Comparing Team Interactions in Traditional and BIM-Lean Design Management

Abstract

:1. Introduction

2. Background

2.1. Design Management

2.2. Lean Design Management

2.3. BIM Uses in the Design and Plan Phases

2.4. Dimensions of Design Team Interaction

2.5. Impact of BIM and Lean on the Performance

3. Materials and Methods

3.1. Case Study Selection

3.2. Description of Design Management

3.3. Interaction Assessment and Case Study Comparison

4. Results and Discussion

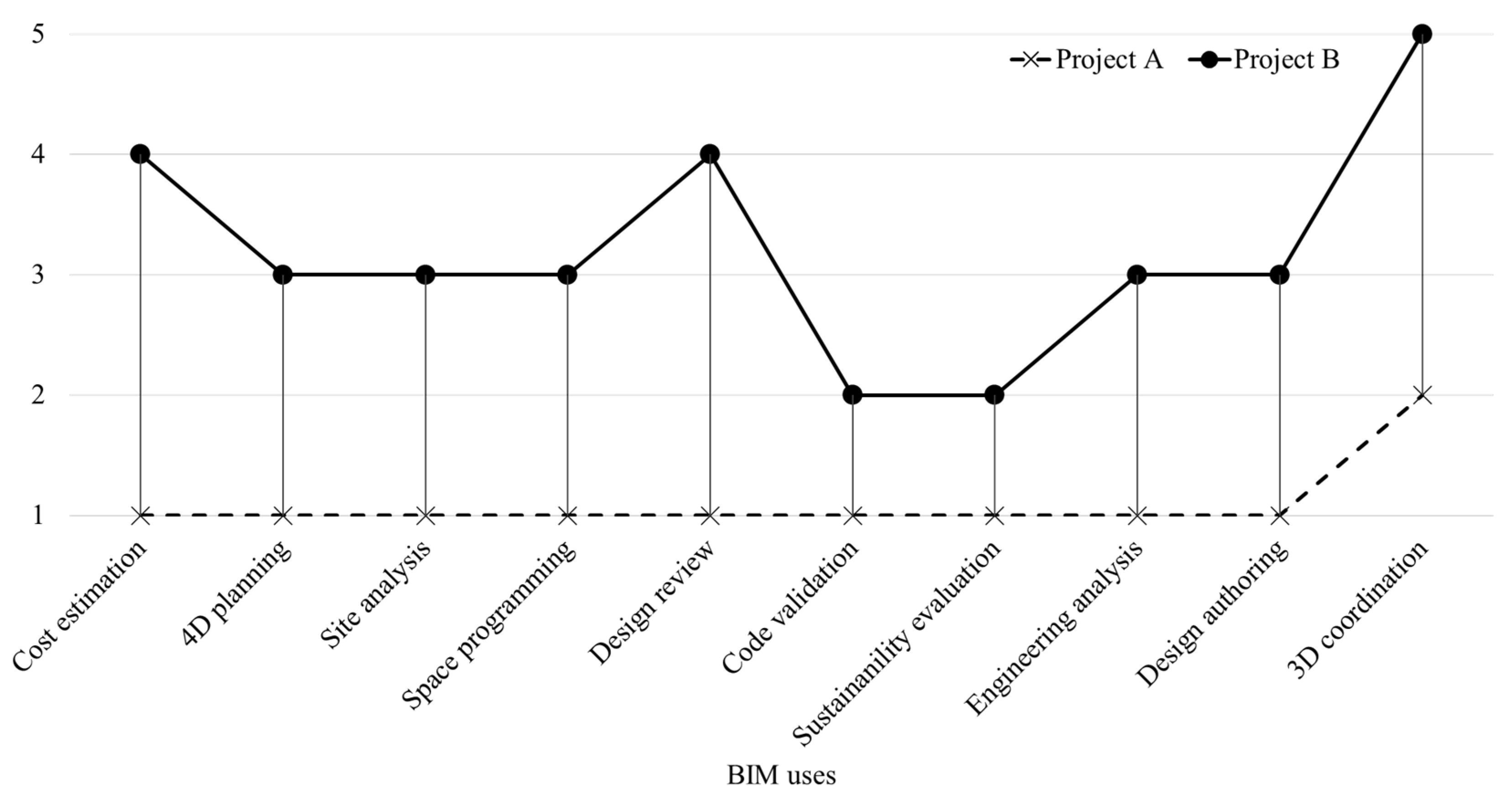

4.1. BIM Uses Assessment

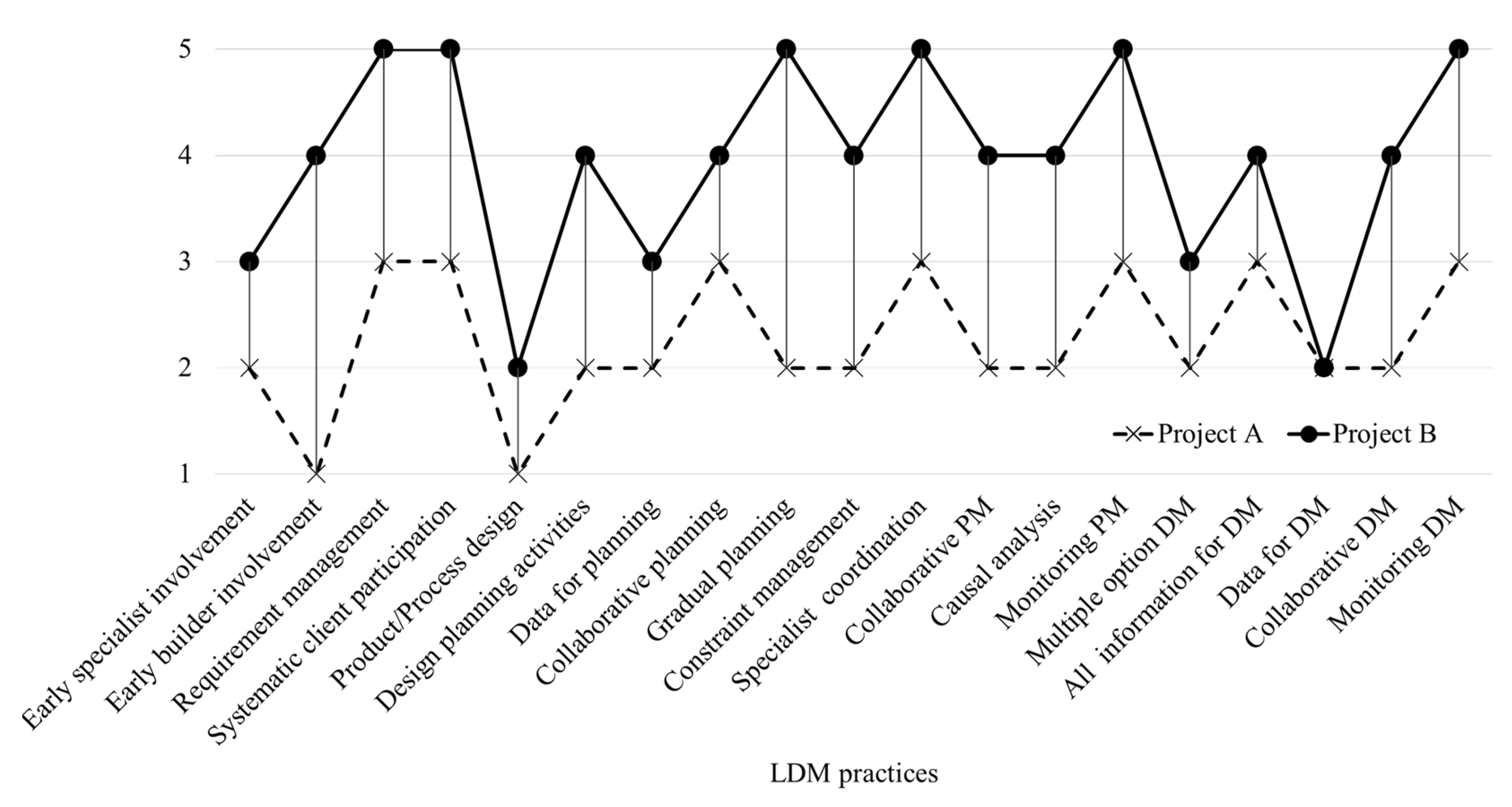

4.2. LDM Practices Assessment

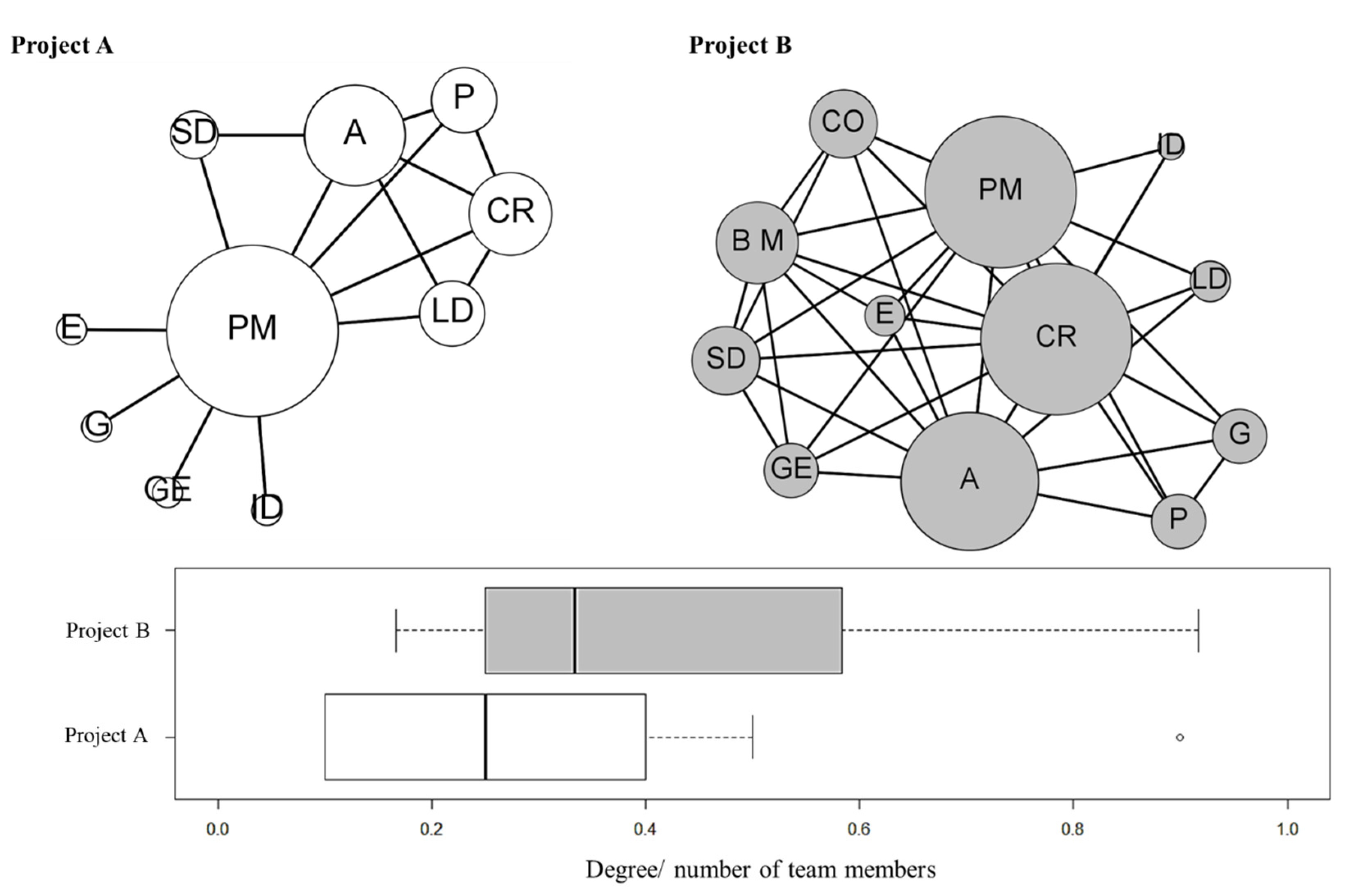

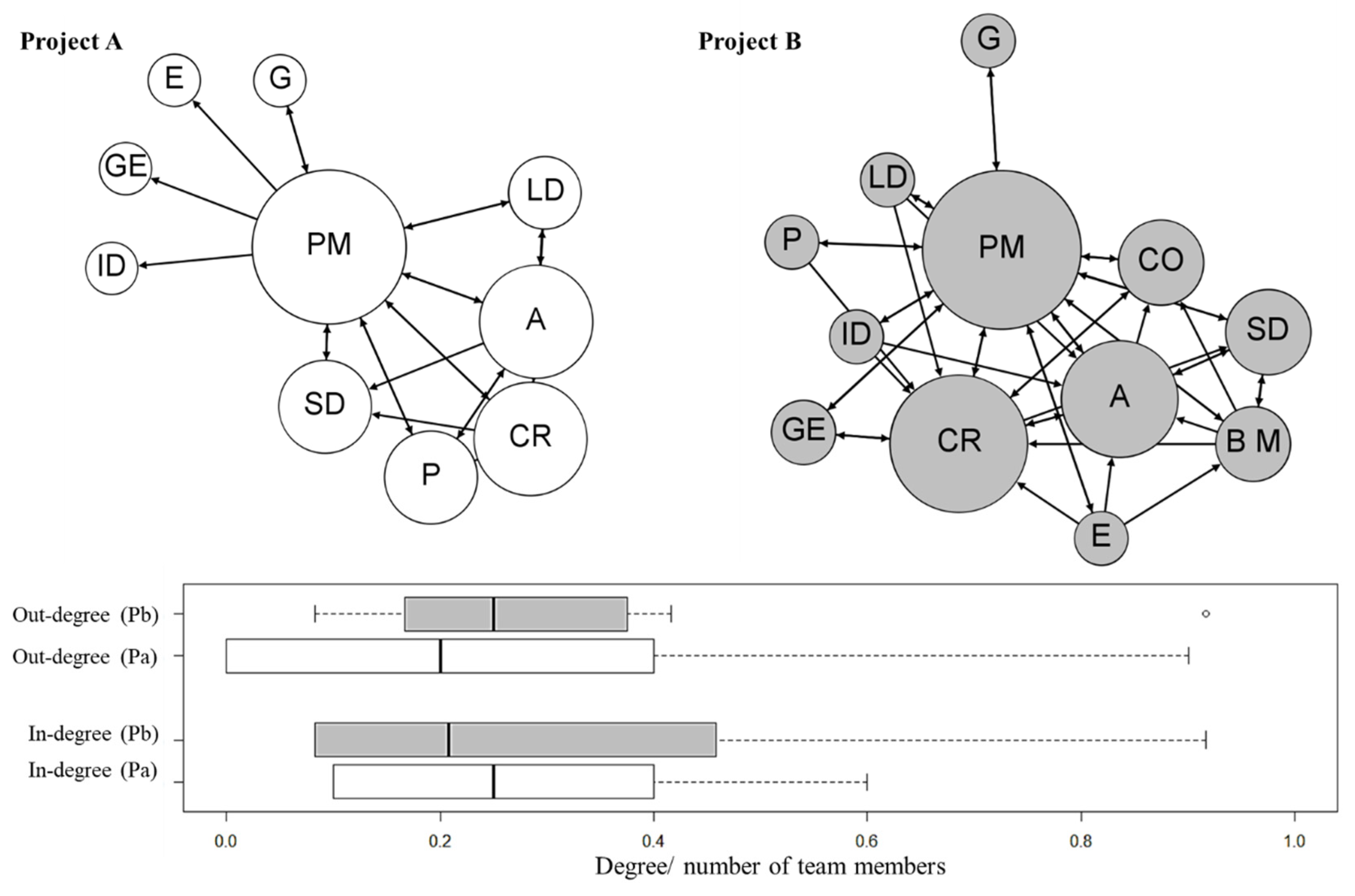

4.3. Interaction’s Assessment and Comparative Analysis of Two Case Studies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baiden, B.; Price, A.; Dainty, A. The extent of team integration within construction projects. Int. J. Proj. Manag. 2006, 24, 13–23. [Google Scholar] [CrossRef]

- Love, P.E.; Irani, Z.; Cheng, E.; Li, H. A model for supporting inter-organizational relations in the supply chain. Eng. Constr. Arch. Manag. 2002, 9, 2–15. [Google Scholar] [CrossRef]

- Othman, M.Z.; Nawi, M.N.M.; Nifa, F.A.A.; Yaakob, M.; Rofie, K.; Zan, Z.M.; Pozin, M.A.A. Atrategy Towards Team Integration Practice for Improving the Design and Construction Process in the Malaysian Industrialized Building Projects. Int. Rev. Manag. Mark. 2016, 6, 226–229. [Google Scholar]

- Dainty, A.R.J.; Briscoe, G.H.; Millett, S.J. Subcontractor perspectives on supply chain alliances. Constr. Manag. Econ. 2001, 19, 841–848. [Google Scholar] [CrossRef]

- Ng, S.T.; Tang, Z. Labour-intensive construction sub-contractors: Their critical success factors. Int. J. Proj. Manag. 2010, 28, 732–740. [Google Scholar] [CrossRef]

- Schöttle, A.; Haghsheno, S.; Gehbauer, F. Defining Cooperation and Collaboration in the Context of Lean Construction. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; Volume 49, pp. 1269–1280. [Google Scholar]

