Worker 4.0: The Future of Sensored Construction Sites

Abstract

:1. Introduction

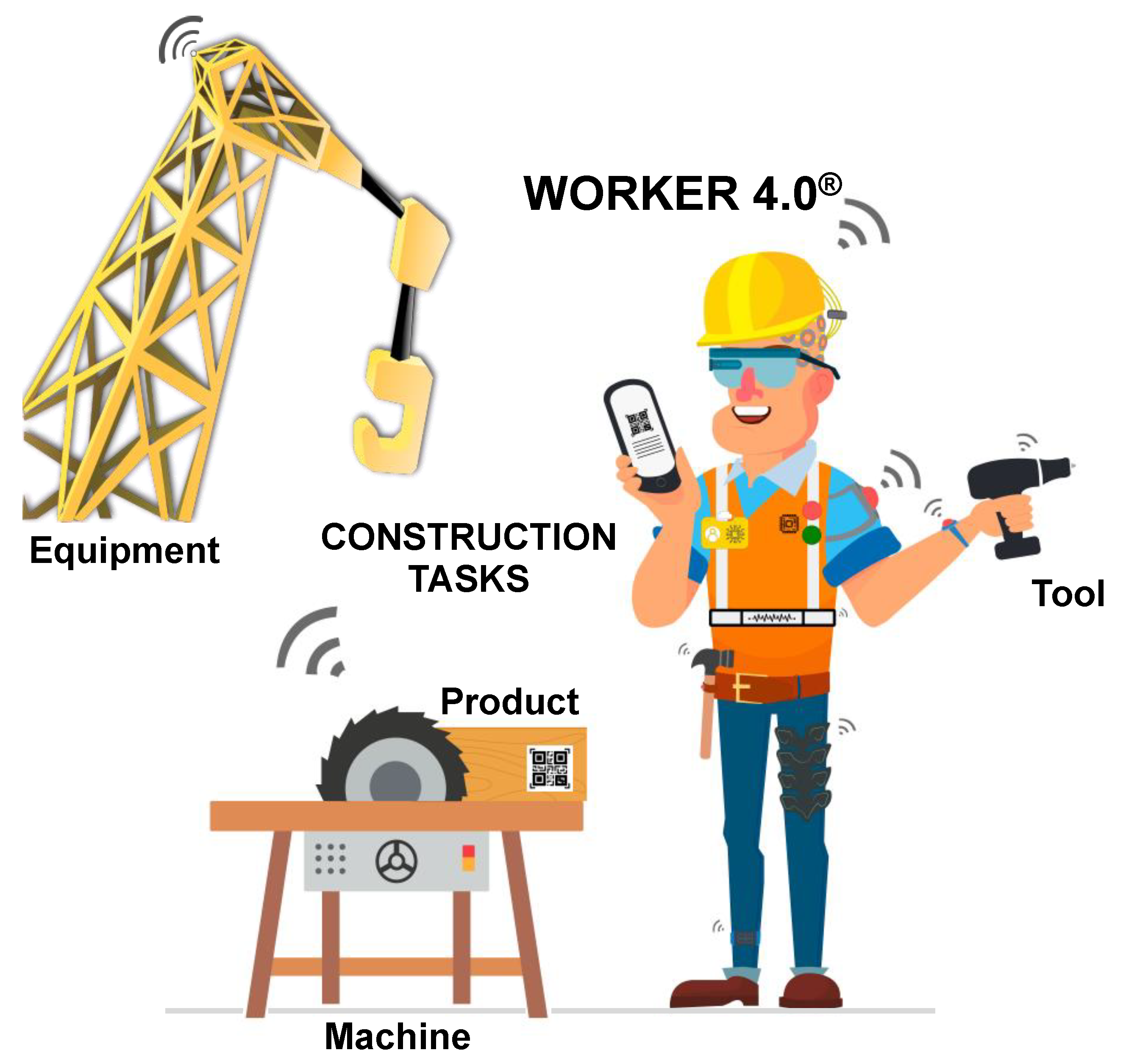

2. Sensored Construction Sites

- Sensored tools (e.g., torque wrench) [85];

- Sensored machines (e.g., welder machines) [86];

- Sensored equipment (e.g., cranes) [87].

- External sensors for measuring environmental factors (e.g., temperature, humidity, noise) [88].

