3.1. Carbonation Treatment

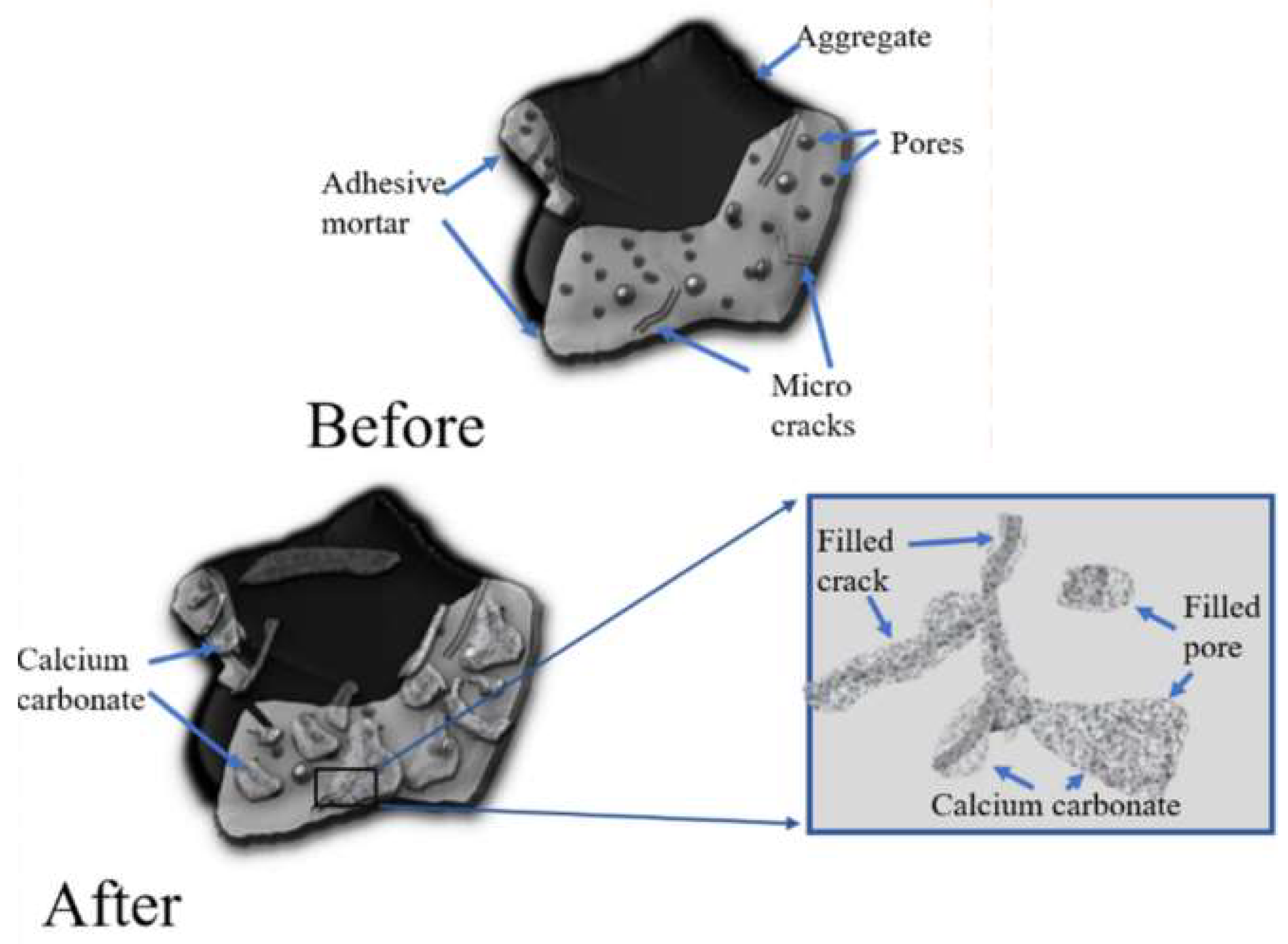

Carbonation is one of the methods which can be used to decrease the porosity and enhance the performance of ITZ. In this process, CO

2 can penetrate into the pores of the RCA and further react with CH and C–S–H to fill fissures [

34]. The treatment can be conducted in different ways, including pretreatment, changing pressure, etc.

Li et al. [

6] analyzed the influence of the carbonation treatment by comparing the properties of RCAs before and after treatment. For this purpose, the RCA was obtained from a parent concrete with w/c equal to 0.36. The mixture proportion contained water, cement, sand, and natural aggregate with 161, 445, 702, and 1098 kg/m

3, respectively. The percentage of air-entraining agent was about 0.03, while compressive strength at 28 days was equal to 55 MPa.

The samples of RCA were preconditioned in a drying chamber to remove excessive moisture content before the carbonation process. Afterward, the carbonation of the samples was carried out in a standard carbonation chamber. A 1% phenolphthalein alcohol solution was sprayed every 12 h on carbonated recycled concrete aggregates (CRCA) to determine if a reaction had occurred. The physical properties of RCA and CRCA are presented in

Table 4. In the study, curing of samples was performed for 3 days at 70 ± 5% relative humidity and the laboratory-maintained 23 ± 2 °C temperature. The Vickers microhardness and SEM analysis were conducted to evaluate the effect of carbonation treatment.

During crushing pattern examination, some differences between RCA and CRCA were identified. In total, four different stages in the load–displacement curve were observed. During stage 1, when a load was applied to the original RCA, the surface was crushed, while in stage 2, the ITZ collapsed, causing the separation of mortar and NA. In stage 3, the mortar was crushed; finally, in stage 4, the aggregate was crushed with an increase in loading. CRCA samples also showed four stages in the load–displacement curve. Stage 1 was similar to that of RCA, where the surface crushed. However, the difference was during stage 2, where the mortar connected to the RA was crushed first. Later, in stage 3, ITZ was crushed with further crushing of the NA during stage 4. The difference between the crushing patterns could be explained by the enhancement of ITZ after the carbonation treatment that increased density and crushing stress.

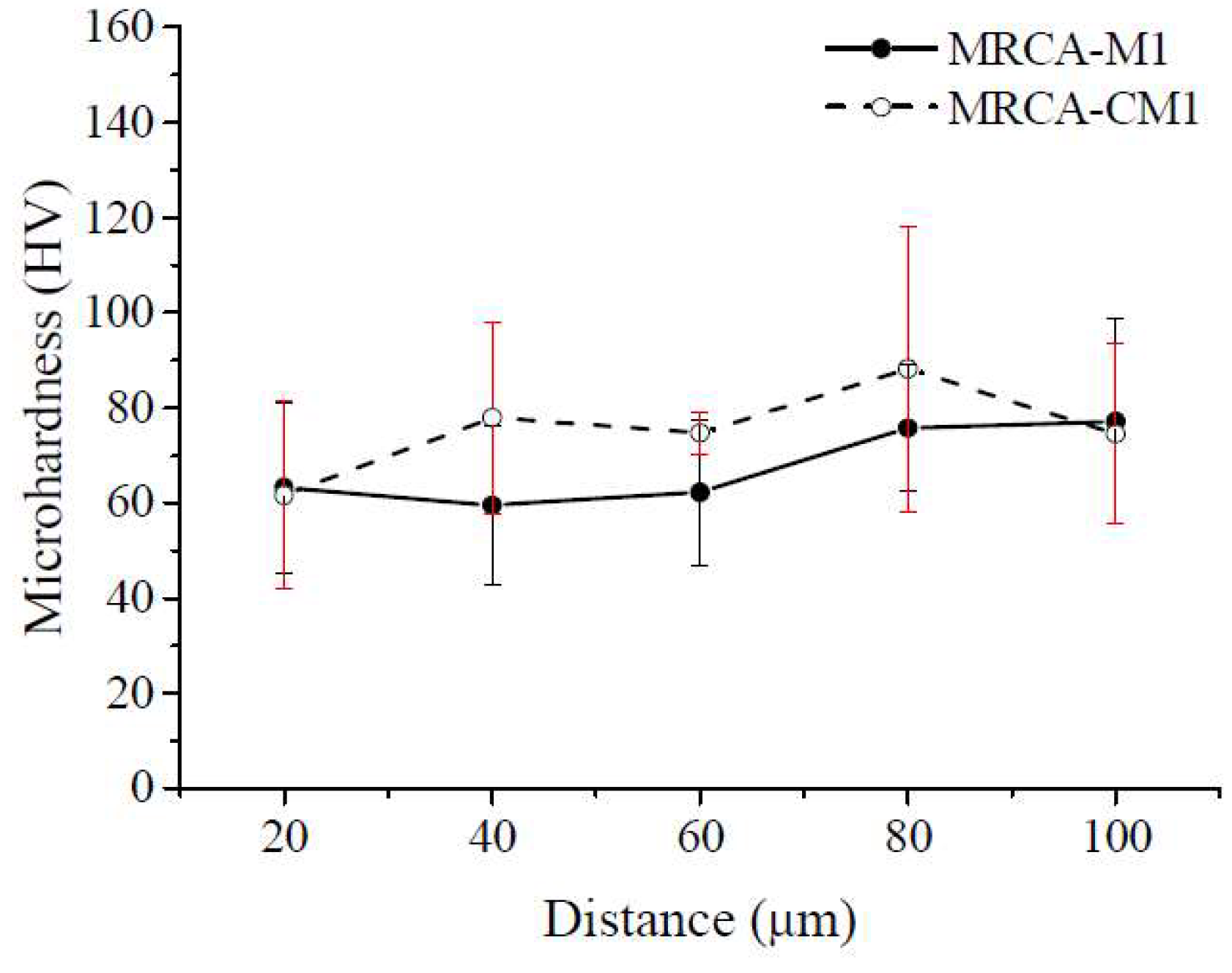

The results of microhardness for RCA and CRCA are presented in

Figure 1. The microhardness of the recycled aggregate increased from 88.6 to 108.7 after carbonation treatment. Consequently,

Figure 1 shows that the microhardness of the ITZ around CRCA was higher than the ITZ around RCA, which also explains the difference between crushing patterns. The measured microhardness of the treated samples (CRCA) in ITZ was 31% higher in comparison to the original RCA, with an average of value equal to 71.8 for CRCA and 56.7 for original RCA. It can be referred to as the lower WA of the CRCA sample resulting in a relatively lower w/c ratio around the CRCA that helps to improve the ITZ. Similarly, the microhardness of CRCA also increased in the adhered mortar. However, the increase was only 17.4%, which is significantly lower compared to the improvement in ITZ. It can be concluded that the improvement in ITZ was greater than the adhered mortar after the carbonation treatment. Thus, compared to the adhered mortar on the surface, the carbonation treatment significantly strengthened the ITZ.