- Merriam-Webster Interaction. Available online: https://www.merriam-webster.com/dictionary/interactions#other-words (accessed on 16 June 2021).

- Socialsci Understanding Social Interactions. Available online: https://socialsci.libretexts.org/@go/page/8023 (accessed on 10 June 2021).

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Addressing Information Flow in Lean Production Management and Control in Construction. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 581–592. [Google Scholar]

- Al Hattab, M.; Hamzeh, F.R. Using social network theory and simulation to compare traditional versus BIM–lean practice for design error management. Autom. Constr. 2015, 52, 59–69. [Google Scholar] [CrossRef]

- Fakhimi, A.H.; Majrouhi Sardroud, J.; Azhar, S. How Can Lean, IPD and BIM Work Together? In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC), Auburn, AL, USA, 18–21 July 2016; pp. 1–8. [Google Scholar]

- Kestle, L.; London, K. Towards the Development of a Conceptual Design Management Model for Remote Sites. In Proceedings of the 10th Annual Conference of the International Group for Lean Construction 2002, IGLC 2002, Gramado, Brazil, 6–8 August 2002; pp. 1–14. [Google Scholar]

- Herrera, R.F.; Mourgues, C.; Alarcon, L.; Pellicer, E. Understanding Interactions between Design Team Members of Construction Projects Using Social Network Analysis. J. Constr. Eng. Manag. 2020, 146, 04020053. [Google Scholar] [CrossRef]

- Long, D.; Arroyo, P. Language, Moods, and Improving Project Performance. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction 2018, IGLC 2018, Chennai, India, 16–22 July 2018; pp. 495–504. [Google Scholar]

- AIA. Integrated Project Delivery: A Guide; The American Institute of Architects: California, CA, USA, 2007; Volume 1. [Google Scholar]