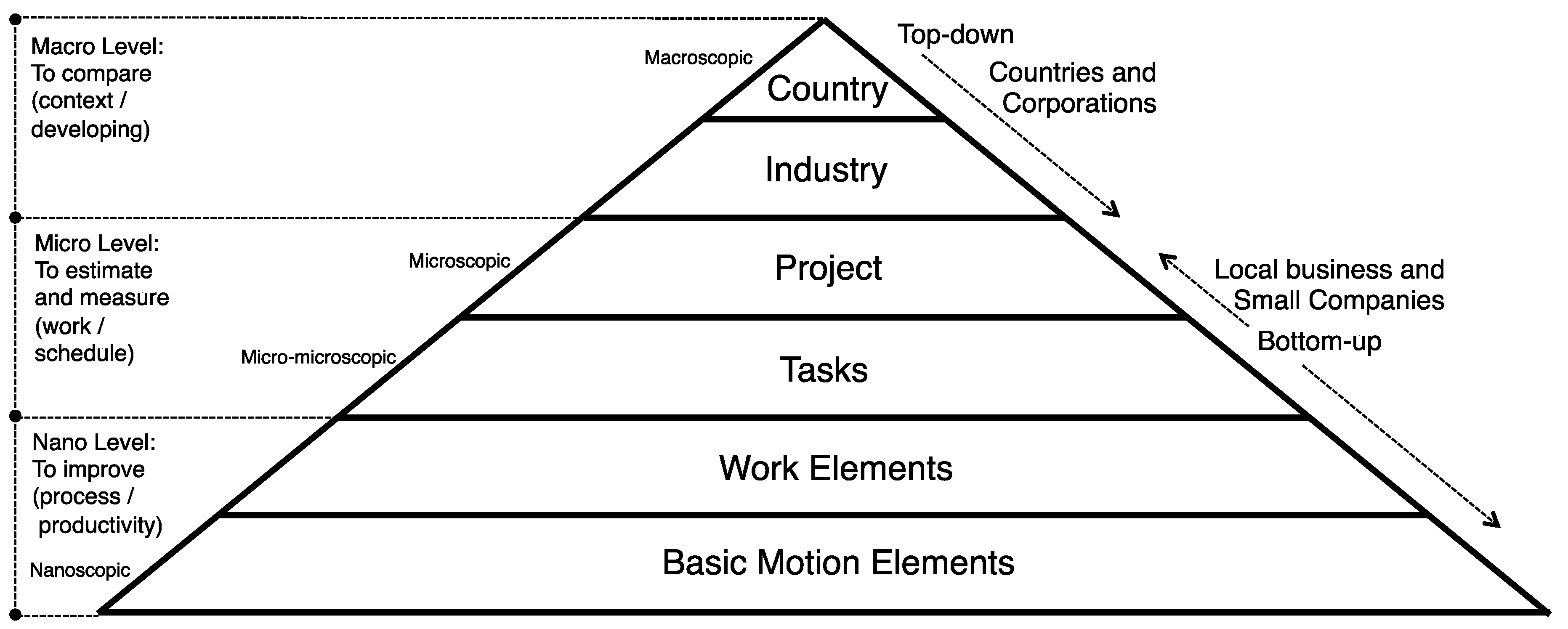

3. Productivity Assessment in the Construction Industry

- Nations/countries;

- Industry (construction);

- Project;

- Activity/tasks.

- Completely manual;

- Hand tool;

- Automated hand tool;

- Machine/workstation;

- Completely automated.