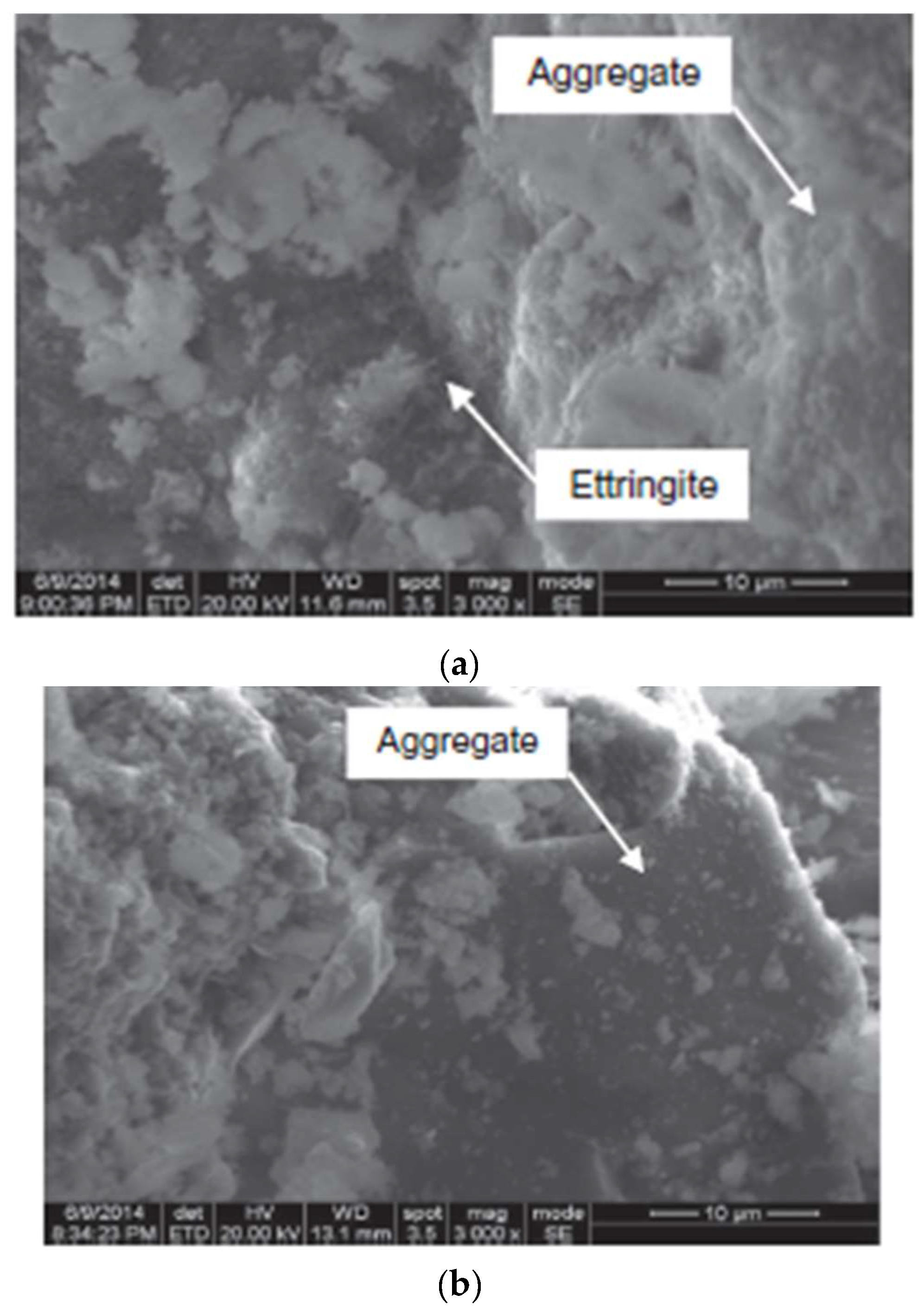

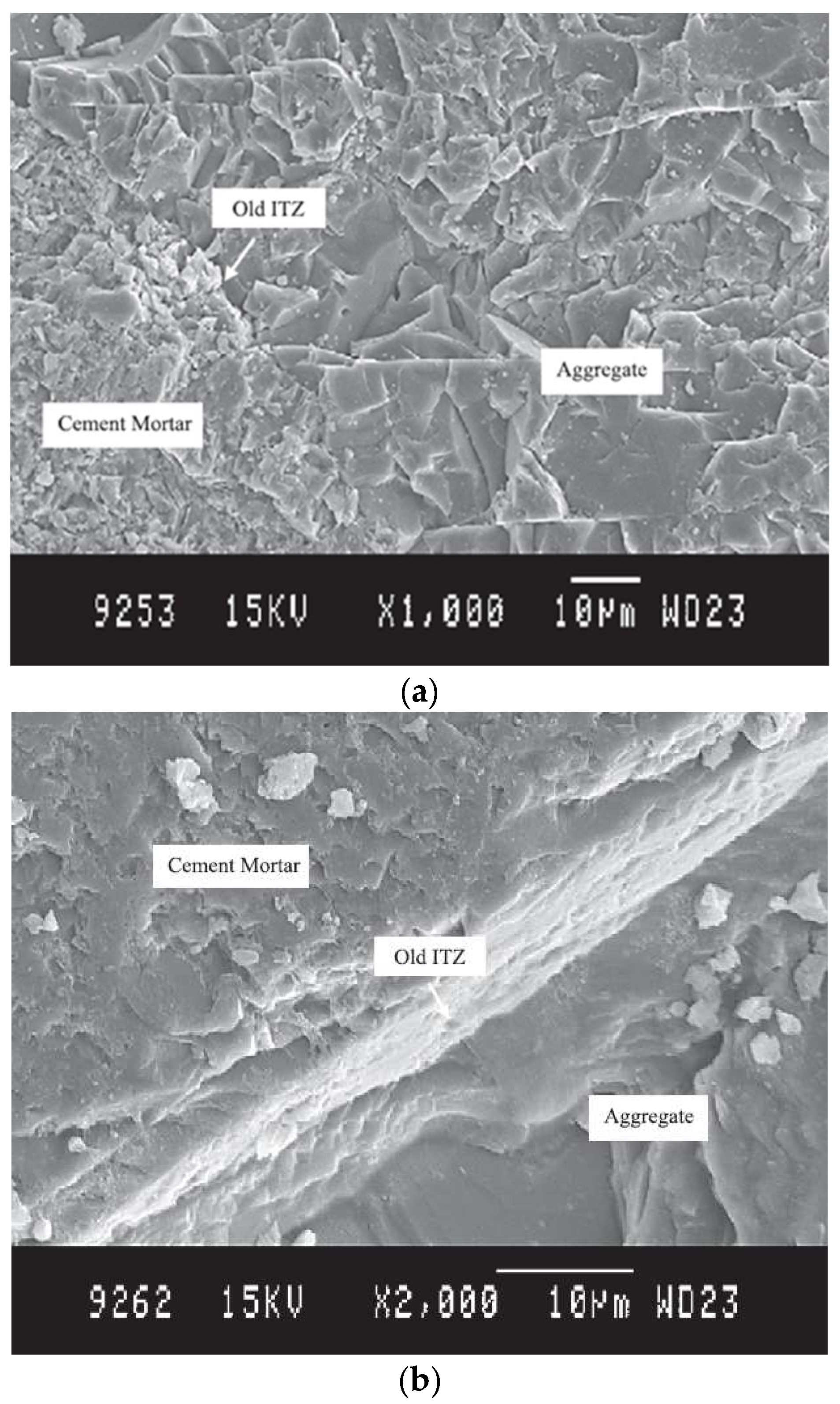

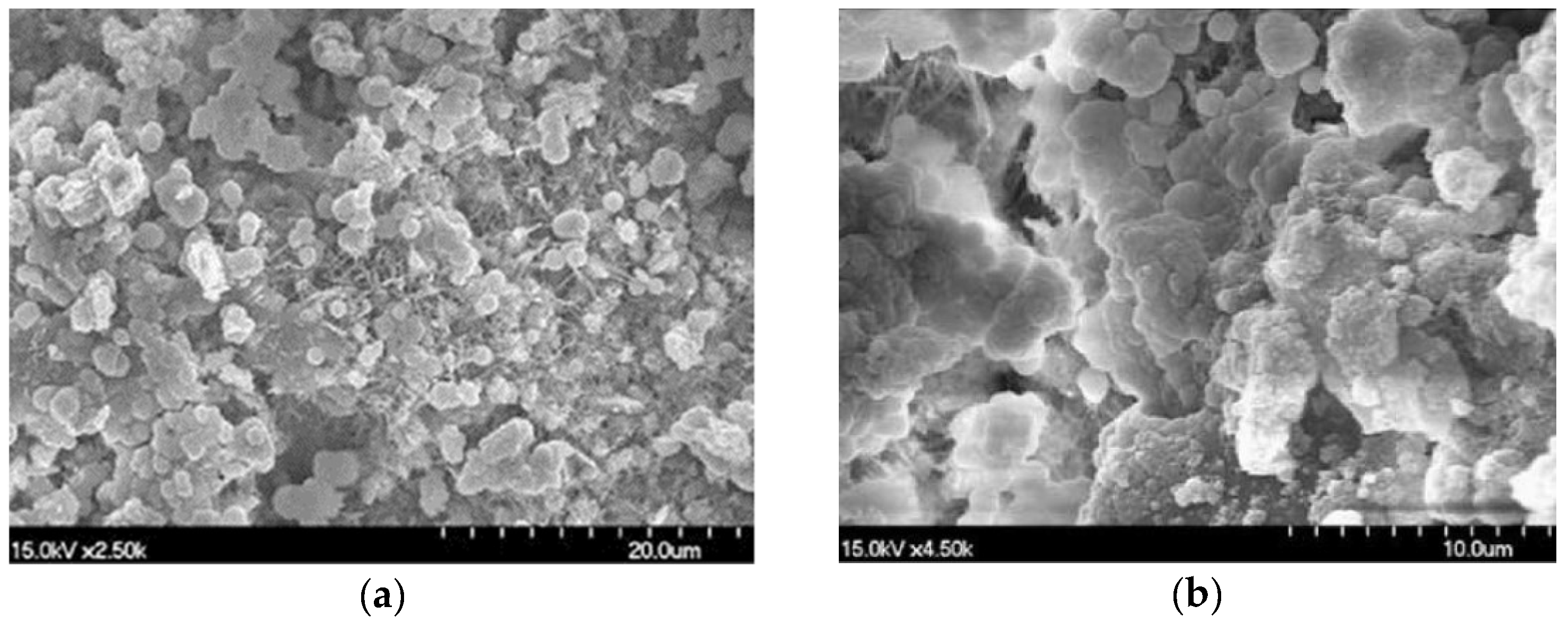

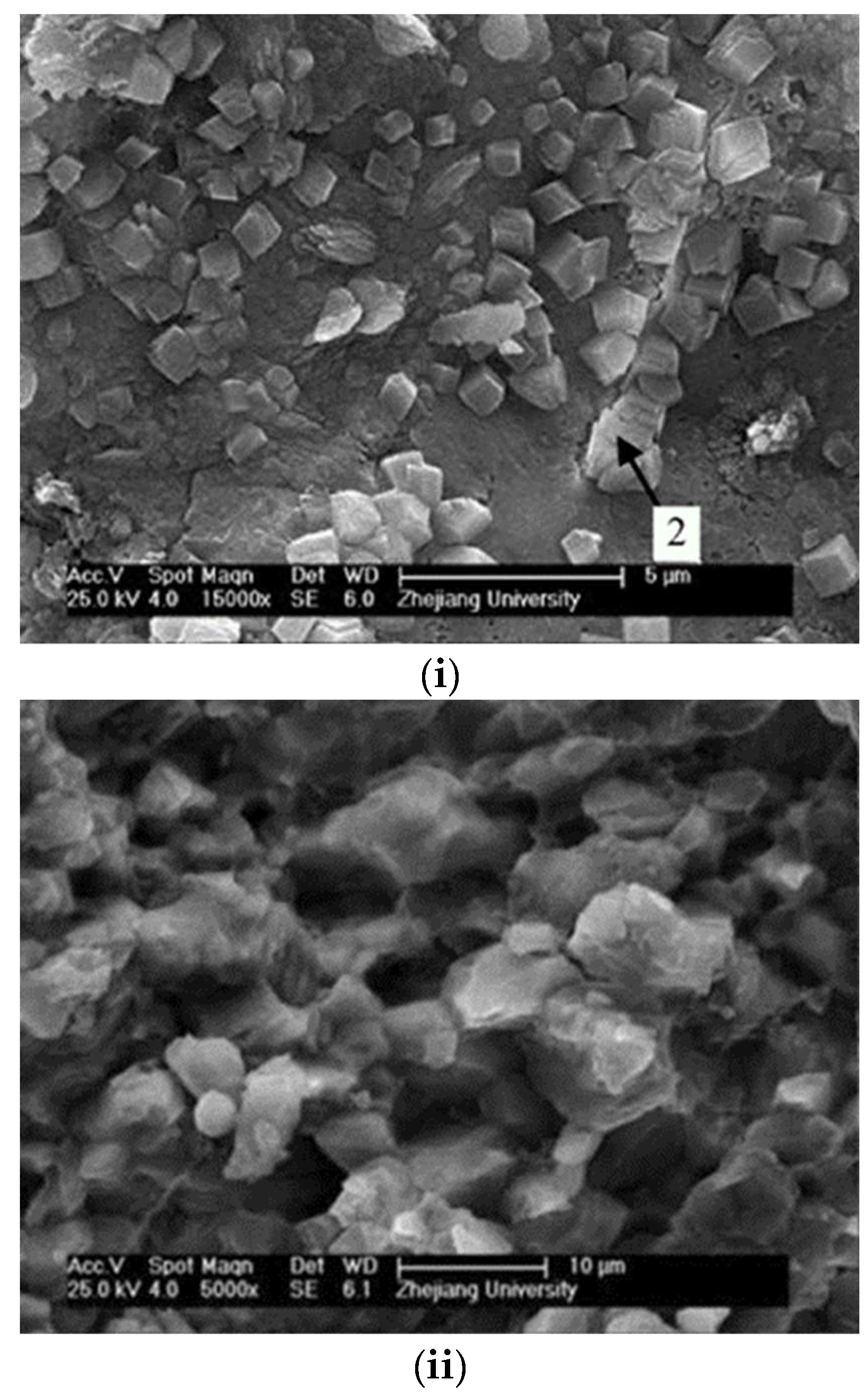

In the same research, the SEM of the attached mortar and ITZs in the RCA and CRCA were compared. Needle-like ettringite can be observed in the adherent mortar of RCA, while no crystals were observed after carbonation due to their complete disappearance. In addition, numerous micro cracks, voids, and loose hydrated products resulted in poor bonding between the attached mortar and NA (

Figure 2a). In contrast,

Figure 2b reveals densified ITZ with hydration products such as CaCO

3, which improved its microhardness. Thus, SEM and Vickers microhardness tests confirm the improvement of ITZ in CRCA. Overall, the main finding was that the carbonation treatment improved the original ITZ together with the adherent mortar in the RCA.

