Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment

Abstract

1. Introduction

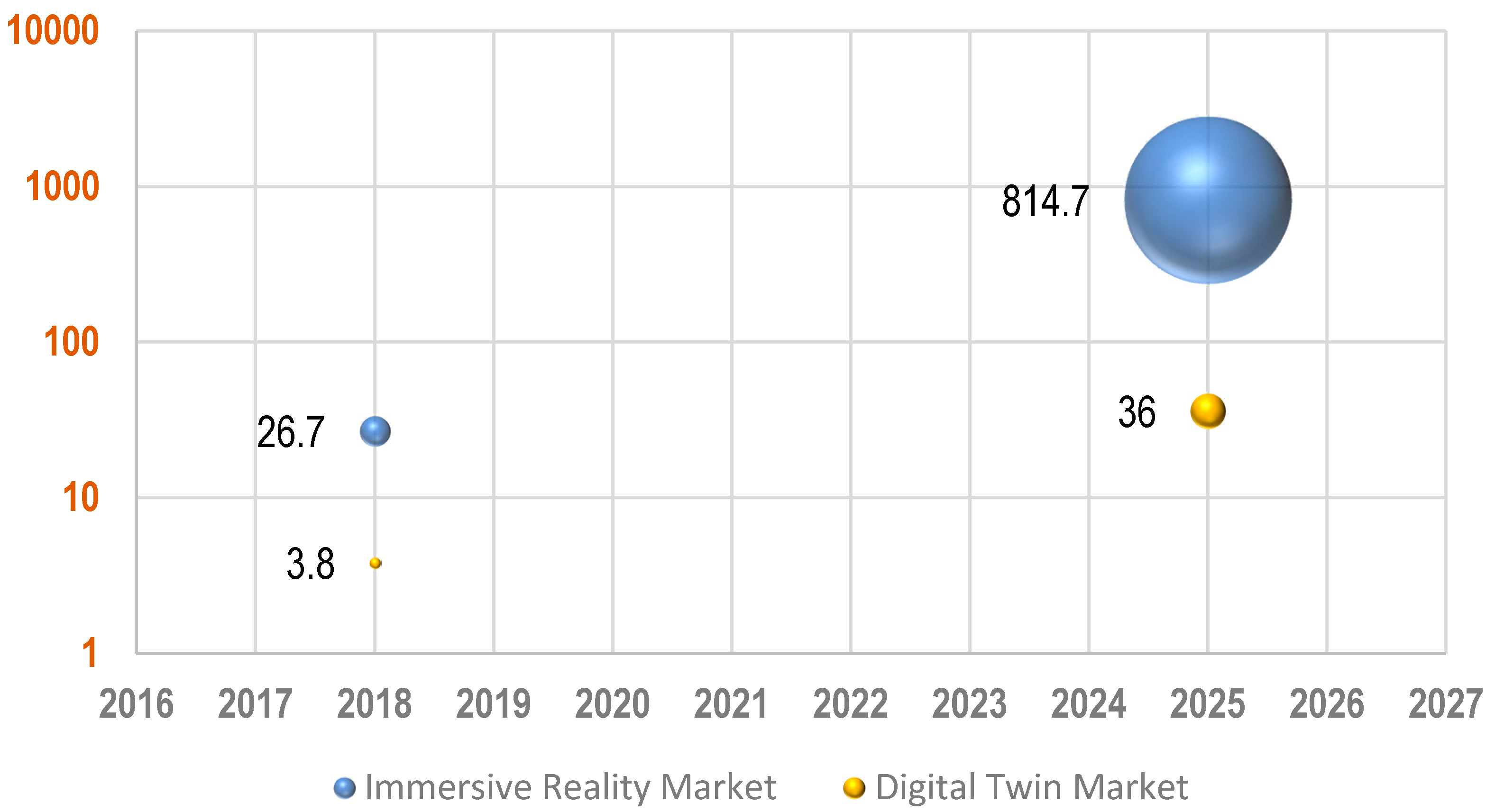

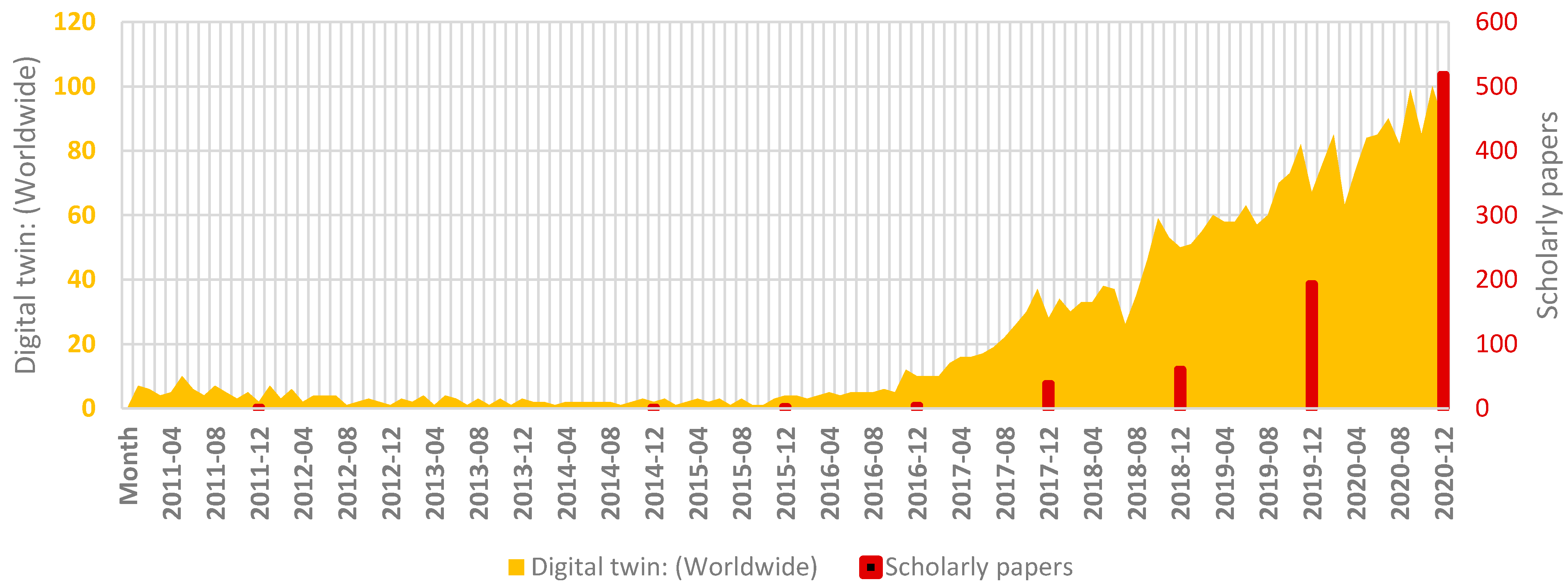

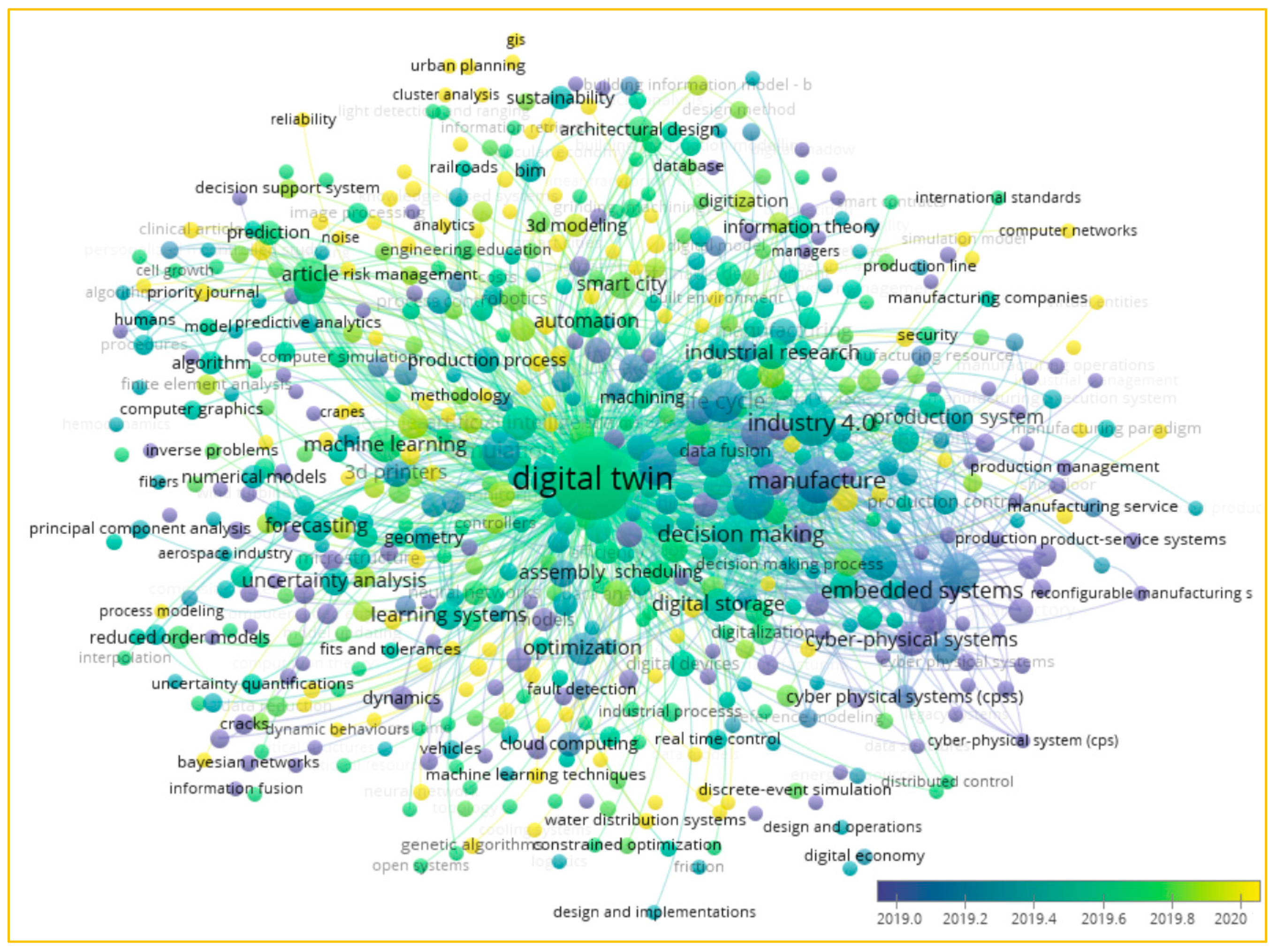

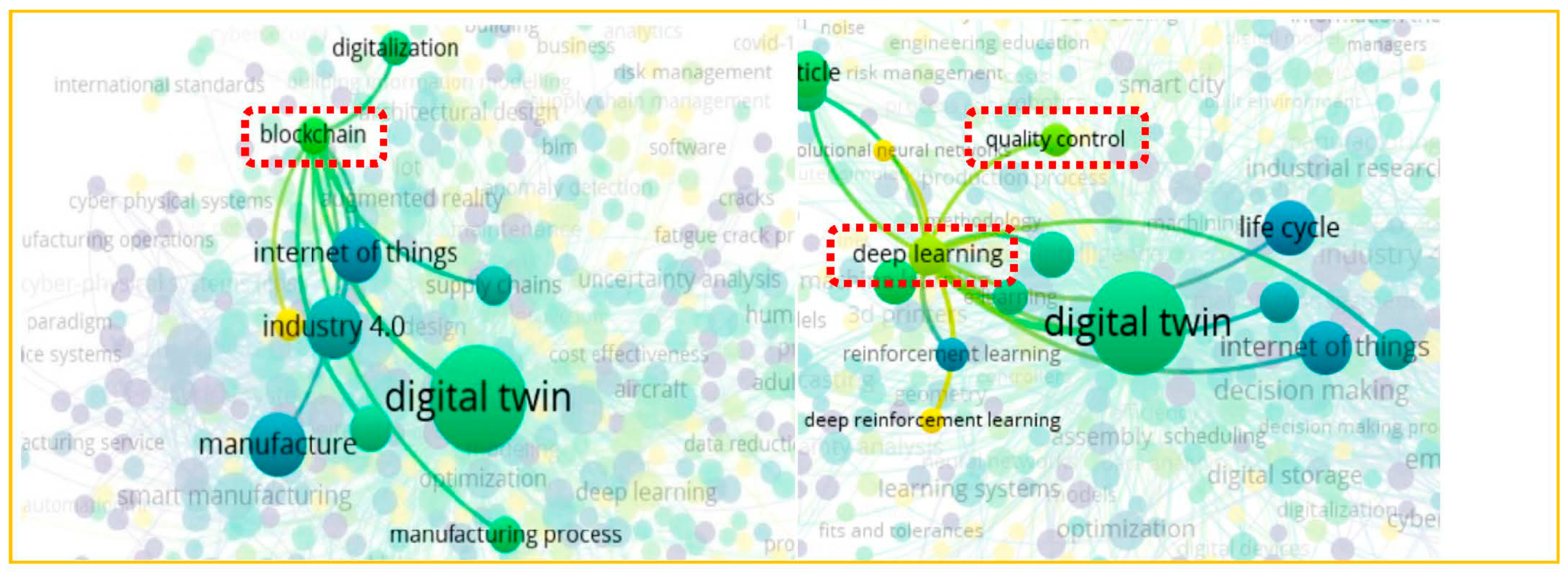

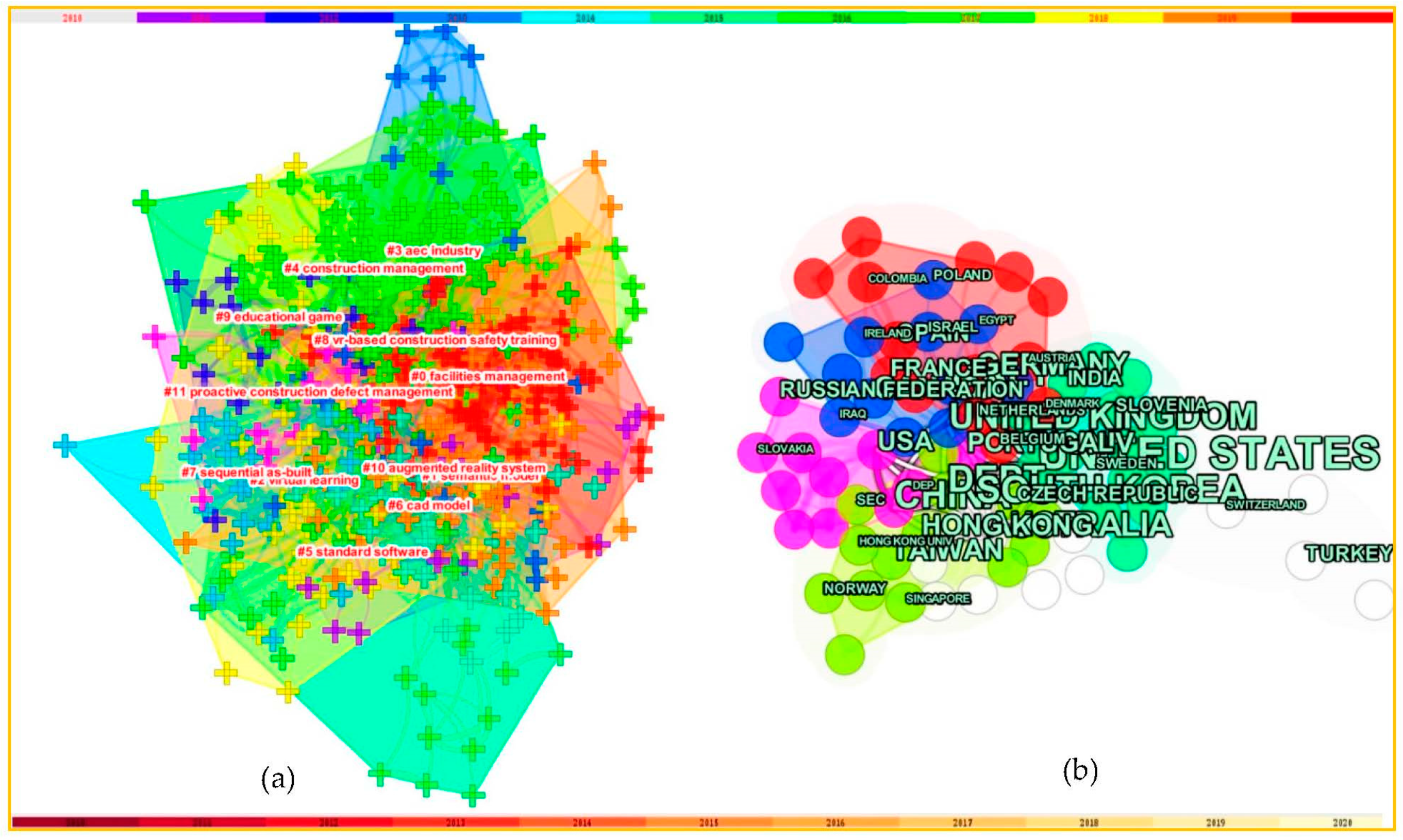

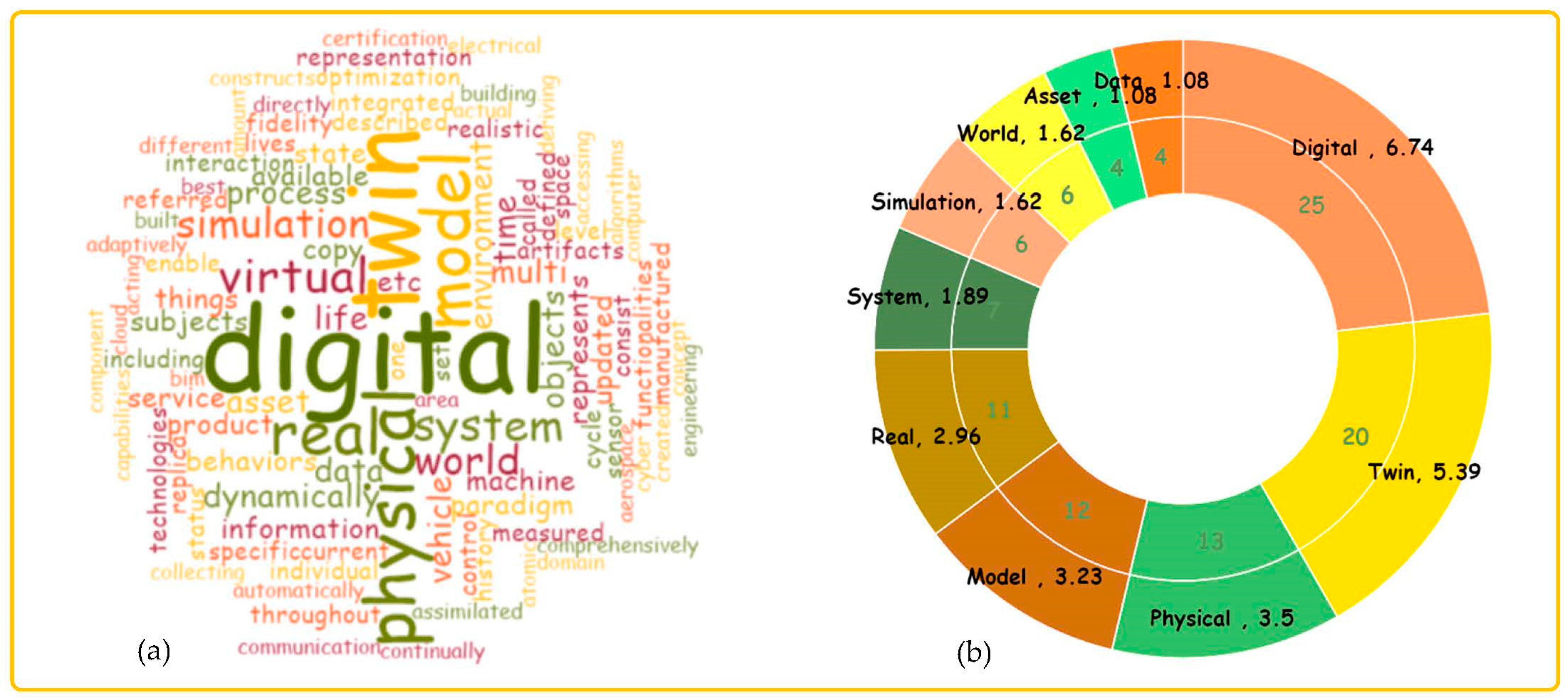

2. Scientometric Analysis and Trends