4. Craft-Workforce-Centered Method

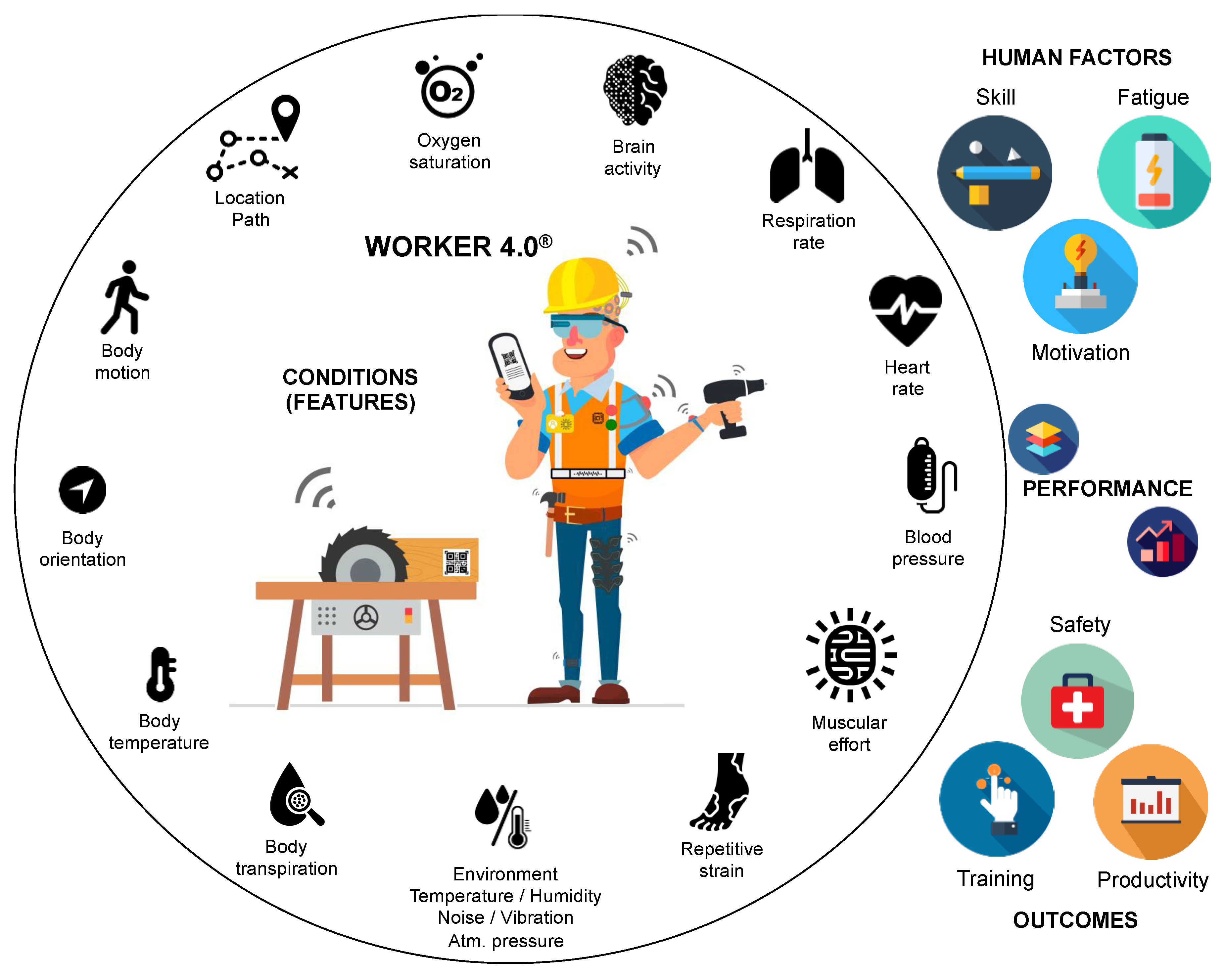

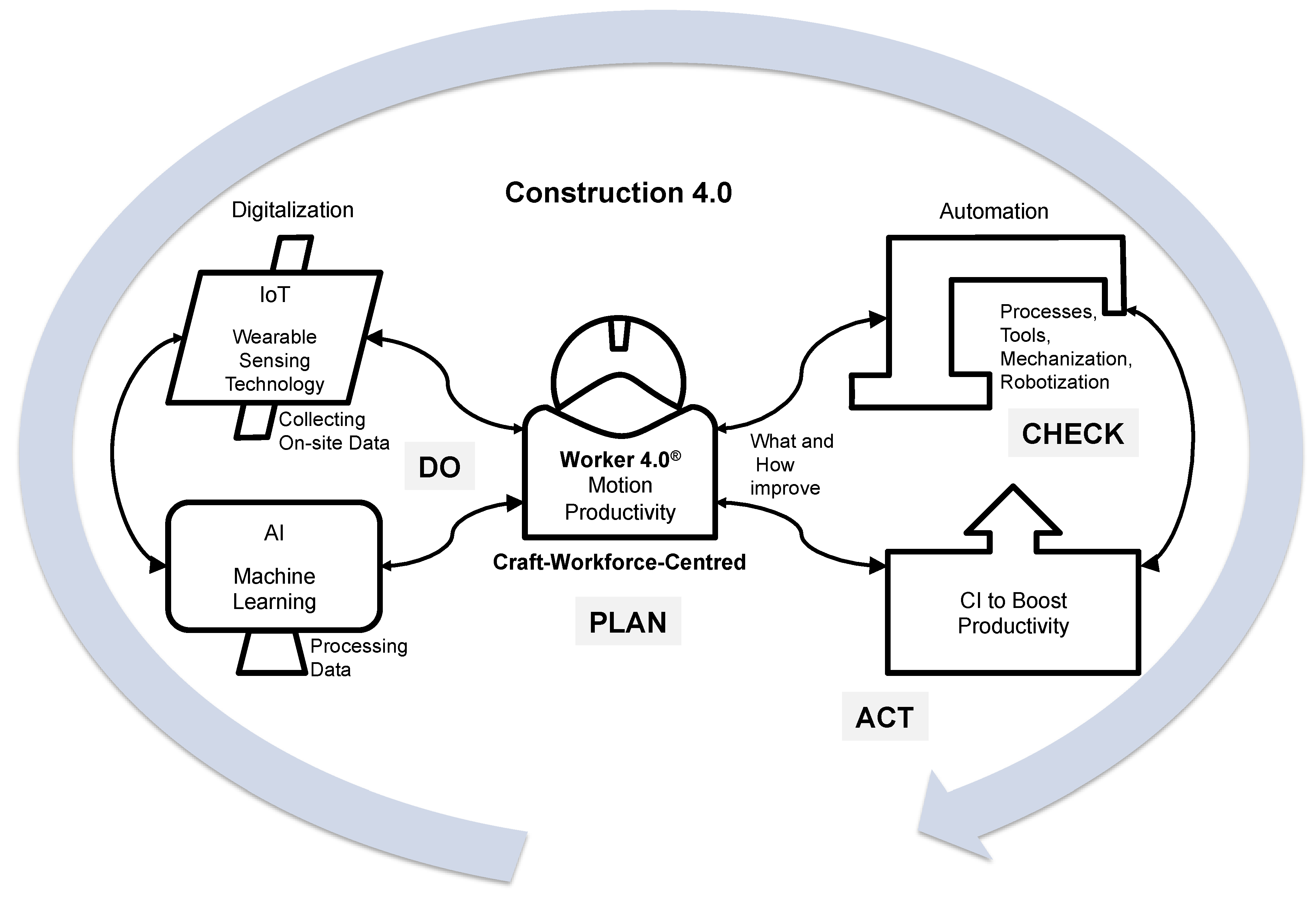

5. Worker 4.0

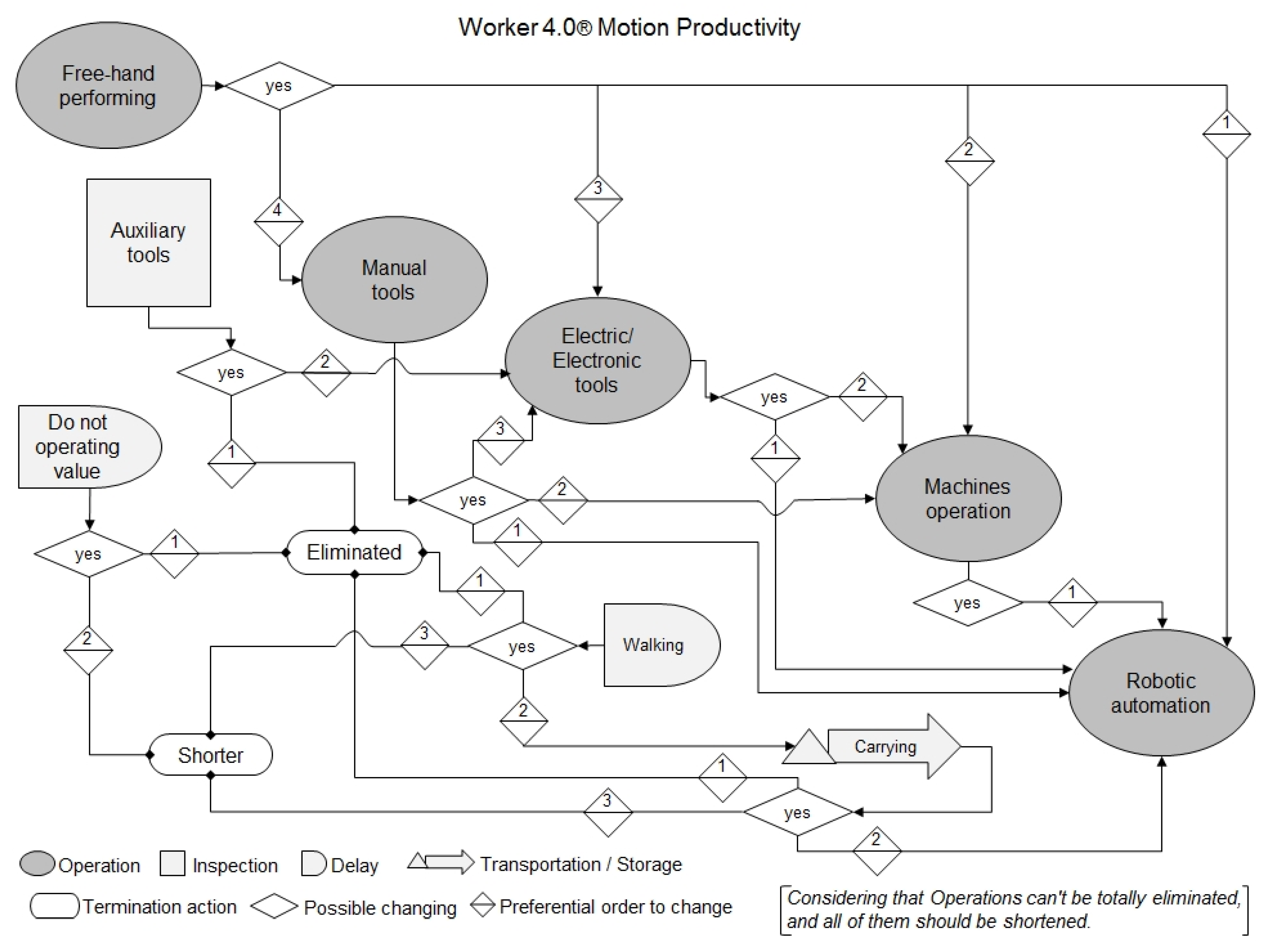

5.1. Motion Productivity

- Processes characteristic (operation, inspection, delay, transportation/storage), processes meanings and symbols follow the same pattern of well-known process chart flow applied in macromotion studies [109];