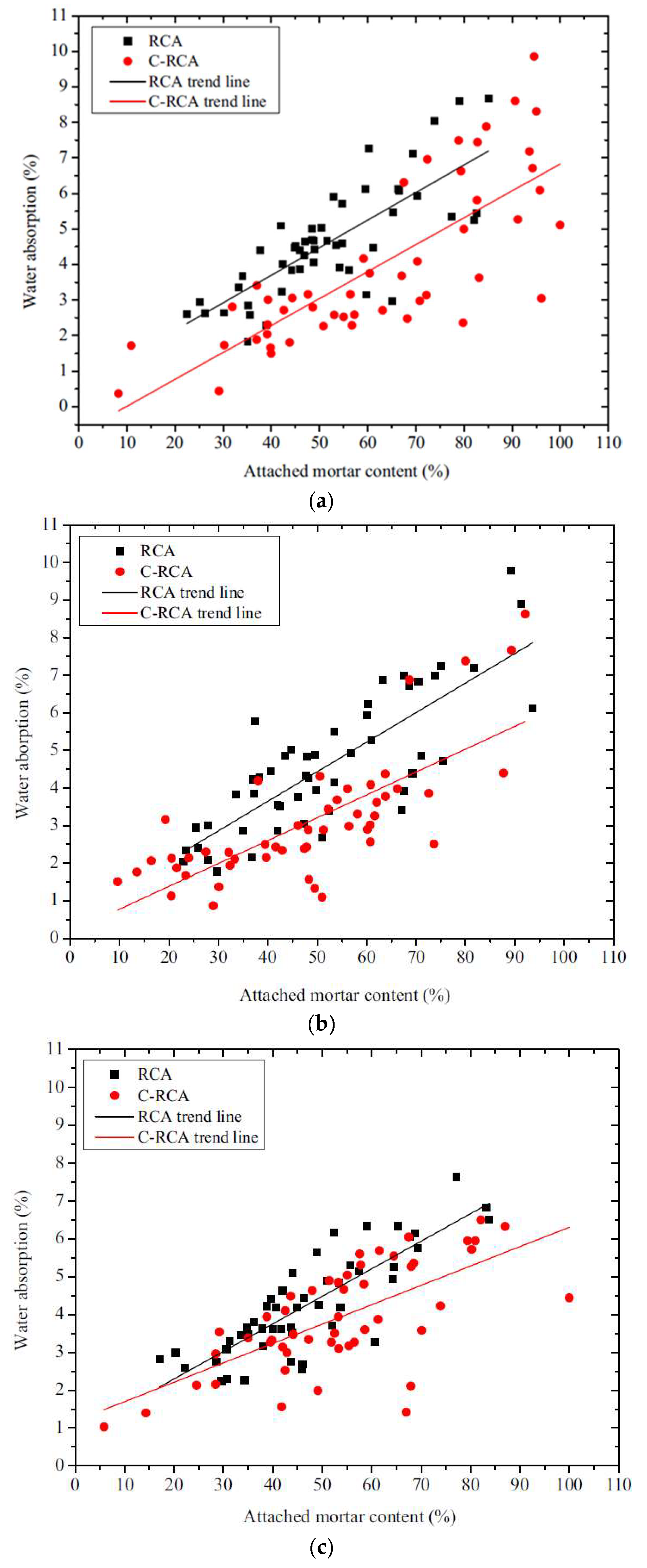

Zhang et al. [

35] aimed to improve the properties of recycled gravel concrete aggregate (G-RCA) and recycled crushed stone concrete aggregate (C-RCA). G-RCA and C-RCA were derived from beams having compressive strength equal to 30 and 50 MPa, respectively. Carbonation treatment was performed at relative humidity, temperature, and CO

2 concentration of 60 ± 5%, 20 ± 2 °C, and 20 ± 2%, respectively. In the experiment, no pretreatment procedure was adopted. However, after a certain period of time, the specimens were sprayed with a 1% alcoholic solution of phenolphthalein to distinguish between carbonated and noncarbonated portions.

