Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii

Abstract

:1. Introduction

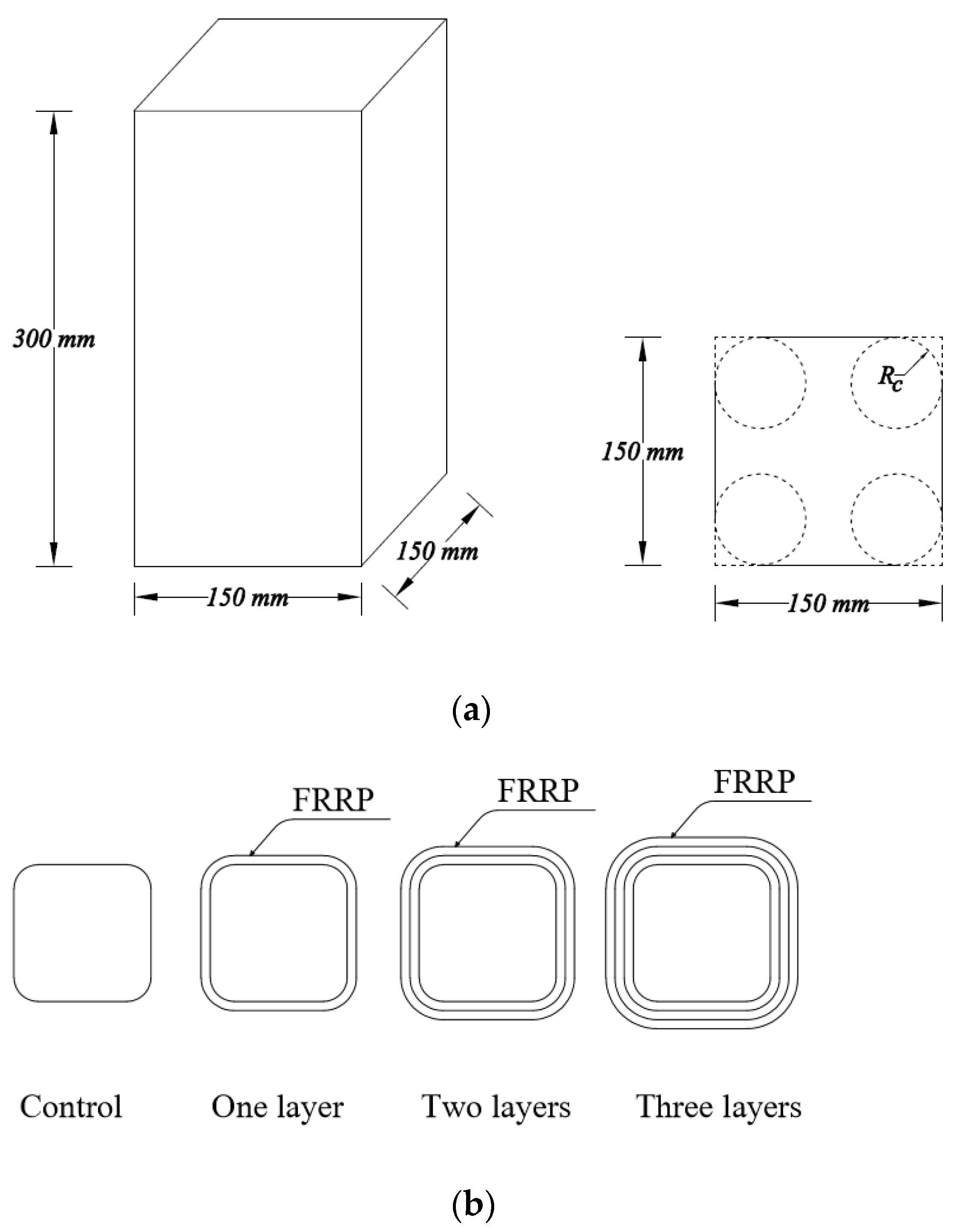

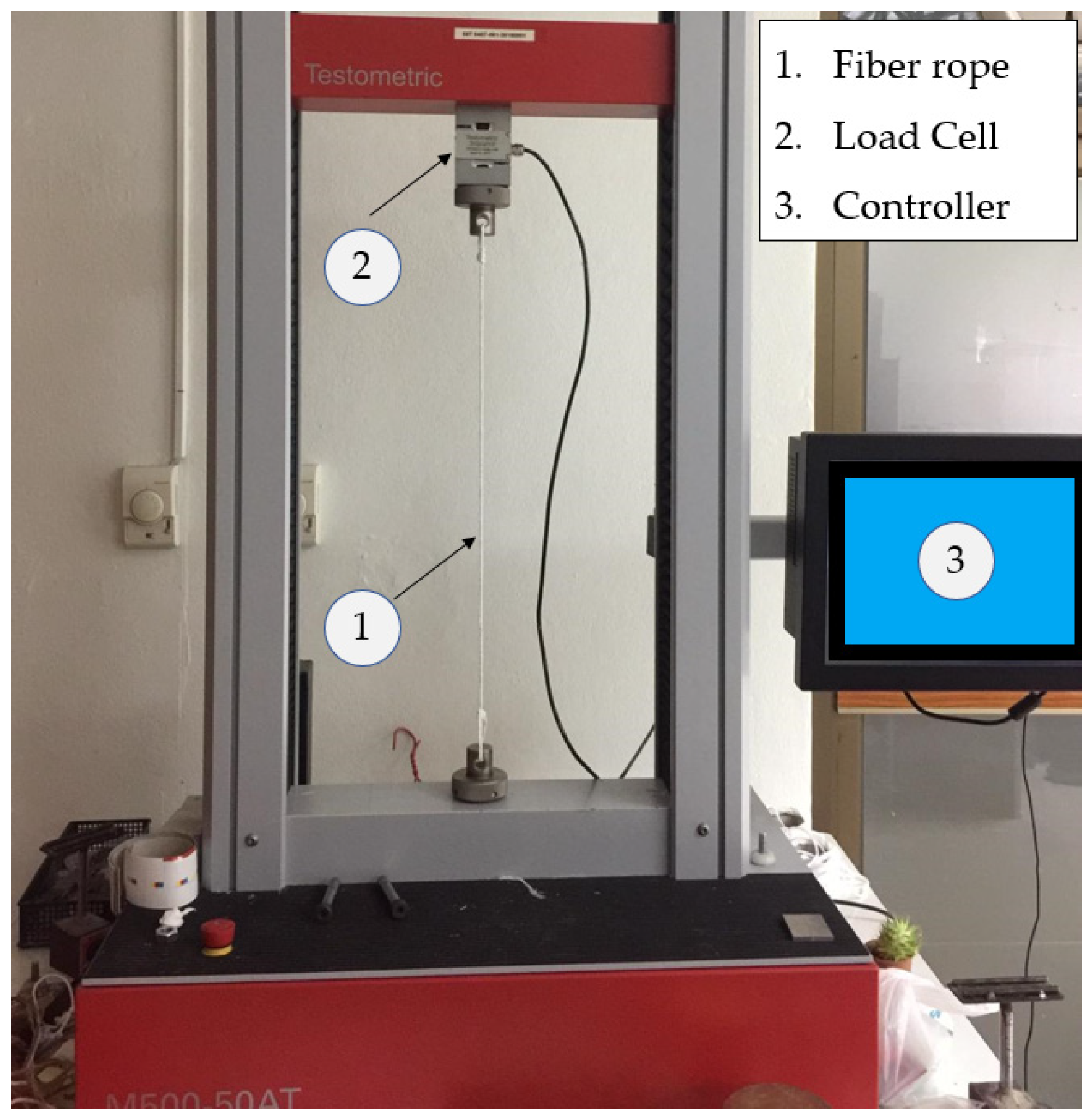

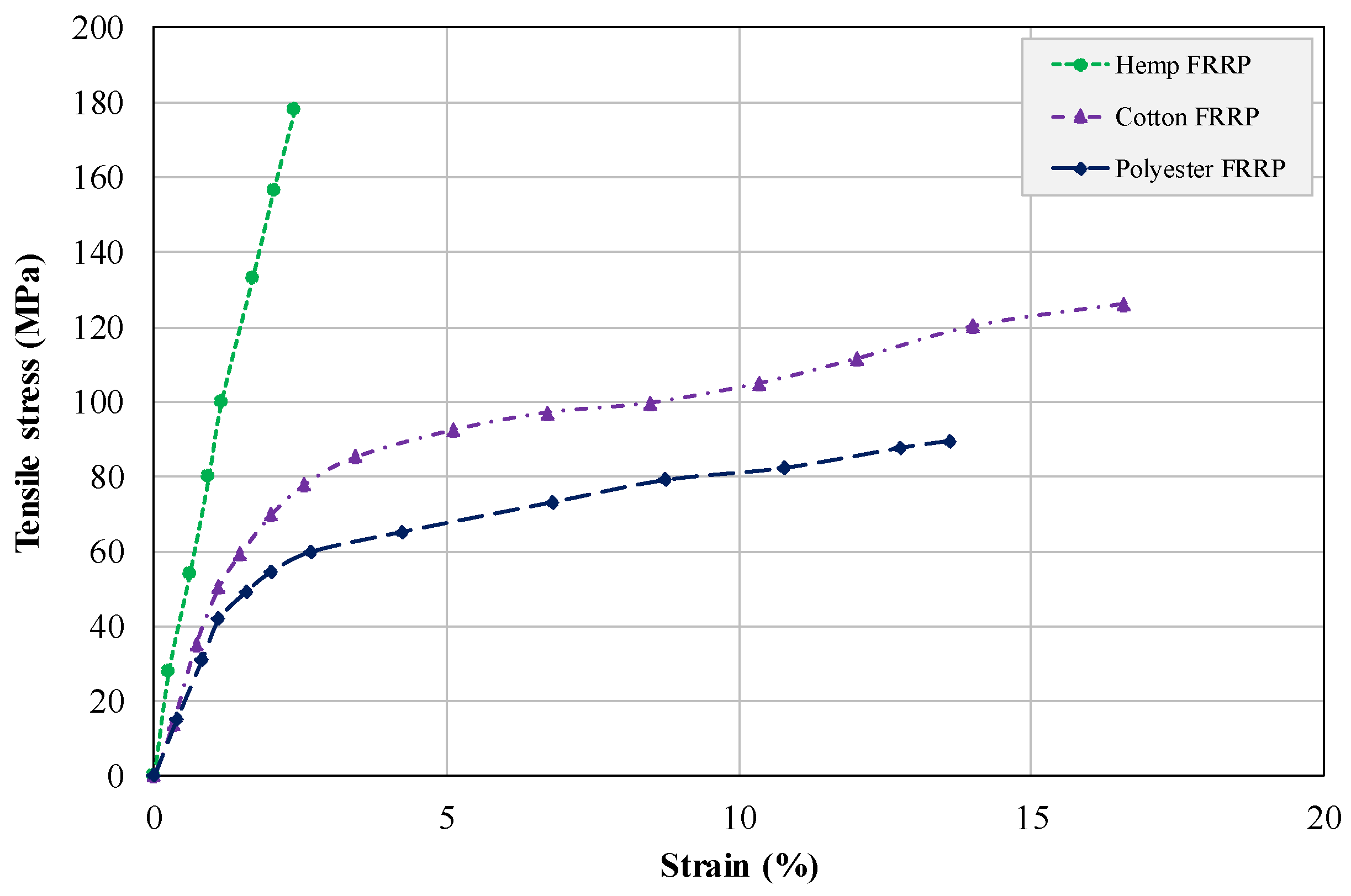

2. Test Program

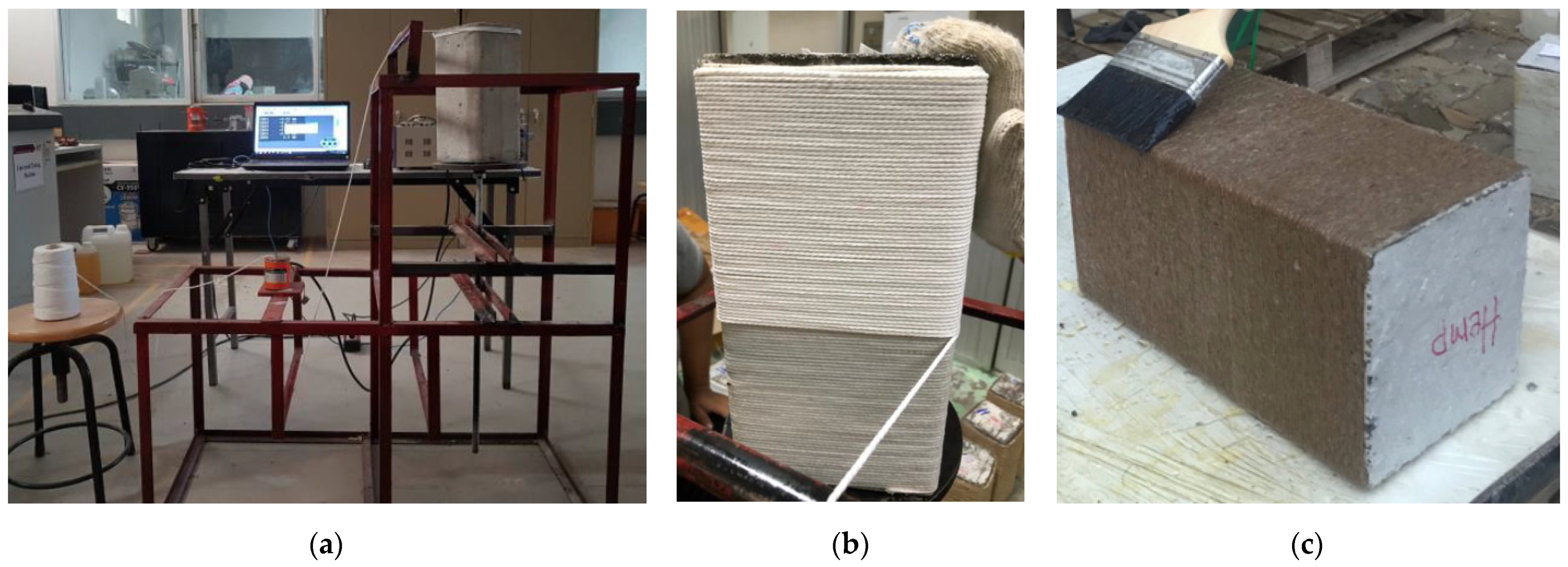

3. Specimen Design and Material Properties

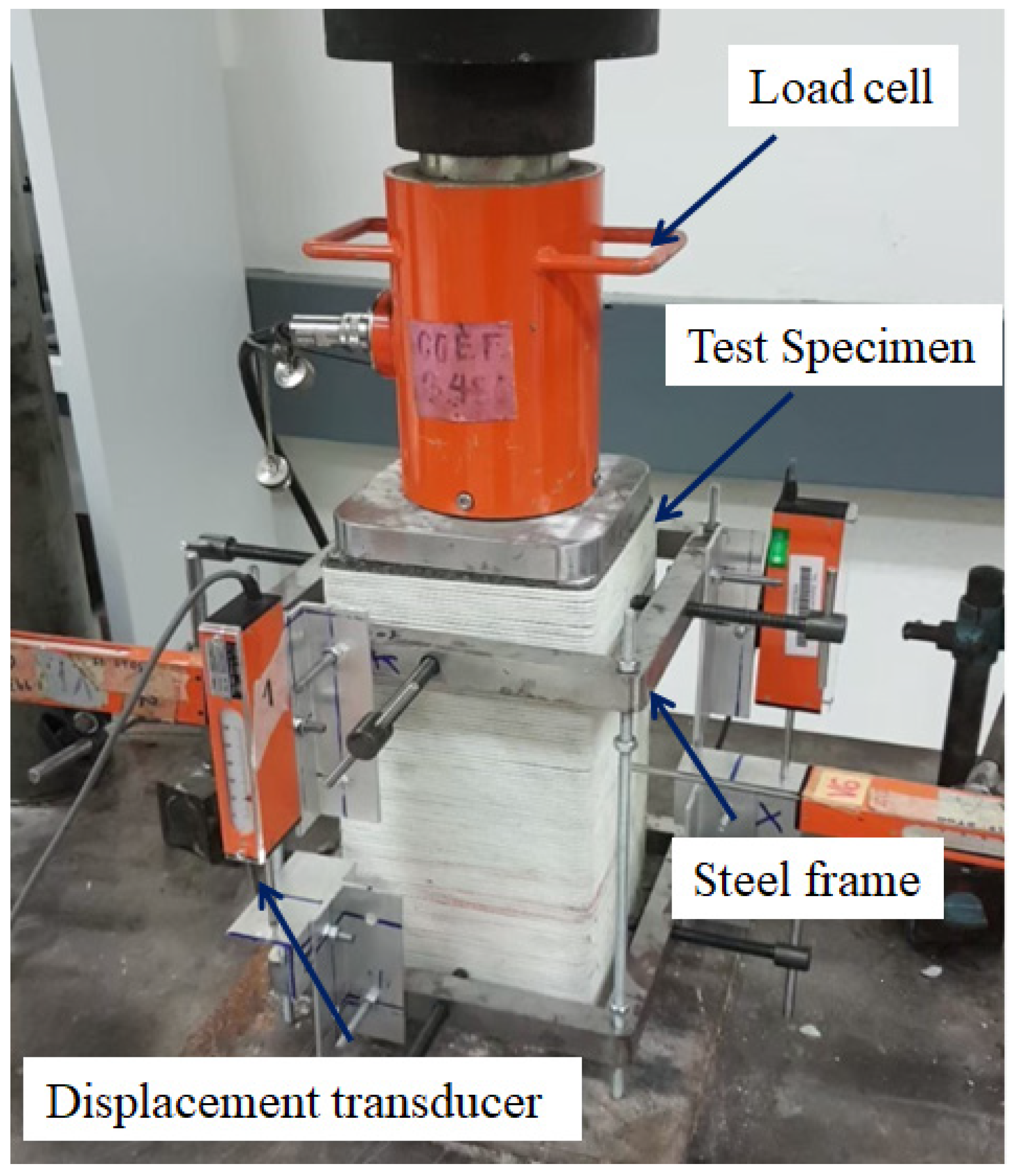

4. Strengthening of Concrete Specimens

5. Instrumentation and Test Setup

6. Experimental Results and Discussions

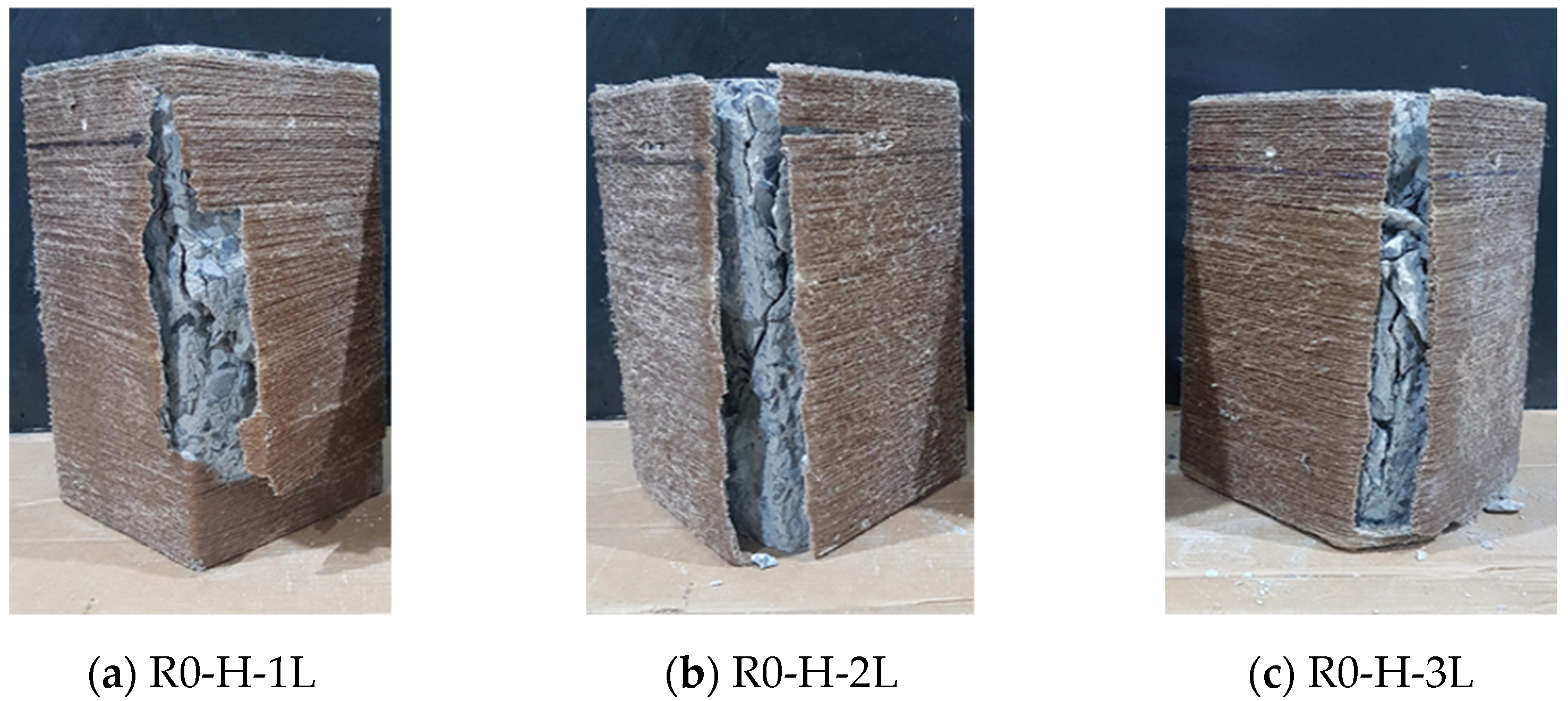

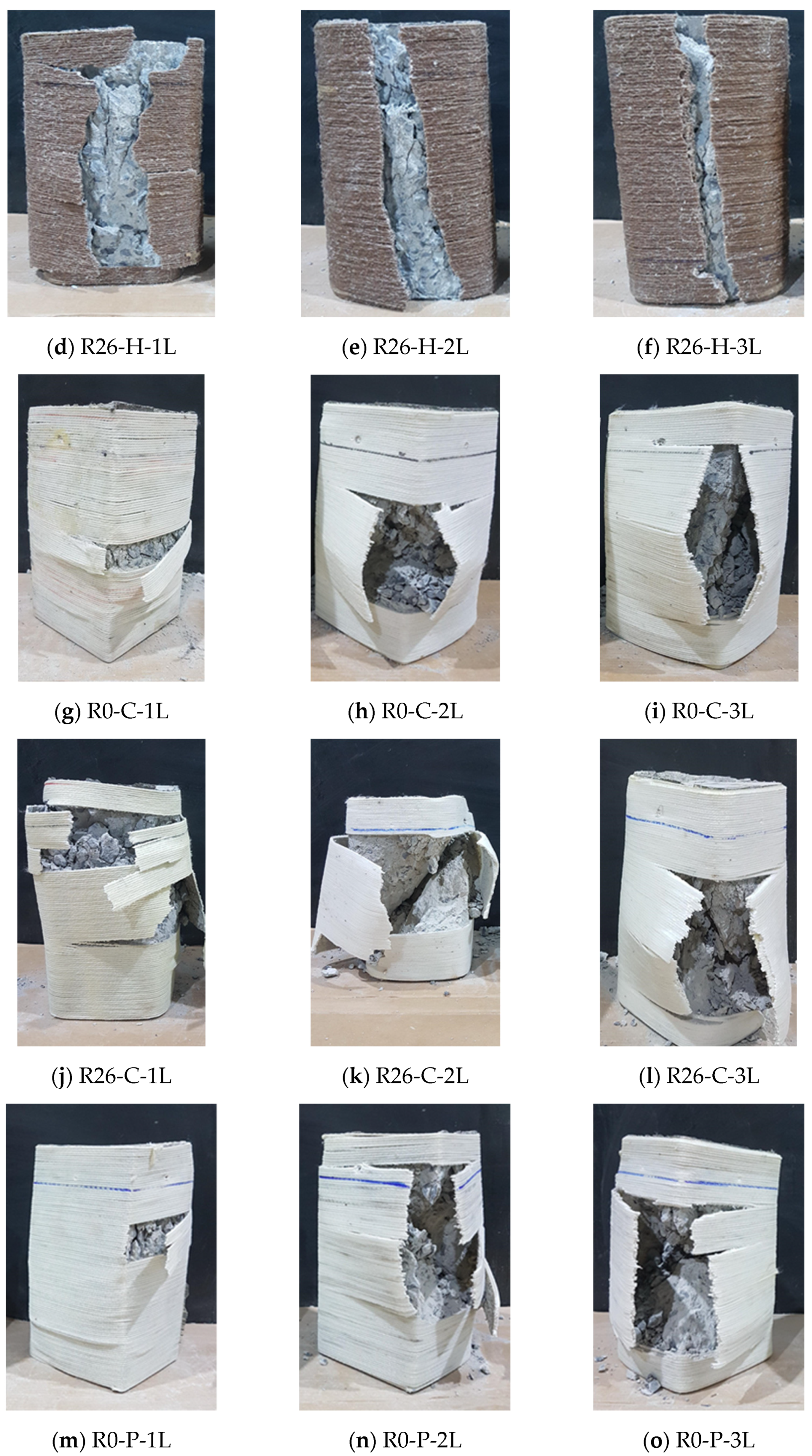

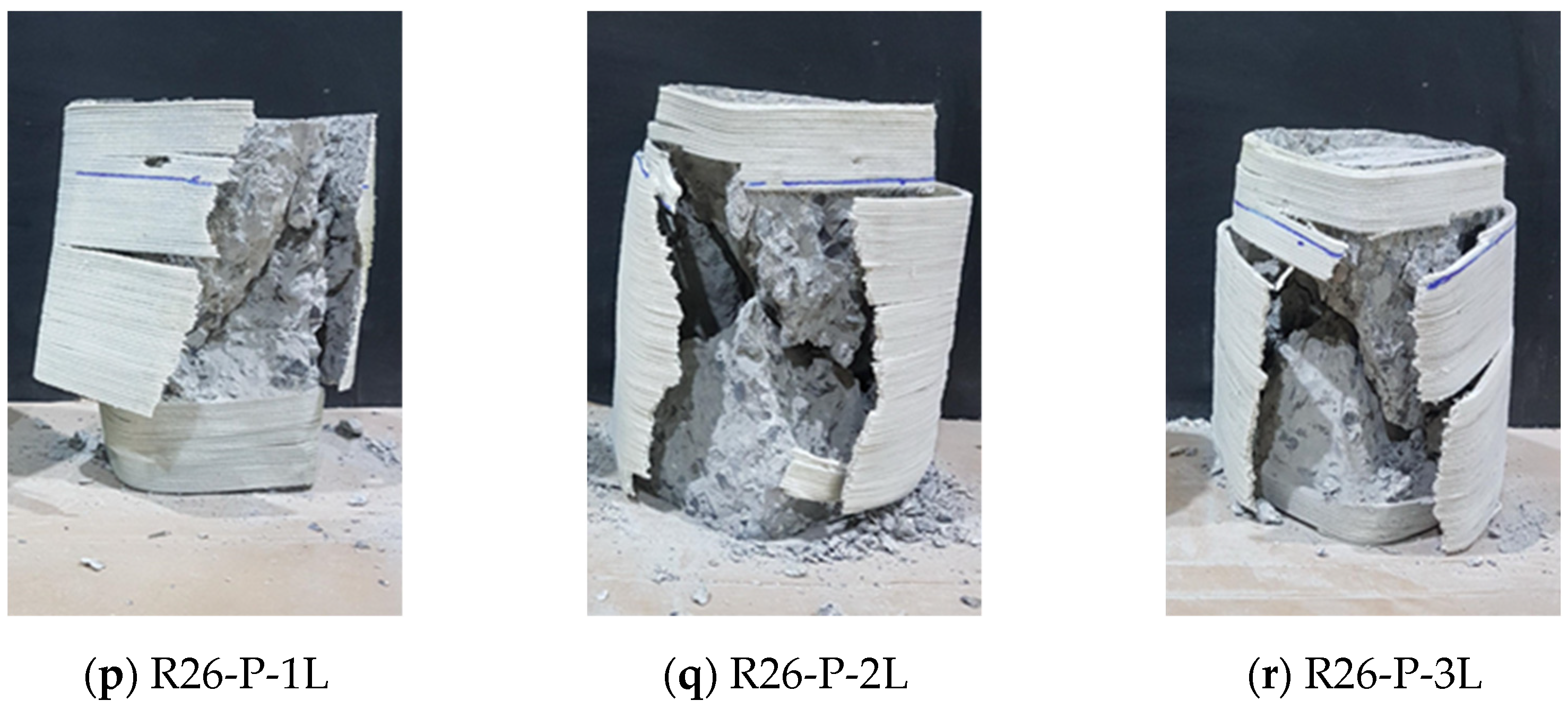

