Abstract

The utilization of waste materials in concrete lowers its cost, and this method of dealing with the problem of trash disposal is viewed as the most environmentally friendly. Fly Ash Cenospheres (FAC) are one of the principal wastes produced by coal power stations. The huge volume of FAC produced worldwide has created a sustainability challenge, owing to the potential implications of inappropriate disposal. Using cenospheres in concrete materials would make effective and efficient use of these waste products while also supplementing what the present raw material, such as river sand, can supply for concrete material production. Though the application of FAC in concrete is currently carried out by the construction industry, there is still a lack of understanding about its performance in concrete with Manufactured Sand (M Sand) as fine aggregate. Therefore, in this paper, a comprehensive study explores the concept of adding FAC to M Sand concrete. The properties of fresh and hardened concrete, such as density, workability, compression, split tensile, flexure, and impact resistance after the addition of FAC in volume replacement (0–100% with a difference of 5% at thirteen different ratios) is represented, followed by microstructural analysis. From the results, it can be concluded that strength reduction takes place as FAC content increases from 0–100%, however, the strength is within the target limit of 31.2 N/mm2 of conventional concrete (CC) of grade M25 when the percentage replacement is below 35% of volume. Therefore, reducing the volume of fine aggregate does not negatively affect the strength properties, but also impacts the environmental concern positively with optimum recommendation of 35% of fine aggregate as FAC.

1. Introduction

Concrete is one of the world’s most widely used construction materials [1]. Aggregates, the essential constituents of concrete, occupy 70–80% of the volume formation. Their impact on concrete has various characteristics and properties, such as reduction in shrinkage and increase of strength, which are undoubtedly considerable [2]. During the last few decades, due to the increase of population and urbanization, the usage of aggregates in construction activity has increased rapidly [3]. In view of this, the usage of natural aggregate sources is increasing, thus leading to its non-availability and scarcity. To alleviate this and nurture a sustainable environment in the future, engineers have been challenged to utilize wastes from the industry as new and alternative building construction materials [4,5]. This provided ample opportunity for introducing industrial waste as a viable option in order to prevent the excessive use of natural resources [6]. In olden days, due to the large amount of carbon dioxide released into the atmosphere, supplementary cementitious materials (SCMs) were utilized as a partial replacement for large amounts of cement in concrete, which were recycled from industrial waste. For example, Feng et al., [7,8] utilized industrial wastes such as fly ash (FA) and nano silica (NS) to recycle aggregate concrete as SCMs in order to improve its pozzolanic reaction and mechanical properties.

The rise in industrialization increased the amount of waste generation to 960 MT solid, of which, inorganic waste from mining sector contributes 290 MT [9]. Different types of industrial wastes are generated, such as coal bottom ash [10,11,12,13,14], copper slag [15,16,17,18], furnace slag [19,20], ferrochrome slag [21], fly ash [22,23,24,25,26], oil palm shell [27,28,29] and coconut shell [30,31,32,33,34] that are used as a partial or full replacement of aggregates (both fine and coarse) in concrete production. Fly ash (FA) is a major indispensable source that is abundantly produced. It accounts for around 800 MT production worldwide each year, mainly by China, India, the United States, and Europe [35].

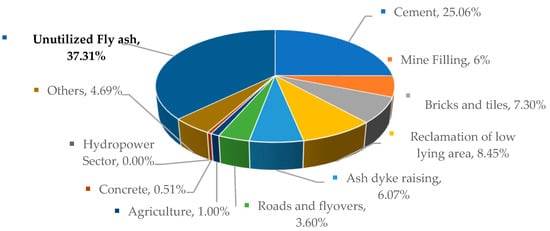

In India, the FA generated from coal thermal plants is used in various applications (Figure 1) such as cement, production of bricks and tiles, mine filling, roads and flyovers, reclamation of low-lying areas, ash dyke raising, hydropower sector, and concrete production. Irrespective of its enormous applications in concrete, its usage is still limited to 1/4th of its production. In order to utilize the FA, numerous studies were conducted, which suggested the incorporation of FA value-added products (unburnt carbon [36], cenosphere [37,38,39,40], plerosphere [41], magnetite [42]) into concrete.

Figure 1.

Report on fly ash generation at coal/lignite-based thermal power stations and its utilization in the country for the years 2020–2021, Central Electricity Authority, Thermal Civil Design Division, New Delhi [37].

Out of all mentioned constituents, fly ash cenosphere (FAC) is the most peculiar by-product, having various characteristics such as lightweightness, high compressive strength and fire-resistance [43]. The name “cenosphere” is derived from two Greek words: kenos (hollow) and sphaira (sphere) [44]. The coal combustion in thermal power plants produces fly ash comprising ceramic particles mostly composed of alumina and silica. They are formed at temperatures ranging from 1500 to 1750 °C (2730 to 3180 °F) through a complex chemical and physical process [45]. The incorporation of FAC in concrete has been studied by different authors, however, they all had a similar objective, which was to understand the performance of FAC through binder and aggregate replacement. Kannan et al., [46] investigated FAC as a replacement for binder in cement mortar for seven different ratios (0%, 5%, 10%, 15%, 20%, 25%, 30%) and concluded that the strength properties of the FAC combination was nearly equal to conventional mortar. Additionally, they observed that it the strength properties were increased by adding silica fume. The same was reported by Hanif et al., [47] wherein the strength enhancement was performed by adding nano silica to 30% of binder replaced with FAC. Zhou and Brooks [48] concluded that FAC was a successful filler material for the production of lightweight concrete until a 50% replacement in volume of fine aggregate. The author also inferred that FAC introduction effectively reduced the density and workability. Patel et al., [49] studied FAC as a fine aggregate replacement to natural sand with 20%, 40%, 60%, 80%, 100% replacement, and evaluated various properties such as workability, compression strength, split tensile strength, and flexural strength. The results indicated that an increase of FAC content decreased the concrete density and strength, which was further enhanced by introducing super-plasticizers.

Although the use of FAC can effectively improve the mechanical properties with reduced concrete density when it is substituted in place of natural river sand, studies regarding the combined use of FAC and M sand (emerging fine aggregate, a duly replaced natural fine aggregate) are still lacking. Due to the different microstructures of FAC and M sand, it is necessary to study the mechanical and microstructural properties of fly ash cenosphere concrete (FACC) to validate the feasibility of FAC in engineering applications. In this study, the fresh and hardened concrete properties, such as the density, workability, compression, split tensile strength, flexure, impact resistance, and non-destructiveness of FACC are discussed. Since the microstructure of the concrete is equally important for any new combination of concrete constituents, Scanning Electron Microscope (SEM) study and X-ray Diffraction (XRD) study is discussed for the different ages. The purpose of this investigation is to explore the optimal amount of the FAC analyzed to provide a reference for engineering FAC applications with good performance.

