Welds Assessment in K-Type Joints of Hollow Section Trusses with I or H Section Chords

Abstract

:1. Introduction

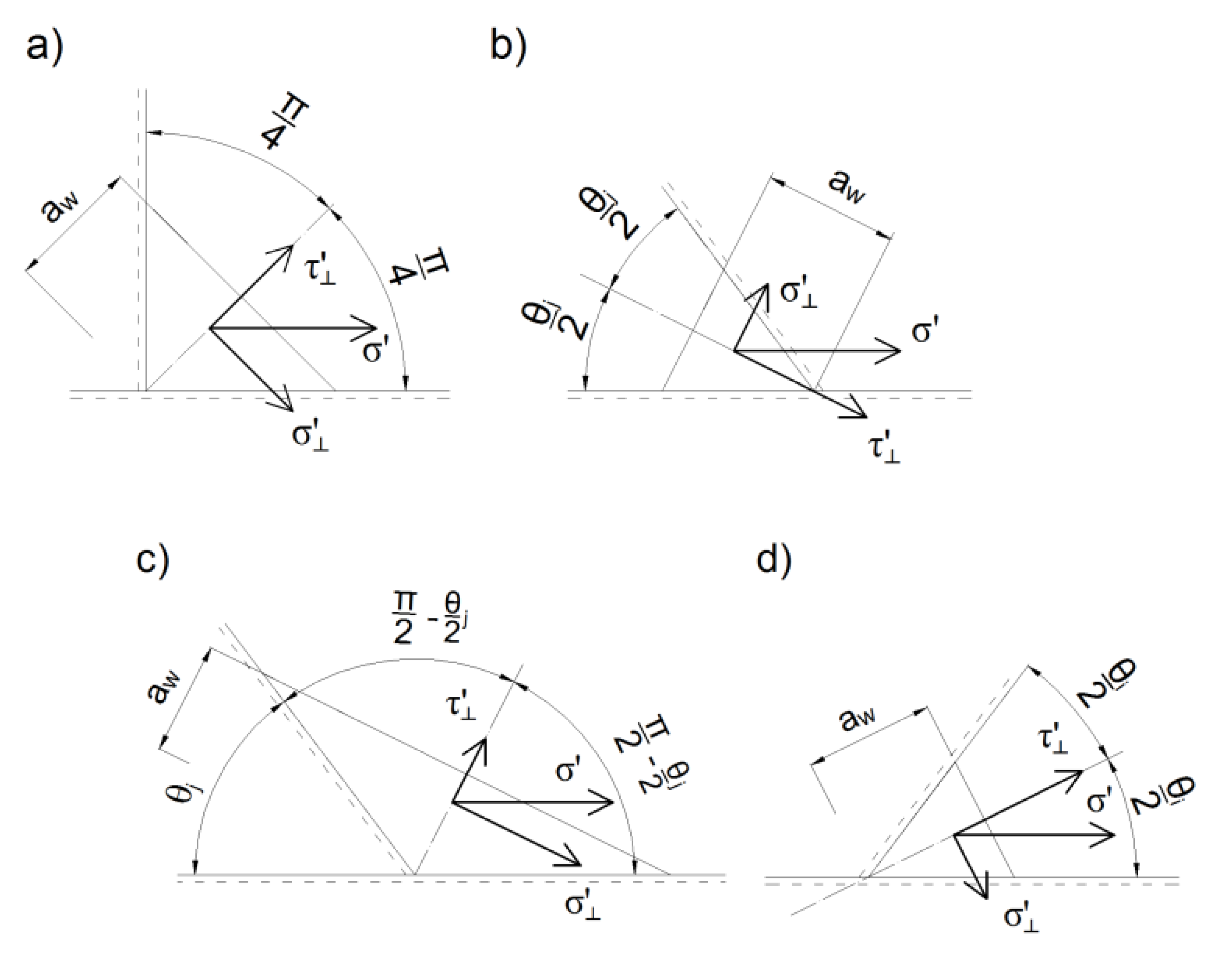

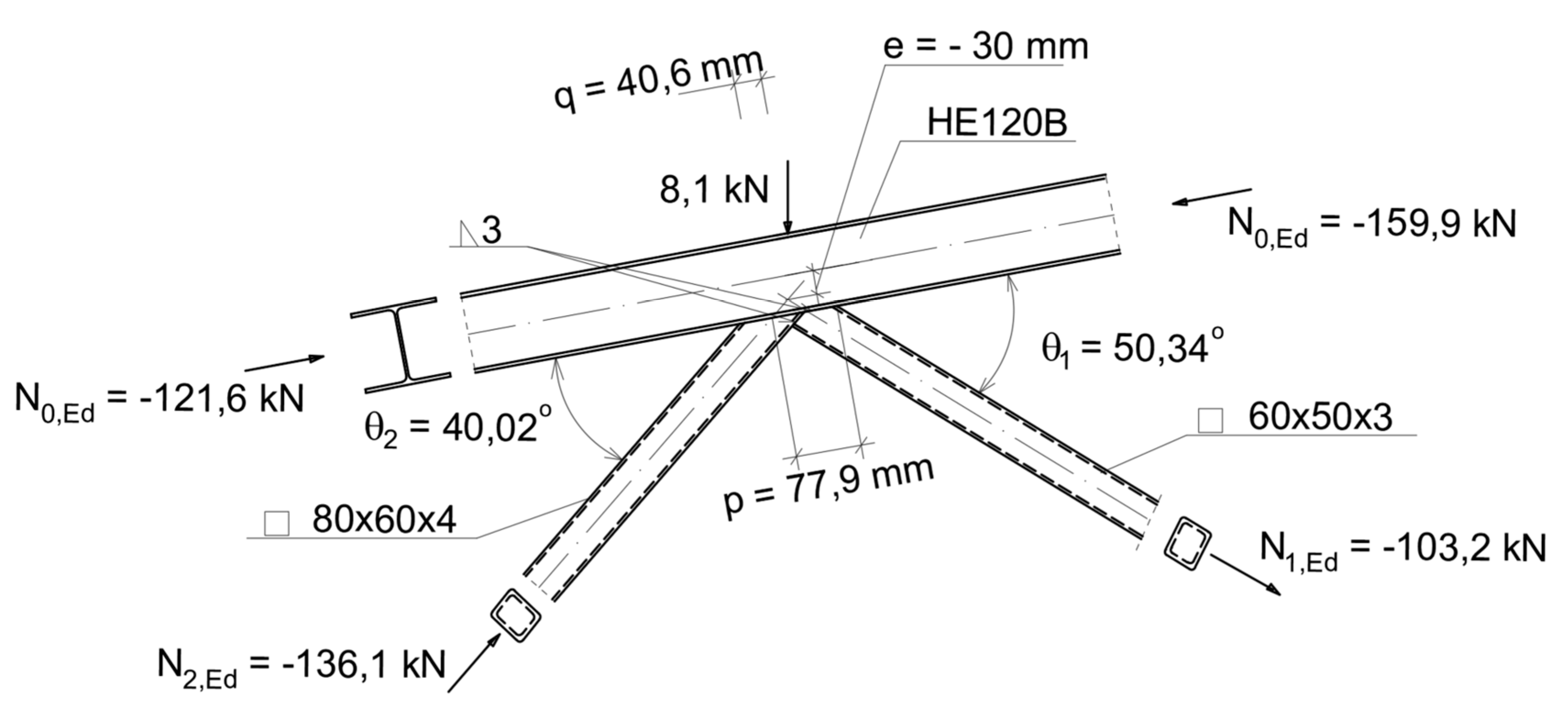

2. Method of Determining the Resistance of Fillet Welds

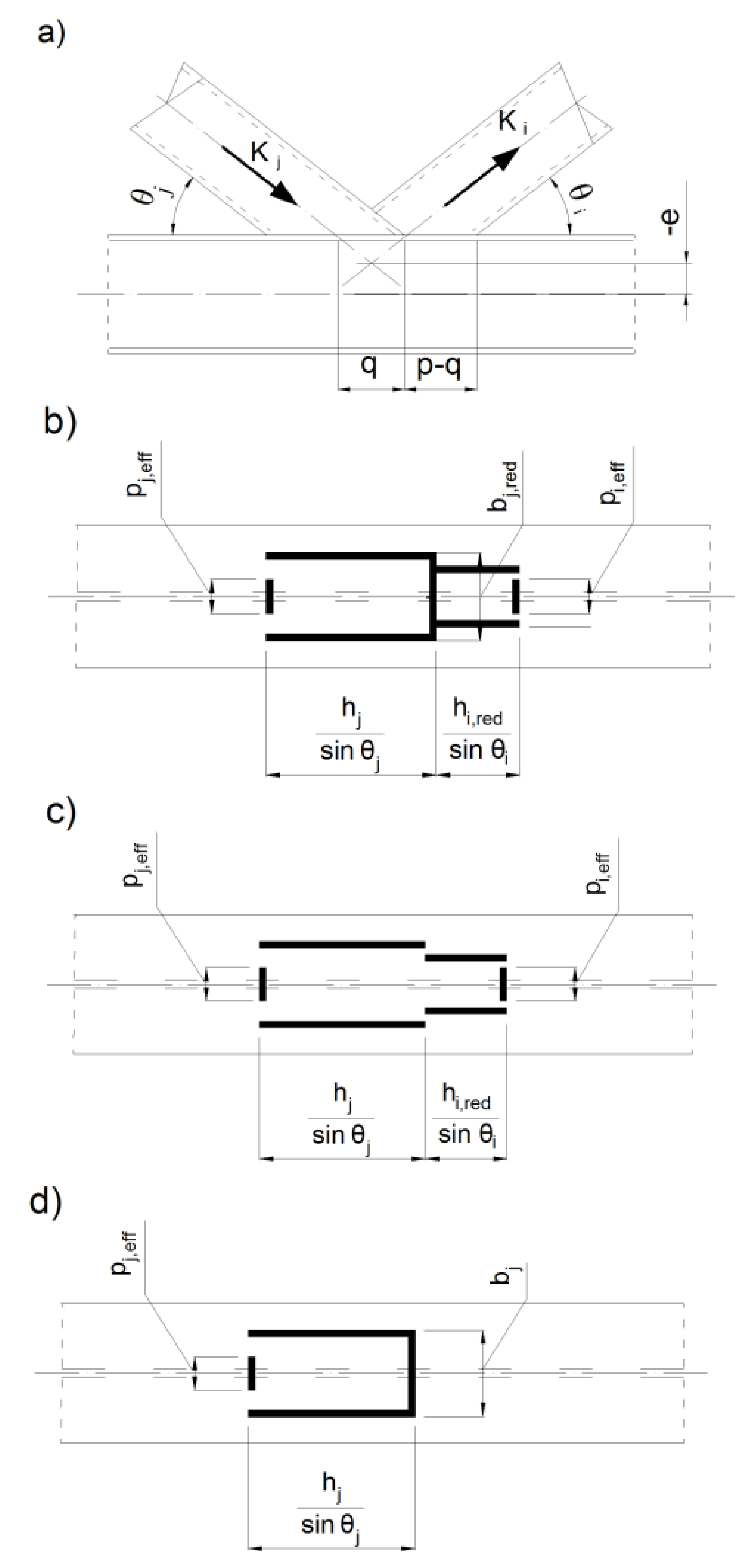