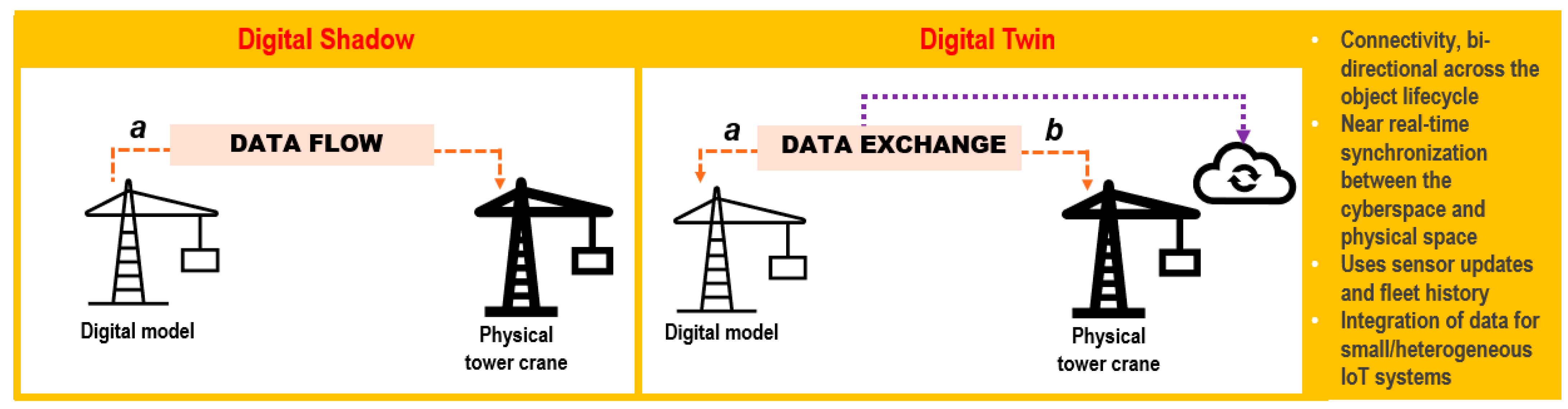

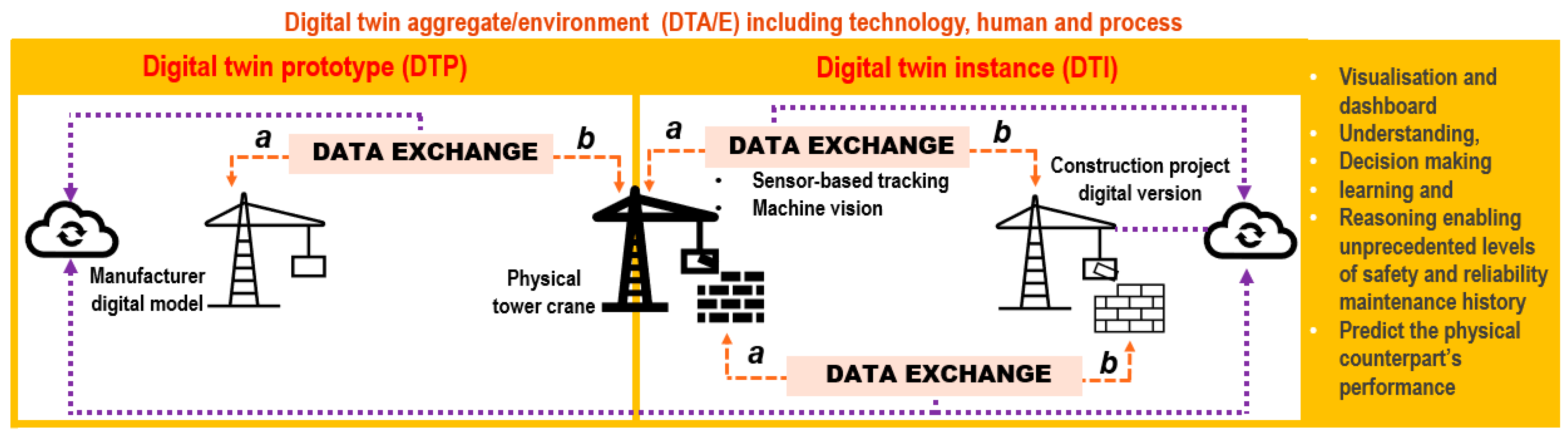

3. Distinction between Digital Shadow and Digital Twin

4. State of Play and an Agenda for Future

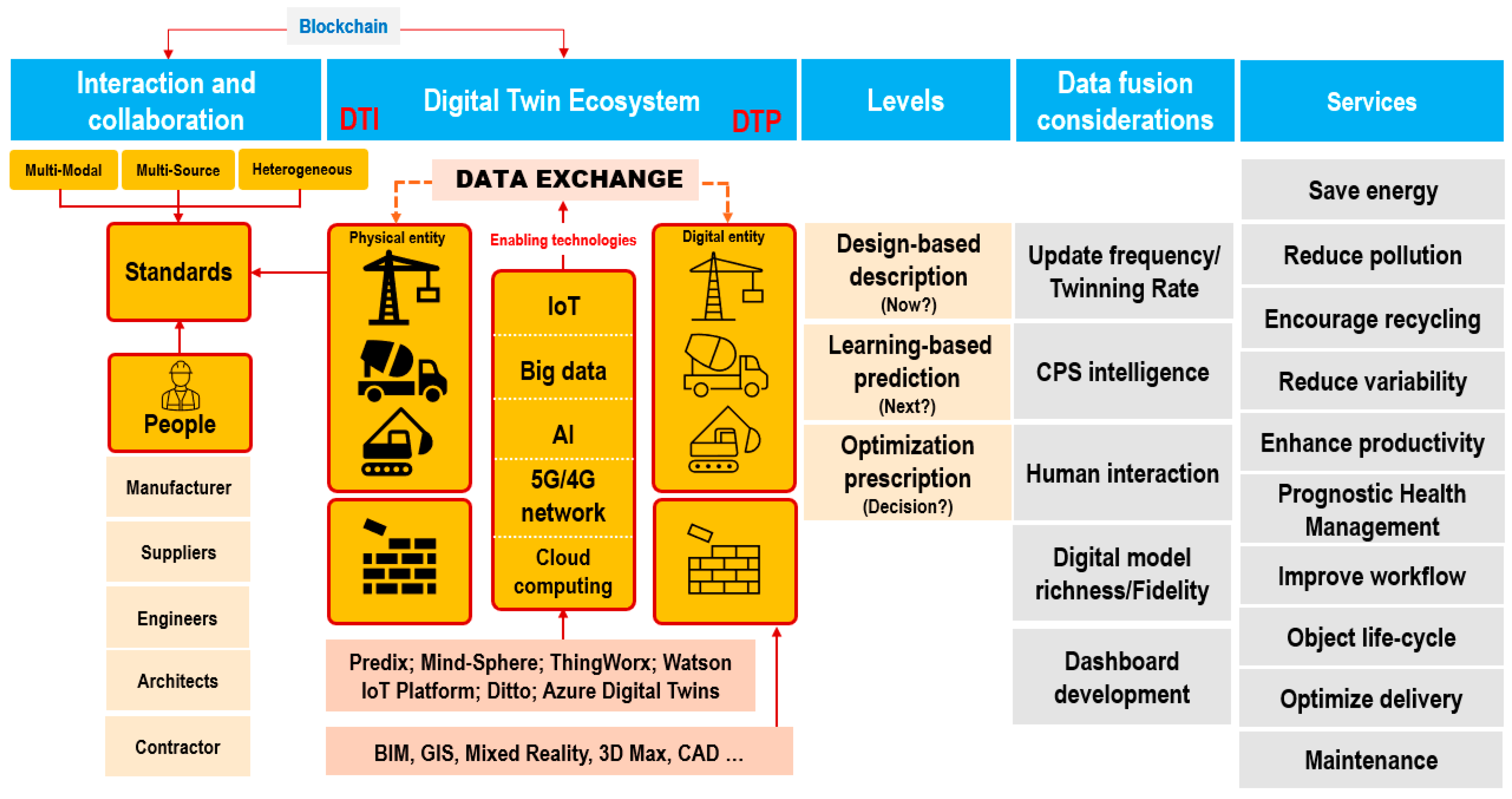

- communication or wireless technologies used for DT, such as the fourth/fifth-generation cellular network (4/5G), NB-IoT, Sigfox, Bluetooth, LoRaWAN, ZigBee, Z-Wave, GSM, 802.11 ah, 802.11 n, LTE-M, BLE, and WirelessHART [35];

- layer protocols applications used for DT, such as HTTP, MQTT, mDNS, CoAP, XMPP, DDS, AMQP, and OPC UA [35];

- recent platforms such as Predix (GE Digital) for data analytics and industrial monitoring; MindSphere (Siemens) for storing operational data; ThingWorx; Watson IoT Platform; Ditto; Azure Digital Twins [85];

- (a)

- Future directions on enabling technologies for modeling and simulation should address the following:

- How different virtual entities or systems, including BIM (e.g., 6D BIM) and GIS, can be integrated with a two-way conversation between them in a project ecosystem that considers all stakeholders (Lack of a common framework for creating digital twin models should be addressed).

