1. Introduction

Resource depletion, degradation of ecosystems and climate change are challenges that have been emphasized recently in many research papers [

1,

2,

3,

4]. Moving towards sustainable processes in the whole life cycle of a building is seen as a solution to tackle those challenges and transform the cities into sustainable systems. One element in achieving this transition is the implementation of environmentally friendly solutions in the design of buildings and engineering structures.

The link between sustainable development and construction is clear. The construction industry is Europe’s largest industrial employer accounting for about 10% of European GDP and has strong environmental and social impacts [

5]. The building or structure designed using environmentally friendly materials is not necessarily sustainable. Successful sustainability cannot be realized considering only environmental issues. The latter have to be harmonized with the economic and social issues [

6]. The adoption of sustainable practices involves the integration of all sustainable principles into the project life cycle and the inclusion of all responsible stakeholders [

7]. Specifically, the design of sustainable buildings, which comply with the variety of sustainability categories, makes the role of the structural engineer very important. In the traditional approach of building design, structural engineers rarely assess the environmental dimension, which has been recognized in the modern integrated building design approach as one of the most important factors [

8]. Structural engineering decisions have a major impact in the areas of waste generation, water consumption, energy use and environmental emissions [

9]. The applications of sustainable construction principles into the design process can improve project sustainability [

10]. However, additional cost, time and limited availability of green suppliers and information were reported as critical barriers [

11]. Additionally, the variety of sustainable structural elements and availability of sustainable materials, the different preferences of clients, architects, and structural designers make the decision-making process difficult [

4].

Sustainability is a multifaceted phenomenon that includes many competing goals. Sustainability by its broad extent carries categories for ensuring the needs and requirements of a project and building users and takes into account the environmental, economic and social aspects [

12,

13]. Sustainability of building solutions could be ensured by achieving the best quality of life in the spaces of a building by providing acoustical, visual and thermal comfort [

14]. Constructability, selection of appropriate building systems, workability, durability and other design aspects mentioned by [

15] as attributes of flexible design in terms of sustainability. For attaining a sustainable structural design, [

16] assessed costs, CO

2 emissions, and service life. As stated by [

17], the cost of energy consumption and carbon emissions must be calculated for every construction project, similar to material and labor costs. A sustainable design includes compliance with building standards, the production of repetitive elements and mass production that enables reduction in costs [

5]. The complexity of commercial buildings and necessity to assess many sustainability categories requires that a robust optimization algorithm should be applied to select the optimum set of sustainable solutions [

18].

The construction industry has been struggling for some time to improve its environmental performance. Comparisons of the eco-efficiency of construction materials used for load-bearing structures have been made [

19,

20]. Comparisons of slab construction techniques indicate overall embodied energy reductions up to 40% being achievable [

21]. Diverse structural behavior, high structural quality, and performance in pursuing sustainability have been reported for scrap steel [

10] and steel-making technologies for CO

2 capturing [

22]. On the contrary, the production of cement and cement-based composites has been recognized as not being as eco-efficient as steel [

23]. In the past decade, investigations have resulted in proposals on how to achieve better environmental and structural performance of concrete. In the last two decades, changing sustainability requirements resulted in a change in building design. It reflected in the models for shaping a sustainable building. For example, the steel construction expresses regular diagonals in the facade of the building, is easier and quicker to assemble and is highly compatible with the concept of a sustainable building [

24].

The review of Liu et al. [

25] revealed that the academic community recognized the potential of BIM in energy and environmental analysis and in sustainable design. The study of Olbina and Elliott [

26] revealed that various stakeholder groups treat BIM as a universal Architecture, Engineering, and Construction (AEC) process that provides benefits on complex and simple projects. Recent research focuses on the integration of BIM and other related technologies, such as energy and carbon emission calculation, for speeding up the decision processes and to enable structural designers and other professionals to deliver their building in a more efficient manner [

27]. A review of Olawumi and Chan [

28] revealed the significant impacts of BIM in several areas of the AEC industry such as design, construction, facility management, safety, and sustainability. BIM can improve the processes of prefabrication, which is considered to be an efficient method to reduce building waste, energy consumption, and CO

2 emissions [

29].

Due to increasing levels of competition, construction companies are considering corporate social responsibility with regard to the social and environmental factors, which define this concept and are included in corporate commitments to the contribution to sustainable economic development [

30]. However, the importance of incorporating sustainable development principles in early project stages is not enough understood by project stakeholders. Designers and structural engineers should be consulted even in the feasibility stage for professional advice on various alternatives and their influences on the project sustainability [

31]. Moreover, various stakeholders’ categories have to be considered to ensure the comprehensive assessment of all sustainability aspects, especially building-specific social impacts [

32].

There are many comprehensive sustainability assessment techniques, such as the well-known examples of The Leadership in Energy and Environment Design (LEED) and Green Globes in the USA, the Building Research Establishment Environmental Assessment Method (BREEAM) in the UK, the Deutsche Gesellschaft für Nachhaltiges Bauen (DGNB) in Germany, the Building Environmental Assessment Method (BEAM Plus) in Hong Kong, the Comprehensive Assessment System for Built Environment Efficiency (CASBEE) in Japan, Green Star in Australia, etc. However, those are time-consuming in their application and do not consider the economic aspect, which is contrary to the ultimate principle of sustainable development. On the one hand, there is a need for environmentally friendly solutions with minimum energy consumption and waste generation; on the other hand, the investor intends to pursue cost-effective projects [

33]. In this regard, the lack of cost analysis is the main weakness of the mentioned sustainability assessment tools [

34]. Additionally, the mentioned Sustainability Assessment and Certification Systems, although adequate to evaluate the sustainability of a building component, is not an appropriate tool in support of architects during the design process [

35]. Moreover, most authors who have analyzed sustainable design methodology note that the cost of eco-efficient products is high [

36,

37,

38,

39]. The weaknesses of sustainability assessment tools have been reported, thus stating the immaturity of sustainable product design tools [

40]. Samani et al. [

41] concluded that one of the major drawbacks of studies on sustainable buildings is that technologically oriented studies are normally lacking in the social dimension of sustainability, while more technical aspects need to be integrated into the socially oriented studies.

More research, including experiments, are needed to test the theoretical innovations in sustainable design and construction proposed by various scientists. A lot of work remains to be done in this area to make the green project financially attractive to the investor. The reported weaknesses of design and sustainability assessments led to the conclusion of a need for fast in application, simple and reliable methods to assess the sustainability of structural solution at the early design stages.