- Knotten, V.; Lædre, O.; Hansen, G.K. Building design management—Key success factors. Arch. Eng. Des. Manag. 2017, 13, 479–493. [Google Scholar] [CrossRef]

- Svalestuen, F.; Frøystad, K.; Drevland, F.; Ahmad, S.; Lohne, J.; Lædre, O. Key Elements to an Effective Building Design Team. In Proceedings of the International Conference on Project Management, Vilamoura, Portugal, 7–9 October 2015; Elsevier Masson SAS: Sapporo, Japan, 2015; Volume 64, pp. 838–843. [Google Scholar]

- Scott, J. Social Network Analysis, 3rd ed.; SAGE Publications Inc.: Thousand Oaks, CA, USA, 2013; ISBN 978-1446209042. [Google Scholar]

- Marin, A.; Wellman, B. Social Network Analysis: An Introduction. In The SAGE Handbook of Social Network Analysis; Scott, J., Carrington, P.J., Eds.; SAGE research methods; SAGE: Thousand Oaks, CA, USA, 2011; pp. 11–25. [Google Scholar]

- Yang, H.-L.; Tang, J.-H. Team structure and team performance in IS development: A social network perspective. Inf. Manag. 2004, 41, 335–349. [Google Scholar] [CrossRef]

- Rosas, E. Integrating the Design Structure Matrix and the Last Planner System into Building Design. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 389–398. [Google Scholar]

- Alarcón, D.M.; Alarcón, I.M.; Alarcón, L.F. Social Network Analysis: A Diagnostic Tool for Information Flow in the Aec Industry. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 947–956. [Google Scholar]

- Ko, C.-H.; Chung, N.-F. Making Design Process Lean. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; Volume 886, pp. 463–474. [Google Scholar]

- Becerik-Gerber, A.B.; Ku, K.; Jazizadeh, F. BIM-Enabled Virtual and Collaborative Construction Engineering and Management. J. Prof. Issues Eng. Educ. Pr. 2012, 138, 234–245. [Google Scholar] [CrossRef]

- Savolainen, J.M.; Saari, A.; Männistö, A.; Kähkonen, K. Indicators of collaborative design management in construction projects. J. Eng. Des. Technol. 2018, 16, 674–691. [Google Scholar] [CrossRef]