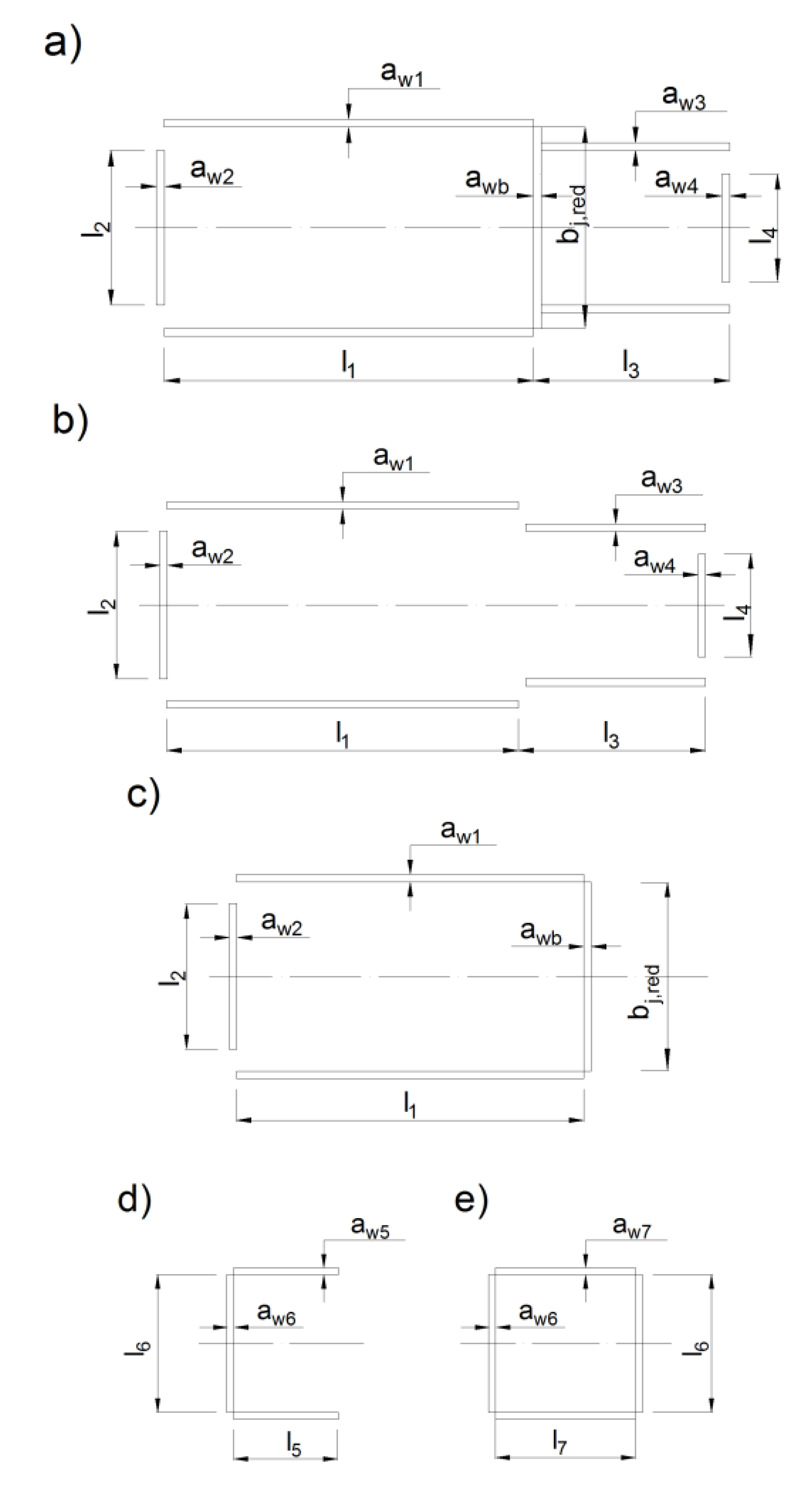

- In the case of the partial overlap:

- In the case of the complete overlap:where θi, θj—inclination angles of the overlapping and overlapped braces in relation to the chord, fy0 —the yield strength of the chord, bi, hi—respectively, the width and the height of the section of the overlapping brace, bj, hj—respectively, the width and the height of the section of the overlapped brace, ti—the wall thickness of the overlapping brace, tj—the wall thickness of the overlapped brace, tf—the flange thickness of the I-section, tw—the web thickness of I-section, r— the radius of the I-section.

