Evaluating Volatile Organic Compound Emissions from Cross-Laminated Timber Bonded with a Soy-Based Adhesive

Abstract

1. Introduction

2. Materials and Methods

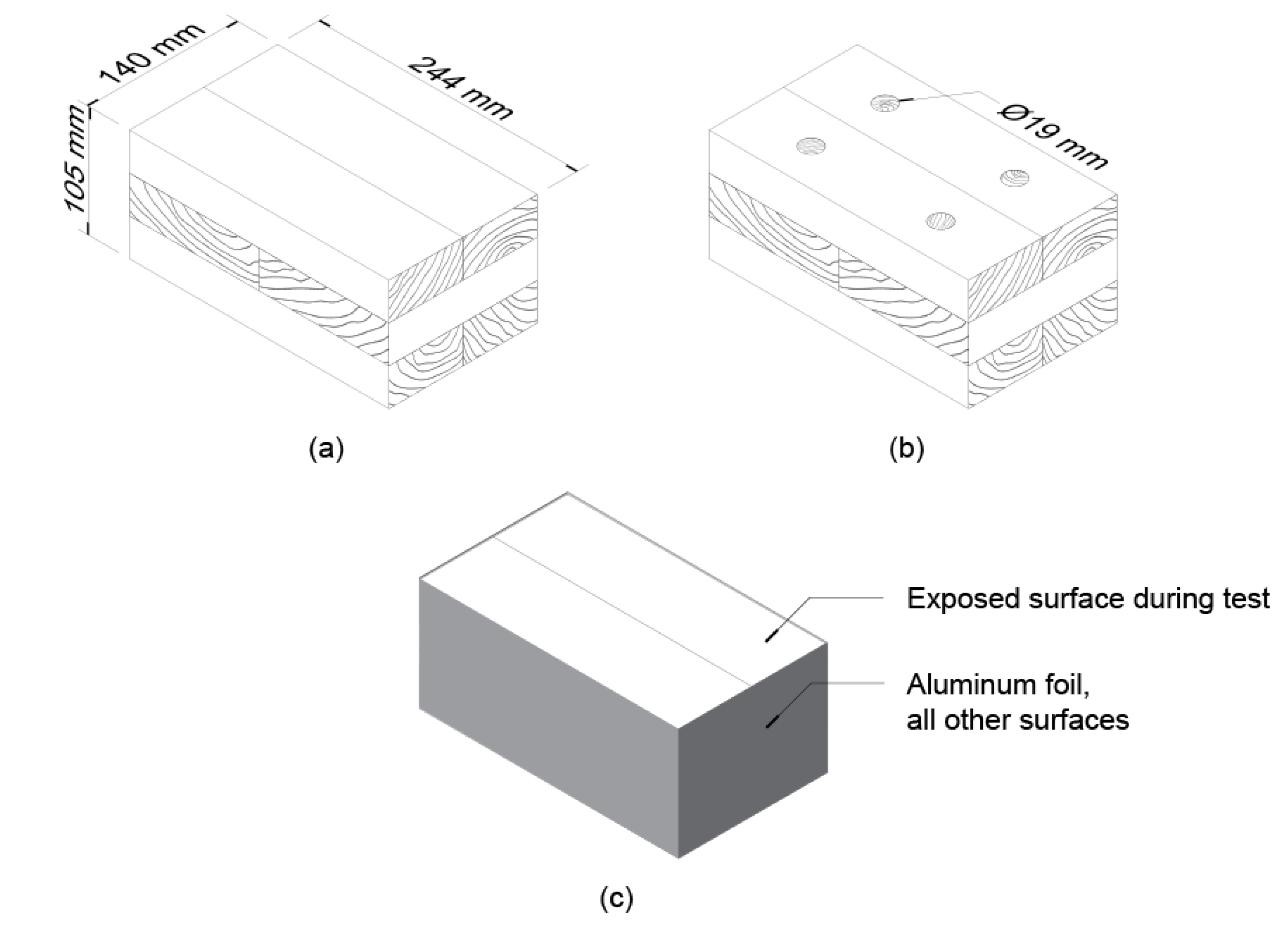

2.1. Test Samples

2.2. Testing Laboratory

2.3. Small-Chamber Testing

2.4. Estimated Indoor Air Concentrations

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cincinelli, A.; Martellini, T. Indoor air quality and health. Int. J. Environ. Res. Public Health 2017, 14, 1286. [Google Scholar] [CrossRef] [PubMed]

