Influence of User Behaviour on the Functioning and Performance of Passive Phase-Change Material Systems after More Than a Decade of Operation

Abstract

1. Introduction

- Do PCMs still function from a technical point of view after being in use for more than a decade?

- How does user behaviour influence the performance of the PCM?

- Is there potential for improvement through behavioural changes on the part of the users?

2. Approach and Methods

2.1. Two Case Studies

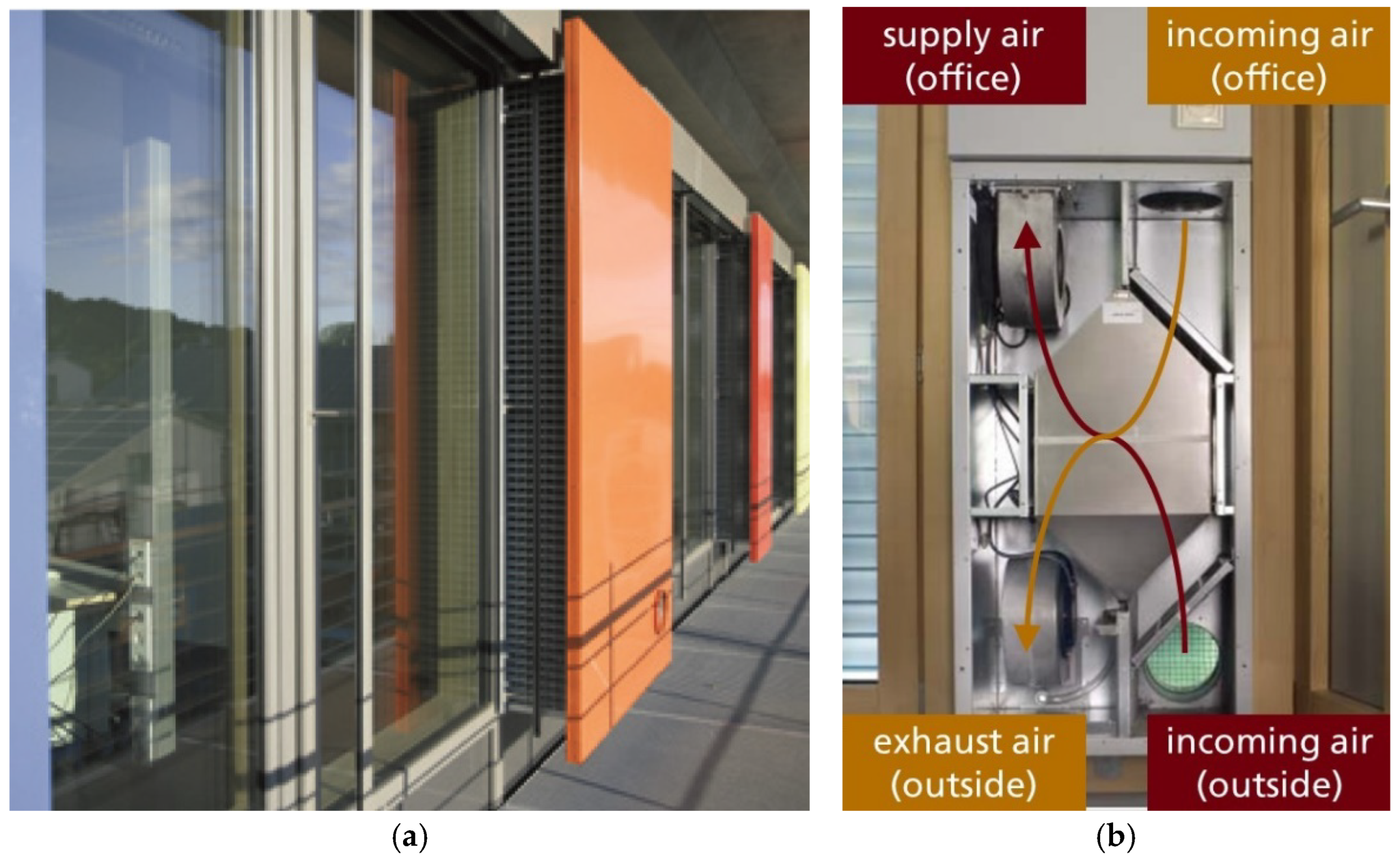

2.1.1. The Sonnenschiff Building

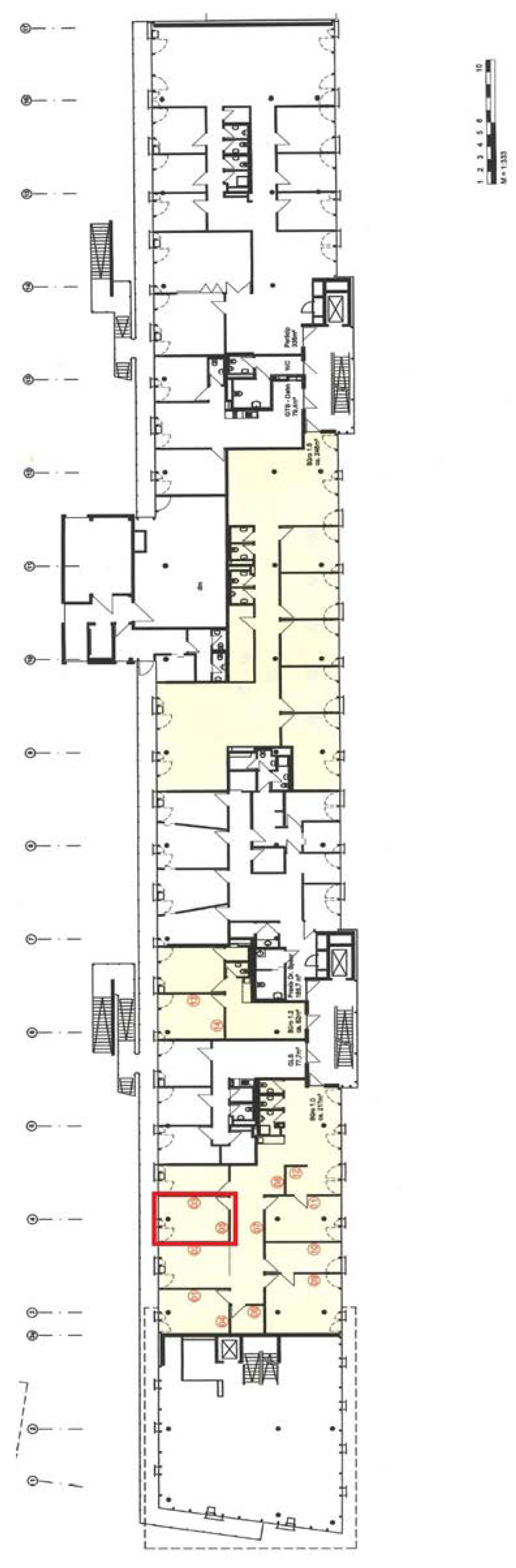

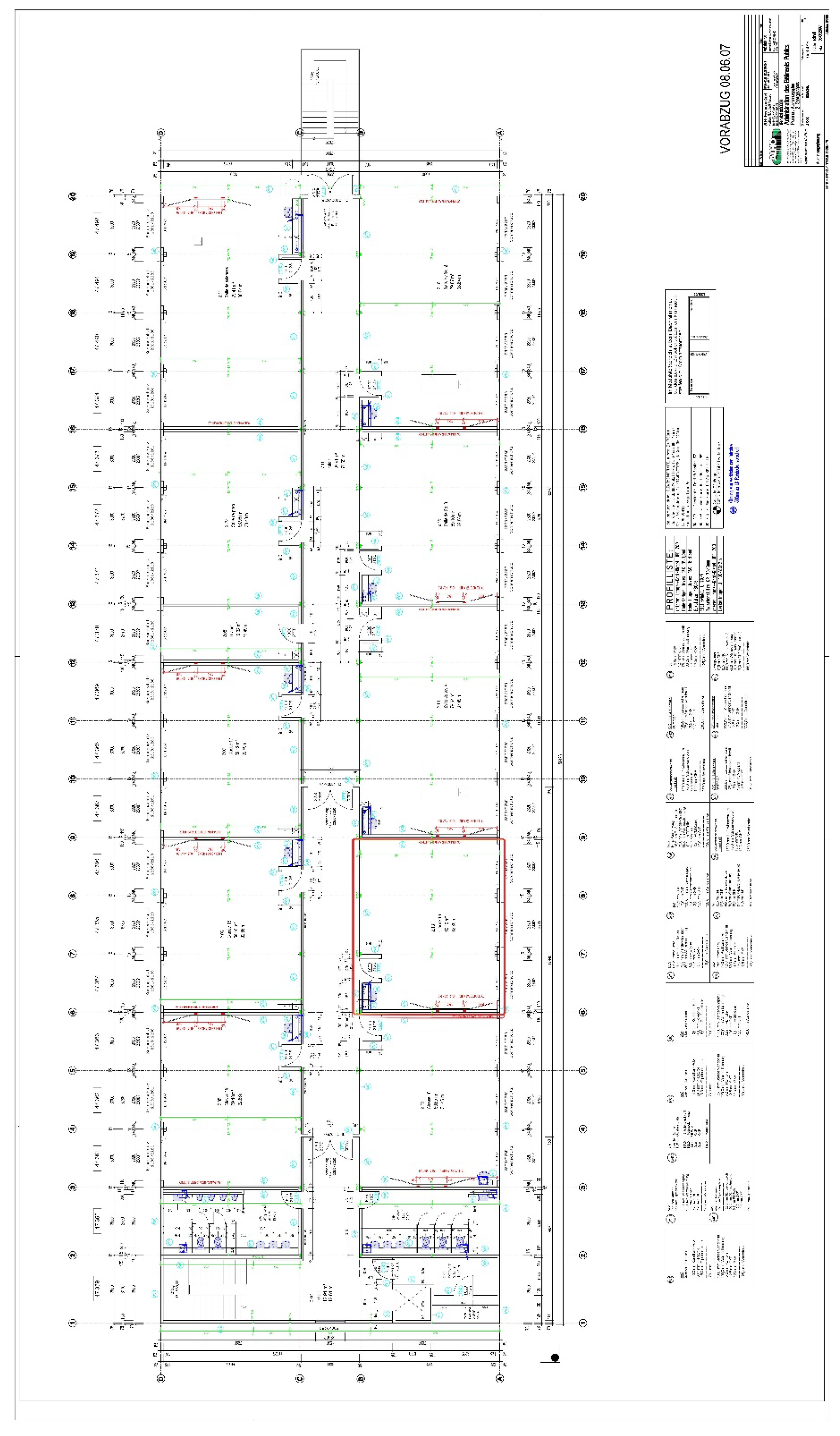

2.1.2. Classroom of a Secondary School

