Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar

Abstract

1. Introduction

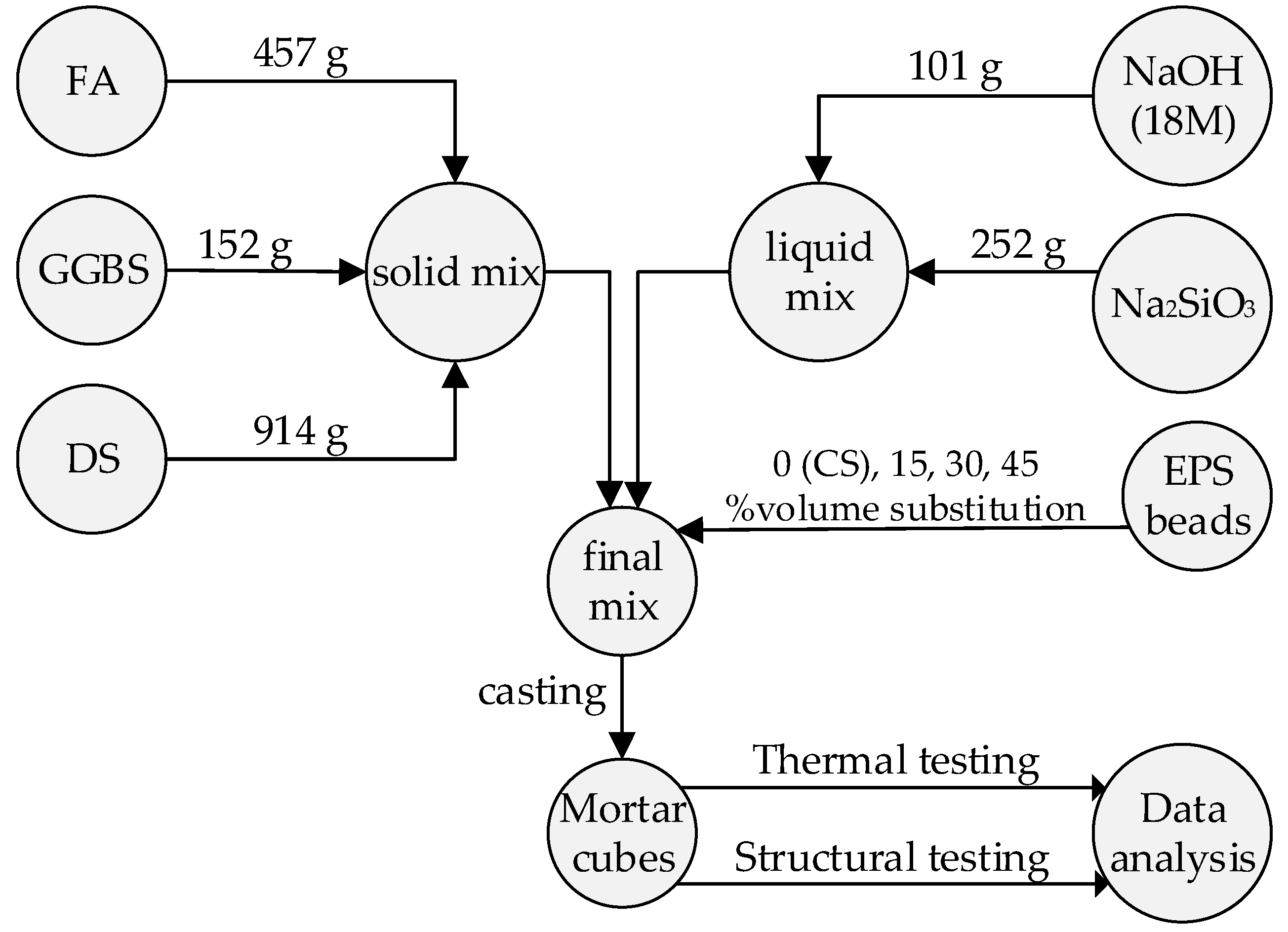

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. Induction of Porosity in Geopolymer

