Requirements Analysis for Development of Off-Site Construction Project Management System: Focusing on Precast Concrete Construction

Abstract

1. Introduction

1.1. Background and Objectives of Research

1.2. Scope and Method of Research

2. Literature Review

2.1. OSC Project Management

2.2. OSC Project Management System

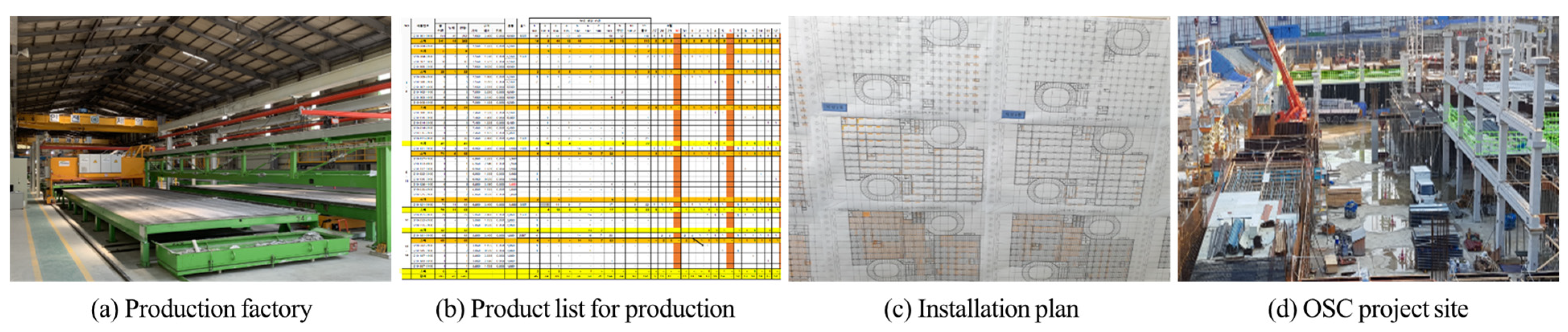

3. Analysis on Managerial Characteristics in OSC Projects

3.1. PC Construction Process Analysis

3.2. Managerial Characteristics of OSC Projects

3.2.1. Production Place and Time

3.2.2. Production Process

3.2.3. Production Method of Construction

3.2.4. Production Method

3.2.5. Production Entity and Facilities

3.2.6. Production Environment

4. Derivation of Requirements for Development of OSC Management System

4.1. System Development Requirements

4.1.1. Production Method Aspect

4.1.2. Aspect in Connection to Factory Production-Transport-Site Installation

4.1.3. Supply Chain Aspect

4.1.4. Equipment Plan and Management Aspect

4.1.5. Information Integration Aspect

4.2. Requirement Specification

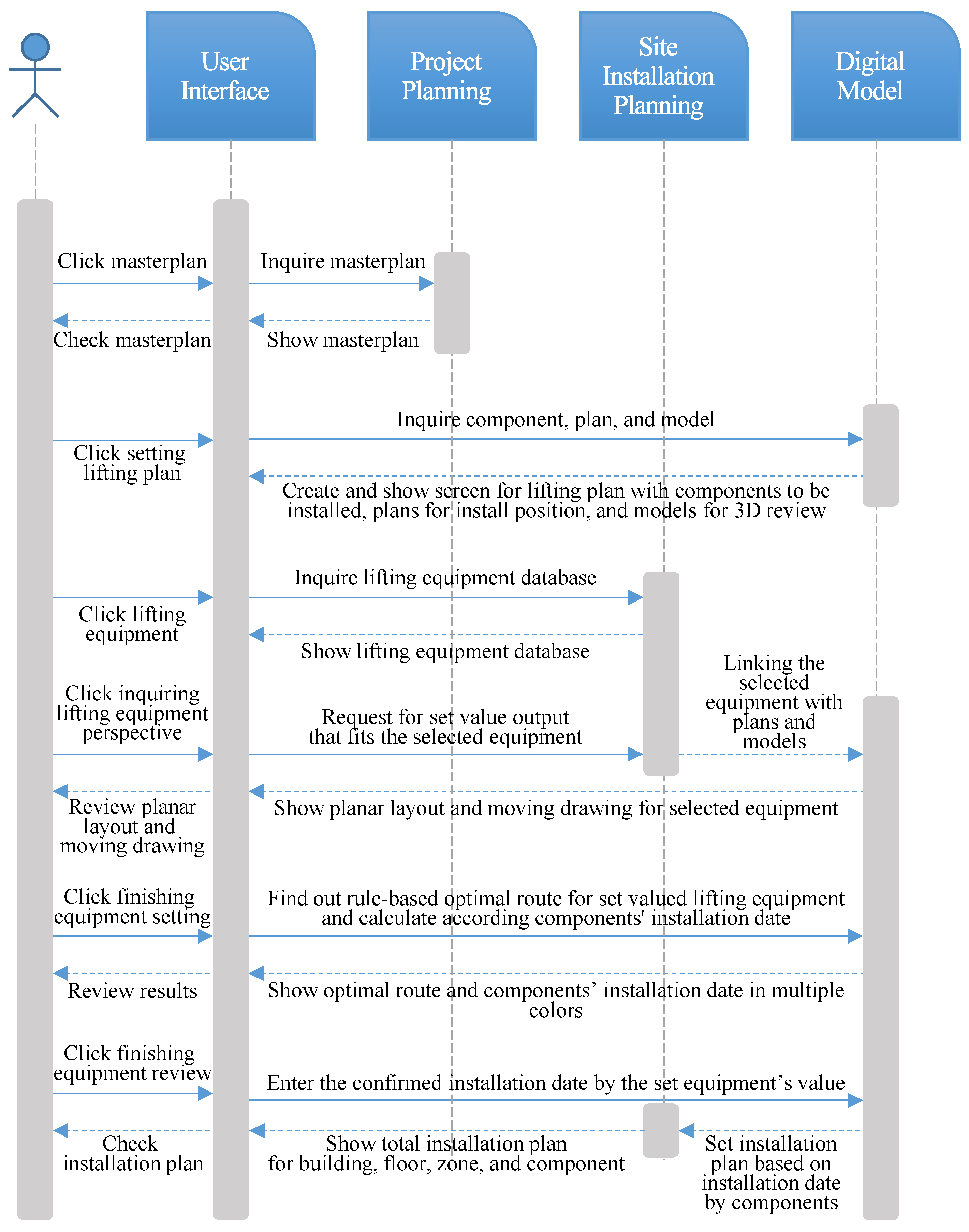

4.2.1. Establishment of Installation Plan

- (1)

- Inquire Masterplan: When a user selects the “Master Plan” menu to call the master plan, which is the basis for the installation plan, the result of the master plan is requested through the project planning module, which is displayed through the user interface.

- (2)

- Inquire Component, Plan, and Model: When a user selects the “Setting Lifting Plan” menu, the drawing to identify the installation location of lifting equipment, and the digital model of the building to review the lifting equipment are used from the database of the management system, displaying a screen showing the components to be installed and lifting equipment plan on the user interface.

- (3)

- Inquire Lifting Equipment Database: When a user selects the “Select Lifting Equipment” menu, the information on lifting equipment stored in the database is requested and outputted onto the user interface. When the user further selects one of the displayed information items on lifting equipment, and then the “Inquire and Select Specification of Lifting Equipment” menu, the specification data for the target equipment are presented, which are linked with the drawing and digital model called at the previous stage.

- (4)

- Find Out Rule-based Optimal Route: When a user selects the “Completion of Lifting Equipment Setting” menu, the lifting equipment plan, and the corresponding route and installation schedule of the lifting equipment are automatically established, considering the type, number of units, installation location, and duration of the equipment selected in the previous stage.

- (5)

- Enter the Confirmed Installation Date: When a user selects the “Completion of Lifting Equipment Review” menu, the installation plan for each component according to the lifting equipment plan set in the previous stage is updated to the digital model and site installation plan, and further displayed on the user interface. The user can select the component from the screen to adjust the schedule, or, conversely, request the date first to set the component. In this manner, this interactive function can be utilized to retrieve or modify the scheduled date of installation for each component.

