The Behaviour of Fresh Concrete with Varying Coarse Aggregate Content at the Concrete-Steel Wall Interface

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

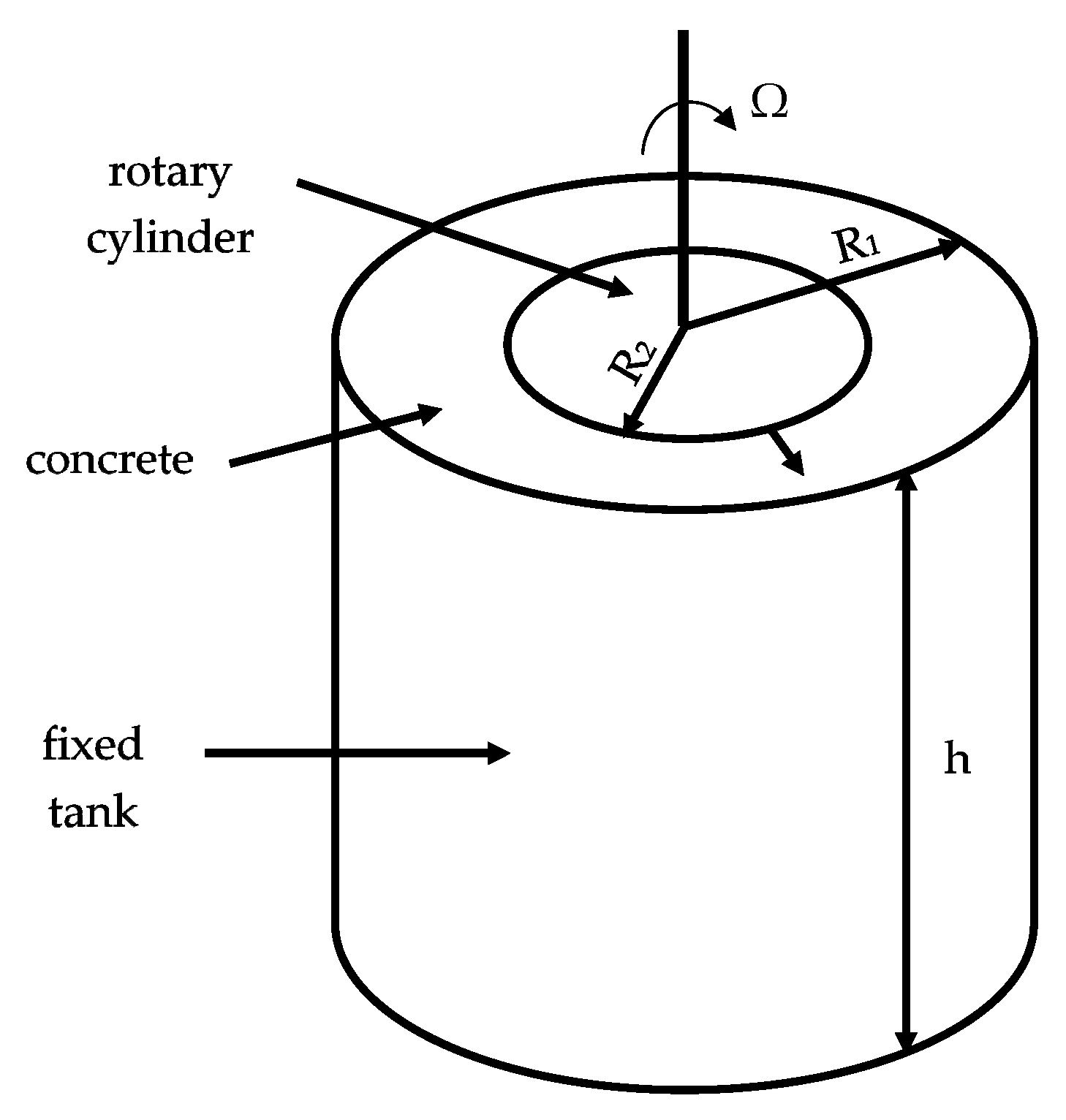

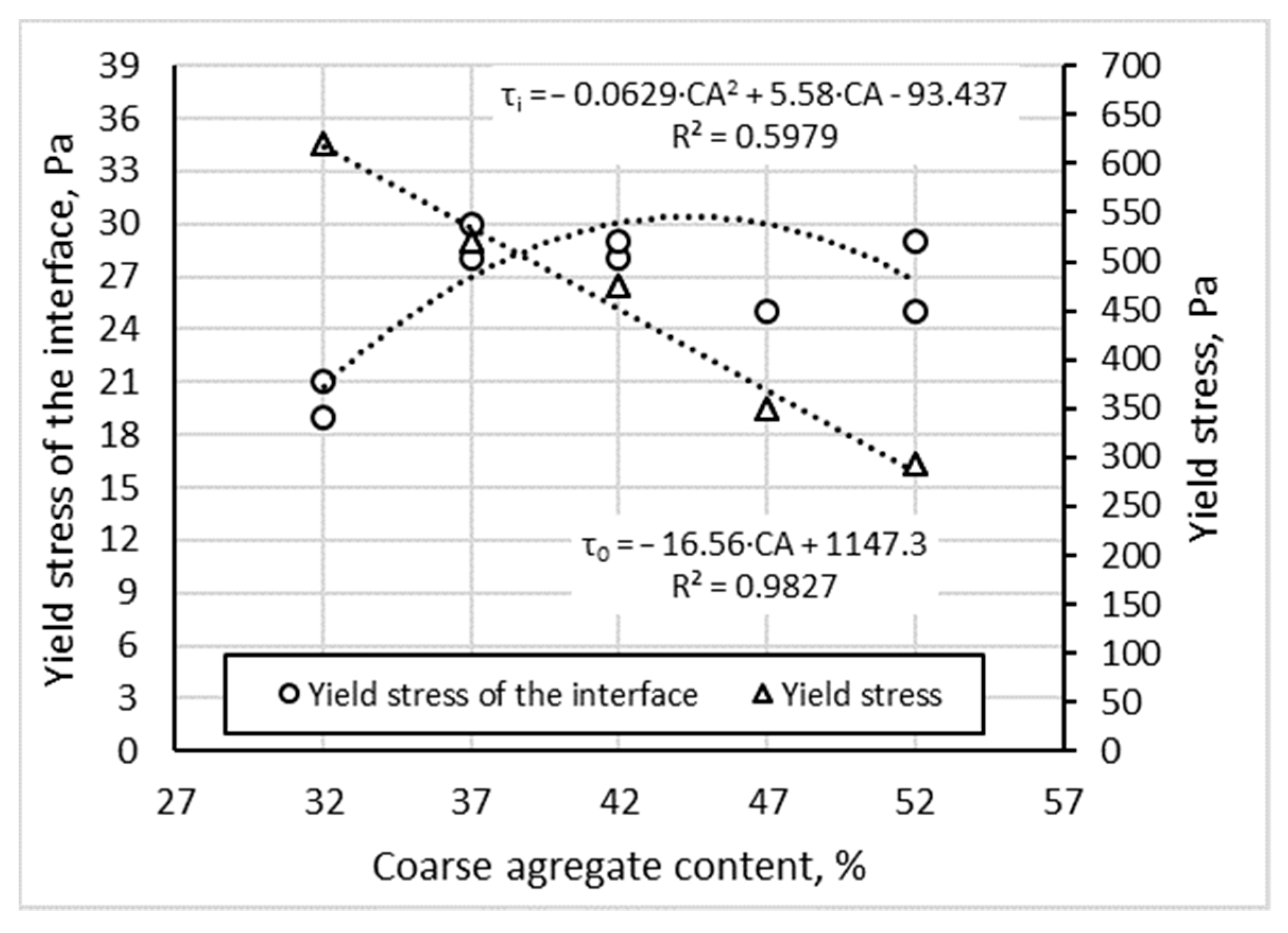

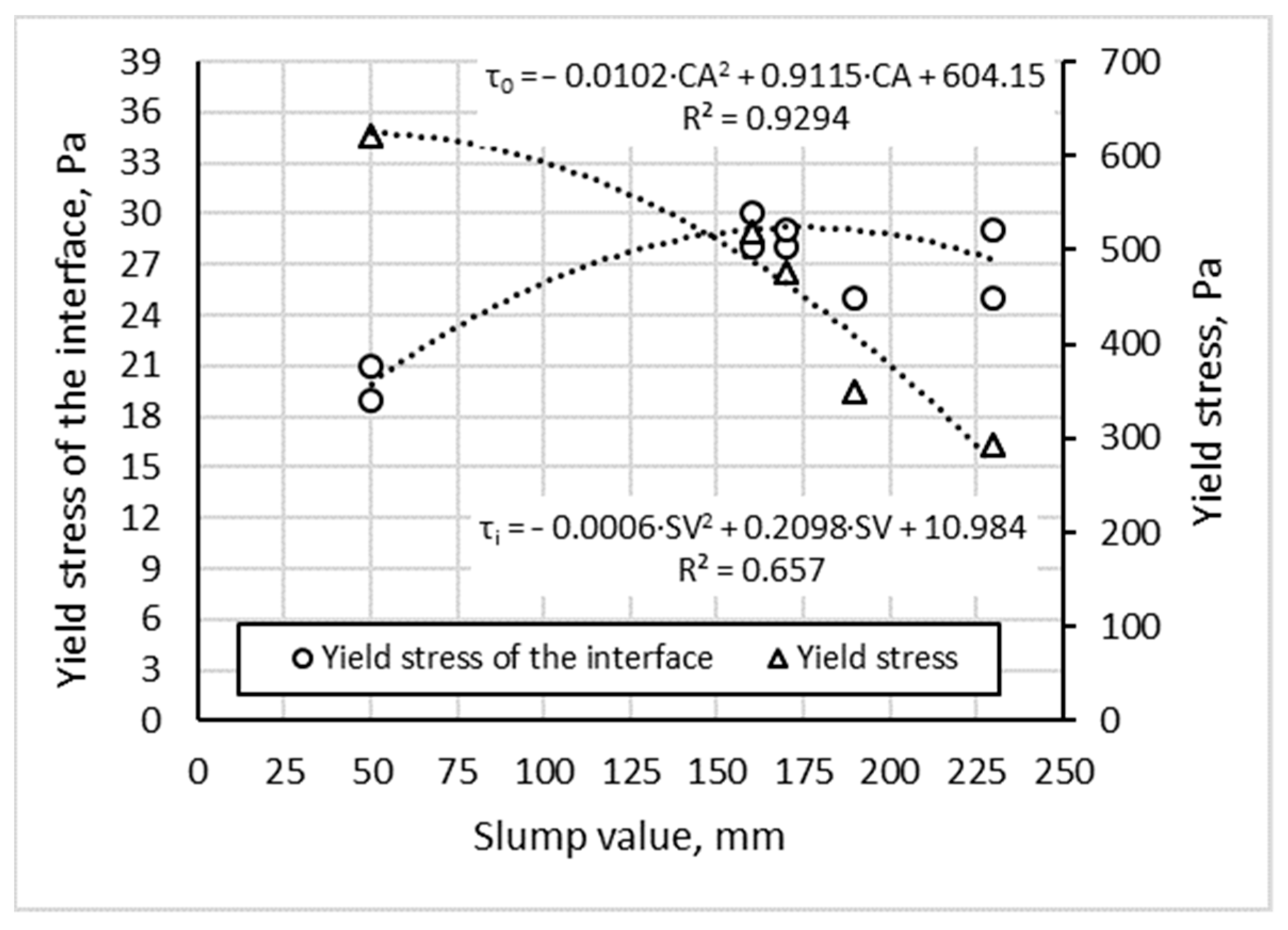

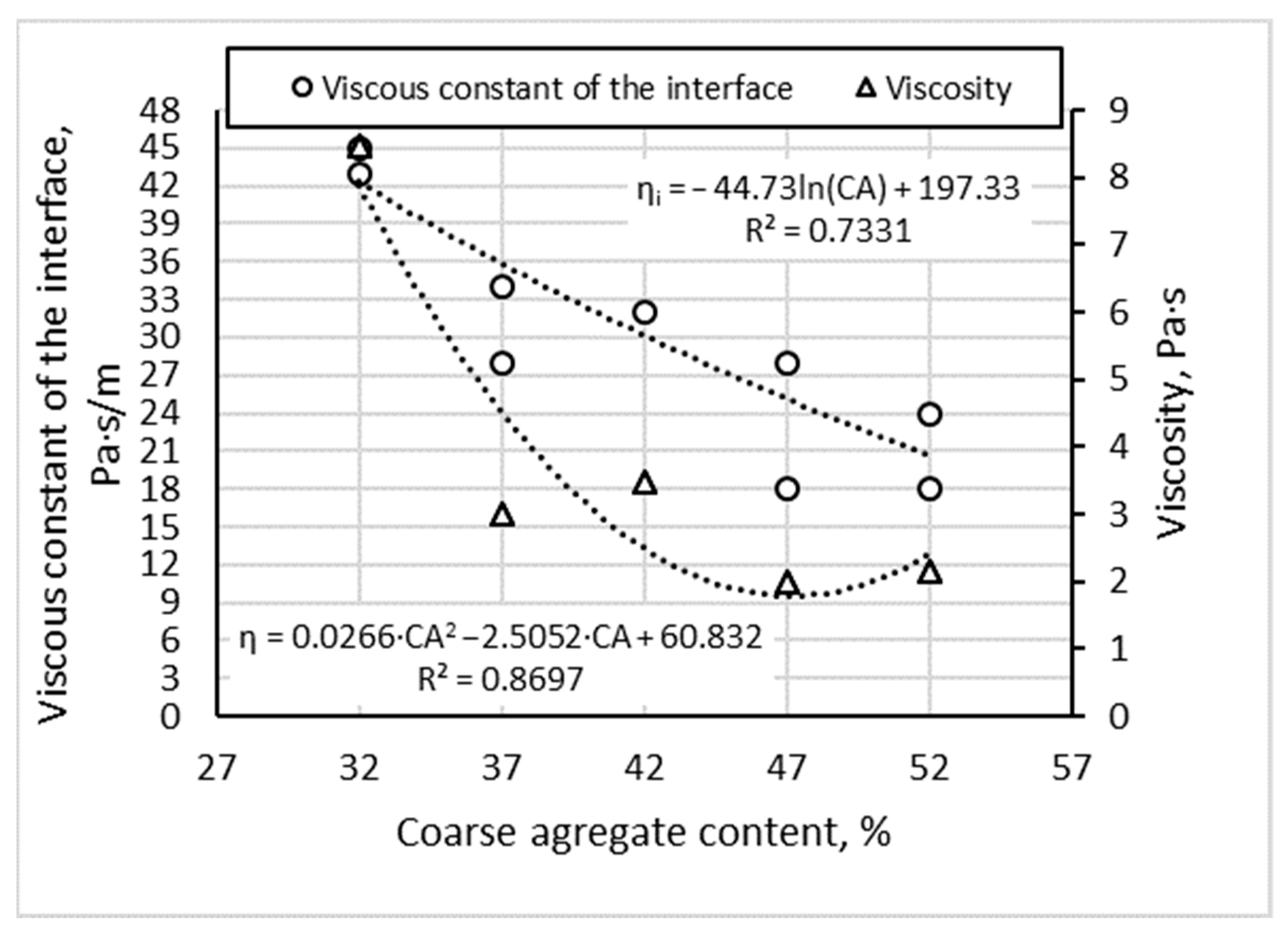

3.1. Effect of Coarse Aggregate Content on Concrete-Steel Wall Interface.

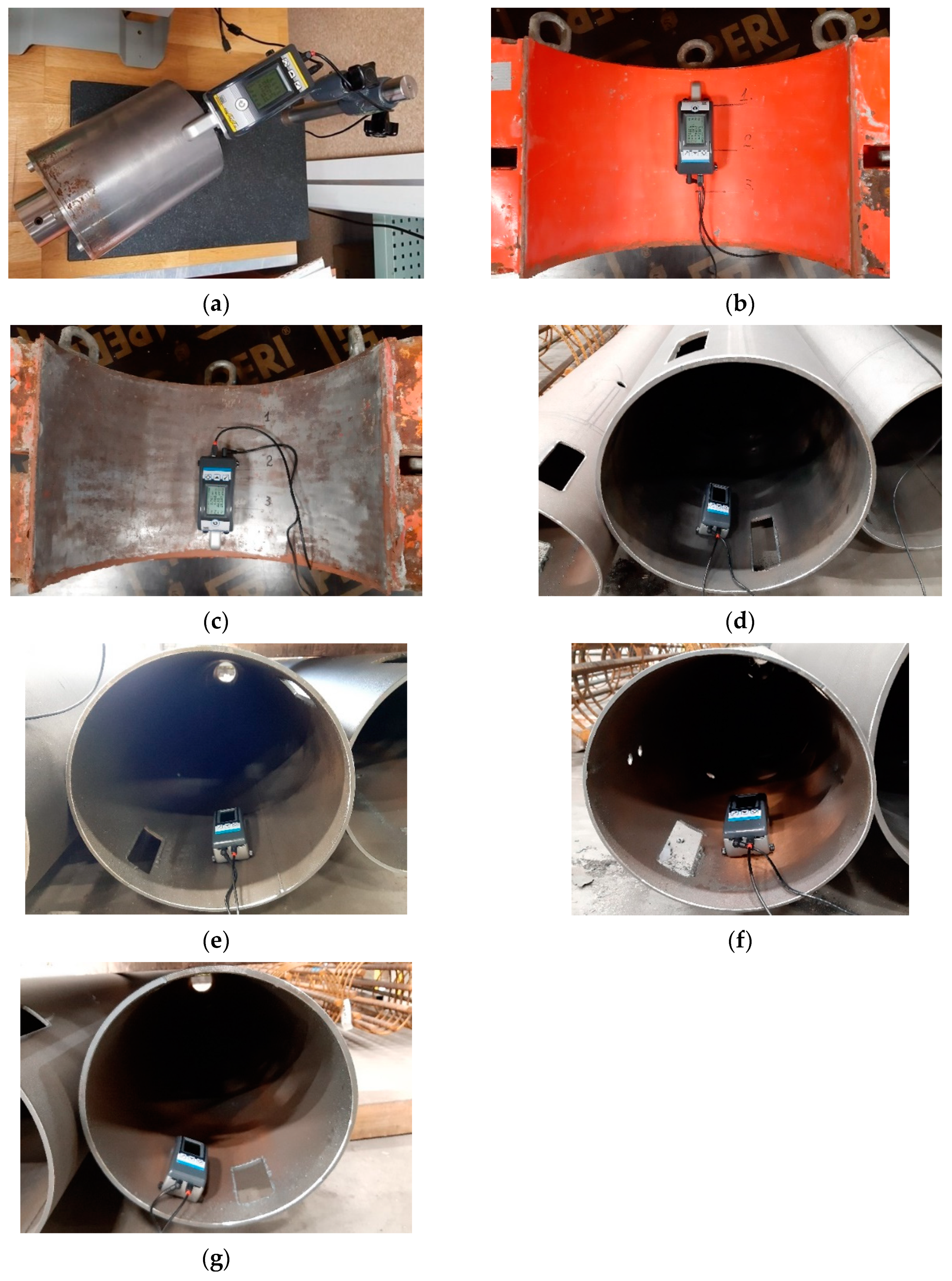

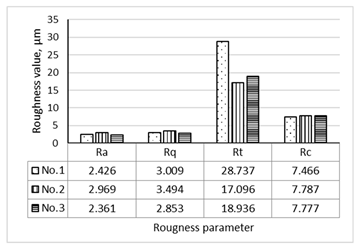

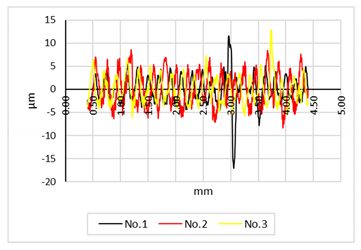

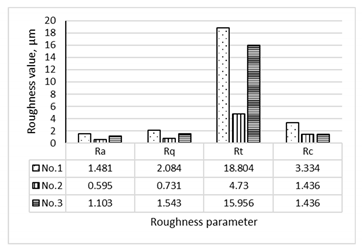