- Productive state (productive or direct work, contributory or support work, nonproduction work) the productive state addresses the workforce performance during the development of tasks [110] and autonomous production in the case of automated robotic equipment;

- Electronic Monitoring (body motion, location, sound/noise), suggests an approach to monitor the performance employing electronic devices. Those three elements are considered the minor features to control and to measure the performance. Electronic monitoring more aspects than the ones indicated would provide more outputs, but as well, it would increase complexity and cost. It is possible to interpreter the activity being performed based on the hands and the legs motions when accomplishing all nine processes. Furthermore, monitoring image-based can identify that elements handling by the workers. At the same time, some activity processes, such as free-hand performing, auxiliary tools, manual tools, and electric/electronic tools can be captured just by the hands’ motion. The legs contribute to this assessment and also provide more useful information for others (for example, do not operate value; walking; carrying). Therefore, it is considered appropriate to wear devices on wrists or arms and legs to, at least, capture that motion acceleration. Beyond this, the monitoring of workers’ body rotation and location, if added, can increase the analysis. As an example, from monitoring the trajectory, it can make it possible to interpret the collection/carrying of elements from storage areas or machine/equipment movement. Furthermore, the sound/noise tracking of electric tools, machines and equipment can allow the identification of operating times and indicate the components-specific type.

5.2. Flowchart to Increase Efficiency and Mechanization Level Measurement

- EET = electric/electronic tools;

- MOP = machines operation;

- RBA = robotic automation;

- Operation process = (FHP + MNT + EET + MOP + RBA);

- FHP = free-hand performing;

- MNT = manual tools.

- Low—0% to 20%;

- Moderate—21% to 40%;

- High—41% to 60%;

- Very high—above 61%.

5.3. Tasks Process Modelling Chart

6. Discussion

- Directors (authorization and sponsoring);

- Manager (project management);

- Field engineers (conduct the implementation and the assessment);

- Human resources specialists (regulation and support);

- Planners and quality engineers (time schedule and improvement plans);

- Craft workers (GDPR consent and work under monitoring).

- Triple perforated ceramic brick, to be coated, 30 cm × 20 cm × 15 cm, for use in protected masonry (piece P), density 650 kg/m³, according to NP EN 771-1. Yield of 0.733 labor-hours per m2. Total cost of 20.08 Euros per m2, where 13.48 Euros (67.13%) are related to craft workforce [111];

- High, straight, reinforced concrete beam, 40 cm × 60 cm, made with C25/30 concrete (XC1 (P); D12; S3; Cl 0.4) prepared on-site and concreting with manual means and A400 NR steel, with an amount of approximately 150 kg/m³; assembly and disassembly of the formwork system, with finish to coat, on floors up to three meters free height. Yield of 10.43 labor-hours per m3. Total cost of 419.51 Euros per m3, where 199.29 Euros (47.51%) are related to craft workforce [111];

- Manual application of two coats of white plastic paint, matte finish, smooth texture, the first coat diluted with 15 to 20% water and the next diluted with 5 to 10% water or undiluted, (yield: 0.1 L/m² each coat); prior application of a coat of acrylic primer regulating the absorption, on the external mortar wall. Yield of 0.25 labor-hours per m2. Total cost of 7.31 Euros per m2, where 4.66 Euros (63.75%) are related to craft workforce [111].

7. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Desruelle, P.; Baldini, G.; Barboni, M.; Bono, F.; Delipetrev, B.; Duch Brown, N.; Fernandez Macias, E.; Gkoumas, K.; Joossens, E.; Kalpaka, A.; et al. Digital Transformation in Transport, Construction, Energy, Government and Public Administration; EUR 29782 EN; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Yang, J.; Park, M.W.; Vela, P.A.; Golparvar-Fard, M. Construction Performance Monitoring via Still Images, Time-Lapse Photos, and Video Streams: Now, Tomorrow, and the Future. Adv. Eng. Inform. 2015, 29, 211–224. [Google Scholar] [CrossRef]

- Freivalds, A. Niebel’s Methods, Standards, and Work Design; Mcgraw-Hill Higher Education: Boston, MA, USA, 2009; Volume 700. [Google Scholar]

- Groover, M.P. Work Systems and the Methods, Measurement, and Management of Work; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Sink, D.S. Productivity Management: Planning, Measurement and Evaluation, Control, and Improvement; John Wiley & Sons: New York, NY, USA, 1985. [Google Scholar]

- Cheng, T.; Teizer, J.; Migliaccio, G.C.; Gatti, U.C. Automated Task-Level Activity Analysis through Fusion of Real Time Location Sensors and Worker’s Thoracic Posture Data. Autom. Constr. 2013, 29, 24–39. [Google Scholar] [CrossRef]