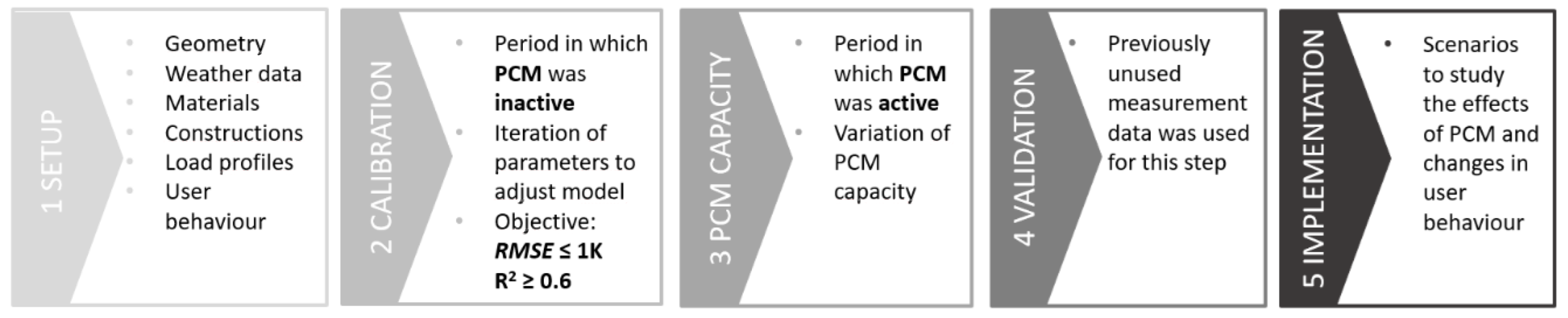

2.2. Model Setup, Integration of PCM and Validation in EnergyPlus

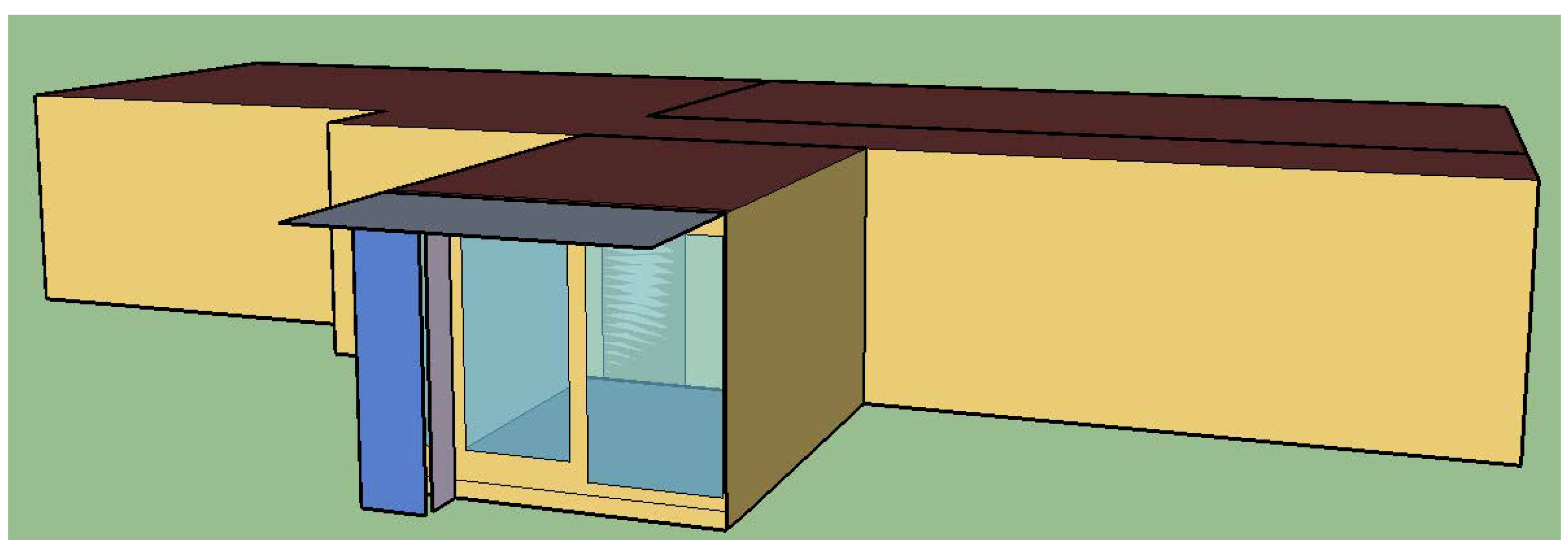

2.2.1. Model Setup

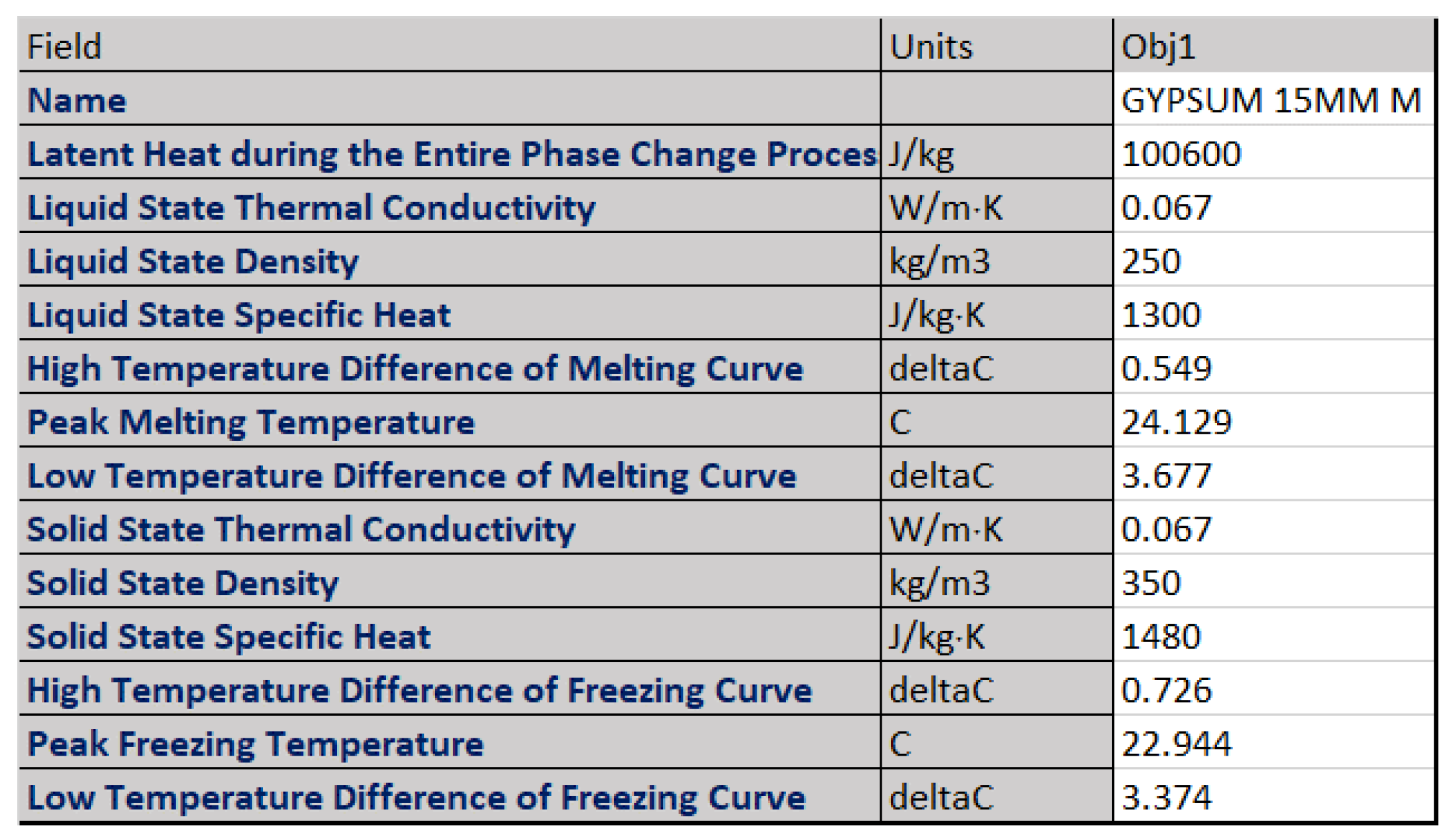

2.2.2. Integration of PCM

2.2.3. Validation

2.3. Implementation of Different Behavioural Scenarios

Office Room

- (a)

- Use of mechanical ventilation during the night

- (b)

- Opening/closing/tilting of windows

- The ventilation panel was open from 5 p.m.–8 a.m.

- The window was open from 8–9 a.m.

- If Top > 26 °C, the window and panel could only be opened if Tamb > Top; else it was closed (We are aware that ventilation for improving the air quality is also useful and practised at higher