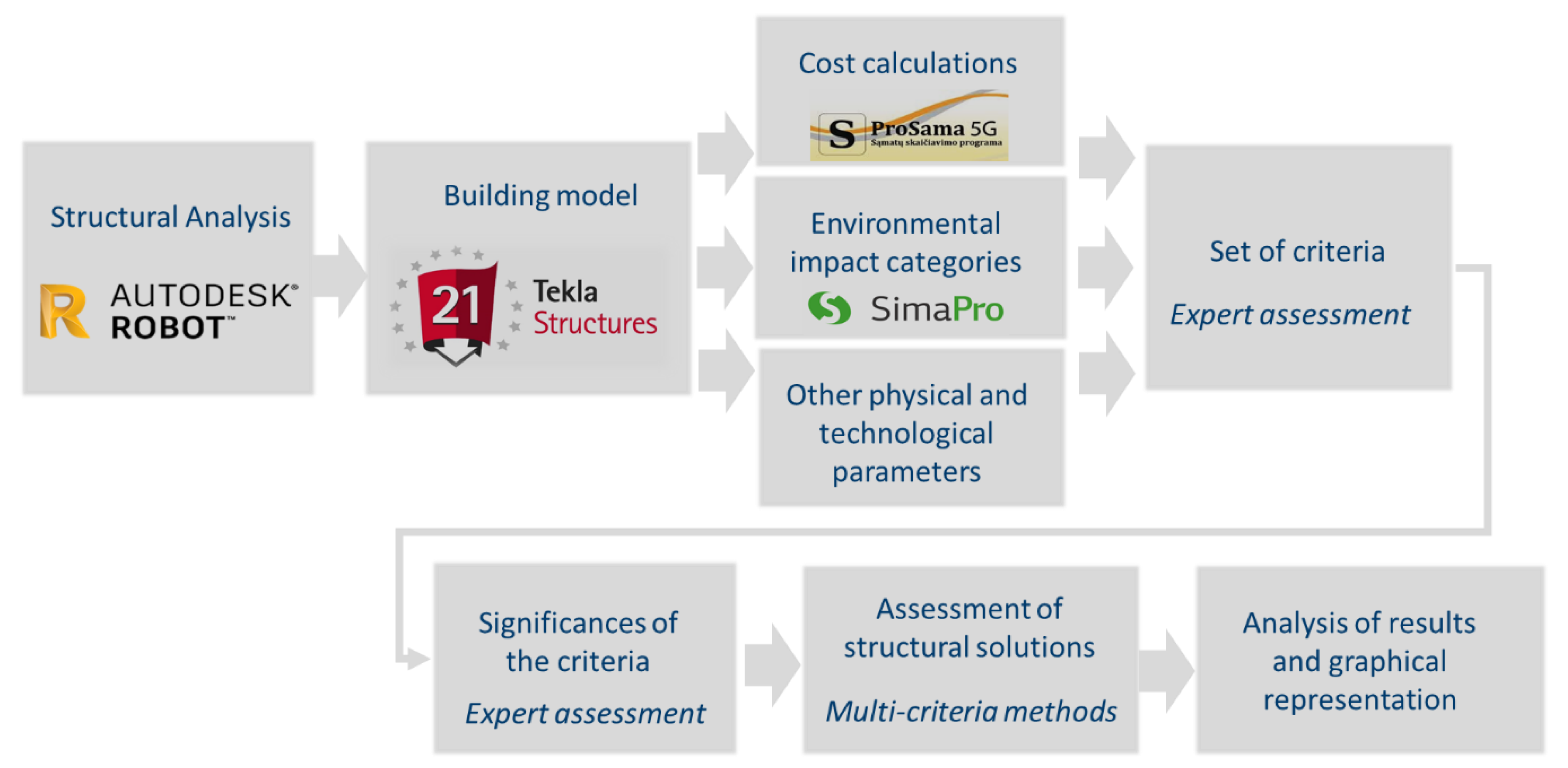

In this study, we propose the approach for sustainability assessment in the early design stage. The aim of this research is to develop a criteria system and decision model for assessing the sustainability of alternative structural solutions in the early design stage. The methodology combines building information modeling (BIM), sustainability criteria and multi-criteria decision aiding methods. The sustainability criteria include physical, economic, technological and environmental aspects. The multi-criteria decision aiding methods included in the approach in order to improve the selection process and to assess the sustainability of alternative structural solutions at an early stage of building design. BIM tools were applied for gathering building data necessary for multi-criteria analysis.

2. Research Methodology

The present study adopts a methodology consisting of an analysis of literature, an expert assessment, and a case study analysis. The sustainability categories selected based on the analysis of the existing studies in the field of sustainable structural design. By using a 3-step Delphi study approach, experts set up the feasible alternatives, selected the criteria system, and determined the weights of criteria. Furthermore, in the case study, the criteria values were calculated and a multi-criteria assessment of the alternatives was performed. The next sections describe in detail the steps followed in the work methodology.

2.1. Sustainability Categories

As it was mentioned above, sustainability by its broad umbrella carries environmental, economic and social categories for ensuring the needs and requirements of a project and users. Variety of technologies distinguish construction processes and requires analyzing the technological aspects as separate and important sustainability category. The sustainability categories used in this research were selected based on the traditional approach and alternative insights, and include environmental, economic, technological and social categories (

Figure 1). A sustainability assessment of alternative solutions implies the use of many criteria; therefore, the model proposes the application of multi-criteria decision adding (MCDA) methods as reliable and versatile tools for decision-making [

42]. Additionally, dealing with many alternatives the decision-maker gathers a big amount of data. The existence of human factors leads to distorted incomplete data and finally to the question of the reliability of gathered data sets. The risk of unreliable data and information could be reduced if automated data gathering and processing are used. The application of Building Information Modeling (BIM) tools provide the solutions, thereat, the model proposes the inclusion of BIM tools for gathering reliable data (e.g., quantities) necessary for sustainability assessment (

Figure 1).

The sustainability of building solutions could be ensured by achieving the best life quality in the spaces of a building by accomplishing acoustical, visual and thermal comfort. Paying attention to the possibility of realizing functions and users’ comfort and satisfaction, the criteria for the sustainability assessment of alternative structural solutions were set (

Table 1). The initial set of sustainability criteria chosen based on the literature analysis and expert assessment through the iterations of the Delphi technique. Users’ comfort and satisfaction were reflected by including, in a proposed set of criteria, the relevant categories expressed by physical criteria—such as the “total area of indoor spaces”, that are important for end-users of building.

2.2. A hybrid MCDA Model for Decision-Making

The present study adopts a triangular approach, consisting of an analysis of literature, expert interviews, and a follow-up case study analysis. The methodology applied includes following steps:

Step 1. A parametric model of building was created, and feasible alternatives formed.

Step 2. Based on the literature analysis, the criteria system for the selection of sustainable structural solutions for buildings was created.

Step 3. The weights of the criteria were determined by experts through a 3-step Delphi study approach.

