Influencing Factors of Human Errors in Metro Construction Based on Structural Equation Modeling (SEM)

Abstract

1. Introduction

2. Literature Review

3. Hypothesis

4. Methodology

4.1. Questionnaire Design

4.2. Sampling and Data Collection

5. Research Procedure and Results Analysis

5.1. Reliability and Validity Test

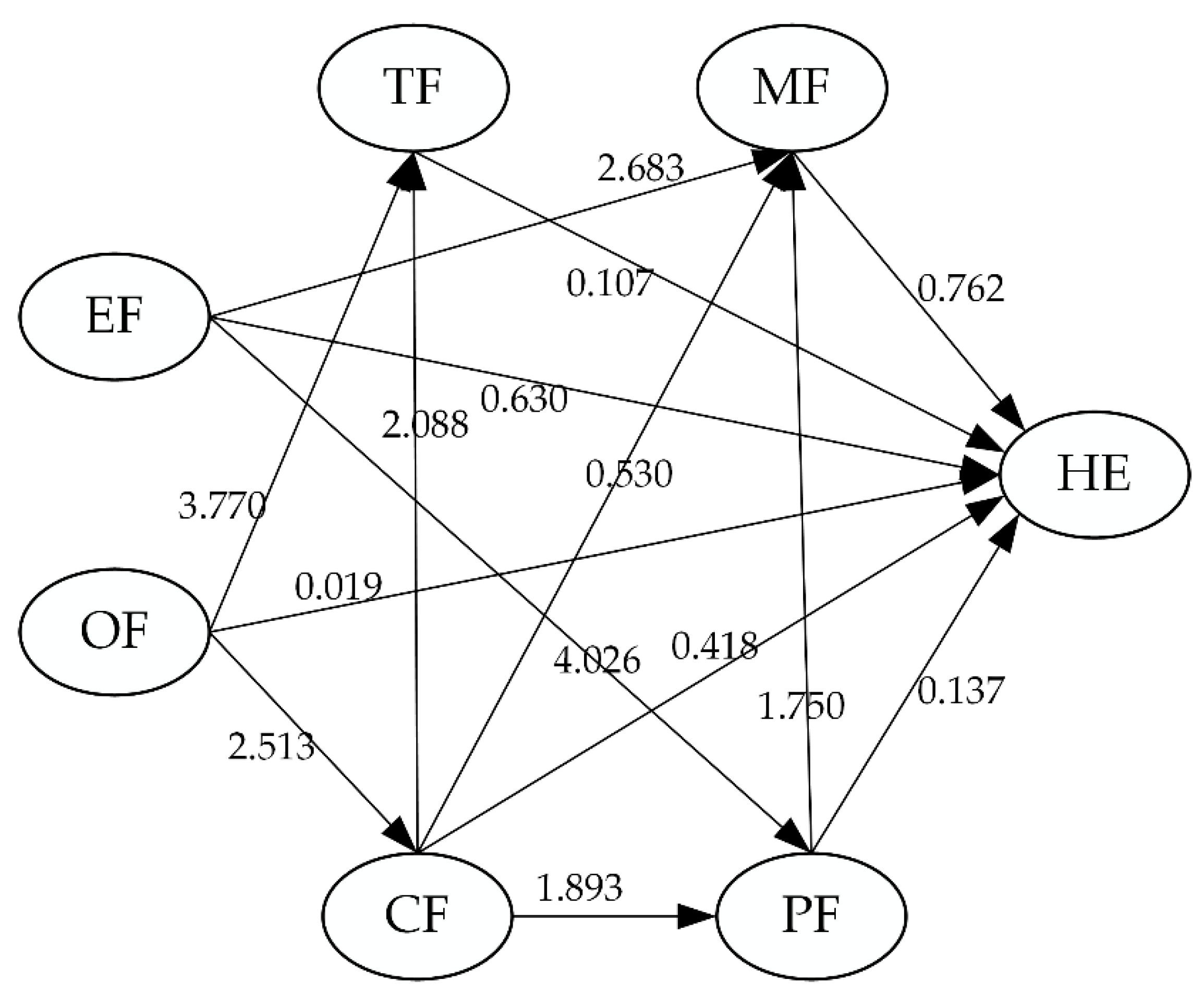

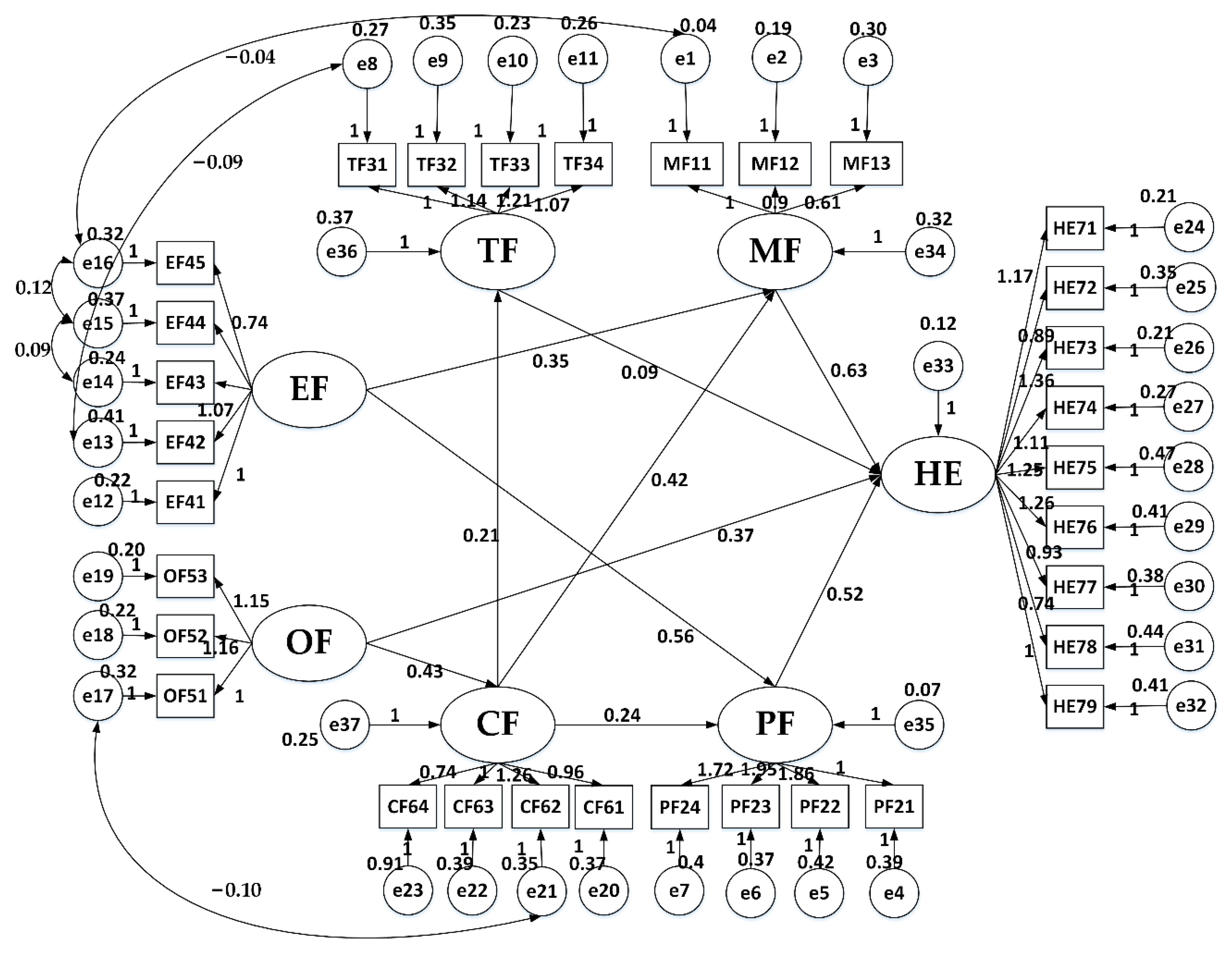

5.2. Model Test and Modification

5.3. Validation of Research Hypotheses

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Huang, M.; Wu, B. Risk Analysis and Control Factors Based on Excavation of a Large Underground Subway Station under Construction. Symmetry 2020, 12, 1629. [Google Scholar] [CrossRef]

- Yu, H.; Peng, Y.; Zhang, L.; Wang, R.; Wang, Q. Statistical Analysis on Urban Metro Accidents during Construction Period. Chin. J. Underground Space Eng. 2019, 15, 852–860. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&filename=BASE2019S2047 (accessed on 1 September 2022). (In Chinese).

- Albert, A.; Hallowell, M.R.; Skaggs, M.; Kleiner, B. Empirical measurement and improvement of hazard recognition skill. Saf. Sci. 2017, 93, 1–8. [Google Scholar] [CrossRef]