outdoor temperatures. In the present study, however, the aspect of air quality was completely neglected, as the focus was on thermal conditions and the influence of the PCM. Therefore, this simplification was adopted to reduce the complexity in the ventilation behaviour pattern)

- (c)

- Shading control

2.4. Evaluation of the Simulation Results

3. Results

3.1. Office Room

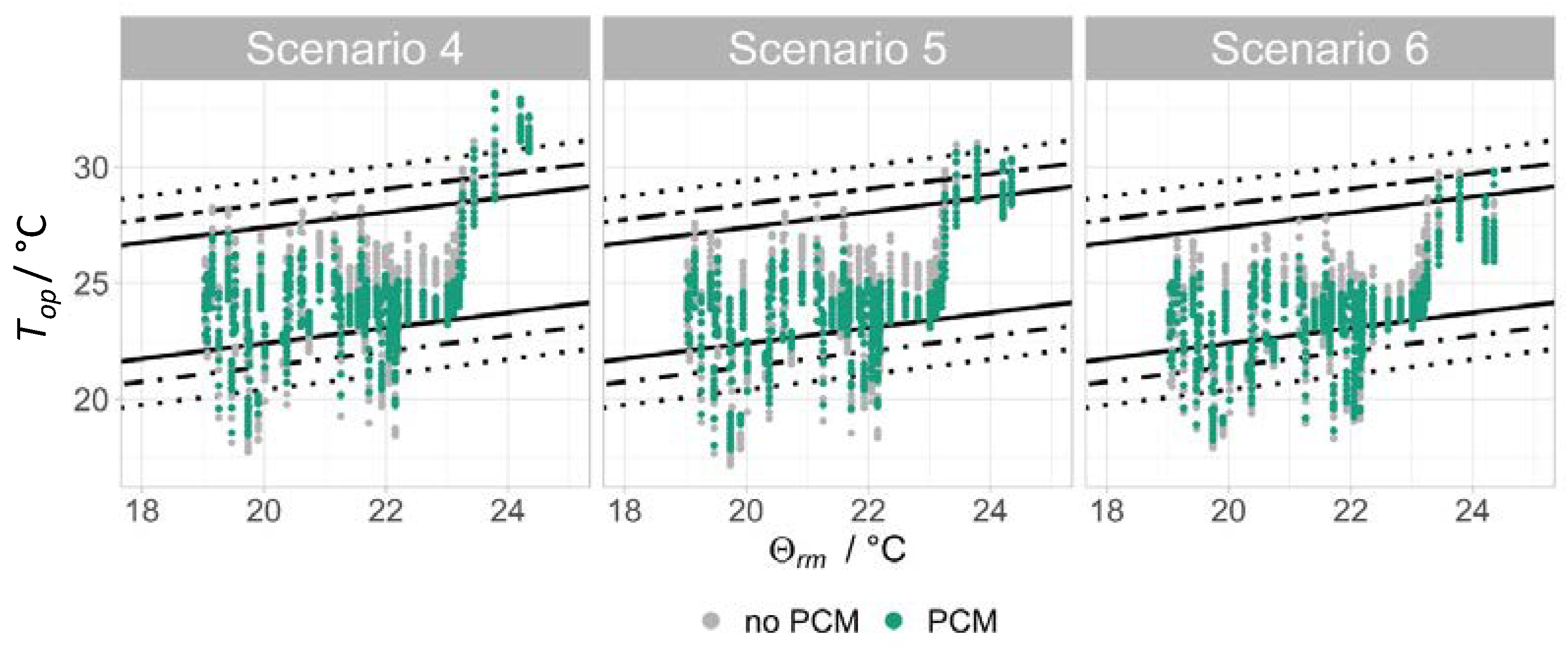

3.2. Classroom

4. Discussion

4.1. Impact of PCM

4.2. Influence of User Behaviour

5. Conclusions

- The occupants did not behave optimally from a technical perspective. Windows were opened when it was too warm outside, blinds were not always closed when there was high irradiation and night ventilation by means of windows or electrical ventilation systems was not used consistently.

- Simulations with different behavioural scenarios showed that the PCM still worked after more than a decade in operation and could positively influence the indoor climate in all the scenarios. However, our results suggested that there was a decrease in the capacity of the PCM in the meantime. The amount of degradation could only be roughly determined and was in the range of 0–50%. Despite the decrease in capacity, it was able to reduce the time of discomfort in the baseline scenarios by 9–45% and improved behaviour led to an increase in the PCM’s effect of 34–52%.