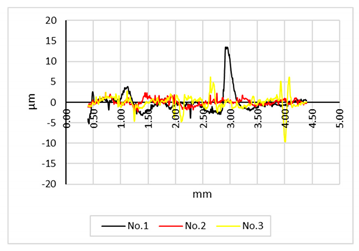

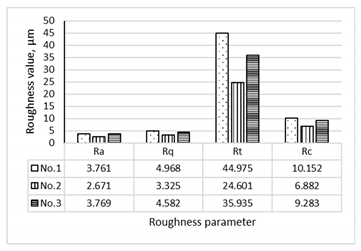

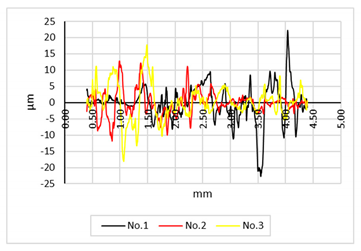

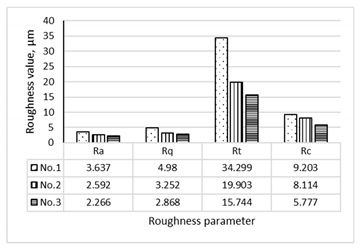

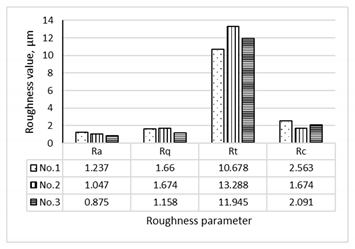

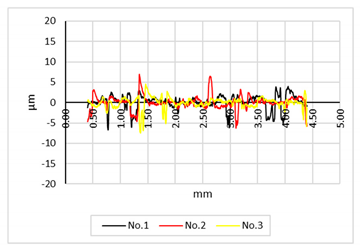

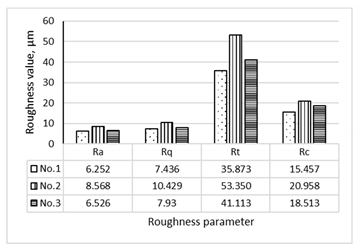

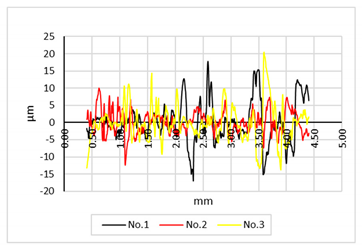

3.2. Effect of Surface Roughness Parameters on Concrete–Steel Wall Interface

4. Conclusions

- Changes of the CA content in the AM from 42 to 52% had minimal effect on the yield stress of the interface and a decrease in the viscous constant of the interface as measured with a tribometer, when Rt values of the rotary cylinder wall were in the range from 17.10 to 28.74 μm. Changes of the CA content in the AM from 42 to 52% decrease the viscosity of concrete, while the yield stress of concrete decreased significantly as calculated with the chosen equations.

- The comparison of surface roughness between steel rotary cylinder, metal form-lining and different types of steel composite columns showed that the maximum profile peak height and the maximum profile valley depth along the sampling length (Rt) values varied in the approximately the same range from 15.00 to 30.00 μm, except for worn metal form-lining and the steel tubes with inner surface which was in part covered in rust, where the Rt values determined were higher. The value of parameter Rt allows for the determination of whether the constituent concrete grains such as cement particle and fine sand particle are in fact capable of lodging inside the asperities and therefore reducing interface friction at the concrete-steel interface.