6.1. Failure Modes of FRRP-Confined Specimens

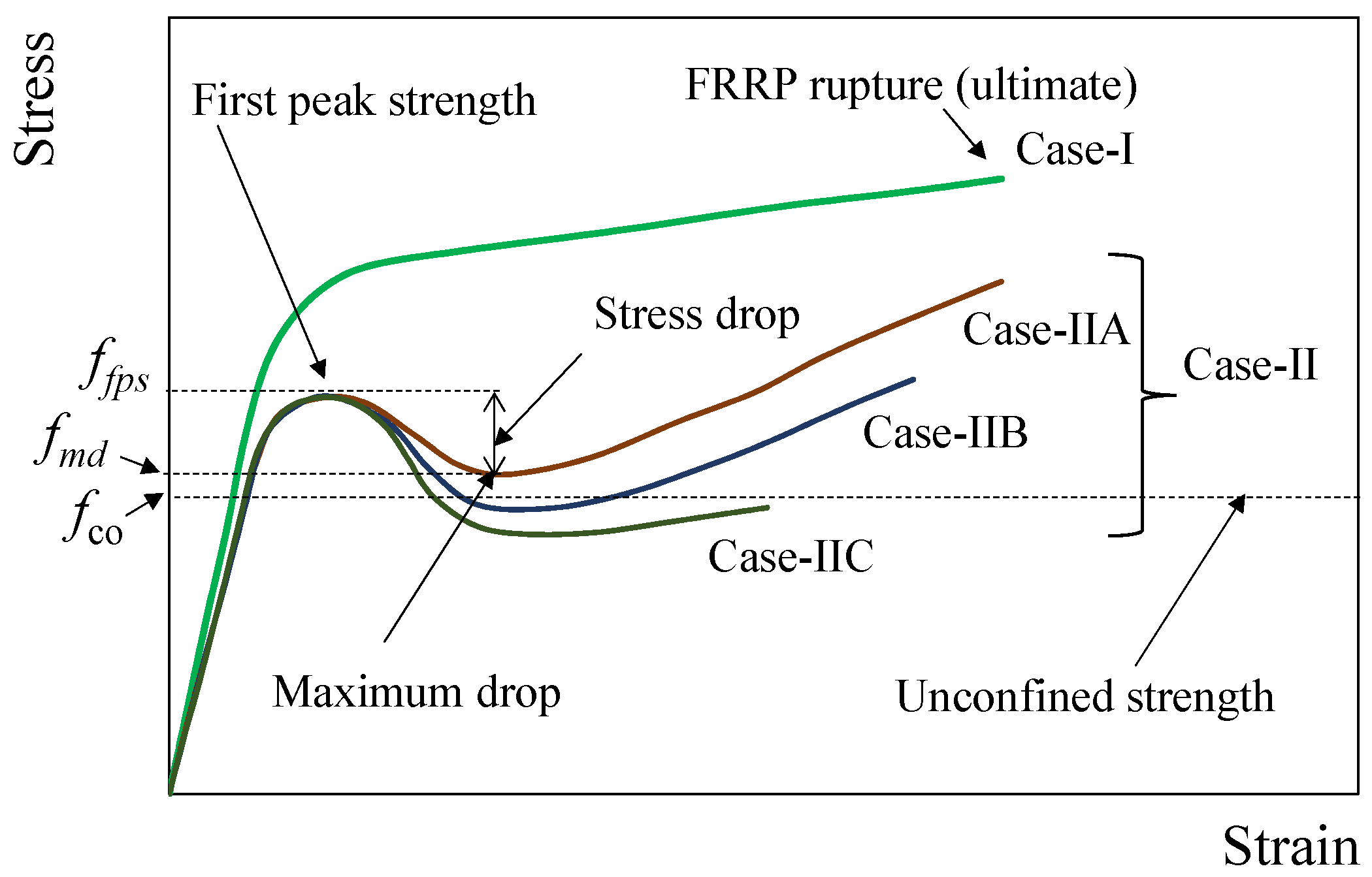

6.2. Axial Stress versus Strain Relationships

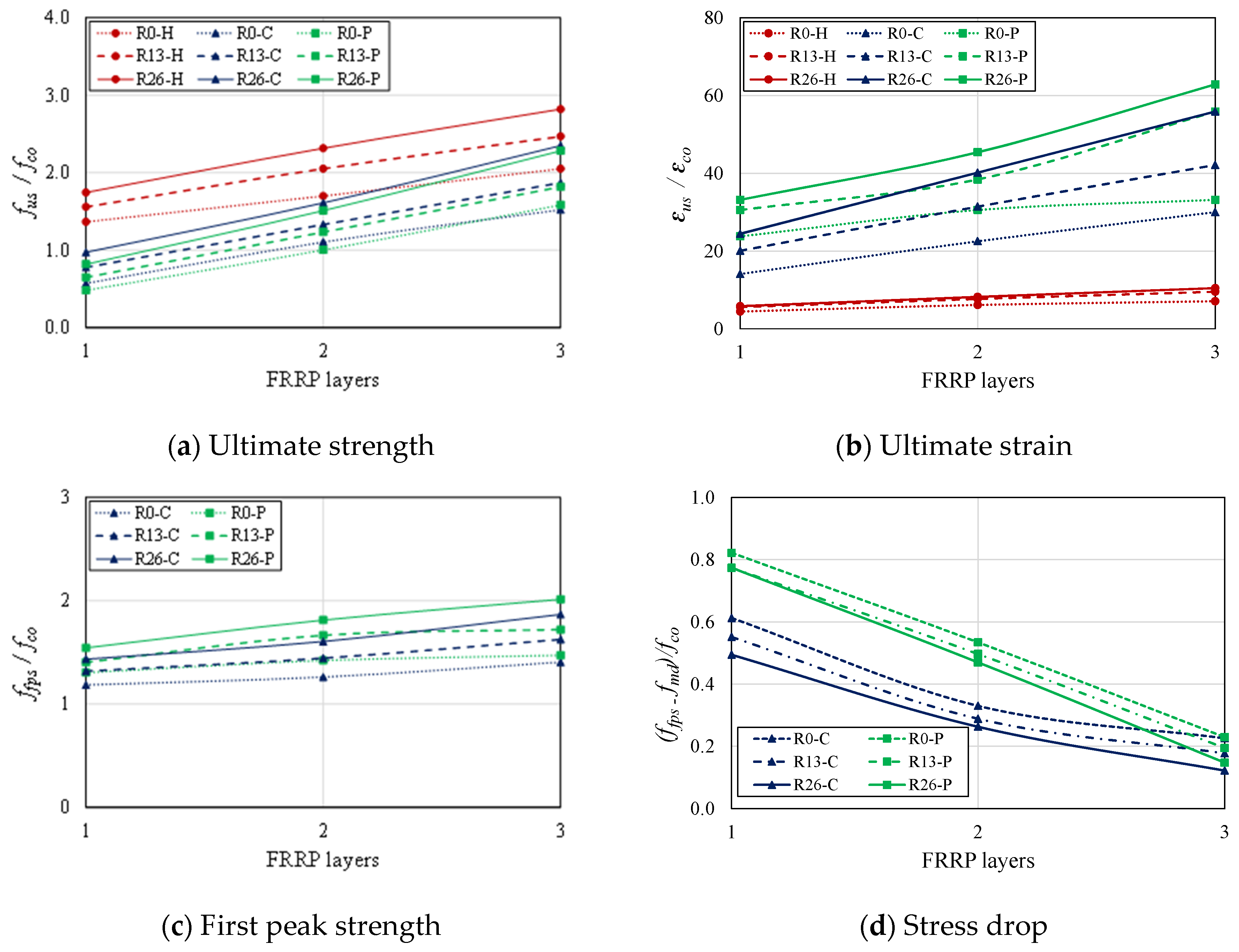

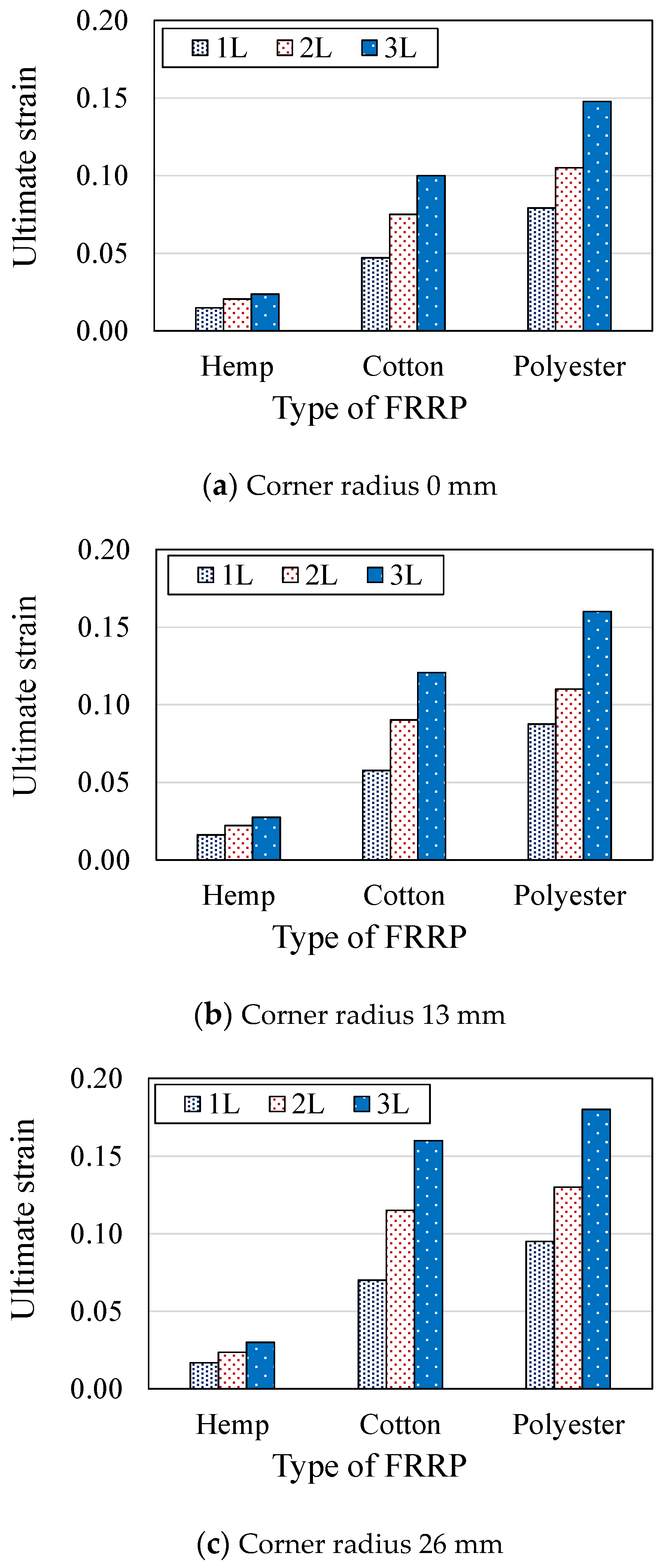

6.3. Effects of FRRP Layers on Ultimate Strength and Strain

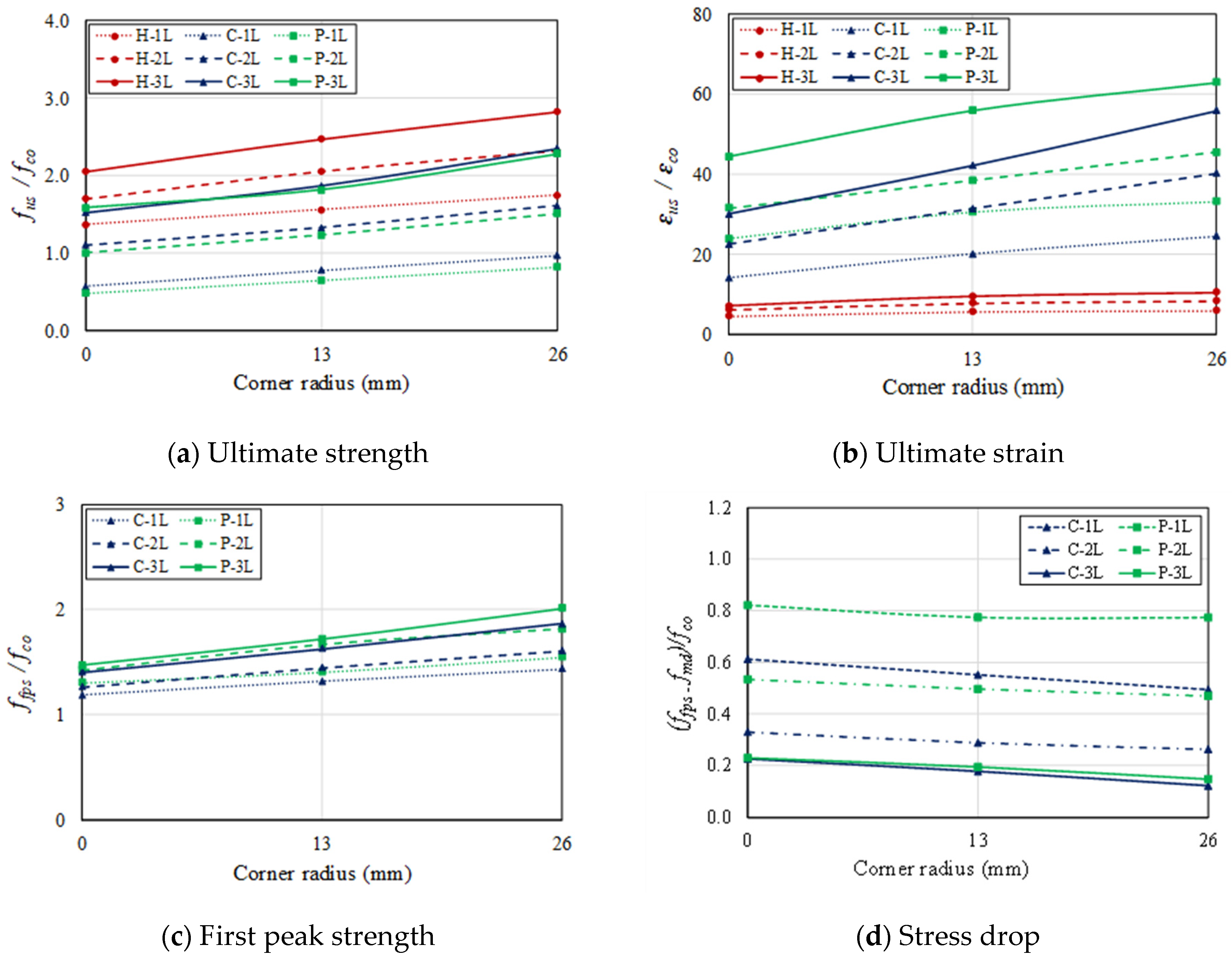

6.4. Effects of Corner Radius

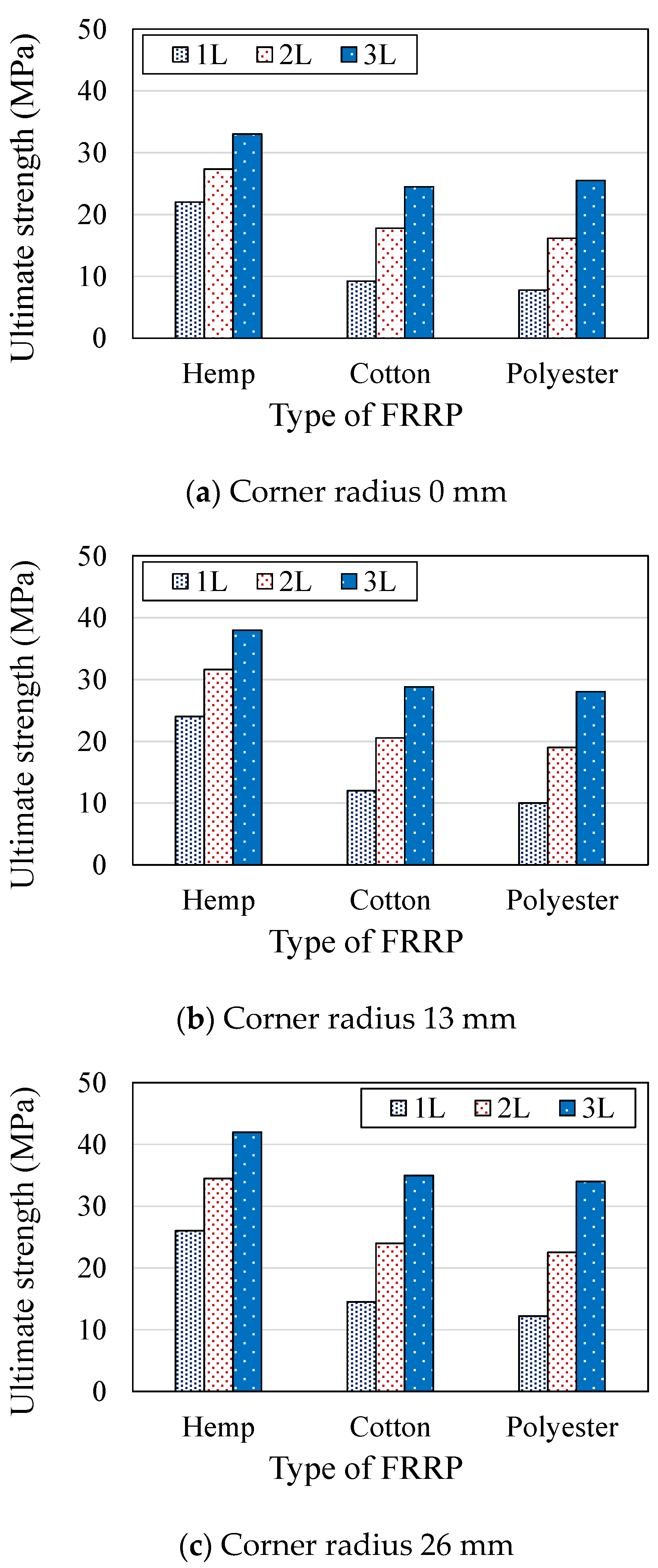

6.5. Effects of Fiber Rope Types

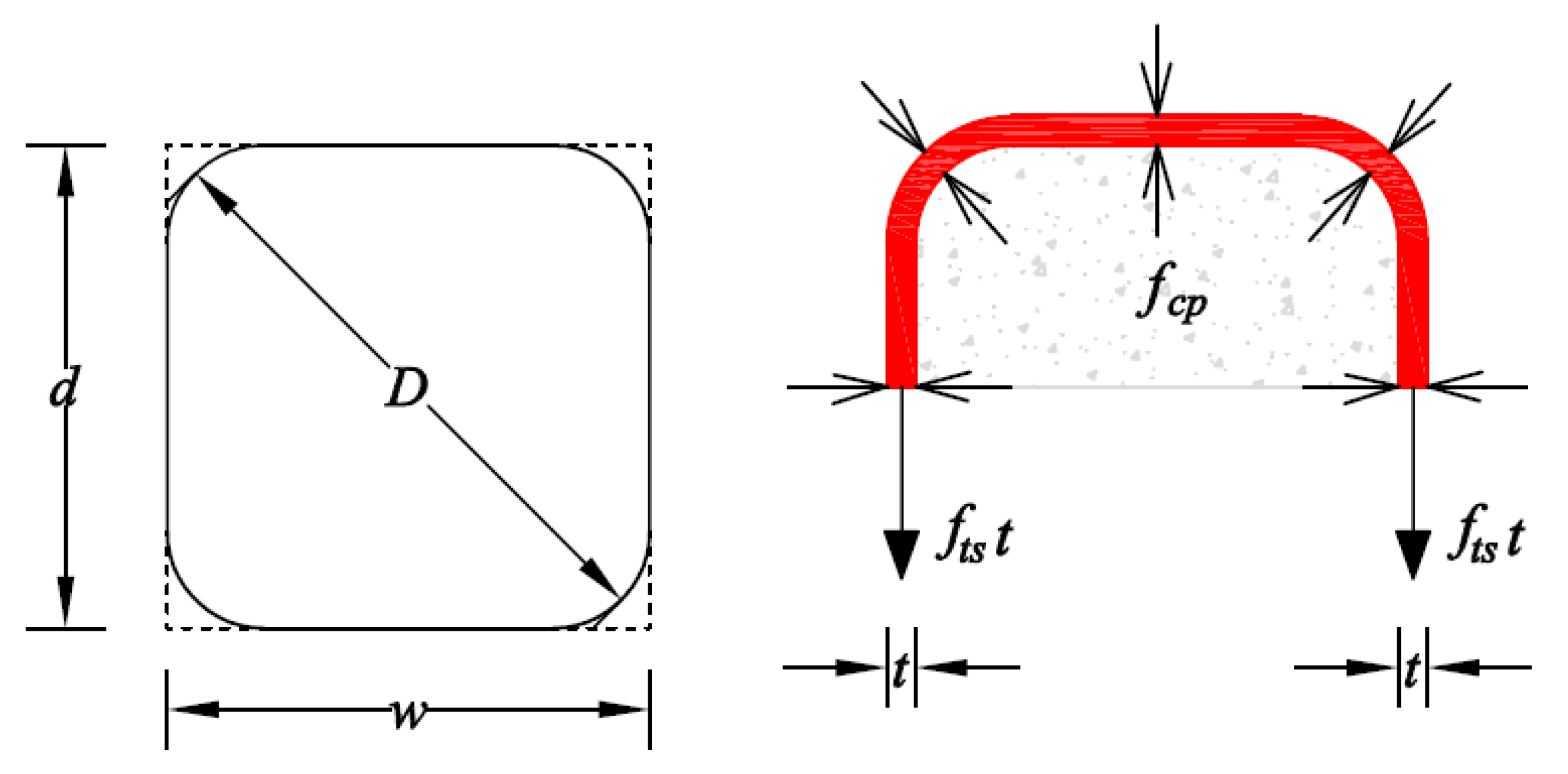

7. Strength and Strain Models

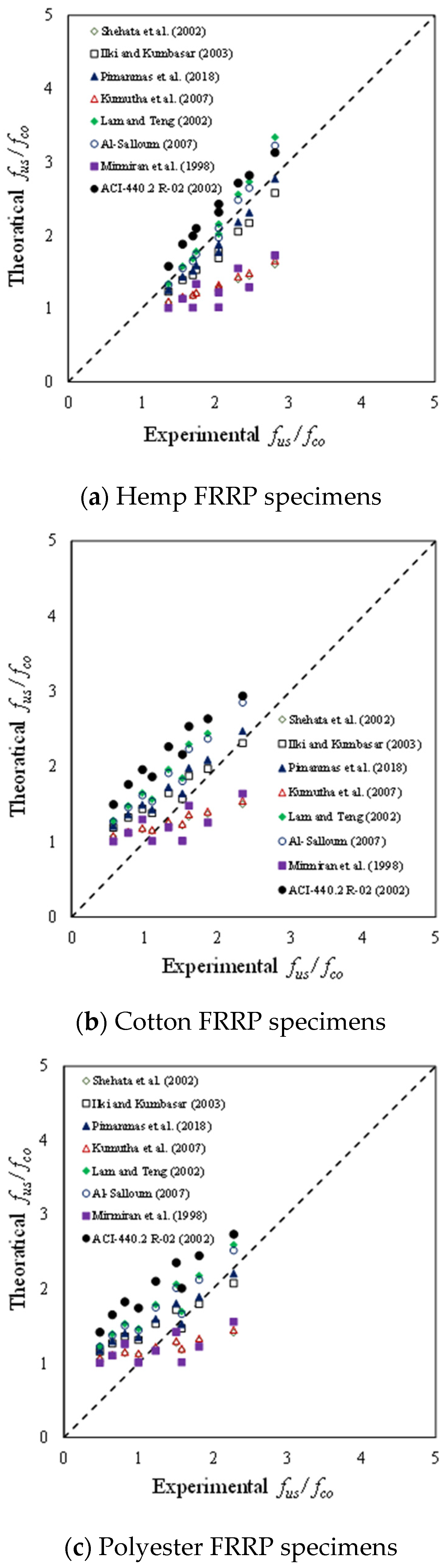