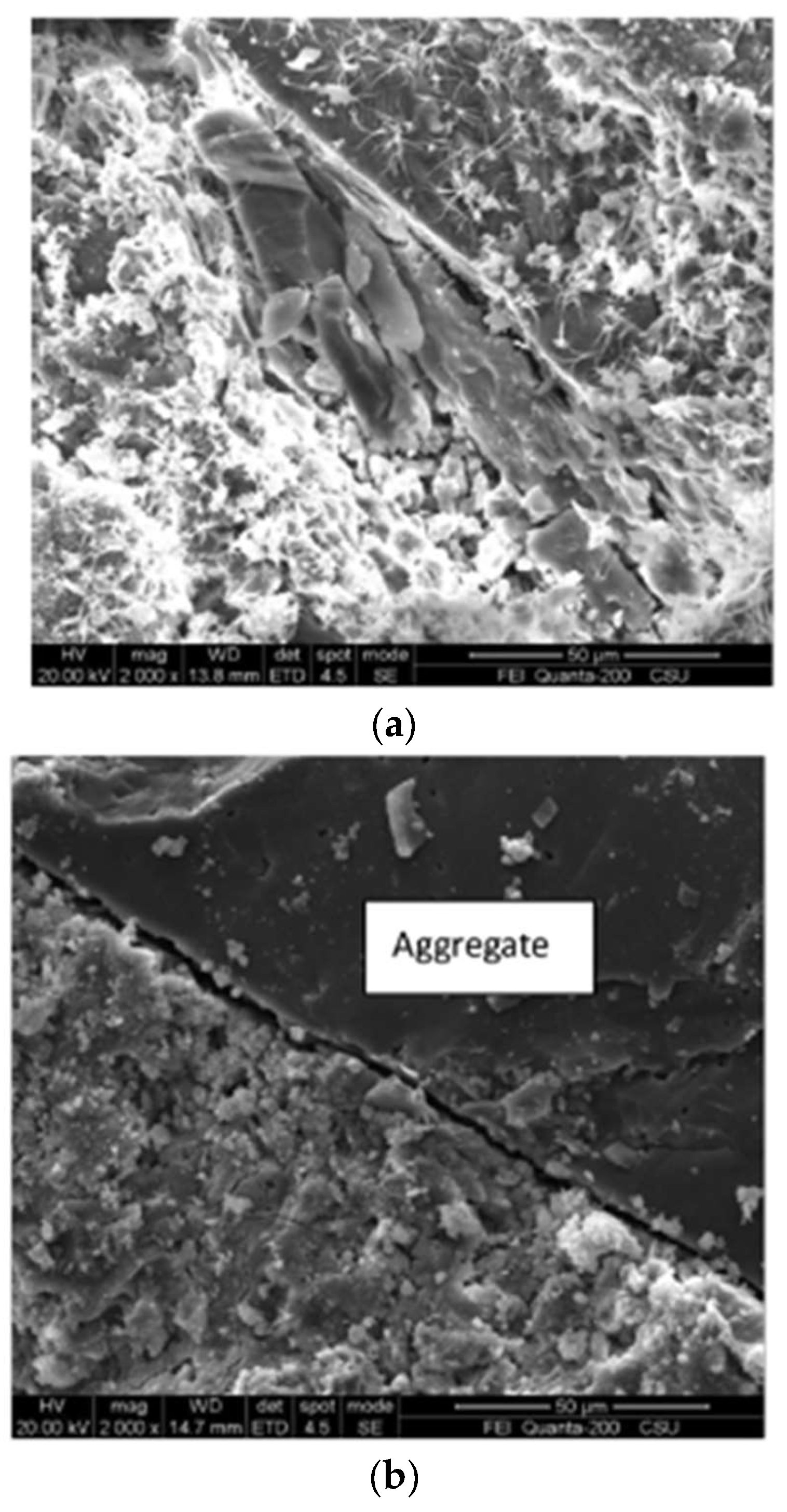

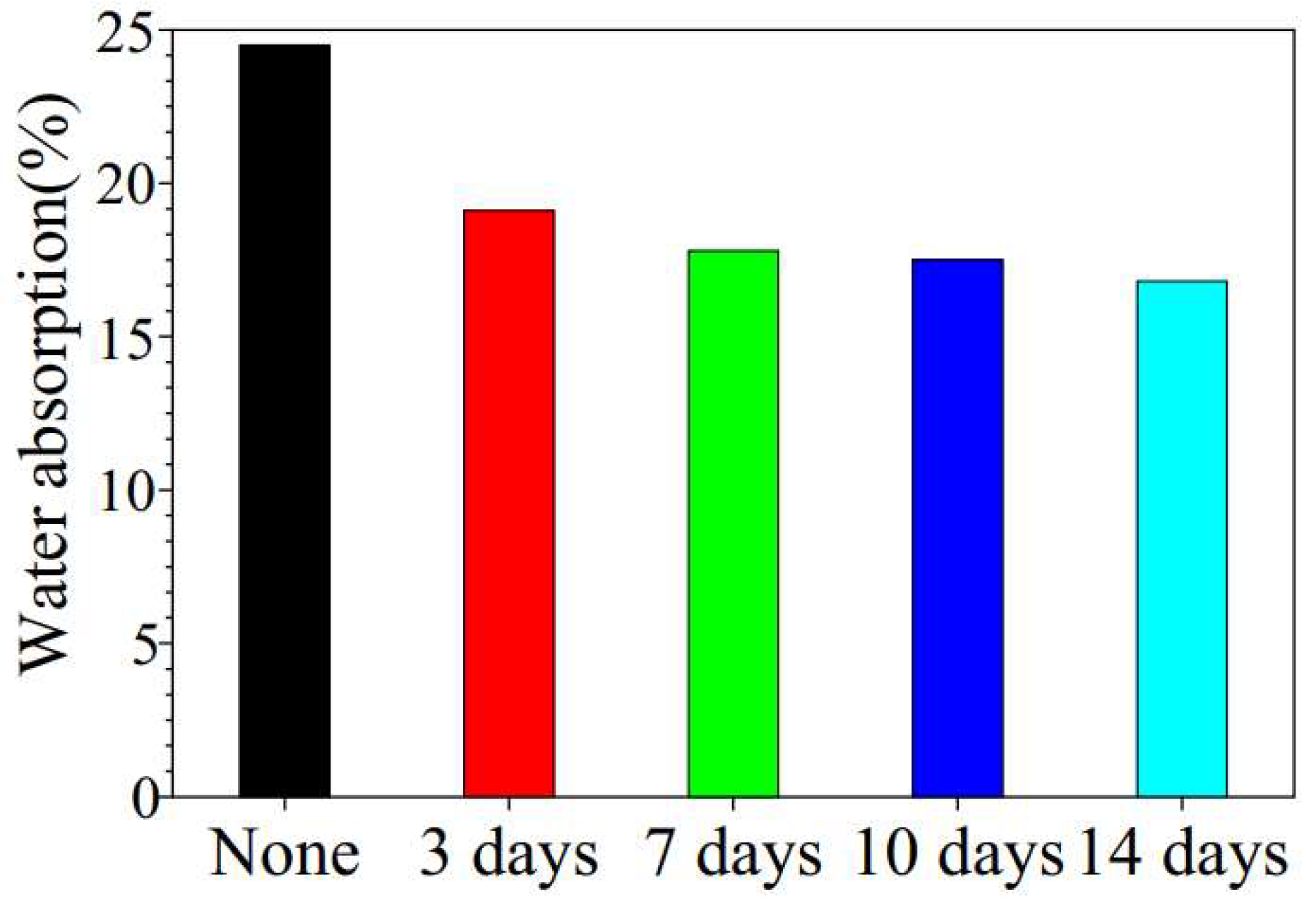

The reaction between CO

2 with the hydration products of cement and unhydrated cement particles, both recycled samples became denser by 4.7–5.6%. Carbonation treatment improved the properties of G-RCA and C-RCA, thus decreasing water absorption by 7.6–9.6% and crushing value by 22.6–28.3%. Consequently, the percentage of mechanical crushing value on average declined by 20%, and the proportion of water absorption lowered by 23–28%. Decreased water absorption value reduced the thickness of the water film, thus enhancing the original ITZ of RCA. SEM images demonstrated that the carbonated sample had a denser ITZ, and fewer large pores between the aggregate and cement paste compared to the porous noncarbonated aggregate (

Figure 3). Overall, the original ITZ and the newly formed ITZ in mortar were improved, as determined by SEM examination.

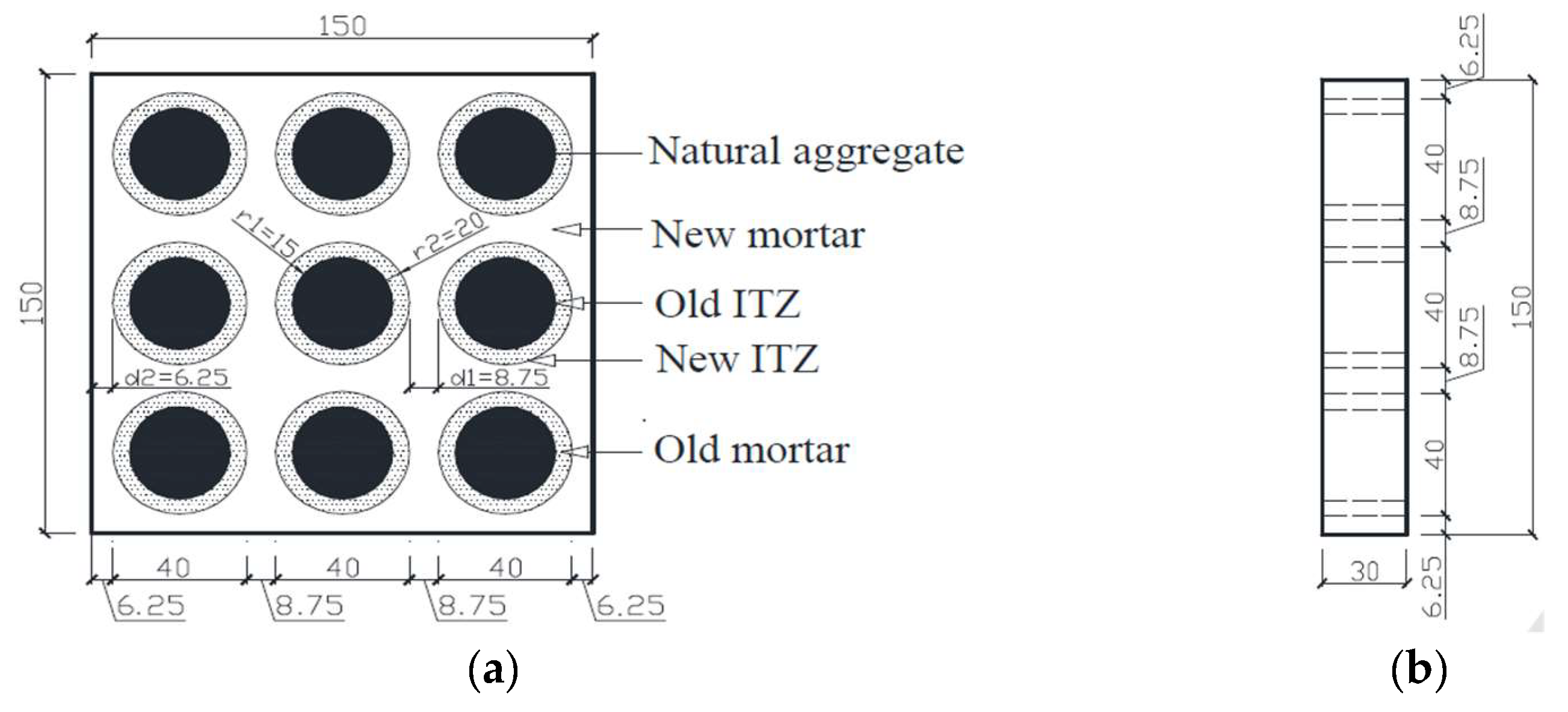

Shi et al. [

36] evaluated the influence of carbonation on the densification of new and old ITZ. The experiment was carried out at relative humidity, temperature, and CO

