Comparison of Wind Tunnel Test Data for Low-Rise Buildings with Main Wind Force Resisting System Design Procedures

Abstract

1. Introduction

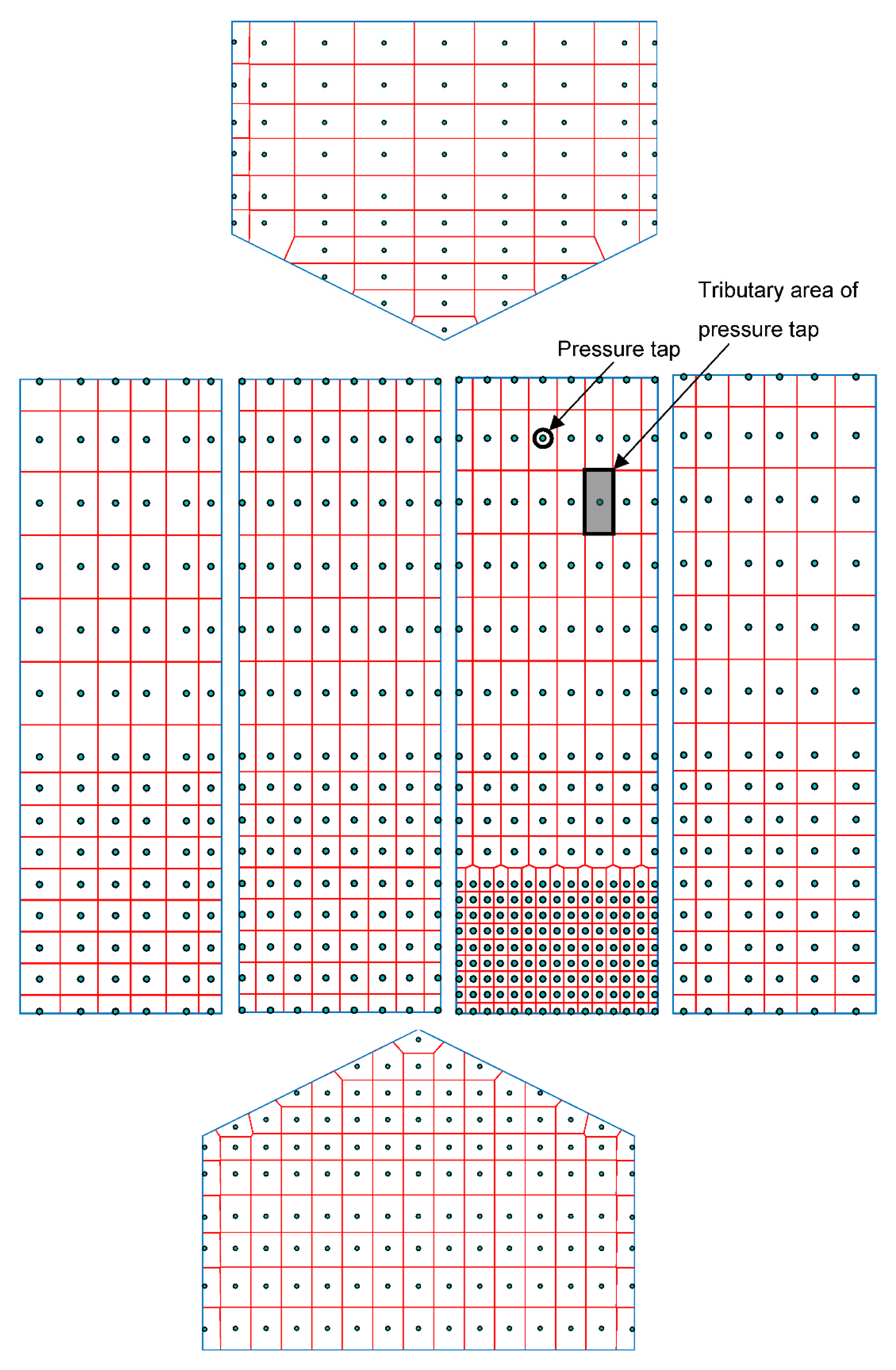

2. Approach

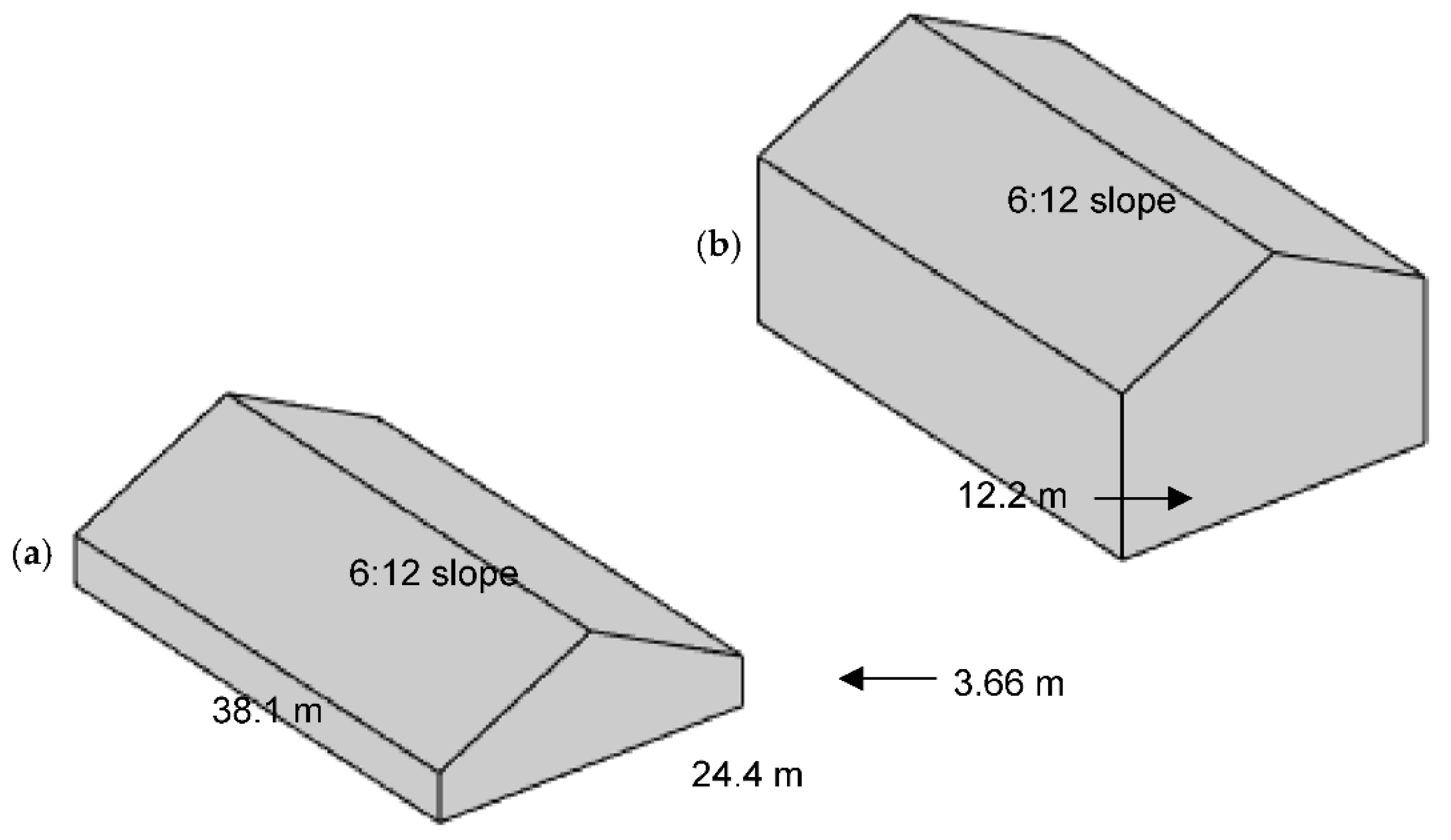

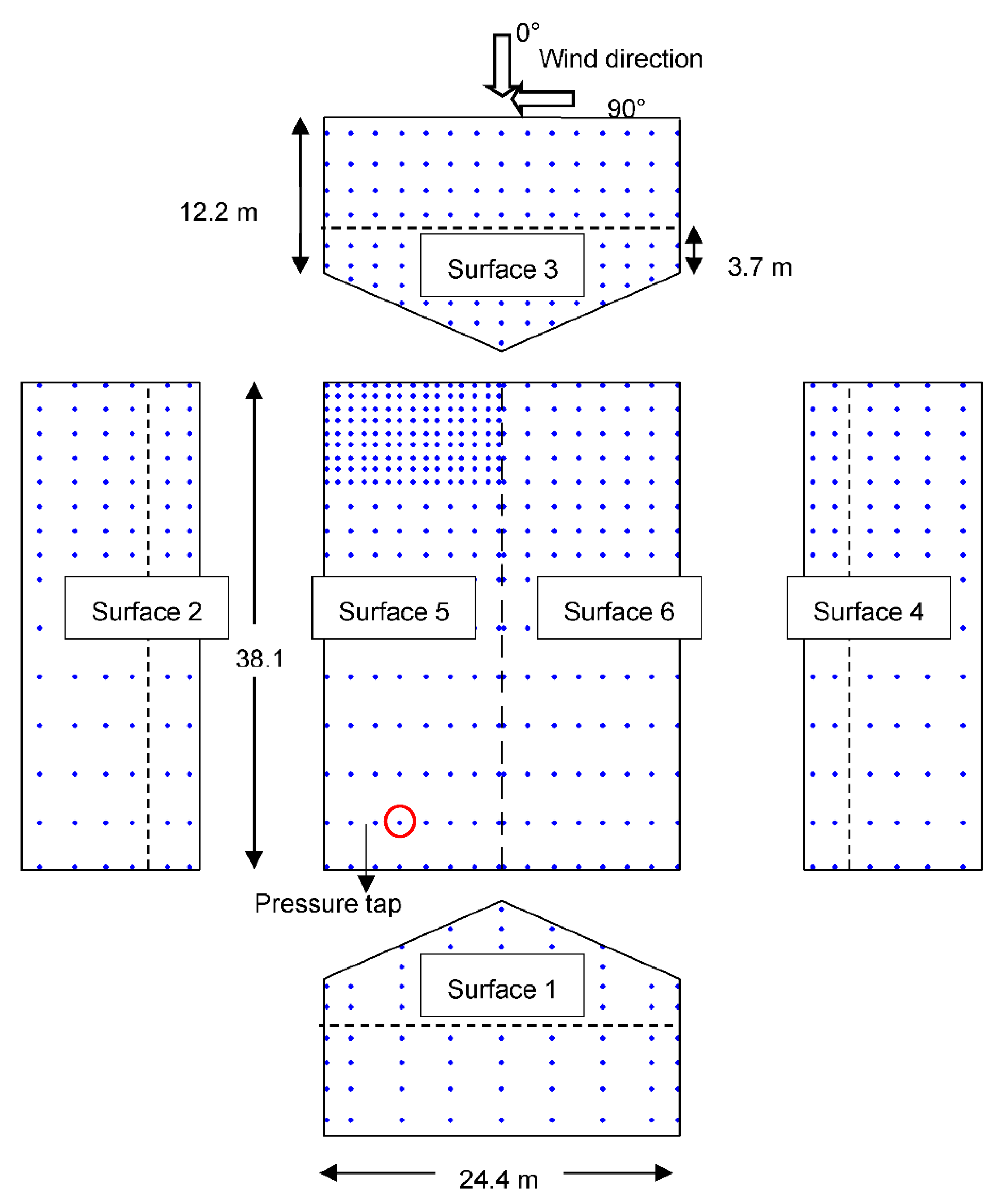

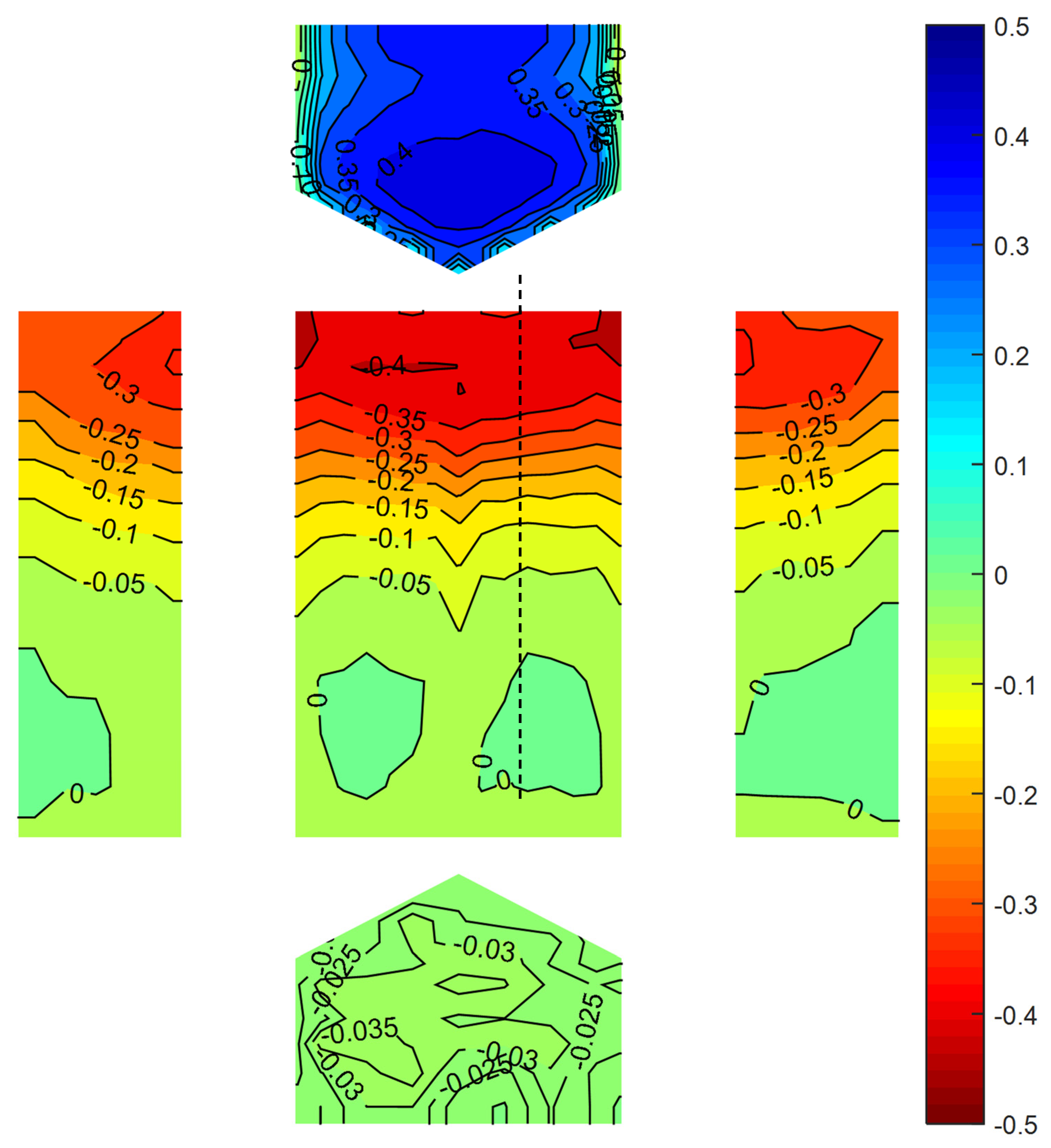

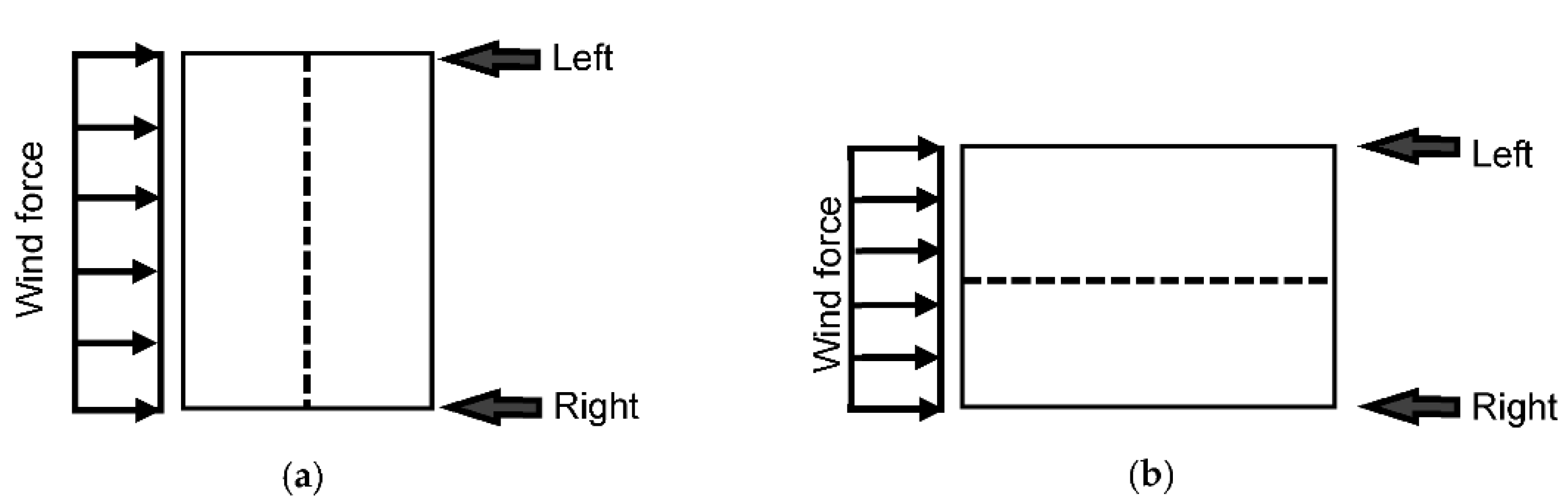

2.1. Building Description

2.2. Design Base Shear

2.3. Base Shear Based on Wind Tunnel Test Data

2.4. Reliability Index

3. Results

3.1. Base Shear