- The improved behaviour itself also provided an improvement in thermal conditions. The effect of behaviour was also visibly greater than the effect attributable to the PCM; the average room temperatures could be reduced by 2.4 K (office) and 0.9 K (classroom) through better blind operation, more consistent window ventilation and, above all, the use of night ventilation (in the office). The same pattern was seen in the CDH.

- The general temperature level also influenced the extent to which behaviour and PCM could have an impact. If the room temperatures were frequently above the melting range, the PCM could not work. If, on the other hand, the temperatures were more frequently within the melting range of the PCM, it was able to unfold its effect.

- Our results confirmed that PCMs can show their strength better in light buildings than in thermally heavy ones.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| PCM | Phase change material |

| DSC | Differential scanning calorimeter |

| DIN | Deutsches Institut für Normung (German Institute for Standardization) |

| EN | European standard |

| CDH | Cooling degree hours |

| RMSE | Root mean square error |

| R² | Coefficient of determination |

| U-Value | Thermal transmittance |

| ACH | Air change per hours |

| Top | Operative room temperature |

| Tamb | Ambient air temperature |

| Tlim | Limit of comfort |

| N | Number of points |

| Θrm | Running mean of ambient temperature |

| Θer_i | Daily running mean of ambient temperature |

Appendix A

| Construction | Material | Thickness | Conductivity | Specific Heat | Density |

|---|---|---|---|---|---|

| [mm] | [W/(m·K)] | [J/(kg·K)] | [kg/m3] | ||

| Ceiling & floor | Beton external | 25 | 2.000 | 950 | 2400 |

| [U = 0.19 W/(m2·K)] | Cement screed | 60 | 1.400 | 1000 | 2000 |

| Styrofoam | 200 | 0.040 | 1500 | 20 | |

| Beton internal | 25 | 2.000 | 950 | 2400 | |

| Internal wall | Smartboard | 15 | 0.250 | 960 | 680 |

| [U = 0.75 W/(m2·K)] | Blown-in insulation | 45 | 0.043 | 2200 | 105 |

| Beton | 10 | 2.000 | 950 | 2400 | |

| Smartboard | 15 | 0.250 | 960 | 680 | |

| Windows | Glass | 6 | 0.760 | 840 | 2500 |

| [U = 0.71 W/(m2·K)] | Air | 16 | 0.000 | 1000 | 1.2 |

| Glass | 6 | 0.760 | 840 | 2500 | |

| Air | 16 | 0.000 | 1000 | 1.2 | |

| Glass | 6 | 0.760 | 840 | 2500 | |

| Post and beam construction | Solid wood | 340 | 0.110 | 1700 | 480 |

| [U = 0.31 W/(m2·K)] | |||||

| External wall | Vacuum insulation | 50 | 0.007 | 800 | 200 |

| [U = 0.14 W/(m2·K)] | Beton | 100 | 2.000 | 950 | 2400 |

| Door | Wooden door | 25 | 0.190 | 2390 | 700 |

| [U = 2.70 W/(m2·K)] |

| Construction | Material | Thickness | Conductivity | Specific Heat | Density |

|---|---|---|---|---|---|

| [mm] | [W/(m·K)] | [J/(kg·K)] | [kg/m3] | ||

| Ceiling | Elastomer sealing sheet | 1.5 | 0.170 | 1000 | 1400 |

| [U = 0.28 W/(m2·K)] | Insulation board | 50 | 0.045 | 1300 | 110 |

| OSB board | 19 | 0.130 | 1700 | 650 | |

| Mineral wool | 100 | 0.035 | 1700 | 650 | |

| Steel girder | 100 | 50.000 | 1000 | 285 | |

| Sealing foil | 0.25 | 0.170 | 1000 | 1100 | |

| Knauf fire protection GKF | 18 | 0.230 | 1100 | 800 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Air layer | 172 | 1.075 | 1000 | 1.2 | |

| Smartboard | 15 | 0.250 | 960 | 680 | |

| Floor | Linoleum | 5 | 0.170 | 1400 | 1200 |

| [U = 0.20 W/(m2·K)] | OSB board | 19 | 0.130 | 1700 | 650 |

| Gypsum plasterboard | 15 | 0.350 | 1100 | 1150 | |

| OSB board | 22 | 0.130 | 1700 | 650 | |

| Sealing foil | 0.25 | 0.170 | 1000 | 1100 | |

| Mineral wool | 140 | 0.035 | 1700 | 650 | |

| Steel girder | 150 | 50.000 | 1000 | 285 | |

| Trapezoidal sheet | 1 | 10.000 | 1000 | 100 | |

| OSB board | 10 | 0.130 | 1700 | 650 | |

| Mineral wool | 100 | 0.035 | 1700 | 650 | |

| Steel girder | 100 | 50.000 | 1000 | 285 | |

| Vapour barrier | 0.25 | 0.170 | 1000 | 1100 | |

| Knauf fire protection GKF | 18 | 0.230 | 1100 | 800 | |

| Knauf fire protection GKF | 15 | 0.230 | 1100 | 800 | |

| Air layer | 172 | 1.075 | 1000 | 1.2 | |

| Smartboard | 15 | 0.250 | 960 | 680 | |

| Facade wall | Synthetic resin plaster | 3 | 0.700 | 1000 | 1200 |

| [U = 0.24 W/(m2·K)] | Styrofoam | 60 | 0.04 | 1500 | 20 |

| Gypsum plasterboard | 15 | 0.350 | 1100 | 1150 | |

| Seal foil | 0.25 | 0.170 | 1000 | 1100 | |

| Mineral wool | 100 | 0.035 | 830 | 20 | |

| Steel girder | 100 | 50.000 | 1000 | 285 | |

| Sealing foil | 0.25 | 0.170 | 1000 | 1100 | |

| Air layer | 135 | 0.750 | 1000 | 1.2 | |

| Steel girder | 75 | 50.000 | 1000 | 285 | |

| Air layer | 75 | 0.750 | 1000 | 1.2 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Smartboard | 15 | 0.250 | 960 | 680 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Chalkboard and rear wall | Knauf GKF | 12.5 | 0.230 | 1100 | 800 |