2. Materials and Methods

Ordinary Portland Cement (OPC) as per IS 12269:1987 [50] is used as a binder throughout the study. M Sand with a maximum size of 4.75mm, conforming to Zone II, as per IS 383:2016 [51] is used as a fine aggregate. Coarse aggregate (CA) with a maximum size of 10 mm was used. The physical properties of binder and aggregates is illustrated in Table 1.

Table 1.

Physical Properties of OPC and Crushed Stone Aggregate.

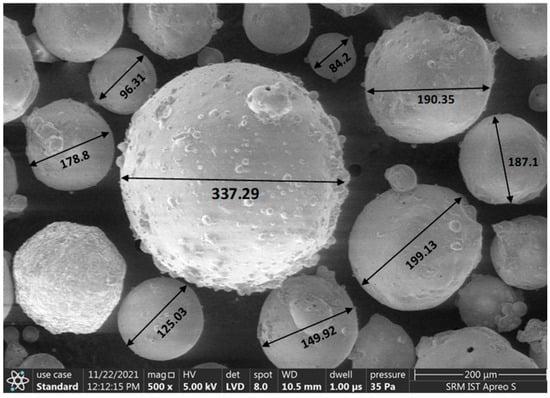

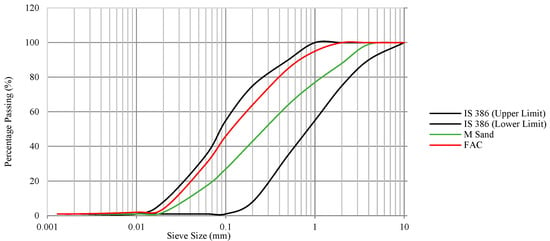

The FAC used in the study were collected from a locally available factory. In practice, they are of different sizes, and are processed through wet and dry separation techniques. In this investigation, most of the sizes range from 100–500 µm, as shown in Figure 2, which was carried out through SEM analysis. The FAC are spherically shaped, having a smooth surface texture. FAC and M Sand were used in surface dry condition. The specific gravity is 0.73 for FAC and 2.70 for M Sand. From the sieve analysis, the fineness modulus is found to be 1.97 for FAC and 3.32 for M Sand. The particle size distribution of FAC is compared with M Sand, as shown in Figure 3. It is observed that FAC falls under the upper and lower limit of fine aggregate gradation, as per IS 383: 2016 [51], even though it has lower fineness modulus and specific gravity than M sand.

Figure 2.

SEM Image of Fly Ash Cenosphere.

Figure 3.

Particle Size Distribution Curve.

Thirteen mix proportions were prepared. Concrete with M Sand is considered as Conventional Concrete (CC) and adopted a strength of 25 N/mm2. According to the codal provision of IS 10262:2019 [52], the mix ratio used for CC is 1:1.95:1.96. FAC were added at different ratios varying from 10 to 100% by equal volume replacement of M Sand by FAC. Table 2 shows thirteen different types of mix proportions for the series of tests to be conducted. In order to determine the properties of fly ash cenosphere concrete (FACC), different tests were conducted, as illustrated in Table 3.

Table 2.

Mix Proportion.

Table 3.

Experiments Conducted and Number of Samples Cast in this Study.

3. Results and Discussion

The fresh concrete properties such as density, workability and hardened concrete properties like compressive strength, flexural strength and split tensile strength results are represented in Table 4 and explained in the subsequent sections.

Table 4.

Fresh and Hardened Concrete Values of CC and FACC Mixes.

3.1. Fresh Concrete Properties

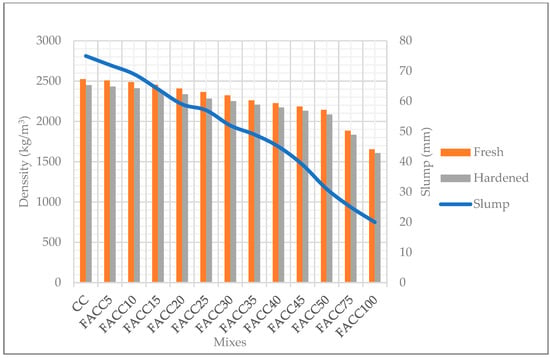

The fresh density of the CC is 2523 kg/m3. The fresh density is found to be 2508 kg/m3 for FACC5, 2483 kg/m3 for FACC10, 2446 kg/m3 for FACC15, 2407 kg/m3 for FACC20, 2352 kg/m3 for FACC25, 2318 kg/m3 for FACC30, 2261 kg/m3 for FACC35, 2226 kg/m3 for FACC40, 2184 kg/m3 for FACC45, 2143 kg/m3 for FACC50, 1885 kg/m3 for FACC75, and 1654 kg/m3 for FACC100. As compared to CC, the fresh densities of the FACC mixes are reduced in the range of 0.60–34.45%. Additionally, a similar trend is exhibited in the hardened densities of the FACC mixes. The hardened density of CC is 2450 kg/m3, which reduces to 2430 kg/m3 for FACC5, 2411 kg/m3 for FACC10, 2375 kg/m3 for FACC15, 2337 kg/m3 for FACC20, 2284 kg/m3 for FACC25, 2251 kg/m3 for FACC30, 2206 kg/m3 for FACC35, 2171 kg/m3 for FACC40, 2131 kg/m3 for FACC45, 2084 kg/m3 for FACC50, 1833 kg/m3 for FACC75, and 1609 kg/m3 for FACC100. As compared to the CC, the hardened densities of the FACC mixes are reduced in the range of 0.80–34.32%. McBride et al., Ref. [56] also inferred the same results when incorporating FAC in reducing the concrete density. The decreasing trend of fresh and hardened density becomes notable at higher fraction of FAC. This reduction of the density of concrete is due to the low density and hollow nature of the FAC. Additionally, the rate of decrement of hardened density is more prominent than that of fresh density because of water of absorption of the specimen during its drying process. It is significant that all the FACC mixes achieved hardened densities in the range of 2430–1609 kg/m3, which is a satisfactory reduction of the density when compared to the 2450 kg/m3 CC. A similar trend was observed by Blanco et al., Ref. [57] where the researchers produced a density of 1510kg/m3 by effectively using the low density FAC in lightweight concrete. Therefore, this suggests the possibility of reducing the density of concrete even further than the present study, which could potentially facilitate the preservation of natural fine aggregate in the environment, in terms of replacing it with FAC.

