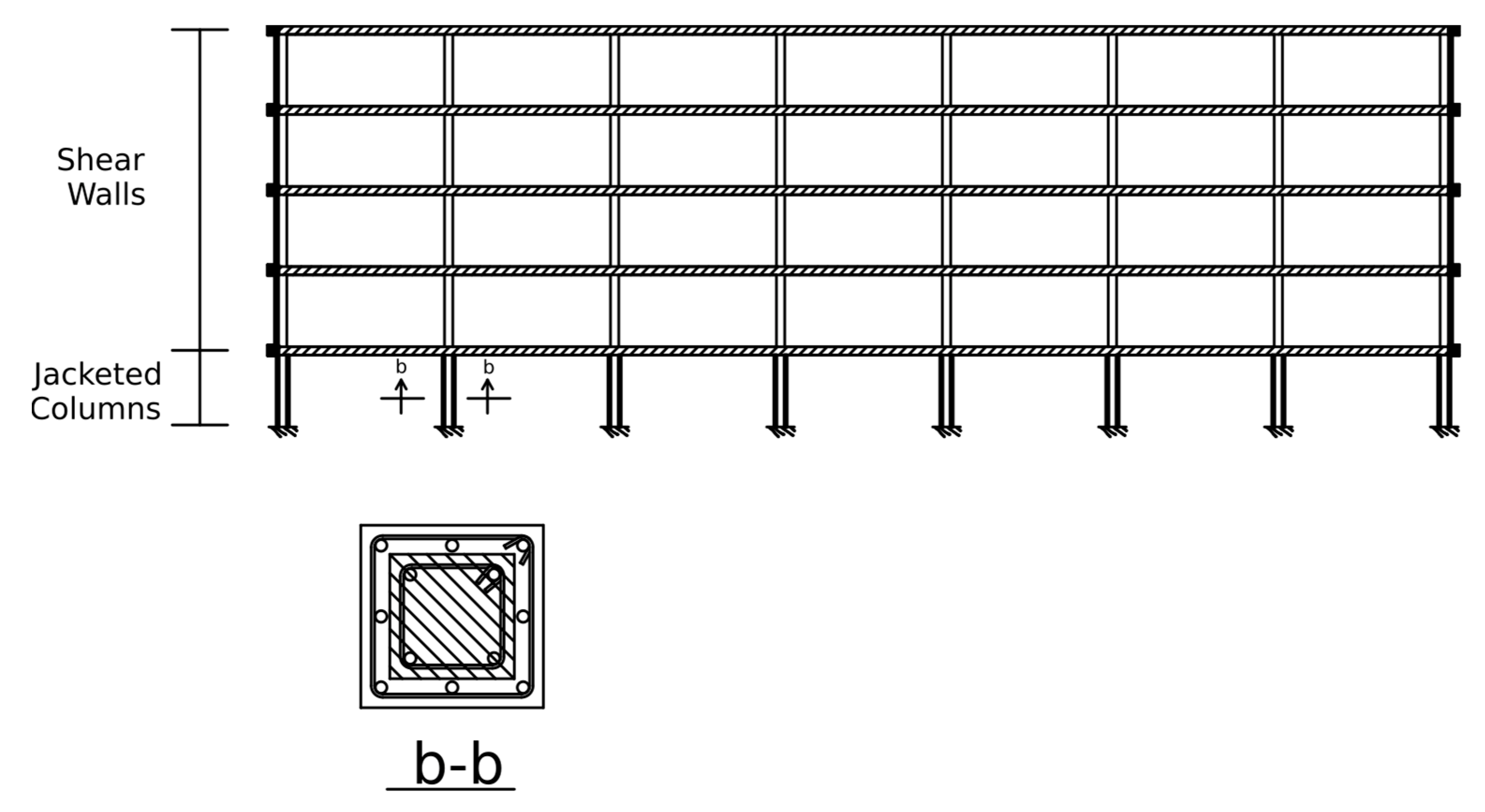

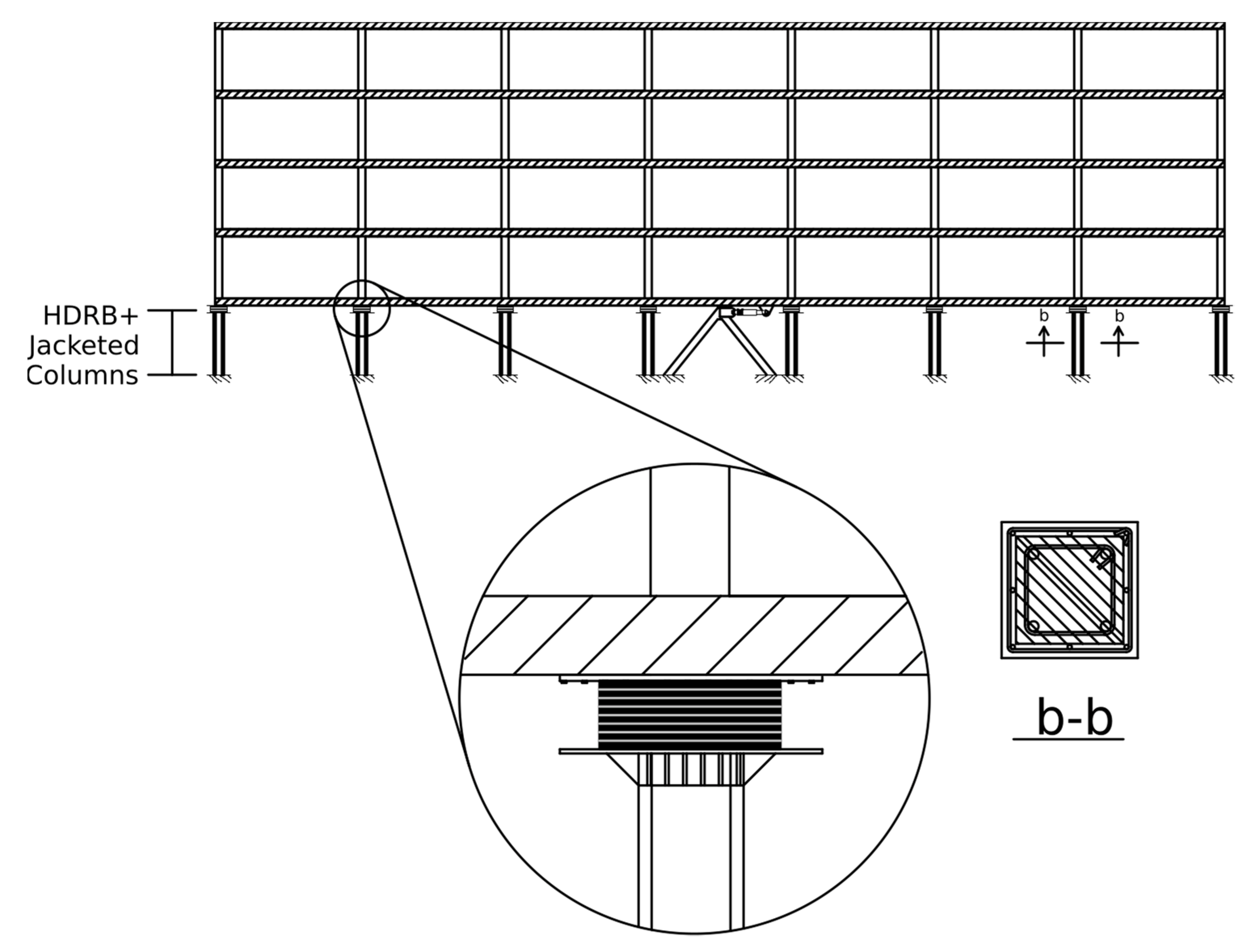

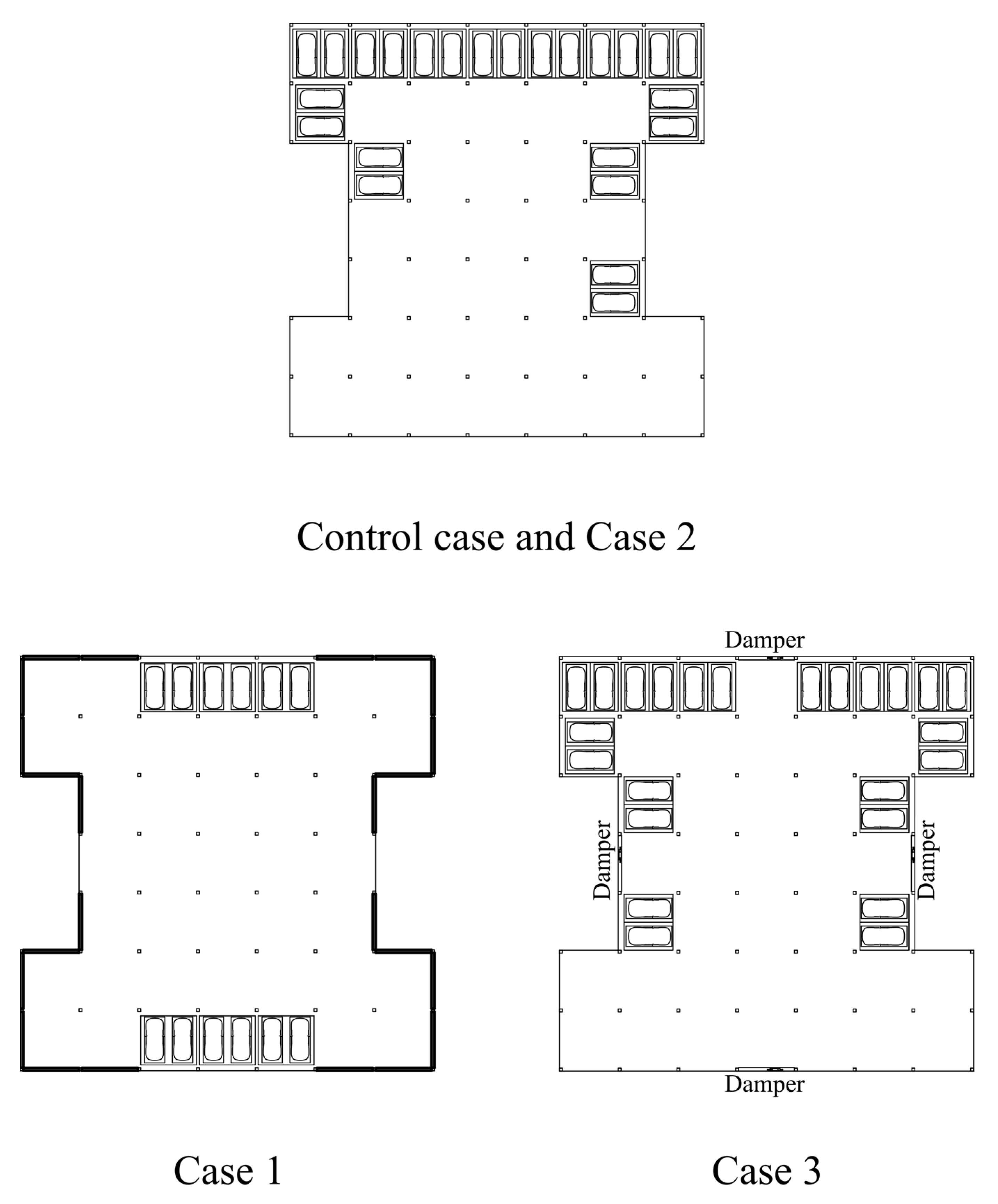

2.2. Seismic Response Analysis

2.3. Environmental Evaluation

2.3.1. LCA Stages

2.3.2. Functional Units and System Boundaries

2.3.3. Life-Cycle Inventory

2.3.4. Life-Cycle Impact Assessment

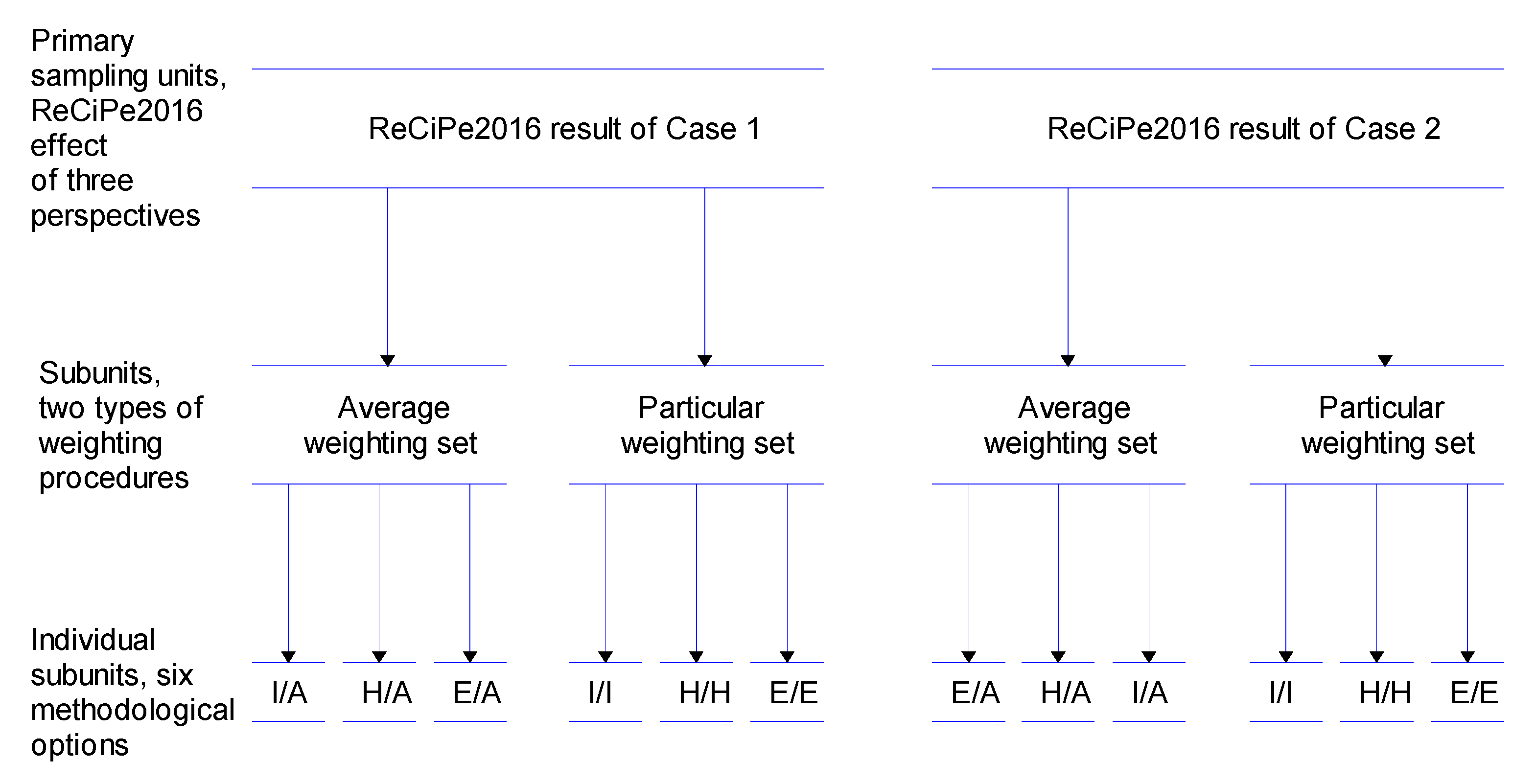

2.4. Statistical Evaluation

3. Results and Discussion

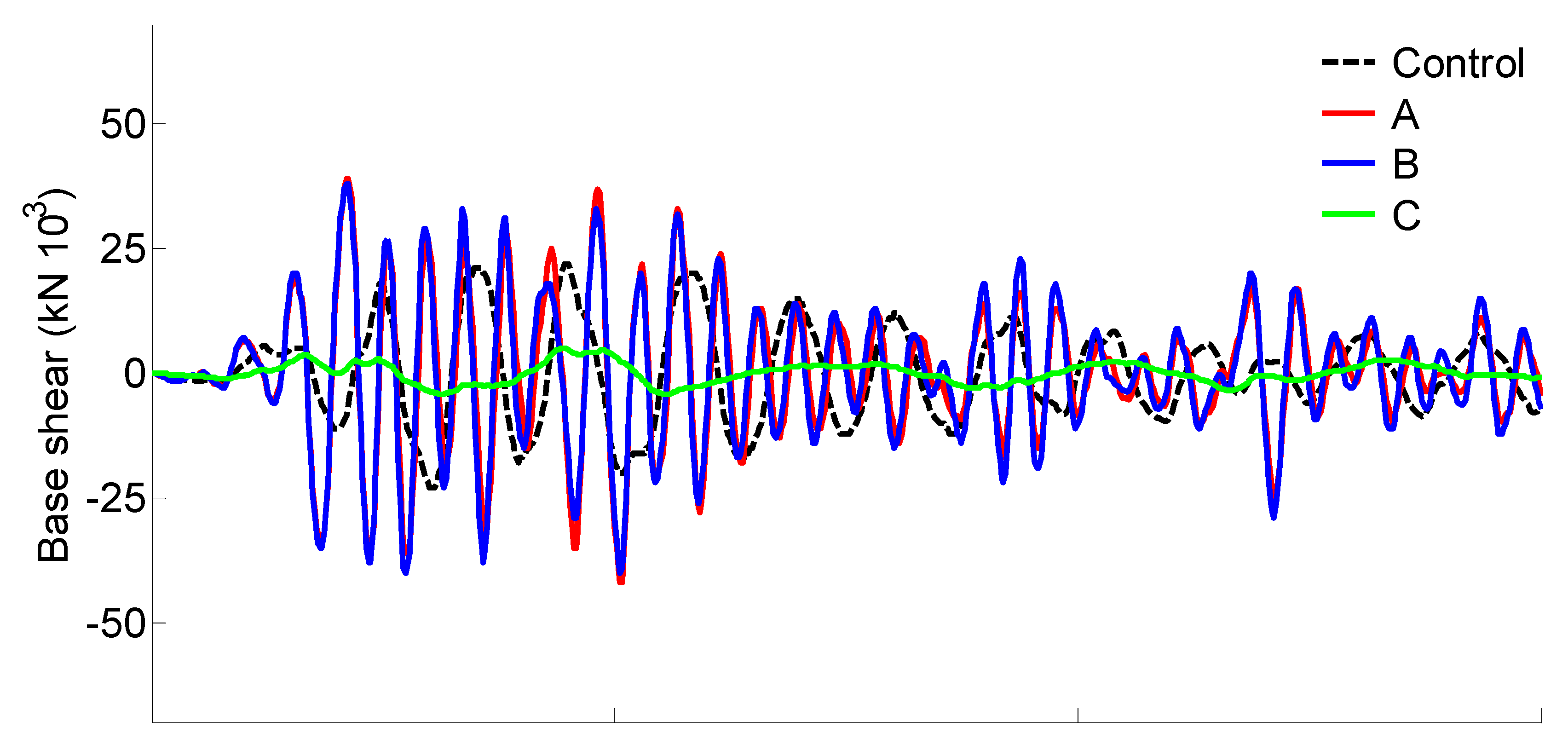

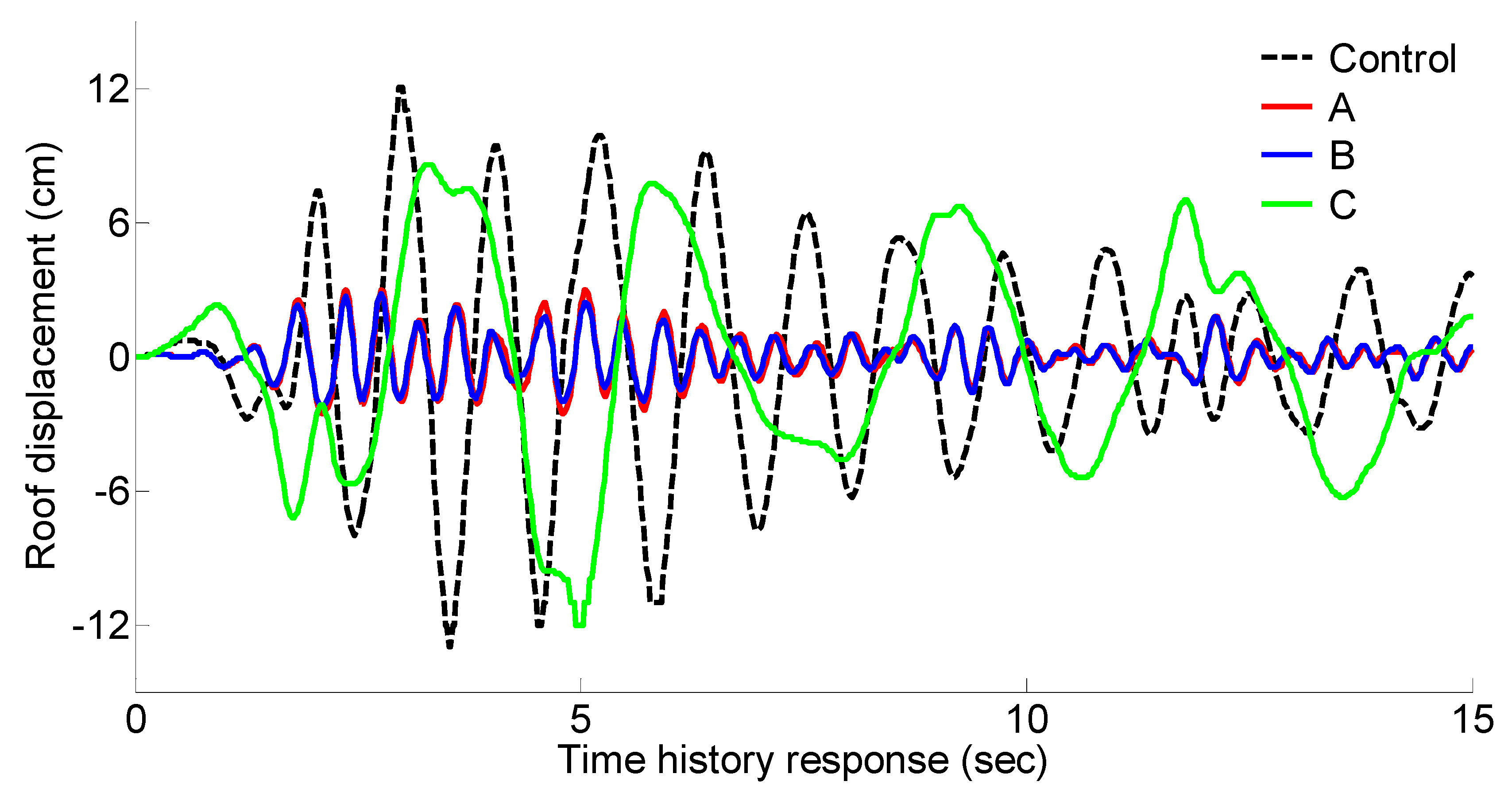

3.1. Seismic Performance

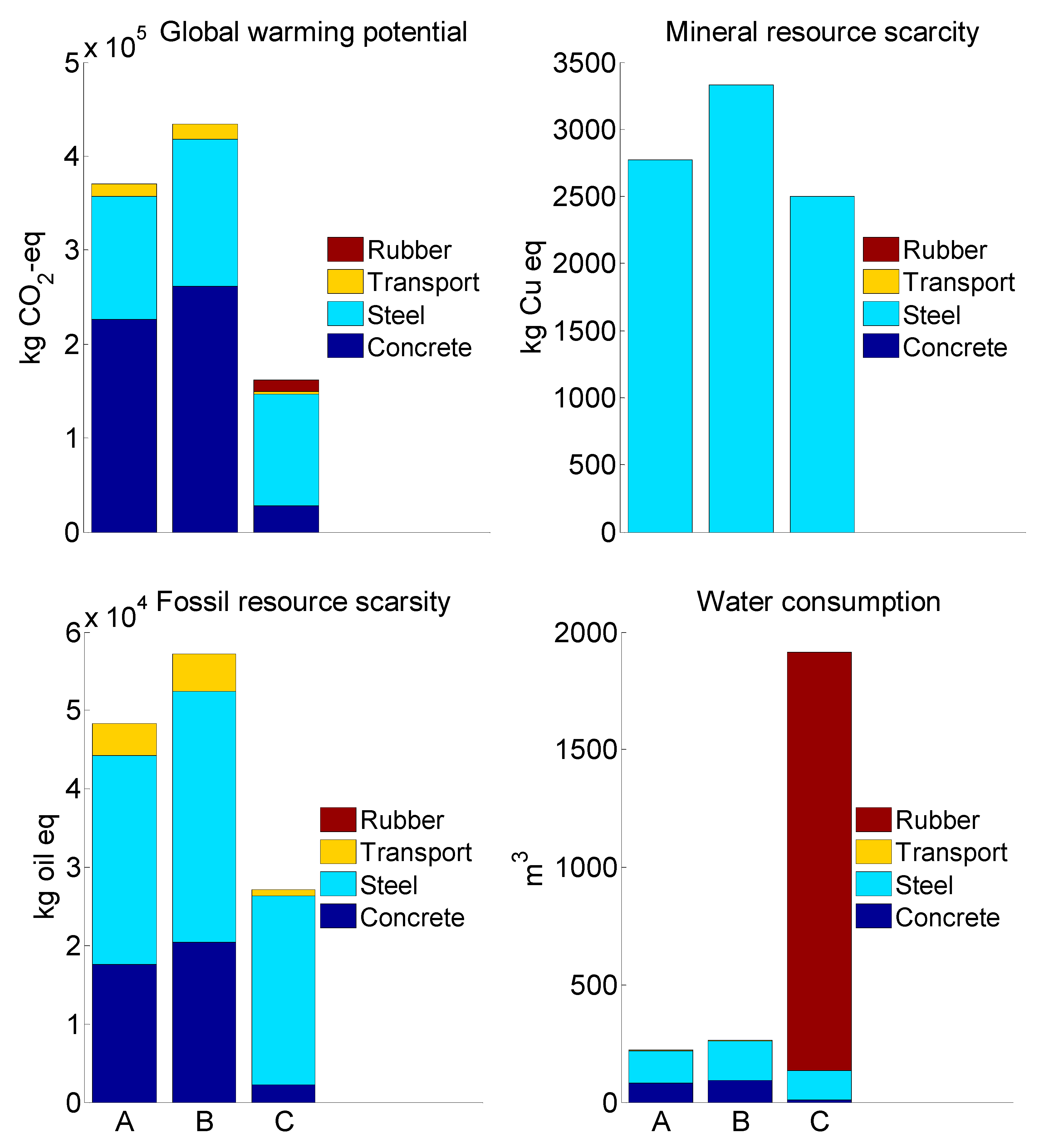

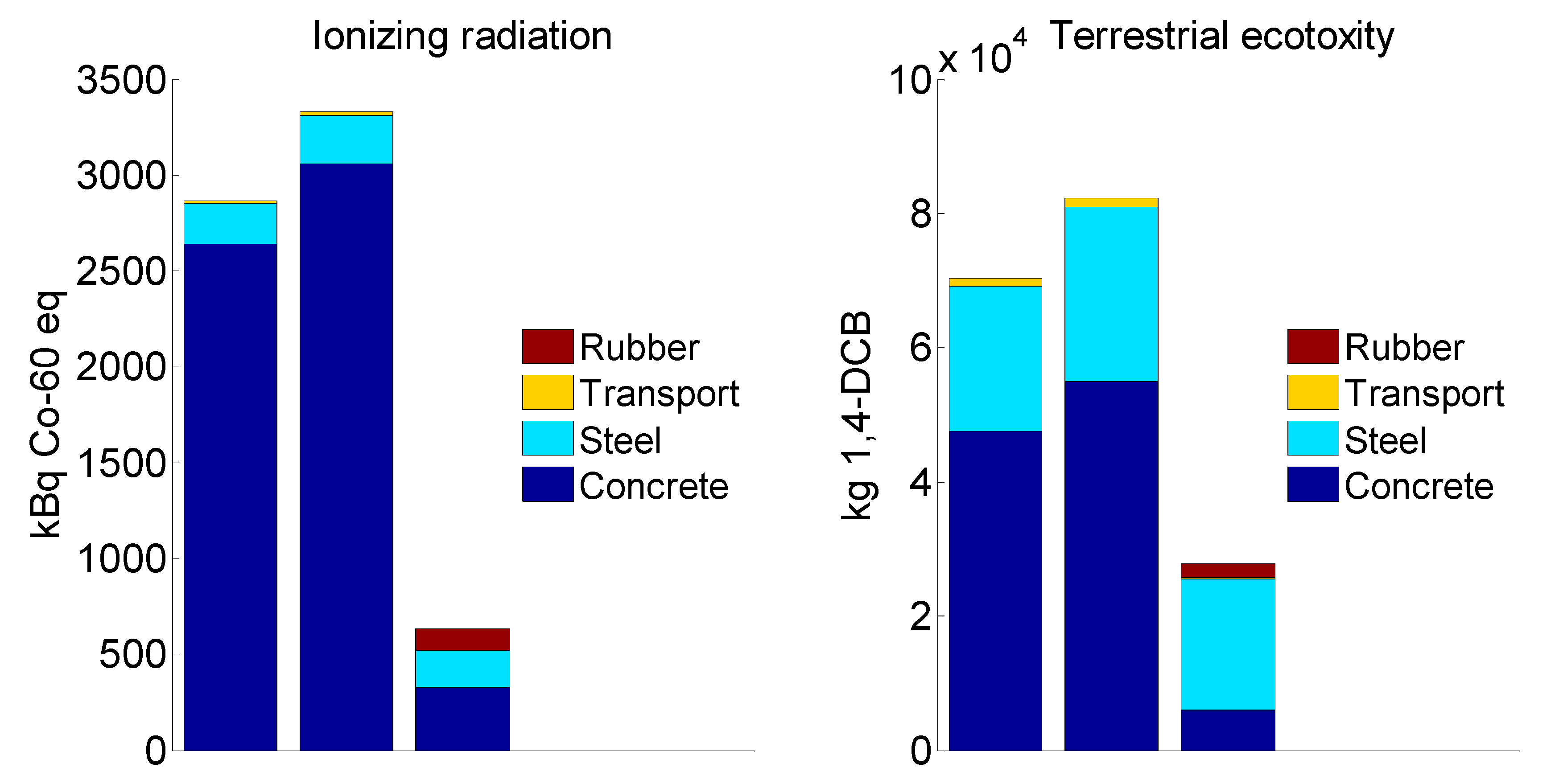

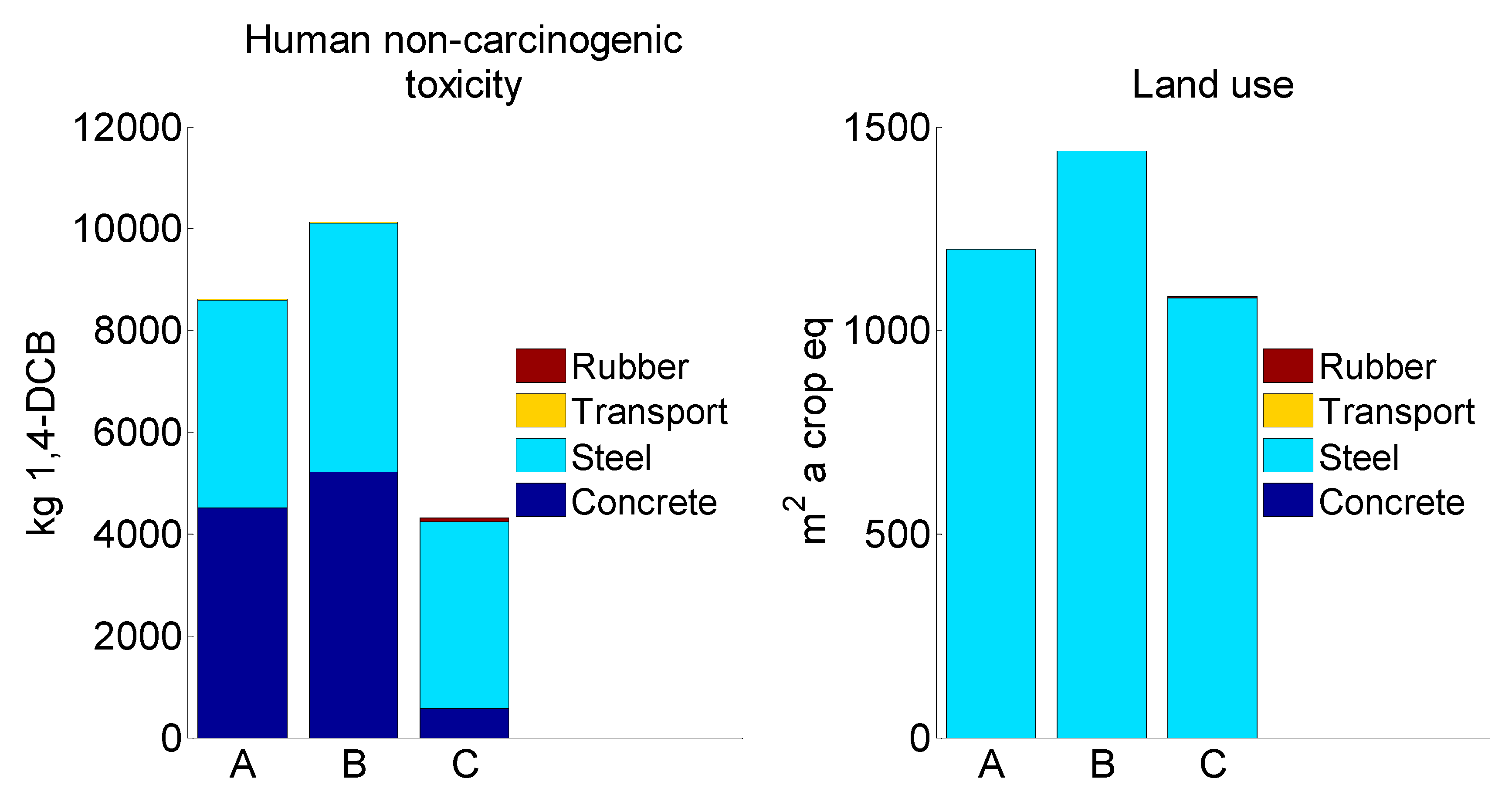

3.2. ReCiPe 2016 Midpoint Results

3.3. ReCiPe 2016 Endpoint Single-Score Results

3.4. The Effect on the Parking Spots

4. Conclusions