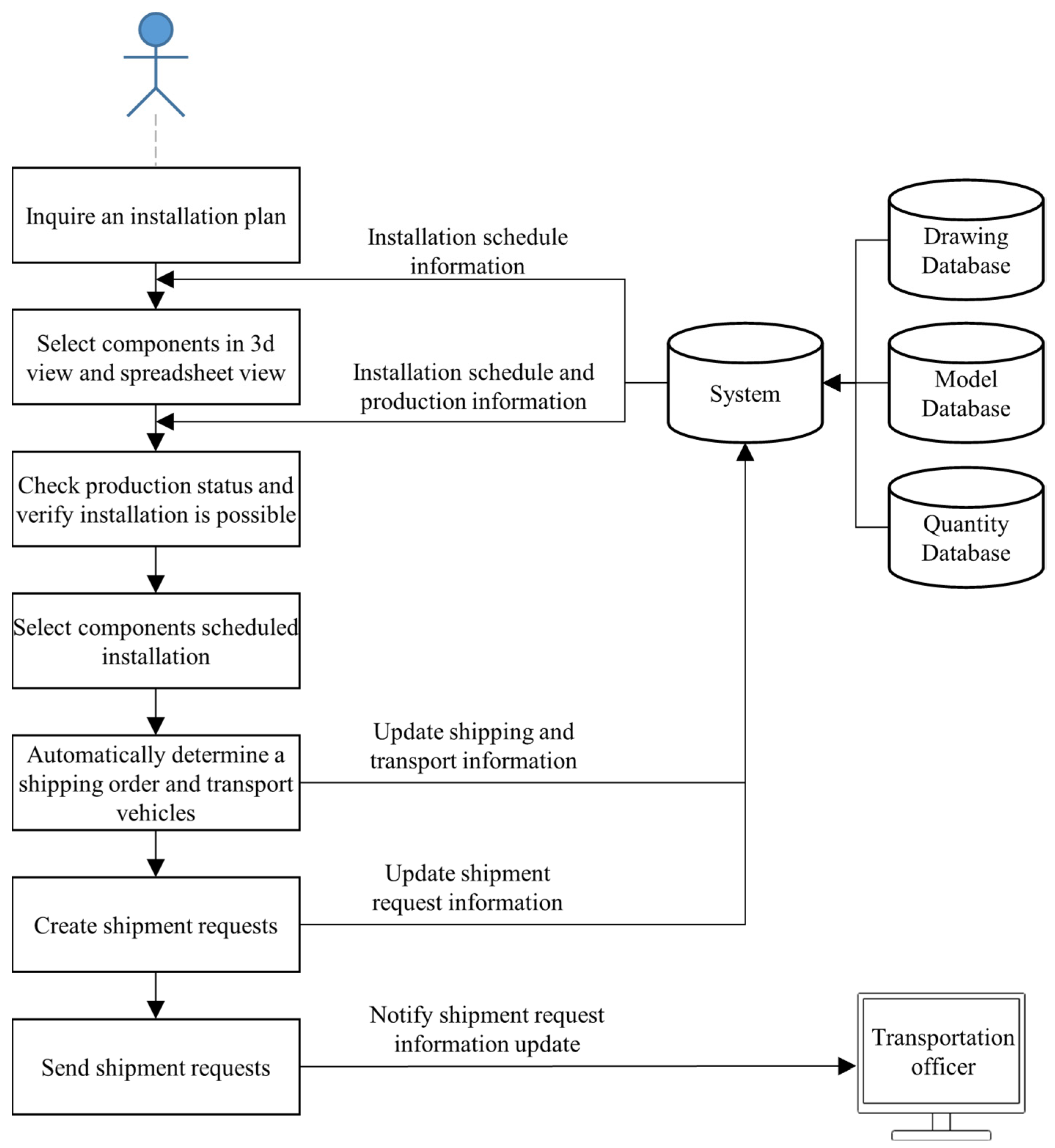

4.2.2. Request for Transport

- (1)

- Request an Installation Plan: When a user in the construction site selects the “Installation Plan” menu, the existing installation plan is inquired in the database of the system, which is displayed on the user interface in the format of 3D model or spreadsheet.