2 concentration of 70 ± 5%, 20 ± 3%, and 20 ± 2 °C, respectively. The surface cleaning and spraying with 1% phenolphthalein solution were used to measure the carbonation depth. The carbonation-treated RCA resulted in the formation of both fiber-like and cotton-like materials, which further filled voids and densified ITZ between RA and adhered mortar. The densification of ITZ after carbonation treatment is shown in the micrographs presented in

Figure 4.

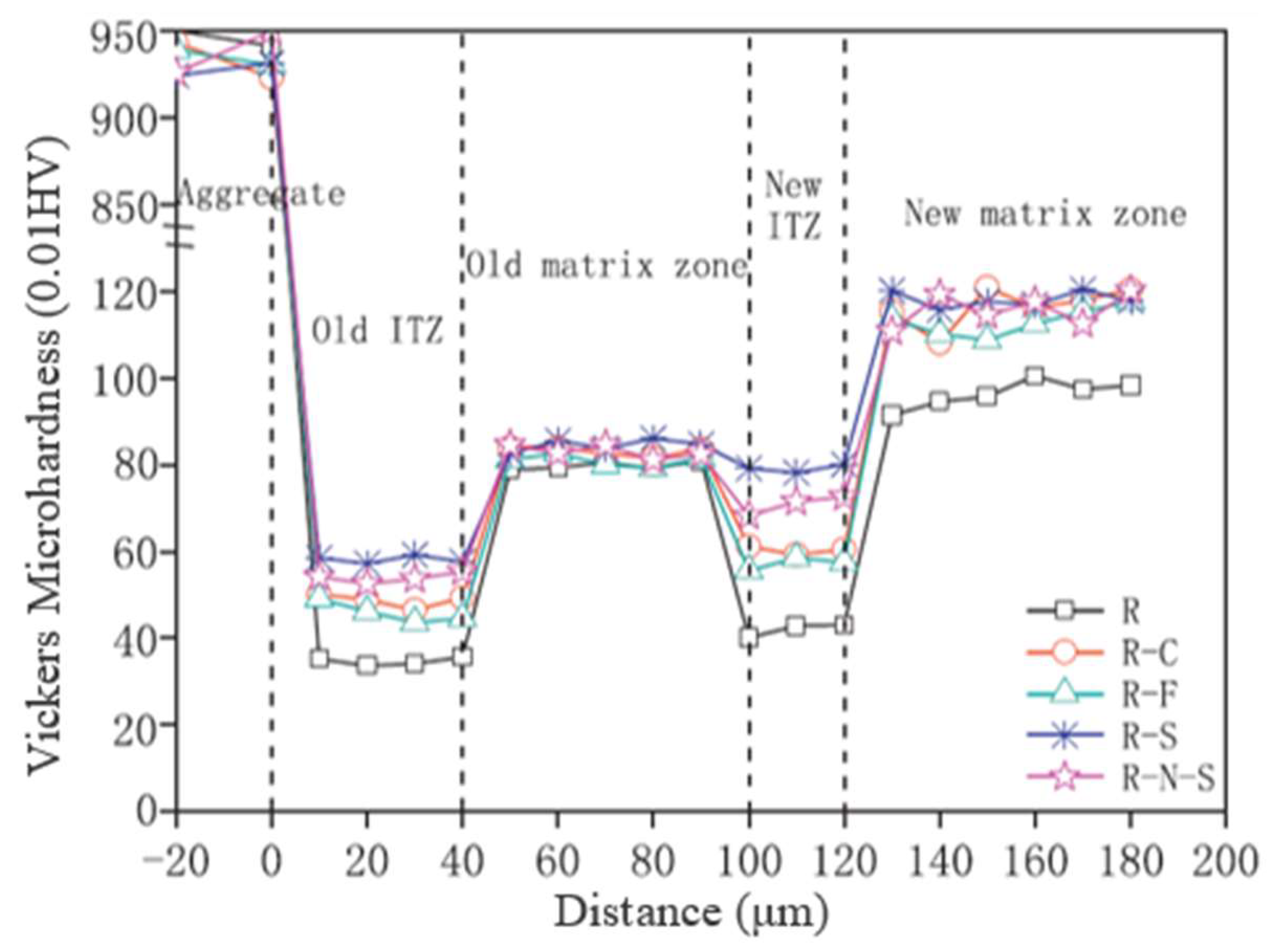

The microhardness of different samples was also investigated, including a reference sample (R), RCA after carbonation treatment (R-C), RCA treated by fly ash (R-F), silica fume (R-S), and nano-SiO

2 slurries (R-N-S). The microhardness results shown in

Figure 5 indicate five different regions: aggregate, old ITZ, old matrix, new ITZ, and new matrix. The reference sample showed the lowest microhardness values compared to the ones treated with pozzolana slurry and CO

2. Overall, the findings of the research indicated that RCA treatment strengthened and resulted in denser new and old ITZs, leading to improved mechanical properties and durability.

Xuan et al. [

37] conducted another study in which the authors compared and evaluated the performance of RCA extracted from a designed concrete (NRCAs) and from an old type of RCA (ORCA) obtained from demolished old buildings. The original NCRA mix proportion included 460 kg/m

3 cement, 205 kg/m

3 water, w/c ratio equal to 0.45, 430 kg/m

3 of 5–10 mm natural aggregate, 530 kg/m

3 of 10–20 mm natural aggregate, 700 kg/m

3 of sand, and 3.47 kg/m

3 of superplasticizer. The NRCA concrete was crushed at a construction waste recycling plant after a six-month external curing period. Before carbonation treatment, the recycled samples was preconditioning in a drying chamber at 25 ± 3 °C and 50 ± 5% relative humidity to remove excess moisture content. This pretreatment procedure controls the optimal moisture of samples in the range 40–70%, hence accelerating the carbonation process. The carbonation treatment of aggregates was carried out in a chamber for 24 h with a carbon dioxide concentration of approximately 100% at a pressure of 0.1 and 5 bar. In the study, the w/c ratio for the concrete with RCA including NRCA and ORCA was equal to 0.55, while the cement content for the mix proportion was 325 kg/m

3. The dosage of the superplasticizer was increased with the increment of RCA to maintain the slump value from 150 to 200 mm.

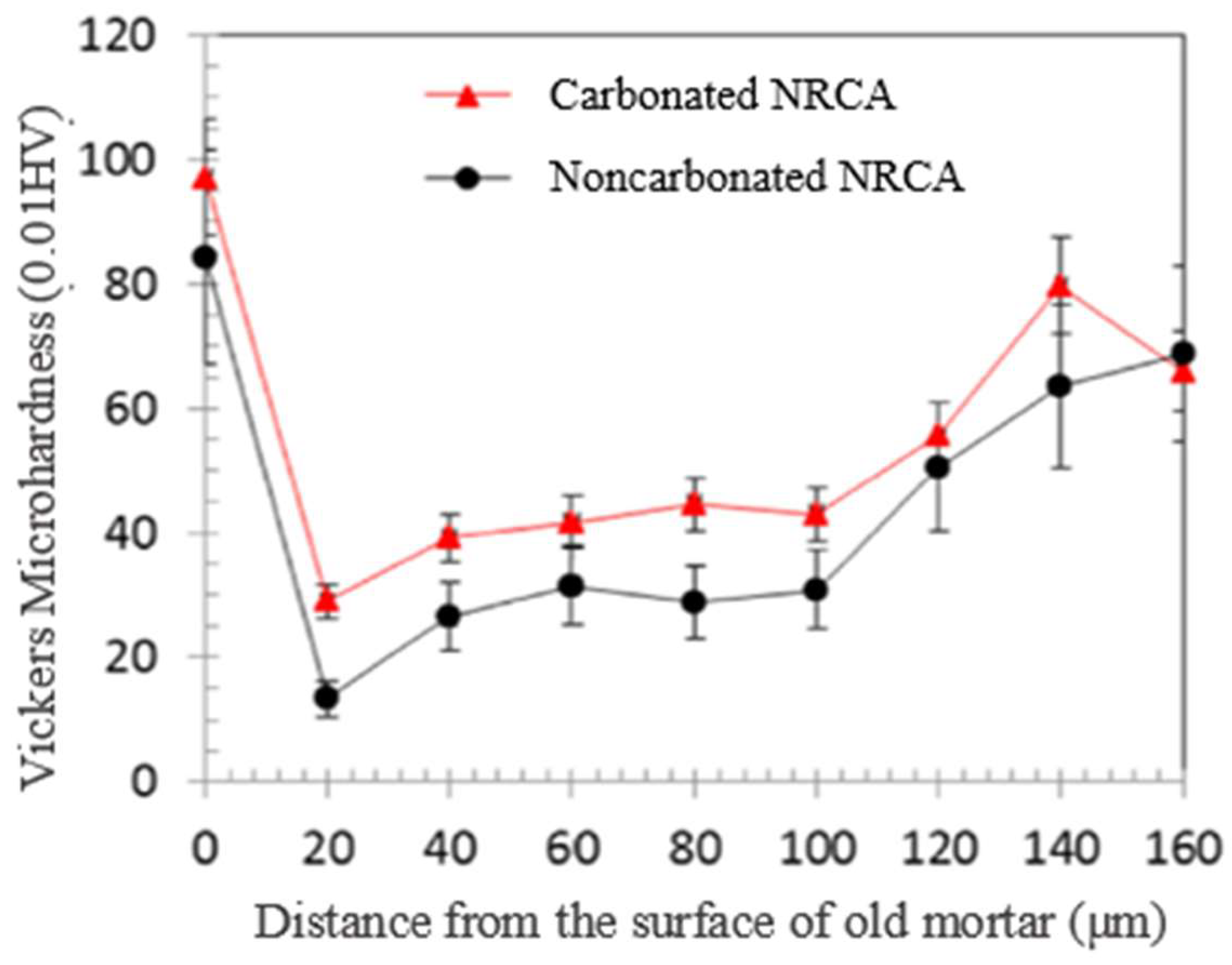

The carbonation results for the sample with NRCA, carried out at 5 bar pressure, showed a slight increase in density, crushing value, and CO