| [U = 0.34 W/(m2·K)] | Smartboard | 15 | 0.250 | 960 | 680 |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Seal foil | 0.25 | 0.170 | 1000 | 1100 | |

| Air layer | 7.5 | 0.010 | 1000 | 1.2 | |

| Steel girder | 75 | 50.000 | 1000 | 285 | |

| Mineral wool | 60 | 0.035 | 830 | 20 | |

| Air layer | 7.5 | 0.010 | 1000 | 1.2 | |

| Air layer | 7.5 | 0.010 | 1000 | 1.2 | |

| Steel girder | 75 | 50.000 | 1000 | 285 | |

| Mineral wool | 60 | 0.035 | 830 | 20 | |

| Air layer | 75 | 0.750 | 1000 | 1.2 | |

| Seal foil | 0.25 | 0.170 | 1000 | 1100 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Corridor wall | Knauf GKF | 12.5 | 0.230 | 1100 | 800 |

| [U = 0.53 W/(m2·K)] | Smartboard | 15 | 0.250 | 960 | 680 |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Air layer | 7.5 | 0.010 | 1000 | 1.2 | |

| Mineral wool | 60 | 0.035 | 830 | 20 | |

| Steel girder | 75 | 50.000 | 1000 | 285 | |

| Air layer | 7.5 | 0.010 | 1000 | 1.2 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Sink wall | Knauf GKF | 12.5 | 0.230 | 1100 | 800 |

| [U = 0.46 W/(m2·K)] | Smartboard | 15 | 0.250 | 960 | 680 |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Steel girder | 75 | 50.000 | 1000 | 285 | |

| Air layer | 275 | 1.528 | 1000 | 1.2 | |

| Seal foil | 0.25 | 0.170 | 1000 | 1100 | |

| Air layer | 75 | 0.750 | 1000 | 1.2 | |

| Mineral wool | 60 | 0.035 | 830 | 20 | |

| Steel girder | 75 | 50.000 | 1000 | 285 | |

| Air layer | 7.5 | 0.010 | 1000 | 1.2 | |

| Seal foil | 0.25 | 0.170 | 1000 | 1100 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Smartboard | 15 | 0.250 | 960 | 680 | |

| Knauf GKF | 12.5 | 0.230 | 1100 | 800 | |

| Windows | Glass | 6 | 0.760 | 840 | 2500 |

| [U = 0.71 W/(m2·K)] | Air | 16 | 0.000 | 1000 | 1.2 |

| Glas | 6 | 0.760 | 840 | 2500 | |

| Air | 16 | 0.000 | 1000 | 1.2 | |

| Glass | 6 | 0.760 | 840 | 2500 | |

| Door | Wooden door | 50 | 0.13 | 1700 | 750 |

| [U = 1.55 W/(m2·K)] |

References

- Mavrigiannaki, A.; Ampatzi, E. Latent heat storage in building elements: A systematic review on properties and contextual performance factors. Renew. Sustain. Energy Rev. 2016, 60, 852–866. [Google Scholar] [CrossRef]

- AL-Saadi, S.N.; Zhai, Z. Modeling phase change materials embedded in building enclosure: A review. Renew. Sustain. Energy Rev. 2013, 21, 659–673. [Google Scholar]

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- James, B.; Delaney, P. Phase Change Materials: Are They Part of Our Energy Efficient Future? In Proceedings of the 2012 ACEEE Summer Study on Energy Efficiency in Build, Pacific Grove, CA, USA, 12–17 August 2012; pp. 160–172. [Google Scholar]

- Ascione, F.; Bianco, N.; de Masi, R.F.; de’ Rossi, F.; Vanoli, G.P. Energy refurbishment of existing buildings through the use of phase change materials: Energy savings and indoor comfort in the cooling season. Appl. Energy 2014, 113, 990–1007. [Google Scholar] [CrossRef]

- Barreneche, C.; Navarro, L.; de Gracia, A.; Fernández, A.I.; Cabeza, L.F. In situ thermal and acoustic performance and environmental impact of the introduction of a shape-stabilized PCM layer for building applications. Renew. Energy 2016, 85, 281–286. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Wu, G. Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Jaworski, M.; Łapka, P.; Furmański, P. Numerical modelling and experimental studies of thermal behaviour of building integrated thermal energy storage unit in a form of a ceiling panel. Appl. Energy 2014, 113, 548–557. [Google Scholar] [CrossRef]

- Karim, L.; Barbeon, F.; Gegout, P.; Bontemps, A.; Royon, L. New phase-change material components for thermal management of the light weight envelope of buildings. Energy Build. 2014, 68, 703–706. [Google Scholar] [CrossRef]

- Royon, L.; Karim, L.; Bontemps, A. Optimization of PCM embedded in a floor panel developed for thermal management of the lightweight envelope of buildings. Energy Build. 2014, 82, 385–390. [Google Scholar] [CrossRef]

- Lamrani, B.; Johannes, K.; Kuznik, F. Phase change materials integrated into building walls: An updated review. Renew. Sustain. Energy Rev. 2021, 140, 110751. [Google Scholar] [CrossRef]

- Schakib-Ekbatan, K.; Çakıcı, F.Z.; Schweiker, M.; Wagner, A. Does the occupant behavior match the energy concept of the building?—Analysis of a German naturally ventilated office building. Build. Environ. 2015, 84, 142–150. [Google Scholar] [CrossRef]

- Fabi, V.; Andersen, R.V.; Corgnati, S.; Olesen, B.W. Occupants’ window opening behaviour: A literature review of factors influencing occupant behaviour and models. Build. Environ. 2012, 58, 188–198. [Google Scholar] [CrossRef]

- Alam, M.; Jamil, H.; Sanjayan, J.; Wilson, J. Energy saving potential of phase change materials in major Australian cities. Energy Build. 2014, 78, 192–201. [Google Scholar] [CrossRef]

- Jamil, H.; Alam, M.; Sanjayan, J.; Wilson, J. Investigation of PCM as retrofitting option to enhance occupant thermal comfort in a modern residential building. Energy Build. 2016, 133, 217–229. [Google Scholar] [CrossRef]

