Magnetic Signal Characteristics in Critical Yield State of Steel Box Girder Based on Metal Magnetic Memory Inspection

Abstract

1. Introduction

2. Experiments

2.1. Material Properties

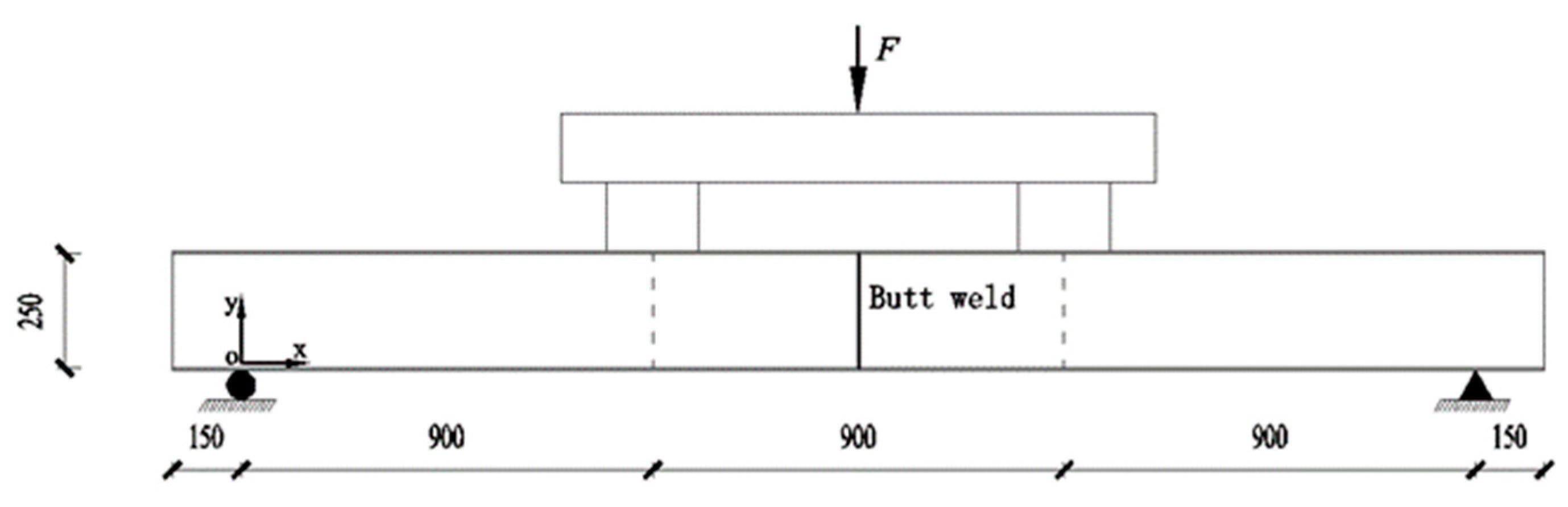

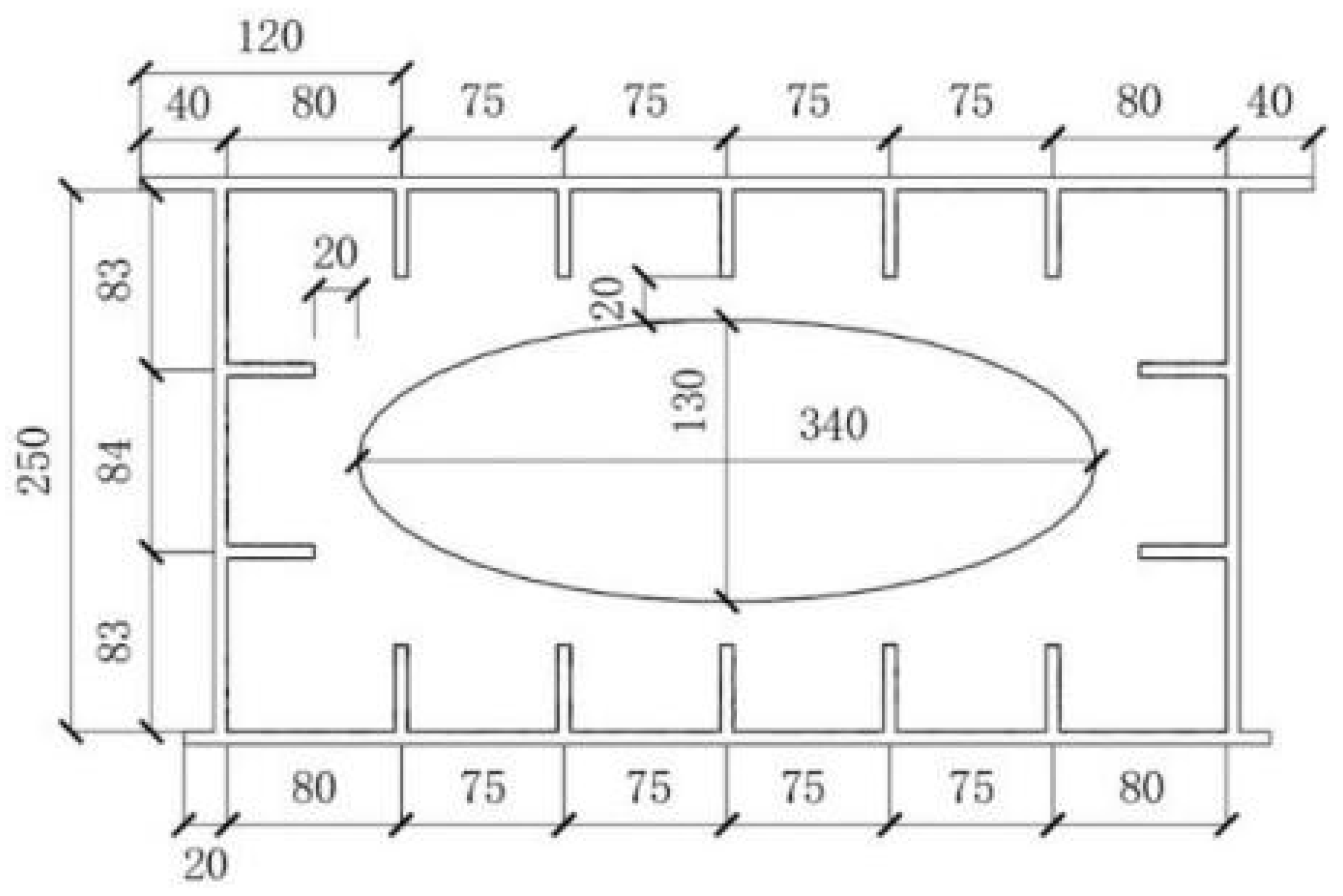

2.2. Specimen Details

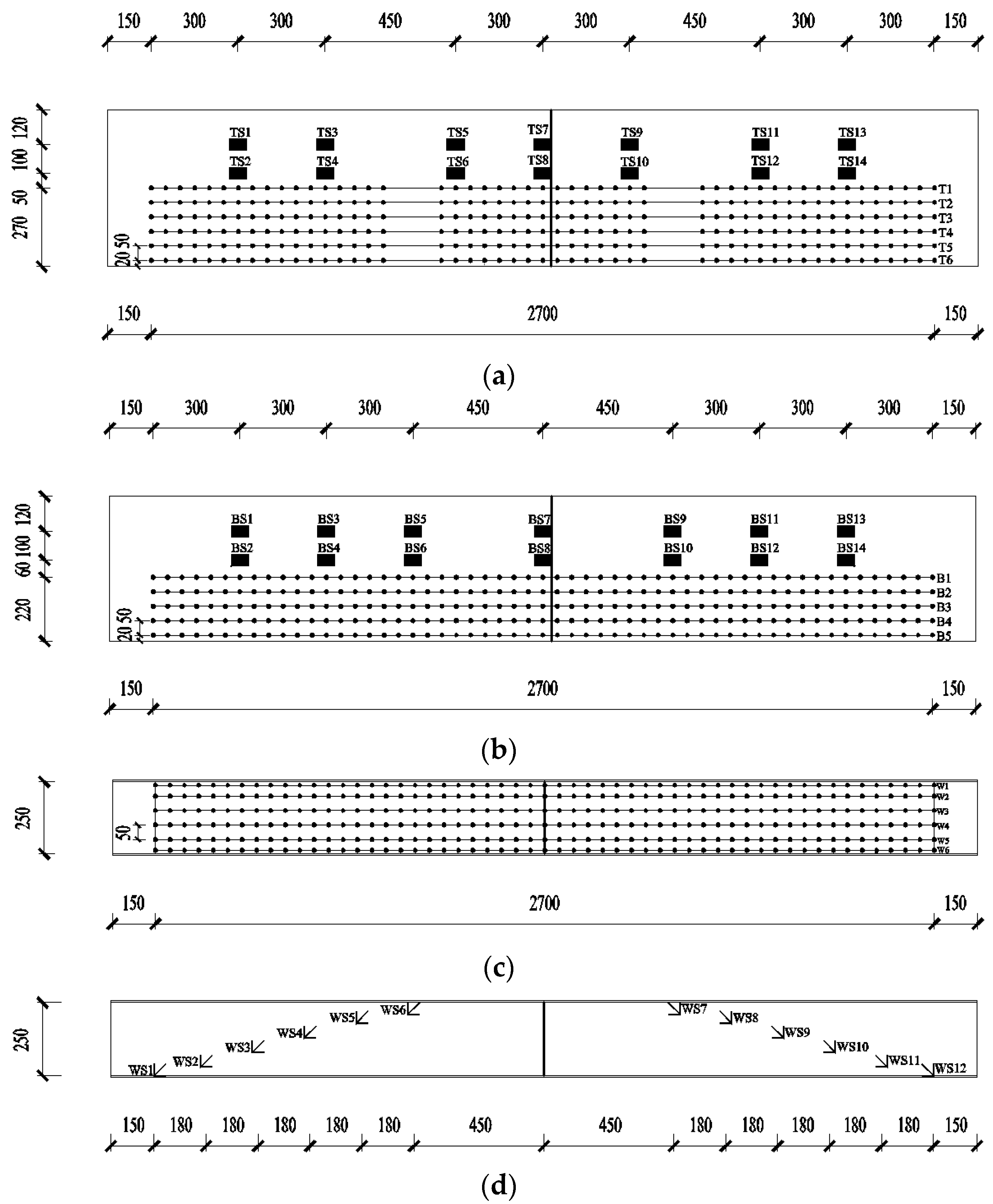

2.3. Layout Plan of Inspection Points

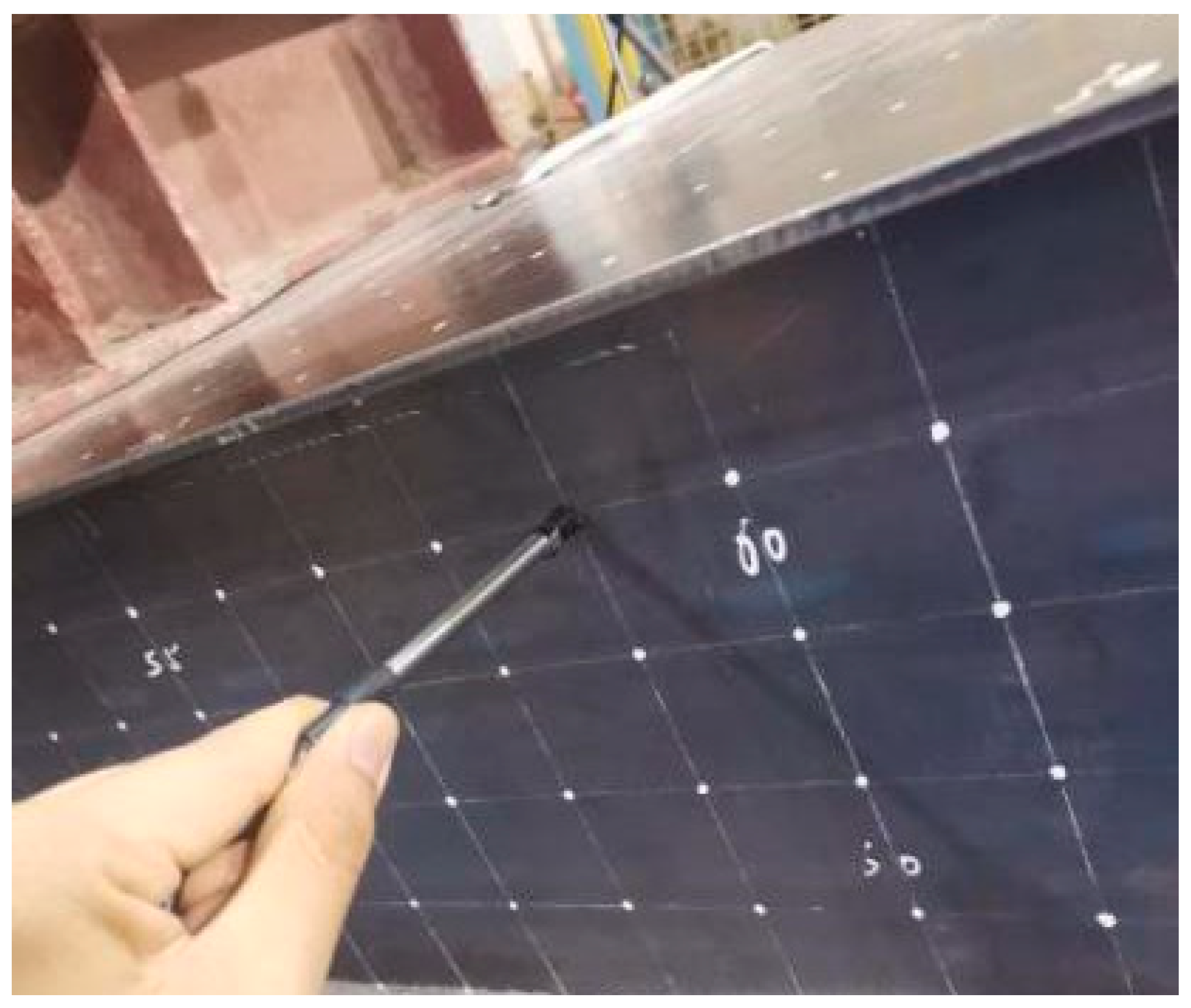

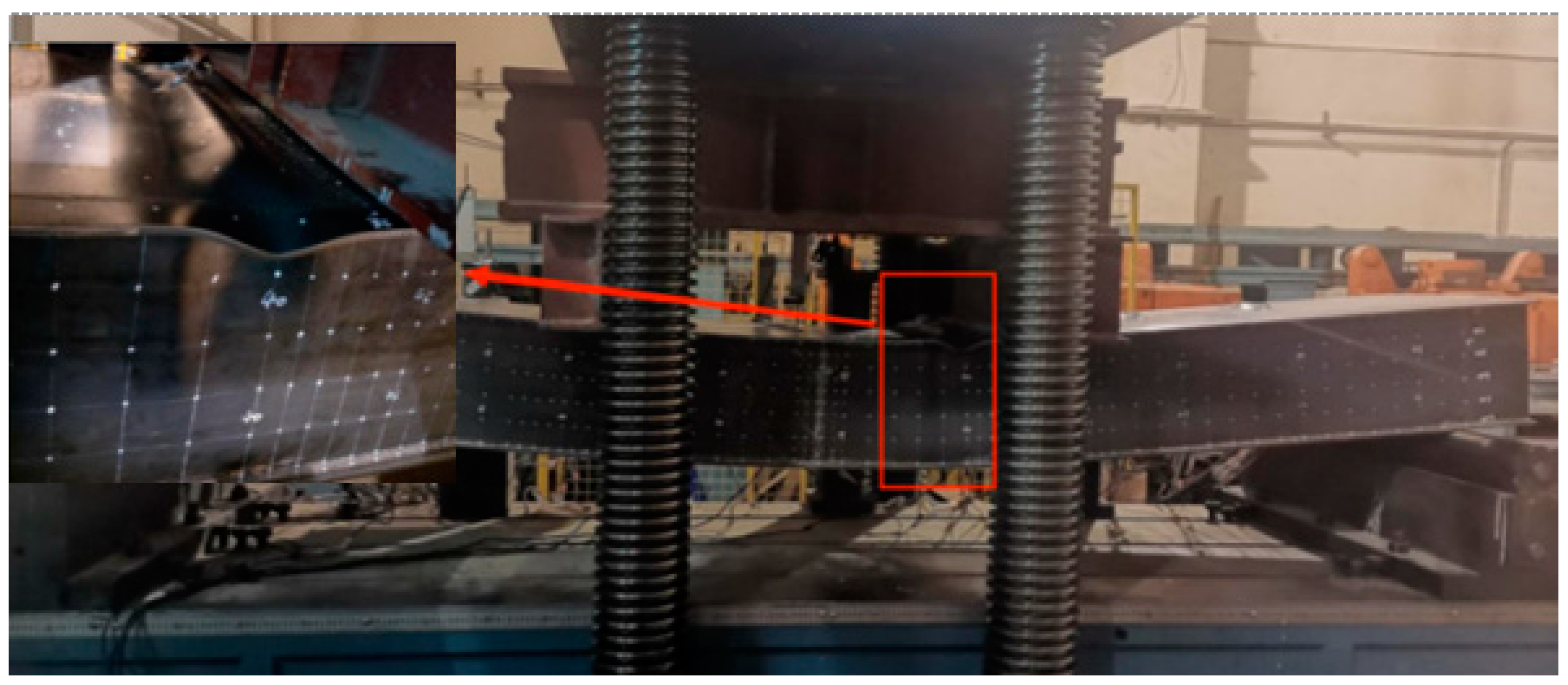

2.4. Experimental Instruments and Test Setup

3. Test Results and Analysis

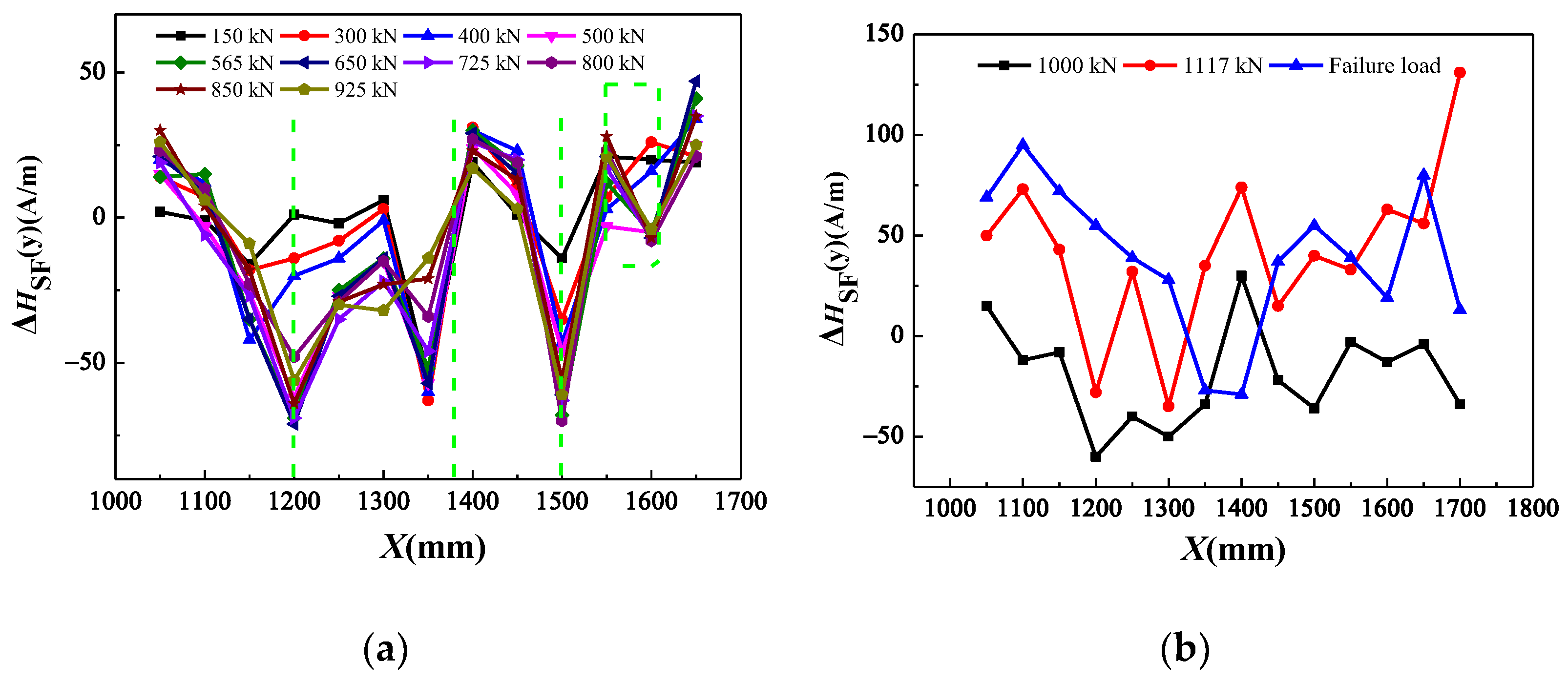

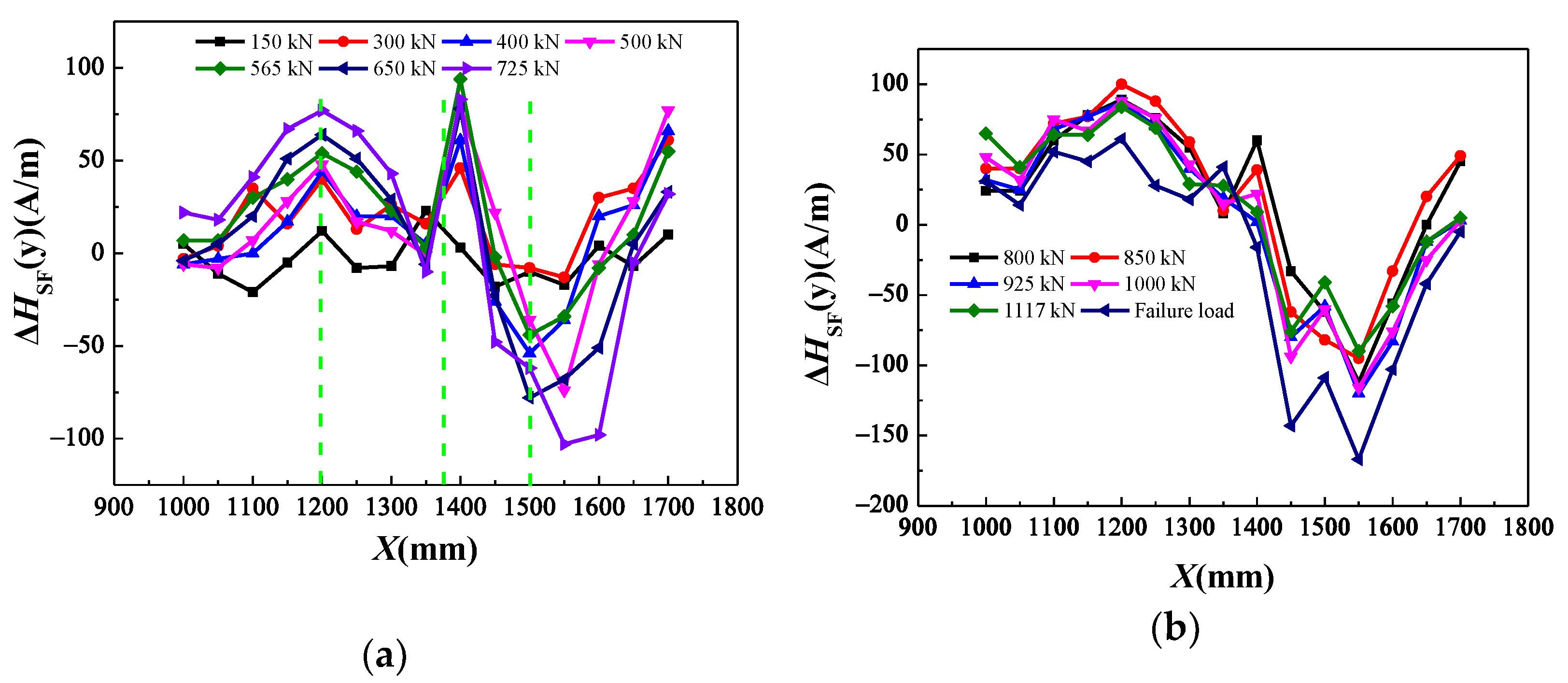

3.1. Distribution Law of Magnetic Signal

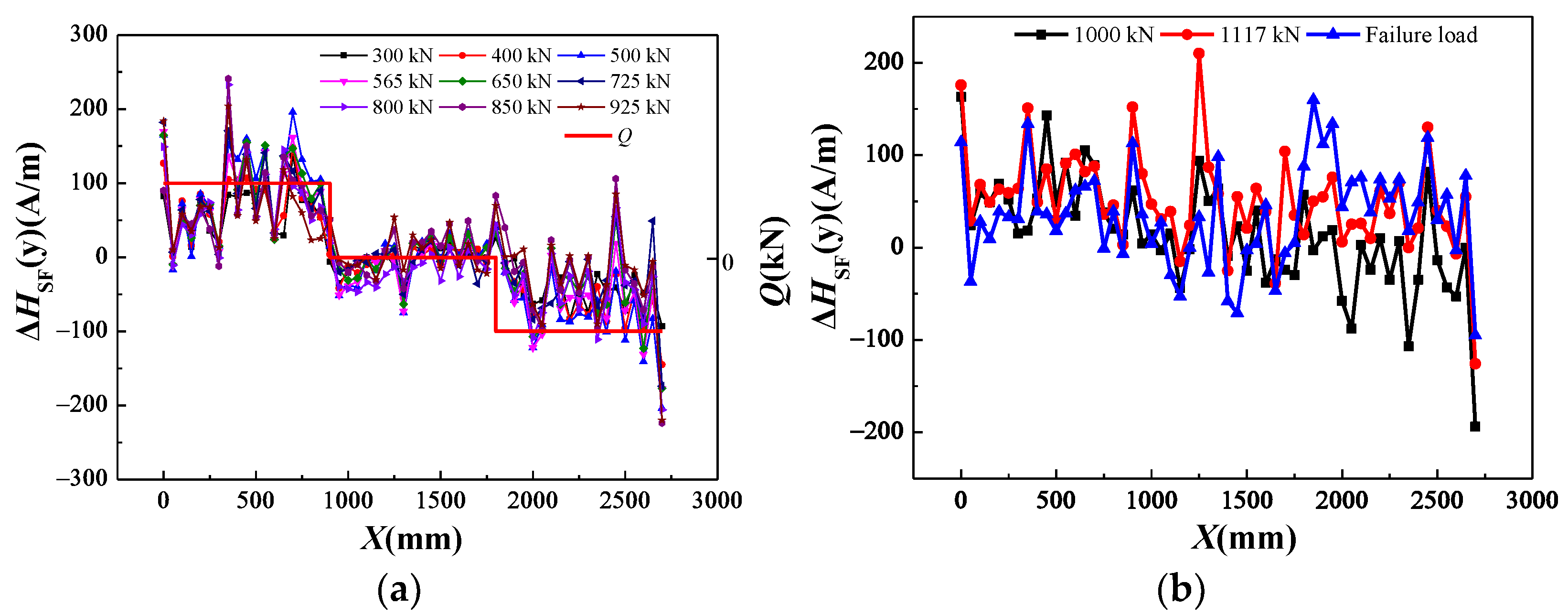

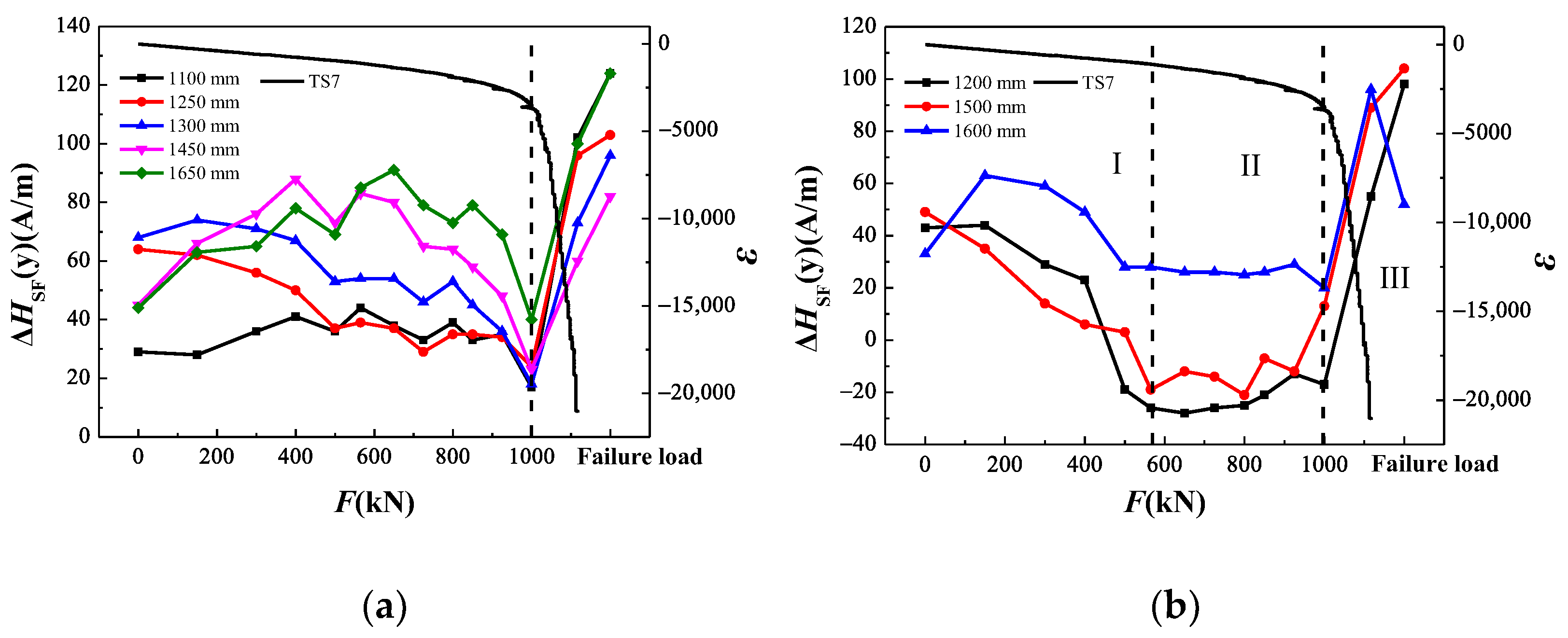

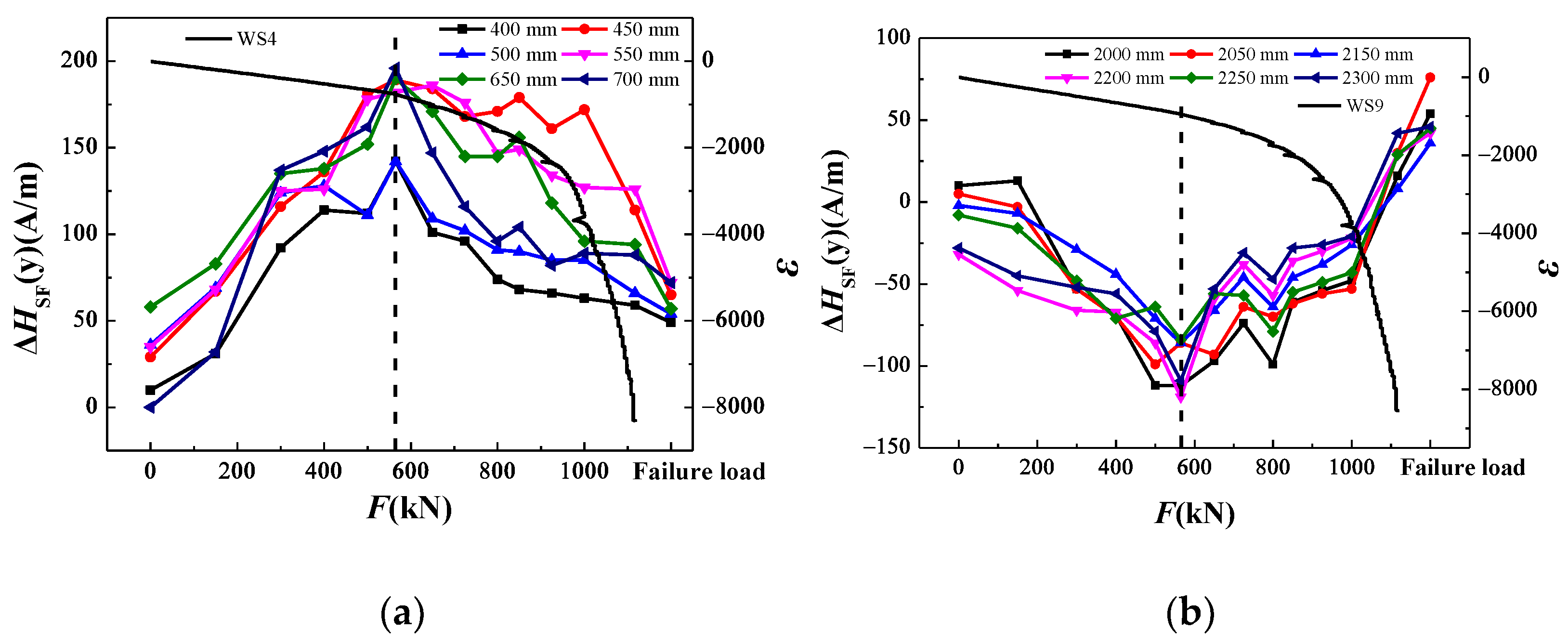

3.2. Force Magnetic Relationship

3.3. Discussion of the Laws of Magnetic Signals

3.3.1. Elastic Loading Stage