- Based on the seismic analyses, the three cases improved the retrofitted building’s seismic-bearing capacity, with a preference for Case 3 as the most effective method. However, the environmental damage caused by these three cases was completely different.

- According to the ReCiPe 2016 midpoint results, the production of Case 3 caused the least damage to the environment, while the production of Case 2 caused the most damage to the environment; Case 1’s production caused moderate environmental damage.

- According to the ReCiPe 2016 endpoint single-score results, the environmental damage in Case 3 was significantly lower than in Cases 1 and 2, which had significantly similar environmental damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ribakov, Y.; Halperin, I.; Pushkar, S. Seismic resistance and sustainable performance of retrofitted buildings by adding stiff diaphragms or seismic isolation. J. Architect. Eng. 2018, 24, 04017028. [Google Scholar] [CrossRef]

- Margalit, T.; Mualam, T. Selective Rescaling, Inequality and Popular Growth Coalitions: The Case of the Israeli National Plan for Earthquake Preparedness. Land Use Policy 2020, 99, 105123. [Google Scholar] [CrossRef]

- Kaliyaperumal, G.; Sengupta, A.K. Seismic retrofit of columns in buildings for flexure using concrete jacket. ISET Earthq. Techn. J. 2009, 46, 77–107. [Google Scholar]

- Aguilar, J.; Juarez, H.; Ortega, R.; Iglesias, J. The Mexico Earthquake of September 19, 1985-Statistics of Damage and of Retrofitting Techniques in Reinforced Concrete Buildings Affected by the 1985 Earthquake. Earthq. Spectra 1989, 5, 145–151. [Google Scholar] [CrossRef]

- Sudha, C.; Sambasivan, A.K.; Rajkumar, P.R.K.; Jegan, M. Investigation on the performance of reinforced concrete columns jacketed by conventional concrete and geopolymer concrete. Eng. Sci. Technol. Int. J. 2022, 101275, in press. [Google Scholar] [CrossRef]