- Alam, M.; Zou, P.X.; Sanjayan, J.; Ramakrishnan, S. Energy saving performance assessment and lessons learned from the operation of an active phase change materials system in a multi-storey building in Melbourne. Appl. Energy 2019, 238, 1582–1595. [Google Scholar] [CrossRef]

- Obergfell, T.; Solano Guzmán, J.; Haussmann, T.; Gschwander, S.; Wagner, A. Long-term functionality of a passive phase-change materials building application after more than a decade of operation. Energy Build. 2021, 249, 111213. [Google Scholar] [CrossRef]

- Wan Mohd Nazi, W.I.; Wang, Y.; Chen, H.; Zhang, X.; Roskilly, T. Passive Cooling Using Phase Change Material and Insulation for High-rise Office Building in Tropical Climate. Energy Procedia 2017, 142, 2295–2302. [Google Scholar] [CrossRef]

- US Department of Energy. EnergyPlus™ Version 9.2.0 Documentation: Input Output Reference. 2019. Available online: https://energyplus.net/documentation (accessed on 20 June 2020).

- Sage-Lauck, J.S.; Sailor, D.J. Evaluation of phase change materials for improving thermal comfort in a super-insulated residential building. Energy Build. 2014, 79, 32–40. [Google Scholar] [CrossRef]

- Oebbeke, A. Latentwärmespeicher Micronal PCM der BASF Auch in Gipsbauplatten. 2005. Available online: https://www.baulinks.de/webplugin/2005/1324.php4 (accessed on 25 June 2022).

- Cellat, K.; Beyhan, B.; Konuklu, Y.; Dündar, C.; Karahan, O.; Güngör, C.; Paksoy, H. 2 years of monitoring results from passive solar energy storage in test cabins with phase change materials. Sol. Energy 2020, 200, 29–36. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Navarro, L.; Pisello, A.L.; Olivieri, L.; Bartolomé, C.; Sánchez, J.; Álvarez, S.; Tenorio, J.A. Behaviour of a concrete wall containing micro-encapsulated PCM after a decade of its construction. Sol. Energy 2020, 200, 108–113. [Google Scholar] [CrossRef]

- BASF SE. Company Website. 2020. Available online: https://www.basf.com/global/de.html (accessed on 20 June 2022).

- Disch, R.; Schüle, R.; Tebel-Haas, S. Innovative Energiefassade für das Sonnenschiff der Solarsiedlung Freiburg: Final Report DBU Research Project. 2009. Available online: https://docplayer.org/64623896-Innovative-energiefassade-fuer-das-sonnenschiff-der-solarsiedlung-freiburg.html (accessed on 20 June 2022).

- Rolf Disch SolarArchitektur. 2022. Available online: http://www.rolfdisch.de/media-de/bildarchiv/ (accessed on 20 June 2022).

- DIN Deutsches Institut für Normung e.V. Teil1: Eingangsparameter für das Innenraumklima zur Auslegung und Bewertung der Energieeffizienz von Gebäuden bezüglich Raumluftqualität, Temperatur, Licht und Akustik. In DIN EN 16798-1: Energetische Bewertung von Gebäuden: Lüftung von Gebäuden; Beuth Verlag GmbH: Berlin, Germany, 2021. [Google Scholar]

- Ross, S.M. Chapter 12 linear regression. In Introductory Statistics, 3rd ed.; Ross, S.M., Ed.; Academic Press: Boston, MA, USA, 2010; pp. 537–604. [Google Scholar]

- Moore, D.; Notz, W.I.; Fligner, M.A. (Eds.) The Basic Practice of Statistics, 6th ed.; W. H. Freeman and Company: New York, NY, USA, 2013. [Google Scholar]

- Halimov, A.; Lauster, M.; Müller, D. Development and Validation of PCM Models Integrated Into the High-order Building Model of Modelica Library—Aixli. In Proceedings of the 16th IBPSA Conference, Rome, Italy, 2–4 September 2019; pp. 4698–4705. [Google Scholar]

- Al-Janabi, A.; Kavgic, M. Application and sensitivity analysis of the phase change material hysteresis method in EnergyPlus: A case study. Appl. Therm. Eng. 2019, 162, 114222. [Google Scholar] [CrossRef]

- DesignBuilder Software Ltd. Phase Change Material—Hysteresis. 2020. Available online: https://designbuilder.co.uk/helpv6.0/Content/PhaseChangeMaterialHysteresis.htm (accessed on 20 June 2022).

- Big Ladder Software. Conduction Finite Difference Solution Algorithm. 2018. Available online: https://bigladdersoftware.com/epx/docs/9-0/engineering-reference/conduction-finite-difference-solution.html (accessed on 20 June 2022).

- Alam, M.; Sanjayan, J.; Zou, P.X.; Ramakrishnan, S.; Wilson, J. A Comparative Study on the Effectiveness of Passive and Free Cooling Application Methods of Phase Change Materials for Energy Efficient Retrofitting in Residential Buildings. Procedia Eng. 2017, 180, 993–1002. [Google Scholar] [CrossRef]

- Long, X.; Zhang, W.; Li, Y.; Zheng, L. Thermal performance improvement of lightweight buildings integrated with phase change material: An experimental and simulation study. Adv. Mech. Eng. 2017, 9, 1687814017702082. [Google Scholar] [CrossRef]

- Ozdenefe, M.; Dewsbury, J. Thermal performance of a typical residential Cyprus building with phase change materials. Build. Serv. Eng. Res. Technol. 2015, 37, 85–102. [Google Scholar] [CrossRef]

- Devaux, P.; Farid, M.M. Benefits of PCM underfloor heating with PCM wallboards for space heating in winter. Appl. Energy 2017, 191, 593–602. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Economic impact of integrating PCM as passive system in buildings using Fanger comfort model. Energy Build. 2016, 112, 159–172. [Google Scholar] [CrossRef]

- Lei, J.; Yang, J.; Yang, E.-H. Energy performance of building envelopes integrated with phase change materials for cooling load reduction in tropical Singapore. Appl. Energy 2016, 162, 207–217. [Google Scholar] [CrossRef]