2 uptake compared to 0.1 bar. WA percentage decreased by 1% and 1.1% at 0.1 and 5 bar, respectively. Thereby, the crushing value of the RA changed from 27.8% to 21.9% at 0.1 bar pressure and to 20.6% at 5 bar. However, the carbonated ORCA demonstrated less improvement on the properties. The microhardness results in

Figure 6 showed that the microhardness of carbonized NRCA was equal to 97 ± 9 and higher than that of noncarbonated NRCA (87 ± 17). As a result of the lower WA, the microhardness of new ITZ in the carbonated NRCAs was higher than that of the uncarbonated sample. Hence, the physical, as well as the mechanical properties of the concrete sample with treated NRCAs, were improved. Overall, carbonation treatment with different pressure implementation had a lesser impact on the enhancement of RCA when subjected to a longer duration of treatment (i.e., 24 h), but generally, carbonated NRCAs demonstrated higher microhardness of the new ITZ than the one around the noncarbonated sample.

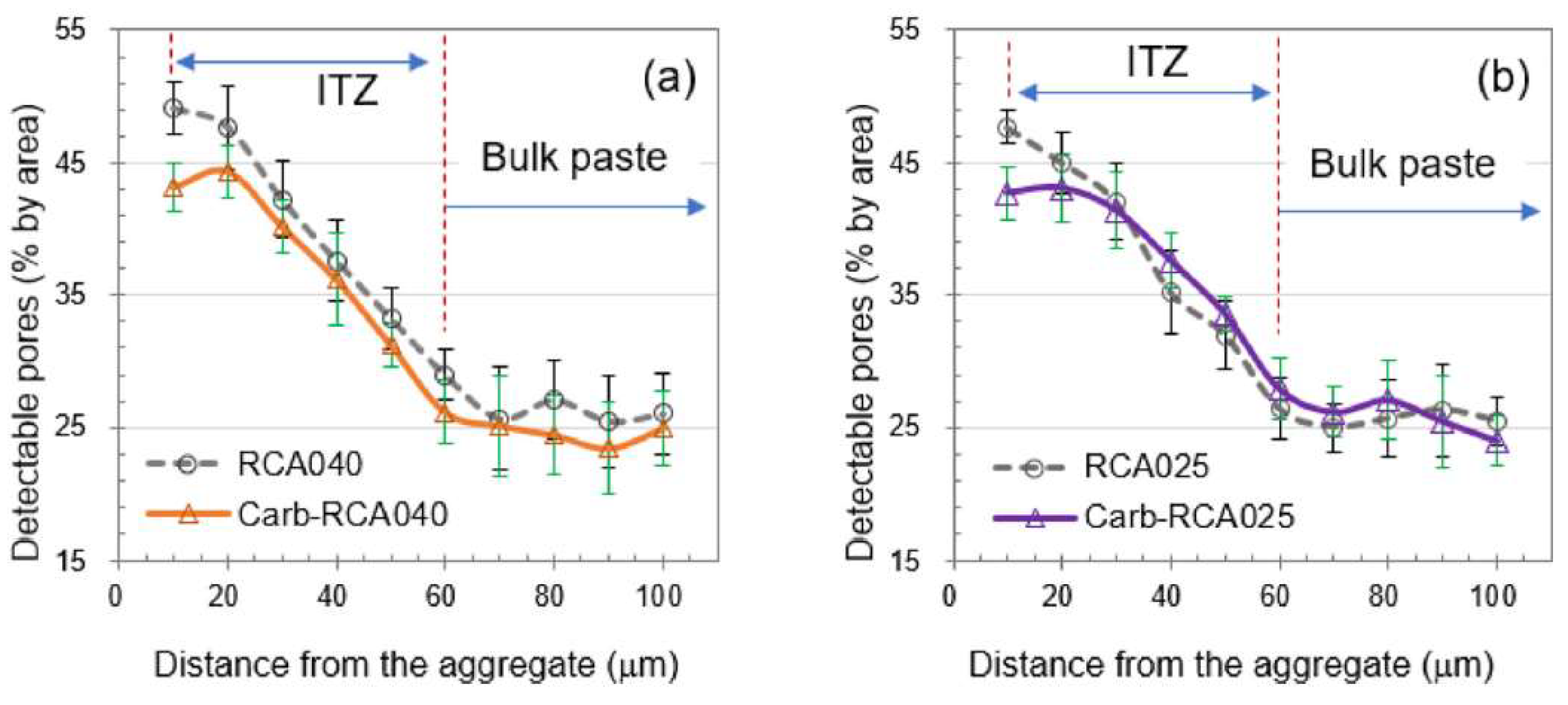

The effect of carbonation treatment on new ITZ of RCA was also investigated in detail by Zhan et al. [

38]. For this purpose, the authors used samples with new cement mortar against the carbonated hydrated cement paste (HCP). To prepare different types of RCA, the w/c ratios 0.25 and 0.40 for HCP were used. Cubic samples of HCP were placed into a CO

2 curing chamber under internal pressure of 1 bar with no temperature regulation but a relative humidity maintained at about 54 ± 5%. Afterward, a prepared new cement mortar having a design strength of 50 MPa was used to fill the space between RCA and the interior wall of the mold with the help of mechanical vibration to ensure complete filling. Mostly, the formation of ITZ is caused by the wall effect and an aqueous film that forms around the aggregate during the fresh state. Consequently, this leads to a less efficient filling of the space with hydration products near the aggregate, and hence there is a higher chance in developing porosity in this area. Therefore, in this research, the authors focused on the porosity profiles within the ITZ.

Figure 7 demonstrates the results of the porosity profile of ITZ against the distance from the aggregate surface. The average detectable pore contents were found to be approximately 25% in the bulk pastes. For RCA at nearly 10 μm, the average porosity was up to 49.1% in RCA040, while in RCA025 it was around 47.3%. When comparing the porosity for the ITZs of carbonated RCA and noncarbonated RCA, it was found that both values are similar, except that the porosity of treated RCA at the innermost 10 μm was slightly lower compared to the untreated sample. This phenomenon indicates that RCA carbonation seems unable to enhance the microstructure properties in terms of porosity.

Yue et al. [

39] analyzed the effect of carbonation treatment by using Vickers hardness values for the ITZ to measure variations in the width and microhardness of old slurry–new slurry (LJ–XJ). During the experiment, the authors used cement with 50.7 MPa compressive strength, a w/c ratio of 0.35, and cylindrical samples 20 mm in depth.

In order to analyze the sample and easily identify the regions, the beat method (matrix point) was used. To conduct the experiment, nine regions were chosen with a 4 × 5 lattice. To avoid the discrepancy in the microhardness of the ITZ and the mortar zone caused by the surface roughness, the unhydrated cement clinker, and the distribution of fine aggregates, researchers used a box diagram. With its help, the outliers in the RBI data can be eliminated, thus allowing for standard hardness identification of the mortar zone.

Figure 8 demonstrates results from the microhardness test of the LG–XJ sample. It can be observed that the microhardness of ITZ increased while the width was reduced after 28 days. Before carbonation, the microhardness of ITZ was around 125–171 MPa and the width was equal to 70–80 μm. After carbonation, however, microhardness was increased to 144–182 MPa, and width was decreased by 20 μm. It can be said that RCA without carbonation has a looser ITZ and, additionally, its concrete has a greater number of pores and cracks [

40]. As a result of carbonation treatment, it can be concluded that the reaction enhances the production of CaCO

3 and thus improves the microstructure of ITZ and decreases its porosity [

40].

To summarize, during the carbonation procedure, the reaction products not only densified the surfaces of RA, but also penetrated into RCA and improved the ITZ. Consequently, RCA itself becomes stronger by having higher microhardness and enhanced properties, which suggests that the carbonation treatment improves the properties of RCA. Carbonation treatment is an environmentally friendly method that can produce a large amount of CaCO3 and enhances the ITZ region.

3.2. Incorporation of Mineral Admixtures

The incorporation of mineral admixtures is one of the alternative methods to improve ITZ of RCA. The enhancement proceeds through the pozzolanic reaction that forms new C–S–H products and densifies ITZ by filling voids [

3]. According to Katz [

33], admixtures work as microfillers in the ITZ between the aggregate surface and the matrix. In this section, the role of mineral admixtures in improving the performance of ITZ is discussed.

One of the mineral admixtures that can be used to enhance the performance of ITZ is silica fume. It reacts with calcium hydroxide and forms a denser layer that covers the surface of the aggregate and strengthens ITZ. In a study conducted by Katz [

33], RCAs were produced from three types of concrete with w/c ratio of 0.77, 0.53, and 0.35, which represented three strength levels: low, medium, and high, respectively. These samples were then crushed to obtain RCA particles. In this experiment, the raw silica fume was used with a superplasticizer to treat RCA samples, where the superplasticizer took the role of a regulation tool to disperse 1 kg of silica fume in 10 L of water. Test results showed that after presoaking for 24 h in a solution and oven-drying, the weight of RCA increased by 0.5–0.8%. The saturated silica fume considerably decreased the number of loose crumbs on the RCA and made it denser, as revealed from the obtained SEM image (refer to Figures 2 and 4 in Reference [

33]).