2.4. Thermal Performance Set-Up

2.5. Heat Transfer Analysis

2.6. Compressive Strength Testing

3. Results and Discussion

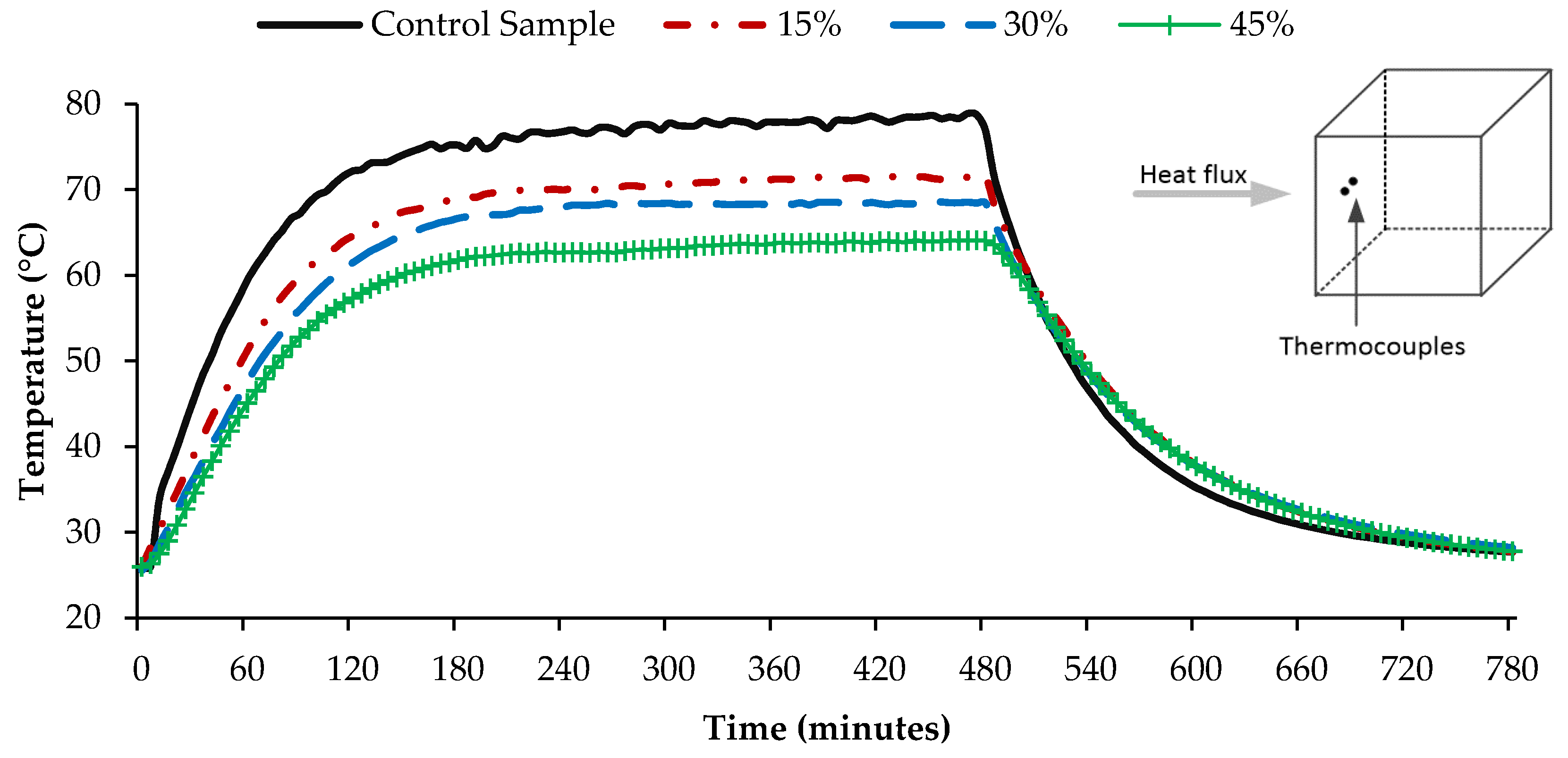

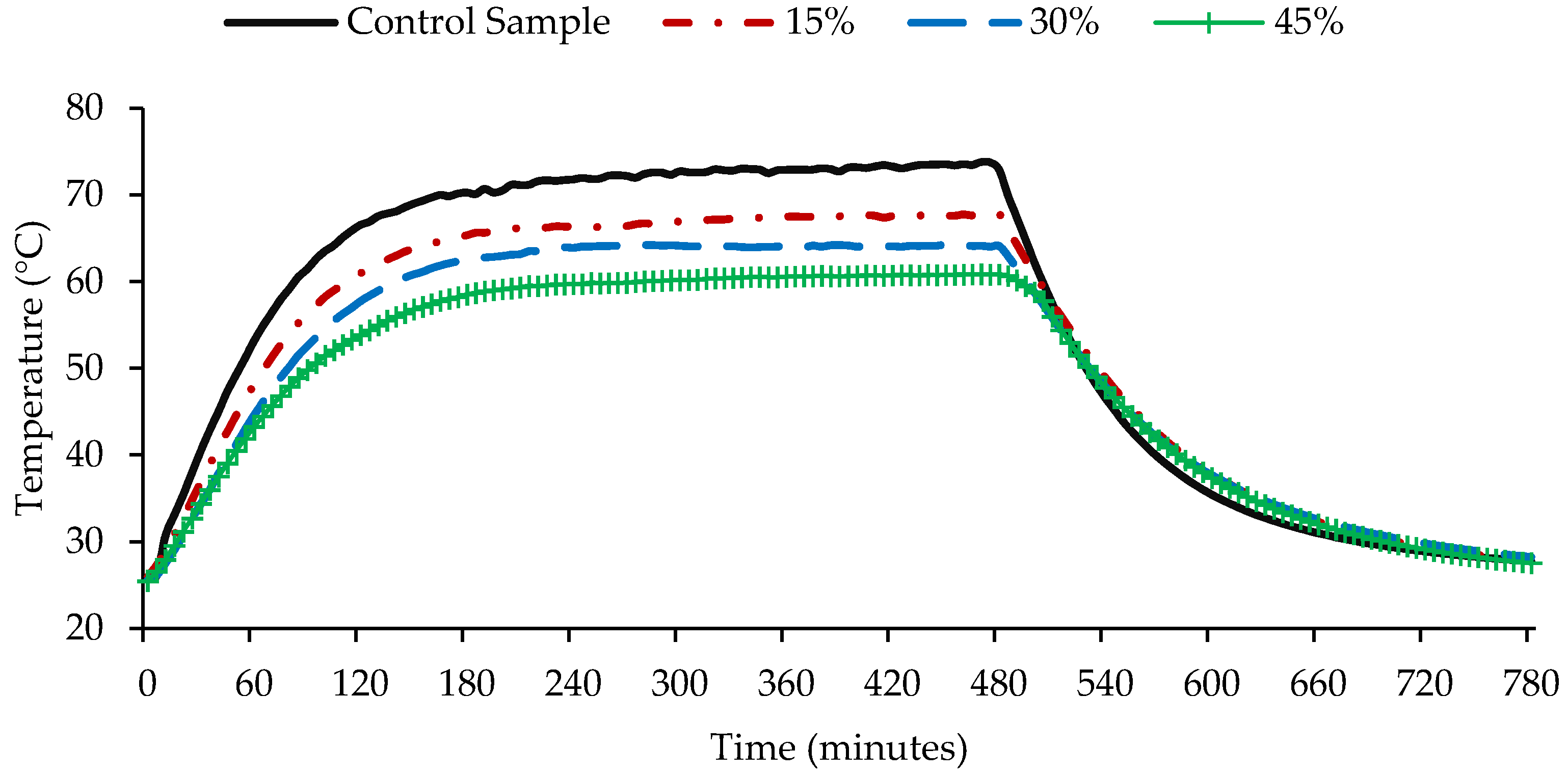

3.1. Thermal Performance

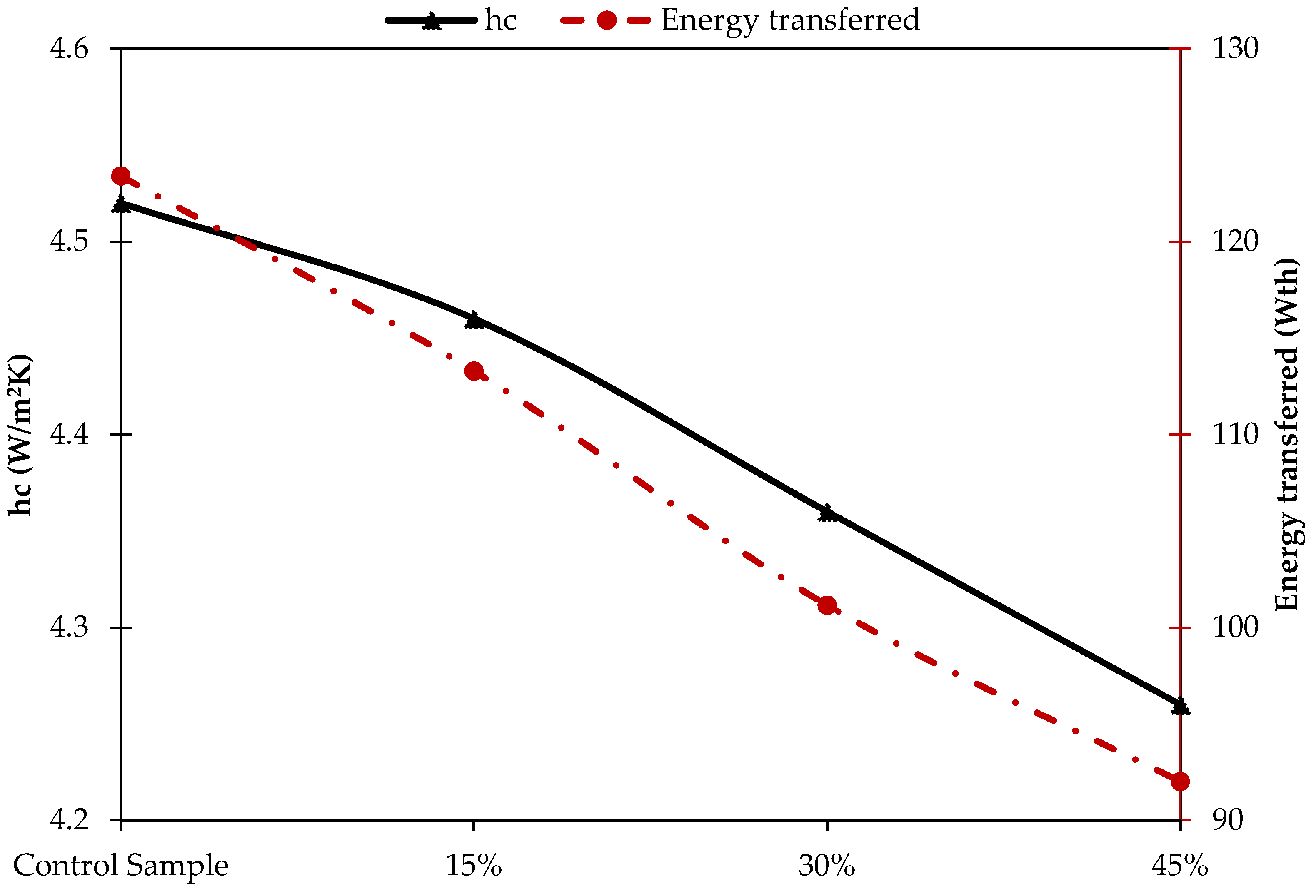

3.2. Cooling Load Reduction

3.3. Porosity Distribution and Density

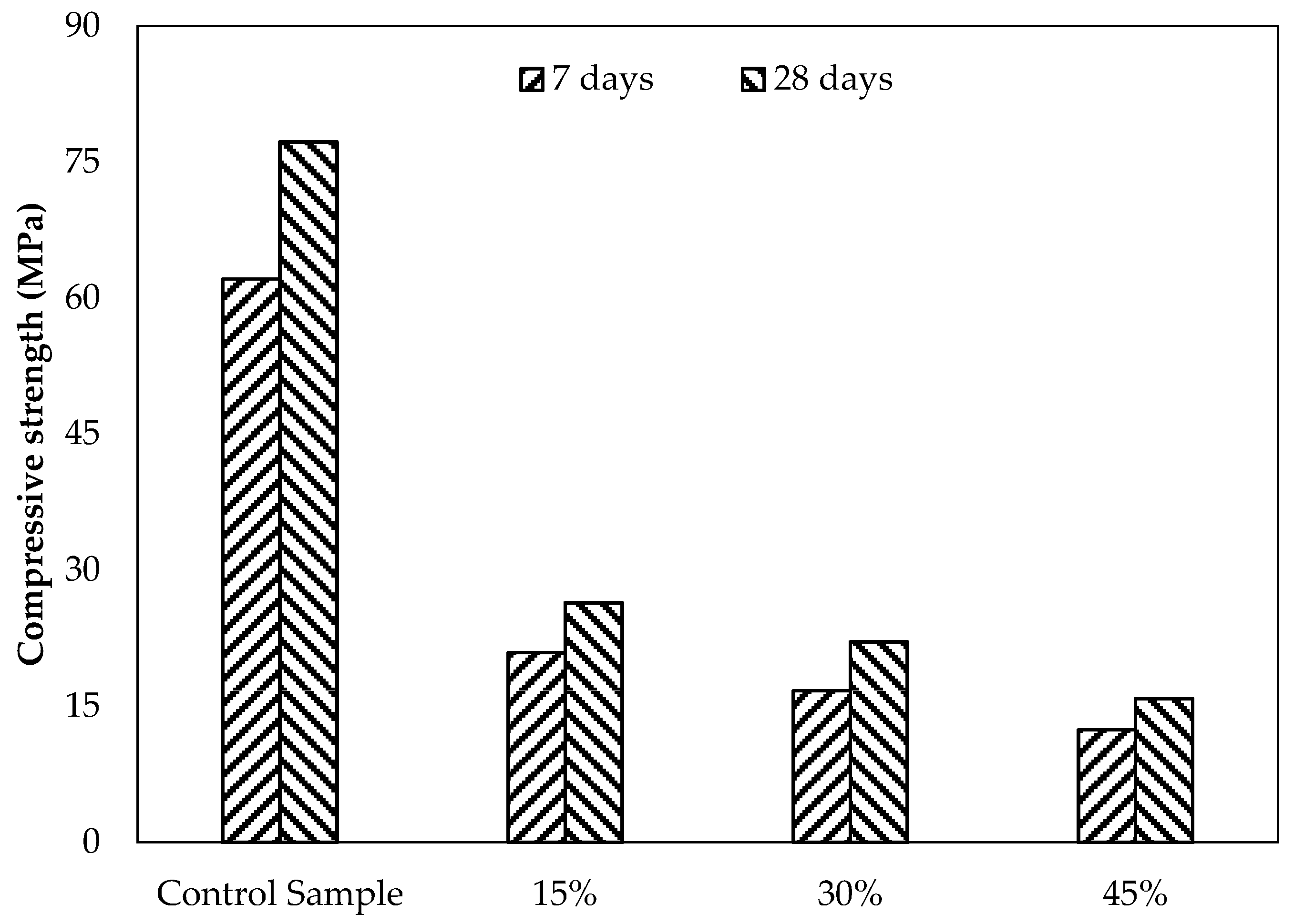

3.4. Compressive Strength

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Summerbell, D.L.; Barlow, C.Y.; Cullen, J.M. Potential reduction of carbon emissions by performance improvement: A cement industry case study. J. Clean. Prod. 2016, 135, 1327–1339. [Google Scholar] [CrossRef]