7.1. Compressive Strength Models

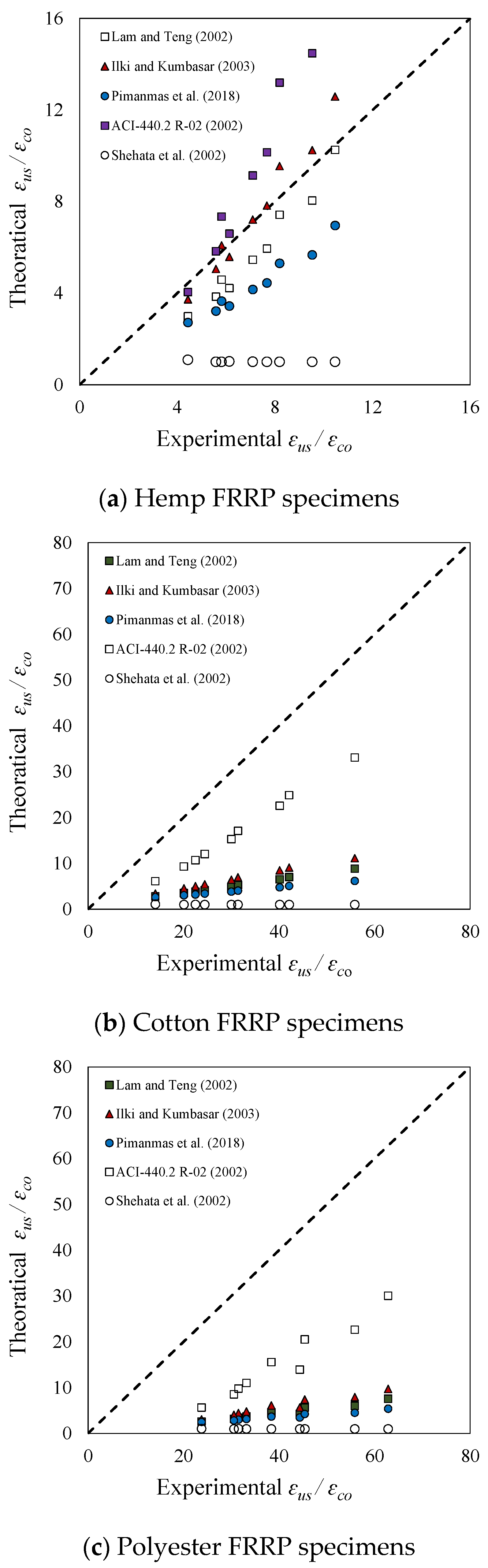

7.2. Ultimate Strain Models

7.3. Assessment of Existing Strength and Strain Models

7.4. Proposed Ultimate Strength Models

7.5. Proposed Ultimate Strain Models

8. Conclusions

- FRRP composites are effective in enhancing the strength and deformability of confined concrete. Compressive strength and deformability for concrete specimens with a certain corner radius increase with the number of FRRP layers.

- The corner radius had a significant effect on the behavior of FRRP-confined specimens. The ultimate strength and strain of FRPP confined concrete increased with the corner radius.