- Brown, S.K. Chamber assessment of formaldehyde and VOC emissions from wood-based panels. Indoor Air 1999, 9, 209–215. [Google Scholar] [CrossRef] [PubMed]

- Annesi-Maesano, I.; Baiz, N.; Banerjee, S.; Rudnai, P.; Rive, S.; SINPHONIE Group. Indoor air quality and sources in schools and related health effects. J. Toxicol. Environ. Health. Part B Crit. Rev. 2013, 16, 491–550. [Google Scholar] [CrossRef] [PubMed]

- Allen, J.G.; MacNaughton, P.; Satish, U.; Santanam, S.; Vallarino, J.; Spengler, J.D. Associations of cognitive function scores with carbon dioxide, ventilation, and volatile organic compound exposures in office workers: A controlled exposure study of green and conventional office environments. Environ. Health Perspect. 2016, 124, 805–812. [Google Scholar] [CrossRef]

- Dales, R.; Liu, L.; Wheeler, A.J.; Gilbert, N.L. Quality of indoor residential air and health. Can. Med Assoc. J. 2008, 179, 147–152. [Google Scholar] [CrossRef]

- Bluyssen, P.M. Towards an integrative approach of improving indoor air quality. Build. Environ. 2009, 44, 1980–1989. [Google Scholar] [CrossRef]

- Steinemann, A.; Wargocki, P.; Rismanchi, B. Ten questions concerning green buildings and indoor air quality. Build. Environ. 2017, 112, 351–358. [Google Scholar] [CrossRef]

- US Environmental Protection Agency (US EPA). US EPA’s 2008 Report on the Environment. 2008. Available online: https://www.epa.gov/report-environment/indoor-air-quality (accessed on 5 March 2020).

- Langer, S.; Bekö, G.; Bloom, E.; Widheden, A.; Ekberg, L. Indoor air quality in passive and conventional new houses in Sweden. Build. Environ. 2015, 93, 92–100. [Google Scholar] [CrossRef]

- OEHHA California Office of Environmental Health Hazard Assessment Proposition 65. 2020. Available online: https://oehha.ca.gov/proposition-65/about-proposition-65 (accessed on 10 March 2020).

- Wei, W.; Ramalho, O.; Mandin, C. Indoor air quality requirements in green building certifications. Build. Environ. 2015, 92, 10–19. [Google Scholar] [CrossRef]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Formaldehyde, 2-butoxyethanol and 1-tert-butoxypropan-2-ol. IARC Monogr. Eval. Carcinog. Risks Hum. 2006, 88, 1–478. [Google Scholar] [PubMed]

- Hauptmann, M.; Lubin, J.H.; Stewart, P.A.; Hayes, R.B.; Blair, A. Mortality from solid cancers among workers in formaldehyde industries. Am. J. Epidemiol. 2004, 159, 1117–1130. [Google Scholar] [CrossRef] [PubMed]

- Songur, A.; Ozen, O.A.; Sarsilmaz, M. The toxic effects of formaldehyde on the nervous system. Rev. Environ. Contam. Toxicol. 2010, 203, 105–118. [Google Scholar] [CrossRef] [PubMed]

- Ruffing, T.C.; Brown, N.R.; Smith, P.M. Review of United States and international formaldehyde emission regulations for interior wood composite panels. Wood Fiber Sci. 2011, 43, 21–31. [Google Scholar]