The slump of the concrete i.e., 75 mm, reduces marginally to 72 mm, 69 mm, 64 mm, 59 mm, 57 mm, 52 mm, 49 mm, 45 mm, 39 mm, 31 mm, 25 mm, and 20 mm for replacement of FAC with 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 75% and 100%, respectively, as shown in Figure 4. Due to the hollow and spherical nature of the FAC particles, air voids are created during the mixing process, which requires a higher amount of water to promote a consistent and homogenous flow. This creates the necessity for a higher water content when the replacement of FAC increases. When FAC is used, the wet mixing is done at a higher rate when compared to the CC in order to a get a workable concrete. Since a constant w/c ratio is maintained throughout the study, there is only a marginal decrease of the slump of FACC concrete.

Figure 4.

Fresh and Hardened Density of CC and FACC along with Slump.

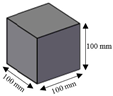

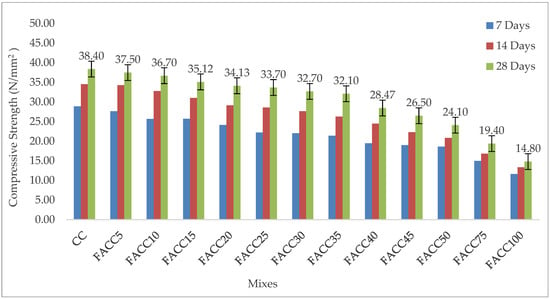

3.2. Compressive Strength

The compressive strength of the thirteen concrete mixes in which M Sand is replaced with FAC with varying percentages of 0–100% at 7, 14, and 28 days are carried out. Additionally, the variation of 7-, 14- and 28-days strength with respect to FAC is graphically represented in Figure 5. The compressive strength of the CC is 28.90 N/mm2 at 7 days, 34.56 N/mm2 at 14 days, and 38.40 N/mm2 at 28 days. The strength values of the corresponding mixes at 28 days are evaluated as 37.50 N/mm2, 36.70 N/mm2, 35.12 N/mm2, 34.13 N/mm2, 33.70 N/mm2, 32.70 N/mm2, 32.10 N/mm2, 28.47 N/mm2, 26.50 N/mm2, 24.10 N/mm2, 19.40 N/mm2, and 14.80 N/mm2, which are 2.34%, 4.43%, 8.54%, 11.12%, 12.24%, 14.84%, 16.41%, 25.87%, 30.99%, 37.24%, 49.48%, and 61.46% lower than that of CC. The strength results show that an increase of FAC content results in a decrease of compressive strength. Previous studies demonstrate that the incorporation of FAC in concrete proportionally decreased its strength with its density. McBride et al., [56] investigated that FAC replacement of 25% as FA to natural sand resulted in the reduction of the compressive strength to 30%. Hanif et al., [47] revealed that compressive strength is reduced up to 30% when cenosphere is incorporated as 10%, 20%, and 30% replacement. Similarly, when comparing the previous work on the state of fine aggregate replacement, Basar [58] reported that the compressive strength of concrete decreases with increasing proportion of Waste Foundary Sand (WSF) from 0–40%. The same was observed by Aggarwal [59], where equal replacement of WSF along with coal bottom ash (CBA) reduced the concrete strength when the replacement was up to 60%. In the present study, the strength reduction is 37.24% on 50% replacement, since most of the researchers studied the effect of FAC up to 50% replacement. Therefore, the present study shows a higher efficiency in terms of preserving the fine aggregate by replacing FAC. However, the decrease of strength of the FACC is attributed to the following reasons:

Figure 5.

Variation of Compressive Strength with Age for CC and FACC Mixes.

- Unfilled voids of FAC particles, which are prone to vulnerable cracking at higher loads.

- A high volume fraction of FAC increases the concrete’s internal porosity, leading to poor packing density.

In addition, there is a decrease of the early age strength of the concrete due to weak interfacial transition zone (ITZ) between the cement paste and FAC, which causes the inferior strength behaviour. However, the ITZ characteristics play a predominant role over the strength criteria. This superior strength could be increased by the addition of supplementary cementitious material and also by increasing the curing period, which would also enhance the long-term strength of the concrete. In addition to the influence of FAC, reduced natural fine aggregate has a positive effect on environmental concerns.

As seen in Figure 5, the concrete mix with 10% FAC and 90% M Sand has achieved maximum compressive strength among all FACC mixes of 37.50 N/mm2 at the age of 28 days, which is less than the compressive strength of CC, i.e., 38.40 N/mm2 at the age of 28 days, however, it satisfies the criteria of M25 grade concrete, as per IS 10262:2019, with a target strength of 31.2 N/mm2. Additionally, FACC10, FACC15, FACC20, FACC25, FACC 30, and FACC35 fulfill the aforementioned requirement. However, from the compressive test results, it can be stated that the optimum FAC that can be used a partial replacement of M sand is 35%, which is on the safer side, given the environmental concerns regarding the use of FAC as fine aggregate for further study.

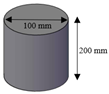

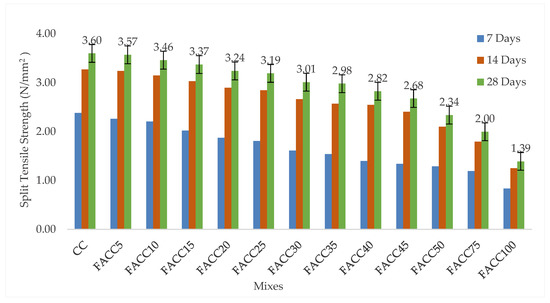

3.3. Split Tensile Strength

The variation in split tensile strength of the thirteen mixes at 28 days is furnished in Figure 6. Similar to compressive strength, the split tensile strength exhibits comparable variation. The CC at 28 days of curing has a split value of 3.60 N/mm2. In the case of FACC mixes, the values of 28-days strength are 3.57 N/mm2 for FACC5, 3.46 N/mm2 for FACC10, 3.37 N/mm2 for FACC15, 3.24 N/mm2 for FACC20, 3.19 N/mm2 for FACC25, 3.01 N/mm2 for FACC30, 2.98 N/mm2 for FACC35, 2.82 N/mm2 for FACC40, 2.68 N/mm2 for FACC45, 2.34 N/mm2 for FACC50, 2.00 N/mm2 for FACC75, and 1.39 N/mm2 for FACC100. The corresponding split tensile values are reduced by 0.80%, 3.85%, 6.36%, 9.97%, 11.36%, 16.36%, 17.19%, 21.53%, 25.66%, 35.10%, 44.54%, and 61.36% as compared to the CC. Limited studies regarding the split tensile strength of FAC incorporation were reported, but in the cases studied by Basar [58] and Aggarwal [59], the strength reduced to nearly 30% when compared to control concrete when WFS and CBA were used as fine aggregate replacement. Therefore, the predominance of the material i.e., in the present study, the FAC content, is responsible for the strength reduction. The low shell strength of the FAC and its brittle nature could be the causes for failure of the FAC concrete. The same was reported by Newman et al., [60] in which cenosphere was found to be more brittle in nature when compared to CC. This can be enhanced by the addition of fibers in FA concrete in order to decrease its brittleness and increase its shell strength.