- Law, D.W.; Adam, A.A.; Molyneaux, T.K.; Patnaikuni, I.; Wardhono, A. Long term durability properties of class F fly ash geopolymer concrete. Mater. Struct. 2015, 48, 721–731. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si+Ca) and metakaolin (Si+Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Gluth, G.J.G.; Rickard, W.D.A.; Werner, S.; Pirskawetz, S. Acoustic emission and microstructural changes in fly ash geopolymer concretes exposed to simulated fire. Mater. Struct. 2016, 49, 5243–5254. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Thermal analysis of geopolymer concrete walls containing microencapsulated phase change materials for building applications. Sol. Energy 2019, 178, 295–307. [Google Scholar] [CrossRef]

- Rashid, Y.; Hassan, A.; Mourad, A.-H.; Ismail, N.; Laghari, M. Thermal and Structural Characterization of Geopolymer-Coated Polyurethane Foam-Phase Change Material Capsules/Geopolymer Concrete Composites. Materials 2019, 12, 796. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Zareei, S.A.; Behforouz, B. Geopolymers vs. alkali-activated materials (AAMs): A comparative study on durability, microstructure, and resistance to elevated temperatures of lightweight mortars. Constr. Build. Mater. 2019, 222, 49–63. [Google Scholar] [CrossRef]

- Sarıdemir, M.; Çelikten, S. Investigation of fire and chemical effects on the properties of alkali-activated lightweight concretes produced with basaltic pumice aggregate. Constr. Build. Mater. 2020, 260, 119969. [Google Scholar] [CrossRef]