- Toole, T.M. Construction Site Safety Roles. J. Constr. Eng. Manag. 2002, 128, 203–210. [Google Scholar] [CrossRef]

- Galvo, N.; Matos, J.C.; Oliveira, D.V. Human Error–Induced Risk in Reinforced Concrete Bridge Engineering. J. Perfor Mance Constr. Facil. 2021, 35, 04021026. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention: A Safety Management Approach; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Reason, J.T. Human Error; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar] [CrossRef]

- Yoo, C.; Kim, J.H. A web-based tunneling-induced building/utility damage assessment system: TURISK. Tunn. Under Ground Space Technol. 2003, 18, 497–511. [Google Scholar] [CrossRef]

- Choi, J. IT-based tunnelling risk management system (IT-TURISK)–Development and implementation. Tunn. Under Ground Space Technol. 2006, 21, 190–202. [Google Scholar] [CrossRef]

- Martins, I.T.; Martins, E.T.; Soares, M.M.; Augusto, L. Human Error in Aviation: The Behavior of Pilots Facing the Modern Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 150–159. [Google Scholar] [CrossRef]

- Goh, Y.M.; Chua, D. Case-Based Reasoning Approach to Construction Safety Hazard Identification: Adaptation and Utilization. J. Constr. Eng. Manag. 2010, 136, 170–178. [Google Scholar] [CrossRef]