- Khan, S.; Tzortzopoulos, P. Effects of the Interactions Between LPS and BIM on Workflow in Two Building Design Projects. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 933–944. [Google Scholar]

- Pryke, S. Social Network Analysis in Construction; Wiley-Blackwell: Hoboken, NJ, USA, 2012; ISBN 1118343913. [Google Scholar]

- Mujumdar, P.; Maheswari, J.U. Design iteration in construction projects—Review and directions. Alex. Eng. J. 2018, 57, 321–329. [Google Scholar] [CrossRef]

- Kestle, L.; Potangaroa, R.; Storey, B. Integration of Lean Design and Design Management and its Influence on the Development of a Multidisciplinary Design Management Model for Remote Site Projects. Arch. Eng. Des. Manag. 2011, 7, 139–153. [Google Scholar] [CrossRef]

- Al Hattab, M.; Hamzeh, F. A Process-Social Perspective for Understanding Design Information Flow. Lean Constr. J. 2017, 11, 1–11. [Google Scholar]

- Herrera, R.F.; Mourgues, C.; Alarcon, L.F.; Pellicer, E. Assessing Design Process Performance of Construction Projects. In Proceedings of the CIB World Building Congress 2019, Hong Kong, China, 17–21 June 2019; pp. 1–10. [Google Scholar]

- Salvatierra, J.L.; Gálvez, M.A.; Bastías, F.; Castillo, T.; Herrera, R.F.; Alarcon, L. Developing a benchmarking system for architecture design firms. Eng. Constr. Arch. Manag. 2019, 26, 139–152. [Google Scholar] [CrossRef] [Green Version]

- Abou-Ibrahim, H.; Hamze, F. Design Management: Metrics and Visual Tools. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 2–12 July 2017; pp. 465–473. [Google Scholar]

- Whyte, J.; Tombesi, P. Challenges of Design Management in Construction. In The Handbook of Design Management; Cooper, R., Junginger, S., Lockwood, T., Eds.; Bloomsbury Academic: London, UK, 2013; pp. 202–2013. [Google Scholar]

- Formoso, C.T.; Tzotzopoulos, P.; Jobim, M.S.; Liedtke, R. Developing a Protocol for Managing the Design Process in the Building Industry. In Proceedings of the 6th Annual Conference of the International Group for Lean Construction 1998, Guarujá, Brazil, 13–15 August 1998. [Google Scholar]

- Koskela, L.; Ballard, G.; Tanhuanpää, V.-P. Towards Lean Design Management. In Proceedings of the 5th Annual Conference of the International Group for Lean Construction 1997, Gold Coast, Australia, 16–17 July 1997; pp. 1–13. [Google Scholar]

- Gambatese, M.J.A.; Pestana, C.; Lee, M.H.W. Alignment between Lean Principles and Practices and Worker Safety Behavior. J. Constr. Eng. Manag. 2017, 143, 04016083. [Google Scholar] [CrossRef]

- Fosse, R.; Ballard, G. Lean Design Management in Practice. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction 2016, Boston, MA, USA, 20–22 July 2016; pp. 33–42. [Google Scholar]

- O’Connor, R.; Swain, B. Implementing Lean in Construction: Lean Tools and Techniques—An Introduction; CIRIA: London, UK, 2013. [Google Scholar]

- Bloom, N.; Van Reenen, J. Measuring and Explaining Management Practices Across Firms and Countries. Q. J. Econ. 2006, 122, 1351–1408. [Google Scholar] [CrossRef]

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. An Assessment of Lean Design Management Practices in Construction Projects. Sustainability 2019, 12, 19. [Google Scholar] [CrossRef] [Green Version]

- Reifi, M.H.E.; Emmitt, S. Perceptions of lean design management. Arch. Eng. Des. Manag. 2013, 9, 195–208. [Google Scholar] [CrossRef]

- Knotten, V.; Svalestuen, F.; Hansen, G. Improving Design Management. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction 2016, Boston, MA, USA, 20–22 July 2016; pp. 173–182. [Google Scholar]

- Alves, T.D.C.L.; Lichtig, W.; Rybkowski, Z.K. Implementing target value design: Tools and techniques to manage the process. Health Environ. Res. Des. J. 2017, 10, 18–29. [Google Scholar] [CrossRef]

- Ko, C.; Chung, N. Lean Design Process. J. Constr. Eng. Manag. 2014, 140, 04014011. [Google Scholar] [CrossRef]

- Ballard, G.; Tommelein, I.D.; Koskela, L.; Howell, G. Lean Construction Tools and Techniques. In Design and Construction: Bulding in Value; Best, R., de Valence, G., Eds.; Butterworth-Heinemann; Elsevier Ltd.: Oxford, UK, 2002; pp. 227–255. [Google Scholar]

- Franco, V.; Picchi, A. Lean Design in Building Projects: Guiding Principles and Exploratoyry. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction 2016, Boston, MA, USA, 20–22 July 2016; pp. 113–122. [Google Scholar]

- Ballard, G.; Howell, G. Lean project management. Build. Res. Inf. 2003, 31, 119–133. [Google Scholar] [CrossRef]

- UUsitalo, P.; Olivieri, H.; Seppänen, O.; Pikas, E.; Peltokorpi, A. Review of Lean Design Management: Processes, Methods and Technologies. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction 2017, Heraklion, Gerrce, 9–12 July 2017; pp. 571–578. [Google Scholar]

- Hamzeh, F.R.; Ballard, G.; Tommelein, I.D. Is the Last Planner System applicable to design? A case study. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction 2009, Taipei, Taiwan, 15–17 July 2009; pp. 407–416. [Google Scholar]

- Tilley, P.A. Lean design management—A New Paradigm for Managing the Design and Documentation Process to Improve Quality? In Proceedings of the 13th Annual Conference of the International Group for Lean Construction 2005, Sydney, Australia, 19–21 July 2005; pp. 283–295. [Google Scholar]

- Arroyo, P.; Fuenzalida, C.; Albert, A.; Hallowell, M.R. Collaborating in decision making of sustainable building design: An experimental study comparing CBA and WRC methods. Energy Build. 2016, 128, 132–142. [Google Scholar] [CrossRef]

- Salgin, B.; Arroyo, P.; Ballard, G. Exploring the Relationship between Lean Design Methods and C&D Waste Reduction: Three Case Studies of Hospital Projects in California. Rev. Ing. Constr. 2016, 31, 191–200. [Google Scholar] [CrossRef] [Green Version]

- Munthe-kaas, T.S.; Hjelmbrekke, H.; Lohne, J. Lean Design versus Traditional Design Approach. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction 2015, IGLC 2015, Perth, Australia, 29–31 July 2015; pp. 578–588. [Google Scholar]

- Taylor, D.W. Decision Making and Problem Solving. In Handbook of Organizations; March, J.G., Ed.; Routledge: New York, NY, USA, 2013; pp. 48–86. [Google Scholar]

- Kapogiannis, G.; Sherratt, F. Impact of integrated collaborative technologies to form a collaborative culture in construction projects. Built Environ. Proj. Asset Manag. 2018, 8, 24–38. [Google Scholar] [CrossRef]

- Kreider, R.G.; Messner, J.I. The Uses of BIM: Classifying and Selecting BIM Uses; The Pennsylvania State University: Centre County, PA, USA, 2013. [Google Scholar]