3.2. Reliability Index

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- American Society of Civil Engineers (ASCE). Minimum Design Loads and Associated Criteria for Buildings and Other Structures; ASCE/SEI 7-16: Reston, VA, USA, 2017. [Google Scholar]

- Metal Building Manufacturers Association (MBMA). Metal Building Systems Manual; MBMA: Cleveland, OH, USA, 2018. [Google Scholar]

- Mehta, K.C.; Coulbourne, W.L. Wind Loads: Guide to the Wind Load Provisions of ASCE 7-10; ASCE: Reston, VA, USA, 2013. [Google Scholar]

- He, J.; Pan, F.; Cai, C.S. A review of wood-frame low-rise building performance study under hurricane winds. Eng. Struct. 2017, 141, 512–529. [Google Scholar] [CrossRef]

- American Institute of Steel Construction (AISC). Seismic Design Manual, 3rd ed.; AISC: Chicago, IL, USA, 2018. [Google Scholar]

- Trautner, C.A.; Ojdrovic, R.P. Comparison of directional and envelope wind load provisions of ASCE 7. J. Struct. Eng. 2014, 140, 04013100. [Google Scholar] [CrossRef]

- He, J.; Pan, F.; Cai, C.S. Assessment of ASCE 7-10 for wind effects on low-rise wood frame buildings with database-assisted design methodology. Wind Struct. 2018, 27, 163–173. [Google Scholar]

- American Society of Civil Engineers. Minimum Design Loads for Buildings and Other Structures; ASCE/SEI 7-10: Reston, VA, USA, 2010. [Google Scholar]

- Ho, T.C.E.; Surry, D.; Morrish, D.; Kopp, G.A. The UWO contribution to the NIST aerodynamic database for wind loads on low buildings: Part 1. Archiving format and basic aerodynamic data. J. Wind Eng. Ind. Aerodyn. 2005, 93, 1–30. [Google Scholar] [CrossRef]

- Ho, T.C.E.; Surry, D.; Morrish, D.P. NIST/TTU Cooperative Agreement-Windstorm Mitigation Initiative: Wind Tunnel Experiments on Generic Low Buildings; BLWT-SS20-2003; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2003. [Google Scholar]

- Ho, T.C.E.; Surry, D.; Nywening, M. NIST/TTU Cooperative Agreement-Windstorm Mitigation Initiative: Further Experiments on Generic Low Buildings; BLWT-SS21-2003; NIST: Gaithersburg, MD, USA, 2003. [Google Scholar]