- Mallo, M.F.L.; Espinoza, O. Awareness, perceptions and willingness to adopt Cross-Laminated Timber by the architecture community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- APA-The Engineered Wood Association. Standard for Performance-Rated Cross Laminated Timber; ANSI/APA PRG 320; APA-The Engineered Wood Association: Tacoma, Washington, WA, USA, 2019. [Google Scholar]

- Muszynski, L.; Hansen, E.; Fernando, S.; Schwarzmann, G.; Rainer, J. Insights into the global cross-laminated timber industry. BioProd. Bus. 2017. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- APA-The Engineered Wood Association. Standard for Adhesives for Use in Structural Glued Laminated Timber; APA-The Engineered Wood Association: Tacoma, Washington, WA, USA, 2018. [Google Scholar]

- Salthammer, T.; Mentese, S.; Marutzky, R. Formaldehyde in the indoor environment. Chem. Rev. 2010, 110, 2536–2572. [Google Scholar] [CrossRef]

- Salem, M.Z.; Böhm, M. Understanding of formaldehyde emissions from solid wood: An overview. BioResources 2013, 8, 4775–4790. [Google Scholar] [CrossRef]

- Baur, X.; Marek, W.; Ammon, J.; Czuppon, A.B.; Marczynski, B.; Raulf-Heimsoth, M.; Roemmelt, H.; Fruhmann, G. Respiratory and other hazards of isocyanates. Int. Arch. Occup. Environ. Health 1994, 66, 141–152. [Google Scholar] [CrossRef]

- Stec, A.A.; Hull, T.R. Assessment of the fire toxicity of building insulation materials. Energy Build. 2011, 43, 498–506. [Google Scholar] [CrossRef]

- Blomqvist, P.; Hertzberg, T.; Tuovinen, H.; Arrhenius, K.; Rosell, L. Detailed determination of smoke gas contents using a small-scale controlled equivalence ratio tube furnace method. Fire Mater. Int. J. 2007, 31, 495–521. [Google Scholar] [CrossRef]

- Stenson, J.; Ishaq, S.L.; Laguerre, A.; Loia, A.; MacCrone, G.; Mugabo, I.; Northcutt, D.; Riggio, M.; Barbosa, A.; Gall, E.T.; et al. Monitored indoor environmental quality of a mass timber office building: A case study. Buildings 2019, 9, 142. [Google Scholar] [CrossRef]

- Li, K.; Peshkova, S.; Geng, X. Investigation of soy protein-Kymene® adhesive systems for wood composites. J. Am. Oil Chem. Soc. 2004, 81, 487–491. [Google Scholar] [CrossRef]

- Huang, J.; Li, K. A new soy flour-based adhesive for making interior type II plywood. J. Am. Oil Chem. Soc. 2008, 85, 63–70. [Google Scholar] [CrossRef]

- Jang, Y.; Li, K. An all-natural adhesive for bonding wood. J. Am. Oil Chem. Soc. 2015, 92, 431–438. [Google Scholar] [CrossRef]

- Mousavi, S.Y.; Huang, J.; Li, K. Investigation of poly (glycidyl methacrylate-co-styrene) as a curing agent for soy-based wood adhesives. Int. J. Adhes. Adhes. 2018, 82, 67–71. [Google Scholar] [CrossRef]

- Karacebeyli, E.; Douglas, B. CLT Handbook-US Edition; FPInnovations and Binational Softwood Lumber Council: Point-Claire, QC, Canada, 2013. [Google Scholar]

- Pizzi, A. Melamine-formaldehyde adhesives. Handb. Adhes. Technol. 2003, 2. [Google Scholar] [CrossRef]

- Dunky, M. Adhesives in the wood industry. Handb. Adhes. Technol. 2003, 2, 50. [Google Scholar]

- Wood Works. Acoustically-Tested Mass Timber Assemblies. Wood Products Council. 2019. Available online: https://www.woodworks.org/wp-content/uploads/Acoustically-Tested-Mass-Timber-Assemblies-WoodWorks.pdf (accessed on 15 February 2020).