3.3.2. Plastic Deformation Stage

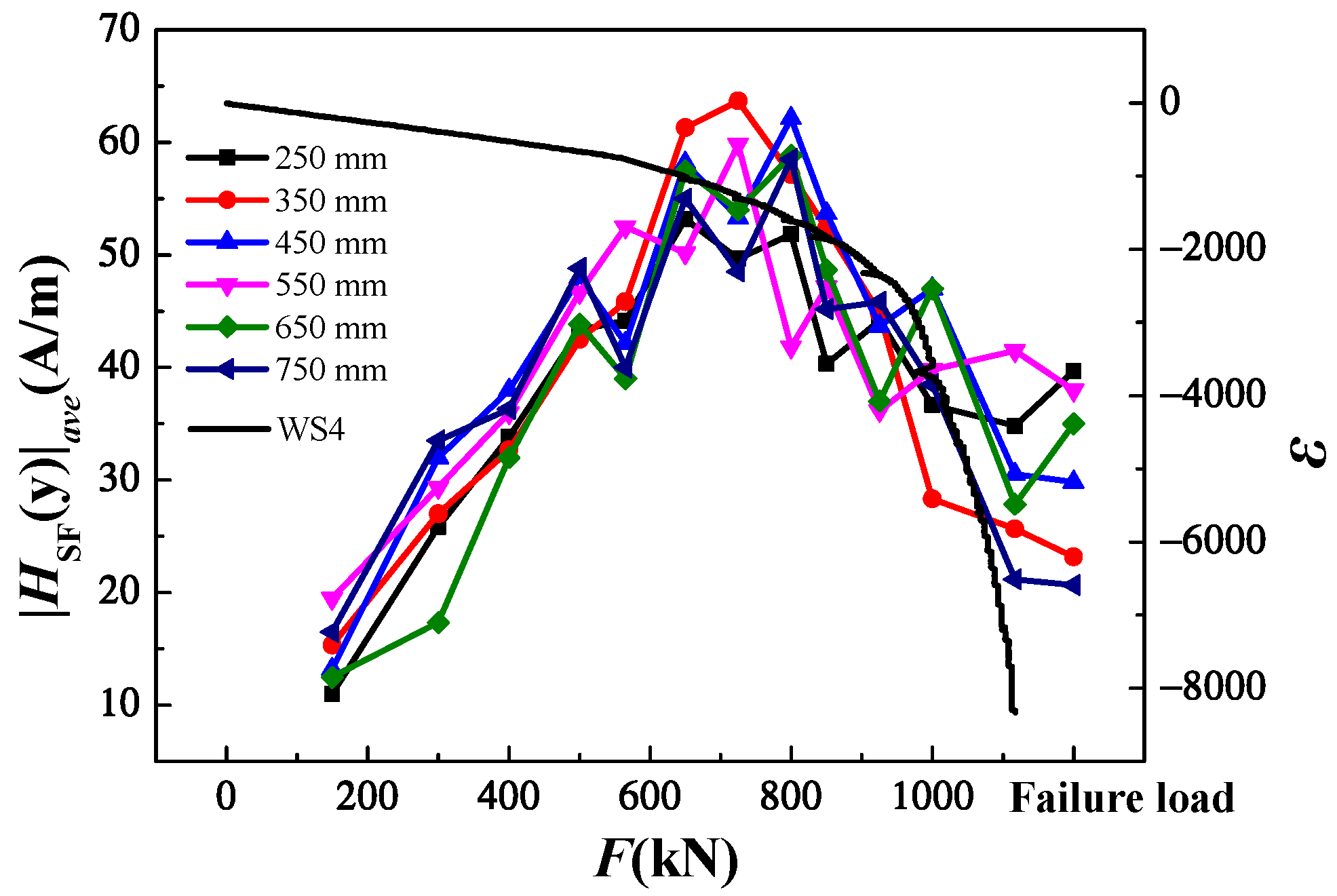

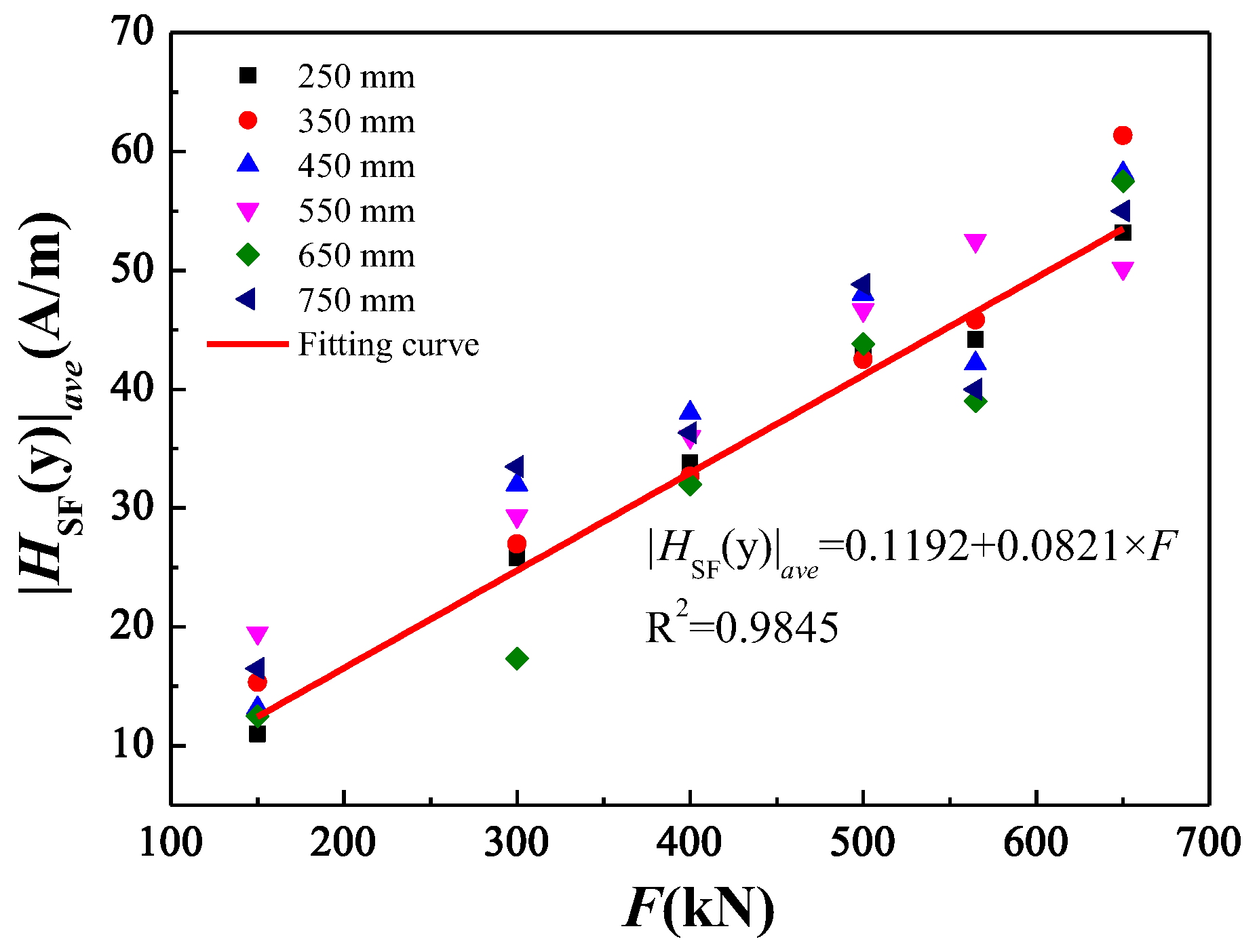

4. Analysis of Magnetic Characteristic Parameters

4.1. Damage Warning Analysis Based on the Magnetic Characteristic Parameter

4.2. Quantitative Evaluation Based on Magnetic Characteristic Parameters

5. Conclusions

- (1)

- Through the peak distribution characteristics of the curve, the early SCZ of the steel box girder could be effectively identified and the buckling position could be predicted. For the SCZ caused by material discontinuity such as butt welds, extremum appeared on both sides of it.

- (2)

- Whether it was the top and bottom flanges or the web, in engineering, the trend reversal of the -F curve could be used to detect whether each part was in the elastic-plastic working stage, and the magnetic characteristic parameter, further