The incorporation of silica fume into RCA helps to enter silica fume particles in loose layers of RCA and into the cracks. Owing to the filler effect, this layer enhances the ITZ during the concrete hardening process. Additionally, the improvement of the weakened RCA region is due to a pozzolanic reaction between silica fume and portlandite. This improved RCA region is further distributed from the NA and the old cement paste to the new cement zone. Impregnation of silica fume particles provides a stronger impact at an early age in comparison to slowly developing pozzolanic reactions. However, the products of the pozzolanic reaction, which were formed inside the aggregate, to some extent, strengthened the new ITZ between RCA and the new cement matrix, and improved the properties of the old paste. The covered layer decreased the WA capacity and increased the density of the sample by penetration of C–S–H into the new ITZ, making it denser.

Shi et al. [

36] used silica fume (SF) slurry, fly ash (FA) slurry, and nano-SiO

2 (NSi) slurry with a water-to-solid ratio of 10:1, 10:1, and 20:1, respectively, to enhance the ITZ of RCA. Ultrasonication was implemented for mixing the slurries to uniformly disperse the particles. RCA was derived from concrete specimens having compressive strength equal to 30 MPa and a particle size less than 4.75 mm. For treatment, RCA was dried for 48 h at 60 °C and then combined with slurry for 0.5 h and soaked for 1 h. After the treatment procedure, all samples were dried for 120 min at 100 °C for further analysis. The investigation of specimens showed that aggregate with the incorporation of fly ash had the largest amount of absorbed pozzolanic products. This was due to dynamic viscosity for admixtures, which was the lowest for fly ash and the highest for nano-SiO

2. After treatment, the microhardness and density of RCA increased. The increased magnitudes of microhardness in the old ITZ were 67.7%, 55.6%, 32.2% by silica fume, nano-SiO

2, and fly ash, respectively. Additionally, the strengthening effect was more evident in new ITZ, and a higher increase in microhardness percentage was identified. Therefore, the impregnation of RCA by silica fume was more beneficial because it showed a higher increase in mortar microhardness and densified ITZs.

The ITZ can also be improved by using different combinations of mineral admixtures. The enhancement in ITZ performance depends on the type and amount of mineral admixture used and their relative ratios with respect to each other. Wang et al. [

41] evaluated the performance of phosphorus slag (PHS), ground granulated blast-furnace slag (GGBS), and FA in various combinations, i.e., 20% PHS (P2), 10% PHS + 10% FA (P1F1), and 10% PHS + 10% GGBS (P1S1). For this experiment, RCA was obtained from the debris of a cement pavement from the town of Hangzhou with a particle size gradation from 0.005 to 0.02 m and WA equal to 3.63% by mass. The concrete cores obtained from the pavement had a compressive strength of 30 MPa. According to the test results, all the treated samples showed improved performance. The mixture of PHS and GGBS was found to be most effective. The improved performance of PHS and GGBS combination can be associated with their simultaneous reaction, which results in a more compacted aggregate with denser new ITZ. In comparison to PHS and FA, GGBS has a higher surface area and it reacts quickly to form pozzolanic products. For the results of the microstructure of RCA treated and untreated samples after 90 days of curing, please refer to Figures 4–7 in Reference [

41]. There are many cracks and voids inside the old ITZ (refer to Figure 4 in Reference [

41]); however, specimens made from P2, P1F1, and P1S1 showed significant improvement. In particular, the sample with the addition of GGBS showed the greatest effectiveness in enhancing the microstructure of the old ITZ (P1S1) compared to P2 and P1F1. It can be seen that the formation of C–S–H and the additional ettringite fills the empty space, thereby increasing compaction [

41].

Summarizing the abovementioned results obtained from the incorporation of single and multiple mineral admixtures, it can be stated that for better impregnation, superplasticizer and/or ultrasonication should be used. Among conventional mineral admixtures, silica fume showed the best performance in improving ITZ and making it denser. In the case of multiple admixtures, the mix of 10% PHS and GGBS was the most effective among different combinations of mineral admixtures (PHS, FA, and GGBS). Therefore implementation of mineral admixtures contributes to the filling of pores and voids and the formation of C–S–H gel, which leads to strengthening of the ITZ region. It should be noted that the incorporation of mineral admixtures has a lower effect in improving the microhardness of treated RCA than carbonation treatment.

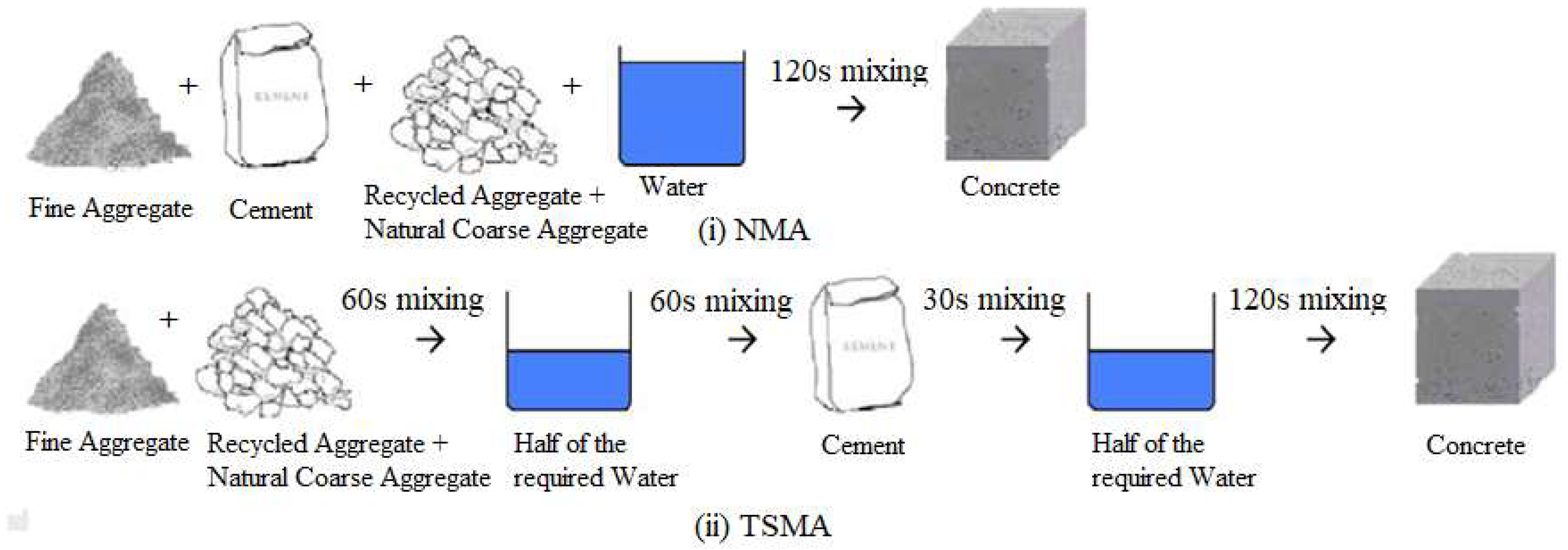

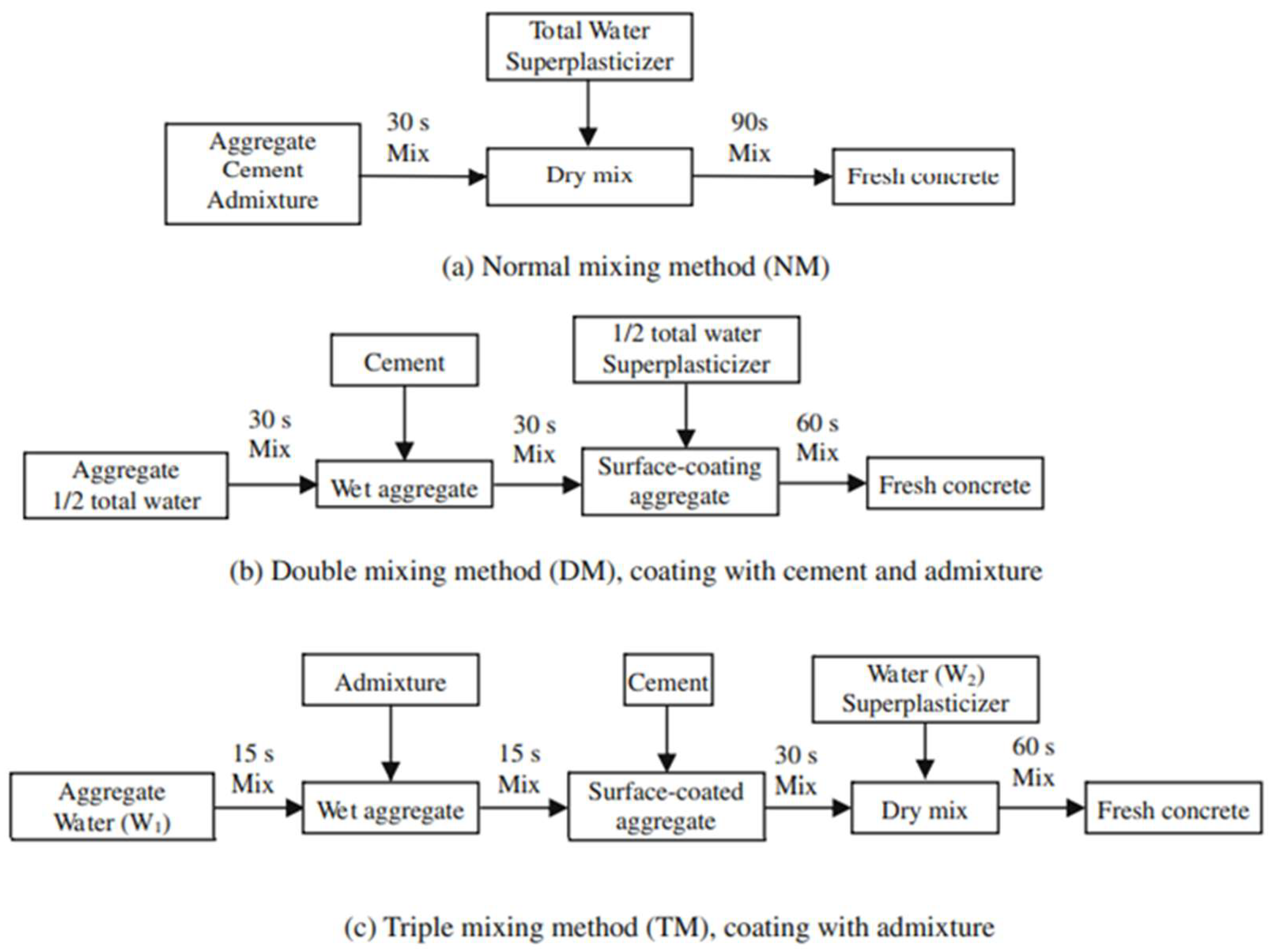

3.3. Mixing Approaches

One of the ways to improve the ITZ is to adopt different mixing strategies. Improving ITZ by adopting different mixing strategies means that the conventional mixing steps are modified to affect the RCA during or at the start of mixing to improve its performance through better microstructure. The mixing approaches are named according to the number of steps in relation to normal/conventional mixing. There are mainly three types of mixing for RCA concrete. These are the normal-mixing method (NM), double-mixing method (DM) or two-step mixing (TSMA), and triple-mixing method (TM).