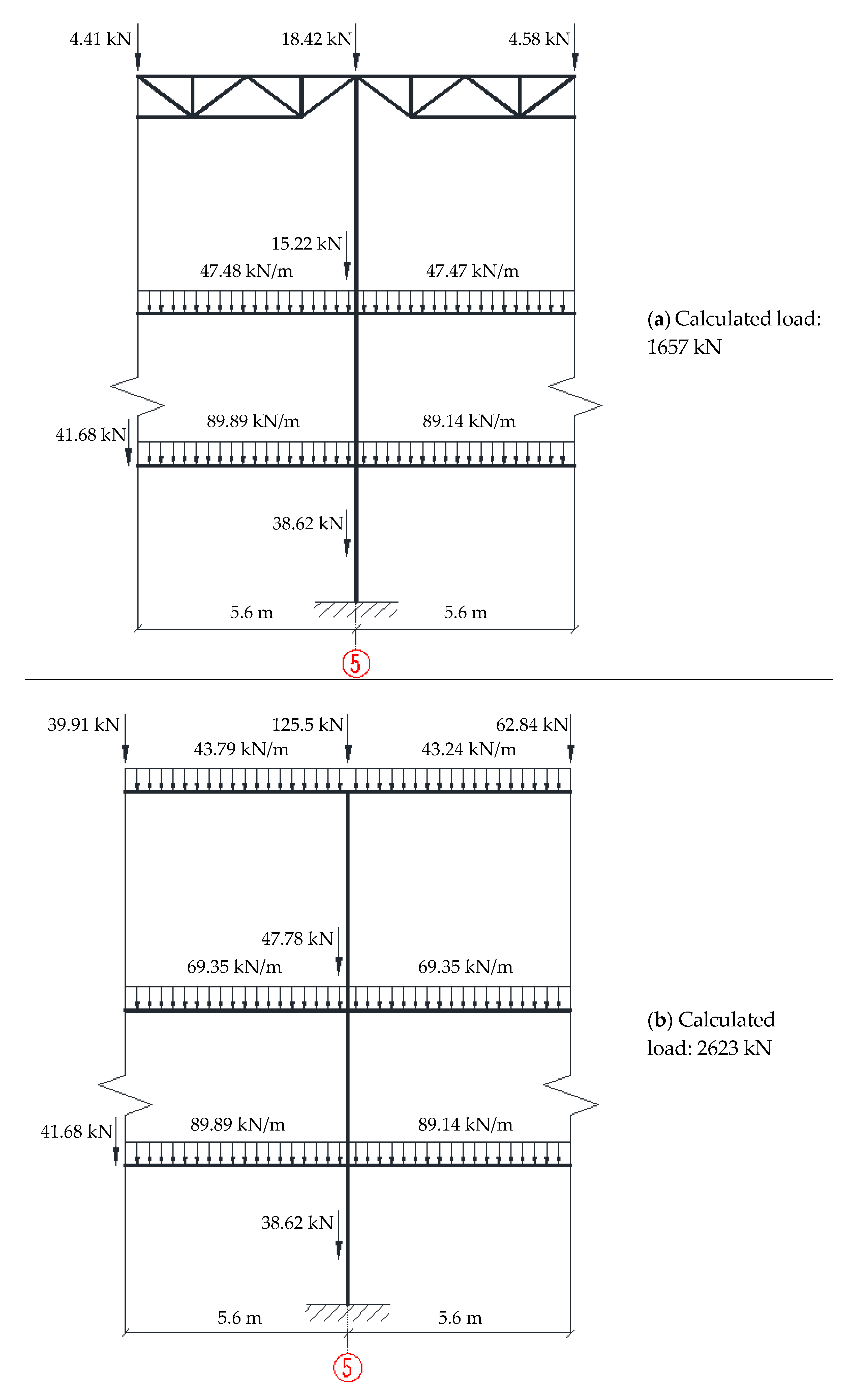

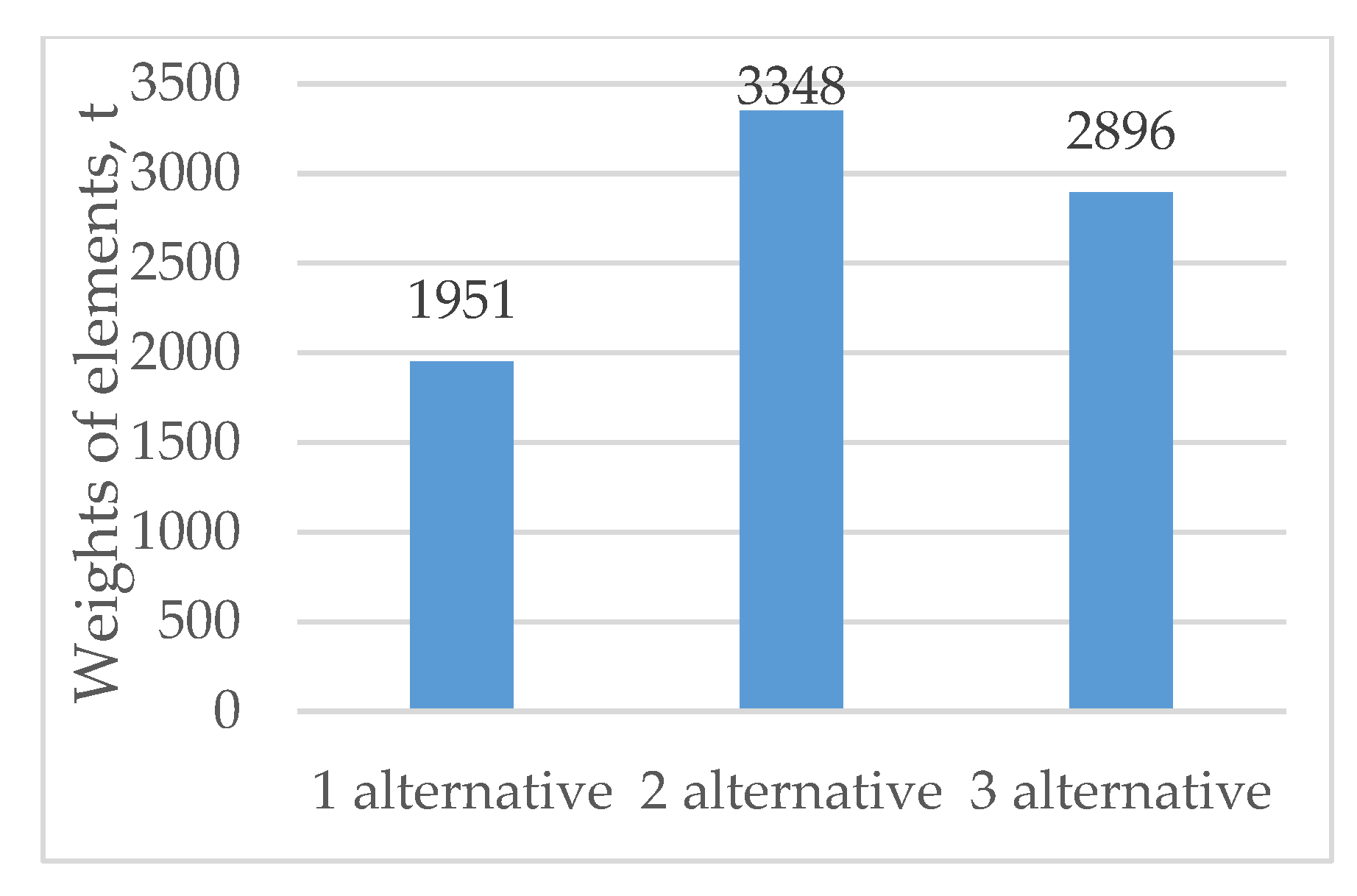

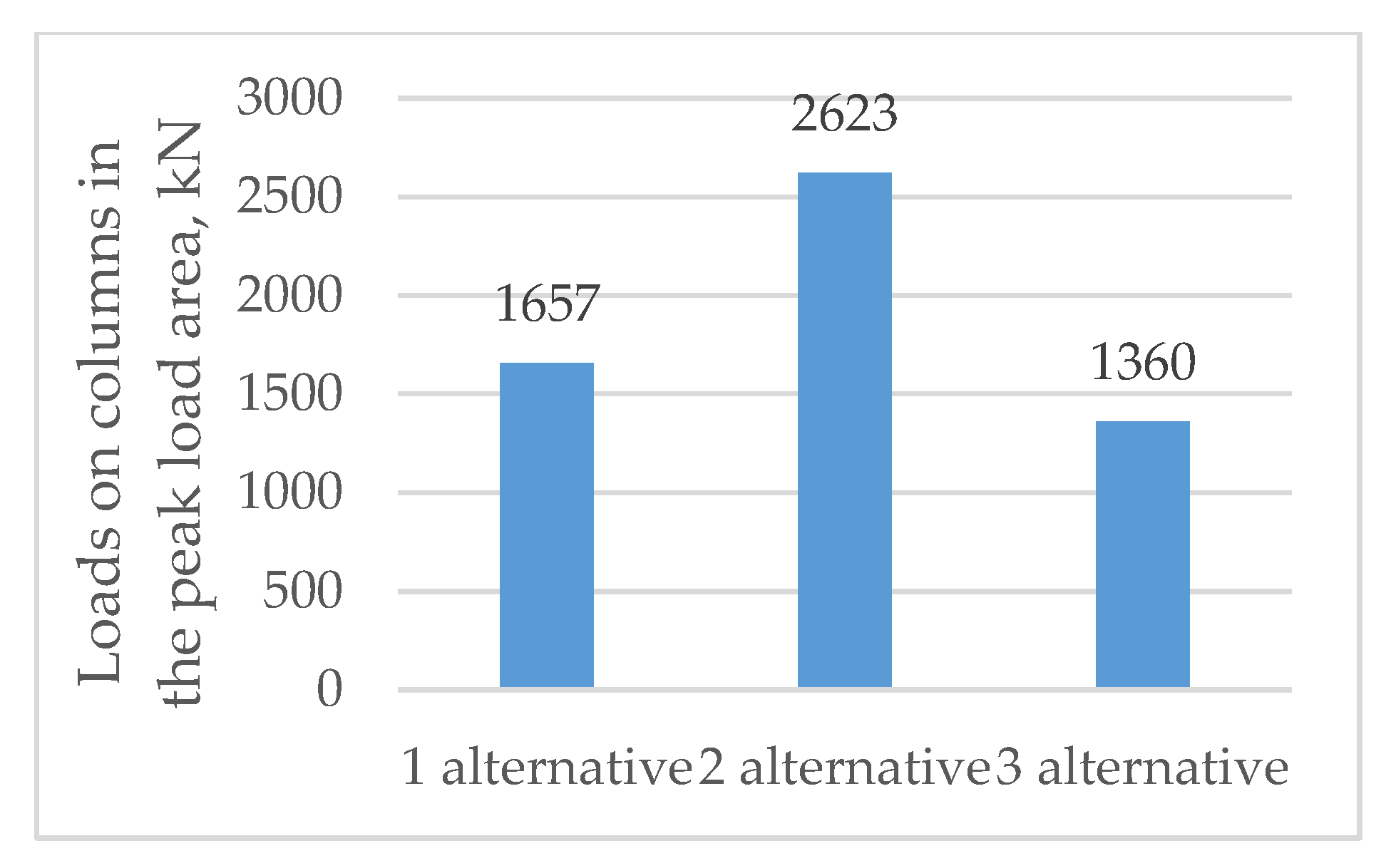

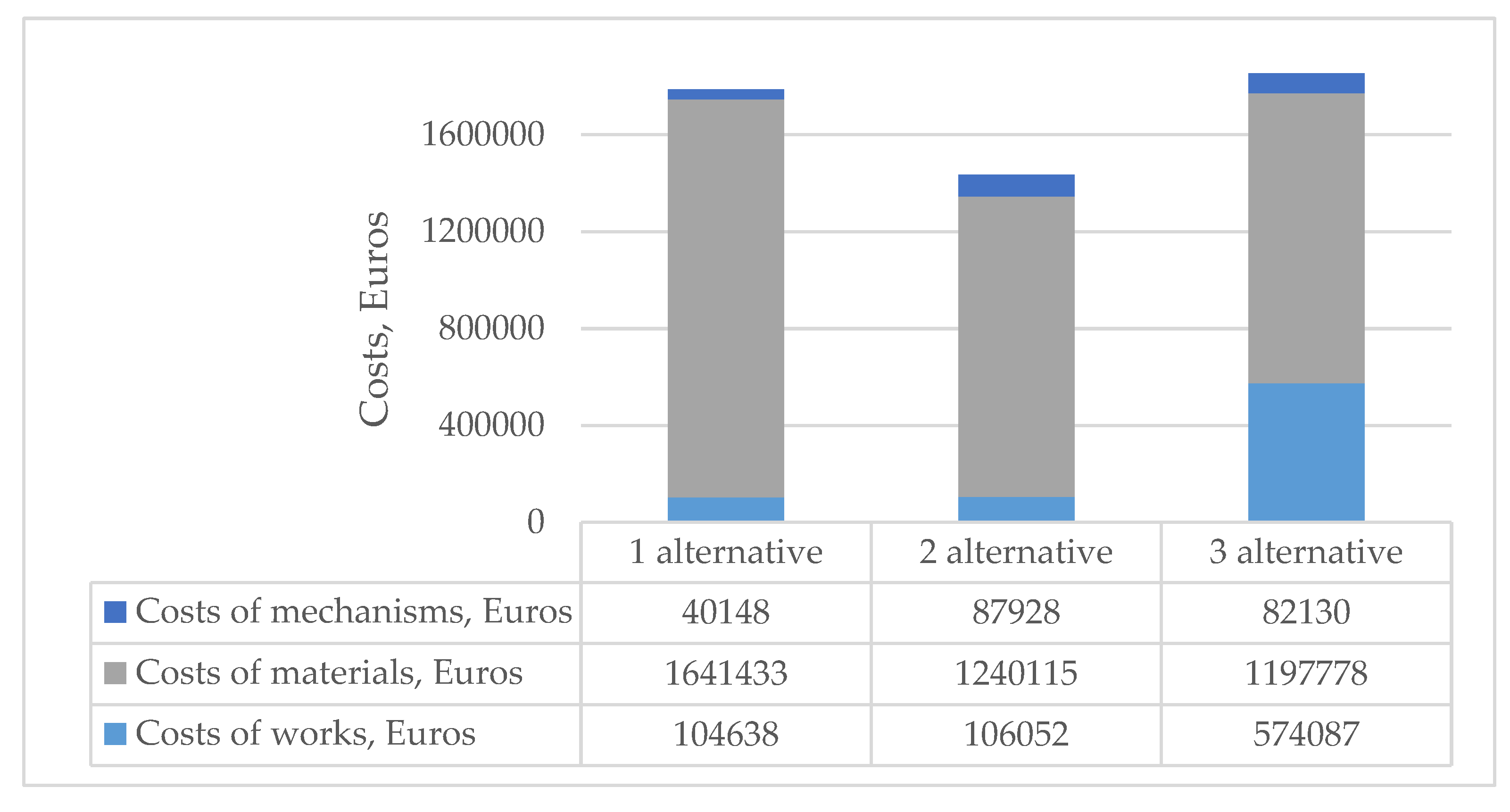

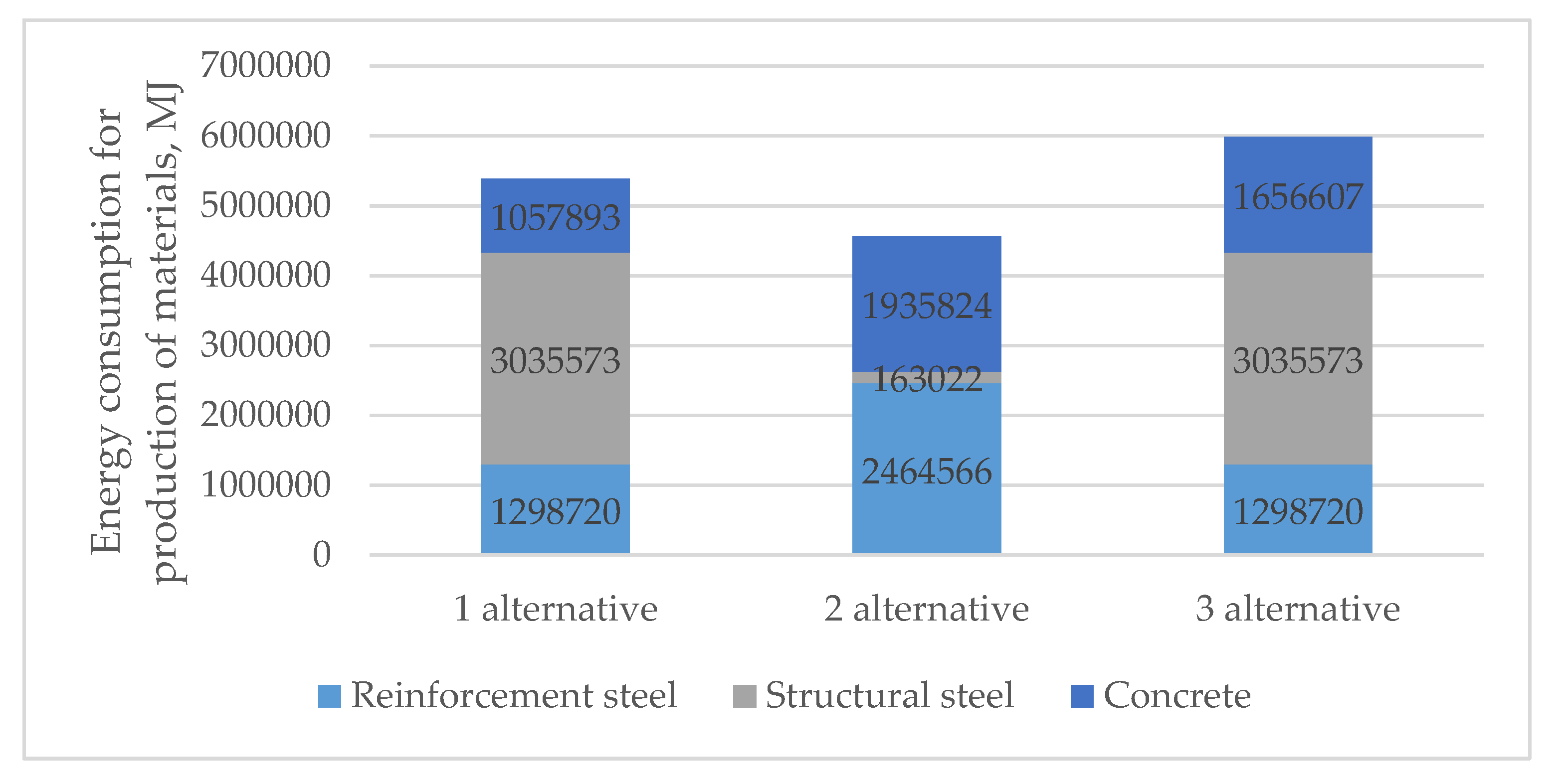