- Rajendran, S.; Gambatese, J.A. Development and Initial Validation of Sustainable Construction Safety and Health Rating System. J. Constr. Eng. Manag. 2009, 135, 1067–1075. [Google Scholar] [CrossRef]

- Rasmussen, J.; Jensen, A. Mental procedures in real-life tasks: A case study of electronic trouble shooting. Ergonomics 1974, 17, 293–307. [Google Scholar] [CrossRef] [PubMed]

- Senders, J.W.; Moray, N. Human Error: Cause, Prediction, and Reduction; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Preliminary Human Safety Assessment (PHSA) for the Improvement of the Behavioral Aspects of Safety Climate in the Construction Industry. Buildings 2019, 9, 69. [Google Scholar] [CrossRef]

- Yong, S.L.; Kim, Y.; Kim, S.H.; Kim, C.; Chang, H.C.; Jung, W.D. Analysis of human error and organizational deficiency in events considering risk significance. Nucl. Eng. Des. 2004, 230, 61–67. [Google Scholar] [CrossRef]

- Bhandari, S.; Hallowell, M.; Van Boven, L.; Gruber, J.; Welker, K. Emotional States and Their Impact on Hazard Identification Skills. In Proceedings of the Construction Research Congress 2016, San Juan, Puerto Rico, 31 May–2 June 2016. [Google Scholar]