Figure 6.

Variation of Split Tensile Strength with Age for CC and FACC Mixes.

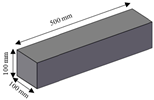

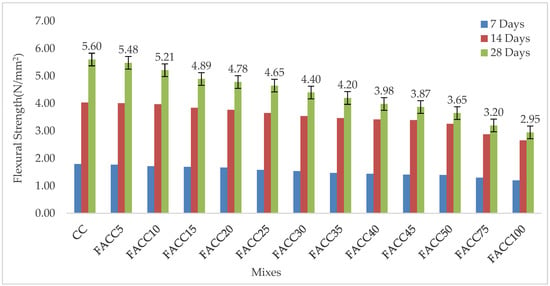

3.4. Flexural Strength

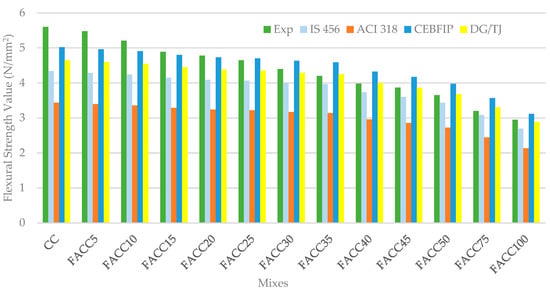

As with compression and split tensile strength, a similar variation of flexural strength is exhibited. The variation of the thirteen mixes at 28 days curing is shown in Figure 7. The CC has a flexural strength of 5.60 N/mm2. In case of FACC mixes, the values of 28-days strength are 5.48 N/mm2 for FACC5, 5.21 N/mm2 for FACC10, 4.89 N/mm2 for FACC15, 4.78 N/mm2 for FACC20, 4.65 N/mm2 for FACC25, 4.40 N/mm2 for FACC30, 4.20 N/mm2 for FACC35, 3.98 N/mm2 for FACC40, 3.87 N/mm2 for FACC45, 3.65 N/mm2 for FACC50, 3.20 N/mm2 for FACC75, and 2.95 N/mm2 for FACC100. When compared to the CC, the corresponding flexural strengths are reduced by 2.14%, 6.96%, 12.68%, 14.64%, 16.96%, 21.43%, 25.00%, 28.93%, 30.89%, 34.82%, 42.86%, and 47.32%, respectively. A typical flexural strength of concrete is between 10–15% of its respective compressive strength [38] and the same can be observed in this study. However, the replacement of FAC proved to be effective, and can be attributed to the same reason mentioned for split tensile strength regarding its reduction in flexural strength.

Figure 7.

Variation of Flexural Strength with Age for CC and FACC.

3.5. Co-Relation between Compression to Split and Flexural Strength

The ratio of split and flexural strength value to compressive strength value at 28 days for all the thirteen mixes is presented in Table 5. It is observed that the ratio of split-to-compression and flexural-to-compression for CC is found to be 0.09 and 0.15, respectively. The ratios for split-to-compression is found to be an average of 0.10, and lies within in a range of 0.09–0.10. It is notable that all FACC mixes comprised of M Sand replaced with FAC from 5–100% are equal or higher than those of CC. This indicates that FACC mixes shows enhanced and superior performance in the split value. Similarly, for flexural-to-compression, the ratio is found to be an average of 0.15, and the range lies between 0.13–0.20. Except for FACC 30 and FACC 35, the ratios are found to be equal or higher than CC; however, there is still a slightly inferior performance demonstrated by the FACC mix in flexural strength when compared to the split tensile strength of the concrete.

Table 5.

Ratio of Split and Flexural Strength Value to Compression Strength Value.

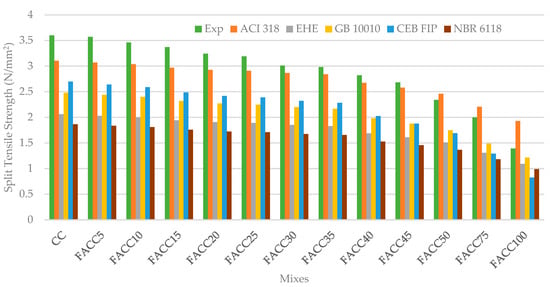

A comparative study of experimental split and flexural strength values to those predicted values from various codal provisions are presented in Table 6. The 28-days cube compressive strength (fc) is taken for the empirical calculation. In case of cylindrical compressive strength (f′c), cube compressive strength is multiplied by a factor of 0.8 [61]. The predicted split tensile strength (fsp) and flexural strength (ft) results are compared with experimental values, as shown in Figure 8 and Figure 9.

Table 6.

Predicted Formula for Split and Flexural Strength from Codal Provisions.

Figure 8.

Comparison of Experimental Value to Predicted Split Tensile Values.

Figure 9.

Comparison of Experimental Value to Predicted Flexural Tensile Values.

Figure 8 shows the predicted empirical values of split tensile strength calculated from various codes along with experimental values. It is observed that for all the FACC mixes, the predicted values of split tensile strength are comparatively lower than those of the experimental values. Similarly, in Figure 9, the experimental value of the FACC mix is higher than the predicted value for the Indian Standard and ACI empirical formula. Whereas, in the cases of CEB-FIP (Euro) and DG/TJ (Shanghai), the strength is relatively higher for CC, FACC5, FACC10, FACC15, and FACC20, and lower in the cases of FACC25, FACC30, FACC35, FACC40, FACC45, FACC50, FACC75 and FACC100. From this observation, it is concluded that the experimental values of the FACC mix are higher than the corresponding predicted values. Additionally, it is worth mentioning that FAC can be used as a replacement for M sand.

3.6. Impact Strength

The required number of blows to produce the initial crack and failure in terms of impact energy are listed in Table 7. Similar to the trend of compression, split, and flexural strength, the impact value of FACC is observed. From the results, it can be deduced that the failure energy of FACC is decreased by 4.41%, 11.76%, 14.71%, 17.65%, 27.94%, 29.41, 47.06% 51.47% 63.24%, 64.70%, 66.18%, and 85.29% compared to that of CC. This variation in the impact strength can be attributed to the following reasons:

Table 7.

Variation in Impact Energy of FACC Mixes with CC.

- Poor interlocking between the aggregates due to the brittle nature of FAC particles.

- Due to lightweight hollow aggregate phase (Specific gravity less than 1), the materials tend to initiate and propagate the cracks when the percentage replacement increases.