Tam et al. [

42] investigated the effect of the two-step mixing approach on the microstructure of RCA. The difference between normal and two-step mixing was in the proportionally splinted required water and sequence of materials utilized during mixing.

Figure 9 represents the detailed steps of both mixing approaches used during the experiment.

In the two-stage mixing approach, half of the water is firstly used to form a thin-coated layer of cement slurry on the RCA [

42], which reduces the high absorption capacity of RCA and fills the minute pores and cracks in RCA. Thereafter, the remaining water was used to finish the mix procedure of the concrete.

Figure 10b shows a clear densification of the old ITZ after implementation of TSMA, whereas there are noticeable gaps in the microstructure RCA concrete made with normal mixing (NMA) (

Figure 10a). The experiment using the two-stage mixing approach was found to be an effective approach to enhance the mechanical properties by developing a stronger and denser old ITZ.

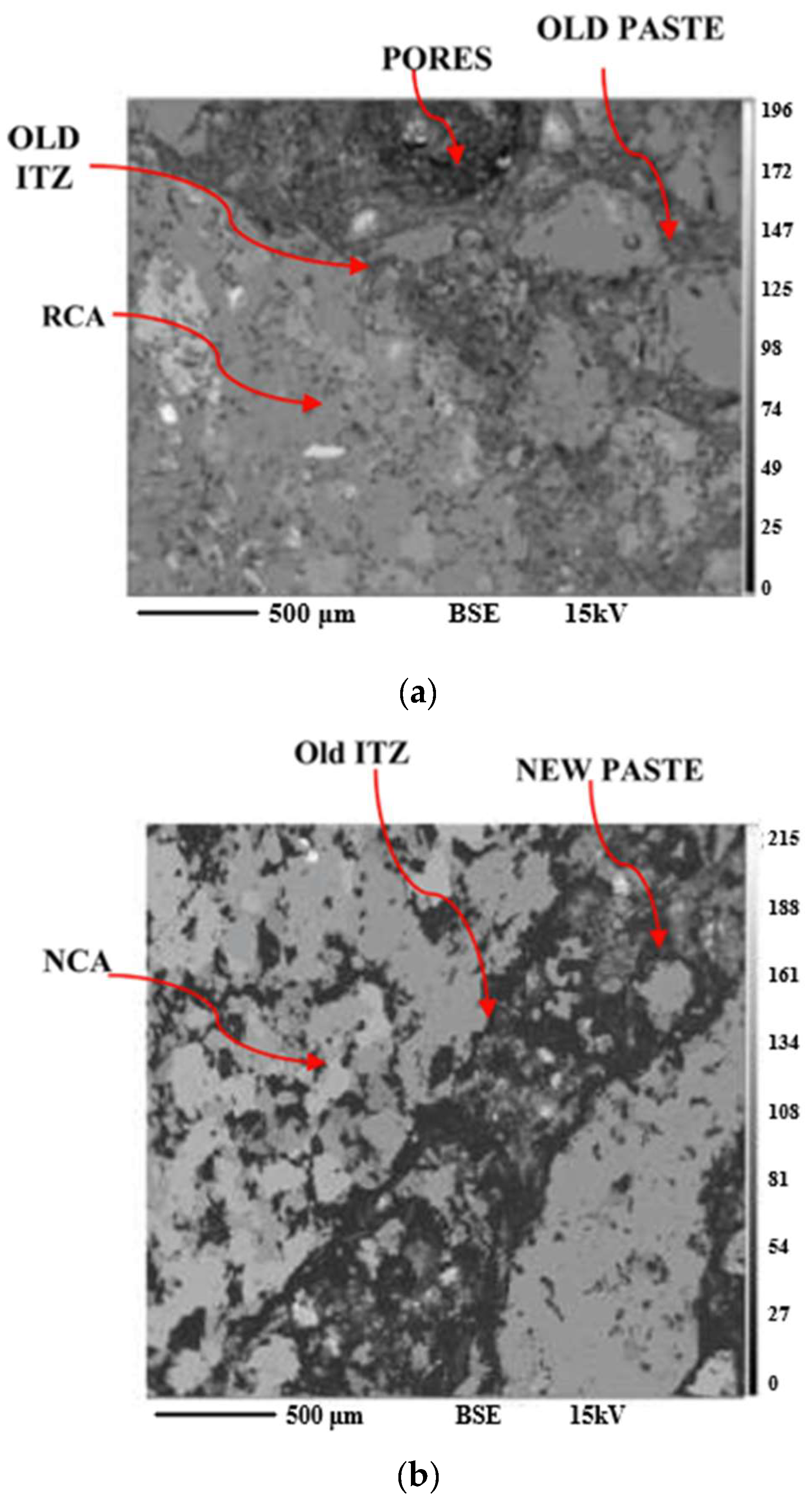

The SEM images of new ITZ obtained after TSMA and NMA presented in

Figure 11 shows that both new and old ITZ were improved. The SEM image of TSMA treatment concrete demonstrated an improvement in the new ITZ (

Figure 11a), which is stronger and denser compared to NMA. Thus, the authors pointed out that a two-step mixing approach can improve both new and old RCA ITZ.

Another two-step mixing approach developed by Kisku et al. [

43] followed the same concept of dividing normal mixing into two main stages. However, the authors added silica fume slurry during the first steps of mixing. The method of mixing design was based on equal mortar volume (EMV), which means that the required amount of mortar in two-stage mixing was identical to the amount in the normal mixing process. Details of the TSMA procedure is shown schematically in

Figure 12.

The RCA was derived from a 45-year-old demolished building located in Dhanbad, India. The water absorption, crushing value, and moisture content were equal to 2.54%, 34.8%, and 1.3, respectively. To demonstrate the influence of the treatment on the ITZ of the RCA, backscattered secondary electron (BSE) image analysis was used. All common characteristics such as voids, cracks, and unhydrated residue inherent in recycled concrete aggregates are visible in

Figure 13a. The slurry made of cement and SF added during the initial stage of mixing was able to penetrate into the RCA. Consequently, the ITZ was densified by the interaction of the clinker compound hydration and the deposition of hydrated products.

Figure 13b demonstrates denser texture of the old ITZ. Therefore, the EMV method of mix design and application of TSMA resulted in an improved and densified ITZ between NA and adhered mortar in RCA.

Kong et al. [

44] compared three mixing approaches, presented in

Figure 14. For the experimental investigation, natural river sand with water absorption of 1.6%, coarse RA derived from concrete having a compressive strength of 40 MPa, and FA with finely ground slag (S) as pozzolanic materials were used. The procedure for DM was adopted from the research conducted by Tam et al. [

42]. For TM, wet aggregates were first obtained by mixing coarse and fine aggregates with a certain amount of water for 15 s. Then, the admixture was added and mixed for 15 s so that the surfaces of the aggregate are coated with the admixture. During the next 30 s, cement was added to the mix. Lastly, a superplasticizer with the rest of the water was added, and mixing was continued for 60 s. Cubic shapes of 100 mm were prepared for experimental tests. By applying TM, coating the RCA with a thin layer of pozzolanic particles in the first mixing stage was achieved.

Figure 15 shows the admixtures not only filled cracks and pores of the RA with fine particles, but also formed new hydration products by reacting with accumulated CH at the curing age of 1 and 3 d, thus improving the properties of the ITZ. Additionally, the surface treatment could affect the density increase in the cement matrix around the RA.

Figure 16 presents the microstructure of the ITZ, which was improved by implementing finely ground slag. No CH crystals accumulated on the surface and additionally, a large amount of newly formed hydration products could be noted to be filling cracks and pores of the RCA. The enhancement of the microstructure of the ITZ could be noticed by using TM. Therefore, the research finding revealed that the compressive strength of the RCA increased significantly by using TM in comparison to DM. Additionally, the SEM images demonstrated the formation of new hydration products and reduction in CH crystal accumulation, which further improved the strength and durability of the RAC.

Similarly, the authors identified the method that enhanced the compressive strength of the samples. It is known that the pores and cracks inside the ITZ of RA significantly affect the ultimate strength of RCA. The high water content in the new ITZ of RCA is caused by high WA of these minute pores and cracks. Large crystals of CH accumulate in the pores of RA and on the surface of the old concrete, which reduces the compressive strength of the RCA compared to NAC, as shown in

Figure 17. By implementing DM on RCA, the strength was found to increase in comparison to NM. The compressive strength of the samples rose due to the application of TM at various curing ages.

Overall, two improvement methods (DM and TM), enhanced ITZ by filling pores and microcracks. Based on different experiments, it can be said that mixing approaches help to improve the mechanical properties and also enable RCA to be applied on a wider scale. However, it would be better to use TM because it demonstrated higher effectiveness in improving the RCA performance compared to DM.

Table 5 summarizes the details of improving old and new ITZ through carbonation, incorporating mineral admixtures, and using different mixing approaches.