- Ribakov, Y.; Halperin, I.; Pushkar, S. Using Eco-indicator 99 and a two-stage nested analysis of variance test to evaluate building mitigation measures under hazard risks. Adv. Struct. Eng. 2016, 19, 860–870. [Google Scholar] [CrossRef]

- Halperin, I.; Ribakov, Y.; Agranovich, G. Optimal viscous dampers gains for structures subjected to earthquakes. Struct. Contr. Health Monit. 2016, 23, 458–469. [Google Scholar] [CrossRef]

- Tiwari, P.; Badal, P.; Suwal, R. Effectiveness of fluid viscous dampers in the seismic performance enhancement of RC buildings. Asian J. Civ. Eng. 2022. [Google Scholar] [CrossRef]

- Naeim, F.; Kelly, J.M. Design of Seismic Isolated Structures: From Theory to Practice, 1st ed.; John Wiley and Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Chen, B.; Dai, J.; Song, T.; Guan, Q. Research and Development of High-Performance High-Damping Rubber Materials for High-Damping Rubber Isolation Bearings: A Review. Polymers 2022, 14, 2427. [Google Scholar] [CrossRef]

- Ribakov, Y. Reduction of structural response to near fault earthquakes by seismic isolation columns and variable friction dampers. Earthq. Eng. Engin. Vib. 2010, 9, 113–122. [Google Scholar] [CrossRef]

- Mori, C.; Sorace, S.; Terenzi, G. Seismic assessment and retrofit of two heritage listed R/C elevated water storage tanks. Soil Dyn. Earthq. Eng. 2015, 77, 123–136. [Google Scholar] [CrossRef]

- Jangid, R.; Kelly, J. Base Isolation for Near-fault Motions. Earthq. Eng. Struct. Dyn. 2001, 30, 691–707. [Google Scholar] [CrossRef]

- Saif, H.; Lee, D.; Retamal, E. Viscous Damping for Base-Isolated Structures, Taylor Devices. 1998. Available online: https://www.taylordevices.com/white-paper/36-viscous-damping-for-base-isolated-structures/ (accessed on 1 November 2022).

- Sorace, S.; Terenzi, G.; Magonette, G.; Molina, F.J. Experimental investigation on a base isolation system incorporating steel–Teflon sliders and pressurized fluid viscous spring dampers. Earthq. Eng. Struct. Dyn. 2008, 37, 225–242. [Google Scholar] [CrossRef]

- Mohebbi, M.; Noruzvand, M.; Dadkhah, H.; Shakeri, K. Direct displacement-based design approach for isolated structures equipped with supplemental fluid viscous damper. J. Build. Eng. 2022, 45, 103684. [Google Scholar] [CrossRef]

- Chen, X.; Xiong, J. Seismic resilient design with base isolation device using friction pendulum bearing and viscous damper. Soil Dyn. Earthq. Eng. 2022, 153, 107073. [Google Scholar] [CrossRef]

- Tsipianitis, A.; Tsompanakis, Y. Improving the seismic performance of base-isolated liquid storage tanks with supplemental linear viscous dampers. Earthq. Eng. Eng. Vib. 2022, 21, 269–282. [Google Scholar] [CrossRef]