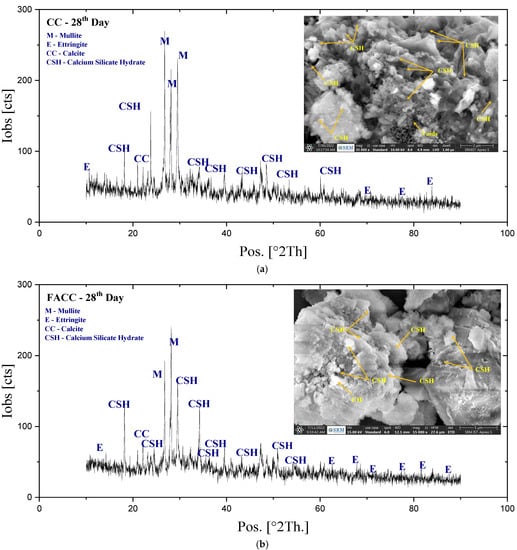

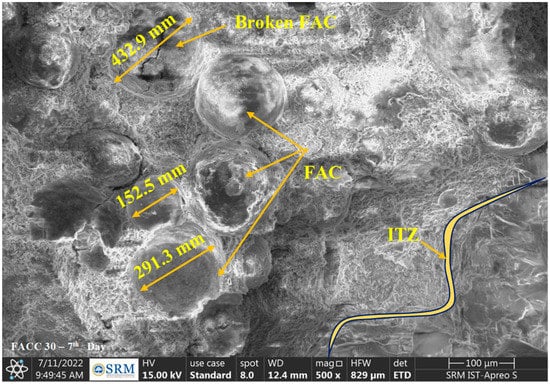

3.7. Microstructural Analysis

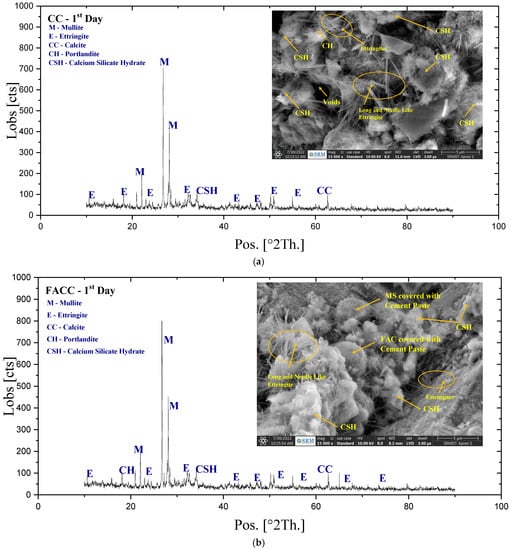

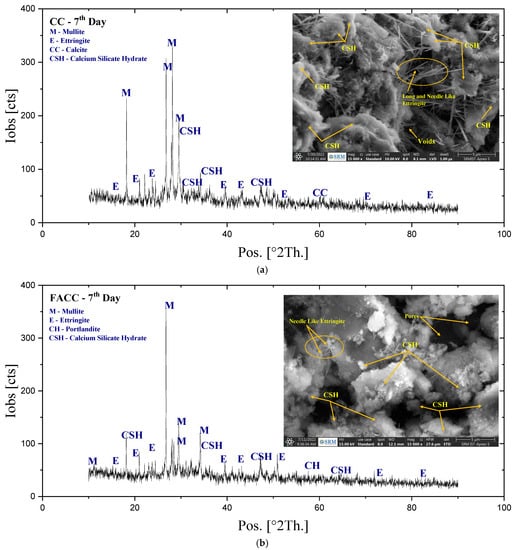

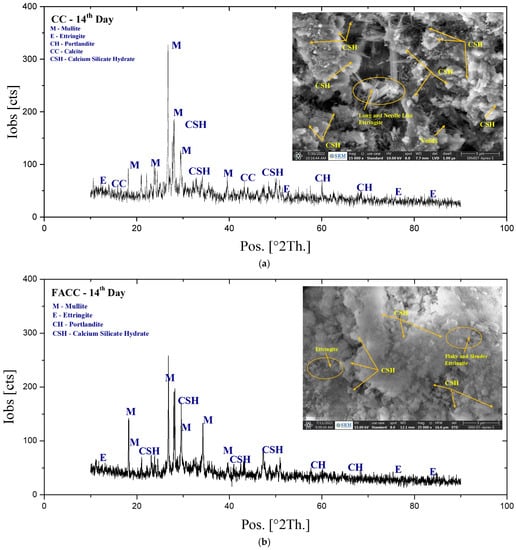

Microstructure of the concrete plays a significant role in concrete strength and durability, in which Interfacial Transition Zone (ITZ) between the cement paste and aggregate is studied. To understand the performance of FAC in concrete, microstructural analyses were carried out by Hi Resolution Scanning Electron Microscope (HRSEM) imaging using Thermosceintific Apreo S. The core samples (tested specimens) were impregnated using an ethanol solution, which was sprayed over the particle surface, and some polished samples were sputter coated with the help of an electron beam in order to vacuumize the wet moisture in the samples. Figure 10, Figure 11, Figure 12 and Figure 13 present the microscopic image of CC and FACC at 1, 7, 14, and 28 days, respectively. The microscopic analysis is studied under less than 20 µm scales. On the microscopic scale, the mixture of cement paste could be visible in the form of hydrated products. Due to the hydration process, clusters of Calcium Silicate Hydrate (CSH), needle and flaky shaped ettringites, unreacted amorphous calcium hydroxide is formed, which can be seen in all Figure 10, Figure 11, Figure 12 and Figure 13a. Similar to CC, the same was observed in FACC mixes, as shown in Figure 10, Figure 11, Figure 12 and Figure 13b. Refined, compact, and dense microstructure is found in the FACC mix when compared to CC. FAC of different sizes are also seen with partially reacted and unreacted ones. Higher magnification revealed the ettringite formation in various shapes, such needle-like, flaky, and slender types.

Figure 10.

XRD and SEM (a) CC (b) FACC on the First Day of Testing.

Figure 11.

XRD and SEM (a) CC (b) FACC on the Seventh Day of Testing.

Figure 12.

XRD and SEM (a) CC (b) FACC on the Fourteenth Day of Testing.

Figure 13.

XRD and SEM (a) CC (b) FACC on the Twenty-Eighth Day of Testing.

Using X-pert High Score Pus software, the XRD analysis at angles of 0–90-degrees was carried out, which can be seen in Figure 10, Figure 11, Figure 12 and Figure 13 for both CC and FACC at the 1st, 7th, 14th, and 28th day of testing. The samples confirm the presence of different hydrated phases, such as Calcium Silicate Hydrate (CSH), Calcium Aluminium Silicate Hydrate (CASH), Ettringites, Mullite (M), Calcium Hydrate (CH) and traces of Calcite (CC). The peak intensity of different phases was predominant in CC as compared to the FACC mixes. The main crystalline peaks observed are CSH phase, with slightly weaker peaks of ettringites. This confirms that the systematic hydration of the cement paste was carried out. When compared to CC, the peak intensity value did not substantially vary from the FACC mix (the peak intensity varied in the range of 200–400 counts). With the development of the curing period, the hydration phase could be observed in both FACC and CC, which confirms the strength development. Therefore, a similar pattern was observed in both CC and FACC.