- St. Pierre, L.M.; Kopp, G.A.; Surry, D.; Ho, T.C.E. The UWO contribution to the NIST aerodynamic database for wind loads on low buildings: Part 2. Comparison of data with wind load provisions. J. Wind Eng. Ind. Aerodyn. 2005, 93, 31–59. [Google Scholar] [CrossRef]

- Coffman, B.F.; Main, J.A.; Duthinh, D.; Simiu, E. Wind effects on low-rise metal buildings: Database-assisted design versus ASCE 7-05 standard estimates. J. Struct. Eng. 2010, 136, 744–748. [Google Scholar] [CrossRef]

- Habte, F.; Chowdhury, A.G.; Yeo, D.; Simiu, E. Design of rigid structures for wind using time series of demand-to-capacity indexes: Application to steel portal frames. Eng. Struct. 2017, 132, 428–442. [Google Scholar] [CrossRef][Green Version]

- Davenport, A.G.; Surry, D.; Stathopoulos, T. Wind Loads on Low-Rise Buildings; Final Report on Phase III, BLWT-SS4; University of Western Ontario: London, ON, Canada, 1978. [Google Scholar]

- Simiu, E.; Letchford, C.; Isyumov, N.; Chowdhury, A.G.; Yeo, D. Assessment of ASCE 7-10 standard methods for determining wind loads. J. Struct. Eng. 2013, 139, 2044–2047. [Google Scholar] [CrossRef][Green Version]

- Wang, J.; Kopp, G.A. Comparisons of aerodynamic data with the main wind force–resisting system provisions of ASCE 7-16. I: Low-rise buildings. J. Struct. Eng. 2021, 147, 04020347. [Google Scholar] [CrossRef]

- Kopp, G.A.; Morrison, M.J. Component and cladding wind loads for low-slope roofs on low-rise buildings. J. Struct. Eng. 2018, 144, 04018019. [Google Scholar] [CrossRef]

- Hoq, S.M.A.; Judd, J.P. Negative external pressure coefficients for design of components and cladding of low-rise buildings with steep-slope gable roofs. J. Aerosp. Eng. 2021, 34, 04020095. [Google Scholar] [CrossRef]

- Hamburger, R.O. How You Can Help ICC Adoption of ASCE 7-16. In Structures Magazine; National Council of Structural Engineers Associations: Chicago, IL, USA, 2016. [Google Scholar]

- DeStefano, J. ASCE 7-16 Controversy. In Structures Magazine; National Council of Structural Engineers Associations: Chicago, IL, USA, 2017. [Google Scholar]

- Gavanski, E.; Kordi, B.; Kopp, G.A.; Vickery, P.J. Wind loads on roof sheathing of houses. J. Wind Eng. Ind. Aerodyn. 2013, 114, 106–121. [Google Scholar] [CrossRef]

- Pfretzschner, K.S.; Gupta, R.; Miller, T.H. Practical modeling for wind load paths in a realistic light-frame wood house. J. Perform. Construct. Facil. 2013, 28, 430–439. [Google Scholar] [CrossRef]

- Allen, T.M.; Nowak, A.S.; Bathurst, R.J. Calibration to Determine Load and Resistance Factors for Geotechnical and Structural Design, Transportation Research E-Circular E-C079; Transportation Research Board: Washington, DC, USA, 2005. [Google Scholar]

- Nowak, A.S.; Collins, K.R. Reliability of Structures; Taylor and Francis, CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Ellingwood, B.R.; Galambos, T.V.; MacGregor, J.G.; Cornell, C.A. Development of a Probability Based Load Criterion for American National Standard A58: Building Code Requirements for Minimum Design Loads in Buildings and Other Structures (Vol. 13); United States Department of Commerce; National Bureau of Standards: Washington DC, USA, 1980.