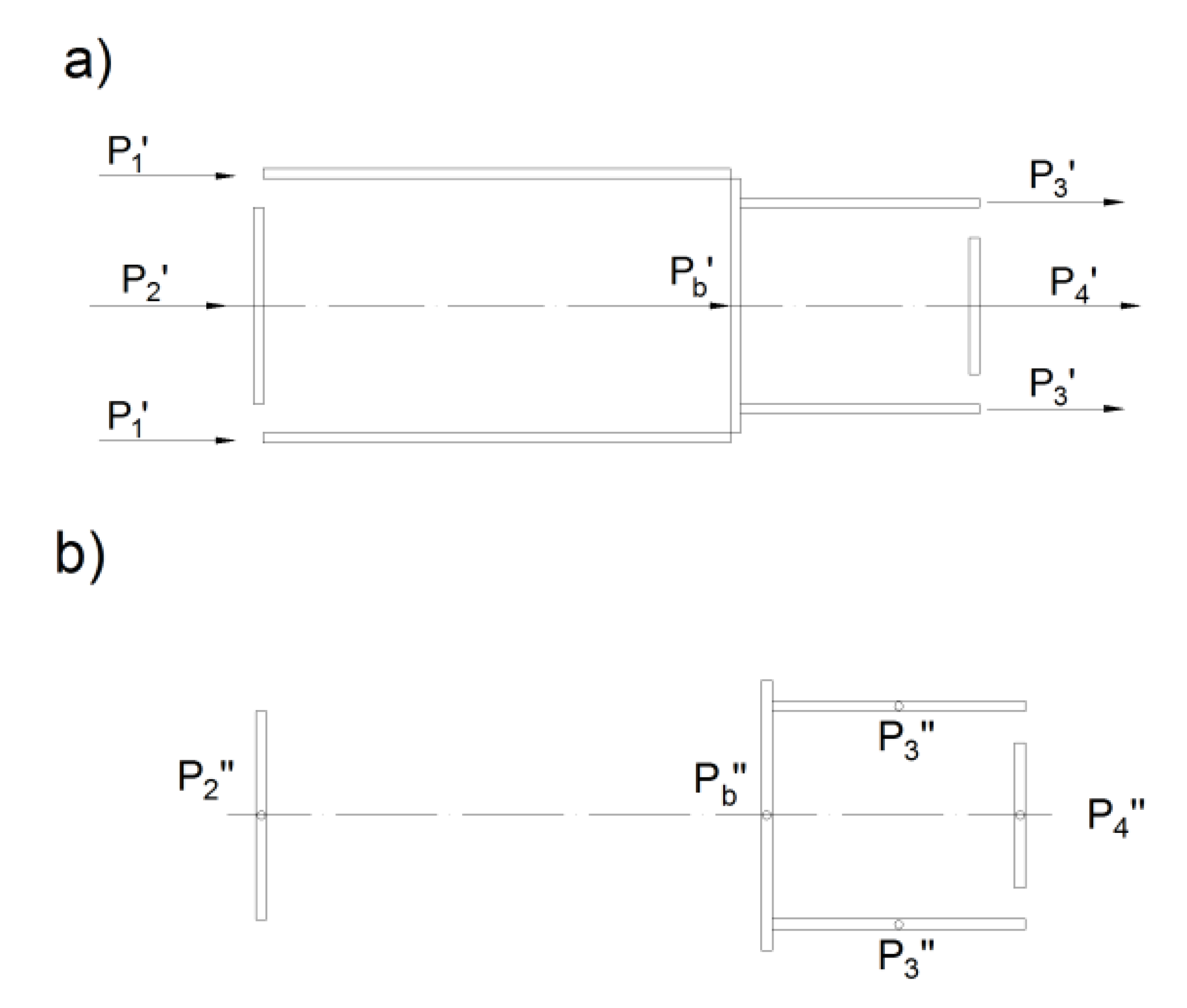

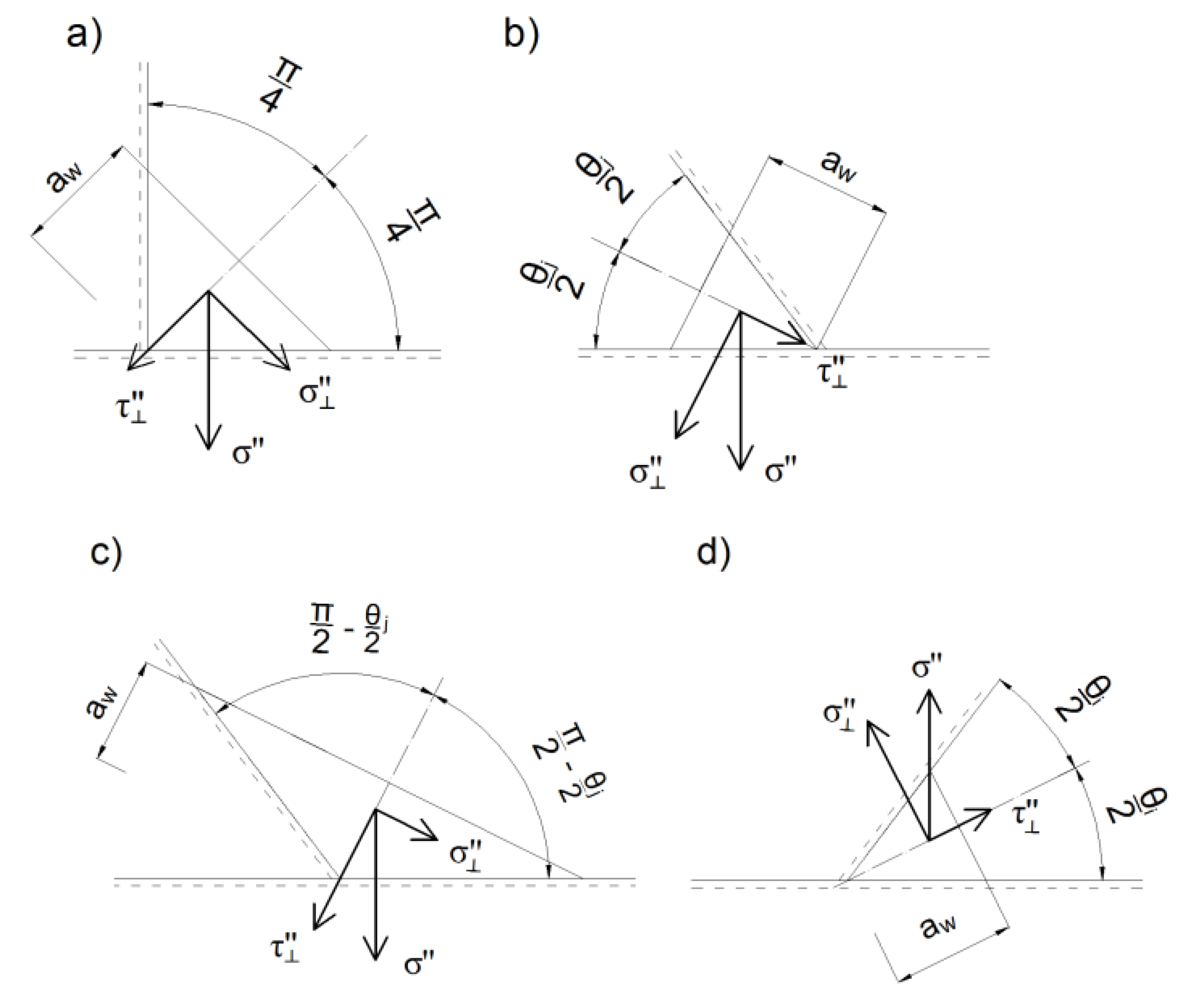

- Loads parallel to the overlapped brace axis:

- Loads perpendicular to the overlapped brace axis:

- Loads parallel to the overlapped brace axis:

- Loads perpendicular to the overlapped brace axis:

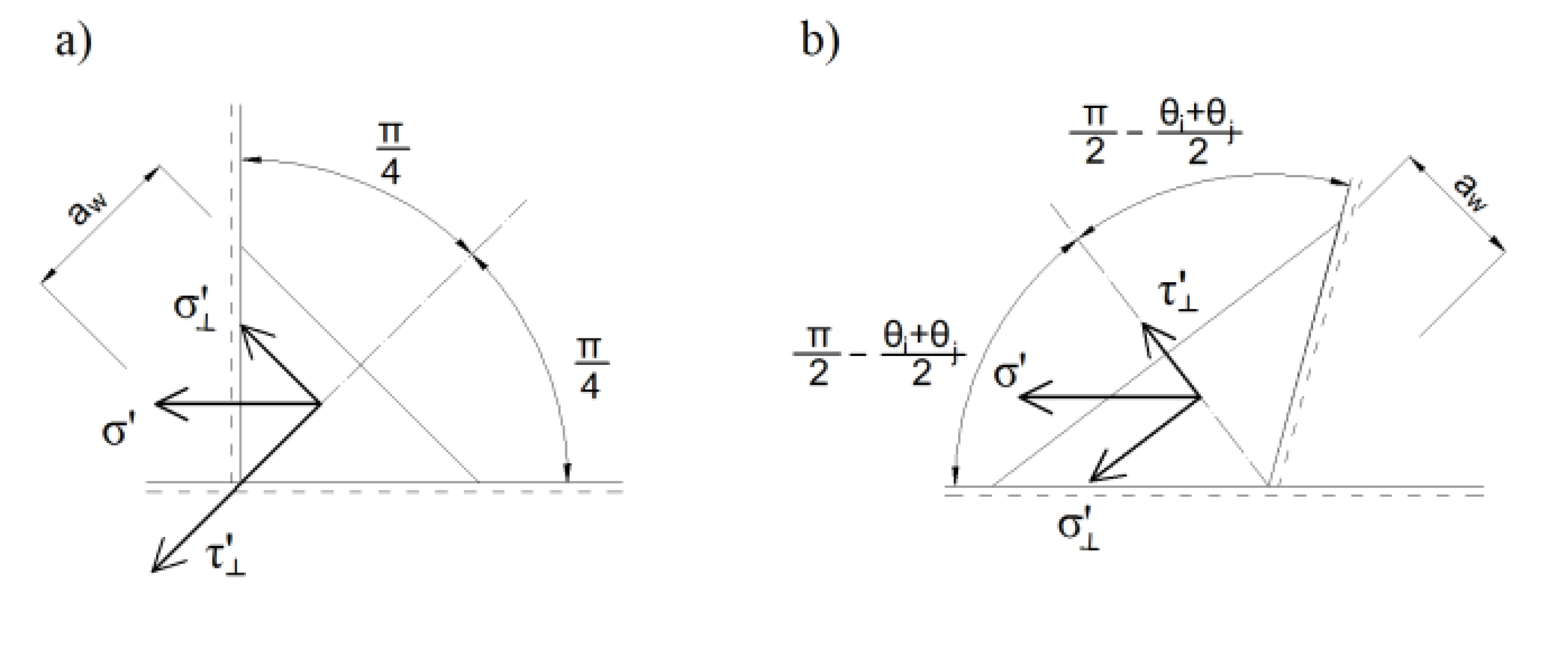

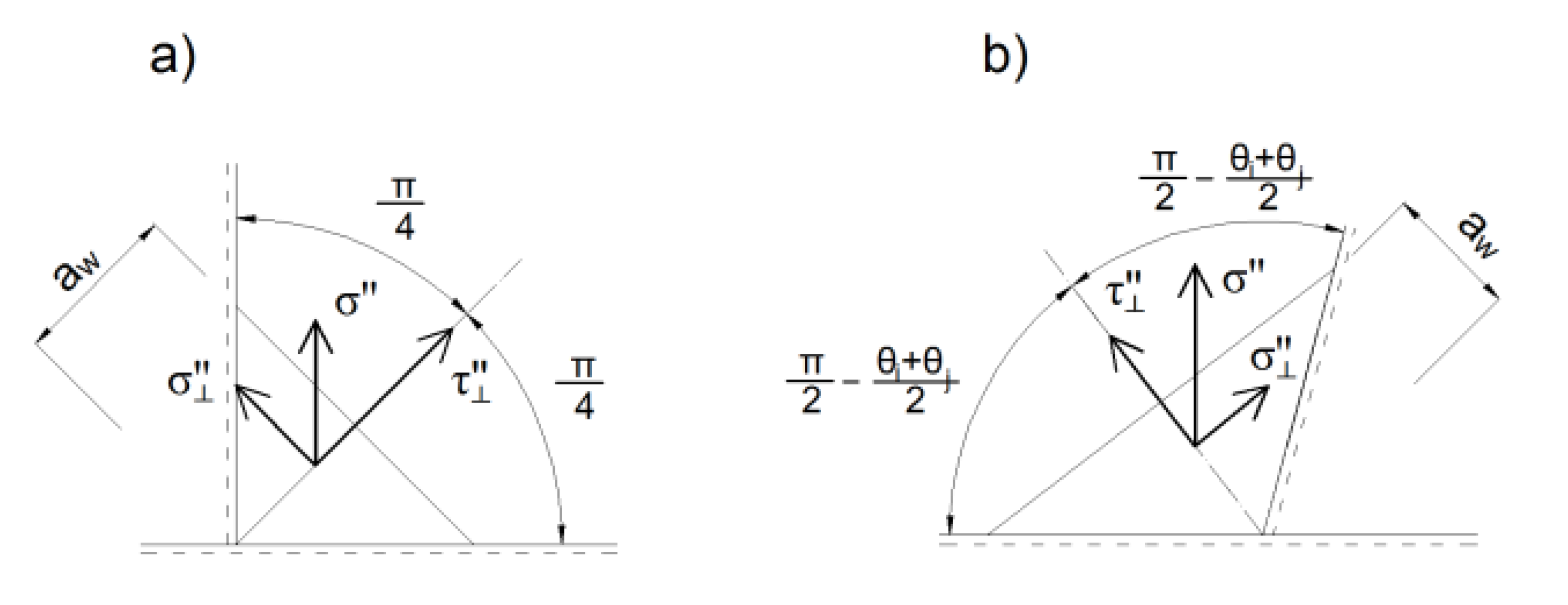

- In the case of welds placed by the overlapped brace’s walls:

- In the case of welds placed by the overlapping brace’s walls:

- In the case of welds placed by the walls of the overlapped brace:

- I the case of welds placed by the walls of the overlapping brace:

3. Conclusions

- -

- longitudinal welds between the lower (overlapped) brace and the chord:

- -

- the not fully effective transverse weld between the lower brace and the chord:

- -

- longitudinal welds between the upper (overlapping) brace and the chord:

- -

- the fully effective transverse weld between the lower brace and the chord:

- -

- the not fully effective transverse weld between the upper brace and the chord:

- -

- longitudinal welds between the upper (overlapping) brace and the lower (overlapped) brace:

- -

- the transverse weld between the upper brace and the lower brace:.

- -

- longitudinal welds between the lower (overlapped) brace and the chord:

- -

- the not fully effective transverse weld between the lower brace and the chord:

- -

- longitudinal welds between the upper (overlapping) brace and the chord:

- -

- the fully effective transverse weld between the lower brace and the chord:

- -

- the not fully effective transverse weld between the upper brace and the chord:

- -

- longitudinal welds between the upper brace and the lower brace:

- -

- the transverse weld between the upper brace and the lower brace:.

- -

- longitudinal welds between the lower brace and the chord:

- -

- the not fully effective transverse weld between the lower brace and the chord:

- -

- longitudinal welds between the upper brace and the chord:

- -