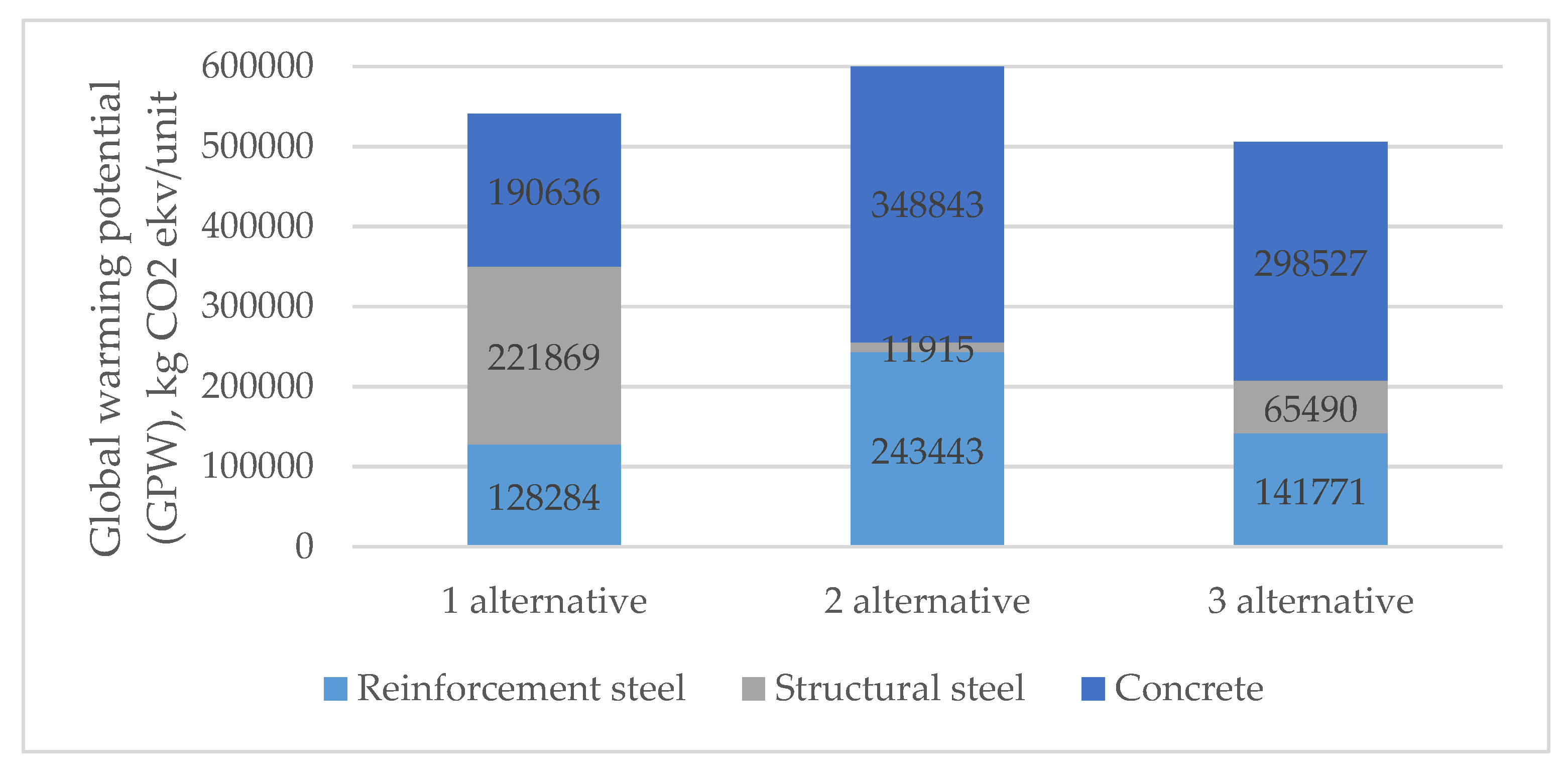

Step 4. This step includes calculation of values of physical criteria of alternative structural solutions, analysis of alternative construction technologies, determining economic criteria (costs) of implementing alternative structural solutions, and assessing the environmental performance of alternative structural solutions.

