Enhanced Seismic Retrofit of a Reinforced Concrete Building of Architectural Interest

Abstract

1. Introduction

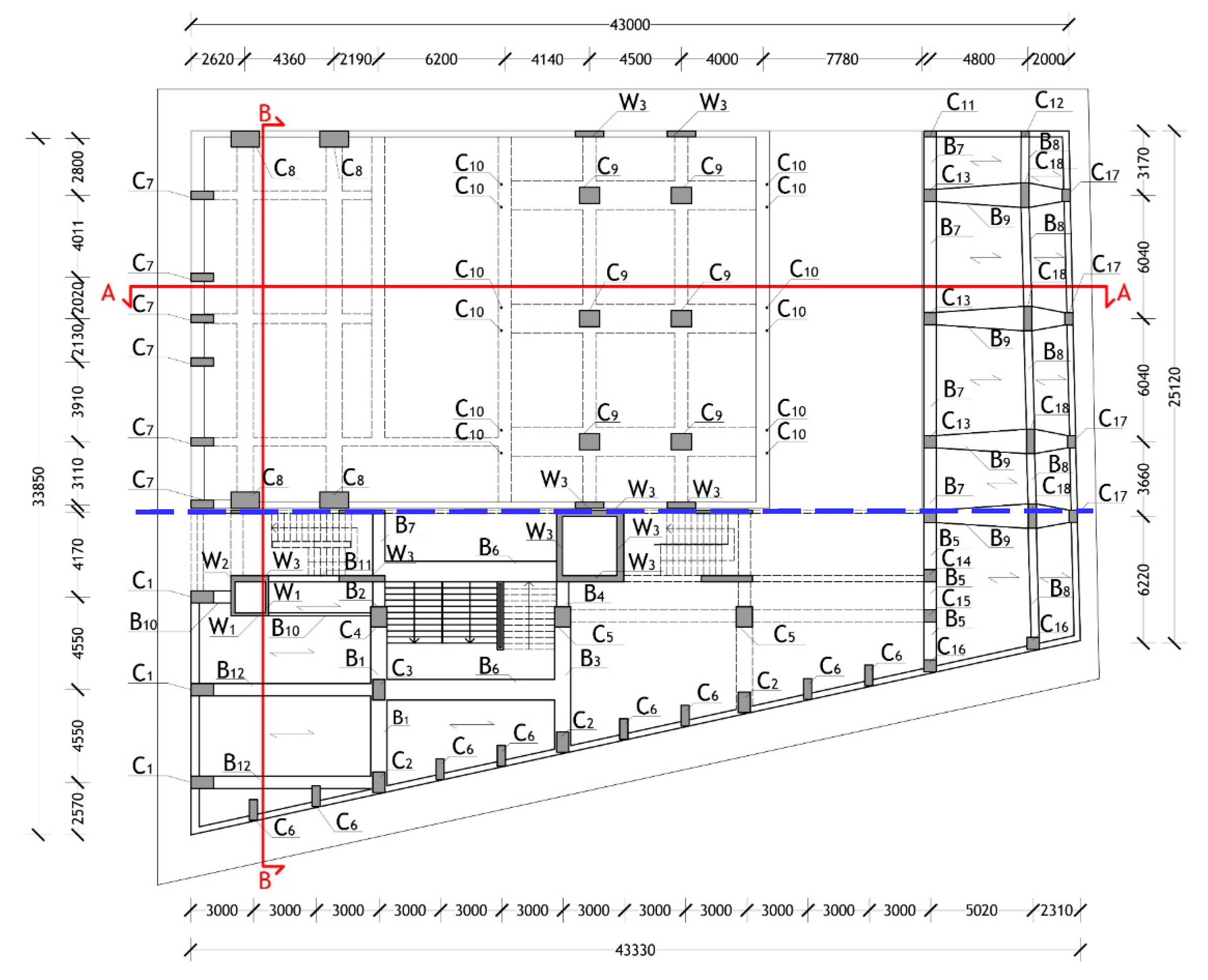

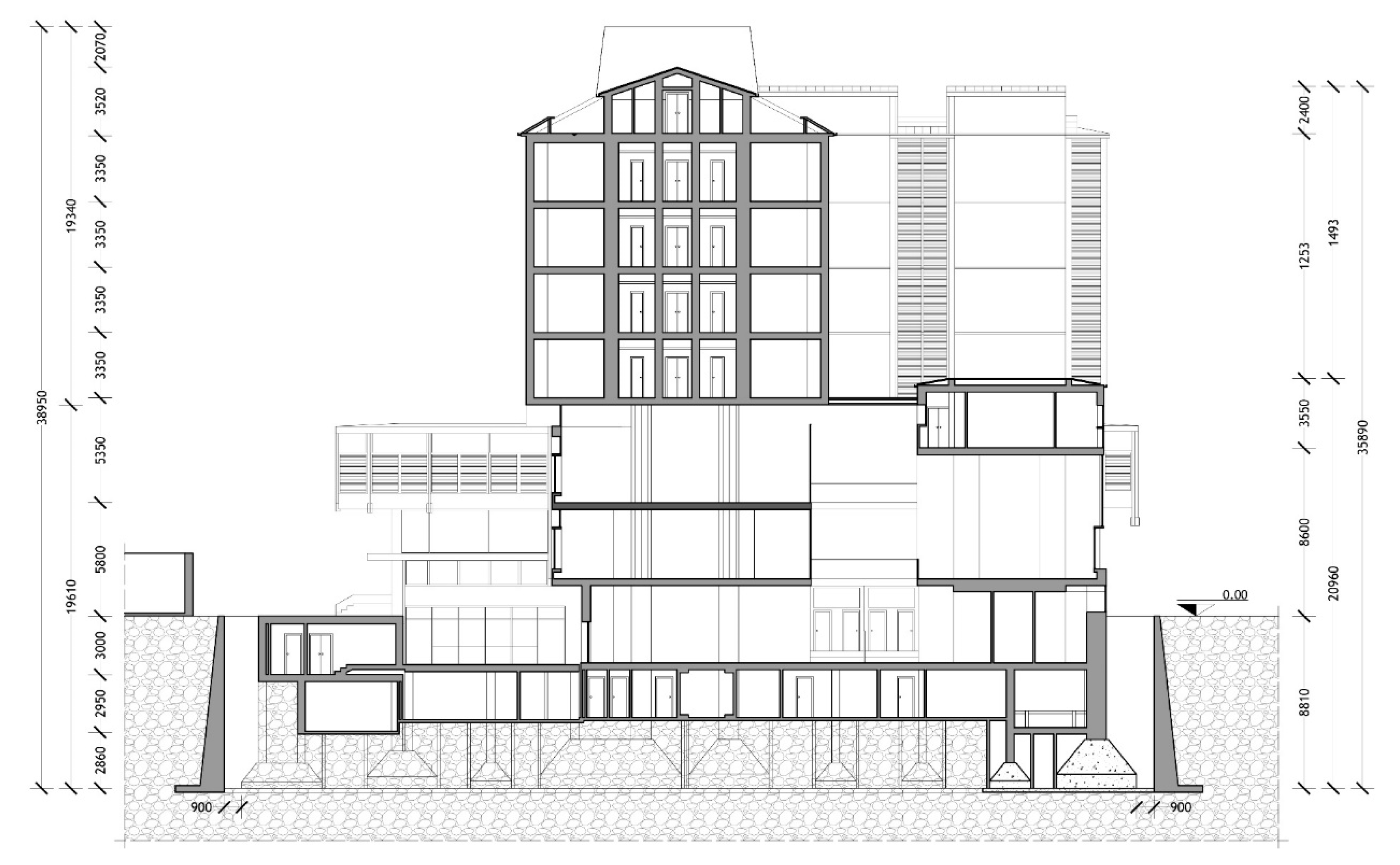

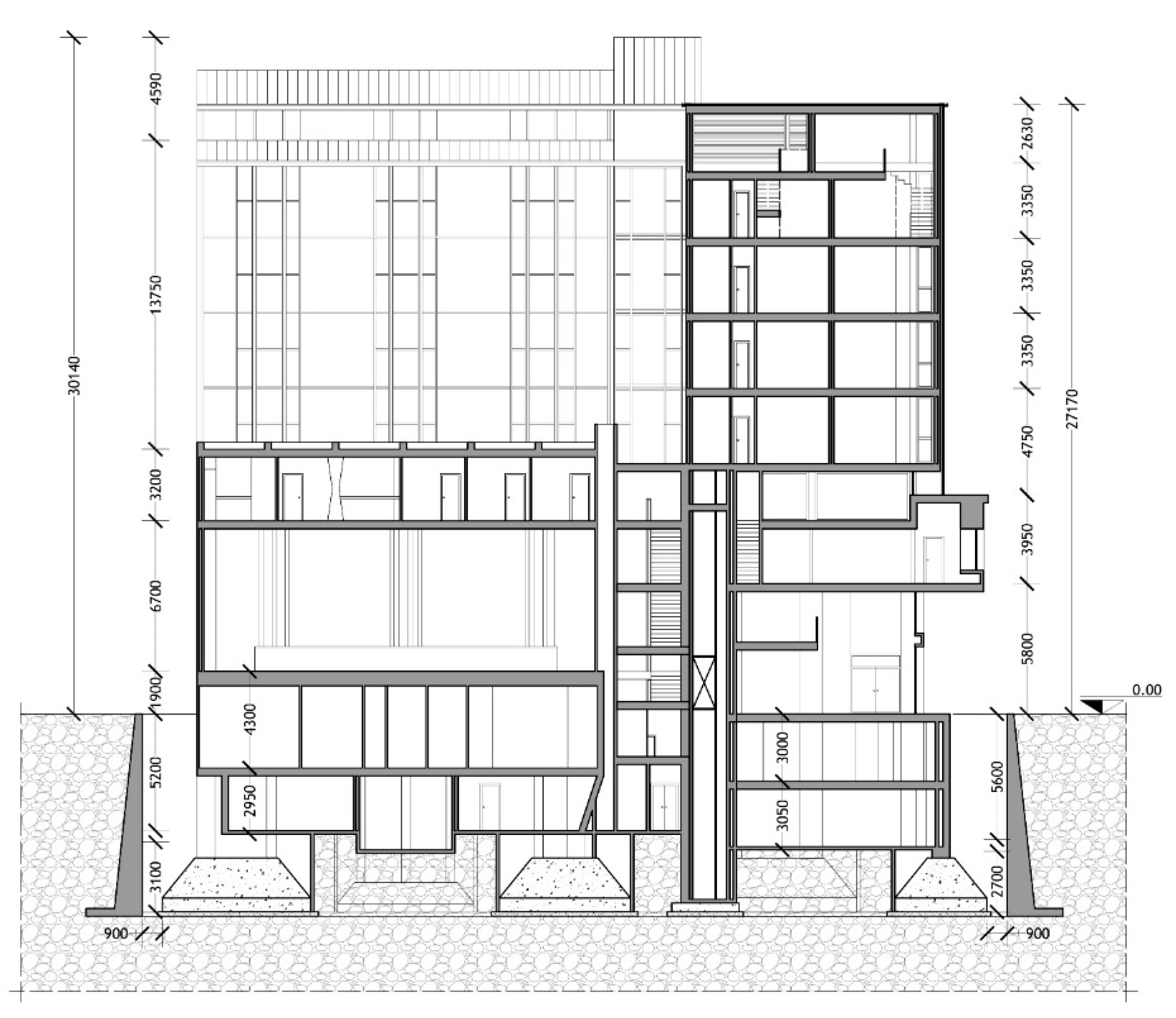

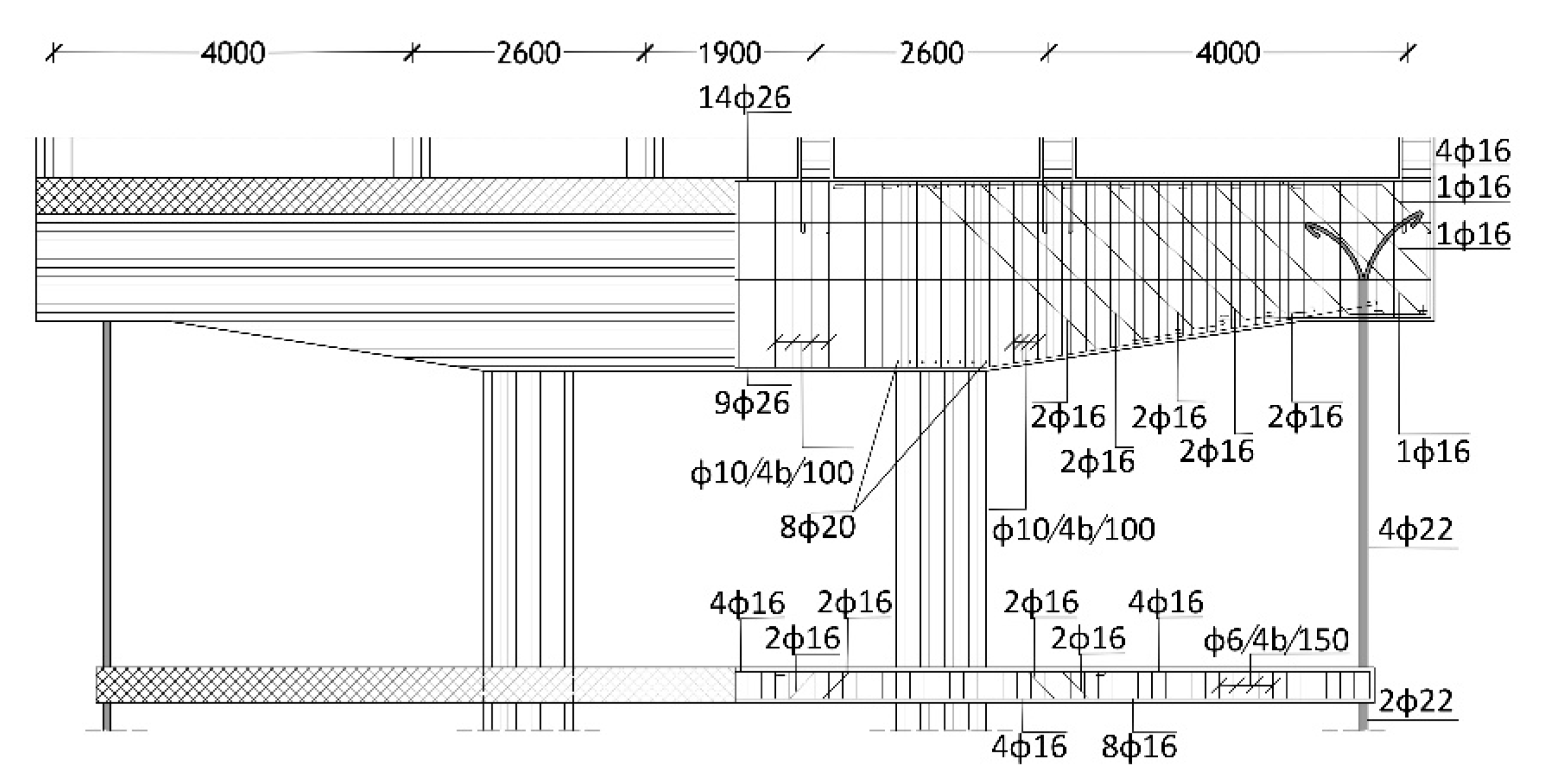

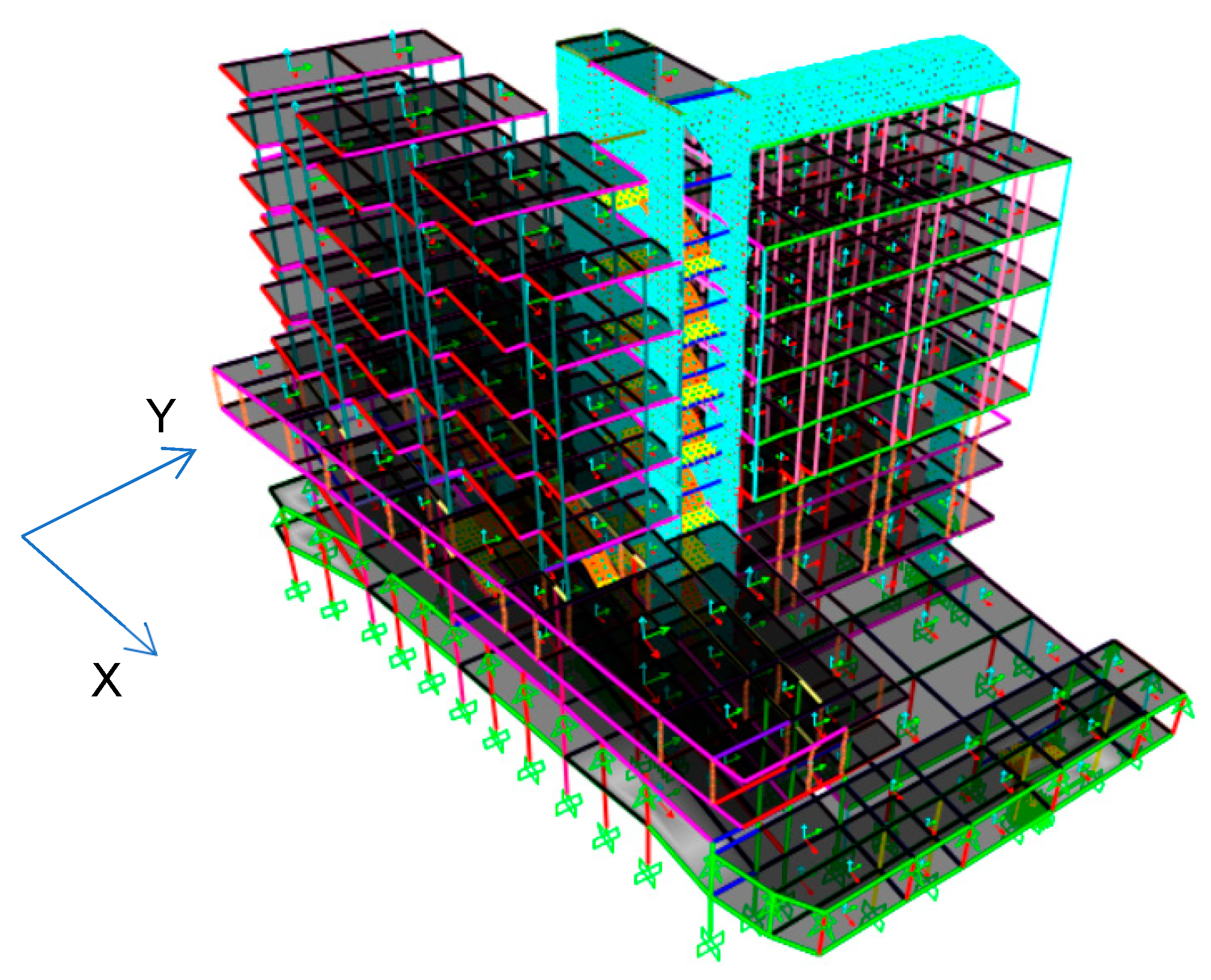

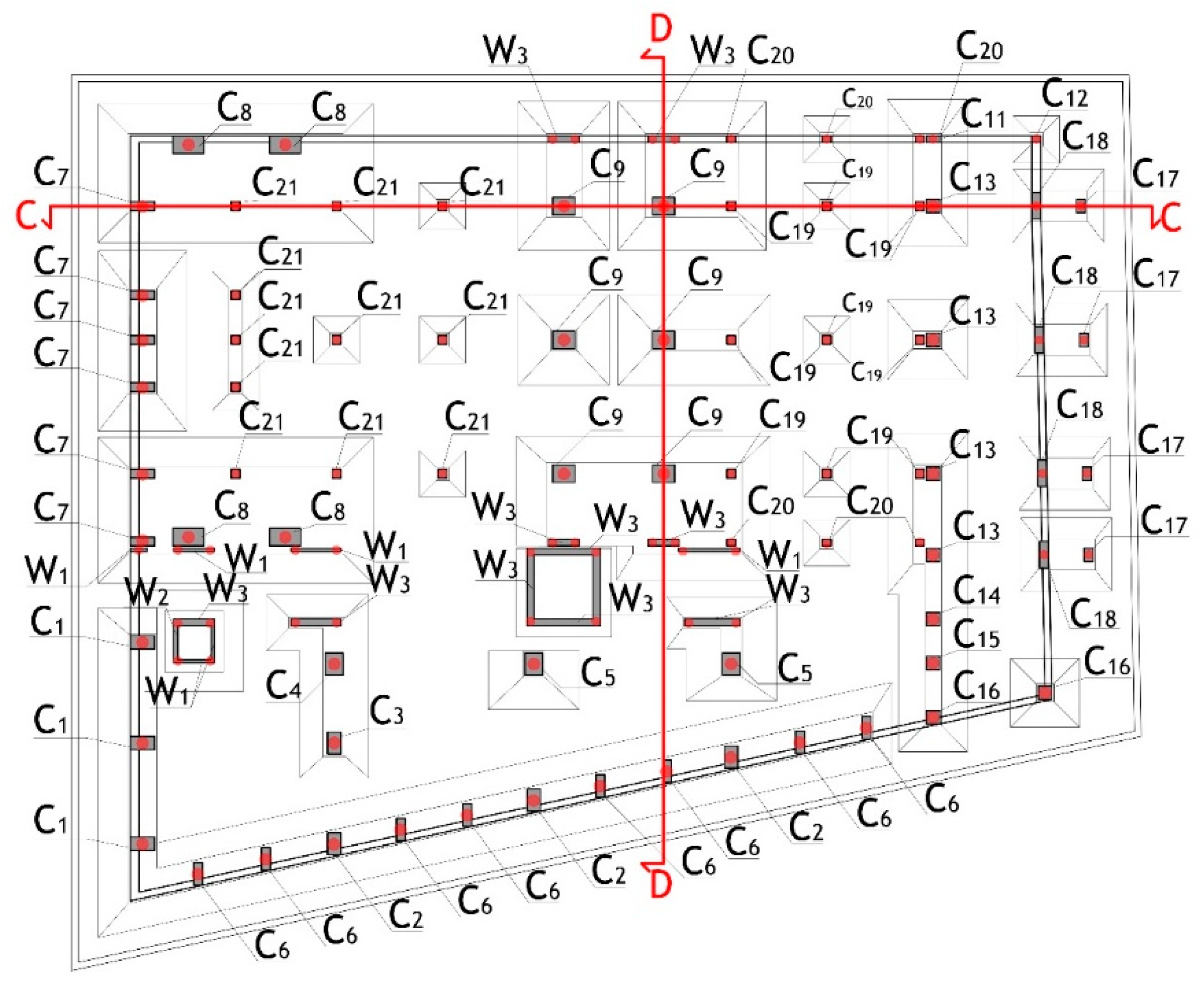

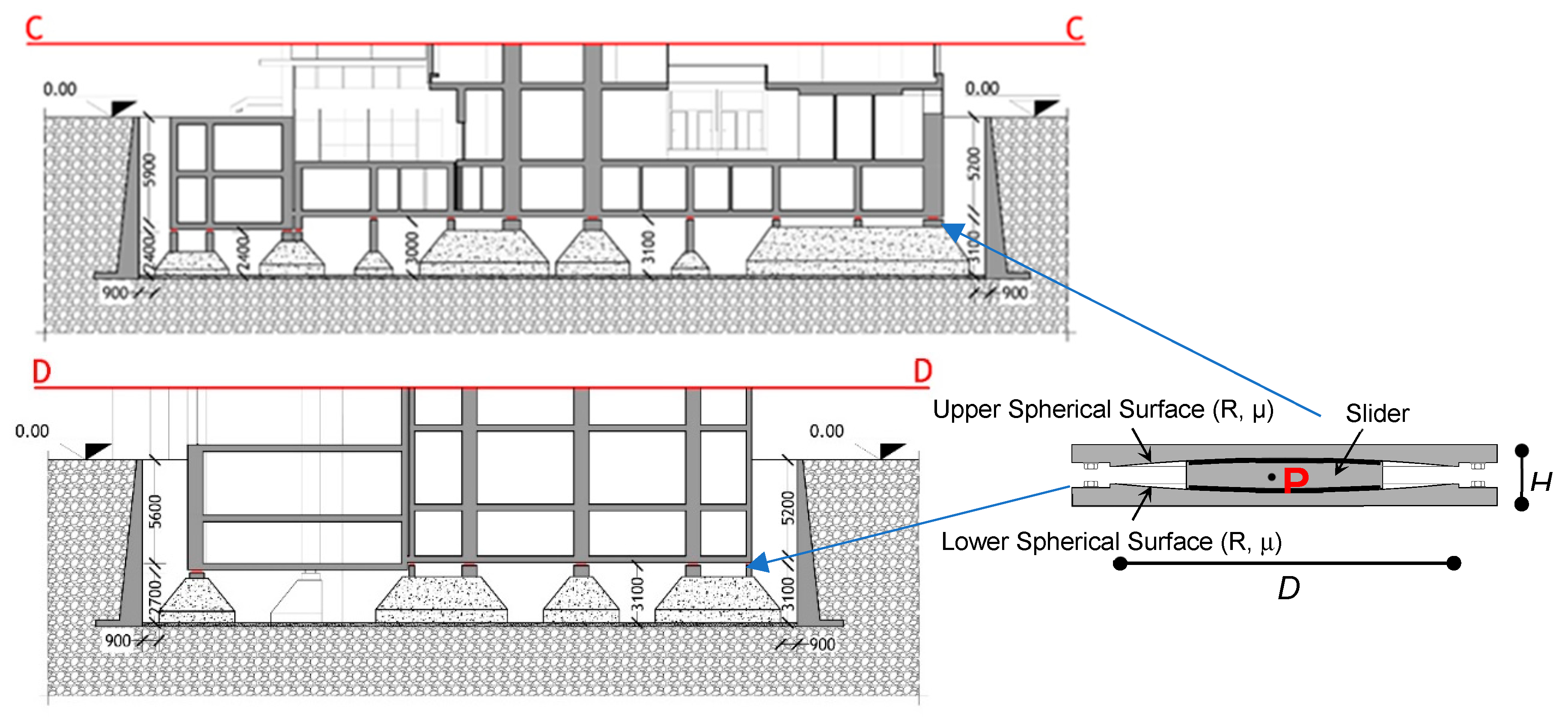

2. Structural Characteristics of the Building

3. Seismic Assessment Analysis in Current Condition

3.1. Modal Analysis

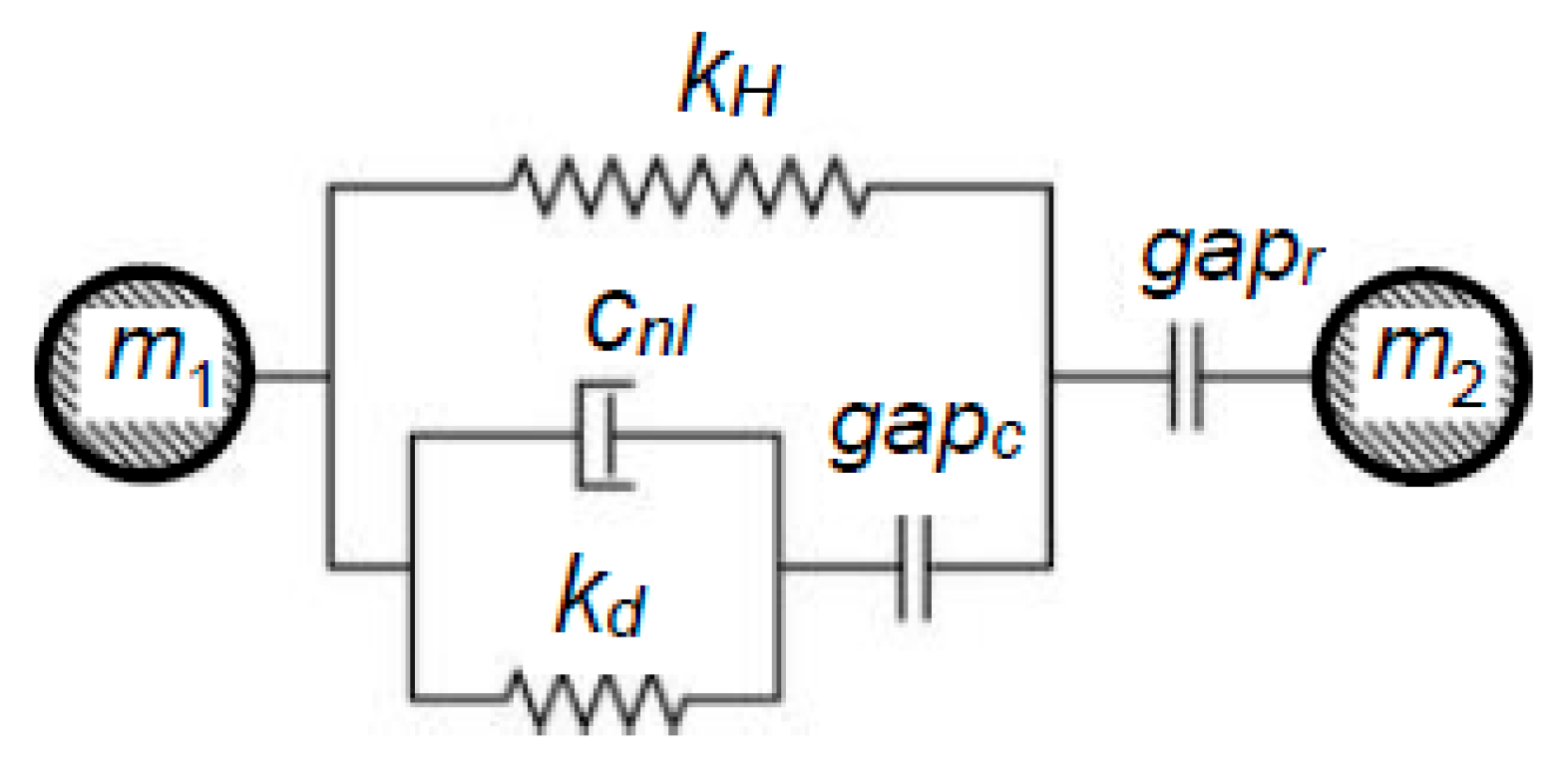

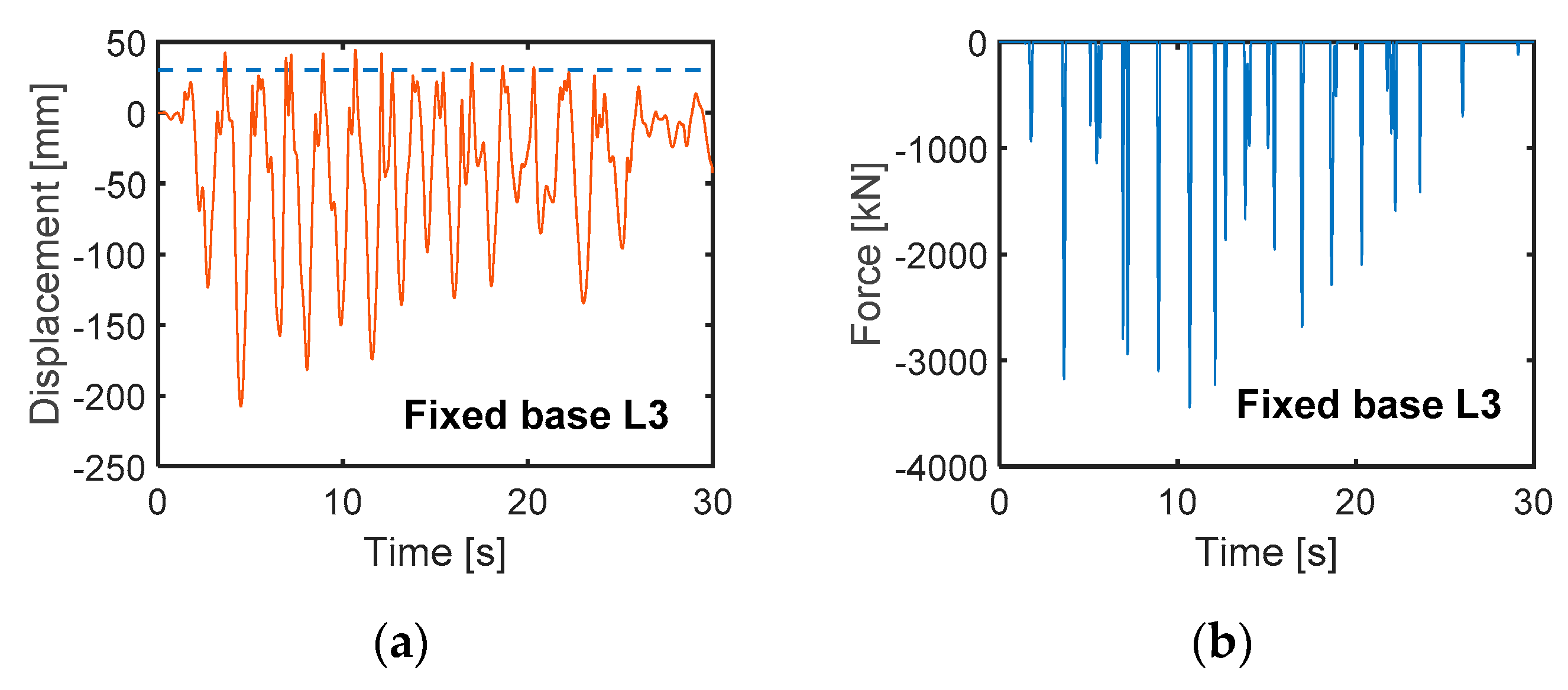

3.2. Time-History and Seismic Performance Assessment Analysis

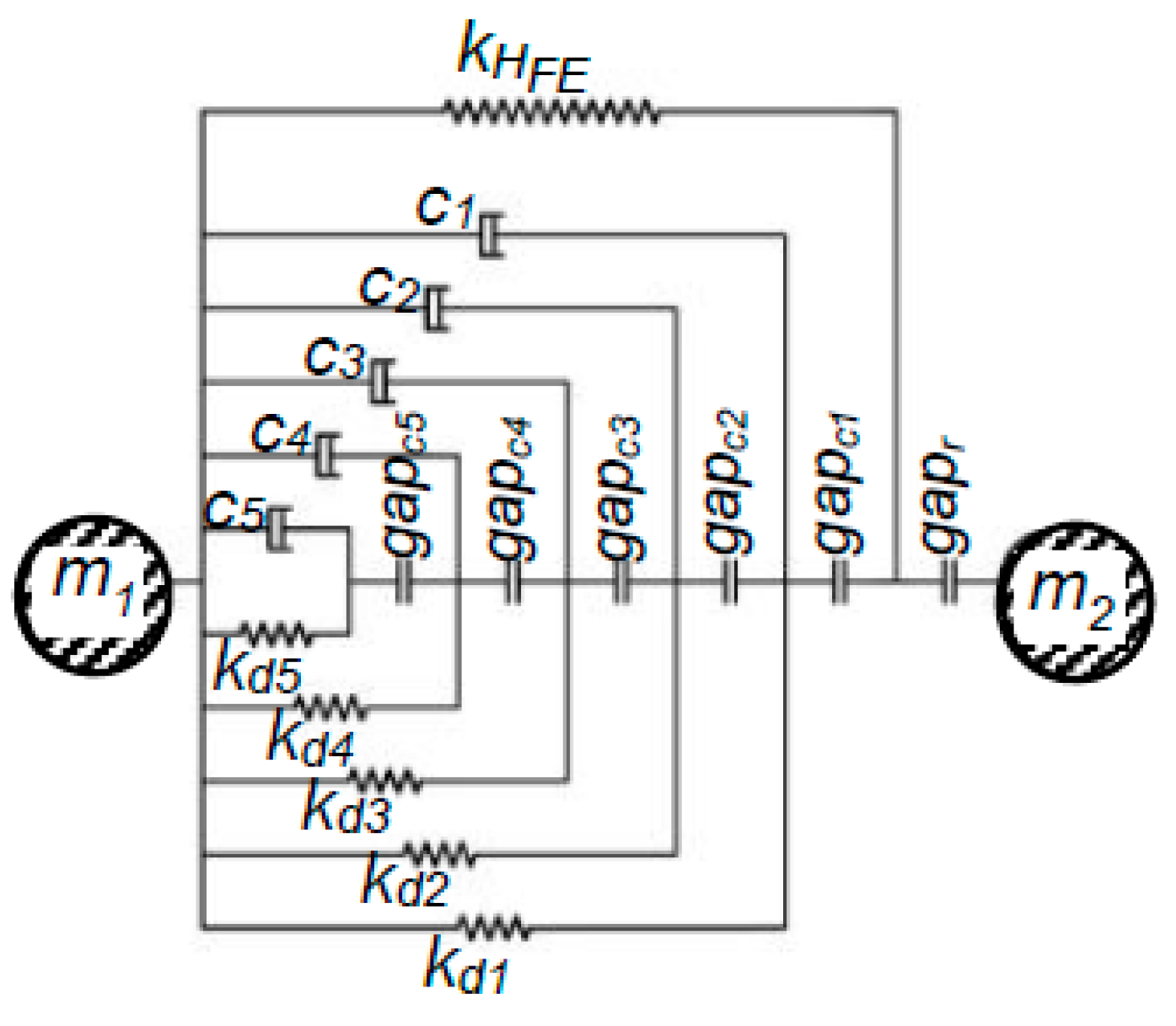

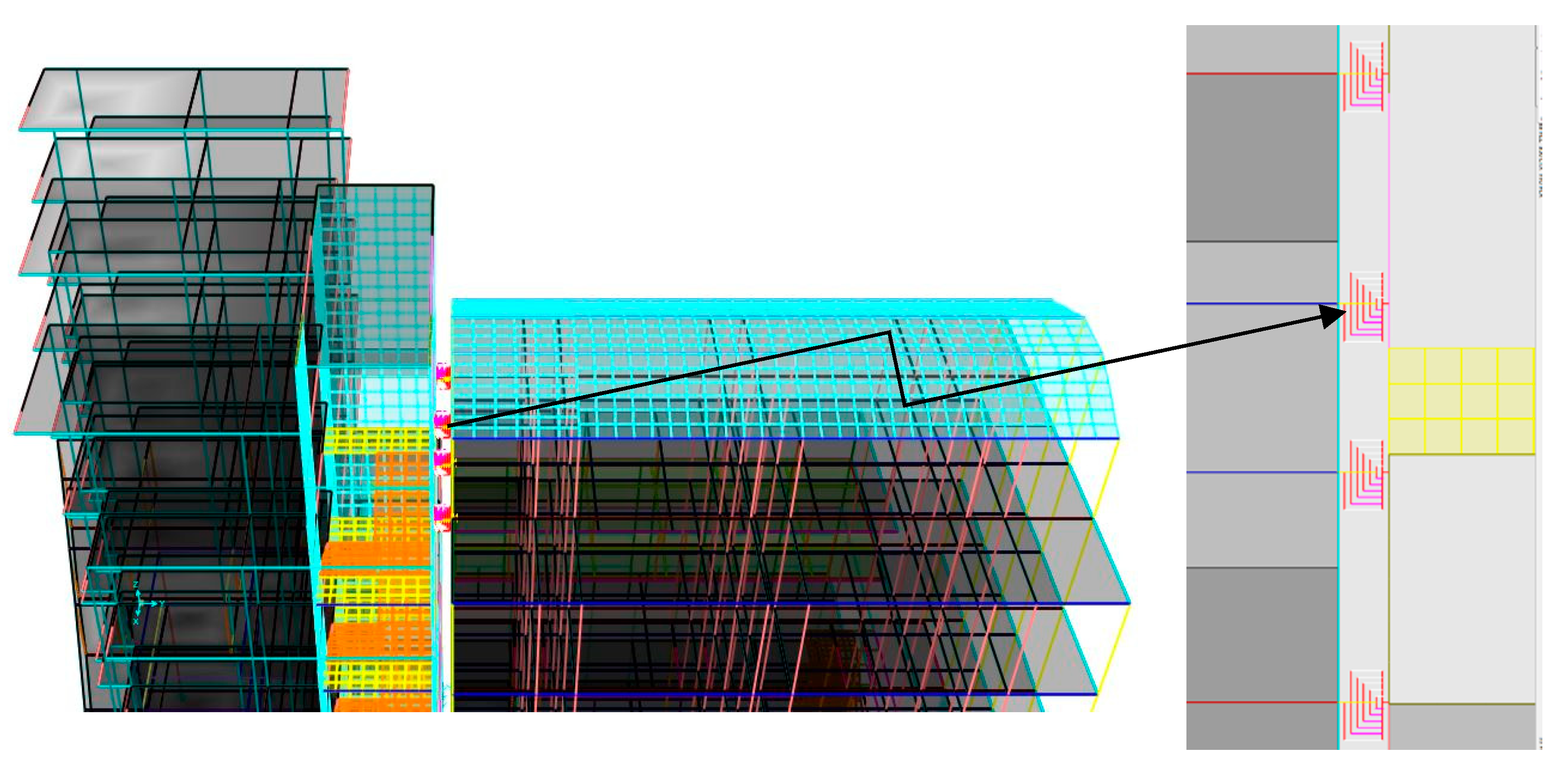

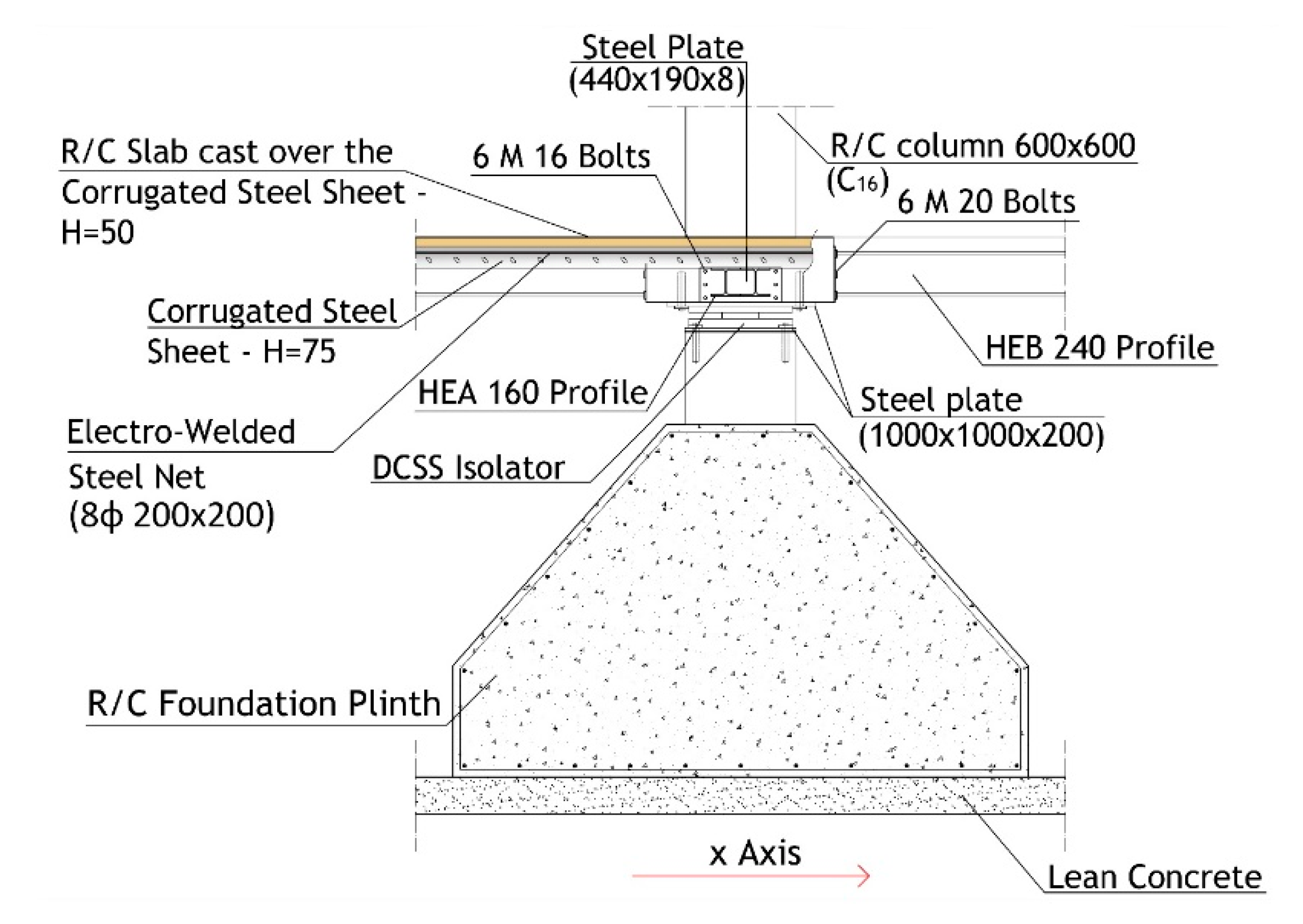

4. Base Isolation Retrofit Hypothesis

4.1. Modal Analysis

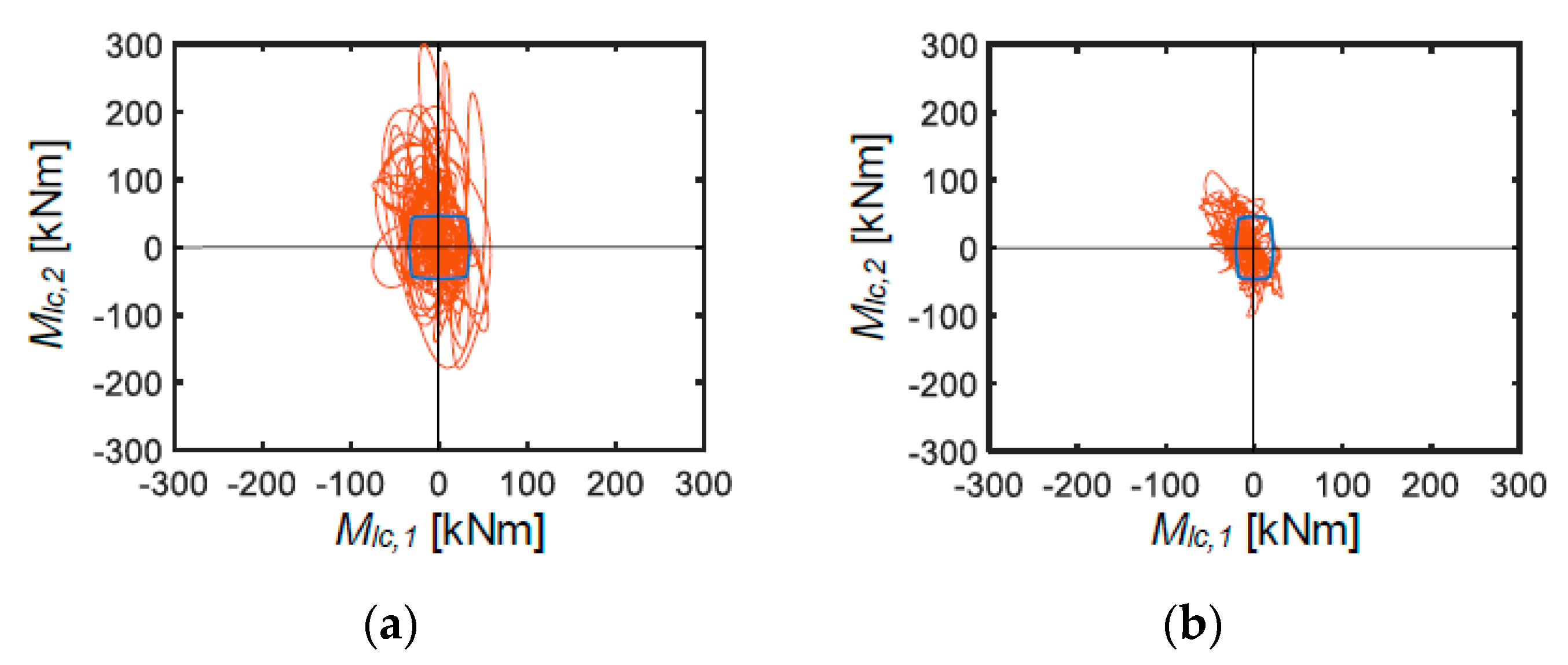

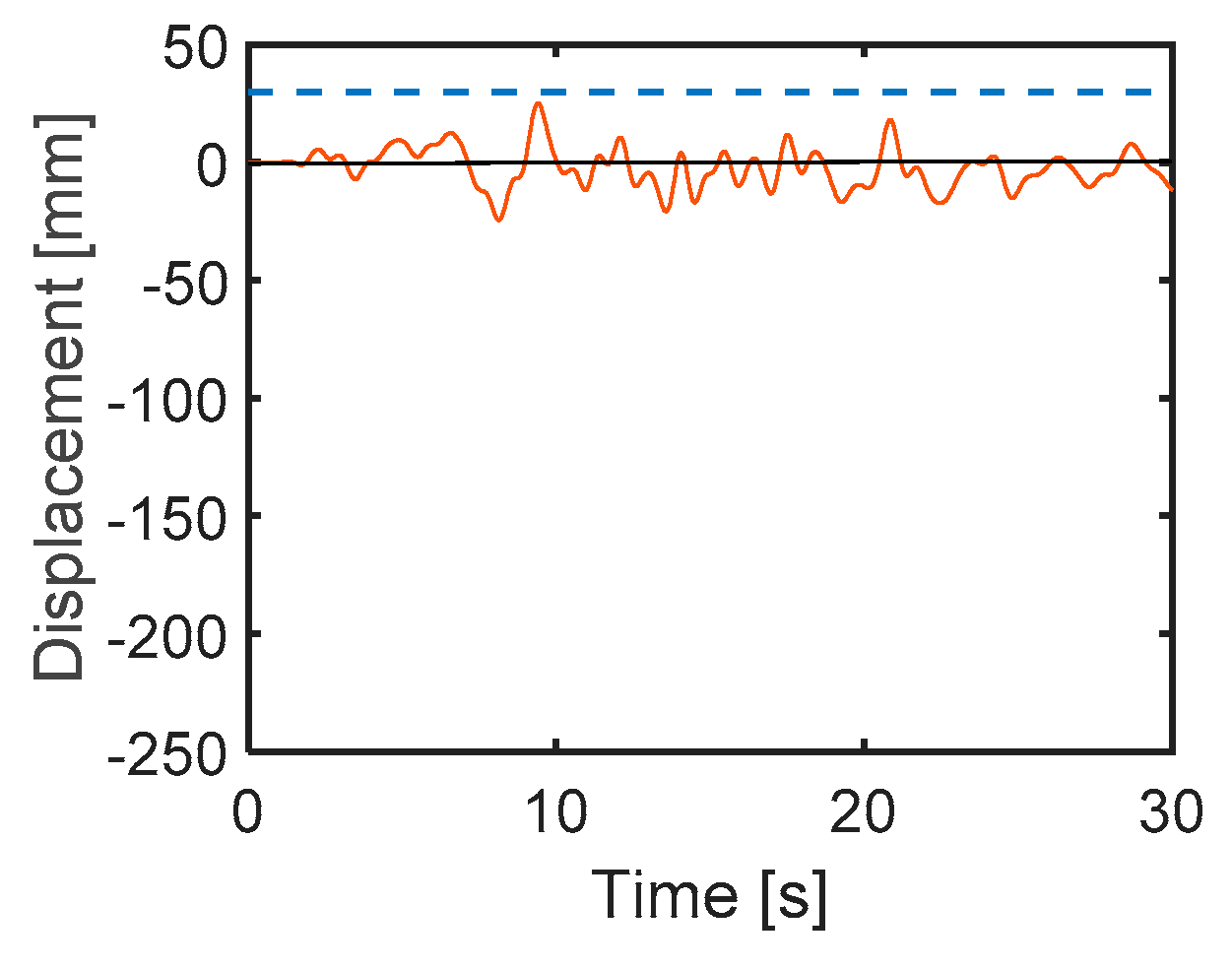

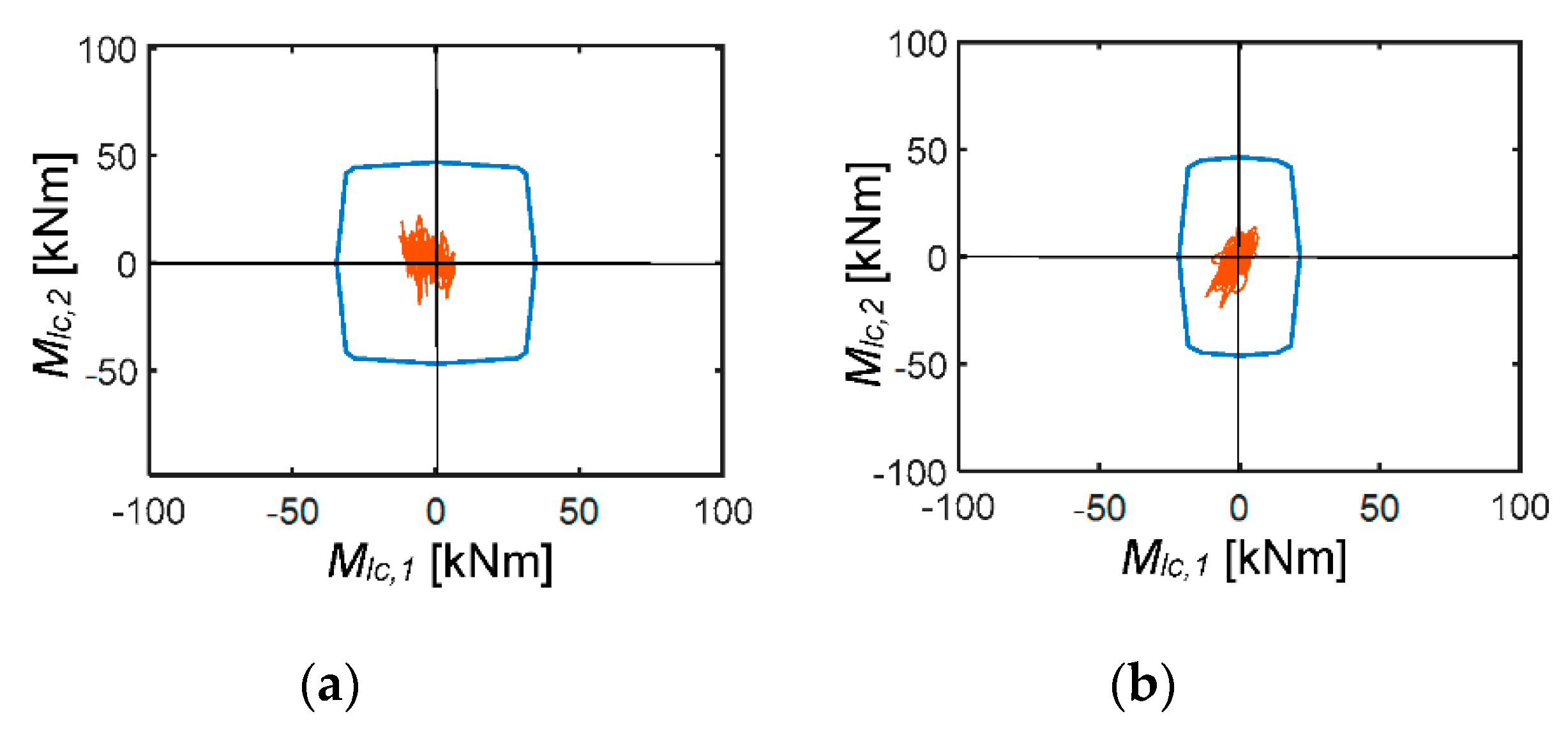

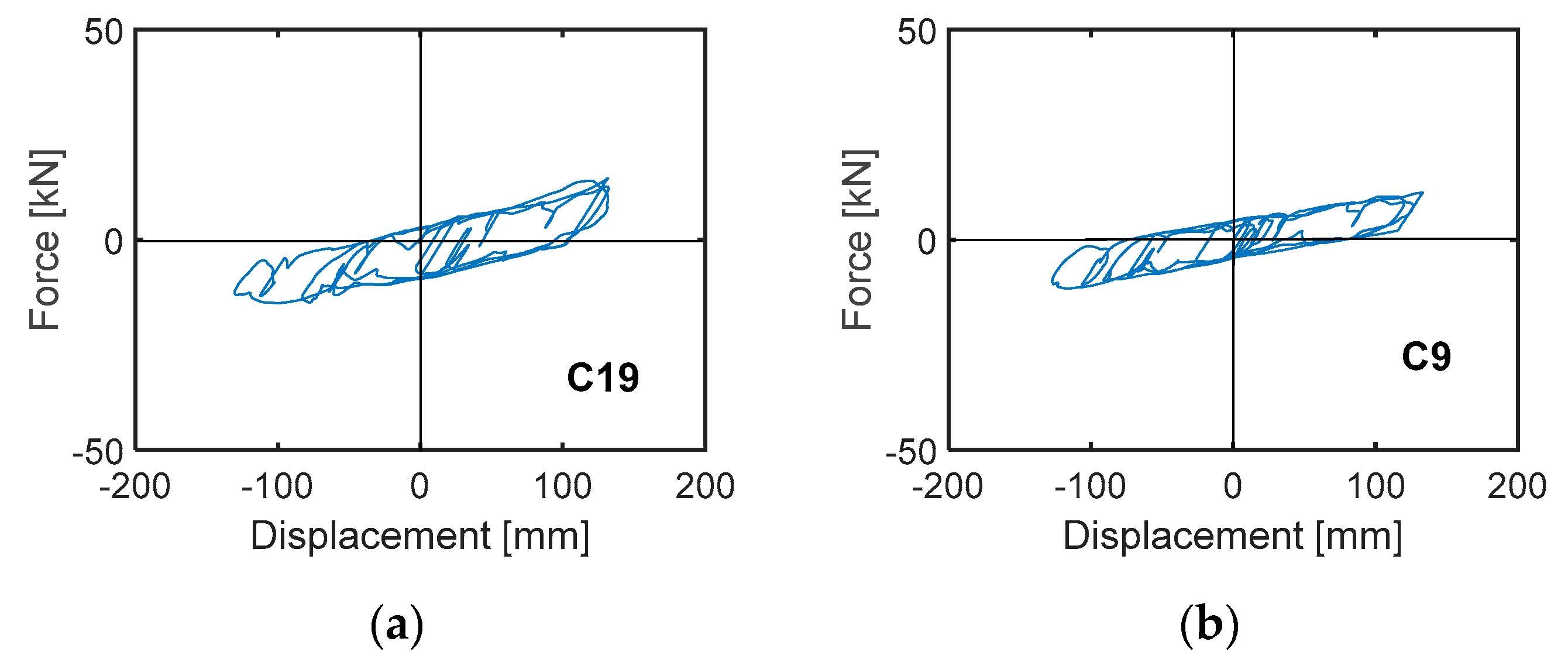

4.2. Time-History and Seismic Performance Verification Analysis

5. Conclusions

- -