- Berkeley Analytical Associates. ISO/IEC 17025: 2005 Laboratory Accreditation. Berkeley Analytical. 2016. Available online: https://berkeleyanalytical.com/working-us/accreditation (accessed on 10 March 2020).

- Smith, K.; Dooley, D.; Brown, E.J. Standard Method for the Testing and Evaluation of Volatile Organic Chemical Emissions from Indoor Sources Using Environmental Chambers Version 1.2; No. 01350; California Department of Public Health: Sacramento, CA, USA, 2017. [Google Scholar]

- State of California. Airborne Toxic Control Measure to Reduce Formaldehyde Emissions from Composite Wood Products; Title 17 California Code of Regulations; State of California: Sacramento, CA, USA, 2007. [Google Scholar]

- Chin, K.; Laguerre, A.; Ramasubramanian, P.; Pleshakov, D.; Stephens, B.; Gall, E.T. Emerging investigator series: Primary emissions, ozone reactivity, and byproduct emissions from building insulation materials. Environ. Sci. Process. Impacts 2019, 21, 1255–1267. [Google Scholar] [CrossRef]

- OEHHA California Office of Environmental Health Hazard Assessment. OEHHA Acute, 8-hour and Chronic Reference Exposure Level (REL) Summary. 2020. Available online: https://oehha.ca.gov/air/general-info/oehha-acute-8-hour-and-chronic-reference-exposure-level-rel-summary (accessed on 16 October 2020).

- Bernstein, J.A.; Alexis, N.; Bacchus, H.; Bernstein, I.L.; Fritz, P.; Horner, E.; Li, N.; Mason, S.; Nel, A.; Oullette, J.; et al. The health effects of nonindustrial indoor air pollution. J. Allergy Clin. Immunol. 2008, 121, 585–591. [Google Scholar] [CrossRef]

- U.S. Green Building Council (USGBC). LEED Reference Guide for Building Design and Construction. 2019. Available online: https://www.usgbc.org/resources/leed-reference-guide-building-design-and-construction (accessed on 27 January 2020).

- World Health Organization. WHO Guidelines for Indoor Air Quality: Selected Pollutants; WHO Regional Office for Europe: Copenhagen, Denmark, 2010. [Google Scholar]

- Underwriters Laboratories (UL). GREENGUARD Certification Criteria for Building Products and Interior Finishes. Available online: https://www.ul.com/resources/ul-greenguard-certification-program (accessed on 8 October 2020).

- Funch, L.W. Determination of Emissions from Solid Wood Elements; Danish Technology Institute: Arhus, Denmark, 2002. [Google Scholar]

- Risholm-Sundman, M.; Lundgren, M.; Vestin, E.; Herder, P. Emissions of acetic acid and other volatile organic compounds from different species of solid wood. Holz. Als. Roh. Und. Werkst. 1998, 56, 125–129. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). Monthly Energy Review April 2020; No. DOE/EIA-0035; EIA: Washington, DC, USA, 2020. [Google Scholar]

- International Energy Agency (IEA). Global Status Report for Buildings and Construction. 2019. Available online: https://www.unenvironment.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 25 March 2020).

| Criteria | Conditioning Period | Test Period |

|---|---|---|

| Duration | 10 days ± 5 h | 4 days ± 2 h |

| Temperature | 23 °C ± 2 °C | 23 °C ± 1 °C |

| Relative Humidity | 50% ± 10% | 50% ± 5% |

| Air Exchange Rate | 2 ACH minimum | 1 ACH ± 0.05 ACH |

| Parameter | Units | Office Value |

|---|---|---|

| Exposed product area | m2 | 11.1 |

| Room volume | m3 | 30.6 |

| Outdoor air flow rate | m3/h | 20.7 |

| Area-specific air flow rate | m3/m2-h | 1.86 |

| Chemical | CAS No. | Estimated Office Indoor Air Concentration (μg/m3) | CDPH Method Allowable Conc. (μg/m3) | |||