- Mazza, F. Base-isolation of a hospital pavilion against in-plane-out-of-plane seismic collapse of masonry infills. Eng. Struct. 2021, 228, 111504. [Google Scholar] [CrossRef]

- Mazza, F. Seismic vulnerability and retrofitting by damped braces of fire-damaged R.C. framed buildings. Eng. Struct. 2015, 101, 179–192. [Google Scholar] [CrossRef]

- Mazza, F. Dissipative steel exoskeletons for the seismic control of reinforced concrete framed buildings. Struct. Contr. Health Monit. 2021, 28, e2683. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G. Non-linear dynamic design procedure of FV spring-dampers for base-isolation–frame building appications. Eng. Struct. 2001, 23, 1568–1576. [Google Scholar] [CrossRef]

- Stengel, T.; Schiessl, P. Life Cycle Assessment (LCA) of Ultra High Performance Concrete (UHPC) Structures. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labeling and Case Studies; Pacheco Torgal, F., Cabeza, L.F., Labrincha, J., DeMagalhaes, A., Eds.; Woodhead Publishing: Sawston, UK, 2014; Volume 49, pp. 528–564. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ’green’concretes: Literature review and theoretical calculations. Cement Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Wei, H.H.; Shohet, I.M.; Skibniewski, M.J.; Shapira, S.; Yao, X. Assessing the lifecycle sustainability costs and benefits of seismic mitigation designs for buildings. J. Archit. Eng. 2016, 22, 04015011. [Google Scholar] [CrossRef]

- Vitiello, U.; Salzano, A.; Asprone, D.; Di Ludovico, M.; Prota, A. Life-Cycle Assessment of Seismic Retrofit Strategies Applied to Existing Building Structures. Sustainability 2016, 8, 1275. [Google Scholar] [CrossRef]

- Salgado, R.A.; Apul, D.; Guner, S. Life cycle assessment of seismic retrofit alternatives for reinforced concrete frame buildings. J. Build. Eng. 2020, 28, 101064. [Google Scholar] [CrossRef]

- Welsh-Huggins, S.J.; Liel, A.B. A life-cycle framework for integrating green building and hazard-resistant design: Examining the seismic impacts of buildings with green roofs. Struct. Infrastruct. 2017, 13, 19–33. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering; Prentice-Hall: Hoboken, NJ, USA, 1995. [Google Scholar]

- Briman, V.; Ribakov, Y. Using seismic isolation columns for retrofitting buildings with soft stories. Struct. Des. Tall Spec. Build 2009, 18, 507–523. [Google Scholar] [CrossRef]

- Spencer, B.F., Jr. Next Generation Benchmark Control Problems for Seismically Excited Buildings. In Proceedings of the 2nd World Conference on Structural Control, Kyoto, Japan, 28 June–1 July 1998; pp. 1335–1360. [Google Scholar]

- Antsaklis, P.J.; Michel, A.N. Linear Systems, 2nd ed.; Birkhäuser: Boston, MA, USA, 2006. [Google Scholar]

- Burl, J.B. Linear Optimal Control-H2 and H∞ Methods; Addison Wesley: Menlo Park, CA, USA, 1999. [Google Scholar]

- IS 413. Israeli Standard–413; Design Provisions for Earthquake Resistance of Structures. Standards Institute of Israel: Tel-Aviv, Israel, 1998. (In Hebrew)

- ISO 13315-1; Environmental Management for Concrete and Concrete Structures, Part. 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2012.

- Martin, J. Long Term Performance of Rubber in Seismic and Non-Seismic Bearings: A Literature Review; U.S. Department of Commerce National Institute of Standards and Technology, Building and Fire Research Laboratory: Galthenburg, MD, USA, 1991; p. 20899.

- Napolano, L.; Menna, C.; Asprone, D.; Prota, A.; Manfredi, G. Life cycle environmental impact of different replacement options for a typical old flat roof. Int. J. Life Cycle Assess. 2015, 20, 694–708. [Google Scholar] [CrossRef]

- Scheuer, C.; Keolian, G.; Reppe, B. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management Life Cycle Assessment Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Bilec, M.M.; Ries, R.J.; Matthews, H.S. Life-cycle assessment modeling of construction processes for buildings. J. Infrastruct. Syst. 2010, 16, 199–205. [Google Scholar] [CrossRef]

- SimaPro, Version 9.0; PRé Consultants: Amersfoort, The Netherlands, 2019; Available online: https://simapro.com/ (accessed on 15 September 2022).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Picquelle, S.J.; Mier, K.L. A practical guide to statistical methods for comparing means from two-stage sampling. Fish Res. 2011, 107, 1–13. [Google Scholar] [CrossRef]

- Pushkar, S. The Effect of Different Concrete Designs on the Life-Cycle Assessment of the Environmental Impacts of Concretes Containing Furnace Bottom-Ash Instead of Sand. Sustainability 2019, 11, 4083. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the substitution of natural materials with industrial byproducts in green roofs using life cycle assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- Hurlbert, S.H.; Lombardi, C.M. Final collapse of the Neyman-Pearson decision theoretic framework and rise of the neoFisherian. Ann. Zool. Fenn 2009, 46, 311–349. Available online: https://www.jstor.org/stable/23736900 (accessed on 20 April 2022).

- MATLAB; [Computer software]. MathWorks: Natick, MA, USA, 2022.

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Ménaché, J.; O’Moore, L.M. Impact of Fly Ash Content and Fly Ash Transportation Distance on Embodied. Greenhouse Gas Emissions and Water Consumption in Concrete. Int. J. Life Cycle Assess. 2009, 7, 621–629. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Petek Gursel, A.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical Properties, Durability, and Life-Cycle Assessment of Self-Consolidating Concrete Mixtures Made with Blended Portland Cements Containing Fly Ash and Limestone Powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Gursel, A.P.; Ostertag, C. Impact of Singapore’s importers on life-cycle assessment of concrete. J. Clean. Prod. 2016, 118, 140–150. [Google Scholar] [CrossRef]

- Conejo, A.N.; Birat, J.-P.; Dutta, A. A review of the current environmental challenges of the steel industry and its value chain. J. Environ. Manag. 2020, 259, 109782. [Google Scholar] [CrossRef]

- Liang, T.; Wang, S.; Lu, C.; Jiang, N.; Long, W.; Zhang, M.; Zhang, R. Environmental impact evaluation of an iron and steel plant in China: Normalized data and direct/indirect contribution. J. Clean. Prod. 2020, 264, 121697. [Google Scholar] [CrossRef]

- Pushkar, S. Using Eco-Indicator 99 to Evaluate Building Technologies under Life Cycle Assessment Uncertainties. J. Architect. Eng. 2014, 20, 04013010-1-10. [Google Scholar] [CrossRef]