verified the accuracy of the results. This feature could be used as an early warning sign before the steel box girder was deformed or destroyed.

- (3)

- Through the reversal of the -F curve, we could accurately judge the critical yield state of the web.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.Y.; Zhang, G.; Kodur, V.; He, S.H.; Huang, Q. Designing method for fire safety of steel box bridge girders. Steel Compos. Struct. 2021, 38, 657–670. [Google Scholar]

- Gao, C.; Zhu, L.; Han, B.; Tang, Q.C.; Su, R. Dynamic Analysis of a Steel–Concrete Composite Box–Girder Bridge–Train Coupling System Considering Slip, Shear–Lag and Time–Dependent Effects. Buildings 2022, 12, 1389. [Google Scholar] [CrossRef]

- Li, L.F. The Analytieal Theory and Model Test Research on Local Stability of Orthotropie Steel Box Girder; Hunan University: Changsha, China, 2005. (In Chinese) [Google Scholar]

- Stamatelos, D.G.; Labeas, G.N.; Tserpes, K.I. Analytical calculation of local buckling and post–buckling behavior of isotropic and orthotropic stiffened panels. Thin–Walled. Struct. 2011, 49, 422–430. [Google Scholar] [CrossRef]

- Wang, F.; Lv, Z.D.; Zhao, Q.K.; Chen, H.L.; Mei, H.L. Experimental and numerical study on welding residual stress of U–rib stiffened plates. J. Construct. Steel Res. 2020, 175, 106362. [Google Scholar] [CrossRef]

- Wang, F.; Tian, L.J.; Lv, Z.D.; Zhao, Z.; Chen, Q.K.; Mei, H.L. Stability of full-scale orthotropic steel plates under axial and biased loading: Experimental and numerical studies. J. Construct. Steel Res. 2021, 181, 106613. [Google Scholar] [CrossRef]

- Wang, F.; Lv, Z.D.; Gu, M.J.; Chen, Q.K.; Zhao, Z.; Luo, J. Experimental study on stability of orthotropic steel box girder of self–anchored suspension cable–stayed bridge. Thin–Walled. Struct. 2021, 163, 107727. [Google Scholar] [CrossRef]