- On the basis of the research results, the hypothesis is based on the principle that a sufficient lubrication layer can be created with the required thickness of fine mortar at the interface between the concrete and the metal form-lining or steel composite column wall, when the CA content in the AM varies in the range from 42 to 52% and the wall roughness parameters (Rt) of these elements varies in the range from 15.00 to 30.00 μm. It allows the prediction of the interface friction variation, with changes in the lubrication layer as a result of variations in the concrete mix composition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tattersall, G.H.; Banfill, P.F.G. The Rheology of Fresh Concrete. Pitman Advanced Pub. Program: San Francisco, CA, USA, 1983; p. 356. [Google Scholar]

- Bartos, P. Fresh Concrete, Properties and Tests. Elsevier Science Publishers B. V.: Amsterdam, UK, 1992; 305 p. [Google Scholar]

- Kaplan, D. Pompage des Betons. Etudes des Recherches des Laboratoires des Ponts et Chaussées: Paris, France, 2001; p. 227. Available online: https://www.ifsttar.fr/fileadmin/user_upload/editions/lcpc/ERLPC/ERLPC-OA-LCPC-OA36.pdf (accessed on 18 October 2016).

- Secrieru, E.; Khodor, J.; Schröfl, C.; Mechtcherine, V. Formation of lubricating layer and flow type during pumping of cement-based materials. Constr. Build. Mater. 2018, 178, 507–517. [Google Scholar] [CrossRef]

- Eckardstein, K.E.V. Pumping Concrete and Concrete Pumps—A Concrete Placing Manual; Schwing: Herne, Germany, 1983; p. 133. [Google Scholar]

- Feys, D.; Khayat, K.H.; Perez-Schell, A.; Khatib, R. Development of a tribometer to characterize lubrication layer properties of self-consolidating concrete. Cem. Concr. Comp. 2014, 54, 40–52. [Google Scholar] [CrossRef]

- Secrieru, E.; Fataei, S.H.; Schröfl, C.H.; Mechtcherine, V. Study on concrete pumpability combining different laboratory tools and linkage to rheology. Constr. Build. Mater. 2017, 144, 451–461. [Google Scholar] [CrossRef]

- Ngo, T.T.; Kadri, E.H.; Bennacer, R.; Cussigh, F. Use of tribometer to estimate interface friction and concrete boundary layer composition during the fluid concrete pumping. Constr. Build. Mater. 2010, 24, 1253–1261. [Google Scholar] [CrossRef]

- Secrieru, E.; Mechtcherine, V.; Schröfl, C.; Borin, D. Rheological characterisation and prediction of pumpability of strainhardening cement-based-composites (SHCC) with and without addition of superabsorbent polymers (SAP) at various temperatures. Constr. Build. Mater. 2016, 112, 581–594. [Google Scholar] [CrossRef]

- Vanhove, Y.; Djelal, C.; Magnin, A. A device for studying fresh concrete friction. Cem. Concr. Aggr. 2004, 26, 35–41. [Google Scholar] [CrossRef]

- Djelal, C.; Vanhove, Y.; Magnin, A. Tribological behaviour of self compacting concrete. Cem. Concr. Res. 2004, 34, 821–828. [Google Scholar] [CrossRef]

- Djelal, C.; De Caro, P.; Libessart, L.; Dubois, I. Comprehension of demoulding mechanisms at the formwork/oil/concrete interface. Mater. Struct. 2008, 41, 571–581. [Google Scholar] [CrossRef]

- Bouharoun, S.; De Caro, P.; Dubois, I.; Djelal, C.; Vanhove, Y. Effects of a superplasticizer on the properties of the concrete/oil/formwork interface. Constr. Build. Mater. 2013, 47, 1137–1144. [Google Scholar] [CrossRef]

- Ngo, T.T.; Kadri, E.H.; Cussigh, F.; Bennacer, R.; Duval, R. Practical Tribometer to Estimate Pumpability of Fresh Concrete. J. Asian Arch. Buil. Eng. 2010, 1, 229–236. [Google Scholar] [CrossRef]

- Djelal, C. Designing and testing of tribometer for the study of friction of a concentrated clay-water mixture against a metallic surface. Mater. Struct. 2001, 34, 51–58. [Google Scholar] [CrossRef]

- Ivkovic, B.; Djurdjanovic, M.; Stamenkovic, D. The Influence of the contact surface roughnesos on the static friction coefficient. Tribol. Indus. 2000, 22, 41–44. [Google Scholar]

- Kwon, S.H.; Phung, Q.T.; Park, H.Y.; Kim, J.H.; Shah, S.P. Effect of wall friction on variation of formwork pressure over time in self-consolidating concrete. Cem. Concr. Res. 2011, 41, 90–101. [Google Scholar] [CrossRef]

- Libessart, L.; De Caro, P.; Djelal, C.; Dubois, I. Correlation between adhesion energy of release agents on the formwork and demoulding performances. Constr. Build. Mater. 2015, 76, 130–139. [Google Scholar] [CrossRef]

- Graubner, C.A.; Boska, E.; Motzko, C.; Proske, T.; Dehn, F. Formwork pressure induced by highly flowable concretes—Design approach and transfer into practice. Struct. Concr. 2012, 13, 51–60. [Google Scholar] [CrossRef]

- Arslan, M.; Simsek, O.; Subasi, S. Effects of formwork surface materials on concrete lateral pressure. Constr. Build. Mater. 2005, 19, 319–325. [Google Scholar] [CrossRef]

- LST EN 197-1:2000. Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements; CEN (European Committee for Standardization): Brussels, Belgium, 2000. [Google Scholar]

- LST EN 12620:2003+A1:2008. Aggregates for Concrete; CEN (European Committee for Standardization): Brussels, Belgium, 2008. [Google Scholar]