- (2)

- Select Components in 3D View and Spreadsheet View: The user selects the desired component from the inquiry results on the installation plan in a 3D model or spreadsheet format.

- (3)

- Check Production Status and Verify Installation is Possible: The user checks when the scheduled installation date of the selected components, and whether their production has been completed to determine when their installation is available.

- (4)

- Select Components Scheduled Installation: The user monitors the scheduled installation date of the selected components, and whether their production has been completed to finalize the selection of the components to be installed.

- (5)

- Automatically Determine a Shipping Order and Transport Vehicles: When the user selects “Shipping Request” menu, the management system automatically determines the sequence of receipts regarding the selected components and assigns the transport vehicle by considering the characteristics of the transport vehicle, as well as the size of the components. Furthermore, the system determines the sequence of transport of the vehicles and stores it into itself.

- (6)

- Create Shipment Requests: The management system automatically generates a transport request depending on the previously determined component, and the transport sequence of the vehicles, and stores the information in itself.

- (7)

- Send Shipment Requests: When the user selects the “Send Shipment Requests” menu, a notification for confirmation of shipment requests is sent to the transport manager in the factory.

4.3. Requirement Validation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction from Projects to Products; McKinsey & Company: Sydney, Australia, 2019. [Google Scholar]

- Ribeirinho, M.J.; Mischke, J.; Strube, G.; Sjödin, E.; Blanco, J.L.; Palter, R.; Biörck, J.; Rockhill, D.; Andersson, T. The Next Normal in Construction; McKinsey and Company: Sydney, Australia, 2020. [Google Scholar]

- Kim, S.; Lee, M.; Yu, I.; Son, J. Key initiatives for digital transformation, green new deal and recovery after COVID-19 within the construction industry in Korea. Sustainability 2022, 14, 8726. [Google Scholar] [CrossRef]

- Barbosa, F.; Woetzel, J.; Mischke, J. Reinventing Construction: A Route of Higher Productivity; McKinsey Global Institute: Washington, DC, USA, 2017. [Google Scholar]

- Jeong, W.; Chang, S.; Son, J.; Yi, J.-S. BIM-integrated construction operation simulation for just-in-time production management. Sustainability 2016, 8, 1106. [Google Scholar] [CrossRef]

- Ottinger, E.; Minglani, H.; Gibson, M. Technological Advancements Disrupting the Global Construction Industry; Ernst & Young LLP: London, UK, 2020. [Google Scholar]

- Southern, J. Smart Construction: How Offsite Manufacturing can Transform Our Industry; Technical Report CRT059791; KPMG: London, UK, 2016. [Google Scholar]

- Bernstein, H.M.; Gudgel, J.E.; Laquidara-Carr, D. Prefabrication and Modularization: Ncreasing Productivity in the Construction Industry; McGraw Hill Construction: New York, NY, USA, 2011. [Google Scholar]

- Oakley, M. The Value of Off-Site Construction to UK Productivity and Growth; WPI Economics: London, UK, 2017. [Google Scholar]

- Krug, D. Offsite Construction: Sustainability Characteristics; Buildoffsite: London, UK, 2013. [Google Scholar]

- Kim, S.; Hwang, S.; Son, J. Safety Management Guidelines for Precast Concrete Production Plants Using Importance-Performance Analysis. J. Constr. Eng. Manag. 2022, 148, 04022038. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Improved Precast Production–Scheduling Model Considering the Whole Supply Chain. J. Comput. Civ. Eng. 2017, 31, 04017013. [Google Scholar] [CrossRef]

- Jang, Y.; Lee, J.-M.; Son, J. Development and application of an integrated management system for off-site construction projects. Buildings 2022, 12, 1063. [Google Scholar] [CrossRef]