- How simulation and optimisation can be done in near real-time.

- (b)

- Future directions on data fusion and integration should address the following:

- How intelligence-enabling technologies (e.g., IoT, CPS, DT, big data analytics) can be integrated to improve smart construction processes or smart cities by automating motion data collection. How virtual and real fusion optimisation processes can be improved with regard to digital mode richness.

- How the combinations of mechanisms, accuracy, quality, and real-time optimisation of data analysis can be improved.

- (c)

- Future directions on interaction and collaboration can address the following:

- How the generated data and digital entity can be shared among various untrusted stakeholders or sub-contractors during a project’s life cycle, considering human interactions (e.g., different types of human–machine, machine–machine, and human–computer–machine interactions).

- How cyber-physical systems (CPS) can be used to develop a self-organising system for different tasks by utilising intelligence-based mechanisms that enable decentralisation and collaboration.

- (d)

- Future directions on DT service and implementation can address the following:

- Technical or managerial barriers and potential solutions to successfully implement a DT in a company. The extent to which companies different in size (e.g., small, medium-sized, and large) are ready to apply innovative DTs for various operational or managerial tasks.

- How the DT and data ownership, privacy, level of accessibility by each stakeholder, and security issues can be resolved using blockchain or other approaches.

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hotový, M. Dynamic model of implementation efficiency of Building Information Modelling (BIM) in relation to the complexity of buildings and the level of their safety. In Proceedings of the MATEC Web of Conferences, Les Ulis, France, 22 January 2018; p. 01010. [Google Scholar]

- Starr, C.W.; Saginor, J.; Worzala, E. The rise of PropTech: Emerging industrial technologies and their impact on real estate. J. Prop. Invest. Financ. 2020, 39. [Google Scholar] [CrossRef]

- García de Soto, B.; Agustí-Juan, I.; Joss, S.; Hunhevicz, J. Implications of Construction 4.0 to the workforce and organizational structures. Int. J. Constr. Manag. 2019, 1–13. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.O.; Oke, A.E.; Liphadzi, M. Appraisal of stakeholders’ willingness to adopt construction 4.0 technologies for construction projects. Built Environ. Proj. Asset Manag. 2020, 10, 547–565. [Google Scholar] [CrossRef]

- Boton, C.; Rivest, L.; Ghnaya, O.; Chouchen, M. What is at the Root of Construction 4.0: A systematic review of the recent research effort. Arch. Comput. Methods Eng. 2020, 1–20. [Google Scholar] [CrossRef]

- Sepasgozar, S.M. Digital technology utilisation decisions for facilitating the implementation of Industry 4.0 technologies. Constr. Innov. 2020. [Google Scholar] [CrossRef]

- Lööw, J.; Abrahamsson, L.; Johansson, J. Mining 4.0—The impact of new technology from a work place perspective. Min. Metall. Explor. 2019, 36, 701–707. [Google Scholar] [CrossRef]

- Faz-Mendoza, A.; Gamboa-Rosales, N.; Medina-Rodríguez, C.; Casas-Valadez, M.; Castorena-Robles, A.; López-Robles, J. Intelligent processes in the context of Mining 4.0: Trends, research challenges and opportunities. In Proceedings of the 2020 International Conference on Decision Aid Sciences and Application (DASA), Sakheer, Kingdom of Bahrain, 8–9 November 2020; pp. 480–484. [Google Scholar]

- Ciolacu, M.; Tehrani, A.F.; Beer, R.; Popp, H. Education 4.0—Fostering student’s performance with machine learning methods. In Proceedings of the 2017 IEEE 23rd International Symposium for Design and Technology in Electronic Packaging (SIITME), Constanta, Romania, 26–29 October 2017; pp. 438–443. [Google Scholar]

- Ramirez-Mendoza, R.A.; Morales-Menendez, R.; Iqbal, H.; Parra-Saldivar, R. Engineering Education 4.0: Proposal for a new Curricula. In Proceedings of the 2018 IEEE Global Engineering Education Conference (EDUCON), Canary Islands, Spain, 18–20 April 2018; pp. 1273–1282. [Google Scholar]

- Hussin, A.A. Education 4.0 made simple: Ideas for teaching. Int. J. Educ. Lit. Stud. 2018, 6, 92–98. [Google Scholar] [CrossRef]

- Lin, W.; Low, Y.; Chong, Y.; Teo, C. Integrated cyber physical simulation modelling environment for manufacturing 4.0. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1861–1865. [Google Scholar]

- Caiado, R.G.G.; Scavarda, L.F.; de Mattos Nascimento, D.L.; Ivson, P.; Cunha, V.H.C. A Maturity Model for Manufacturing 4.0 in Emerging Countries. In Proceedings of the International Conference on Production and Operations Management Society, Operations Management for Social Good, Rio de Janiero, Brazil, 10–12 December 2012; p. 393. [Google Scholar]

- Hernandez, J.D.; Cespedes, E.S.; Gutierrez, D.A.; Sanchez-Londoño, D.; Barbieri, G.; Abolghasem, S.; Romero, D.; Fumagalli, L. Human-Computer-Machine Interaction for the Supervision of Flexible Manufacturing Systems: A Case Study. In Proceedings of the 21st IFAC (International Federation of Automatic Control) World Congress 2020, Berlin, Germany, 12–17 July 2020. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Arditi, D.; Kale, S.; Tangkar, M. Innovation in Construction Equipment and Its Flow into the Construction Industry. J. Constr. Eng. Manag. 1997, 123, 371–378. [Google Scholar] [CrossRef]

- Skibniewski, M.J.; Zavadskas, E.K. Technology Development in Construction: A Continuum From Distant Past into the Future. J. Civ. Eng. Manag. 2013, 19, 136–147. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Loosemore, M.; Davis, S.R. Conceptualising information and equipment technology adoption in construction A critical review of existing research. Eng. Constr. Archit. Manag. 2016, 23, 158–176. [Google Scholar] [CrossRef]

- MacKenzie, D.; Wajcman, J. The Social Shaping of Technology; Open University Press: Buckingham, UK, 1999. [Google Scholar]

- Bijker, W.E. How Is Technology Made?—That Is the Question! Camb. J. Econ. 2010, 34, 63–76. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Davis, S. Construction Technology Adoption Cube: An Investigation on Process, Factors, Barriers, Drivers and Decision Makers Using NVivo and AHP Analysis. Buildings 2018, 8, 74. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Davis, S. Digital Construction Technology and Job-site Equipment Demonstration: Modelling Relationship Strategies for Technology Adoption. Buildings 2019, 9, 158. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, H.; Liu, X.; Tian, G.; Wu, M.; Cao, L.; Wang, W. Dynamic evaluation method of machining process planning based on digital twin. IEEE Access 2019, 7, 19312–19323. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H.; Ding, X.; Liu, S.; Weng, G. Connotation, architecture and trends of product digital twin. Comput. Integr. Manuf. Syst. 2017, 23, 753–768. [Google Scholar]

- Wang, K.-J.; Lee, T.-L.; Hsu, Y. Revolution on digital twin technology—A patent research approach. Int. J. Adv. Manuf. Technol. 2020, 107, 4687–4704. [Google Scholar] [CrossRef]

- Halenar, I.; Juhas, M.; Juhasova, B.; Borkin, D. Virtualization of production using digital twin technology. In Proceedings of the 2019 20th International Carpathian Control Conference (ICCC), Kraków-Wieliczka, Poland, 26–29 May 2019; pp. 1–5. [Google Scholar]