- Rojas, M.J.; Herrera, R.F.; Mourgues, C.; Ponz-Tienda, J.L.; Alarcon, L.; Pellicer, E. BIM Use Assessment (BUA) Tool for Characterizing the Application Levels of BIM Uses for the Planning and Design of Construction Projects. Adv. Civ. Eng. 2019, 2019, 9094254. [Google Scholar] [CrossRef]

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. Analyzing the Association between Lean Design Management Practices and BIM Uses in the Design of Construction Projects. J. Constr. Eng. Manag. 2021, 147, 04021010. [Google Scholar] [CrossRef]

- Arellano, K. Assesment of the Level of Use of BIM in the Planning and Design Phases in the AEC Industry in Ecuador; National University of Chimborazo: Riobamba, Ecuador, 2020. [Google Scholar]

- Gu, N.; London, K. Understanding and facilitating BIM adoption in the AEC industry. Autom. Constr. 2010, 19, 988–999. [Google Scholar] [CrossRef]

- Kleinsmann, M.; Deken, F.; Dong, A.; Lauche, K. Development of design collaboration skills. J. Eng. Des. 2012, 23, 485–506. [Google Scholar] [CrossRef]

- Castillo, T.; Alarcón, L.F.; Salvatierra, J.L. Effects of Last Planner System Practices on Social Networks and the Performance of Construction Projects. J. Constr. Eng. Manag. 2018, 144, 04017120. [Google Scholar] [CrossRef]

- Priven, V.; Sacks, R. Social Network Development in Last Planner System Implementations. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 474–485. [Google Scholar]

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F. Assessment of Lean Practices, Performance and Social Networks in Chilean Airport Projects. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction 2018, IGLC 2018, Chennai, India, 16–22 July 2018; pp. 603–613. [Google Scholar]

- Viana, D.D.; Formoso, C.T.; Isatto, E.L. Modelling the Network of Commitments in the Last Planner System. Lean Constr. J. 2011, 7, 55–67. [Google Scholar]

- Valentine, M.A.; Nembhard, I.M.; Edmondson, A.C. Measuring Teamwork in Health Care Settings: A Review of Survey Instruments. Med. Care 2015, 53, e16–e30. [Google Scholar] [CrossRef] [PubMed]

- Cisterna, D.A. Application of Social Network Analysis in Lean Infraestructure Projects; Universität Stuttgart: Stuttgart, Germany, 2017. [Google Scholar]

- Searle, J.R. Speech Acts: An Essay in the Philosophy of Language; Cambridge University Press: Cambridge, UK, 1969; ISBN 978-0521096263. [Google Scholar]

- Medina-Mora, R.; Winograd, T.; Flores, R.; Flores, F. The action workflow approach to workflow management technology. In Proceedings of the CSCW 92, Toronto, ON, Canada, 1–4 November 1992; pp. 281–288. [Google Scholar] [CrossRef]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors, 2nd ed.; John Wiley & Sons Ltd.: New Jersey, NJ, USA, 2011. [Google Scholar]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of Lean and Building Information Modeling in Construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef] [Green Version]

- Schimanski, C.P.; Monizza, G.P.; Marcher, C.; Matt, D.T. Conceptual Foundations for a New Lean BIM-Based Production System in Construction. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 3–5 July 2019; pp. 877–888. [Google Scholar]

- Nascimento, D.L.D.M.; Caiado, R.; Tortorella, G.; Ivson, P.; Meiriño, M. Digital Obeya Room: Exploring the synergies between BIM and lean for visual construction management. Innov. Infrastruct. Solut. 2018, 3, 19. [Google Scholar] [CrossRef]

- Dave, B.A. Developing a Construction Management System Based on Lean Construction and Building Information Modelling; University of Salford: Salford, UK, 2013. [Google Scholar]

- Sacks, R.; Barak, R.; Belaciano, B.; Gurevich, U. Field Tests of the KanbimTM Lean Production Management System. In Proceedings of the 19th Annual Conference of the International Group for Lean Construction, Lima, Perú, 13–15 July 2011; pp. 1–12. [Google Scholar]

- Mahalingam, A.; Yadav, A.K.; Varaprasad, J. Investigating the Role of Lean Practices in Enabling BIM Adoption: Evidence from Two Indian Cases. J. Constr. Eng. Manag. 2015, 141, 05015006. [Google Scholar] [CrossRef]

- Dave, B.; Koskela, L.; Kiviniemi, A.; Owen, R.; Tzortzopoulos, P. Implementing Lean in Construction; CIRIA: London, UK, 2013; ISBN 9780860177272. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods; SAGE Publications: New York, NY, USA, 2009. [Google Scholar]

- Ridder, H.-G. The theory contribution of case study research designs. Bus. Res. 2017, 10, 281–305. [Google Scholar] [CrossRef] [Green Version]

- European Comission. Commission recommendation concerning the definition of micro, small and medium-sized enterprises. Off. J. Eur. Union 2003, 361, 1–6. [Google Scholar] [CrossRef]

- Woodside, A.G. Case Study Research. Theory, Methods and Practice; Emerald: Bingley, UK, 2010. [Google Scholar]

- Bloom, N.; Van Reenen, J. New Approaches to Surveying Organizations. Am. Econ. Rev. 2010, 100, 105–109. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Ashuri, B. BIM log mining: Discovering social networks. Autom. Constr. 2018, 91, 31–43. [Google Scholar] [CrossRef]

- Craft, R.C.; Leake, C. The Pareto principle in organizational decision making. Manag. Decis. 2002, 40, 729–733. [Google Scholar] [CrossRef]

- Alarcón, L.F.; Ashley, D.B.; De Hanily, A.S.; Molenaar, K.R.; Ungo, R. Risk Planning and Management for the Panama Canal Expansion Program. J. Constr. Eng. Manag. 2011, 137, 762–771. [Google Scholar] [CrossRef]

- Bastian, M.; Heymann, S.; Jacomy, M. Gephi: An Open Source Software for Exploring and Manipulating Networks. In Proceedings of the Third International AAAI Conference on Weblogs and Social Media, San Jose, CA, USA, 17–20 May 2009. [Google Scholar]

- Hickethier, G.; Tommelein, I.D.; Lostuvali, B. Social Network Analysis of Information Flow in an IPD-Project Design Organization. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 319–328. [Google Scholar]

- Hoppe, B.; Reinelt, C. Social network analysis and the evaluation of leadership networks. Leadersh. Q. 2010, 21, 600–619. [Google Scholar] [CrossRef]

- Shafiq, M.T.; Matthews, J.; Lockley, S. A study of BIM collaboration requirements and available features in existing model collaboration systems. J. Inf. Technol. Constr. 2013, 18, 148–161. [Google Scholar]

- Anvuur, A.M.; Kumaraswamy, M.M. Effects of Teamwork Climate on Cooperation in Crossfunctional Temporary Multi-Organization Workgroups. J. Constr. Eng. Manag. 2016, 142, 04015054. [Google Scholar] [CrossRef] [Green Version]