- Daniel, A.J.; Sivakamasundari, S.; Abhilash, D. Comparative Study on the Behaviour of Geopolymer Concrete with Hybrid Fibers under Static Cyclic Loading. Procedia Eng. 2017, 173, 417–423. [Google Scholar] [CrossRef]

- Pires, E.F.C.; Lima, T.V.; Marinho, F.J.V.; de Vargas, A.S.; Mounzer, E.C.; Darwish, F.A.I.; Silva, F.J. Physical nonlinearity of precast reinforced geopolymer concrete beams. J. Mater. Res. Technol. 2019, 8, 2083–2091. [Google Scholar] [CrossRef]

- Palanisamy, P.; Kumar, P.S. Effect of molarity in geo polymer earth brick reinforced with fibrous coir wastes using sandy soil and quarry dust as fine aggregate. (Case study). Case Stud. Constr. Mater. 2018, 8, 347–358. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Marini, A.; Passoni, C.; Pastore, T. Lightweight cement-free alkali-activated slag plaster for the structural retrofit and energy upgrading of poor quality masonry walls. Cem. Concr. Compos. 2019, 104, 103341. [Google Scholar] [CrossRef]

- Samal, S.; Phan Thanh, N.; Petríková, I.; Marvalová, B.; Vallons, K.A.M.; Lomov, S.V. Correlation of microstructure and mechanical properties of various fabric reinforced geo-polymer composites after exposure to elevated temperature. Ceram. Int. 2015, 41, 12115–12129. [Google Scholar] [CrossRef]

- Demirboga, R.; Kan, A. Thermal conductivity and shrinkage properties of modified waste polystyrene aggregate concretes. Constr. Build. Mater. 2012, 35, 730–734. [Google Scholar] [CrossRef]