- Kong, T.; Hu, T.; Zhou, T.; Ye, Y. Data construction method for the applications of workshop digital twin system. J. Manuf. Syst. 2021, 58, 323–328. [Google Scholar] [CrossRef]

- Haag, S.; Anderl, R. Digital twin–Proof of concept. Manuf. Lett. 2018, 15, 64–66. [Google Scholar] [CrossRef]

- He, B.; Cao, X.; Hua, Y. Data fusion-based sustainable digital twin system of intelligent detection robotics. J. Clean. Prod. 2021, 280, 124181. [Google Scholar] [CrossRef]

- Liu, L.; Du, H.; Wang, H.; LIU, T. Construction and application of digital twin system for production process in workshop. Comput. Integr. Manuf. Syst. 2019, 25, 1536–1545. [Google Scholar]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. A reconfigurable modeling approach for digital twin-based manufacturing system. Procedia CIRP 2019, 83, 118–125. [Google Scholar] [CrossRef]

- Vachálek, J.; Bartalský, L.; Rovný, O.; Šišmišová, D.; Morháč, M.; Lokšík, M. The digital twin of an industrial production line within the industry 4.0 concept. In Proceedings of the 2017 21st International Conference on Process Control (PC), Štrbské Pleso, Slovakia, 6–9 June 2017; pp. 258–262. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Susila, N.; Sruthi, A.; Usha, S. Impact of cloud security in digital twin. In Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2020; Volume 117, pp. 247–263. [Google Scholar]

- Augustine, P. The industry use cases for the digital twin idea. In Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2020; Volume 117, pp. 79–105. [Google Scholar]

- Wang, P.; Yang, M.; Peng, Y.; Zhu, J.; Ju, R.; Yin, Q. Sensor control in anti-submarine warfare—A digital twin and random finite sets based approach. Entropy 2019, 21, 767. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Raj, P.; Evangeline, P. The Digital Twin Paradigm for Smarter Systems and Environments: The Industry Use Cases; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Aydemir, H.; Zengin, U.; Durak, U. The Digital Twin Paradigm for Aircraft Review and Outlook. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 0553. [Google Scholar]

- McNamara, A.J.; Sepasgozar, S.M. Intelligent contract adoption in the construction industry: Concept development. Autom. Constr. 2021, 122, 103452. [Google Scholar] [CrossRef]

- Sepasgozar, S.; Karimi, R.; Farahzadi, L.; Moezzi, F.; Shirowzhan, S.; M Ebrahimzadeh, S.; Hui, F.; Aye, L. A Systematic Content Review of Artificial Intelligence and the Internet of Things Applications in Smart Home. Appl. Sci. 2020, 10, 3074. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.M.E.; Edwards, D.J.; Li, H.; Wang, C. BIM compatibility and its differentiation with interoperability challenges as an innovation factor. Autom. Constr. 2020, 112, 103086. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Trinder, J.; Osmond, P. New Metrics for Spatial and Temporal 3D Urban Form Sustainability Assessment Using Time Series Lidar Point Clouds and Advanced GIS Techniques. In Urban Design; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Tan, W.; Sepasgozar, S.M. Digital Twin and CyberGIS for Improving Connectivity and Measuring the Impact of Infrastructure Construction Planning in Smart Cities; Multidisciplinary Digital Publishing Institute: Basel, Swittserland, 2020; Volume 9. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Shi, A.; Yang, L.; Shirowzhan, S.; Edwards, D.J. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings 2020, 10, 231. [Google Scholar] [CrossRef]

- Shi, A.; Shirowzhan, S.; Sepasgozar, S.M.; Kaboli, A. 5D BIM Applications in Quantity Surveying: Dynamo and 3D Printing Technologies. In Smart Cities and Construction Technologies; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Sepasgozar, S.M.; Shirowzhan, S.; Niemela, M.; Tripp, A.; Nagabhyrava, S.; Alonso-Marroquin, F. Criteria development for sustainable construction manufacturing in Construction Industry 4.0. Constr. Innov. 2020, 20, 379–400. [Google Scholar] [CrossRef]

- Tankova, T.; da Silva, L.S. Robotics and Additive Manufacturing in the Construction Industry. Curr. Robot. Rep. 2020, 1, 13–18. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Lim, S.; Trinder, J.; Li, H.; Sepasgozar, S.M.E. Data mining for recognition of spatial distribution patterns of building heights using airborne lidar data. Adv. Eng. Inform. 2020, 43, 101033. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.M.E.; Li, H.; Trinder, J. Spatial compactness metrics and Constrained Voxel Automata development for analyzing 3D densification and applying to point clouds: A synthetic review. Autom. Constr. 2018, 96, 236–249. [Google Scholar] [CrossRef]

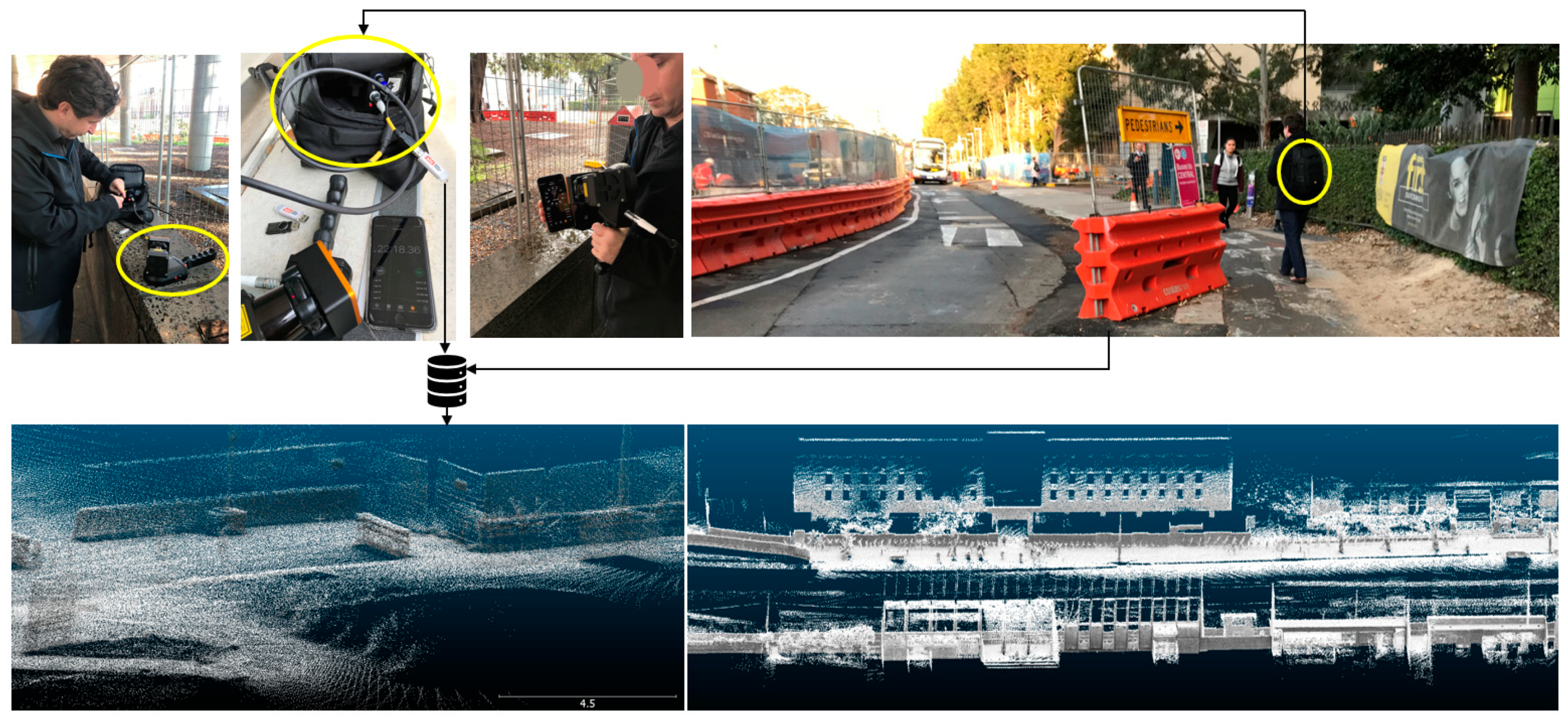

- Sepasgozar, S.M.; Lim, S.; Shirowzhan, S. Implementation of Rapid As-built Building Information Modeling Using Mobile LiDAR. In Proceedings of the Construction Research Congress 2014, Construction in a Global Network, Atlanta, Georgia, 19–21 May 2014; pp. 209–218. [Google Scholar]