- Hu, Q.; Found, P.; Williams, S.; Mason, R. Lean Thinking and Organisational Learning: How Can They Facilitate Each Other? In Understanding the Lean Enterprise. Measuring Operations Performance; Chiriani, A., Found, P., Rich, N., Eds.; Springer: Cham, Switzerland, 2016; pp. 61–77. ISBN 978-3319199955. [Google Scholar]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Salazar, L.A.; Retamal, F.; Ballard, G.; Arroyo, P.; Alarcón, L.F. Results of Indicators from the Linguistic Action Perspective in the Last Planner® System. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 1–7 July 2019; pp. 1241–1250. [Google Scholar]

| Category | Id | Definition |

|---|---|---|

| Stakeholder management | SM1 | Specialist designers are involved during early stages of the project. |

| SM2 | Builders are involved during early stages of the project. | |

| SM3 | The identification of requirements of the stakeholders is exhaustive, where requirements, constraints, technical specifications and special requirements are defined. | |

| SM4 | The participation of clients in the design phase involves the systematic participation and support during meetings concerning decision making and resolution of problems. | |

| SM5 | The design of the product and the construction process are carried out simultaneously. | |

| Planning and control | PC1 | Project planning considers delivery dates, phases, milestones, task subdivision programs and control instances. All of the above, immersed in a scheme in which gaps, buffers and points are clarified, can be used to perform pull/push actions within the program. |

| PC2 | With regard to project planning, this is considered information of internal and/or external projects of the organization, generated through a benchmarking exercise. | |

| PC3 | Project planning is conducted collaboratively among various stakeholders. | |

| PC4 | Project planning is carried out at different levels (global, phase, intermediate and weekly). | |

| PC5 | The constraints in the design process are identified and registered collaboratively and released by a responsible person. Then, the constraints are followed. | |

| PC6 | The coordination of project information between the different stakeholders is performed through a single platform, which allows systematic updates and continuous communication between stakeholders. | |

| Decision making | DM1 | There exists a protocol to solve problems collaboratively. |

| DM2 | The last planner identifies the problem and performs a causal analysis (e.g., the 5 why’s method). | |

| DM3 | The solution to the problem is implemented, monitored and documented, to verify that the problem was solved. | |

| DM4 | In the decision-making process, options are evaluated, designed, and tested, and the results validated and applied. | |

| DM5 | The moment to make decisions is the last responsible moment, and all the information that could be gathered at that moment is used. | |

| DM6 | To make decisions, information of internal and/or external projects of the organization is used, generated through a benchmarking exercise. | |

| DM7 | The decision-making mechanism is a meeting with all stakeholders involved, where a specific technique is used, for example, Choosing By Advantages (CBA) or others. | |

| DM8 | After making the decision, specific actions are taken to verify whether satisfactory results were obtained. In addition, the lessons learned are identified and documented. |

| Id | Use | Definition |

|---|---|---|

| U1 | Cost Estimation | A BIM model is used to generate accurate quantity take-offs and cost estimates. |

| U2 | 4D Planning | A 4D BIM model is utilized to effectively plan, especially spatial planning, including spatial clashes and paths. |

| U3 | Site Analysis | BIM/GIS is used to select and evaluate a site location and to select a building position on the site. |

| U4 | Space Programming | A BIM model is used to design and analyze the project spaces and rooms and to assign to each space a use and its measurements. |

| U5 | Design Review | A process in which stakeholders interact with a BIM model and provide their feedback to validate multiple design aspects |

| U6 | Code Validation | A process in which code validation software is utilized to check the model parameters against project-specific design or construction codes or norms. |

| U7 | Sustainability Evaluation | A process in which the sustainability of a facility is evaluated and tracked using a sustainability metric system. |

| U8 | Engineering Analysis | A BIM model and specialized software are used to conduct an engineering analysis to identify the most efficient method or design. |

| U9 | Design Authoring | A process in which 3D software is used to develop a building information model. A project is designed in a BIM model, where the typical iterations of a project are made, and everything is built directly in the BIM software. |

| U10 | 3D Coordination | A process in which 3D coordination software is used to identify 3D geometric conflicts by comparing 3D models of building systems. |

| Type | Metrics |

|---|---|

| Knowledge of roles and responsibilities | When person A knows the role and responsibility of person B, a one-way link is created between the two people. This network is fundamental, since if the link does not exist, it is difficult to make another type of interaction [13] |

| Global interaction | Refers to any type of interaction between two people, these include telephone conversations, mail exchanges, conversations or business meetings [22] |

| Relevant work information | Relevant work information is that flow where person A sends necessary information to person B that adds value to the project but is not openly available [63] |

| Collaboration | Collaboration refers to the act of joint work between two or more people. It is considered that working together implies working with another person on the same task and at the same time, either in person or virtually [13] |

| Planning and problem solving | Collaborative planning and problem solving refer to the joint act of two or more people to define and redefine tasks, schedules, resources, costs, risks, etc. [63] |

| Trust | When a person A trusts the work of a person B, a one-way bond of trust between A-B is created [64] |

| Learning | When a person A learns something new from a person B, a learning link between A-B is created. What is learned can be something technical related to knowledge, some skill or competence, or even an attitude at work [65] |

| Request for requirement | The speaker (customer) is asking a potential performer for action around a requirement [14] |