- LST EN 206:2013+A1:2017. Concrete-Specification, Performance, Production and Conformity; CEN (European Committee for Standardization): Brussels, Belgium, 2017. [Google Scholar]

- LST EN 12350-2:2019. Testing Fresh Concrete. Part 2: Slump-Test; CEN (European Committee for Standardization): Brussels, Belgium, 2019. [Google Scholar]

- LST EN 12350-6:2019. Testing Fresh Concrete. Part 6: Density; CEN (European Committee for Standardization): Brussels, Belgium, 2019. [Google Scholar]

- LST EN 12350-7:2019. Testing Fresh Concrete. Part 7: Air Content—Pressure Methods; CEN (European Committee for Standardization): Brussels, Belgium, 2019. [Google Scholar]

- De Larrard, F.; Sedran, T. Mixture-proportioning of high performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Ngo, T.T.; Kadri, E.H.; Cussigh, F.; Bennacer, R. Relationships between concrete composition and boundary layer composition to optimise concrete pumpability. Eur. J. Environ. Civ. Eng. 2012, 16, 157–177. [Google Scholar] [CrossRef]

- Skripkiūnas, G. Optimization of Concrete Macrostructure According to Technological and Performance Properties and Raw Material Resources. Ph.D. Thesis, Kaunas University of Technology, Kaunas, Lithuania, 1993. [Google Scholar]

- Skripkiūnas, G. Properties and Structure of Construction Conglomerates; Vitae Litera: Kaunas, Lithuania, 2007; p. 225. [Google Scholar]

- Klovas, A.; Daukšys, M. The Influence of Admixtures on the Technological Properties of Fresh Concrete Mixture. Mater. Scien. 2015, 21, 595–600. [Google Scholar] [CrossRef][Green Version]

- Daukšys, M.; Klovas, A. Calculation of plastic viscosity of concrete mixture using the modified empirical formula. IOP Conf. Ser. Mater. Sci. Eng. 2018, 442, 1–10. [Google Scholar] [CrossRef]

- Klovas, A. The Influence of Concrete Mixture‘s Rheological Properties on Formed Monolithic Concrete Surface Quality and Its Evaluation. Ph.D. Thesis, Kaunas University of Technology, Kaunas, Lithuania, 2016. [Google Scholar]

- Hu, C. Rhéology des bÉtons Fluides. Ph.D. Thesis, Ecole Nationale des Ponts et Chaussées, Paris, France, 1995. Available online: https://pastel.archives-ouvertes.fr/tel-00523283 (accessed on 8 October 2020).

- Hu, C.; De Larrard, F. The rheology of fresh high-peformance concrete. Cem. Concr. Res. 1996, 26, 283–294. [Google Scholar] [CrossRef]

- Kaplan, D.; Sedran, T.; De Larrard, F.; Vachon, M.; Marchese, G. Forecasting Pumping Parameters. In Proceedings of the 2nd International RILEM Symposium on Self-Compacting Concrete, Sanjo, Tokyo, 23–25 October 2001; pp. 555–564. [Google Scholar]

- LST EN ISO 4287:2007/A1:2009. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; CEN (European Committee for Standardization): Brussels, Belgium, 2009. [Google Scholar]

- Daukšys, M.; Skripkiūnas, G. Testing of rheological properties of concrete mixtures using a special vibroviscometer. J. Mater. Civ. Eng. 2018, 30, 1–8. [Google Scholar] [CrossRef]

- Kurokawa, Y.; Tanigawa, Y.; Mori, H.; Nishinosono, K. Analytical study on effect of volume fraction of coarse aggregate on Bingham’s constants of fresh concrete. T. Jpn. Concr. I. 1996, 18, 37–44. [Google Scholar]

- Hu, J.; Wang, K. Effect of coarse aggregate characteristics on concrete rheology. Constr. Build. Mater. 2011, 25, 1196–1204. [Google Scholar] [CrossRef]

- Secrierua, E.; Cotardo, D.; Mechtcherine, V.; Lohaus, L.; Schröfl, C.; Begemann, C. Changes in concrete properties during pumping and formation of lubricating material under pressure. Cem. Concr. Res. 2018, 108, 129–139. [Google Scholar] [CrossRef]

- Choi, M.S.; Kim, Y.J.; Kwon, S.H. Prediction on pipe flow of pumped concrete based on shear-induced particle migration. Cem. Concr. Res. 2013, 52, 216–224. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Mathia, T.G. Influence of roughness on contact interface in fretting under dry and boundary lubricated sliding regimes. Wear 2009, 267, 315–321. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Bigerelle, M.; Mathia, T.G.; Dubois, A.; Dubar, L. Dynamic Evolution of Interface Roughness During Friction and Wear Processes. Scanning 2014, 36, 30–38. [Google Scholar] [CrossRef]

- Chen, X.; McLaury, B.S.; Shirazi, S.A. Effects of Applying A Stochastic Rebound Model in Erosion Prediction of Elbows and Plugged Tee. Available online: https://asmedigitalcollection.asme.org/FEDSM/proceedings-abstract/FEDSM2002/36169/247/296539 (accessed on 5 October 2020).