- Cable, D.M.; Edwards, J.R. Complementary and supplementary fit: A theoretical and empirical integration. J. Appl. Psychol. 2004, 89, 822–834. [Google Scholar] [CrossRef] [PubMed]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Processes 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Yang, J.; Ye, G.; Xiang, Q.; Kim, M.; Yue, H. Insights into the mechanism of construction workers’ unsafe behaviors from an individual perspective. Saf. Sci. 2021, 133, 105004. [Google Scholar] [CrossRef]

- Wang, D.; Chen, J.; Zhao, D.; Dai, F.; Zheng, C.; Wu, X. Monitoring workers’ attention and vigilance in construction activities through a wireless and wearable electroencephalography system. Autom. Constr. 2017, 82, 122–137. [Google Scholar] [CrossRef]

- Powell, R.; Copping, A. Sleep Deprivation and Its Consequences in Construction Workers. J. Constr. Eng. Ing Manag. 2010, 136, 1086–1092. [Google Scholar] [CrossRef]

- Vinodkumar, M.N.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef]

- Chen, C.F.; Chen, S.C. Measuring the effects of Safety Management System practices, morality leadership and self-efficacy on pilots’ safety behaviors: Safety motivation as a mediator. Saf. Sci. 2014, 62, 376–385. [Google Scholar] [CrossRef]

- Shin, I.J. Factors that affect safety of tower crane installation/dismantling in construction industry. Saf. Sci. 2015, 72, 379–390. [Google Scholar] [CrossRef]

- Rundmo, T. Safety climate, attitudes and risk perception in Norsk Hydro. Saf. Sci. 2000, 34, 47–59. [Google Scholar] [CrossRef]

- Roberts, A.C.; Christopoulos, G.I.; Car, J.; Soh, C.; Lu, M. Psycho-biological factors associated with underground spaces: What can the new era of cognitive neuroscience offer to their study? Tunn. Undergr. Space Technol. 2016, 55, 118–134. [Google Scholar] [CrossRef]

- Wu, C.; You, B.; Li, Z.J.; Liao, H.M.; Zhou, S.L.; Wang, C.W.; Xu, Y.L.; Liu, L.; Destech, P.I. Development of an Artificial Intelligence System for Simulating Working Environment of Deep Underground Mines. In Proceedings of the Conference on Industrial Engineering and Management Science (ICIEMS), Shanghai, China, 28–30 October 2013; pp. 71–78. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=IPFD&filename=XYSW201309001009 (accessed on 19 September 2022).

- Dement, J.; Welch, L.; Ringen, K.; Cranford, K.; Quinn, P. Hearing loss among older construction workers: Updated analyses. Am. J. Ind. Med. 2018, 61, 326–335. [Google Scholar] [CrossRef]

- Zohar, D.; Erev, I. On the difficulty of promoting workers’ safety behaviour: Overcoming the underweighting of routine risks. Int. J. Risk Assess. Manag. 2007, 7, 122–136. [Google Scholar] [CrossRef]

- Thanet, A.; Hadikusumo, B. Gap Analysis Approach for Construction Safety Program Improvement. J. Constr. Dev. Ctries. 2007, 12, 77–97. Available online: http://eprints.usm.my/id/eprint/42424 (accessed on 1 September 2022).

- Mullen, J. Investigating factors that influence individual safety behavior at work. J. Saf. Res. 2004, 35, 275–285. [Google Scholar] [CrossRef]

- Cooper, M.D. Towards a model of safety culture. Saf. Sci. 2000, 36, 111–136. [Google Scholar] [CrossRef]

- Colley, S.K.; Lincolne, J.; Neal, A. An examination of the relationship amongst profiles of perceived organizational values, safety climate and safety outcomes. Saf. Sci. 2013, 51, 69–76. [Google Scholar] [CrossRef]