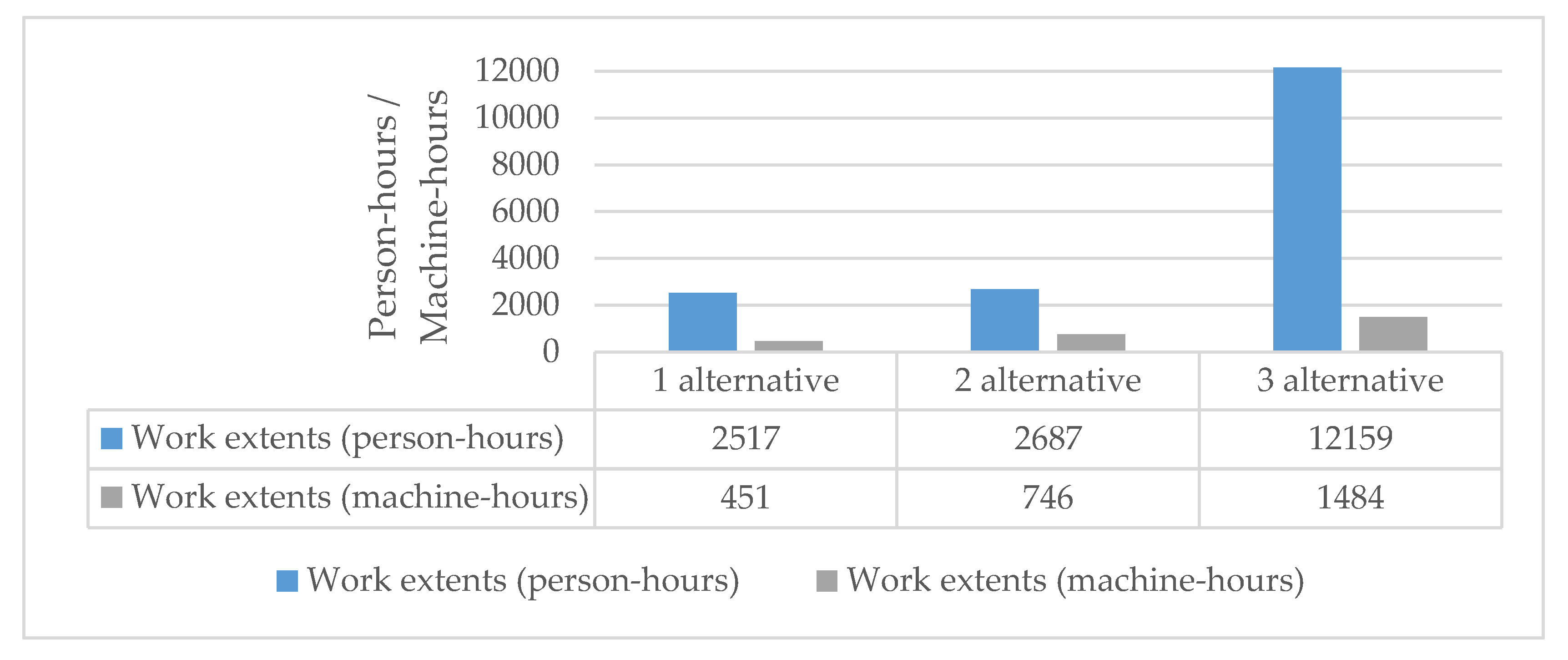

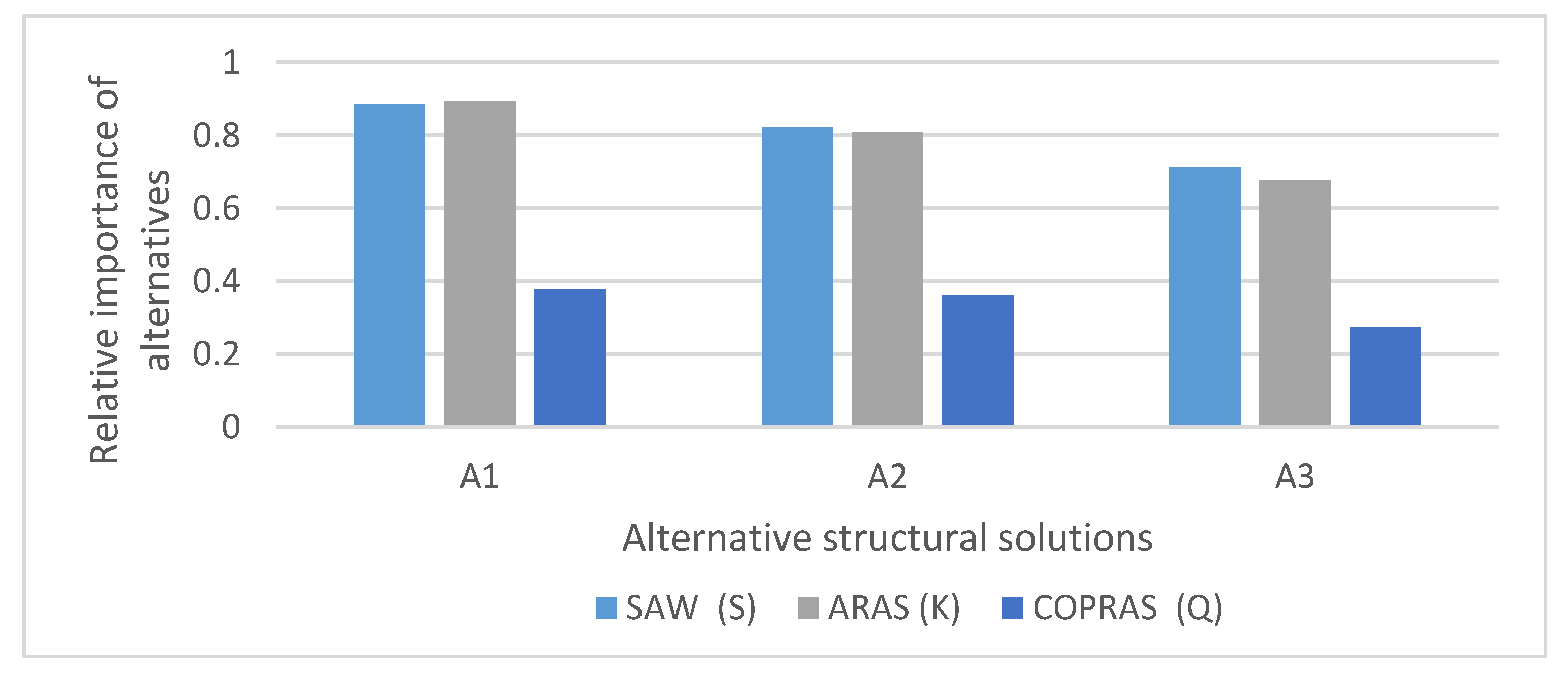

Step 5. Application of the multi-criteria aiding methods SAW, ARAS and COPRAS and assessment of alternative structural solutions in terms of sustainability. This step also includes the analysis of results.

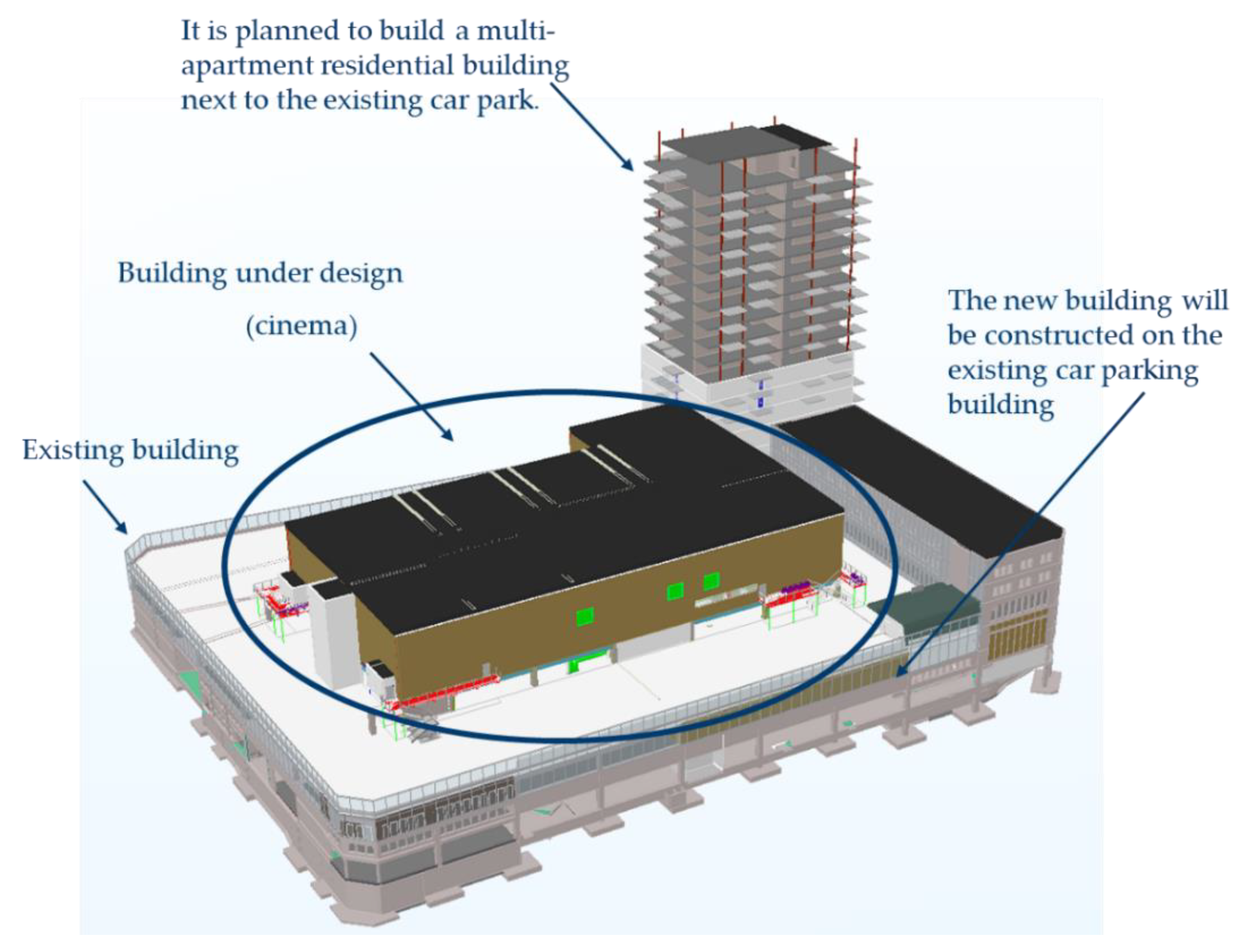

Figure 2 depicts the main steps of the methodology followed in this research.