- Soares, N.; Reinhart, C.F.; Hajiah, A. Simulation-based analysis of the use of PCM-wallboards to reduce cooling energy demand and peak-loads in low-rise residential heavyweight buildings in Kuwait. Build. Simul. 2017, 10, 481–495. [Google Scholar] [CrossRef]

- Auzeby, M.; Wei, S.; Underwood, C.; Tindall, J.; Chen, C.; Ling, H.; Buswell, R. Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors. Energies 2016, 9, 605. [Google Scholar] [CrossRef]

- Jiao, F.; Xu, P. Simulation and Feasibility Analysis of PCM Based Passive Cooling Technique in Residential House. Procedia Eng. 2015, 121, 1969–1976. [Google Scholar] [CrossRef]

- Medved, S.; Arkar, C. Correlation between the local climate and the free-cooling potential of latent heat storage. Energy Build. 2008, 40, 429–437. [Google Scholar] [CrossRef]

- Assawamartbunlue, K. An Investigation of Cooling and Heating Degree-Hours in Thailand. J. Clean Energy Technol. 2013, 1, 87–90. [Google Scholar] [CrossRef][Green Version]

- Evola, G.; Marletta, L.; Sicurella, F. A methodology for investigating the effectiveness of PCM wallboards for summer thermal comfort in buildings. Build. Environ. 2013, 59, 517–527. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e.V. DIN 4108-2. Wärmeschutz und Energie-Einsparung in Gebäuden: Teil 2: Mindestanforderungen an den Wärmeschutz; Beuth Verlag GmbH: Berlin, Germany, 2013. [Google Scholar]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Zeynali Famileh, I.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Y.; Zhang, G. Numerical study on cooling performance of a ventilated Trombe wall with phase change materials. Build. Simul. 2018, 11, 677–694. [Google Scholar] [CrossRef]

- Soudian, S.; Berardi, U. Assessing the effect of night ventilation on PCM performance in high-rise residential buildings. J. Build. Phys. 2019, 43, 229–249. [Google Scholar] [CrossRef]

- BASF SE. Product Overview: Polymer Dispersions, Powders and Additives for Sealants, Flooring Adhesives and New Building Materials, Ludwigshafen, Germany. 2011. Available online: https://dokumen.tips/documents/polymer-dispersions-powders-and-additives-for-overview-polymer-dispersions.html?page=1 (accessed on 3 March 2021).

- Navarro, L.; Solé, A.; Martín, M.; Barreneche, C.; Olivieri, L.; Tenorio, J.A.; Cabeza, L.F. Benchmarking of useful phase change materials for a building application. Energy Build. 2019, 182, 45–50. [Google Scholar] [CrossRef]

- Ubakus—der Abakus für den U-Wert, “U-Wert-Rechner”. 2020. Available online: https://www.ubakus.de/der-abakus-fuer-den-u-wert/ (accessed on 20 June 2022).

| PCM Capacity [%] | Office Room | Classroom | ||

|---|---|---|---|---|

| R2 | RMSE [K] | R2 | RMSE [K] | |

| 100 | 0.66 | 0.60 | 0.63 | 0.88 |

| 75 | 0.65 | 0.54 | 0.64 | 0.78 |

| 50 | 0.65 | 0.52 | 0.62 | 0.81 |

| 25 | 0.64 | 0.53 | 0.63 | 0.90 |

| 0 | 0.63 | 0.56 | 0.64 | 1.08 |

| Night Ventilation [ACH] | Max. Temperature Reduction [K] | Mean Temperature Reduction [K] |

|---|---|---|

| 1 | 3.8 | 1.8 |

| 2 | 4.0 | 2.3 |

| 3 | 4.0 | 2.6 |

| Scenario | PCM | PCM Capacity [%] | Natural Ventilation & Shading | Mechanical Night Ventilation | Max. Temperature Reduction by PCM [K] | Mean Temperature Reduction by PCM [K] |

|---|---|---|---|---|---|---|

| S1 | +/− | 50 | Real | Real | 0.69 | 0.21 |

| 100 | 1.22 | 0.38 | ||||

| S2 | +/− | 50 | Improved | Real | 0.66 | 0.26 |

| 100 | 0.94 | 0.31 | ||||

| S3 | +/− | 50 | Improved | Improved | 1.00 | 0.35 |

| 100 | 1.01 | 0.35 |

| Scenario | PCM | Shading | Ventilation | Max. Temperature Reduction by PCM [K] | Mean Temperature Reduction by PCM [K] |

|---|---|---|---|---|---|

| 4 | +/− | Real | Real | 2.35 | 0.94 |

| 5 | +/− | Improved | Real | 2.24 | 0.87 |

| 6 | +/− | Improved | Improved | 2.15 | 0.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obergfell, T.; Gölz, S.; Haussmann, T.; Gschwander, S.; Wagner, A. Influence of User Behaviour on the Functioning and Performance of Passive Phase-Change Material Systems after More Than a Decade of Operation. Buildings 2022, 12, 1797. https://doi.org/10.3390/buildings12111797

Obergfell T, Gölz S, Haussmann T, Gschwander S, Wagner A. Influence of User Behaviour on the Functioning and Performance of Passive Phase-Change Material Systems after More Than a Decade of Operation. Buildings. 2022; 12(11):1797. https://doi.org/10.3390/buildings12111797

Chicago/Turabian StyleObergfell, Tabea, Sebastian Gölz, Thomas Haussmann, Stefan Gschwander, and Andreas Wagner. 2022. "Influence of User Behaviour on the Functioning and Performance of Passive Phase-Change Material Systems after More Than a Decade of Operation" Buildings 12, no. 11: 1797. https://doi.org/10.3390/buildings12111797

APA StyleObergfell, T., Gölz, S., Haussmann, T., Gschwander, S., & Wagner, A. (2022). Influence of User Behaviour on the Functioning and Performance of Passive Phase-Change Material Systems after More Than a Decade of Operation. Buildings, 12(11), 1797. https://doi.org/10.3390/buildings12111797