- Gong, J.; Caldas, C.H. An Object Recognition, Tracking, and Contextual Reasoning-Based Video Interpretation Method for Rapid Productivity Analysis of Construction Operations. Autom. Constr. 2011, 20, 1211–1226. [Google Scholar] [CrossRef]

- Khosrowpour, A.; Niebles, J.C.; Golparvar-Fard, M. Vision-Based Workface Assessment Using Depth Images for Activity Analysis of Interior Construction Operations. Autom. Constr. 2014, 48, 74–87. [Google Scholar] [CrossRef]

- Mani, N.; Kisi, K.P.; Rojas, E.M.; Foster, E.T. Estimating Construction Labor Productivity Frontier: Pilot Study. J. Constr. Eng. Manag. 2017, 143. [Google Scholar] [CrossRef]

- Aryal, A.; Ghahramani, A.; Becerik-Gerber, B. Monitoring Fatigue in Construction Workers Using Physiological Measurements. Autom. Constr. 2017, 82, 154–165. [Google Scholar] [CrossRef]

- Guo, H.; Yu, Y.; Xiang, T.; Li, H.; Zhang, D. The Availability of Wearable-Device-Based Physical Data for the Measurement of Construction Workers’ Psychological Status on Site: From the Perspective of Safety Management. Autom. Constr. 2017, 82, 207–217. [Google Scholar] [CrossRef]

- Leaps, S.R.O. Social Distancing Monitor|LEAPS. Available online: https://www.leapslabs.com/sdm (accessed on 30 July 2020).

- RIBA (Ed.) The RIBA Plan of Work 2020; RIBA Architecture: London, UK, 2020. [Google Scholar]

- Mêda, P.; Hjelseth, E.; Sousa, H. Construction Information Framework—The Role of Classification Systems. In eWork and eBusiness in Architecture, Engineering and Construction, Proceedings of the 11th European Conference on Product and Process Modelling (ECPPM 2016), Limassol, Cyprus, 7–9 September 2016; CRC Press: London, UK, 2016; ISBN 978-1-38-03280-4. [Google Scholar]

- Calvetti, D.; Gonçalves, M.C.; Magalhães, P.N.M.; de Sousa, H.J.C. Sensing Technologies Embedding Construction Workers Outcomes/Key Performance Indicators. In Proceedings of the 36th CIB W78 2019 Conference: Advances in ICT in Design, Construction and Management in Architecture, Engineering, Construction and Operations (AECO), Newcastle, UK, 18–20 September 2019; Kumar, B., Rahimian, F., Greenwood, D., Hartmann, T., Eds.; CIB W78: Newcastle, UK, 2019; pp. 890–900, ISBN (Print) 9781861354877, ISBN (eBook) 9781861354860. [Google Scholar]

- ISO 12006-2. ISO 12006-2:2015 Building Construction—Organization of Information about Construction Works—Part 2: Framework for Classification; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Liou, F.; Borcherding John, D. Work Sampling Can Predict Unit Rate Productivity. J. Constr. Eng. Manag. 1986, 112, 90–103. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A. Wearable Sensor-Based Activity Recognition for Data-Driven Simulation of Construction Workers’ Activities. In Proceedings of the Proceedings—Winter Simulation Conference, Huntington Beach, CA, USA, 6–9 December 2016; Volume 2016, pp. 3333–3344. [Google Scholar] [CrossRef]

- Akhavian, R.; Brito, L.; Behzadan, A. Integrated Mobile Sensor-Based Activity Recognition of Construction Equipment and Human Crews. In Proceedings of the Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015; pp. 1–20. [Google Scholar]

- Akhavian, R.; Behzadan, A.H. Smartphone-Based Construction Workers’ Activity Recognition and Classification. Autom. Constr. 2016, 71, 198–209. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A.H. Coupling Human Activity Recognition and Wearable Sensors for Data-Driven Construction Simulation. J. Inf. Technol. Constr. 2018, 23, 1–15. [Google Scholar]

- Akhavian, R.; Behzadan, A.H. Productivity Analysis of Construction Worker Activities Using Smartphone Sensors. In Proceedings of the 16th International Conference on Computing in Civil and Building Engineering (ICCCBE), Osaka, Japan, 6–8 July 2016; pp. 1067–1074. [Google Scholar]

- Zhang, M.; Chen, S.; Zhao, X.; Yang, Z. Research on Construction Workers’ Activity Recognition Based on Smartphone. Sensors 2018, 18, 2667. [Google Scholar] [CrossRef] [Green Version]

- Zheng, X.; Wang, M.; Ordieres-Meré, J. Comparison of Data Preprocessing Approaches for Applying Deep Learning to Human Activity Recognition in the Context of Industry 4.0. Sensors 2018, 18, 2146. [Google Scholar] [CrossRef] [Green Version]

- Tao, W.; Lai, Z.H.; Leu, M.C.; Yin, Z. Worker Activity Recognition in Smart Manufacturing Using IMU and SEMG Signals with Convolutional Neural Networks. Procedia Manuf. 2018, 26, 1159–1166. [Google Scholar] [CrossRef]