- the fully effective transverse weld between the lower brace and the chord:

- -

- the not fully effective transverse weld between the upper brace and the chord:

- -

- longitudinal welds between the upper brace and the lower brace:

- -

- the transverse weld between the upper brace and the lower brace:

- -

- longitudinal welds between the lower brace and the chord:

- -

- the not fully effective transverse weld between the lower brace and the chord:

- -

- longitudinal welds between the upper brace and the chord:

- -

- the fully effective transverse weld between the lower brace and the chord:

- -

- the not fully effective transverse weld between the upper brace and the chord:

- -

- longitudinal welds between the upper brace and the lower brace:

- -

- the transverse weld between the upper brace and the lower brace:The safety coefficient is equal: .

Author Contributions

Funding

Conflicts of Interest

References

- Eekhout, M. Tubular Structures in Architecture, 2nd ed.; Delft University of Technology: Delft, The Netherlands, 2011; 127p. [Google Scholar]

- Wardenier, J.; Packer, J.A.; Zhao, X.L.; Van der Vegte, G.J. Hollow Sections in Structural Applications; John Wiley & Sons: Hoboken, NJ, USA, 2010; 232p. [Google Scholar]

- Brodka, J.; Broniewicz, M. Steel Structures from Hollow Sections; Arkady: Warsaw, Poland, 2001; 383p. [Google Scholar]

- Dutta, D. Structures with Hollow Sections, 1st ed.; Ernst & Sohn: Berlin, Germany, 2002; 600p. [Google Scholar]

- Packer, J.A.; Wardenier, J. Design rules for welds in RHS K, T, Y and X connections. In Proceedings of the IIW International Conference on Engineering Design in Welded Constructions, Madrid, Spain, 7–8 September 1992; pp. 113–120. [Google Scholar]