- Chen, K.; Xu, G.; Xue, F.; Zhong, R.Y.; Liu, D.; Lu, W. A Physical Internet-enabled Building Information Modelling System for prefabricated construction. Int. J. Comput. Integr. Manuf. 2017, 31, 349–361. [Google Scholar] [CrossRef]

- Viana, D.D. Integrated production planning and control model for engineer-to-order prefabricated building systems. Ph.D. Thesis, Federal University of Rio Grande do Sul, Rio Grande do Sul, Brazil, 2015. [Google Scholar]

- Dallasega, P.; Rauch, E.; Frosolini, M. A lean approach for real-time planning and monitoring in engineer-to-order construction projects. Buildings 2018, 8, 38. [Google Scholar] [CrossRef]

- Royce, W.W. Managing the development of large software systems: Concepts and techniques. In Proceedings of the 9th international conference on Software Engineering, Monterey, CA, USA, 30 March–2 April 1987; pp. 328–338. [Google Scholar]

- Beck, K.; Beedle, M.; Van Bennekum, A.; Cockburn, A.; Cunningham, W.; Fowler, M.; Grenning, J.; Highsmith, J.; Hunt, A.; Jeffries, R. Manifesto for Agile Software Development. Available online: https://agilemanifesto.org (accessed on 1 August 2022).

- Sommerville, I. Software Engineering, 9/E; Pearson Education India: Noida, India, 2011. [Google Scholar]

- Chen, W.; Zhao, Y.; Yu, Y.; Chen, K.; Arashpour, M. Collaborative Scheduling of On-Site and Off-Site Operations in Prefabrication. Sustainability 2020, 12, 9266. [Google Scholar] [CrossRef]

- Salama, T. Optimized Planning and Scheduling for Modular and Offsite Construction. Ph.D. Thesis, Concordia University, Montréal, QC, Canada, 2018. [Google Scholar]

- Alvanchi, A.; Azimi, R.; Lee, S.; AbouRizk, S.M.; Zubick, P. Off-site construction planning using discrete event simulation. J. Archit. Eng. 2012, 18, 114–122. [Google Scholar] [CrossRef]

- Zhang, Y.; Flood, I. Planning and scheduling prefabrication construction projects using dependency structure matrix (DSM). In Proceedings of the International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; pp. 1457–1464. [Google Scholar]

- Leu, S.-S.; Hwang, S.-T. GA-based resource-constrained flow-shop scheduling model for mixed precast production. Autom. Constr. 2002, 11, 439–452. [Google Scholar] [CrossRef]

- Zhai, X.; Tiong, R.L.; Bjornsson, H.C.; Chua, D.K. A simulation-GA based model for production planning in precast plant. In Proceedings of the 2006 Winter Simulation Conference, Monterey, CA, USA, 3–6 December 2006; pp. 1796–1803. [Google Scholar]

- Ko, C.-H.; Wang, S.-F. GA-based decision support systems for precast production planning. Autom. Constr. 2010, 19, 907–916. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Abbasi, B.; Lee, E.W.M.; Minas, J. Off-site construction optimization: Sequencing multiple job classes with time constraints. Autom. Constr. 2016, 71, 262–270. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Fraework for modeling operational uncertainty to optimize offsite production scheduling of precast components. Autom. Constr. 2018, 86, 69–80. [Google Scholar] [CrossRef]

- Kim, T.; Kim, Y.-W.; Cho, H. Dynamic production scheduling model under due date uncertainty in precast concrete construction. J. Clean. Prod. 2020, 257, 120527. [Google Scholar] [CrossRef]

- Du, J.; Dong, P.; Sugumaran, V. Dynamic production scheduling for prefabricated components considering the demand fluctuation. Intell. Autom. Soft Comput. 2020, 26, 715–723. [Google Scholar] [CrossRef]

- Yazdani, M.; Kabirifar, K.; Fathollahi-Fard, A.M.; Mojtahedi, M. Production scheduling of off-site prefabricated construction components considering sequence dependent due dates. Environ. Sci. Pollut. Res. 2021, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Wu, L.J.; Cao, Y.Z. Multiple precast component orders acceptance and scheduling. Math. Probl. Eng. 2020, 2020, 3849561. [Google Scholar] [CrossRef]