- The Automobile Club Headquarters in Florence, selected as a representative case study for this stock of buildings, showed seismic performance capacities even poorer than expected for ordinary buildings of the same period. This is due to the peculiar characteristics of its structural system, notably irregular both in plan and elevation, with staggered levels in the lower storeys, some of which suspended to cantilevered beams, poor redundancy of several frame members and a 30-mm-wide only technical gap separating the two main constituting wings.

- -

- Indeed, the results of the time-history performance evaluation analysis highlight that around 15% of columns do not pass stress checks even at the serviceability design earthquake level, with unsafety factors reaching 1.6.

- -

- At the same time, severe pounding conditions, as assessed by peak interpenetration depth values of 11.1 mm, as well as generally unsafe conditions of structural members quantified by nominal unsafety factors up to 4.3, are found at the basic design earthquake level.

- -

- The interpenetration depth reaches 14.1 mm at the maximum considered earthquake level, with corresponding total collision forces greater than 13,000 kN, which would cause severe damage to the infills in contact with the columns of the colliding alignments and complete disruption of the concrete cover of relevant beams. In addition, the increase in the stress states of the columns belonging to these alignments and the neighboring zones determines nominal unsafety values equal to around 6.

- -

- The maximum inter-storey drift, assumed as basic damage index for the evaluation of the performance of infills and glazed curtain walls, exceeds 1% of the storey height at all storeys at the MCE. This corresponds to the development of diffused cracks both in the infill panels and the glass panes, requiring extensive post-quake repair works for the former and the complete replacement for the latter.

- -

- The proposed base isolation retrofit intervention guarantees non-pounding response conditions and safe stress states for all members up to the MCE.

- -

- The maximum inter-storey drifts are correspondingly shifted below the operational performance level-related limit of 0.33% of the storey height. This prevents damage to infills, plants, finishes and the other drift-sensitive non-structural elements, including the imposing glazed curtain walls.