- Pushkar, S. Life Cycle Assessment of Flat Roof Technologies for Office Buildings in Israel. Sustainability 2016, 8, 54. [Google Scholar] [CrossRef]

| Floor | Case 1 | Case 2 |

|---|---|---|

| Ground | Type I | - |

| 1 | Type I | Type I |

| 2 | Type II | Type I |

| 3 | Type II | Type II |

| 4 | Type II | Type II |

| Mode | Control Case | Case 1 | Case 2 | Case 3 |

|---|---|---|---|---|

| 1 | 88.3% | 82.14% | 91.26% | 99.93% |

| 2 | 8.61% | 10.24% | 7.3% | 0.07% |

| 3 | 2.3% | 7.46% | 1.07% | - |

| 4 | 0.66% | 0.11% | 0.24% | - |

| 5 | 0.13% | 0.05% | 0.13% | - |

| Mode | El Centro | Kobe | Hachinohe | Northridge |

|---|---|---|---|---|

| Earthquake name | Imperial Valley | Kobe | Tokachi-oki | Northridge |

| Date (UTC) | 18 May 1940 | 16 January 1995 | 16 May 1968 | 17 January 1994 |

| Magnitude | 6.9 Mw | 6.9 Mw | 8.3 Mw | 6.7 Mw |

| Station | El Centro (No. 117) | KJMA | Hachinohe Port | Sylmar, county hospital parking lot |

| Epicentral distance | 11.5 km | 14.6 km | 158 km | 15.3 km |

| Original PGA | 0.349 g | 0.82 g | 0.23 g | 0.84 g |

| Scaled PGA | 0.3 g | 0.3 g | 0.3 g | 0.3 g |

| Record’s duration | 50.02 s | 59.98 s | 36.01 s | 60.02 s |

| Retrofitting Measure | Material per Retrofitting Measure (tons) | |||

|---|---|---|---|---|

| Concrete | Steel | Rubber | ||

| Case 1 | Shear walls | 587 | 16.6 | - |

| Circumferential beams | 401 | 11.4 | - | |

| Foundations | 864 | 28.6 | - | |

| Total | 1852 | 56.6 | - | |

| Case 2 | Columns’ jacketing | 52 | 1.5 | - |

| Shear walls | 489 | 16.6 | - | |

| Circumferential beams | 401 | 11.4 | - | |

| Foundations | 1201 | 38.5 | - | |

| Total | 2142 | 68 | - | |

| Case 3 | Isolators | - | 40.2 | 2.59 |

| Dampers | 6.7 | 1.6 | - | |

| Columns’ jacketing | 19.7 | 0.7 | - | |

| Foundations | 205 | 8.6 | - | |

| Total | 231.4 | 51.1 | 2.59 | |

| Material/Process | Reference |

|---|---|

| Concrete | Pre-cast concrete, production mixture C 20/25/RER U |

| Steel | Steel rebar/EU |

| Rubber | Acrylonitrile–butadiene–styrene copolymer, ABC, at plant/RER U |

| Transportation | Lorry transport, Euro 0, 1, 2, 3, 4 mix, 22 t total weight, 17.3 t |

| Material/Process | Concrete (1 kg) | Steel (1 kg) | Rubber (1 kg) | Transport (1 tkm) |

|---|---|---|---|---|

| GWP (kg CO2) | 0.122 | 2.31 | 4.73 | 0.376 |

| MRS (kg Cu eq) | - | 0.049 | - | - |

| FRS (kg oil eq) | 0.00951 | 0.471 | - | - |

| WC (m3) | 0.0000438 | 0.00246 | 0.688 | 0.225 |

| IO (kBq Co-60 eq) | 0.00143 | 0.00371 | 0.0439 | 0.047 |

| TE (kg 1,4-DCB) | 0.0257 | 0.381 | 0.821 | 1.14 |

| HNCT (kg 1,4-DCB) | 0.00244 | 0.0718 | 0.0256 | 0.0813 |

| LU (m2 a crop eq) | - | 0.0211 | 0.00166 | - |

| Floor | Control | Case 1 | Case 2 | Case 3 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| El Centro | Hachinohe | Kobe | Northridge | El Centro | Hachinohe | Kobe | Northridge | El Centro | Hachinohe | Kobe | Northridge | El Centro | Hachinohe | Kobe | Northridge | |

| 1 | 36 | 43 | 48 | 47 | 6 | 7 | 9 | 9 | 10 | 14 | 17 | 19 | 6 | 9 | 5 | 8 |

| 2 | 32 | 39 | 44 | 37 | 10 | 12 | 15 | 16 | 5 | 6 | 7 | 8 | 6 | 10 | 5 | 8 |

| 3 | 30 | 34 | 35 | 31 | 4 | 5 | 5 | 6 | 5 | 6 | 7 | 8 | 6 | 8 | 5 | 7 |

| 4 | 22 | 28 | 26 | 26 | 9 | 11 | 12 | 14 | 5 | 7 | 7 | 9 | 4 | 6 | 4 | 5 |

| 5 | 10 | 15 | 12 | 13 | 3 | 4 | 4 | 5 | 3 | 4 | 4 | 5 | 2 | 2 | 2 | 2 |

| Case | J1 | J2 |

|---|---|---|

| Case 1 | 0.32 | 1.62 |

| Case 2 | 0.34 | 1.58 |

| Case 3 | 0.28 | 0.27 |

| Case | A | B | C |

|---|---|---|---|

| A | X | 0.0807 | 0.0044 |

| B | X | 0.0030 | |

| C | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushkar, S.; Halperin, I.; Ribakov, Y. Life-Cycle Assessment of Contemporary and Classical Seismic Retrofitting Approaches Applied to a Reinforced Concrete Building in Israel. Buildings 2022, 12, 1854. https://doi.org/10.3390/buildings12111854

Pushkar S, Halperin I, Ribakov Y. Life-Cycle Assessment of Contemporary and Classical Seismic Retrofitting Approaches Applied to a Reinforced Concrete Building in Israel. Buildings. 2022; 12(11):1854. https://doi.org/10.3390/buildings12111854

Chicago/Turabian StylePushkar, Svetlana, Ido Halperin, and Yuri Ribakov. 2022. "Life-Cycle Assessment of Contemporary and Classical Seismic Retrofitting Approaches Applied to a Reinforced Concrete Building in Israel" Buildings 12, no. 11: 1854. https://doi.org/10.3390/buildings12111854

APA StylePushkar, S., Halperin, I., & Ribakov, Y. (2022). Life-Cycle Assessment of Contemporary and Classical Seismic Retrofitting Approaches Applied to a Reinforced Concrete Building in Israel. Buildings, 12(11), 1854. https://doi.org/10.3390/buildings12111854