- Liu, J.; Lu, M. Robust Dual-Level Optimization Framework for Resource-Constrained Multiproject Scheduling for a Prefabrication Facility in Construction. J. Comput. Civ. Eng. 2019, 33, 04018067. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, Z.; Liu, S.; Wu, S. Optimized rescheduling of multiple production lines for flowshop production of reinforced precast concrete components. Autom. Constr. 2018, 95, 86–97. [Google Scholar] [CrossRef]

- Nasirian, A.; Arashpour, M.; Abbasi, B.; Akbarnezhad, A. Optimal work assignment to multiskilled resources in prefabricated construction. J. Constr. Eng. Manag. 2019, 145, 04019011. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J.; Ma, X.; Xiong, W. Precast supply chain management in off-site construction: A critical literature review. J. Clean. Prod. 2019, 232, 1204–1217. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Arashpour, M.; Bai, Y.; Aranda-mena, G.; Bab-Hadiashar, A.; Hosseini, R.; Kalutara, P. Optimizing decisions in advanced manufacturing of prefabricated products: Theorizing supply chain configurations in off-site construction. Autom. Constr. 2017, 84, 146–153. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, L. Dynamic transportation planning for prefabricated component supply chain. Eng. Constr. Archit. Manag. 2020, 27, 2553–2576. [Google Scholar] [CrossRef]

- Salari, S.A.-S.; Mahmoudi, H.; Aghsami, A.; Jolai, F.; Jolai, S.; Yazdani, M. Off-site construction three-echelon supply chain management with stochastic constraints: A modelling approach. Buildings 2022, 12, 119. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Huang, G.Q. Towards operational hedging for logistics uncertainty management in prefabrication construction. IFAC-PapersOnLine 2015, 48, 1128–1133. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, M.; Pan, W.; Zhang, Z. Sources of uncertainties in offsite logistics of modular construction for high-rise building projects. J. Manag. Eng. 2021, 37, 04021011. [Google Scholar] [CrossRef]

- Du, J.; Sugumaran, V. Ontology-based information integration and decision making in prefabricated construction component supply chain. In Proceedings of the Americas Conference on Information Systems, Boston, MA, USA, 10–12 August 2017; pp. 1–10. [Google Scholar]

- Xiong, W.; Yang, J.; Wang, Z.; Hu, H.; Xu, F.; Zhang, J. Improving supply chain communications for off-site construction using Process Specification Language. In Proceedings of the International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018; pp. 1–9. [Google Scholar]

- Du, J.; Jing, H.; Choo, K.-K.R.; Sugumaran, V.; Castro-Lacouture, D. An ontology and multi-agent based decision support framework for prefabricated component supply chain. Inf. Syst. Front. 2019, 22, 1467–1485. [Google Scholar] [CrossRef]

- Du, J.; Sugumaran, V.; Gao, B. RFID and multi-agent based architecture for information sharing in prefabricated component supply chain. IEEE Access 2017, 5, 4132–4139. [Google Scholar] [CrossRef]

- Zhang, W.; Kang, K.; Zhong, R.Y. A cost evaluation model for IoT-enabled prefabricated construction supply chain management. Ind. Manag. Data Syst. 2021, 121, 2738–2759. [Google Scholar] [CrossRef]

- Li, X.; Lu, W.; Xue, F.; Wu, L.; Zhao, R.; Lou, J.; Xu, J. Blockchain-enabled IoT-BIM platform for supply chain management in modular construction. J. Constr. Eng. Manag. 2022, 148, 04021195. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital twin for supply chain coordination in modular construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Blismas, N.; Maqsood, T. Autonomous production tracking for augmenting output in off-site construction. Autom. Constr. 2015, 53, 13–21. [Google Scholar] [CrossRef]