- -

- The absence of intrusion in the building interiors guaranteed by the proposed retrofit solution helps in preserving its fine architectural appearance, in addition to the advantages offered to ordinary buildings (i.e., no significant interruption of usage during the execution of works, no architectural obstruction and reduction of floor areas caused by the incorporation of new structural members and/or by the strengthening of the existing ones, etc.).

- -

- In addition, the estimated cost of the intervention is around 50% lower than the cost of conventional rehabilitation designs.

Author Contributions

Funding

Conflicts of Interest

References

- Iervolino, I.; Manfredi, G.; Polese, M.; Verderame, G.M.; Fabbrocino, G. Seismic risk of R.C. building classes. Eng. Struct. 2007, 29, 813–820. [Google Scholar] [CrossRef]

- Jalayer, F.; Elefante, L.; Iervolino, I.; Manfredi, G. Knowledge-Based Performance Assessment of Existing RC Buildings. J. Earthq. Eng. 2011, 15, 362–389. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G. Structural assessment of a modern heritage building. Eng. Struct. 2013, 49, 743–755. [Google Scholar] [CrossRef]

- Custance-Baker, A.; Mcdonald, S. Conserving Concrete Heritage; The Getty Conservation Institute: Los Angeles, CA, USA, 2014. [Google Scholar]

- Sorace, S.; Terenzi, G. A viable base isolation strategy for the advanced seismic retrofit of an R/C building. Contemp. Eng. Sci. 2014, 7, 817–834. [Google Scholar] [CrossRef]

- Mori, C.; Sorace, S.; Terenzi, G. Seismic assessment and retrofit of two heritage-listed R/C elevated water storage tanks. Soil Dyn. Earthq. Eng. 2015, 77, 123–136. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G.; Bitossi, C.; Mori, E. Mutual seismic assessment and isolation of different art objects. Soil Dyn. Earthq. Eng. 2016, 85, 91–102. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G.; Costoli, I. Base isolation strategy for seismic retrofit of water tanks with shaft staging. Int. J. Civ. Eng. Technol. 2018, 9, 891–902. [Google Scholar]

- Sorace, S.; Terenzi, G. Analysis, design, and construction of a base-isolated multiple building structure. Adv. Civ. Eng. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- Ministry of Infrastructure and Transport. Update of Technical Standards for Constructions; Ordinary supplement to G.U. no. 42: Rome, Italy, 2018; (In Italian). Available online: https://www.gazzettaufficiale.it/eli/gu/2018/02/20/42/so/8/sg/pdf (accessed on 20 September 2020).