- Shi, P.P.; Su, S.Q.; Chen, Z.M. Overview of researches on the nondestructive testing method of metal magnetic memory, status and challenges. J. Nondestruct. Eval. 2020, 39, 1–37. [Google Scholar] [CrossRef]

- Shi, P.P.; Jin, K.; Zheng, X.J. A magnetomechanical model for the magnetic memory method. Int. J. Mech. Sci. 2017, 124, 229–241. [Google Scholar] [CrossRef]

- Shi, P.P.; Bai, P.G.; Chen, H.E.; Su, S.Q.; Chen, Z.M. The magneto-elastoplastic coupling effect on the magnetic flux leakage signal. J. Magn. Magn. Mater. 2020, 504, 166669. [Google Scholar] [CrossRef]

- Bao, S.; Jin, P.; Zhao, Z.; Fu, M. A Review of the Metal Magnetic Memory Method. J. Nondestruct. Eval. 2020, 39, 1–14. [Google Scholar] [CrossRef]

- Kashefi, M.; Clapham, L.; Krause, T.W.; Krause, P.; Ross, U.; Anthony, K.K. Stress–Induced Self–Magnetic Flux Leakage at Stress Concentration Zone. IEEE Trans. Magn. 2021, 57, 6200808. [Google Scholar] [CrossRef]

- Zhang, H.; Leng, L.; Zhao, R.Q.; Zhou, J.T.; Yang, M.; Xia, R.C. The non–destructive test of steel corrosion in reinforced concrete bridges using a micro–magnetic sensor. Sensors 2016, 16, 1439. [Google Scholar] [CrossRef] [PubMed]

- Roskosz, M.; Bieniek, M. Evaluation of residual stress in ferromagnetic steel based on residual magnetic feld measurements. NDT&E. Int. 2012, 45, 55–62. [Google Scholar]

- Roskosz, M.; Bieniek, M. Analysis of the universality of the residual stress evaluation method based on residual magnetic feld measurements. NDT&E. Int. 2013, 54, 63–68. [Google Scholar]

- Dong, L.H.; Xu, B.S.; Dong, S.Y.; Chen, Q.Z. Characterisation of stress concentration of ferromagnetic materials by metal magnetic memory testing. Nondestruct. Test. Eva. 2010, 25, 145–151. [Google Scholar] [CrossRef]

- Huang, H.H.; Jiang, S.L.; Yang, C.; Liu, Z.F. Stress concentration impact on the magnetic memory signal of ferromagnetic structural steel. Nondestruct. Test. Eval. 2014, 29, 377–390. [Google Scholar] [CrossRef]

- Bao, S.; Fu, M.L.; Lou, H.J.; Bai, S.Z.; Hu, S.N. Evaluation of stress concentration of a low-carbon steel based on residual magnetic field measurements. Insight 2016, 58, 678–682. [Google Scholar] [CrossRef]

- Dubov, A.A. Diagnostics of austenitic steel tubes in the superheaters of steam boilers using scattered magnetic fields. Therm. Eng. 1999, 46, 369–372. [Google Scholar]

- Liu, L.L.; Yang, L.J.; Gao, S.W. Propagation Characteristics of Magnetic Tomography Method Detection Signals of Oil and Gas Pipelines Based on Boundary Conditions. Sensors 2022, 22, 6055. [Google Scholar] [CrossRef]