- Khoukhi, M. The combined effect of heat and moisture transfer dependent thermal conductivity of polystyrene insulation material: Impact on building energy performance. Energy Build. 2018, 169. [Google Scholar] [CrossRef]

- Cadere, C.A.; Barbuta, M.; Rosca, B.; Serbanoiu, A.A.; Burlacu, A.; Oancea, I. Engineering properties of concrete with polystyrene granules. Procedia Manuf. 2018, 22, 288–293. [Google Scholar] [CrossRef]

- Adam, A.A.; Horianto, X.X.X. The Effect of Temperature and Duration of Curing on the Strength of Fly Ash Based Geopolymer Mortar. Procedia Eng. 2014, 95, 410–414. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K.; Rangan, V.B. Early Age Properties of Low-calcium Fly Ash Geopolymer Concrete Suitable for Ambient Curing. Procedia Eng. 2015, 125, 601–607. [Google Scholar] [CrossRef]

- Muhammad, N.; Baharom, S.B.; Amirah, N.; Ghazali, M.; Alias, N.A. Effect of Heat Curing Temperatures on Fly Ash-Based Geopolymer Concrete. Int. J. Eng. Technol. 2019, 8, 15–19. [Google Scholar]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef]

- Ismail, N.; El-Hassan, H. Development and Characterization of Fly Ash–Slag Blended Geopolymer Mortar and Lightweight Concrete. J. Mater. Civ. Eng. 2018, 30, 04018029. [Google Scholar] [CrossRef]

- Rashid, Y. Thermal and Structural Characterization of Macro-Encapsulated Phase Change Material Integrated Into Concrete Cubes. Master’s Thesis, United Arab Emirates University, Al Ain, UAE, 2018. [Google Scholar]

- Ayati, B.; Ferrándiz-Mas, V.; Newport, D.; Cheeseman, C. Use of clay in the manufacture of lightweight aggregate. Constr. Build. Mater. 2018, 162, 124–131. [Google Scholar] [CrossRef]

- Omnexus. Expanded Polystyrene (EPS): Ultimate Guide on Foam Insulation Material. 2020. Available online: https://omnexus.specialchem.com/selection-guide/expanded-polystyrene-eps-foam-insulation#:~:text=Polystyrene%20granulate%20is%20prefoamed%20at,50%20times%20its%20original%20size (accessed on 14 August 2020).

- Schneider, E.; Steinweg, J.; Machelett, L.; Giovannetti, F. Solar Assisted Production of Expanded Polystyrene with High Efficiency Flat Plate Collectors. In Proceedings of the 11th ISES EuroSun 2016 Conference, Palma de Mallorca, Spain, 11–14 October 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Sen, I. Degradation Mechanism of Expanded Polystyrene (EPS) Foam in Lost Foam Casting, PIPS Approach for Synthesis and Novel Expansion Techniques for Cellular Foam. Ph.D. Thesis, University of Tennessee, Knoxville, TN, USA, 2007. [Google Scholar]

- Awbi, H.B. Calculation of convective heat transfer coefficients of room surfaces for natural convection. Energy Build. 1998, 28, 219–227. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Xie, P.; Najm, H. Analysis of thermal conductivity of porous concrete using laboratory measurements and microstructure models. Constr. Build. Mater. 2019, 218, 90–98. [Google Scholar] [CrossRef]

- Hasan, A.; Alnoman, H.; Rashid, Y. Impact of integrated photovoltaic-phase change material system onbuilding energy efficiency in hot climate. Energy Build. 2016, 130, 495–505. [Google Scholar] [CrossRef]

- Ahmad, H.; Khaled, A.-S.; Alnoman, H.; Yasir, R.; Shaimaa, A. Effect of Phase Change Materials (PCMs) Integrated into a Concrete Block on Heat Gain Prevention in a Hot Climate. Sustainability 2016, 8, 1009. [Google Scholar]