In Figure 14, an indication of a thin layer of hydration product could be observed. This thin layer over the surface of the FAC could indicated the later-ages strengthening bond between aggregates. When compared to CC, the enhancement of the paste microstructure of FACC is not only due to its pozzolanic reaction, but it could be the reason for the effective filler effect of the FAC as fine aggregate. Therefore, this results in the obstruction of voids or pores in the concrete mix. We can conclude the overall microstructural behaviour is not affected due to the addition of FAC in the concrete, and that it is also similar to that of the normal concrete performance. Additionally, a systematic formation of CSH networks is formed in both CC and FACC mixes. Hence, the replacement of M Sand by FAC does not affect the conventional cement hydration process.

Figure 14.

Macroscopic view of ITZ view in FACC.

3.8. Non-Destructive Testing

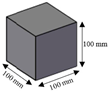

According to IS 13311 Part (1), an Ultrasonic Pulse Velocity (UPV) test was performed. The test was carried out in 100 mm cube size by advanced UPV test setup. A thin layer of grease was applied at either end of the smoothened surface of the cube to connect the transducers. The variation in the UPV reading of the thirteen concrete mix is shown in Table 8.

Table 8.

UPV and RN Values of CC and FACC.

As per the codal provision [55], the concrete quality is defined as doubtful when the range is less than 3 km/s, medium when it is between 3.0–3.5 km/s, good when it is between 3.5–4.5 km/s, and excellent when it is greater than 4.5 km/s. UPV values of all the FACC mixes are in the range of more than 3 km/s, which confirms that the mixes are in the good quality, except for the medium mix of FACC 75 and FACC 100. It is found that an increase of FAC content decreases the UPV values, which can be attributed to the internal voids and the existence of water in the wet medium of the concrete. The rebound numbers (RN) of the thirteen mixes are presented in the Table 8. The variation in the rebound number is similar to the UPV results. The RN of the CC is found to be 42.10, whereas for the remaining FACC mixes, the value ranges between 19.80–36.10. The same trend was observed in the case of compressive strength of the CC and FACC mixes as well, where an increase of FAC content decreased the strength of the concrete.

4. Conclusions

A comprehensive investigation is carried out on the behaviour of fly ash cenosphere as a fine aggregate replacement for M sand by varying its proportion from 0% to 100%. The fresh and hardened concrete properties were evaluated by microstructural studies and compared with CC. The following conclusions can be drawn from the current study.

The fresh and hardened density of the FACC is reduced to 34.32% when compared to CC. The FACC achieved within the range of 1609–2430 kg/m3. The workability of concrete decreased with increase of FAC content. Due to its spherical shape and porosity, the nature water absorption capacity increased due to the creation of large capillary voids. Therefore, it is necessary to use a water-reducing agent to improve workability after adding FAC, so that it can compensate for the reduction of the workability of the concrete.

The use of FAC in concrete reduced the compressive strength when compared to CC. The decrease of strength is due to its hollow nature, which makes it prone to vulnerable cracking. However, FACC achieved a compressive strength of more than 25 N/mm2 and the target strength of 31.2 N/mm2, as per IS 10262:2019, when the percentage replacement was more than 35%. Therefore, it can be stated that the optimum FAC that can be used a partial replacement of M sand is 35%, which is on the safer side, given the environmental concerns regarding the use of FAC as fine aggregate for further study.

The reduction of the split tensile strength of FACC was found to be a maximum of 61.36% in FACC100 and a minimum of 0.80% in FACC5 when compared to CC. Regarding the optimum content of FACC35, the strength reduction is found to be 17.19% after a 28-day curing period. Similarly, the maximum reduction of the flexural strength of FACC is found to be 47.32 N/mm2 for FACC100 and the minimum was 2.14% in FACC5 when compared to CC. Regarding the optimum content of FACC35, the strength reduction is found to be 25.00% after a 28-day curing period. Additionally, a similar trend was carried out in impact strength, that is FACC showed lesser impact than CC. The decrease of strength is due to filler effect of FAC, which leads the concrete to exhibit a brittle nature in when the percentage replacement increases. This shows the reason for concern regarding the mechanical properties. Further investigations may be performed by adding supplementary cementitious materials, such as silica fume, nano silica, or fly ash, for the enhancement of concrete properties.

The ratio of split strength-to-compression shows an equal or superior performance when compared to CC, whereas it shows an inferior performance in the case of flexural strength-to-compression strength. It was also concluded that the experimental values of FACC show higher and better performance when compared to different empirical equations of codal provisions.

The microstructural and XRD analysis results show that the hydration process is not affected by changes in fine aggregate with varying percentages of FAC, as similar variation is found in both CC and FACC specimens. In fact, the FACC turns out to be more compact, more uniform, and has a denser microstructure compared to CC.

From the results of UPV through FACC specimens, it can be concluded that excellent-, good-, and medium-quality concrete can be produced using fly ash cenosphere as fine aggregate. The rebound number results were also in line with the compressive strength results.

The above mentioned discussion reveals that the possibility of substituting M Sand with industrial by-product, such as fly ash cenosphere, offers economic advantages, thereby demonstrating great importance in the present context of sustainability in the construction industry.

Author Contributions

Conceptualization and methodology, writing—original draft preparation, M.K.; validation, editing and supervision, S.S.N.; data curation and supervision, A.S.; formal analysis and supervision, P.T.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge the XRD FACILITY at SRMIST set up with support from MNRE (Project No. 31/03/2014-15/PVSE-R&D), Government of India. We acknowledge SRMIST for high resolution scanning electron microscope (HR-SEM) facility.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shetty, M.S. “Concrete Technology”, Theory and Practice; Chand & Company Ltd.: New Delhi, India, 2005. [Google Scholar]

- Gunasekaran, K.; Kumar, P.; Lakshmipathy, M. Study on Properties of Coconut Shell as an Aggregate for Concrete. Ind. J. Ind. Concr. Ins. 2011, 12, 27–33. [Google Scholar]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A Decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Cillari, G.; Ricciardi, P.; Miino, M.C.; Torretta, V.; Rada, E.C.; Abbà, A. The Production of Sustainable Concrete with the Use of Alternative Aggregates: A Review. Sustainability 2020, 12, 7903. [Google Scholar] [CrossRef]