- Experimental results demonstrate a nearly linear relationship between the strength gains of FRRP-confined square concrete specimens and corner radius.

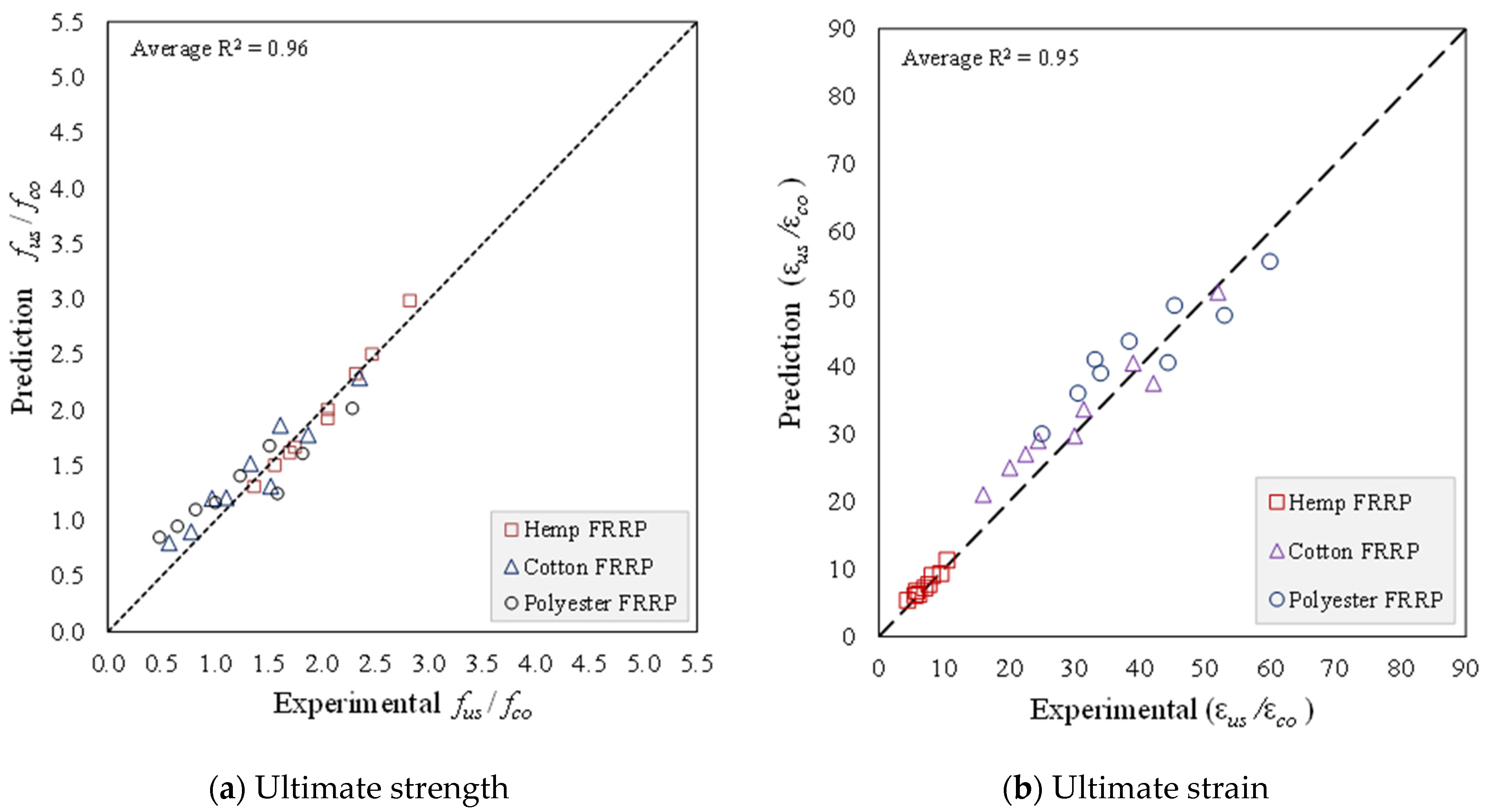

- Previously developed models to estimate the ultimate strength and strain of FRP-confined square columns are found incapable of precisely estimating the ultimate strength and strain of the FRRP-confined square specimens of this study. Newly developed unified models are accurate in estimating the ultimate strength and strain of FRRP-confined square columns.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tastani, S.P.; Pantazopoulou, S.J. Experimental evaluation of FRP jackets in upgrading RC corroded columns with substandard detailing. Eng. Struct. 2004, 26, 817–829. [Google Scholar] [CrossRef]

- Cardone, D.; Flora, A.; Picione, M.D.L.; Martoccia, A. Estimating direct and indirect losses due to earthquake damage in residential RC buildings. Soil Dyn. Earthq. Eng. 2019, 126, 105801. [Google Scholar] [CrossRef]

- Sezen, H.; Lodhi, M.S. Seismic Response of Reinforced Concrete Columns. In Earthquake-Resistant Structures: Design, Assessment and Rehabilitation; BoD–Books on Demand: Norderstedt, Germany, 2012. [Google Scholar]

- Hadi, M.N.; Pham, T.M.; Lei, X. New method of strengthening reinforced concrete square columns by circularizing and wrapping with fiber-reinforced polymer or steel straps. J. Compos. Constr. 2013, 17, 229–238. [Google Scholar] [CrossRef]

- Tsonos, A.D. Performance enhancement of R/C building columns and beam–column joints through shotcrete jacketing. Eng. Struct. 2010, 32, 726–740. [Google Scholar] [CrossRef]