- Peeters, L.; Beausoleil-Morrison, I.; Novoselac, A. Internal convective heat transfer modeling: Critical review and discussion of experimentally derived correlations. Energy Build. 2011, 43, 2227–2239. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Nonloadbearing Concrete Masonry Units. In ASTM C129-17; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM International. Standard Specification for Pedestrian and Light Traffic Paving Brick. In ASTM C902-15; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Liu, Y.; Tang, W.; Singh, R. Study on Compressive Strength and Water Permeability of Steel Slag-Fly Ash Mixed Permeable Brick. Appl. Sci. 2019, 9, 1542. [Google Scholar] [CrossRef]

- Mora, O.; Alvarado, D.; Torres, A. Economic analysis of the application of porous pavements on Bogota roads. In Proceedings of the 12nd International Conference on Urban Drainage, Porto Alegre, Brazil, 11–16 September 2011. [Google Scholar]

- Elizondo-Martinez, E.; Andrés-Valeri, V.; Jato-Espino, D.; Rodriguez-Hernandez, J. Review of porous concrete as multifunctional and sustainable pavement. J. Build. Eng. 2019, 27. [Google Scholar] [CrossRef]

- Bubeník, J.; Zach, J. The use of foam glass based aggregates for the production of ultra-lightweight porous concrete for the production of noise barrier wall panels. Transp. Res. Procedia 2019, 40, 639–646. [Google Scholar] [CrossRef]

| Material | Source | Main Components | Proportions | Density (kg/m3) |

|---|---|---|---|---|

| Dune sand (DS) | Al Ain (UAE) | SiO2, CaO, Al2O3 | 63.9%, 14.1%, 3%, | 1693 |

| Fly Ash (FA) | Ashtech International (Dubai, UAE) | SiO2, Al2O3, Fe2O3, CaO | 48%, 23.1%, 12.5%, 3.3% | 1262 |

| Ground granulated blast furnace slag (GGBS) | Emirates Cement factory (Al Ain, UAE) | CaO, SiO2, Al2O3, MgO | 42%, 34.7%, 14.4%, 6.9% | 1236 |

| Sodium silicate solution | Sigma-Aldrich (St. Louis, MO, USA) | – | – | – |

| Sodium hydroxide | Sigma-Aldrich (St. Louis, MO, USA) | – | – | – |

| Control Sample (°C) | 15% (°C) | 30% (°C) | 45% (°C) | |

|---|---|---|---|---|

| Front surface | 78.5 | 71.4 | 68.6 | 64.1 |

| Back surface | 68.4 | 63.8 | 59.5 | 57.2 |

| Side 1 (Top Surface) | 73.5 | 68.0 | 63.6 | 61.2 |

| Side 2(Down Surface) | 74.1 | 67.4 | 63.3 | 59.9 |

| Side 3 (Left Surface) | 73.8 | 67.9 | 64.3 | 60.8 |

| Side 4 (Right Surface) | 73.7 | 67.1 | 64.1 | 60.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qadir, G.; Rashid, Y.; Hassan, A.; Vall, E.; Saleh, S.; Salim, K. Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar. Buildings 2021, 11, 1. https://doi.org/10.3390/buildings11010001

Qadir G, Rashid Y, Hassan A, Vall E, Saleh S, Salim K. Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar. Buildings. 2021; 11(1):1. https://doi.org/10.3390/buildings11010001

Chicago/Turabian StyleQadir, Ghulam, Yasir Rashid, Ahmed Hassan, Esma Vall, Shamsa Saleh, and Khadega Salim. 2021. "Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar" Buildings 11, no. 1: 1. https://doi.org/10.3390/buildings11010001

APA StyleQadir, G., Rashid, Y., Hassan, A., Vall, E., Saleh, S., & Salim, K. (2021). Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar. Buildings, 11(1), 1. https://doi.org/10.3390/buildings11010001