- Galambos, T.V.; Ellingwood, B.R.; MacGregor, J.G.; Cornell, C.A. Probability based load criteria: Assessment of current design practice. J. Struct. Div. 1982, 108, 959–977. [Google Scholar] [CrossRef]

- American Wood Council (AWC). Special Design Provisions for Wind and Seismic with Commentary; AWC: Leesburg, VA, USA, 2015. [Google Scholar]

- van de Lindt, J.W.; Huart, J.N.; Rosowsky, D.V. Strength-based seismic reliability of wood shear walls designed according to AF&PA/ASCE 16. J. Struct. Eng. 2005, 131, 1307–1312. [Google Scholar]

- Seaders, P. Performance of Partially and Fully Anchored Wood Frame Shear Walls Under Monotonic, Cyclic and Earthquake Loads. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2004. [Google Scholar]

- Ellingwood, B.R.; Rosowsky, D.V.; Li, Y.; Kim, J.H. Fragility assessment of light-frame wood construction subjected to wind and earthquake hazards. J. Struct. Eng. 2004, 130, 1921–1930. [Google Scholar] [CrossRef]

- van de Lindt, J.W.; Dao, T.N. Performance-based wind engineering for wood-frame buildings. J. Struct. Eng. 2009, 135, 169–177. [Google Scholar] [CrossRef]

- van de Lindt, J.W.; Walz, M.A. Development and application of wood shear wall reliability model. J. Struct. Eng. 2003, 129, 405–413. [Google Scholar] [CrossRef]

- Standohar-Alfano, C.D.; van de Lindt, J.W.; Ellingwood, B.R. Vertical load path failure risk analysis of residential wood-frame construction in tornadoes. J. Struct. Eng. 2017, 143, 04017045. [Google Scholar] [CrossRef]

- Peng, X.; Yang, L.; Gavanski, E.; Gurley, K.; Prevatt, D. A comparison of methods to estimate peak wind loads on buildings. J. Wind Eng. Ind. Aerodyn. 2014, 126, 11–23. [Google Scholar] [CrossRef]

- Gavanski, E.; Gurley, K.R.; Kopp, G.A. Uncertainties in the estimation of local peak pressures on low-rise buildings by using the Gumbel distribution fitting approach. J. Struct. Eng. 2016, 142, 04016106. [Google Scholar] [CrossRef]