- Vanhove, Y.; Djelal, C. Friction mechanisms of fresh concrete under pressure. I. J. Civ. Eng. Tech. 2013, 4, 67–81. [Google Scholar]

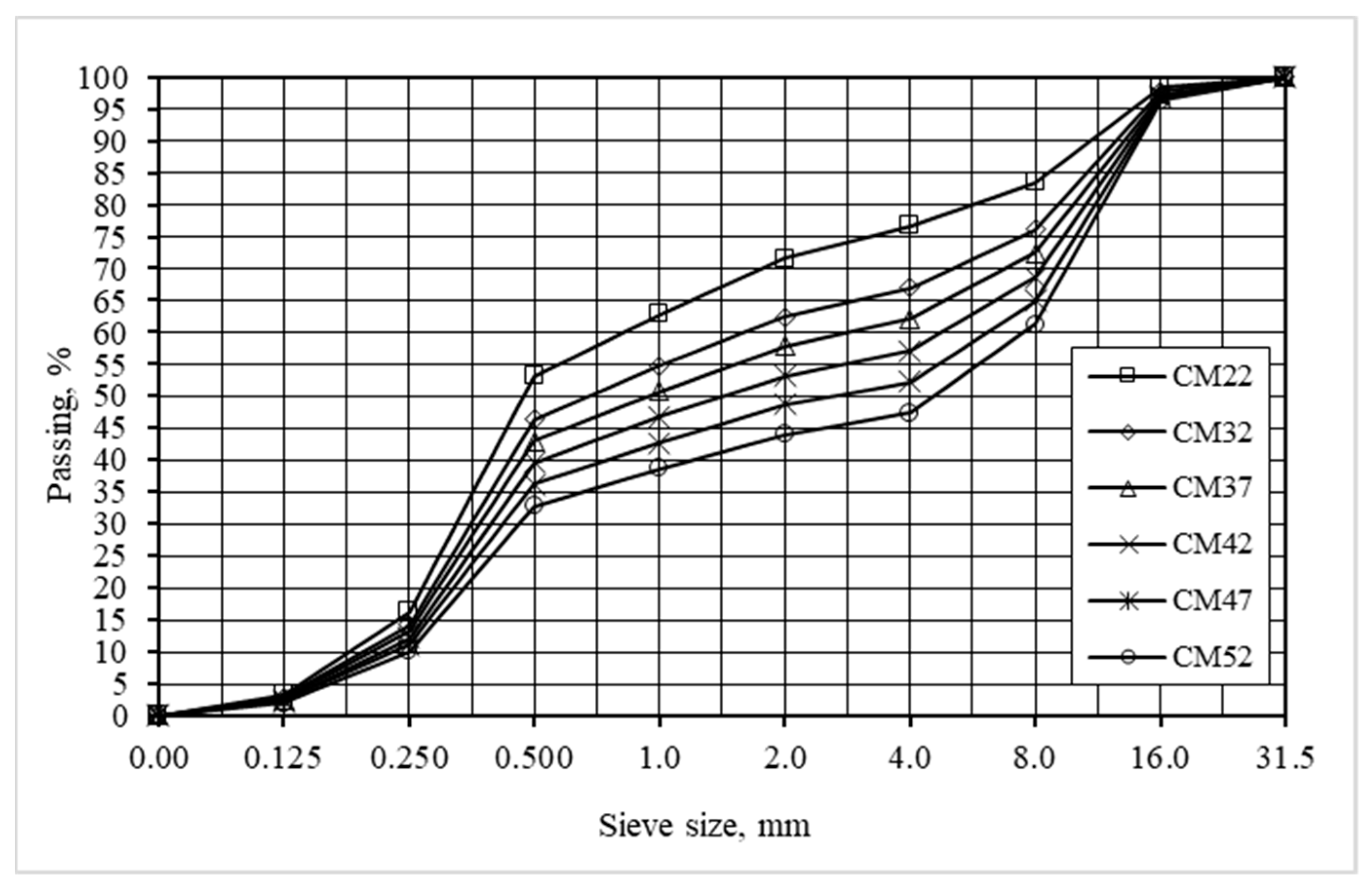

| Sieve Size, mm | Passing (%) | ||

|---|---|---|---|

| Sand in Fracture 0–1 mm | Sand in Fracture 0–4 mm | Gravel in Fracture 4–16 mm | |

| 31.5 | - | - | 100.0 |

| 16.0 | - | - | 93.0 |

| 8.0 | - | 100.0 | 25.4 |

| 4.0 | 100.0 | 97.5 | 0.4 |

| 2.0 | 99.9 | 87.7 | 0.0 |

| 1.0 | 98.1 | 71.9 | 0.0 |

| 0.500 | 92.5 | 56.0 | 0.0 |

| 0.250 | 28.0 | 17.4 | 0.0 |

| 0.125 | 3.2 | 4.6 | 0.0 |

| 0 | 0.0 | 0.0 | 0.0 |

| Marking | The Amount of Materials per cu. m. of Concrete Mixture (kg) | Technological Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Content of CA (%) | Portland Cement | Gravel Fraction 4/16 | Sand Fraction 0/4 | Sand Fraction 0/1 | Water | Super-Plasticizer | Slump Value (mm) | Density (kg/m3) | Air Content (%) | |