- Sepasgozar, S.M.; Wang, C.; Shirowzhan, S. Challenges and Opportunities for Implementation of Laser Scanners in Building Construction. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC 2016), Auburn, AL, USA, 18 July 2016; pp. 742–751. [Google Scholar]

- Gheisari, M.; Esmaeili, B. Unmanned aerial systems (UAS) for construction safety applications. In Proceedings of the Construction Research Congress 2016, San Juan, Puerto Rico, 31 May–2 June 2016; pp. 2642–2650. [Google Scholar]

- Gheisari, M.; Esmaeili, B. Applications and requirements of unmanned aerial systems (UASs) for construction safety. Saf. Sci. 2019, 118, 230–240. [Google Scholar] [CrossRef]

- Moselhi, O.; Bardareh, H.; Zhu, Z. Automated data acquisition in construction with remote sensing technologies. Appl. Sci. 2020, 10, 2846. [Google Scholar] [CrossRef]

- Li, H.; Chan, G.; Wong, J.K.W.; Skitmore, M. Real-time locating systems applications in construction. Autom. Constr. 2016, 63, 37–47. [Google Scholar] [CrossRef]

- Boschert, S.; Heinrich, C.; Rosen, R. Next generation digital twin. In Proceedings of the Tmce (Tools and Methods of Competitive Engineering), Las Palmas de Gran Canaria, Spain, 7–11 May 2018; pp. 209–218. [Google Scholar]

- Sepasgozar, S.M. Digital Twin and Web-Based Virtual Gaming Technologies for Online Education: A Case of Construction Management and Engineering. Appl. Sci. 2020, 10, 4678. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean Practices Using Building Information Modeling (BIM) and Digital Twinning for Sustainable Construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Ruiz-Rosero, J.; Ramirez-Gonzalez, G.; Williams, J.M.; Liu, H.; Khanna, R.; Pisharody, G. Internet of things: A scientometric review. Symmetry 2017, 9, 301. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Karimi, R.; Shirowzhan, S.; Mojtahedi, M.; Ebrahimzadeh, S.; McCarthy, D. Delay Causes and Emerging Digital Tools: A Novel Model of Delay Analysis, Including Integrated Project Delivery and PMBOK. Buildings 2019, 9, 191. [Google Scholar] [CrossRef]

- Sood, S.K.; Rawat, K.S. A scientometric analysis of ICT-assisted disaster management. Nat. Hazards 2021, 1–19. [Google Scholar]

- Khan, A.; Sepasgozar, S.; Liu, T.; Yu, R. Integration of BIM and Immersive Technologies for AEC: A Scientometric-SWOT Analysis and Critical Content Review. Buildings 2021, 11, 126. [Google Scholar] [CrossRef]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Rungskunroch, P.; Welsh, J. A digital-twin evaluation of net zero energy building for existing buildings. Sustainability 2019, 11, 159. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Modeling, simulation, information technology & processing roadmap. Natl. Aeronaut. Space Adm. 2012, TA 11, 1–170. [Google Scholar]

- Brenner, B.; Hummel, V. Digital twin as enabler for an innovative digital shopfloor management system in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

- Padovano, A.; Longo, F.; Nicoletti, L.; Mirabelli, G. A digital twin based service oriented application for a 4.0 knowledge navigation in the smart factory. IFAC-PapersOnLine 2018, 51, 631–636. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, Q.; Wen, Z. Information modeling for cyber-physical production system based on digital twin and AutomationML. Int. J. Adv. Manuf. Technol. 2020, 1–19. [Google Scholar] [CrossRef]

- Wang, P.; Luo, M. A digital twin-based big data virtual and real fusion learning reference framework supported by industrial internet towards smart manufacturing. J. Manuf. Syst. 2021, 58, 16–32. [Google Scholar] [CrossRef]

- Chen, G.; Wang, P.; Feng, B.; Li, Y.; Liu, D. The framework design of smart factory in discrete manufacturing industry based on cyber-physical system. Int. J. Comput. Integr. Manuf. 2020, 33, 79–101. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhang, C.; Wei, Y. Digital twin for CNC machine tool: Modeling and using strategy. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1129–1140. [Google Scholar] [CrossRef]

- Hochhalter, J.D.; Leser, W.P.; Newman, J.A.; Glaessgen, E.H.; Gupta, V.K.; Yamakov, V.; Cornell, S.R.; Willard, S.A.; Heber, G. Coupling Damage-Sensing Particles to the Digitial Twin Concept; National Aeronautics and Space Administration, Langley Research Center: Hampton, VA, USA, 2014. [Google Scholar]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Schluse, M.; Priggemeyer, M.; Atorf, L.; Rossmann, J. Experimentable digital twins—Streamlining simulation-based systems engineering for industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 1722–1731. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Zheng, X. From surveillance to digital twin: Challenges and recent advances of signal processing for industrial internet of things. IEEE Signal Process. Mag. 2018, 35, 120–129. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Berlin, Germany, 2017; pp. 85–113. [Google Scholar]

- Luo, C.; Franciosa, P.; Mo, Z.; Ceglarek, D. A Framework for Tolerance Modeling Based on Parametric Space Envelope. J. Manuf. Sci. Eng. 2020, 142, 061007. [Google Scholar] [CrossRef]

- Kwon, S.; Monnier, L.V.; Barbau, R.; Bernstein, W.Z. Enriching standards-based digital thread by fusing as-designed and as-inspected data using knowledge graphs. Adv. Eng. Inform. 2020, 46, 101102. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Singh, J.; Siahpour, S. Integration of digital twin and deep learning in cyber-physical systems: Towards smart manufacturing. IET Collab. Intell. Manuf. 2020, 2, 34–36. [Google Scholar] [CrossRef]

- Magargle, R.; Johnson, L.; Mandloi, P.; Davoudabadi, P.; Kesarkar, O.; Krishnaswamy, S.; Batteh, J.; Pitchaikani, A. A simulation-based digital twin for model-driven health monitoring and predictive maintenance of an automotive braking system. In Proceedings of the 12th International Modelica Conference, Prague, Czech Republic, 15–17 May 2017; pp. 35–46. [Google Scholar]