| Story | 2-Story Residential Building 1 | 4-Story Office Building 2 | ||

|---|---|---|---|---|

| NS Direction | EW Direction | NS Direction | EW Direction | |

| 3 | -- | -- | 1.62 | 1.51 |

| 2 | 1.16 | 1.27 | 1.54 | 1.43 |

| 1 | 1.08 | 0.94 | 1.54 | 1.43 |

| Wind Direction | MWFRS Orientation | Reaction Force | MWFRS Procedure | |||

|---|---|---|---|---|---|---|

| Directional | Envelope | |||||

| Eave Height | ||||||

| 3.7 m | 12.2 m | 3.7 m | 12.2 m | |||

Normal to Ridge (90°) | Normal to Ridge | Total | 273 | 513 | 166 | 405 |

| Left | 137 | 257 | 80.6 | 195 | ||

| Right 1 | 137 | 257 | 85.0 | 209 | ||

Oblique (45°) | Normal to Ridge | Total | 205 | 385 | -- | -- |

| Left | 103 | 192 | -- | -- | ||

| Right 1 | 103 | 192 | -- | -- | ||

| Parallel to Ridge | Total | 96.1 | 211 | -- | -- | |

| Left 1 | 48.1 | 105 | -- | -- | ||

| Right | 48.1 | 105 | -- | -- | ||

Parallel to Ridge (0°) | Parallel to Ridge | Total | 128 | 281 | 92.5 | 208 |

| Left 1 | 64.1 | 141 | 47.3 | 108 | ||

| Right | 64.1 | 141 | 45.0 | 100 | ||

| Wind Direction | MWFRS Orientation | Reaction Force | Eave Height | |||

|---|---|---|---|---|---|---|

| 3.7 m | 12.2 m | |||||

Normal to Ridge (90°) | Normal to Ridge | Total | 104 | 25.8 | 212 | 56.4 |

| Left | 51.9 | 14.4 | 106 | 30.6 | ||

| Right | 52.7 | 14.6 | 108 | 31.1 | ||

| Parallel to Ridge | ||||||

Oblique (45°) | Normal to Ridge | Total | 100 | 30.5 | 219 | 59.3 |

| Left | 36.2 | 12.9 | 85.8 | 25.7 | ||

| Right | 64.4 | 19.4 | 135 | 36.5 | ||

| Parallel to Ridge | Total | 37.2 | 11.1 | 98.4 | 30.2 | |

| Left | 24.8 | 7.50 | 61.9 | 19.3 | ||

| Right | 12.5 | 4.60 | 36.4 | 12.4 | ||

Parallel to Ridge (0°) | Normal to Ridge | |||||

| Parallel to Ridge | Total | 47.6 | 15.1 | 125 | 36.1 | |

| Left | 23.9 | 8.30 | 62.7 | 19.7 | ||

| Right | 23.7 | 8.30 | 61.9 | 19.3 | ||

| Wind Direction | MWFRS Orientation | Base Shear | Directional | Envelope | ||

|---|---|---|---|---|---|---|

| Eave Height | ||||||

| 3.7 m | 12.2 m | 3.7 m | 12.2 m | |||

| Low Variability in MWFRS Capacity | ||||||

Normal to Ridge (90°) | Normal to Ridge | Total | 4.97 | 4.42 | 2.47 | 3.25 |

| Left R. | 4.73 | 4.25 | 2.42 | 3.26 | ||

| Right R. | 4.65 | 4.15 | 2.35 | 3.17 | ||

Oblique (45°) | Normal to Ridge | Total | 4.68 | 4.22 | 2.31 | 3.05 |

| Left R. | 5.76 | 5.14 | 3.35 | 3.85 | ||

| Right R. | 3.50 | 3.20 | 1.35 | 2.22 | ||

| Parallel to Ridge | Total | 5.79 | 4.88 | 4.29 | 3.45 | |

| Left R. | 4.45 | 3.75 | 2.99 | 2.50 | ||

| Right R. | 6.88 | 5.97 | 5.47 | 4.46 | ||

Parallel to Ridge (0°) | Parallel to Ridge | Total | 4.53 | 3.88 | 2.98 | 2.44 |

| Left R. | 4.29 | 3.67 | 2.88 | 2.43 | ||

| Right R. | 4.30 | 3.75 | 2.89 | 2.50 | ||

| High Variability in MWFRS Capacity | ||||||

Normal to Ridge (90°) | Normal to Ridge | Total | 2.67 | 2.60 | 2.21 | 2.40 |

| Left R. | 2.66 | 2.60 | 2.23 | 2.42 | ||

| Right R. | 2.65 | 2.58 | 2.21 | 2.40 | ||

Oblique (45°) | Normal to Ridge | Total | 2.68 | 2.57 | 2.22 | 2.36 |

| Left R. | 2.86 | 2.74 | 2.50 | 2.54 | ||

| Right R. | 2.48 | 2.39 | 1.93 | 2.17 | ||

| Parallel to Ridge | Total | 2.82 | 2.71 | 2.61 | 2.48 | |

| Left R. | 2.64 | 2.53 | 2.38 | 2.28 | ||

| Right R. | 2.99 | 2.87 | 2.83 | 2.67 | ||

Parallel to Ridge (0°) | Parallel to Ridge | Total | 2.66 | 2.54 | 2.39 | 2.24 |

| Left R. | 2.65 | 2.52 | 2.39 | 2.26 | ||

| Right R. | 2.66 | 2.53 | 2.40 | 2.28 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoq, S.M.A.; Judd, J.P. Comparison of Wind Tunnel Test Data for Low-Rise Buildings with Main Wind Force Resisting System Design Procedures. Buildings 2021, 11, 342. https://doi.org/10.3390/buildings11080342

Hoq SMA, Judd JP. Comparison of Wind Tunnel Test Data for Low-Rise Buildings with Main Wind Force Resisting System Design Procedures. Buildings. 2021; 11(8):342. https://doi.org/10.3390/buildings11080342

Chicago/Turabian StyleHoq, S. M. Ashfaqul, and Johnn P. Judd. 2021. "Comparison of Wind Tunnel Test Data for Low-Rise Buildings with Main Wind Force Resisting System Design Procedures" Buildings 11, no. 8: 342. https://doi.org/10.3390/buildings11080342

APA StyleHoq, S. M. A., & Judd, J. P. (2021). Comparison of Wind Tunnel Test Data for Low-Rise Buildings with Main Wind Force Resisting System Design Procedures. Buildings, 11(8), 342. https://doi.org/10.3390/buildings11080342