- Nam, S.; Lee, D.; Cho, B.; Kim, K. Integrated management software for factory production of modular buildings. Adv. Civ. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Altaf, M.S.; Bouferguene, A.; Liu, H.; Al-Hussein, M.; Yu, H. Integrated production planning and control system for a panelized home prefabrication facility using simulation and RFID. Autom. Constr. 2018, 85, 369–383. [Google Scholar] [CrossRef]

- Altaf, M.S.; Lei, Z.; Han, S.; Bouferguene, A.; Al-Hussein, M. Demand-dependent inventory management system for an offsite construction facility. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020; pp. 29–37. [Google Scholar]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An internet of things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Lee, G.; Kim, M.; Lee, C.; Koo, C.; Kim, T. Towards a transportation support system for off-site construction: Identifying key functions and diagramming functional blocks. Korean J. Constr. Eng. Manag. 2021, 22, 21–30. [Google Scholar] [CrossRef]

- Si, T.; Li, H.X.; Lei, Z.; Liu, H.; Han, S. A dynamic just-in-time component delivery framework for off-site construction. Adv. Civ. Eng. 2021, 2021, 9953732. [Google Scholar] [CrossRef]

- Liu, D.H.; Xin, L.; Chen, J.J.; Jin, R. Real-time optimization of precast concrete component transportation and storage. Adv. Civ. Eng. 2020, 2020, 5714910. [Google Scholar] [CrossRef]

- Niu, S.; Yang, Y.; Pan, W. Logistics planning and visualization of modular integrated construction projects based on BIM-GIS integration and vehicle routing algorithm. In Proceedings of the Modular and Offsite Construction (MOC) Summit, Banff, AB, Canada, 21–24 May 2019; pp. 579–586. [Google Scholar]

- Taghaddos, H.; Hermann, U.; AbouRizk, S.; Mohamed, Y. Simulation-based multiagent approach for scheduling modular construction. J. Comput. Civ. Eng. 2014, 28, 263–274. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.; Al-Hussein, M. Automation of quantity take-off for modular construction. In Proceedings of the Modular and Offsite Construction (MOC) Summit, Edmonton, AB, Canada, 19–21 May 2015; pp. 458–465. [Google Scholar]

- Hyun, H.; Park, M.; Lee, D.; Lee, J. Tower crane location optimization for heavy unit lifting in high-rise modular construction. Buildings 2021, 11, 121. [Google Scholar] [CrossRef]

- Han, S.H.; Hasan, S.; Bouferguène, A.; Al-Hussein, M.; Kosa, J. Utilization of 3D visualization of mobile crane operations for modular construction on-site assembly. J. Manag. Eng. 2015, 31, 04014080. [Google Scholar] [CrossRef]

- Taghaddos, H.; Hermann, U.; Abbasi, A. Automated crane planning and optimization for modular construction. Autom. Constr. 2018, 95, 219–232. [Google Scholar] [CrossRef]

- Ezzeddine, A.; de Soto, B.G. Connecting teams in modular construction projects using game engine technology. Autom. Constr. 2021, 132, 103887. [Google Scholar] [CrossRef]

- Son, J.; Han, S.H.; Rojas, E.M. Embeddedness and collaborative venture networks among Korean construction firms for overseas construction projects. J. Civ. Eng. Manag. 2015, 21, 478–491. [Google Scholar] [CrossRef]

- Wu, C.; Jiang, R.; Li, X. Integration of BIM and computer simulations in modular construction, A case study. In Proceedings of the Modular and Offsite Construction (MOC) Summit, Edmonton, AB, Canada, 29 September–1 October 2016. [Google Scholar]

- Son, J.; Rojas, E.M.; Shin, S.-W. Application of agent-based modeling and simulation to understanding complex management problems in CEM research. J. Civ. Eng. Manag. 2015, 21, 998–1013. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhong, R.Y.; Xue, F.; Xu, G.; Chen, K.; Huang, G.G.; Shen, G.Q. Integrating RFID and BIM technologies for mitigating risks and improving schedule performance of prefabricated house construction. J. Clean. Prod. 2017, 165, 1048–1062. [Google Scholar] [CrossRef]