- Ministry of Infrastructure and Transport. Instructions for the Application of the Update of Technical Standards for Constructions; Ordinary supplement to G.U. no. 35: Rome, Italy, 2019; (In Italian). Available online: https://www.gazzettaufficiale.it/eli/id/2019/02/11/19A00855/sg (accessed on 20 September 2020).

- Toniolo, G.; Di Prisco, M. Reinforced Concrete Design to Eurocode 2; Springer Tracts in Civil Engineering, Springer Nature: Wien, Austria, 2017. [Google Scholar]

- Khosravani, M.R.; Wagner, P.; Fröhlich, D.; Weinberg, K. Dynamic fracture investigations of ultra-high performance concrete by spalling tests. Eng. Struct. 2019, 201, 109844. [Google Scholar] [CrossRef]

- SAP2000NL. Theoretical and Users’ Manual. Release 21.08; Computers & Structures Inc.: Berkeley, CA, USA, 2020. [Google Scholar]

- Pratesi, F.; Sorace, S.; Terenzi, G. Analysis and mitigation of seismic pounding of a slender R/C bell tower. Eng. Struct. 2014, 71, 23–34. [Google Scholar] [CrossRef]

- Licari, M.; Sorace, S.; Terenzi, G. Nonlinear Modeling and Mitigation of Seismic Pounding between R/C Frame Buildings. J. Earthq. Eng. 2015, 19, 431–460. [Google Scholar] [CrossRef]

- Jankowski, R. Non-linear viscoelastic modelling of earthquake-induced structural pounding. Earthq. Eng. Struct. Dyn. 2005, 34, 595–611. [Google Scholar] [CrossRef]

- Anagnostopoulos, S.A.; Spiliopoulos, K.V. An investigation of earthquake induced pounding between adjacent buildings. Earthq. Eng. Struct. Dyn. 1992, 21, 289–302. [Google Scholar] [CrossRef]

- Jankowski, R. Analytical expression between the inpact damping ratio and the coefficient of restitution in the non-linear viscoelastic model of structural pounding. Earthq. Eng. Struct. Dyn. 2006, 35, 517–524. [Google Scholar] [CrossRef]

- Goldsmith, W.; Frasier, J.T. Impact: The Theory and Physical Behavior of Colliding Solids. J. Appl. Mech. 1961, 28, 639. [Google Scholar] [CrossRef]

- Vanmarcke, E.H.; Fenton, G.A.; Heredia-Zavoni, E. SIMQKE-II—Conditioned Earthquake Ground Motion Simulator: User’s Manual, Version 2.1; Princeton University: Princeton, NJ, USA, 1999; Available online: http://nisee.berkeley.edu/documents/SW/SIMQKE-II-V2-1.pdf (accessed on 7 August 2020).