- Dukerich, J.M.; Golden, B.R.; Shortell, S.M. Beauty Is in the Eye of the Beholder: The Impact of Organizational Identification, Identity, and Image on the Cooperative Behaviors of Physicians. Adm. Ence Q. 2002, 47, 507–533. [Google Scholar] [CrossRef]

- Evia, C. Localizing and Designing Computer-Based Safety Training Solutions for Hispanic Construction Workers. J. Constr. Eng. Manag. 2011, 137, 452–459. [Google Scholar] [CrossRef]

- Gist, M.E.; Schwoerer, C.; Rosen, B. Effects of alternative training methods on self-efficacy and performance in computer training. J. Appl. Psychol. 1989, 74, 884–891. [Google Scholar] [CrossRef]

- Leung, M.Y.; Chan, R.S.; Yuen, R.W. Impacts of Stressors and Stress on the Injury Incidents of Construction Workers in Hong Kong. J. Constr. Eng. Manag. 2010, 136, 1093–1103. [Google Scholar] [CrossRef]

- Ju, D.; Qin, X.; Xu, M.; DiRenzo, M.S. Boundary conditions of the emotional exhaustion-unsafe behavior link: The dark side of group norms and personal control. Asia Pac. J. Manag. 2016, 33, 113–140. [Google Scholar] [CrossRef]

- He, C.; Jia, G.; Mccabe, B.; Chen, Y.; Sun, J. Impact of psychological capital on construction worker safety behavior: Communication competence as a mediator. J. Saf. Res. 2019, 71, 231–241. [Google Scholar] [CrossRef]

- Abdelhamid, T.; Everett, J. Physiological Demands during Construction Work. J. Constr. Eng. Man Agement 2002, 128, 427–437. [Google Scholar] [CrossRef]

- Chalder, T.; Berelowitz, G.; Pawlikowska, T.; Watts, L.; Wallace, E.P. Development of a fatigue scale. J. Psychosom. Res. 1993, 37, 147–153. [Google Scholar] [CrossRef]

- Kang, X.Q.; Liu, S.L.; Yang, F.X. The Study on Impact Factors on Human Error of the Employees in the Large Equipment Manufacturing Industry. Ind. Eng. Manag. 2015, 20, 131–137. (In Chinese) [Google Scholar] [CrossRef]

- Inoue, K.; Gotoh, E.; Ishigaki, I.; Hasegawa, T. Factor analysis of risk-taking behavior in forest work. J. For. Res. 1999, 4, 201–206. [Google Scholar] [CrossRef]

- Garrett, J.; Teizer, J. Human Factors Analysis Classification System Relating to Human Error Awareness Taxonomy in Construction Safety. J. Constr. Eng. Manag. 2009, 135, 754–763. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, X.; Skibniewski, M. Perceiving Interactions on Construction Safety Behaviors: Workers’ Perspective. J. Manag. Eng. 2016, 32, 4016012. [Google Scholar] [CrossRef]

- Li, H.; Wang, D.; Chen, J.; Luo, X.; Li, J.; Xing, X. Pre-service fatigue screening for construction workers through wearable EEG-based signal spectral analysis. Autom. Constr. 2019, 106, 102851. [Google Scholar] [CrossRef]

- Yeow, J.; Khan, M.; Ng, P.K. Enforcement of Safety and Health Policy Reduces Human Error in SMEs in the Manufacturing Industry. Adv. Sci. Lett. 2017, 23, 10656–10659. [Google Scholar] [CrossRef]

- Robson, L.S.; Stephenson, C.M.; Schulte, P.A.; Amick, B.C.; Irvin, E.; Eggerth, D.E.; Chan, S.; Bielecky, A.; Wang, A.; Heidotting, T.; et al. A systematic review of the effectiveness of occupational health and safety training. Scand. J. Work. Environ. Health 2012, 38, 193–208. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Yang, M. Impact Mode of Safety Culture on Safety Behavior. China Saf. Sci. J. 2001, 5, 17–19. (In Chinese) [Google Scholar] [CrossRef]