- El Saddik, A. Digital twins: The convergence of multimedia technologies. IEEE Multimed. 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, Y.; Wang, Z. Digital twin to improve the virtual-real integration of industrial IoT. J. Ind. Inf. Integr. 2021, 22, 100196. [Google Scholar] [CrossRef]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R. A method for identification and sequence optimisation of geometry spot welds in a digital twin context. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5610–5621. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Fan, C.; Zhang, C.; Yahja, A.; Mostafavi, A. Disaster City Digital Twin: A vision for integrating artificial and human intelligence for disaster management. Int. J. Inf. Manag. 2019, 56, 102049. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient Intell. Humanized Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Bauer, P.; Stevens, B.; Hazeleger, W. A digital twin of Earth for the green transition. Nat. Clim. Chang. 2021, 11, 1–4. [Google Scholar] [CrossRef]

- Ford, D.N.; Wolf, C.M. Smart cities with digital twin systems for disaster management. J. Manag. Eng. 2020, 36, 04020027. [Google Scholar] [CrossRef]

- White, G.; Zink, A.; Codecá, L.; Clarke, S. A digital twin smart city for citizen feedback. Cities 2021, 110, 103064. [Google Scholar] [CrossRef]

- Zaballos, A.; Briones, A.; Massa, A.; Centelles, P.; Caballero, V. A Smart Campus’ Digital Twin for Sustainable Comfort Monitoring. Sustainability 2020, 12, 9196. [Google Scholar] [CrossRef]

- Francisco, A.; Mohammadi, N.; Taylor, J.E. Smart City Digital Twin–Enabled Energy Management: Toward Real-Time Urban Building Energy Benchmarking. J. Manag. Eng. 2020, 36, 04019045. [Google Scholar] [CrossRef]

- McNamara, A.J.; Sepasgozar, S.M. Developing a theoretical framework for intelligent contract acceptance. Constr. Innov. 2020, 20, 421–445. [Google Scholar] [CrossRef]

- Zhang, M.; Zuo, Y.; Tao, F. Equipment energy consumption management in digital twin shop-floor: A framework and potential applications. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–5. [Google Scholar]

- He, B.; Bai, K.-J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020. [Google Scholar] [CrossRef]

- Raj, P. Empowering digital twins with blockchain. Adv. Comput. 2021, 121, 267. [Google Scholar]

- Gopinath, V.; Srija, A.; Sravanthi, C.N. Re-design of smart homes with digital twins. J. Phys. Conf. Ser. 2019, 1228, 012031. Available online: https://www.researchgate.net/publication/333573394_Re-design_of_smart_homes_with_digital_twins (accessed on 24 February 2021).

- Sepasgozar, S.; Lim, S.; Shirowzhan, S.; Kim, Y.; Nadoushani, Z.M. Utilisation of a New Terrestrial Scanner for Reconstruction of As-built Models: A Comparative Study. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining, Oulu, Finland, 15–18 June 2015; p. 1. [Google Scholar]

- Sepasgozar, S.M.; Forsythe, P.; Shirowzhan, S. Evaluation of terrestrial and mobile scanner technologies for part-built information modeling. J. Constr. Eng. Manag. 2018, 144, 04018110. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Lim, S.; Shirowzhan, S.; Kim, Y.M. Implementation of As-Built Information Modelling Using Mobile and Terrestrial Lidar Systems. In Proceedings of the The 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC 2014), Sydney, Australia, 9–11 July 2014. [Google Scholar]

- Tahmasebinia, F.; Niemelä, M.; Ebrahimzadeh Sepasgozar, S.; Lai, T.; Su, W.; Reddy, K.; Shirowzhan, S.; Sepasgozar, S.; Marroquin, F. Three-Dimensional Printing Using Recycled High-Density Polyethylene: Technological Challenges and Future Directions for Construction. Buildings 2018, 8, 165. [Google Scholar] [CrossRef]

- Bauernhansl, T. WGP-Standpunkt Industrie 4.0; Wissenschaftliche Gesellschaft für Produktionstechnik: Germany, 2016; Available online: https://www.ipa.fraunhofer.de/content/dam/ipa/de/documents/Presse/Presseinformationen/2016/Juni/WGP_Standpunkt_Industrie_40.pdf (accessed on 24 February 2021).

| Task-Based Technologies | Examples of Relevant Technologies | More Information or Selected Applications |

|---|---|---|

| (i) office work and management technologies | General applications and software that are used for communications and paperwork, including emails, the cloud, and Intelligent Systems. | iContract [42], artificial intelligence [43] |

| (ii) design and planning technologies | Building Information Modelling, Geographic Information Systems, virtual reality (VR), Cybersecurity, Simulations, Big Data and analytics | BIM [44], GIS [45], CyberGIS [46], VR |

| (iii) production technologies | 3D Printing (3DP), robotics, Tunnel Boring Machine (TBM), automation, autonomous haulage system, Digital Twin. | 3DP [47,48,49], robotics [50] |

| (iv) job-site vision technologies | Radio frequency identification (RFID), sensors, Internet of Things (IoT), light detection and ranging (lidar), laser scanners, cameras for site management, unmanned aerial systems (UAS), physical progress monitoring, and productivity, safety, and security. | Lidar applications [51,52,53,54], UAS [55,56] |

| (v) dependent high-tech | Global positioning system (GPS), radar, real-time locating system, remote controlling devices and diagnostic systems attached or imbedded in heavy equipment such as graders or cranes. | Remote sensing applications [57], Real-time locating systems [58] |

| Direction | State of Play–Key Tools or Limitations | Suggestions for Future Applications or Investigations |

|---|---|---|

| Technology development | Predix (GE Digital) for data analytics and industrial monitoring; MindSphere (Siemens) for storing operational data; ThingWorx; Watson IoT Platform; Ditto; Ansys simulation platform [89]; Azure Digital Twins | Develop an autonomous resilient response to breakdown and failures in systems or processes [85]; response to unexpected incidents before occurring [90] Address network gaps in the field and underground sites |

| Connectivity, data mapping, and data fusion | The use of individual technologies such as data mapping tools [66]; fuzzy sets, rule-based reasoning, and intelligent algorithms [91]; 5G; wireless sensor networks, industrial AI; blockchain; and transfer learning; Beacons and RTLS (real-time locating system) [58]; and RFID (radio-frequency identification) [92] for collecting motion data from mobile production equipment such as cranes and excavators. | Collect quality motion data from sites and optimise in near real-time; apply advanced analytics methods to enhance self-configure, self-adapt, and self-learning capability of the DT [85]; integrate and connect to BIM [44,48]; collect multi-modal (e.g., radar, laser, or lidar), multi-source and homogeneous data, apply multi-actor game-theory decision algorithms considering dynamic factors [93]; connecting energy networks; decentralised digital twin models [94] and integration with blockchain. |

| Application identification, learning, and decision-making | Earth-DT with the integration of the human dimensions for achieving SDGs [95]; further development of disaster city-DT [93,96] for emergency management; DT for smart city [96,97]; optimise life cycle management [33,81]; smart campus’ DT for comfort assessment [98]; DT-Enabled Energy Management [99]. | Apply optimisation scenarios for decision-making [85]. Develop autonomous resilience control; apply decision-support tools. |

| Readiness investigations | Advantages, drivers, and barriers of technology acceptance. | Develop novel digital business models for post-COVID-19 based on DT; Shared technology and process for the circular economy. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. https://doi.org/10.3390/buildings11040151

Sepasgozar SME. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings. 2021; 11(4):151. https://doi.org/10.3390/buildings11040151

Chicago/Turabian StyleSepasgozar, Samad M. E. 2021. "Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment" Buildings 11, no. 4: 151. https://doi.org/10.3390/buildings11040151

APA StyleSepasgozar, S. M. E. (2021). Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings, 11(4), 151. https://doi.org/10.3390/buildings11040151