- Shi, M.J.; Liang, Y.B.; Zhang, M.F.; Huang, Z.Q.; Feng, L.; Zhou, Z.Q. Pipeline Damage Detection Based on Metal Magnetic Memory. IEEE Trans. Magn. 2021, 57, 1–15. [Google Scholar] [CrossRef]

- Roskosz, M.; Rusin, A.; Kotowicz, J. The metal magnetic memory method in the diagnostics of power machinery component. J. Achiev. Mater. Manuf. Eng. 2010, 1, 362–370. [Google Scholar]

- Su, S.Q.; Zhao, X.R.; Wang, W.; Zhang, X.H. Metal Magnetic Memory Inspection of Q345 Steel Specimens with Butt Weld in Tensile and Bending Test. J. Nondestruct. Eval. 2019, 38, 64. [Google Scholar] [CrossRef]

- Su, S.Q.; Ma, X.P.; Wang, W.; Yang, Y.Y. Stress-dependent magnetic charge model for micro-defects of steel wire based on the magnetic memory method. Res. Nondest. Eval. 2020, 31, 24–47. [Google Scholar] [CrossRef]

- Li, M.L.; Yao, H.; Feng, J.R.; Yao, E.T.; Wang, P.; Shi, Y. Calculation and experimental verification of force-magnetic coupling model of magnetised rail based on density functional theory. Insight 2021, 63, 597–603. [Google Scholar] [CrossRef]

- Broniewicz, M.; Broniewicz, F. Welds assessment in k–type joints of hollow section trusses with I or H section chords. Buildings 2020, 10, 43. [Google Scholar] [CrossRef]

- Qiao, G.Y.; Liu, Y.M.; Han, X.L.; Wang, X.; Xiao, F.R. Simulation study on effects of geometry size of weld joint on bearing capacity of steel pipe. Trans. China Weld. Inst. 2017, 38, 33–36. [Google Scholar]

- Gorkunov, E. Different remanence states and their resistance to external effects. Discussing the “method of magnetic memory”. Russ. J. Nondestruct. 2014, 50, 617–633. [Google Scholar] [CrossRef]

- Gatelier–Rothea, C.; Chicois, J.; Fougeres, R.; Fleischmann, P. Characterization of pure iron and (130 P.P.M.) carbon–iron binary alloy by Barkhausen noise measurements, study of the influence of stress and microstructure. Acta. Mater. 1998, 46, 4873–4882. [Google Scholar] [CrossRef]

- Chen, X.; Liu, C.K.; Tao, C.H.; Dong, S.Y.; Wang, D.; Shi, C.L. Research on metal magnetic memory signal change of a ferromagnetic material under static tension. Nondestruct. Test. 2009, 31, 345–348. (In Chinese) [Google Scholar]

- Su, S.Q.; Yi, S.C.; Wang, W.; Sun, H.J.; Ren, G.C. Bending experimental study of structural steel beam on magnetic field gradient based on modified Jiles-Atherton model. Int. J. Appl. Electrom. 2017, 55, 409–421. [Google Scholar] [CrossRef]

- Guo, H.; Su, S.Q.; Wang, W.; Ma, X.P.; Yi, S.C.; Zhao, X.R. Relationship between applied force and magnetic field in a pseudo-static test of a portal frame. Int. J. Appl. Electrom. 2021, 66, 1–19. [Google Scholar] [CrossRef]

- Su, S.Q.; Qin, Y.L.; Wang, W.; Zuo, F.F.; Deng, R.Z.; Liu, X.W. Stress–magnetization of the state of flange damage to a bridge steel box beam based on magnetic memory inspection. Chin. J. Eng. 2022, 44, 900–910. (In Chinese) [Google Scholar]

- Yi, S.C.; Wang, W.; Su, S.Q. Bending experimental study on metal magnetic memory signal based on von Mises yield criterion. Int. J. Appl. Electrom. 2015, 49, 547–556. [Google Scholar] [CrossRef]

- Sablik, M.J.; Jiles, D.C. Coupled magnetoelastic theory of magnetic and magnetostrictive hysteresis. IEEE. Trans. Magn. 1993, 29, 2113. [Google Scholar] [CrossRef]

- Jiles, D.C.; Devine, M.K. Recent developments in modeling of the stress derivative of magnetization in ferromagnetic materials. J. Appl. Phys. 1994, 76, 7015. [Google Scholar] [CrossRef]

- Jiles, D.C. Theory of the magnetomechanical effect. J. Phys. D. Appl. Phys. 1995, 28, 1537. [Google Scholar] [CrossRef]

- Yang, E.; Li, L.M.; Chen, X. Magnetic field aberration induced by cycle stress. J. Magn. Magn. Mater. 2007, 312, 72–77. [Google Scholar]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; John Wiley Press: Hoboken, NJ, USA, 2008. [Google Scholar]

- Pitman, K.C. The influence of stress on ferromagnetic hysteresis. IEEE. Trans. Magn. 1990, 26, 1978–1980. [Google Scholar] [CrossRef]

- Bao, S.; Yang, J.; Gu, Y.B. Effect of strain rate history on the piezomagnetic field of ferromagnetic steels. J. Magn. Magn. Mater. 2021, 526, 167760. [Google Scholar] [CrossRef]

- Huang, H.H.; Qian, Z.C. Effect of Temperature and Stress on Residual Magnetic Signals in Ferromagnetic Structural Steel. IEEE Trans. Magn. 2017, 53, 6200108. [Google Scholar] [CrossRef]

- Zhao, X.R.; Su, S.Q.; Wang, W.; Zhang, X.H. Metal magnetic memory inspection of Q345B steel beam in four point bending fatigue test. J. Magn. Magn. Mater. 2020, 514, 167155. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, S.; Zuo, F.; Wang, W.; Liu, X.; Deng, R.; Li, J. Magnetic Signal Characteristics in Critical Yield State of Steel Box Girder Based on Metal Magnetic Memory Inspection. Buildings 2022, 12, 1835. https://doi.org/10.3390/buildings12111835

Su S, Zuo F, Wang W, Liu X, Deng R, Li J. Magnetic Signal Characteristics in Critical Yield State of Steel Box Girder Based on Metal Magnetic Memory Inspection. Buildings. 2022; 12(11):1835. https://doi.org/10.3390/buildings12111835

Chicago/Turabian StyleSu, Sanqing, Fuliang Zuo, Wei Wang, Xinwei Liu, Ruize Deng, and Junting Li. 2022. "Magnetic Signal Characteristics in Critical Yield State of Steel Box Girder Based on Metal Magnetic Memory Inspection" Buildings 12, no. 11: 1835. https://doi.org/10.3390/buildings12111835

APA StyleSu, S., Zuo, F., Wang, W., Liu, X., Deng, R., & Li, J. (2022). Magnetic Signal Characteristics in Critical Yield State of Steel Box Girder Based on Metal Magnetic Memory Inspection. Buildings, 12(11), 1835. https://doi.org/10.3390/buildings12111835