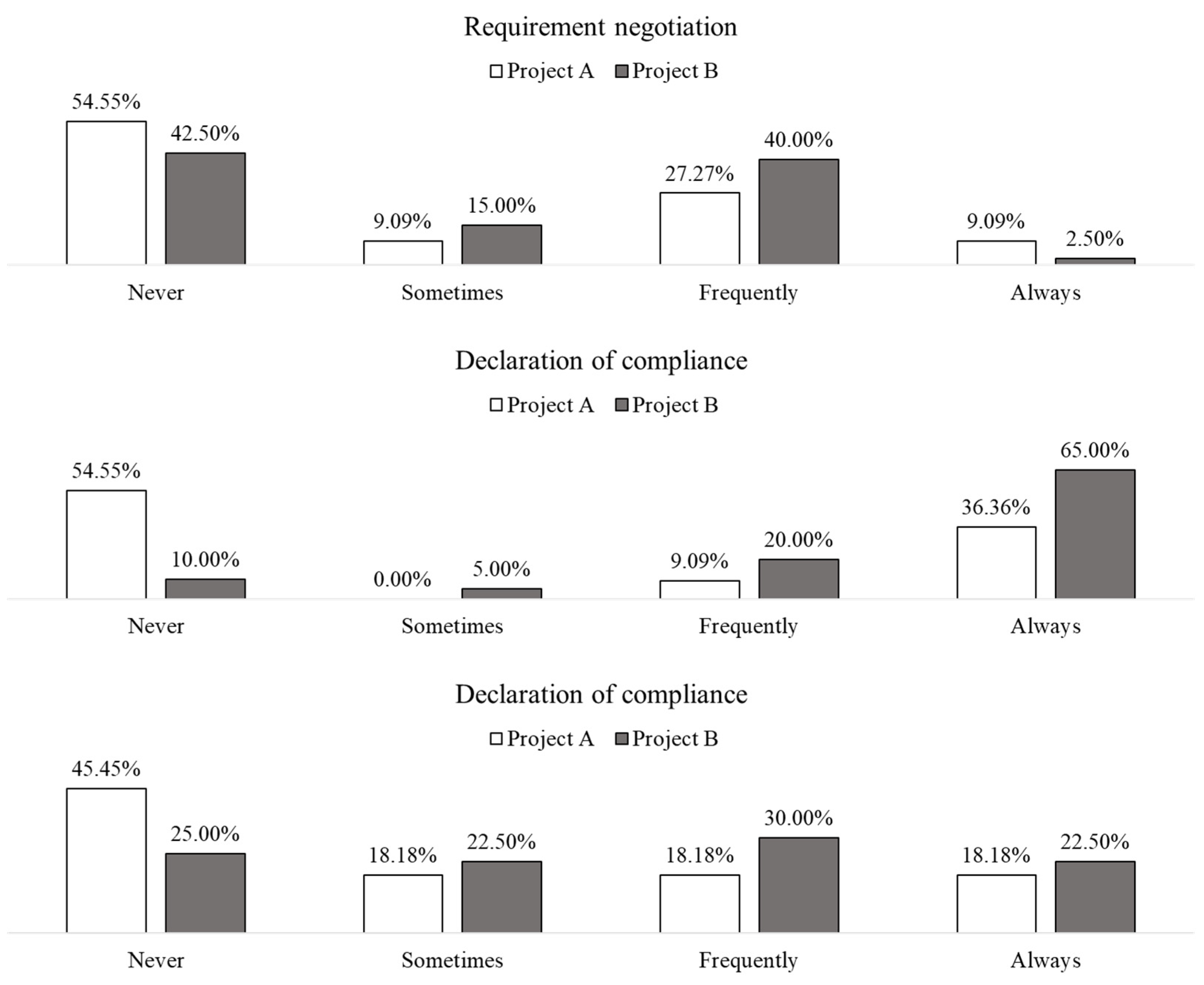

| Requirement negotiation | The customer and the performer clarify the requirement and define conditions of satisfaction, based on time, cost and performance [66] |

| Declaration of compliance | The performer reports facts and is prepared to offer evidence about the compliance of the requirement [14]. |

| Declaration of satisfaction | The customer reports a level of satisfaction and feedback about the compliance of the requirement [14] |

| Selection Criteria | Project A | Project B |

|---|---|---|

| 1. Type of project: high-rise building | ✓ | ✓ |

| 2. Delivery method: design-bid-build | ✓ | ✓ |

| 3. Client and constructor are the same corporative group | ✓ | ✓ |

| 4. Size of client: large [81] | ✓ | ✓ |

| 5. All specialists and designers are from different organizations | ✓ | ✓ |

| 6. All design team members are located in Santiago, Chile | ✓ | ✓ |

| 7. Project location: Santiago, Chile | ✓ | ✓ |

| 8. Project size: numbers of floors (m2) | 22 (14,200) | 24 (15,000) |

| 9. Explicit Lean tool application (as reported by the client company) | x | x |

| 10. Explicit BIM application (as reported by the client company) | x | ✓ |

| Type | Metric | Definition |

|---|---|---|

| Node | Degree | How many other nodes a node is connected to [22]. |

| Betweenness | How many pairs of individuals are connected through a node with the least number of steps: brokerage role [88]. | |

| Closeness | How close a node is to other nodes; depends on the shortest average length [10]. | |

| Network | Density | How many actual links exist between nodes divided by the number of total possible links in the network [22]. |

| Mean degree | How many other nodes a node is connected to, on average [22]. | |

| Clustering | How clustered groups of people are compared with the rest of the network; the existence of closed triads and small communities [88]. | |

| Average path length | How many steps on average nodes require to reach each other [10]. | |

| Diameter | How many steps nodes require to reach each other (maximum) [10]. | |

| Modularity | How dense are the connections between nodes within groups compared with nodes with another group [88]. |

| Type | Metrics |

|---|---|

| Knowledge of roles and responsibilities (directed) | In-degree of each node (total number of other nodes that have links directed towards it); mean in-degree of the network |

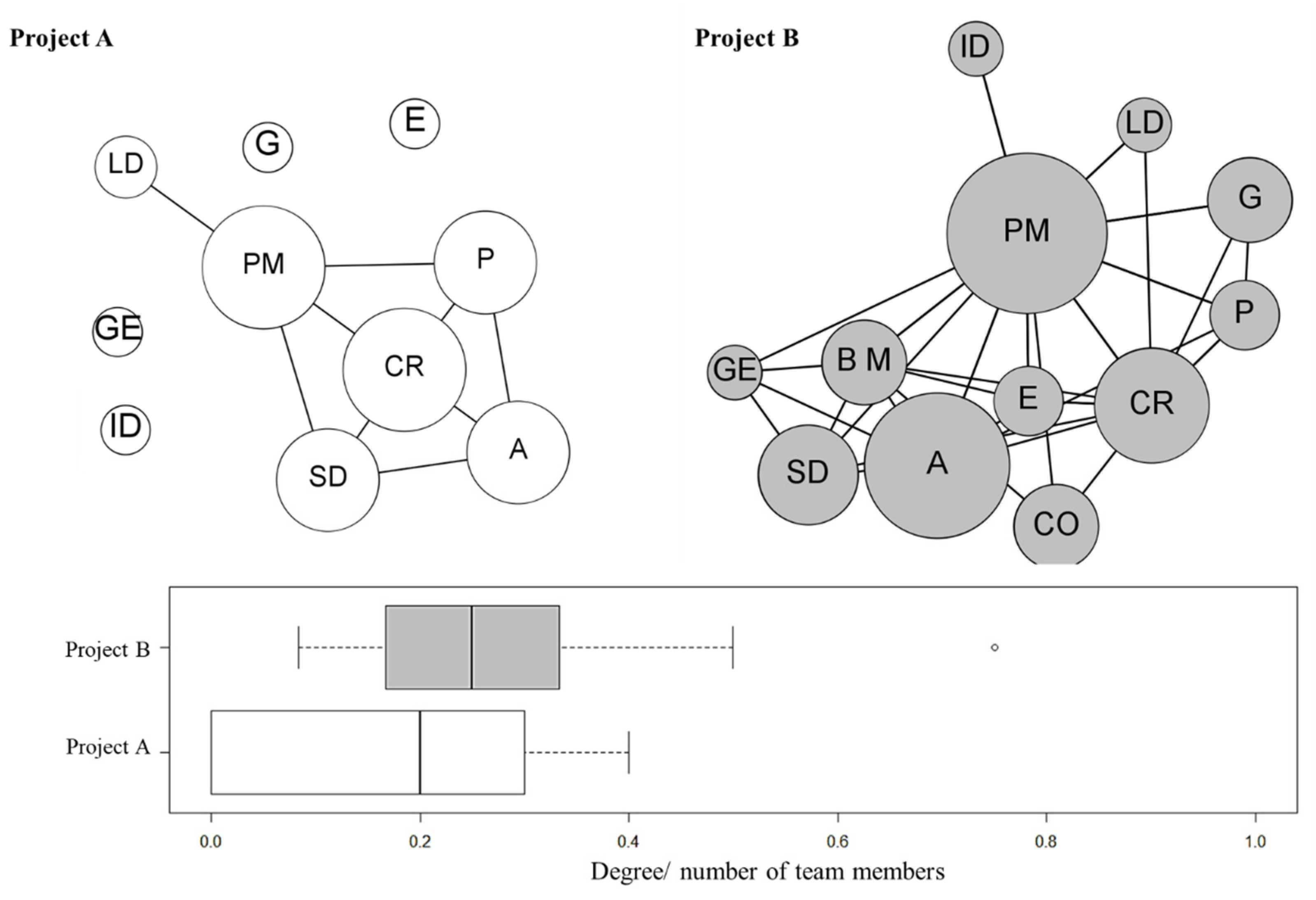

| Global interaction (undirected) | Degree of each node (total number of other nodes that are incident to the node); mean and range degree of the network; # of connected components |