|---|---|---|---|---|---|---|

| Dowel | Soy | PUR | MF * | |||

| Formaldehyde | 50-00-0 | 2.3 | 2.5 | 1.4 | 54.4 | 9 |

| Acetaldehyde | 75-07-0 | 7.1 | 4.5 | - | 5.0 | 70 |

| Toluene | 108-88-3 | 2.9 | - | - | - | 150 |

| Acetic Acid | 64-19-7 | 30.5 | 44.7 | 12.0 | 9.5 | - |

| 2-Propanone (acetone) | 67-64-1 | 12.6 | 2.8 | - | 2.3 | - |

| Hexanal | 66-25-1 | 24.5 | 11.7 | 4.2 | - | - |

| Pentanal | 110-62-3 | 4.1 | 2.1 | - | - | - |

| 2-Furancarboxaldehyde (furfural) | 98-01-1 | - | 4.6 | 3.7 | 3.9 | - |

| (+/−)-alpha-Pinene | 80-56-8 | 862.0 | 146.4 | 101.3 | 71.6 | - |

| beta-Pinene | 127-91-3 | 9.5 | 4.4 | - | - | - |

| d-Limonene | 5989-27-5 | 75.3 | 5.9 | - | 6.3 | - |

| beta Myrcene | 123-35-3 | 9.0 | - | - | - | - |

| 3-Carene | 13466-78-9 | 10.4 | - | - | - | - |

| p-Cymene | 99-87-6 | 15.9 | - | - | - | - |

| alpha-Terpineol | 10482-56-1 | - | 2.3 | - | 2.4 | - |

| Tricyclene | 508-32-7 | 6.8 | - | - | - | - |

| Camphene | 79-92-3 | 7.4 | - | - | - | - |

| (+)-Camphene | 5794-03-6 | 52.4 | - | - | - | - |

| a-Phellandrene | 99-83-2 | 2.2 | - | - | - | - |

| beta-Phellandrene | 555-10-2 | 2.9 | - | - | - | - |

| Benzene, 1-methyl-2-(1- methylethyl)-; (o-cymene) | 527-84-4 | 2.2 | - | - | - | - |

| Dehydrosabinene | 36262-09-6 | 4.0 | - | - | - | - |

| Terpinolene | 586-62-9 | 15.5 | - | - | 3.5 | - |

| 1-Pentanol | 71-41-0 | 2.4 | - | - | - | - |

| p-(1 propenyl)-toluene | 104-46-1 | 17.7 | - | - | - | - |

| o-Isopropenyltoluene | 7399-49-7 | 29.1 | - | - | - | - |

| Triethylphosphate | 78-40-0 | 2.1 | 2.1 | - | - | - |

| Methyl acetate | 79-20-9 | - | - | - | 23.8 | - |

| 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate (Texanol) | 25265-77-4 | - | - | 2.2 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yauk, M.; Stenson, J.; Donor, M.; Van Den Wymelenberg, K. Evaluating Volatile Organic Compound Emissions from Cross-Laminated Timber Bonded with a Soy-Based Adhesive. Buildings 2020, 10, 191. https://doi.org/10.3390/buildings10110191

Yauk M, Stenson J, Donor M, Van Den Wymelenberg K. Evaluating Volatile Organic Compound Emissions from Cross-Laminated Timber Bonded with a Soy-Based Adhesive. Buildings. 2020; 10(11):191. https://doi.org/10.3390/buildings10110191

Chicago/Turabian StyleYauk, Michael, Jason Stenson, Micah Donor, and Kevin Van Den Wymelenberg. 2020. "Evaluating Volatile Organic Compound Emissions from Cross-Laminated Timber Bonded with a Soy-Based Adhesive" Buildings 10, no. 11: 191. https://doi.org/10.3390/buildings10110191

APA StyleYauk, M., Stenson, J., Donor, M., & Van Den Wymelenberg, K. (2020). Evaluating Volatile Organic Compound Emissions from Cross-Laminated Timber Bonded with a Soy-Based Adhesive. Buildings, 10(11), 191. https://doi.org/10.3390/buildings10110191