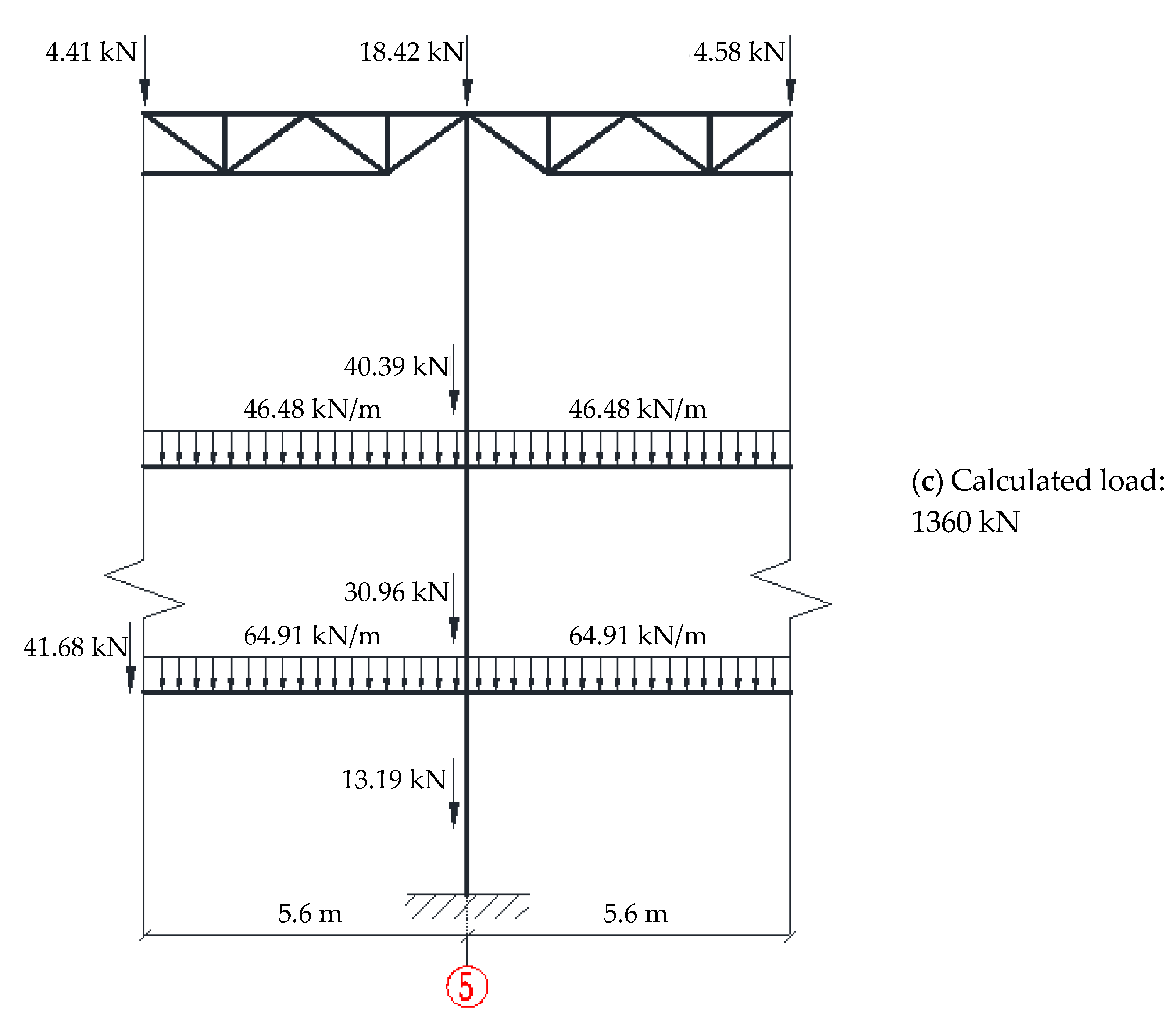

Though a structure of a building consists of many components, this study focused on the load-bearing structures of commercial buildings. In the case study, we considered only three types of load-bearing structures—building bearing structure made from reinforced concrete prefabricated elements and structural steel, bearing elements made of prefabricated reinforced concrete, building frame made from monolithic reinforced concrete.

3-step Delphi study approach applied for expert assessment of criteria weights presented in

Section 2.3. Multi-criteria aiding methods SAW, ARAS and COPRAS applied for the assessment of alternative structural solutions presented in

Section 2.4,

Section 2.5 and

Section 2.6.

Dozens of multi-criteria decision aiding methods have been developed recently to address a large variety of problems emerging in civil engineering [

8,

43,

44,

45,

46]. They classified into two classes depending on how they combine the data: discrete MCDM or MADM and continuous MODM (Multi-Objective Decision Making) optimization methods [

44]. They all require the definition of options and criteria, and most of them demand a measure (e.g., weights) for assessing the relative significance of the criteria.

However, the application of a single function in the decision-making process is not a sufficient condition. There is no single method that could be suitable for solution of all problems. Different MCDM methods sometimes yield different results [

42]. Researchers and practitioners have recently increasingly supported the use of hybrid methods, because integrating different utility functions in one decision-making model can increase the reliability and transparency of the decision-making process in real-life situations [

47]. Integrated approaches most frequently use two or more MCDM methods or a combination of the MCDM methods and other decision support approaches [

43,

44,

45,

46,

47,

48,

49,

50,

51].

The typical MCDM problem has the task of ranking a finite number of decision alternatives explicitly described in terms of different decision criteria, which have to be taken into account simultaneously. This work uses a hybrid method, i.e., a combination of Delphi technique, SAW, ARAS and COPRAS methods. The method SAW (Simple Additive Weighting) is one of the simplest and most widely used multiple criteria assessment methods [

52]. However, SAW uses only criteria of maximizing optimality function, while criteria with minimizing optimality direction should be converted into the maximizing ones prior to their application. This limitation is eliminated in the method COPRAS (Complex Proportional Assessment). In COPRAS method, the influence of maximizing and minimizing criteria assessed separately. The calculation results obtained by COPRAS method depend on the number of minimizing criteria and their values. The comparative analysis [

52] of SAW and COPRAS methods revealed that the calculation results obtained by these two methods might differ. Therefore, the third method needed to more accurately evaluate and validate the calculation results. For this purpose, the ARAS (Additive Ratio Assessment) method [

53] was applied. According to the ARAS method, the utility function value determining the complex efficiency of a feasible alternative is directly proportional to the relative effect of values and weights of the main criteria [

53].

2.3. Delphi Technique

The Delphi study is an iterative process, based on the principle that decisions from a structured group of experts are more accurate than from individual or unstructured assessment. The Delphi technique has been used in many professional fields, such as facilities management [

42], road engineering [

54], healthcare [

55], energy [

56], manufacturing [

57] and education [

58].

The key methodological features of the Delphi study include a multi-stage procedure, ensured anonymity, feedback and experts’ independent views. The Delphi technique was applied in this study to select the main criteria, reject the less important, and to assess the weights of criteria.