- ASTM E-1300-04. Standard Practice for Determining Load Resistance of Glass in Buildings; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- BS 6262-4. Glazing for buildings. Code of Practice for Safety Related to Human Impact; BSI Committee B/520/4: London, UK, 2005. [Google Scholar]

- Fenz, D.M.; Constantinou, M.C. Behaviour of the double concave Friction Pendulum bearing. Earthq. Eng. Struct. Dyn. 2006, 35, 1403–1424. [Google Scholar] [CrossRef]

- Mazza, F.; Mazza, M. Nonlinear seismic analysis of irregular r.c. framed buildings base-isolated with friction pendulum system under near-fault excitations. Soil Dyn. Earthq. Eng. 2016, 90, 299–312. [Google Scholar] [CrossRef]

- Bhagat, S.; Wijeyewickrema, A.C. Seismic response evaluation of base-isolated reinforced concrete buildings under bidirectional excitation. Earthq. Eng. Eng. Vib. 2017, 16, 365–382. [Google Scholar] [CrossRef]

- Mazza, F.; Mazza, M. Sensitivity to modelling and design of curved surface sliding bearings in the nonlinear seismic analysis of base-isolated r.c. framed buildings. Soil Dyn. Earthq. Eng. 2017, 100, 144–158. [Google Scholar] [CrossRef]

- Habieb, A.B.; Valente, M.; Milani, G. Effectiveness of different base isolation systems for seismic protection: Numerical insights into an existing masonry bell tower. Soil Dyn. Earthq. Eng. 2019, 125. [Google Scholar] [CrossRef]

- De Angelis, F.; Cancellara, D. Dynamic analysis and vulnerability reduction of asymmetric structures: Fixed base vs base isolated system. Compos. Struct. 2019, 219, 203–220. [Google Scholar] [CrossRef]

- FIP. Anti-Seismic Devices Product Division. 2019. Available online: http://www.fip-group.it (accessed on 4 October 2020).

- Foroutan, M.; Kassim, A.B.; Amiri, S.T.; Molkararei, P. Coupling effects of suction variation on riverbank stability. Electron. J. Geotech. Eng. 2014, 19, 4427–4438. [Google Scholar]

- Luo, Z.; Kong, J.; Ji, Z.; Shen, C.; Lu, C.; Xin, P.; Zhao, Z.; Li, L.; Barry, D. Watertable fluctuation-induced variability in the water retention curve: Sand column experiments. J. Hydrol. 2020, 589, 125125. [Google Scholar] [CrossRef]

| Beams | Size (mm × mm) | Half-Span Section | End Sections | Stirrups | ||

|---|---|---|---|---|---|---|

| Top Bars | Bottom Bars | Top Bars | Bottom Bars | ϕ/Spacing | ||

| B1 | 800 × 350 | 2ϕ16 + 4ϕ20 | 2ϕ16 + ϕ20 | 2ϕ16 + 6ϕ20 | 2ϕ16 + 6ϕ20 | ϕ10/150 |

| B2 | 600 × 350 | 2ϕ16 | 2ϕ16 | 2ϕ16 | 2ϕ16 | ϕ10/150 |

| B3 | 800 × 350 | 4ϕ12 | 4ϕ12 + 3ϕ16 | 4ϕ12 + 5ϕ16 | 4ϕ12 | ϕ10/150 |

| B4 | 600 × 350 | 2ϕ12 | 2ϕ12 | 2ϕ12 | 2ϕ12 | ϕ10/150 |

| B5 | 800 × 350 | 2ϕ12 | 4ϕ12 | 4ϕ12 | 2ϕ12 | ϕ8/150 |

| B6 | 1000 × 350 | 18ϕ22 | 18ϕ22 | 18ϕ22 | 18ϕ22 | ϕ8/150 |

| B7 | 600 × 350 | 2ϕ12 | 4ϕ12 | 4ϕ12 | 2ϕ12 | ϕ8/150 |

| B8 | 400 × 350 | 2ϕ12 | 4ϕ12 | 4ϕ12 | 2ϕ12 | ϕ8/150 |

| B9 | 600 × 300 | 4ϕ12 | 2ϕ12 | 4ϕ12 | 2ϕ12 | ϕ8/150 |

| B10 | 350 × 150 | 2ϕ12 | 2ϕ12 | 2ϕ12 | 2ϕ12 | ϕ8/150 |

| B11 | 300 × 350 | 2ϕ12 | 4ϕ12 | 4ϕ12 | 2ϕ12 | ϕ8/150 |

| B12 | 600 × 350 | 2ϕ16 | 2ϕ16 + 2ϕ12 | 2ϕ16 + 4ϕ12 | 2ϕ16 | ϕ8/150 |

| B13 | 300 × 350 | 2ϕ16 | 2ϕ16 + 2ϕ20 | 2ϕ16 + 2ϕ20 | 2ϕ16 | ϕ8/150 |

| B14 | 300 × 350 | 2ϕ16 | 3ϕ16 | 3ϕ16 | 2ϕ16 | ϕ10/150 |

| B17 | 400 × 350 | 2ϕ16 | 2ϕ16 | 2ϕ16 | 2ϕ16 | ϕ10/150 |

| B18 | 500 × 650 | 4ϕ16 | 4ϕ16 | 4ϕ16 | 4ϕ16 | ϕ10/150 |

| Columns | Size (mm × mm) | Reinforcing Bars | Stirrups |

|---|---|---|---|

| C1 | 1100 × 600 | 8ϕ26 | ϕ10/250 |

| C2 | 1000 × 600 | 8ϕ26 | ϕ10/250 |

| C3 | 1000 × 600 | 8ϕ26 | ϕ10/250 |

| C4 | 1000 × 800 | 8ϕ26 | ϕ10/250 |

| C5 | 1000 × 800 | 8ϕ26 | ϕ10/250 |

| C6 | 1000 × 400 | 6ϕ26 | ϕ10/250 |

| C7 | 1000 × 400 | 6ϕ26 | ϕ10/250 |

| C8 | 1400 × 800 | 8ϕ30 + 8ϕ20 | ϕ8/200 |

| C9 | 1000 × 800 | 8ϕ30 + 10ϕ20 + 4ϕ16 | ϕ8/200 |

| C10 | Steel Cable | ϕ22 | − |

| C11 | 600 × 300 | 4ϕ20 | ϕ10/200 |

| C12 | 400 × 300 | 4ϕ20 | ϕ10/200 |

| C13 | 600 × 600 | 8ϕ20 | ϕ10/200 |

| C14 | 600 × 600 | 8ϕ20 | ϕ10/200 |

| C15 | 600 × 600 | 6ϕ26 | ϕ10/250 |

| C16 | 600 × 600 | 4ϕ20 | ϕ10/200 |

| C17 | 600 × 400 | 4ϕ20 | ϕ10/200 |

| C18 | 1200 × 400 | 8ϕ26 | ϕ10/200 |

| C19 | 300 × 300 | 4ϕ20 | ϕ10/150 |

| C20 | 400 × 200 | 4ϕ16 | ϕ10/150 |

| C21 | 400 × 300 | 4ϕ16 | ϕ10/150 |

| Walls | Size (mm × mm) | Reinforcing Bars | Stirrups |

|---|---|---|---|

| W1 | 1850 × 150 | 14ϕ8 | ϕ12/20 |

| W2 | 1850 × 300 | 14ϕ8 | ϕ12/20 |

| W3 | 1400 × 300 | 12ϕ8 | ϕ12/20 |

| W3 | 1850 × 300 | 14ϕ8 | ϕ12/20 |

| W3 | 1850 × 300 | 20ϕ8 | ϕ12/20 |

| W3 | 2250 × 300 | 24ϕ8 | ϕ12/20 |

| W1 | 1850 × 150 | 14ϕ8 | ϕ12/20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terenzi, G.; Fuso, E.; Sorace, S.; Costoli, I. Enhanced Seismic Retrofit of a Reinforced Concrete Building of Architectural Interest. Buildings 2020, 10, 211. https://doi.org/10.3390/buildings10110211

Terenzi G, Fuso E, Sorace S, Costoli I. Enhanced Seismic Retrofit of a Reinforced Concrete Building of Architectural Interest. Buildings. 2020; 10(11):211. https://doi.org/10.3390/buildings10110211

Chicago/Turabian StyleTerenzi, Gloria, Elena Fuso, Stefano Sorace, and Iacopo Costoli. 2020. "Enhanced Seismic Retrofit of a Reinforced Concrete Building of Architectural Interest" Buildings 10, no. 11: 211. https://doi.org/10.3390/buildings10110211

APA StyleTerenzi, G., Fuso, E., Sorace, S., & Costoli, I. (2020). Enhanced Seismic Retrofit of a Reinforced Concrete Building of Architectural Interest. Buildings, 10(11), 211. https://doi.org/10.3390/buildings10110211