- Neal, A.; Griffin, M.A.; Hart, P.M. The impact of organizational climate on safety climate and individual behavior. Saf. Sci. 2000, 34, 99–109. [Google Scholar] [CrossRef]

- Watson, D.; Clark, L.A.; Tellegen, A. Development and validation of brief measures of positive and negative affect: The PANAS scales. J. Personal. Soc. Psychol. 1988, 54, 1063–1070. [Google Scholar] [CrossRef]

- Fogarty, G. Shaw, Safety climate and the Theory of Planned Behavior: Towards the prediction of unsafe behavior. Accid. Anal. Prev. 2010, 42, 1455–1459. [Google Scholar] [CrossRef]

- Beurskens, A.; Bültmann, U.; Kant, I.; Vercoulen, J.; Bleijenberg, G.; Swaen, G. Fatigue among working people: Validity of a questionnaire measure. Occup. Environ. Med. 2000, 57, 353–357. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Schwarzer, R. Measuring optimistic self-beliefs: A Chinese adaptation of the General Self-Efficacy Scale. Psychology 1995, 38, 174–181. [Google Scholar] [CrossRef]

- Eysenck, S.B.G.; Eysenck, H.J. Impulsiveness and Venturesomeness: Their Position in a Dimensional System of Personality Description. Psychol. Rep. 1978, 43, 1247–1255. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Huang, G.; Huang, H.; Wang, S.; Xiao, Y.; Chen, W. Safety climate, safety behavior, and worker injuries in the Chinese manufacturing industry. Saf. Sci. 2015, 78, 173–178. [Google Scholar] [CrossRef]

- Zohar, D.; Luria, G. A Multilevel Model of Safety Climate: Cross-Level Relationships Between Organization and Group-Level Climates. J. Appl. Psychol. 2005, 90, 616–628. [Google Scholar] [CrossRef] [PubMed]

- Neal, A.; Griffin, M. A Study of the Lagged Relationships among Safety Climate, Safety Motivation, Safety Behavior, and Accidents at the Individual and Group Levels. J. Appl. Psychol. 2006, 91, 946–953. [Google Scholar] [CrossRef]

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics, 5th ed.; Allyn and Bacon: New York, NY, USA, 2007. [Google Scholar]

- Hair, J.F.; Anderson, R.E.; Tatham, R.L.; Black, W.C. Multivariate Data Analysis, 5th ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1998. [Google Scholar]

- Bentler, P.M.; Chou, C.P. Practical Issues in Structural Modeling. Sociol. Methods Res. 1987, 16, 78–117. [Google Scholar] [CrossRef]

- Wang, W. Theory and Application of Structural Equation Modeling; China Renmin University Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Zhang, W. Causation mechanism of coal miners’ human errors in the perspective of life events. Int. J. Min. Sci. Technol. 2014, 24, 581–586. [Google Scholar] [CrossRef]

- Hu, L.T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Modeling 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Parry, G.W. Suggestions for an improved HRA method for use in Probabilistic Safety Assessment. Reliab. Eng. Syst. Saf. 1995, 49, 1–12. [Google Scholar] [CrossRef]

| Category | Factor | Source | Code |

|---|---|---|---|

| Mental Factors | Emotional Attitude | Bhandari et al. [17], Ajzen [19] | MF |

| Subjective Norms | Daniel et al. [18], Ajzen [19] | ||

| Intuitive Behavior | Ajzen [19] | ||

| Physiological Factors | Visual | Yang et al. [20] | PF |

| Auditory | |||

| Attention | Wang et al. [21] | ||

| Fatigue | Powell and Copping [22] | ||

| Technical Factors | Knowledge Level | Vinodkumar et al. [23] | TF |

| Self-efficacy | Chen and Chen [24] | ||

| Skill Level | Shin [25] | ||

| Safety Perception | Rundmo [26] | ||

| Environmental Factors | Temperature | Roberts et al. [27], Wu [28], John et al. [29] | EF |