- Jeong, W.; Son, J. An algorithm to translate building topology in building information modeling into object-oriented physical modeling-based building energy modeling. Energies 2016, 9, 50. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Peng, Y.; Xue, F.; Fang, J.; Zou, W.; Luo, H.; Thomas Ng, S.; Lu, W.; Shen, G.Q.P.; Huang, G.Q. Prefabricated construction enabled by the Internet-of-Things. Autom. Constr. 2017, 76, 59–70. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Mbachu, J. Development of intelligent prefabs using IoT technology to improve the performance of prefabricated construction projects. Sensors 2019, 19, 4131. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.Y.; Lu, W.S. Design for manufacture and assembly in construction: A review. Build. Res. Informat. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Ji, Y.; Li, K.; Liu, G.; Shrestha, A.; Jing, J. Comparing greenhouse gas emissions of precast in-situ and conventional construction methods. J. Clean. Prod. 2018, 173, 124–134. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Sandanayake, M.; Luo, W.; Zhang, G. Direct and indirect impact assessment in off-site construction—A case study in China. Sustain. Cities Soc. 2019, 48, 101520. [Google Scholar] [CrossRef]

- Rosson, M.B.; Carroll, J.M. Usability Engineering: Scenario-Based Development of Human-Computer Interaction; Morgan Kaufmann: Burlington, VT, USA, 2002. [Google Scholar]

- Rosson, M.B.; Carroll, J.M. Scenario based design. In Human-Computer Interaction; CRC Press: Boca Raton, FL, USA, 2009; pp. 145–162. [Google Scholar]

- Lim, J.; Cho, H.; Im, S.; Lee, Y.; Hyun, S. Ubiquitous computing application service development method using scenario-based development method. In Proceedings of the Conference of the Korean Society of Human Computer Interaction, Jeong-seon, Korea, 13–16 February 2006; pp. 188–196. [Google Scholar]

- Ruijer, E.; Grimmelikhuijsen, S.; Hogan, M.; Enzerink, S.; Ojo, A.; Meijer, A. Connecting societal issues, users and data. Scenario-based design of open data platforms. Gov. Inf. Q. 2017, 34, 470–480. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Asadi-Gangraj, E. Scenario-based design of a steel sustainable closed-loop supply chain network considering production technology. J. Clean. Prod. 2020, 277, 123298. [Google Scholar] [CrossRef]

- Li, X. A scenario-based development framework for autonomous driving. arXiv 2020, arXiv:2011.01439. [Google Scholar]

- Bäumler, I.; Kotzab, H. Scenario-based development of intelligent transportation systems for road freight transport in Germany. In Urban Freight Transportation Systems; Elsevier: Amsterdam, The Netherlands, 2020; pp. 183–202. [Google Scholar]

| Aspect | Requirements | System Users |

|---|---|---|

| Production Method |

|

|

| Connection to Factory Production-Transport-Site Installation |

|

|

| Supply Chain |

|

|

| Equipment Plan and Management |

|

|

| Information Integration |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, Y.; Son, J.; Hwang, S. Requirements Analysis for Development of Off-Site Construction Project Management System: Focusing on Precast Concrete Construction. Buildings 2022, 12, 1499. https://doi.org/10.3390/buildings12101499

Jang Y, Son J, Hwang S. Requirements Analysis for Development of Off-Site Construction Project Management System: Focusing on Precast Concrete Construction. Buildings. 2022; 12(10):1499. https://doi.org/10.3390/buildings12101499

Chicago/Turabian StyleJang, YeEun, JeongWook Son, and Sungjoo Hwang. 2022. "Requirements Analysis for Development of Off-Site Construction Project Management System: Focusing on Precast Concrete Construction" Buildings 12, no. 10: 1499. https://doi.org/10.3390/buildings12101499

APA StyleJang, Y., Son, J., & Hwang, S. (2022). Requirements Analysis for Development of Off-Site Construction Project Management System: Focusing on Precast Concrete Construction. Buildings, 12(10), 1499. https://doi.org/10.3390/buildings12101499