- Rodriguez, M.; Park, R. Repair and strengthening of reinforced concrete buildings for seismic resistance. Earthq. Spectra 1991, 7, 439–459. [Google Scholar] [CrossRef]

- Naji, A.J.; Al-Jelawy, H.M.; Saadoon, S.A.; Ejel, A.T. Rehabilitation and strengthening techniques for reinforced concrete columns. J. Phys. Conf. Ser. 2021, 1895, 012049. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-confined concrete in circular sections: Review and assessment of stress–strain models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Rodsin, K.; Hussain, Q.; Suparp, S.; Nawaz, A. Compressive behavior of extremely low strength concrete confined with low-cost glass FRP composites. Case Stud. Constr. Mater. 2020, 13, e00452. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Gao, Y. Composite jacketed concrete under uniaxial compression—Verification of simple design equations. J. Mater. Civ. Eng. 1997, 9, 185–193. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New hybrid basalt/E-glass FRP jacketing for enhanced confinement of recycled aggregate concrete with clay brick aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar]

- Avossa, A.M.; Picozzi, V.; Ricciardelli, F. Load-Carrying Capacity of Compressed Wall-Like RC Columns Strengthened with FRP. Buildings 2021, 11, 285. [Google Scholar] [CrossRef]

- Li, X.; Lu, J.; Ding, D.D.; Wang, W. Axial strength of FRP-confined rectangular RC columns with different cross-sectional aspect ratios. Mag. Concr. Res. 2017, 69, 1011–1026. [Google Scholar] [CrossRef]

- Mufti, A.A. FRPs and FOSs lead to innovation in Canadian civil engineering structures. Constr. Build. Mater. 2003, 17, 379–387. [Google Scholar] [CrossRef]

- Montoya, E.; Vecchio, F.J.; Sheikh, S.A. Numerical evaluation of the behaviour of steel-and FRP-confined concrete columns using compression field modelling. Eng. Struct. 2004, 26, 1535–1545. [Google Scholar] [CrossRef]

- Rochette, P.; Labossiere, P. Axial testing of rectangular column models confined with composites. J. Compos. Constr. 2000, 4, 129–136. [Google Scholar] [CrossRef]

- Pessiki, S.; Harries, K.A.; Kestner, J.T.; Sause, R.; Ricles, J.M. Axial behavior of reinforced concrete columns confined with FRP jackets. J. Compos. Constr. 2001, 5, 237–245. [Google Scholar] [CrossRef]

- Karam, G.; Tabbara, M. Corner effects in CFRP-wrapped square columns. Mag. Concr. Res. 2004, 56, 461–464. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Moshiri, N.; Mortazavi, N. Effect of corner radius and aspect ratio on compressive behavior of rectangular concrete columns confined with CFRP. Mater. Struct. 2015, 48, 107–122. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Lin, G.; Teng, J.G.; Chan, T.M.; Zeng, J.J.; Li, L.J. FRP-confined square concrete columns with section curvilinearization under axial compression. J. Compos. Constr. 2020, 24, 04020004. [Google Scholar] [CrossRef]

- Han, Q.; Yuan, W.; Bai, Y.; Du, X. Compressive behavior of large rupture strain (LRS) FRP-confined square concrete columns: Experimental study and model evaluation. Mater. Struct. 2020, 53, 1–20. [Google Scholar] [CrossRef]

- Mukherjee, A.; Boothby, T.E.; Bakis, C.E.; Joshi, M.V.; Maitra, S.R. Mechanical behavior of fiber-reinforced polymer-wrapped concrete columns—Complicating effects. J. Compos. Constr. 2004, 8, 97–103. [Google Scholar] [CrossRef]

- Zou, Y.; Hong, H.P. Reliability assessment of FRP-confined concrete columns designed for buildings. Struct. Infrastruct. Eng. 2011, 7, 243–258. [Google Scholar] [CrossRef]

- Mai, A.D.; Sheikh, M.N.; Hadi, M.N. Performance evaluation of intermittently CFRP wrapped square and circularised square reinforced concrete columns under different loading conditions. Struct. Infrastruct. Eng. 2019, 15, 696–710. [Google Scholar] [CrossRef] [Green Version]

- Algburi, A.H.; Sheikh, M.N.; Hadi, M.N. New technique for strengthening square-reinforced concrete columns by the circularisation with reactive powder concrete and wrapping with fibre-reinforced polymer. Struct. Infrastruct. Eng. 2019, 15, 1392–1403. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhou, C. Analytical model of large-scale circular concrete columns confined by pre-stressed carbon fibre reinforced polymer composites under axial compression. Struct. Infrastruct. Eng. 2021, 17, 1062–1075. [Google Scholar] [CrossRef]

- Shehata, I.A.; Carneiro, L.A.; Shehata, L.C. Strength of short concrete columns confined with CFRP sheets. Mater. Struct. 2020, 35, 50–58. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete in rectangular columns. J. Reinf. Plast. Compos. 2003, 22, 1149–1186. [Google Scholar] [CrossRef]

- Jiang, J.; Li, P.; Nistico, N. Local and global prediction on stress-strain behavior of FRP-confined square concrete sections. Compos. Struct. 2019, 226, 111205. [Google Scholar] [CrossRef]

- Shan, B.; Gui, F.C.; Monti, G.; Xiao, Y. Effectiveness of CFRP confinement and compressive strength of square concrete columns. J. Compos. Constr. 2019, 23, 04019043. [Google Scholar] [CrossRef]

- Boyd, A.J. Rehabilitation of Reinforced Concrete Beams with Sprayed Glass Fiber Reinforced Polymers. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2000. [Google Scholar]

- Hussain, Q.; Pimanmas, A. Shear strengthening of RC deep beams with openings using sprayed glass fiber reinforced polymer composites (SGFRP): Part 1. experimental study. KSCE J. Civ. Eng. 2015, 19, 2121–2133. [Google Scholar] [CrossRef]

- Hussain, Q.; Pimanmas, A. Shear strengthening of RC deep beams with sprayed fibre-reinforced polymer composites (SFRP) and anchoring systems: Part 1. Experimental study. Eur. J. Environ. Civ. Eng. 2016, 20, 79–107. [Google Scholar] [CrossRef]

- Hussain, Q.; Rattanapitikon, W.; Pimanmas, A. Axial load behavior of circular and square concrete columns confined with sprayed fiber-reinforced polymer composites. Polym. Compos. 2016, 37, 2557–2567. [Google Scholar] [CrossRef]

- Wei, Y.Y.; Wu, Y.F. Unified stress–strain model of concrete for FRP-confined columns. Constr. Build. Mater. 2012, 26, 381–392. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Efficacy of bio derived jute FRP composite based technique for shear strength retrofitting of reinforced concrete beams and its comparative analysis with carbon and glass FRP shear retrofitting schemes. Sustain. Cities Soc. 2014, 13, 105–124. [Google Scholar] [CrossRef]

- Pimanmas, A.; Hussain, Q.; Panyasirikhunawut, A.; Rattanapitikon, W. Axial strength and deformability of concrete confined with natural fibre-reinforced polymers. Mag. Concr. Res. 2019, 71, 55–70. [Google Scholar] [CrossRef]

- Sen, T.; Paul, A. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar] [CrossRef] [Green Version]

- Sen, T.; Reddy, H.J. Flexural strengthening of RC beams using natural sisal and artificial carbon and glass fabric reinforced composite system. Sustain. Cities Soc. 2014, 10, 195–206. [Google Scholar] [CrossRef]

- Rousakis, T.C. Hybrid confinement of concrete by fiber-reinforced polymer sheets and fiber ropes under cyclic axial compressive loading. J. Compos. Constr. 2013, 17, 732–743. [Google Scholar] [CrossRef]

- Rousakis, T.C. Elastic fiber ropes of ultrahigh-extension capacity in strengthening of concrete through confinement. J. Mater. Civ. Eng. 2014, 26, 34–44. [Google Scholar] [CrossRef]

- Rousakis, T.C. Reusable and recyclable nonbonded composite tapes and ropes for concrete columns confinement. Compos. Part B Eng. 2016, 103, 15–22. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P. Behavior of concrete confined with epoxy bonded fiber ropes under axial load. Constr. Build. Mater. 2020, 263, 120093. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A. Influence of edge sharpness on the strength of square concrete columns confined with FRP composite laminates. Compos. Part B Eng. 2007, 38, 640–650. [Google Scholar] [CrossRef]

- Wang, L.M.; Wu, Y.F. Effect of corner radius on the performance of CFRP-confined square concrete columns: Test. Eng. Struct. 2008, 30, 493–505. [Google Scholar] [CrossRef]

- Fitzwilliam, J.; Bisby, L.A. Slenderness effects on circular CFRP confined reinforced concrete columns. J. Compos. Constr. 2010, 14, 280–288. [Google Scholar] [CrossRef]

- Na, L.; Yiyan, L.; Shan, L.; Lan, L. Slenderness effects on concrete-filled steel tube columns confined with CFRP. J. Construct. Steel Res. 2018, 143, 110–118. [Google Scholar] [CrossRef]

- ASTM A931-08. Standard Test Method for Tension Testing of Wire Ropes and Strand; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM E8/E8M-13. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Li, P.; Sui, L.; Xing, F.; Li, M.; Zhou, Y.; Wu, Y.F. Stress–strain relation of FRP-confined predamaged concrete prisms with square sections of different corner radii subjected to monotonic axial compression. J. Compos. Constr. 2019, 23, 04019001. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Al-Baali, A.Q.; Hadi, M.N. Compressive behaviour of partially FRP confined concrete: Experimental observations and assessment of the stress-strain models. Constr. Build. Mater. 2018, 192, 785–797. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Sheikh, M.N.; Hadi, M.N. Axial compressive behaviour of concrete confined with polymer grid. Mater. Struct. 2016, 49, 3893–3908. [Google Scholar] [CrossRef]

- Wang, W.; Wu, C.; Liu, Z.; Si, H. Compressive behavior of ultra-high performance fiber-reinforced concrete (UHPFRC) confined with FRP. Compos. Struct. 2018, 204, 419–437. [Google Scholar] [CrossRef]