- Ordóñez, F.J.; Roggen, D. Deep Convolutional and LSTM Recurrent Neural Networks for Multimodal Wearable Activity Recognition. Sensors 2016, 16, 115. [Google Scholar] [CrossRef] [Green Version]

- Juhyeong, R.; Seo, J.; Liu, M.; Lee, S.; Haas, C.T. Action Recognition Using a Wristband-Type Activity Tracker: Case Study of Masonry Work. In Construction Research Congress 2016; ASCE: San Juan, Puerto Rico, 2016; pp. 790–799. [Google Scholar]

- Ryu, J.; Seo, J.; Jebelli, H.; Lee, S. Automated Action Recognition Using an Accelerometer-Embedded Wristband-Type Activity Tracker. J. Constr. Eng. Manag. 2019, 145, 04018114. [Google Scholar] [CrossRef]

- Joshua, L.; Varghese, K. Classification of Bricklaying Activities in Work Sampling Categories Using Accelerometers. In Construction Research Congress 2012: Construction Challenges in a Flat World; ASCE: West Lafayette, Indiana, 2012; pp. 919–928. [Google Scholar] [CrossRef]

- Joshua, L.; Varghese, K. Automated Recognition of Construction Labour Activity Using Accelerometers in Field Situations. Int. J. Product. Perform. Manag. 2014, 63, 841–862. [Google Scholar] [CrossRef]

- Joshua, L.; Varghese, K. Accelerometer-Based Activity Recognition in Construction. J. Comput. Civ. Eng. 2011, 25, 370–379. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Li, J.; Costin, A.; Kibert, C.; Qian, S. Investigating U.S. Industry Practitioners’ Perspectives towards the Adoption of Emerging Technologies in Industrialized Construction. Buildings 2020, 10, 85. [Google Scholar] [CrossRef]

- Moradi, S.; Kähkönen, K.; Aaltonen, K. Project Managers’ Competencies in Collaborative Construction Projects. Buildings 2020, 10, 50. [Google Scholar] [CrossRef] [Green Version]

- Cheng, T.; Mantripragada, U.; Teizer, J.; Vela, P.A. Automated Trajectory and Path Planning Analysis Based on Ultra Wideband Data. J. Comput. Civ. Eng. 2012, 26, 151–160. [Google Scholar] [CrossRef]

- Kumari, P.; Mathew, L.; Syal, P. Increasing Trend of Wearables and Multimodal Interface for Human Activity Monitoring: A Review. Biosens. Bioelectron. 2017, 90, 298–307. [Google Scholar] [CrossRef]

- Khoury, H.; Chdid, D.; Oueis, R.; Elhajj, I.; Asmar, D. Infrastructureless Approach for Ubiquitous User Location Tracking in Construction Environments. Autom. Constr. 2015, 56, 47–66. [Google Scholar] [CrossRef]

- Nguyen, L.V.; La, H.M.; Sanchez, J.; Vu, T. A Smart Shoe for Building a Real-Time 3D Map. Autom. Constr. 2016, 71, 2–12. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Li, H.; Li, A.R.; Zhang, H. Wearable IMU-Based Real-Time Motion Warning System for Construction Workers’ Musculoskeletal Disorders Prevention. Autom. Constr. 2017, 74, 2–11. [Google Scholar] [CrossRef]

- Dupont, Q.F.M.; Chua, D.K.H.; Tashrif, A.; Abbott, E.L.S. Potential Applications of UAV along the Construction’s Value Chain. Procedia Eng. 2017, 182, 165–173. [Google Scholar] [CrossRef]

- Han, K.K.; Golparvar-Fard, M. Potential of Big Visual Data and Building Information Modeling for Construction Performance Analytics: An Exploratory Study. Autom. Constr. 2017, 73, 184–198. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Lee, S. A Vision-Based Motion Capture and Recognition Framework for Behavior-Based Safety Management. Autom. Constr. 2013, 35, 131–141. [Google Scholar] [CrossRef]

- Kurien, M.; Kim, M.-K.; Kopsida, M.; Brilakis, I. Real-Time Simulation of Construction Workers Using Combined Human Body and Hand Tracking for Robotic Construction Worker System. Autom. Constr. 2018, 86, 125–137. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Guo, H.; Ding, Q.; Li, H.; Skitmore, M. An Experimental Study of Real-Time Identification of Construction Workers’ Unsafe Behaviors. Autom. Constr. 2017, 82, 193–206. [Google Scholar] [CrossRef] [Green Version]

- Teizer, J.; Caldas, C.H.; Haas, C.T. Real-Time Three-Dimensional Occupancy Grid Modeling for the Detection and Tracking of Construction Resources. J. Constr. Eng. Manag. 2007, 133, 880–888. [Google Scholar] [CrossRef]