- Frater, G.S.; Packer, J.A. Weldment design for RHS truss connections. I: Applications. J. Struct. Eng. 1992, 118, 2784–2803. [Google Scholar] [CrossRef]

- Frater, G.S.; Packer, J.A. Weldment design for RHS truss connections. II: Experimentation. J. Struct. Eng. 1992, 118, 2804–2820. [Google Scholar] [CrossRef]

- Teh, L.H.; Rasmussen, K.J.R. Strength of Butt Welded Connections between Equal Width Rectangular Hollow Sections; Research Report No. R817; Department of Civil Engineering, University of Sydney: Sydney, Australia, 2002; 27p. [Google Scholar]

- Packer, J.A.; Henderson, J.E. Hollow Structural Section Connections and Truss—A Design Guide, 2nd ed.; Canadian Institute of Steel Construction: Toronto, ON, Canada, 1997; 447p. [Google Scholar]

- Packer, J.A.; Sherman, D.R.; Lecce, M. HSS Connections. Steel Design Guide No. 24; American Institute of Steel Construction: Chicago, IL, USA, 2009; 146p. [Google Scholar]

- IIW. Recommendations for Fatigue Design of Welded Joints and Components; Commission XV. IIW Docs, IIW-1823-07; International Institute of Welding: Paris, France, 1823. [Google Scholar]

- ISO 14346. Static Design Procedure for Welded Hollow Section Joints—Recommendations; International Institute of Welding: Paris, France, 2013. [Google Scholar]

- IIW. Static Design Procedure for Welded Hollow Section Joints—Recommendations, 3rd ed.; Commission XV. IIW Doc. XV-1329-09; International Institute of Welding: Paris, France, 2009. [Google Scholar]

- Packer, J.A.; Wardenier, J.; Zhao, X.L.; Van der Vegte, G.J.; Kurobane, Y. Design Guide for Rectangular Hollow Section (RHS) Joints under Predominantly Static Loading; LSS Verlag, CIDECT: Koln, Germany, 2009; pp. 149p. [Google Scholar]

- Brodka, J.; Broniewicz, M. Design of welded joints of trusses made of hollow sections. In Steel Construction; No 1; Polish Chamber of Steelwork: Warsaw, Poland, 2002; p. 29. [Google Scholar]

- Brodka, J.; Broniewicz, M. Assessing of resistance of connections according to EN 1993-1-8:2006. In Steel Construction; No 1; Polish Chamber of Steelwork: Warsaw, Poland, 2007; pp. 32–38. [Google Scholar]

- Brodka, J.; Broniewicz, M. Calculation of welding trusses overlap joints. In Archives of Civil Engineering; Committee for Civil Engineering, Polish Academy of Sciences: Warsaw, Poland, 2013; 24p. [Google Scholar]

- Davies, G.; Crockett, P. Effect of the hidden weld on RHS partial overlap K joint capacity. In Proceedings of the 6th International Symposium on Tubular Structures, Melbourne, Australia, 14–16 December 1994; Balkema: Rotterdam, The Netherlands, 1994; pp. 573–579. [Google Scholar]

- Dexter, E.M.; Lee, M.M.K. Effect of overlap on the behaviour of axially loaded CHS K-joints. In Proceedings of the 8th International Symposium on Tubular Structures, Singapore, 26–28 August 1998; Balkema: Rotterdam, The Netherlands, 1998; pp. 249–258. [Google Scholar]

- EN 1993-1-8. Eurocode 3: Design of Steel Structures. Part 1–8: Design of Joints; European Committee For Standardization: Brussels, Belgium, 2006. [Google Scholar]

- Brodka, J.; Broniewicz, M. Calculation of welding trusses overlap joints made of rectangular hollow sections. Arch. Civ. Eng. 2013, 59, 441–468. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broniewicz, M.; Broniewicz, F. Welds Assessment in K-Type Joints of Hollow Section Trusses with I or H Section Chords. Buildings 2020, 10, 43. https://doi.org/10.3390/buildings10030043

Broniewicz M, Broniewicz F. Welds Assessment in K-Type Joints of Hollow Section Trusses with I or H Section Chords. Buildings. 2020; 10(3):43. https://doi.org/10.3390/buildings10030043

Chicago/Turabian StyleBroniewicz, Miroslaw, and Filip Broniewicz. 2020. "Welds Assessment in K-Type Joints of Hollow Section Trusses with I or H Section Chords" Buildings 10, no. 3: 43. https://doi.org/10.3390/buildings10030043

APA StyleBroniewicz, M., & Broniewicz, F. (2020). Welds Assessment in K-Type Joints of Hollow Section Trusses with I or H Section Chords. Buildings, 10(3), 43. https://doi.org/10.3390/buildings10030043