- Vailati, M.; Mercuri, M.; Angiolilli, M.; Gregori, A. Natural-Fibrous Lime-Based Mortar for the Rapid Retrofitting of Heritage Masonry Buildings. Fibers 2021, 9, 68. [Google Scholar] [CrossRef]

- Kowsalya, M.; Sindhu Nachiar, S.; Anandh, S. A Review on Fly Ash Cenosphere as a Solid Waste in Concrete Application. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Feng, W.; Tang, Y.; Zhang, Y.; Qi, C.; Ma, L.; Li, L. Partially Fly Ash and Nano-Silica Incorporated Recycled Coarse Aggregate Based Concrete: Constitutive Model and Enhancement Mechanism. J. Mater. Res. Technol. 2022, 17, 192–210. [Google Scholar] [CrossRef]

- Yunchao, T.; Zheng, C.; Wanhui, F.; Yumei, N.; Cong, L.; Jieming, C. Combined Effects of Nano-Silica and Silica Fume on the Mechanical Behavior of Recycled Aggregate Concrete. Nanotechnol. Rev. 2021, 10, 819–838. [Google Scholar] [CrossRef]

- Pappu, A.; Saxena, M.; Asolekar, S.R. Solid Wastes Generation in India and Their Recycling Potential in Building Materials. Build. Environ. 2007, 42, 2311–2320. [Google Scholar] [CrossRef]

- Singh, M. Coal Bottom Ash. In Waste and Supplementary Cementitious Materials in Concrete: Characterisation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–50. ISBN 9780081021569. [Google Scholar]

- Andrade, L.B.; Rocha, J.C.; Cheriaf, M. Influence of Coal Bottom Ash as Fine Aggregate on Fresh Properties of Concrete. Constr. Build. Mater. 2009, 23, 609–614. [Google Scholar] [CrossRef]

- Cadersa, A.S. Use of Unprocessed Coal Bottom Ash as Partial Fine Aggregate Replacement in Concrete. Univ. Maurit. Res. J. 2014, 20, 62–84. [Google Scholar]

- Singh, M.; Siddique, R. Strength Properties and Micro-Structural Properties of Concrete Containing Coal Bottom Ash as Partial Replacement of Fine Aggregate. Constr. Build. Mater. 2014, 50, 246–256. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Bindiganavile, V. Constitutive Model of Uniaxial Compressive Behavior for Roller-Compacted Concrete Using Coal Bottom Ash Entirely as Fine Aggregate. Buildings 2021, 11, 191. [Google Scholar] [CrossRef]

- dos Anjos, M.A.G.; Sales, A.T.C.; Andrade, N. Blasted Copper Slag as Fine Aggregate in Portland Cement Concrete. J. Environ. Manag. 2017, 196, 607–613. [Google Scholar] [CrossRef] [PubMed]

- Al-Jabri, K.S.; Hisada, M.; Al-Saidy, A.H.; Al-Oraimi, S.K. Performance of High Strength Concrete Made with Copper Slag as a Fine Aggregate. Constr. Build. Mater. 2009, 23, 2132–2140. [Google Scholar] [CrossRef]

- Alnuaimi, A.S. Effects of Copper Slag as a Replacement for Fine Aggregate on the Behavior and Ultimate Strength of Reinforced Concrete Slender Columns. J. Eng. Res. 2012, 9, 90–102. [Google Scholar] [CrossRef]

- Naganur, J.; Chethan, B.A. Effect of Copper Slag as a Partial Replacement of Fine Aggregate on the Properties of Cement Concrete by Jayapal Naganur & Chethan B. A. Int. J. Res. 2014, 1, 882–893. [Google Scholar]

- Yüksel, I.; Bilir, T.; Özkan, Ö. Durability of Concrete Incorporating Non-Ground Blast Furnace Slag and Bottom Ash as Fine Aggregate. Build. Environ. 2007, 42, 2651–2659. [Google Scholar] [CrossRef]

- Bheel, N.; Ali, M.O.A.; Liu, Y.; Tafsirojjaman, T.; Awoyera, P.; Sor, N.H.; Romero, L.M.B. Utilization of Corn Cob Ash as Fine Aggregate and Ground Granulated Blast Furnace Slag as Cementitious Material in Concrete. Buildings 2021, 11, 422. [Google Scholar] [CrossRef]

- Dash, M.K.; Patro, S.K. Performance Assessment of Ferrochrome Slag as Partial Replacement of Fine Aggregate in Concrete. Eur. J. Environ. Civ. Eng. 2021, 25, 635–654. [Google Scholar] [CrossRef]

- Harasymiuk, J.; Rudziński, A. Old Dumped Fly Ash as a Sand Replacement in Cement Composites. Buildings 2020, 10, 67. [Google Scholar] [CrossRef]

- Rajamane, N. Fly Ash as a Sand Replacement Material in Concrete—A Study. Indian Concr. J. 2013, 1–7. [Google Scholar]

- Zhang, D.; Wang, Y.; Ma, M.; Guo, X.; Zhao, S.; Zhang, S.; Yang, Q. Effect of Equal Volume Replacement of Fine Aggregate with Fly Ash on Carbonation Resistance of Concrete. Materials 2022, 15, 1550. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R. Effect of Fine Aggregate Replacement with Class F Fly Ash on the Mechanical Properties of Concrete. Cem. Concr. Res. 2003, 33, 539–547. [Google Scholar] [CrossRef]

- Christy, F.; Tensing, D. Effect of Class-F Fly Ash as Partial Replacement with Cement and Fine Aggregate in Mortar. CSIR 2010, 17, 140–144. [Google Scholar]

- Mannan, M.A.; Ganapathy, C. Engineering Properties of Concrete with Oil Palm Shell as Coarse Aggregate. Constr. Build. Mater. 2002, 16, 29–34. [Google Scholar] [CrossRef]

- Mannan, M.A.; Ganapathy, C. Concrete from an Agricultural Waste-Oil Palm Shell(OPS). Fuel Energy Abstr. 2004, 45, 441–448. [Google Scholar] [CrossRef]

- Ng, C.H.; Mannan, M.A.; Kameswara Rao, N.S.V. Structural Performance of Precast Floor Panel Using Oil Palm Shell Solid Waste. J. Infrastruct. Syst. 2016, 22, A4016002. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties. Materials 2018, 11, 1726. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Study on Durability Properties of Coconut Shell Concrete with Coconut Fiber. Buildings 2019, 9, 107. [Google Scholar] [CrossRef]

- Kumar, V.; Gunasekaran, K.; Professor, A. A Study on Mechanical Properties of Conventional Concrete and Coconut Shell Concrete by Replacing Cement with Silica Fume. J. Eng. Technol. 2018, 7, 437–442. [Google Scholar]

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and Bond Properties of Coconut Shell Concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Ramasubramani, R.; Gunasekaran, K. Sustainable Alternate Materials for Concrete Production from Renewable Source and Waste. Sustainability 2021, 13, 1204. [Google Scholar] [CrossRef]

- Woszuk, A.; Bandura, L.; Franus, W. Fly Ash as Low Cost and Environmentally Friendly Filler and Its Effect on the Properties of Mix Asphalt. J. Clean. Prod. 2019, 235, 493–502. [Google Scholar] [CrossRef]

- Central Electricity Authority; Thermal Civil Design Division. Report on Fly Ash Generation at Coal/Lignite Based Thermal Power Stations and Its Utilization in the Country for the Year 2020–2021; Central Electric Authority: New Delhi, India, 2021.