| Humidity | |||

| Lighting | |||

| Noise | |||

| Dust | |||

| Organizational Factors | Safety System | Zohar and Erev [30] | OF |

| Organizational Support | Thanet et al. [31] | ||

| Safety Leadership | Mullen [32] | ||

| Cultural Factors | Promotion Form | Cooper [33] | CF |

| Organizational Values | Colley et al. [34] | ||

| Organizational Identity | Dukerich et al. [35] | ||

| Communication | Evia [36] |

| Variable | Category | Number | Percentage |

|---|---|---|---|

| Age | ≤25 | 62 | 25.41 |

| 26–30 | 100 | 40.98 | |

| 31–35 | 43 | 17.62 | |

| 36–40 | 18 | 7.38 | |

| >40 | 21 | 8.61 | |

| Education level | Graduate degree or above | 48 | 19.67 |

| Bachelor degree | 148 | 60.66 | |

| Technical school | 41 | 16.80 | |

| High school or below | 7 | 2.87 | |

| Length of service | ≤2 | 81 | 33.20 |

| 3–5 | 57 | 23.36 | |

| 6–10 | 60 | 24.59 | |

| >10 | 46 | 18.85 | |

| Work type | Project department general employee | 116 | 47.54 |

| Project department technician | 46 | 18.85 | |

| Functional department general employee | 60 | 24.59 | |

| High-level functional departments | 21 | 8.61 | |

| Enterprise high-level | 1 | 0.41 | |

| Work unit type | Supervision enterprise | 45 | 18.44 |

| Agent construction unit | 12 | 4.92 | |

| Construction enterprises | 95 | 38.93 | |

| Government institutions | 45 | 18.44 | |

| Other enterprises | 47 | 19.26 | |

| Province | Jiangsu | 109 | 44.67 |

| Shandong | 35 | 14.34 | |

| Shanghai | 33 | 13.52 | |

| Guanddong | 23 | 9.43 | |

| Beijing | 12 | 4.92 | |

| Anhui | 9 | 3.69 | |

| Hubei | 9 | 3.69 | |

| Liaoning | 4 | 1.64 | |

| Fujian | 3 | 1.23 | |

| Jiangxi | 3 | 1.23 | |

| Henan | 2 | 0.82 | |

| Shanxi | 2 | 0.82 |

| Variable | Number of Item | Cronbach’s α Value | Cronbach’s α Value of Scale |

|---|---|---|---|

| Mental factors | 3 | 0.794 | 0.870 |

| Physiological factors | 4 | 0.732 | |

| Technical factors | 4 | 0.888 | |

| Environmental factors | 5 | 0.878 | |

| Organizational factors | 3 | 0.864 | |

| Cultural factors | 4 | 0.718 | |

| Human errors | 9 | 0.923 |

| Variable | KMO | χ2 | df | Sig |

|---|---|---|---|---|

| Mental factors | 0.642 | 264.693 | 3 | 0.000 |

| Physiological factors | 0.694 | 212.086 | 6 | 0.000 |

| Technical factors | 0.834 | 542.811 | 6 | 0.000 |

| Environmental factors | 0.839 | 627.363 | 10 | 0.000 |

| Organizational factors | 0.724 | 352.065 | 3 | 0.000 |

| Cultural factors | 0.721 | 210.599 | 6 | 0.000 |

| Human errors | 0.604 | 155.385 | 3 | 0.000 |

| Variable | Index | Factor Load | Variable | Index | Factor Load |

|---|---|---|---|---|---|

| Mental Factors | MF11 | 0.938 | Organizational Factors | OF51 | 0.749 |

| MF12 | 0.750 | OF52 | 0.833 | ||