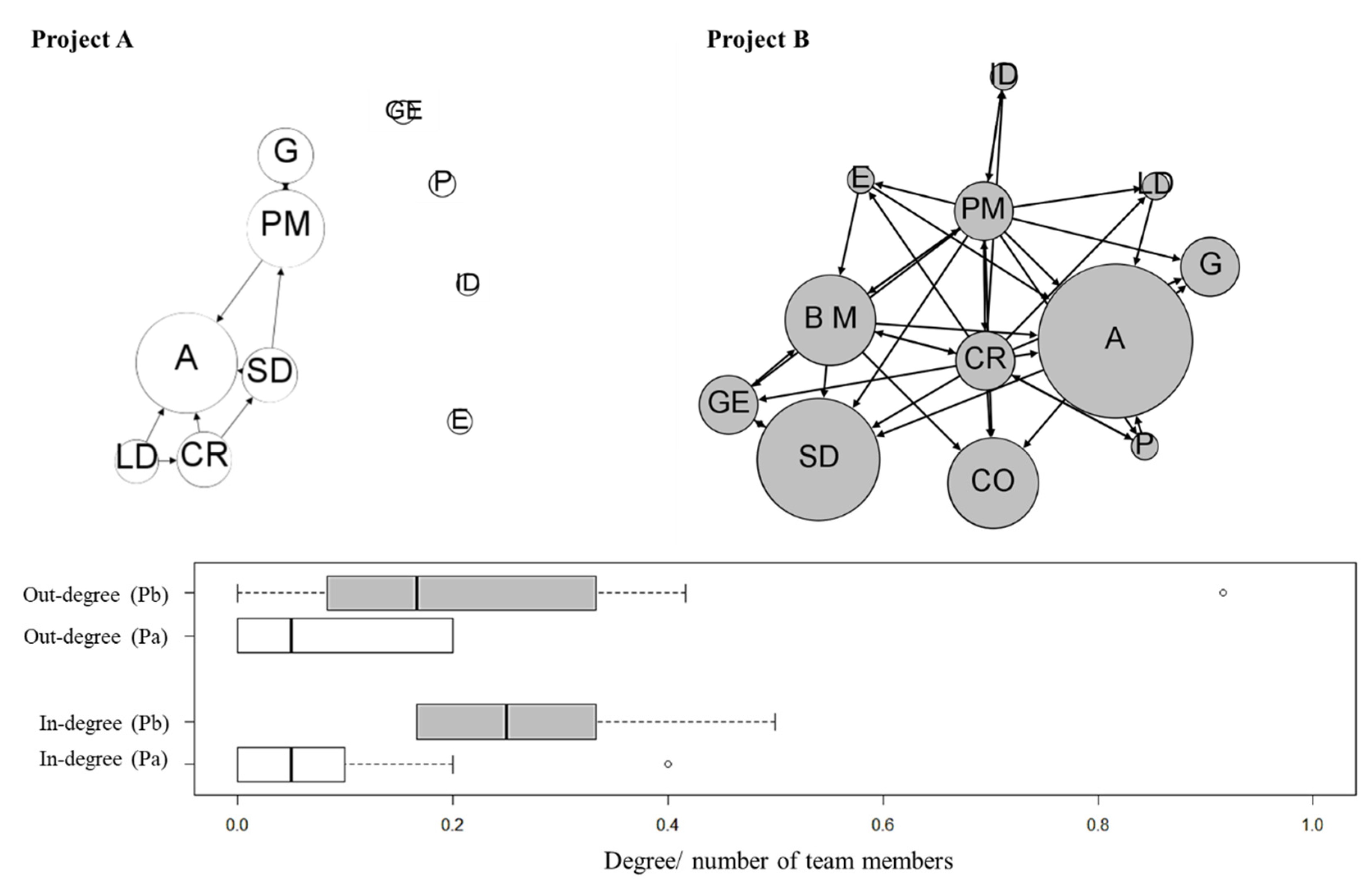

| Relevant work information (directed) | Percentage of bidirectional links; in-degree and out-degree of each node (total number of other nodes to which it directs links); mean and range degree of the network; # of weakly connected and of strongly connected components |

| Learning (directed) | |

| Planning and problem solving (undirected) | Percentage of bidirectional links; degree of each node; mean and range degree of the network; # of connected components |

| Collaboration (undirected) | |

| Trust (directed) | # of links in the trust network/# of links in the knowledge of roles network |

| Request for requirement (directed) | Requirement links |

| Requirement negotiation (undirected) | Negotiated links/requirement links |

| Declaration of compliance (directed) | Compliance declaration links/requirement links |

| Declaration of satisfaction (directed) | Satisfaction declaration links/requirement links |

| Activity | Tool | Source of Information |

|---|---|---|

| Assessment of 10 BIM uses (Table 2) and Benchmark with 25 projects. | BUA tool | Project A: 1 interview with project manager and client representative Project B: 2 interviews with project manager, client representative and BIM manager Data from [58]. |

| Assessment of 19 LDM practices (Table 1) and benchmark with 64 projects | LDM practices questionnaire | Project A: 1 interview with project manager and client representative Project B: 1 interview with project manager and client representative Data from [41]. |

| SNA: information capture of 11 types of interactions (Table 3) | Survey of types of interactions [13] | Project A: 10 responses (all design team members) Project B: 12 responses (all design team members) |

| SNA: data processing. Calculate of PVC, software processing, create sociograms and calculate metrics (Table 6) | Gephi Recommendations from [13] | Project A: 10 responses (all design team members) Project B: 12 responses (all design team members) |

| Interactions’ assessment and comparative analysis of two case studies | Gephi Comparative analysis | BUA tool responses LDM practices questionnaire responses SNA metrics and sociograms |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. Comparing Team Interactions in Traditional and BIM-Lean Design Management. Buildings 2021, 11, 447. https://doi.org/10.3390/buildings11100447

Herrera RF, Mourgues C, Alarcón LF, Pellicer E. Comparing Team Interactions in Traditional and BIM-Lean Design Management. Buildings. 2021; 11(10):447. https://doi.org/10.3390/buildings11100447

Chicago/Turabian StyleHerrera, Rodrigo F., Claudio Mourgues, Luis F. Alarcón, and Eugenio Pellicer. 2021. "Comparing Team Interactions in Traditional and BIM-Lean Design Management" Buildings 11, no. 10: 447. https://doi.org/10.3390/buildings11100447

APA StyleHerrera, R. F., Mourgues, C., Alarcón, L. F., & Pellicer, E. (2021). Comparing Team Interactions in Traditional and BIM-Lean Design Management. Buildings, 11(10), 447. https://doi.org/10.3390/buildings11100447