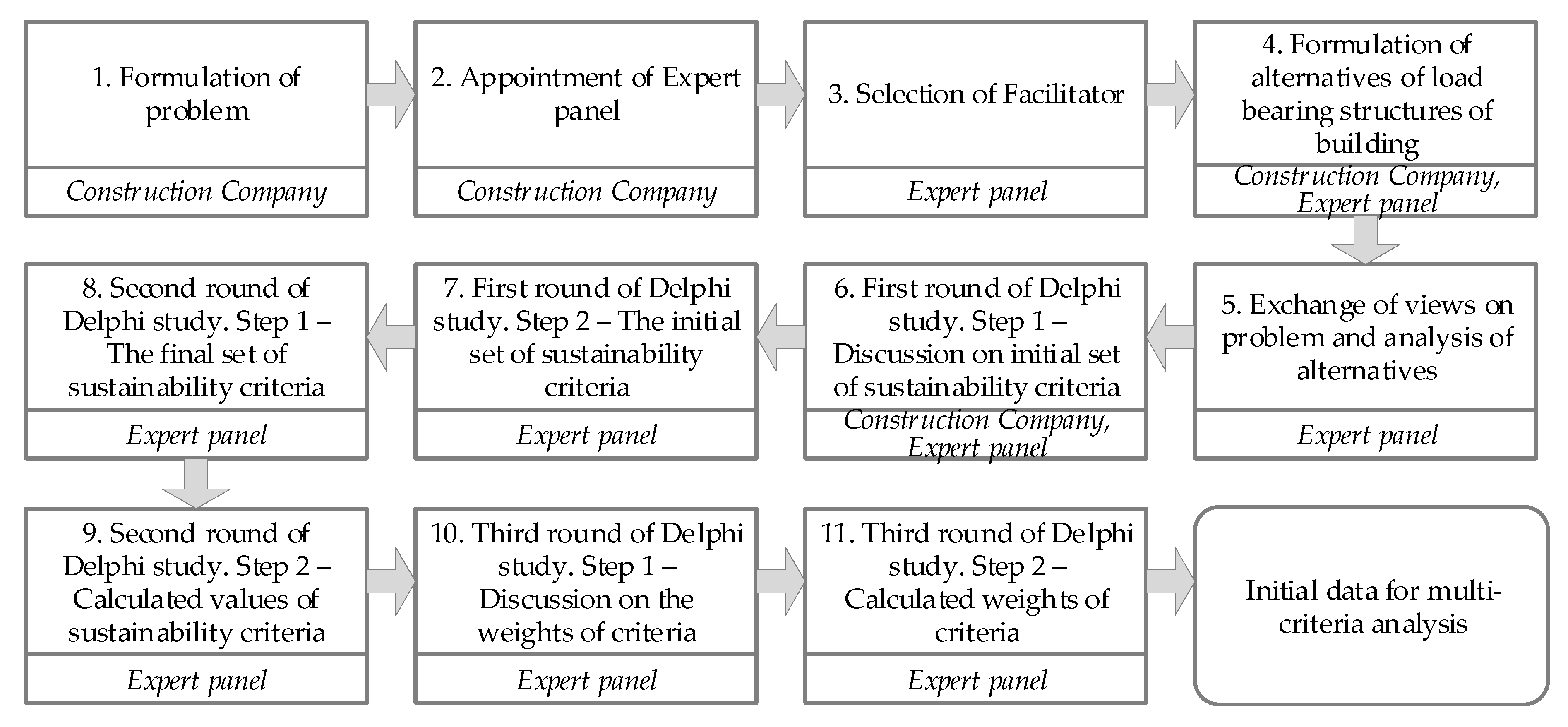

This Delphi study was conducted in three rounds (

Figure 3). First, the group of experts chose the facilitator—a neutral university expert who had experience in Delphi technique applications. During the Delphi study, experts exchanged viewpoints and each independently gave estimates to the facilitator. The experts had a task to decide on a set of criteria that should be relevant and universal for application in other cases. Ten experts of experienced and knowledgeable people from construction companies and academic institutions were selected for the panel (

Table 2). Experts were required to have knowledge and experience in the field of civil engineering, participated in international projects, and performed consultancies in the construction sector. During the evaluation process, the main criteria for selection were that candidates had to have a masters’ degree or higher and five or more years of experience in the field of civil engineering.

In the first round, experts were asked to review the object-related sustainability criteria, to reject the less relevant, and then to decide on the initial set of sustainability criteria. In the second round, experts were asked to set up the final list of sustainability criteria and to provide insights on comparative analysis of criteria. In the third round, experts were asked to decide on the weights of criteria necessary for the multi-criteria assessment of alternatives. When experts assigned the weights for the criteria, the compatibility of expert opinions was checked. The results of the expert assessment were summarized by the mean calculation.

After the experts identified the weights of criteria, the multi-criteria decision aiding methods were applied to rank the alternatives.

2.4. Simple Additive Weighting Method

Simple Additive Weighting (SAW) method is a widely known and practically used method [

52,

59].

The sum of the weights of all criteria must be equal to one ().

The problem is solved by the method in the following order:

Step 1. An initial decision matrix D is formed:

Step 2. Normalization (or transformation) of decision matrix to obtain dimensionless values:

where

rij is converted

i-th criterion’s value for

j-th alternative,

xmin is the smallest

i-th criterion’s value and the

xmax is the largest criterion’s value for all compared alternatives.

Formula (2) is used for the transformation of criteria if maximum values are preferable. Formula (3) is used for the transformation of criteria if minimum values are preferable.

Step 3. The sum

Sj of the weighted normalized values of all the criteria is calculated for the

j-th object:

Step 4. Ranking of alternatives and selection of rationale. The largest value of the criterion Sj corresponds to the rational alternative. The alternatives compared should be ranked in the decreasing order of the calculated values of the criterion Sj.

2.5. ARAS Method

The Additive Ratio Assessment (ARAS) method [

53] was applied in following steps:

Step 1. The decision-making matrix is composed.

If optimal value of j criterion is unknown, then:

Step 2. The purpose of this step is to receive dimensionless weighted values of the criteria. The initial values of all the criteria are normalized defining values

of normalized decision-making matrix

:

The criteria, whose preferable values are high, are normalized as follows:

The criteria, whose preferable values are low, are normalized by applying two-stage procedure:

Step 3. The next step is defining the normalized-weighted matrix

. It is possible to evaluate the criteria with weights 0 <

wj < 1. The values of weight

wj are usually determined by the expert assessment method. The sum of weights

wj would be limited as follows:

Normalized-weighted values of all the criteria are calculated as follows:

where

wj is the weight of the

j criterion and

is the normalized value of the

j criterion.

Step 4. The values of optimality function are determined as follows:

here

Si is the value of optimality function of

i alternative.

The greater the value of the optimality function Si, the more effective the alternative. The priorities of alternatives can be determined according to the value Si.

Step 5. The degree of the utility is determined by a comparison of the alternative, which is analyzed, with the ideally best one

S0. The equation used for the calculation of the utility degree

Ki of an alternative

ai is given below:

where

Si and

S0 are the optimality criterion values, obtained from Equation (10).

The calculated values Ki are in the interval [0; 1] and ordered in an increasing sequence, which is the wanted order of preference.

2.6. COPRAS Method

The preference ranking method of complex proportional assessment (COPRAS) [

60] was applied in the following steps:

Step 1. The initial decision-making matrix is normalizing with the goal is to get the dimensionless values. The authors use normalization with the weights:

Here xij—value j of i criterion; m—the number of criteria; n—the number of compared evaluations; qi—the weight of i criteria.

Step 2. Normalized-weighted values of all the criteria are calculated as follows:

Here j—the criterion, —the weight of j criterion.

Step 3. The sums of minimizing

S–j and maximizing

S+j normalized indicators calculated:

Step 4. The relative importance of the alternatives according to the characterizing positive

S+j and negative

S–j qualities is determined. The relative importance

Qj of each alternative

aj is determined by the following formula:

where

Step 5. The utility degree of each alternative is determined:

where

Step 6. Ranking of the alternatives. The priority order of compared alternatives is determined based on their relative importance

Qj. The alternative with higher relative importance has higher priority (or rank), and the alternative with the highest relative importance is the most acceptable:

4. Discussion and Conclusions

The proposed approach for sustainability analysis integrates the analysis of environmental, social, technological and economic factors. MCDA methods integrated into the approach ensure that the assessment is reliable. The study revealed that it is rational to use multi-criteria decision-aiding methods to assess the sustainability of alternative structural solutions at an early stage of building design. MCDA application allows the investor to better assess the attractiveness of alternatives. Multiple-criteria decision-aiding methods give the possibility to improve the decision-making process. By integrating three different utility functions represented in applied MCDA methods, we show the possibilities to enhance the robustness of decision-making. The proposed model is versatile, and therefore can be applied to different cases.

The results of the study show that the inclusion of environmentally friendly solutions will raise the cost of the project. For example, the third alternative is optimal in terms of energy consumption and environmental performance, but the cost of implementing this alternative will be 23% higher than that of the other alternatives, and construction work will take 79% longer than that of a rational alternative. More research is needed in the future to prove the results of this study.

The reported weaknesses of sustainability assessments led to the conclusion that there is a need for fast-in-application, simple and reliable methods to assess the sustainability of structural solutions at early design stages. The use of cloud-based BIM technologies that store “big data” should be considered to manage the sustainability of buildings. In the future, BIM—as a promising technology—should be promoted for environmental sustainability management throughout the life cycle of buildings.

The decision-making process in the selection of sustainable solutions on the early design stage requires utilizing additional techniques to optimize the assessment of many alternatives. Building Information Modelling (BIM) offers the possibility to assess different design alternatives at the conceptual stage of a project. BIM also helps structural designers select the right type of materials more easily during the early design stage. With the help of integrated tools, structural designers can assess environmental impacts throughout the building’s life cycle. However, there are some challenges related to data loss during data transfer from one software package to another (due to the low interoperability of software packages). This is the main limitation, and attempts must be made to solve this problem.

The case study revealed that the new BIM-based approach requires solutions that allow performing tasks on different software platforms that can operate in parallel or sequence. Future research will focus on developing a solution for the automated selection of the structural elements to form alternative bearing structures of building. More research is needed with a focus on developing a solution for better data exchange between the different software packages used in the assessment.