| MF13 | 0.580 | OF53 | 0.871 | ||

| Physiological Factors | PF21 | 0.571 | Cultural Factors | CF61 | 0.712 |

| PF22 | 0.691 | CF62 | 0.800 | ||

| PF23 | 0.748 | CF63 | 0.605 | ||

| PF24 | 0.644 | CF64 | 0.523 | ||

| Technical Factors | TF31 | 0.799 | Human Error | HE71 | 0.618 |

| TF32 | 0.789 | HE72 | 0.722 | ||

| TF33 | 0.863 | HE73 | 0.601 | ||

| TF34 | 0.821 | HE74 | 0.551 | ||

| Environmental Factors | EF41 | 0.800 | HE75 | 0.572 | |

| EF42 | 0.728 | HE76 | 0.609 | ||

| EF43 | 0.831 | HE77 | 0.589 | ||

| EF44 | 0.745 | HE78 | 0.624 | ||

| EF45 | 0.754 | HE79 | 0.660 |

| Index | Initial Model | Modified Model | Ideal Value |

|---|---|---|---|

| RMR | 0.067 | 0.046 | <0.05 |

| RMSEA | 0.065 | 0.042 | <0.08 |

| GFI | 0.814 | 0.851 | >0.90 |

| AGFI | 0.936 | 0.905 | >0.90 |

| NFI | 0.770 | 0.937 | >0.90 |

| TLI | 0.855 | 0.938 | >0.90 |

| CFI | 0.967 | 0.910 | >0.90 |

| PGFI | 0.796 | 0.710 | >0.50 |

| PNFI | 0.702 | 0.737 | >0.50 |

| χ2/df | 2.017 | 1.431 | <2.00 |

| Influence Path | C.R. | p-Value | Results | ||

|---|---|---|---|---|---|

| H1: | MF→HE | 3.189 | *** | Proved | |

| H2a: | PF→HE | 4.865 | *** | Proved | |

| H3: | TF→HE | 2.015 | 0.037 | Proved | |

| H4b: | EF→MF→HE | EF→MF | 5.246 | *** | Proved |

| MF→HE | 3.189 | *** | |||

| H4c: | EF→PF→HE | EF→PF | 2.984 | *** | Proved |

| PF→HE | 4.865 | *** | |||

| H5a: | OF→HE | 2.494 | 0.015 | Proved | |

| H5c: | OF→CF | 4.897 | *** | Proved | |

| H6b: | CF→MF→HE | CF→MF | 2.672 | *** | Proved |

| MF→HE | 3.189 | *** | |||

| H6c: | CF→PF→HE | CF→PF | 5.358 | *** | Proved |

| PF→HE | 4.865 | *** | |||

| H6d: | CF→TF→HE | CF→TF | 3.486 | *** | Proved |

| TF→HE | 2.015 | 0.022 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Liu, Y.; Zhang, D.; Li, R.; Qiao, Y.; Opoku, A.; Cui, C. Influencing Factors of Human Errors in Metro Construction Based on Structural Equation Modeling (SEM). Buildings 2022, 12, 1498. https://doi.org/10.3390/buildings12101498

Shi X, Liu Y, Zhang D, Li R, Qiao Y, Opoku A, Cui C. Influencing Factors of Human Errors in Metro Construction Based on Structural Equation Modeling (SEM). Buildings. 2022; 12(10):1498. https://doi.org/10.3390/buildings12101498

Chicago/Turabian StyleShi, Xiaobo, Yan Liu, Dongyan Zhang, Ruixu Li, Yaning Qiao, Alex Opoku, and Caiyun Cui. 2022. "Influencing Factors of Human Errors in Metro Construction Based on Structural Equation Modeling (SEM)" Buildings 12, no. 10: 1498. https://doi.org/10.3390/buildings12101498

APA StyleShi, X., Liu, Y., Zhang, D., Li, R., Qiao, Y., Opoku, A., & Cui, C. (2022). Influencing Factors of Human Errors in Metro Construction Based on Structural Equation Modeling (SEM). Buildings, 12(10), 1498. https://doi.org/10.3390/buildings12101498

_Chen.png)