| CM22 | 22 | 330 | 417 | 986 | 492 | 178 | 3.3 | 30 | 2180 | 7.9 |

| CM32 | 32 | 330 | 607 | 860 | 429 | 178 | 3.3 | 50 | 2160 | 7.9 |

| CM37 | 37 | 330 | 702 | 797 | 397 | 178 | 3.3 | 160 | 2340 | 3.9 |

| CM42 | 42 | 330 | 796 | 733 | 366 | 178 | 3.3 | 170 | 2290 | 5.9 |

| CM47 | 47 | 330 | 891 | 671 | 334 | 178 | 3.3 | 190 | 2380 | 2.1 |

| CM52 | 52 | 330 | 986 | 607 | 303 | 178 | 3.3 | 230 | 2400 | 1.6 |

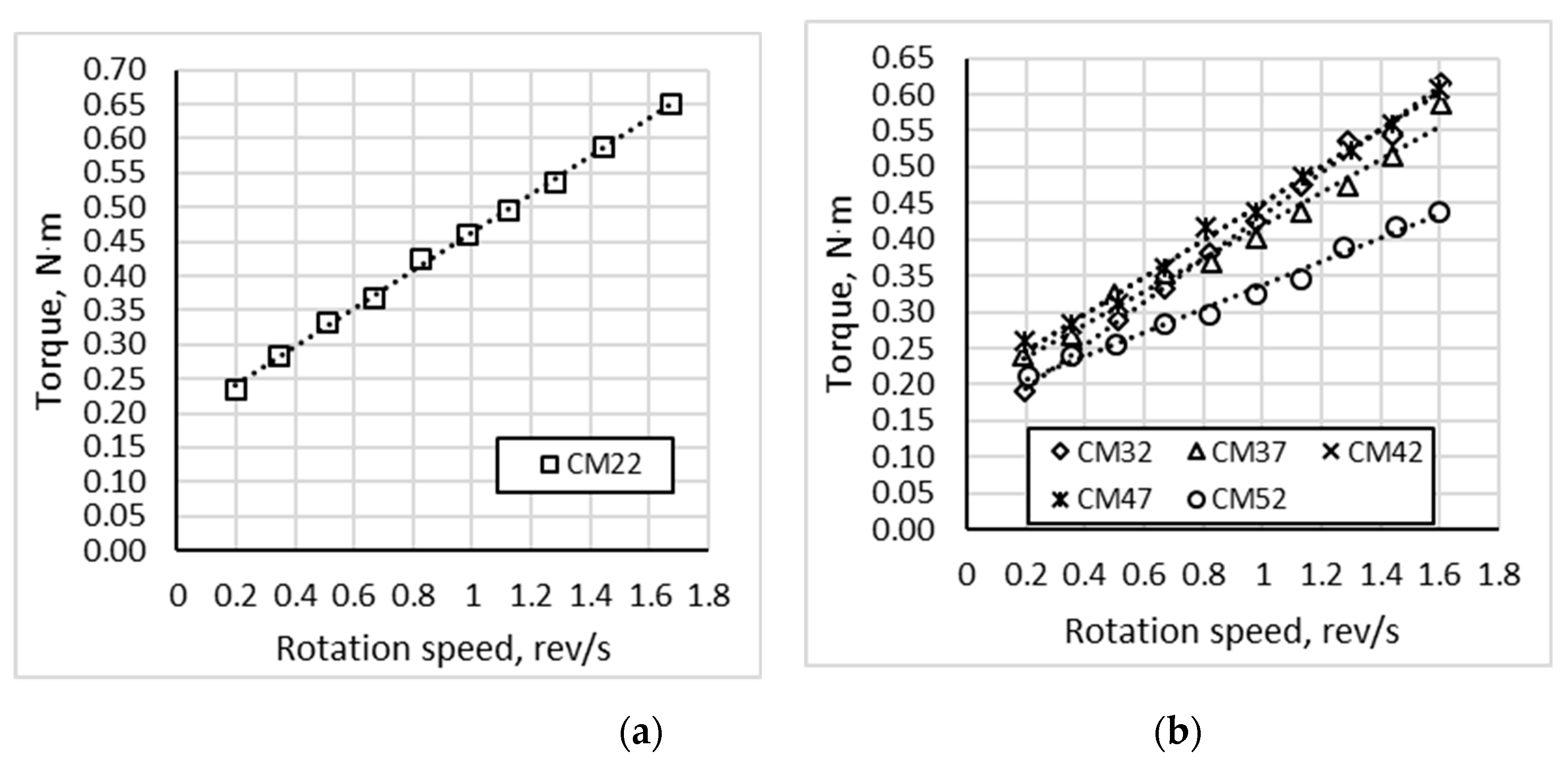

| Marking | Calculated Input Data | Output Data from the Tribometer | ||||||

|---|---|---|---|---|---|---|---|---|

| First Series | Second Series | |||||||

| Yield Stress (Pa) | Viscosity (Pa·s) | Coefficient of Correlation (r) | Yield Stress of the Interface (Pa) | Viscous Constant of the Interface (Pa·s/m) | Coefficient of Correlation (r) | Yield Stress of the Interface (Pa) | Viscous Constant of the Interface (Pa·s/m) | |

| CM22 | 727 | 54.84 | 0.9951 | 28 | 44 | 0.9994 | 26 | 41 |

| CM32 | 621 | 8.47 | 0.9976 | 19 | 45 | 0.9969 | 21 | 43 |

| CM37 | 520 | 3.00 | 0.9923 | 28 | 34 | 0.9794 | 30 | 28 |

| CM42 | 476 | 3.46 | 0.9969 | 28 | 38 | 0.9904 | 29 | 32 |

| CM47 | 350 | 2.00 | 0.9950 | 25 | 28 | 0.9708 | 35 | 18 |

| CM52 | 292 | 2.14 | 0.9960 | 25 | 24 | 0.9951 | 29 | 18 |

| The Basic Parameters of Roughness | Roughness Profile |

|---|---|

| Rotary Steel Cylinder | |

|  |

| New Metal Form-Lining | |

|  |

| Worn Metal Form-Lining | |

|  |

| Steel Composite Column No.1 | |

|  |

| Steel Composite Column No.2 | |

|  |

| Steel Composite Column No.3 | |

|  |

| Steel Composite Column No.4 | |

|  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rugytė, A.; Daukšys, M.; Juočiūnas, S.; Borg, R.P. The Behaviour of Fresh Concrete with Varying Coarse Aggregate Content at the Concrete-Steel Wall Interface. Buildings 2021, 11, 2. https://doi.org/10.3390/buildings11010002

Rugytė A, Daukšys M, Juočiūnas S, Borg RP. The Behaviour of Fresh Concrete with Varying Coarse Aggregate Content at the Concrete-Steel Wall Interface. Buildings. 2021; 11(1):2. https://doi.org/10.3390/buildings11010002

Chicago/Turabian StyleRugytė, Audrė, Mindaugas Daukšys, Svajūnas Juočiūnas, and Ruben Paul Borg. 2021. "The Behaviour of Fresh Concrete with Varying Coarse Aggregate Content at the Concrete-Steel Wall Interface" Buildings 11, no. 1: 2. https://doi.org/10.3390/buildings11010002

APA StyleRugytė, A., Daukšys, M., Juočiūnas, S., & Borg, R. P. (2021). The Behaviour of Fresh Concrete with Varying Coarse Aggregate Content at the Concrete-Steel Wall Interface. Buildings, 11(1), 2. https://doi.org/10.3390/buildings11010002