- Saleem, S.; Hussain, Q.; Pimanmas, A. Compressive behavior of PET FRP–confined circular, square, and rectangular concrete columns. J. Compos. Constr. 2017, 21, 04016097. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T. Behavior of square and rectangular ultra high-strength concrete-filled FRP tubes under axial compression. Compos. Part B Eng. 2013, 54, 97–111. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandtzæg, A.; Brown, R.L. A Study of the Failure of Concrete under Combined Compressive Stresses; University of Illinois at Urbana Champaign, College of Engineering. Engineering Experiment Station: Champaign, IL, USA, 1928. [Google Scholar]

- Benzaid, R.; Mesbah, H.; Chikh, N.E. FRP-confined concrete cylinders: Axial compression experiments and strength model. J. Reinf. Plast. Compos. 2010, 29, 2469–2488. [Google Scholar] [CrossRef]

- ACI. 440.2 R-02: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 1981. [Google Scholar]

- Fardis, M.N.; Khalili, H. Concrete encased in fiberglass-reinforced plastic. J. Proc. 2002, 78, 440–446. [Google Scholar]

- Ilki, A.; Kumbasar, N. Compressive behaviour of carbon fibre composite jacketed concrete with circular and non-circular cross-sections. J. Earthq. Eng. 2003, 7, 381–406. [Google Scholar] [CrossRef]

- Kumutha, R.; Vaidyanathan, R.; Palanichamy, M.S. Behaviour of reinforced concrete rectangular columns strengthened using GFRP. Cem. Concr. Compos. 2007, 29, 609–615. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Strength models for fiber-reinforced plastic-confined concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M.; Samaan, M.; Echary, H.E.; Mastrapa, J.C.; Pico, O. Effect of column parameters on FRP-confined concrete. J. Compos. Constr. 1998, 2, 175–185. [Google Scholar] [CrossRef]

- Wu, Y.F.; Wang, L.M. Unified strength model for square and circular concrete columns confined by external jacket. J. Struct. Eng. 2009, 135, 253–261. [Google Scholar] [CrossRef]

| Group | Concrete Specimen | Corner Radius (Mm) | FRRP Type | Number of FRRP Layers | Number of Specimens |

|---|---|---|---|---|---|

| I | R0-CONT | 0 | - | - | 2 |

| R0-H-1L | 0 | Hemp | 1 | 2 | |

| R0-H-2L | 0 | Hemp | 2 | 2 | |

| R0-H-3L | 0 | Hemp | 3 | 2 | |

| R0-C-1L | 0 | Cotton | 1 | 2 | |

| R0-C-2L | 0 | Cotton | 2 | 2 | |

| R0-C-3L | 0 | Cotton | 3 | 2 | |

| R0-P-1L | 0 | Polyester | 1 | 2 | |

| R0-P-2L | 0 | Polyester | 2 | 2 | |

| R0-P-3L | 0 | Polyester | 3 | 2 | |

| II | R13-CONT | 13 | - | - | 2 |

| R13-H-1L | 13 | Hemp | 1 | 2 | |

| R13-H-2L | 13 | Hemp | 2 | 2 | |

| R13-H-3L | 13 | Hemp | 3 | 2 | |

| R13-C-1L | 13 | Cotton | 1 | 2 | |

| R13-C-2L | 13 | Cotton | 2 | 2 | |

| R13-C-3L | 13 | Cotton | 3 | 2 | |

| R13-P-1L | 13 | Polyester | 1 | 2 | |

| R13-P-2L | 13 | Polyester | 2 | 2 | |

| R13-P-3L | 13 | Polyester | 3 | 2 | |

| III | R26-CONT | 26 | - | - | 2 |

| R26-H-1L | 26 | Hemp | 1 | 2 | |

| R26-H-2L | 26 | Hemp | 2 | 2 | |

| R26-H-3L | 26 | Hemp | 3 | 2 | |

| R26-C-1L | 26 | Cotton | 1 | 2 | |

| R26-C-2L | 26 | Cotton | 2 | 2 | |

| R26-C-3L | 26 | Cotton | 3 | 2 | |

| R26-P-1L | 26 | Polyester | 1 | 2 | |

| R26-P-2L | 26 | Polyester | 2 | 2 | |

| R26-P-3L | 26 | Polyester | 3 | 2 |

| Group | Specimen | fco (MPa) | ffps (MPa) | fmd (MPa) | fus (MPa) | Ɛco | Ɛus | ffps/fco | fmd/ffps | fus/fco | Ɛus/Ɛco | Case |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | R0-CON | 16.1 | - | - | - | 0.0030 | - | - | - | - | - | - |

| R0-H-1L | 16.1 | - | - | 22.0 | 0.0030 | 0.015 | - | - | 1.37 | 4.44 | I | |

| R0-H-2L | 16.1 | - | - | 27.4 | 0.0030 | 0.020 | - | - | 1.70 | 6.14 | I | |

| R0-H-3L | 16.1 | - | - | 33.0 | 0.0030 | 0.024 | - | - | 2.05 | 7.09 | I | |

| R0-C-1L | 16.1 | 19.1 | 9.2 | 9.2 | 0.0030 | 0.047 | 1.19 | 0.48 | 0.57 | 14.10 | IIC | |

| R0-C-2L | 16.1 | 20.3 | 15.0 | 17.8 | 0.0030 | 0.075 | 1.26 | 0.74 | 1.11 | 22.50 | IIB | |

| R0-C-3L | 16.1 | 22.6 | 19.0 | 24.5 | 0.0030 | 0.100 | 1.41 | 0.84 | 1.52 | 30.00 | IIA | |

| R0-P-1L | 16.1 | 21.0 | 7.8 | 7.8 | 0.0030 | 0.079 | 1.30 | 0.37 | 0.48 | 23.76 | IIC | |

| R0-P-2L | 16.1 | 22.9 | 14.3 | 16.1 | 0.0030 | 0.105 | 1.42 | 0.62 | 1.00 | 31.50 | IIC | |

| R0-P-3L | 16.1 | 23.7 | 20.0 | 25.5 | 0.0030 | 0.148 | 1.47 | 0.84 | 1.58 | 44.33 | IIA | |

| II | R13-CON | 15.4 | - | - | - | 0.0029 | - | - | - | - | - | - |

| R13-H-1L | 15.4 | - | - | 24.0 | 0.0029 | 0.016 | - | - | 1.56 | 5.58 | I | |

| R13-H-2L | 15.4 | - | - | 31.6 | 0.0029 | 0.022 | - | - | 2.05 | 7.68 | I | |

| R13-H-3L | 15.4 | - | - | 38.0 | 0.0029 | 0.027 | - | - | 2.47 | 9.53 | I | |

| R13-C-1L | 15.4 | 20.3 | 11.8 | 12.0 | 0.0029 | 0.058 | 1.32 | 0.58 | 0.78 | 20.07 | IIC | |

| R13-C-2L | 15.4 | 22.2 | 17.8 | 20.5 | 0.0029 | 0.090 | 1.44 | 0.80 | 1.33 | 31.41 | IIA | |

| R13-C-3L | 15.4 | 25.0 | 22.3 | 28.8 | 0.0029 | 0.121 | 1.63 | 0.89 | 1.87 | 42.12 | IIA | |

| R13-P-1L | 15.4 | 21.6 | 9.7 | 10.0 | 0.0029 | 0.088 | 1.40 | 0.45 | 0.65 | 30.54 | IIC | |

| R13-P-2L | 15.4 | 25.7 | 18.0 | 19.0 | 0.0029 | 0.110 | 1.67 | 0.70 | 1.23 | 38.39 | IIB | |

| R13-P-3L | 15.4 | 26.5 | 23.5 | 28.0 | 0.0029 | 0.160 | 1.72 | 0.89 | 1.82 | 55.84 | IIA | |

| III | R26-CON | 14.9 | - | - | - | 0.0029 | - | - | - | - | - | - |

| R26-H-1L | 14.9 | - | - | 26.0 | 0.0029 | 0.017 | - | - | 1.74 | 5.82 | I | |

| R26-H-2L | 14.9 | - | - | 34.5 | 0.0029 | 0.023 | - | - | 2.32 | 8.20 | I | |

| R26-H-3L | 14.9 | - | - | 42.0 | 0.0029 | 0.030 | - | - | 2.82 | 10.47 | I | |

| R26-C-1L | 14.9 | 21.4 | 14.0 | 14.5 | 0.0029 | 0.070 | 1.43 | 0.66 | 0.97 | 24.43 | IIC | |

| R26-C-2L | 14.9 | 23.9 | 20.0 | 24.0 | 0.0029 | 0.115 | 1.61 | 0.84 | 1.61 | 40.14 | IIA | |

| R26-C-3L | 14.9 | 27.8 | 26.0 | 35.0 | 0.0029 | 0.160 | 1.87 | 0.93 | 2.35 | 55.84 | IIA | |

| R26-P-1L | 14.9 | 23.0 | 11.5 | 12.2 | 0.0029 | 0.095 | 1.54 | 0.50 | 0.82 | 33.16 | IIC | |

| R26-P-2L | 14.9 | 27.0 | 20.0 | 22.5 | 0.0029 | 0.130 | 1.81 | 0.74 | 1.51 | 45.37 | IIA | |

| R26-P-3L | 14.9 | 30.0 | 27.8 | 34.0 | 0.0029 | 0.180 | 2.01 | 0.93 | 2.28 | 62.83 | IIA |

| Researcher | Ultimate Strength Model | Ultimate Strain Model |

|---|---|---|

| Shehata et al. (2002) [27] | ||

| Ilki and Kumbasar (2003) [60] | ||

| Pimanmas et al. (2019) [37] | ||

| Kumutha et al. (2007) [61] | - | |

| Lam and Teng (2002) [62] | ||

| Al-Salloum (2007) [44] | - | |

| Mirmiran et al. (1998) [63] | - | |

| ACI-440.2 R-02 (2002) [58] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. https://doi.org/10.3390/buildings11080355

Hussain Q, Ruangrassamee A, Tangtermsirikul S, Joyklad P, Wijeyewickrema AC. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings. 2021; 11(8):355. https://doi.org/10.3390/buildings11080355

Chicago/Turabian StyleHussain, Qudeer, Anat Ruangrassamee, Somnuk Tangtermsirikul, Panuwat Joyklad, and Anil C. Wijeyewickrema. 2021. "Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii" Buildings 11, no. 8: 355. https://doi.org/10.3390/buildings11080355

APA StyleHussain, Q., Ruangrassamee, A., Tangtermsirikul, S., Joyklad, P., & Wijeyewickrema, A. C. (2021). Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings, 11(8), 355. https://doi.org/10.3390/buildings11080355