- Li, G.; Deng, L.; Liu, J.; Cao, Y.; Zhang, H.; Ran, J. A New Technique for Removing Unburned Carbon from Coal Fly Ash at an Industrial Scale. Int. J. Coal Prep. Util. 2015, 35, 273–279. [Google Scholar] [CrossRef]

- Lauf, R.J. Cenospheres in Fly Ash and Conditions Favouring Their Formation. Fuel 1981, 60, 1177–1179. [Google Scholar] [CrossRef]

- Wrona, J.; Zukowski, W.; Bradlo, D.; Czuprynśki, P. Recovery of Cenospheres and Fine Fraction from Coal Fly Ash by a Novel Dry Separation Method. Energies 2020, 13, 3576. [Google Scholar] [CrossRef]

- Hirajima, T.; Petrus, H.T.B.M.; Oosako, Y.; Nonaka, M.; Sasaki, K.; Ando, T. Recovery of Cenospheres from Coal Fly Ash Using a Dry Separation Process: Separation Estimation and Potential Application. Int. J. Miner. Process. 2010, 95, 18–24. [Google Scholar] [CrossRef]

- Choudhary, N.; Yadav, V.K.; Malik, P.; Khan, S.H.; Inwati, G.K.; Suriyaprabha, R.; Singh, B.; Yadav, A.K.; Ravi, R.K. Recovery of Natural Nanostructured Minerals. In Handbook of Research on Emerging Developments and Environmental Impacts of Ecological Chemistry; IGI Global: Hershey, PA, USA, 2020; pp. 450–470. [Google Scholar]

- Chavez Alcala, J.F.; Morales Davila, R.; Lastra Quintero, R. Recovery of Cenospheres and Magnetite from Coal Burning Power Plant Fly Ash. Trans. Iron Steel Inst. Jpn. 1987, 27, 531–538. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A Review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A. Formation Mechanism and Applications of Cenospheres: A Review. J. Mater. Sci. 2020, 55, 4539–4557. [Google Scholar] [CrossRef]

- Adesina, A. Sustainable Application of Cenospheres in Cementitious Materials—Overview of Performance. Dev. Built Environ. 2020, 4, 100029. [Google Scholar] [CrossRef]

- Senthamarai Kannan, K.; Andal, L.; Shanmugasundaram, M. An Investigation on Strength Development of Cement with Cenosphere and Silica Fume as Pozzolanic Replacement. Adv. Mater. Sci. Eng. 2016, 2016, 9367619. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties Improvement of Fly Ash Cenosphere Modified Cement Pastes Using Nano Silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Zhou, H.; Brooks, A.L. Thermal and Mechanical Properties of Structural Lightweight Concrete Containing Lightweight Aggregates and Fly-Ash Cenospheres. Constr. Build. Mater. 2019, 198, 512–526. [Google Scholar] [CrossRef]

- Patel, S.K.; Satpathy, H.P.; Nayak, A.N.; Mohanty, C.R. Utilization of Fly Ash Cenosphere for Production of Sustainable Lightweight Concrete. J. Inst. Eng. Ser. A 2020, 101, 179–194. [Google Scholar] [CrossRef]

- IS 12269:2013; Ordinary Portland Cement, 53 Grade—Specification. Bureau of Indian Standard: New Delhi, India, 2013.

- IS 383:2016; Coarse and Fine Aggregate for Concrete—Specification. Bureau of Indian Standard: New Delhi, India, 2016.

- IS 10262:2019; Concrete Mix Proportioning. Bureau of Indian Standard: New Delhi, India, 2019.

- IS 516:2018; Method of Tests for Strength of Concrete. Bureau of Indian Standard: New Delhi, India, 2018.

- ACI 544.1R-96; State-of-the-Art Report on Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2001.

- IS 13311-1:1992; Method of Non-Destructive Testing of Concret, Part 1: Ultrasonic Pulse Velocity. Bureau of Indian Standard: New Delhi, India, 1992.

- McBride, S.P.; Shukla, A.; Bose, A. Processing and Characterization of a Lightweight Concrete Using Cenospheres. J. Mater. Sci. 2002, 37, 4217–4225. [Google Scholar] [CrossRef]

- Blanco, F.; García, P.; Mateos, P.; Ayala, J. Characteristics and Properties of Lightweight Concrete Manufactured with Cenospheres. Cem. Concr. Res. 2000, 30, 1715–1722. [Google Scholar] [CrossRef]

- Basar, H.M.; Deveci Aksoy, N. The Effect of Waste Foundry Sand (WFS) as Partial Replacement of Sand on the Mechanical, Leaching and Micro-Structural Characteristics of Ready-Mixed Concrete. Constr. Build. Mater. 2012, 35, 508–515. [Google Scholar] [CrossRef]

- Aggarwal, Y.; Siddique, R. Microstructure and Properties of Concrete Using Bottom Ash and Waste Foundry Sand as Partial Replacement of Fine Aggregates. Constr. Build. Mater. 2014, 54, 210–223. [Google Scholar] [CrossRef]

- Newman, J.; Owens, P. Properties of Light Weight Concrete. In Advanced Concrete Technology, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2003. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Person Education Limited: New Delhi, India, 2013. [Google Scholar]

- ACI 318; Building Code Requirement for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- IS 456:2000; Plain and Reinforced Concrete—Code of Practice (Fourth Revision). Bureau of Indian Standard: New Delhi, India, 2000.

- EHE. Spanish Code for Structural Concrete; Real Decreto 2661/1998; Ministerio de Fomento: Madrid, Spain, 1998. [Google Scholar]

- GB:10010; Code for Design of Concrete Structures. Chinese Standard; China Building Science Academy: Beijing, China, 2002.

- Comite Euro-International du Beton. CEB-FIP Model Code 1990; Thomas Telford: London, UK, 1991. [Google Scholar]

- NBR 6118; Design of Concrete Structures. Brazilian Association of Technical Standards: Sao Paulo, Brazil, 2003.

- DG/TJ; Technical Code for Application of Recycled Aggregate Concrete. Shangai Construction Standard Society (SCSS): Shangai, China, 2008.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).