- Han, K.K.; Cline, D.; Golparvar-Fard, M. Formalized Knowledge of Construction Sequencing for Visual Monitoring of Work-in-Progress via Incomplete Point Clouds and Low-LoD 4D BIMs. Adv. Eng. Inform. 2015, 29, 889–901. [Google Scholar] [CrossRef] [Green Version]

- Han, K.K.; Golparvar-Fard, M. Appearance-Based Material Classification for Monitoring of Operation-Level Construction Progress Using 4D BIM and Site Photologs. Autom. Constr. 2015, 53, 44–57. [Google Scholar] [CrossRef]

- Rebolj, D.; Pučko, Z.; Babič, N.Č.; Bizjak, M.; Mongus, D. Point Cloud Quality Requirements for Scan-vs-BIM Based Automated Construction Progress Monitoring. Autom. Constr. 2017, 84, 323–334. [Google Scholar] [CrossRef]

- Costin, A.; Pradhananga, N.; Teizer, J. Leveraging Passive RFID Technology for Construction Resource Field Mobility and Status Monitoring in a High-Rise Renovation Project. Autom. Constr. 2012, 24, 1–15. [Google Scholar] [CrossRef]

- Kelm, A.; Laußat, L.; Meins-Becker, A.; Platz, D.; Khazaee, M.J.; Costin, A.M.; Helmus, M.; Teizer, J. Mobile Passive Radio Frequency Identification (RFID) Portal for Automated and Rapid Control of Personal Protective Equipment (PPE) on Construction Sites. Autom. Constr. 2013, 36, 38–52. [Google Scholar] [CrossRef]

- Teizer, J.; Allread, B.S.; Fullerton, C.E.; Hinze, J. Autonomous Pro-Active Real-Time Construction Worker and Equipment Operator Proximity Safety Alert System. Autom. Constr. 2010, 19, 630–640. [Google Scholar] [CrossRef]

- Woo, S.; Jeong, S.; Mok, E.; Xia, L.; Choi, C.; Pyeon, M.; Heo, J. Application of WiFi-Based Indoor Positioning System for Labor Tracking at Construction Sites: A Case Study in Guangzhou MTR. Autom. Constr. 2011, 20, 3–13. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L.Y. Safety Barrier Warning System for Underground Construction Sites Using Internet-of-Things Technologies. Autom. Constr. 2017, 83, 372–389. [Google Scholar] [CrossRef]

- Cheng, T.; Teizer, J. Real-Time Resource Location Data Collection and Visualization Technology for Construction Safety and Activity Monitoring Applications. Autom. Constr. 2013, 34, 3–15. [Google Scholar] [CrossRef]

- Cheng, T.; Migliaccio, G.C.; Teizer, J.; Gatti, U.C. Data Fusion of Real-Time Location Sensing and Physiological Status Monitoring for Ergonomics Analysis of Construction Workers. J. Comput. Civ. Eng. 2013, 27, 320–335. [Google Scholar] [CrossRef]

- Cheng, T.; Venugopal, M.; Teizer, J.; Vela, P.A. Performance Evaluation of Ultra Wideband Technology for Construction Resource Location Tracking in Harsh Environments. Autom. Constr. 2011, 20, 1173–1184. [Google Scholar] [CrossRef]

- Choi, B.; Hwang, S.; Lee, S.H. What Drives Construction Workers’ Acceptance of Wearable Technologies in the Workplace? Indoor Localization and Wearable Health Devices for Occupational Safety and Health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Teizer, J.; Cheng, T. Proximity Hazard Indicator for Workers-on-Foot near Miss Interactions with Construction Equipment and Geo-Referenced Hazard Areas. Autom. Constr. 2015, 60, 58–73. [Google Scholar] [CrossRef]

- Teizer, J.; Cheng, T.; Fang, Y.H. Location Tracking and Data Visualization Technology to Advance Construction Ironworkers’ Education and Training in Safety and Productivity. Autom. Constr. 2013, 35, 53–68. [Google Scholar] [CrossRef]

- Calvetti, D. Evaluation of the Electronic Methodology for Monitoring the Performance of Welders in Pipe Manufacturing; Federal Fluminense University: Niterói, Brazil, 2016. [Google Scholar]

- Jiang, H.; Lin, P.; Qiang, M.; Fan, Q. A Labor Consumption Measurement System Based on Real-Time Tracking Technology for Dam Construction Site. Autom. Constr. 2015, 52, 1–15. [Google Scholar] [CrossRef]

- Navon, R. Automated Project Performance Control of Construction Projects. Autom. Constr. 2005, 14, 467–476. [Google Scholar] [CrossRef]

- Navon, R.; Goldschmidt, E. Monitoring Labor Inputs- Automated-Data-Collection Model and Enabling Technologies. Autom. Constr. 2002, 12, 185–199. [Google Scholar] [CrossRef]

- Navon, R.; Goldschmidt, E. Can Labor Inputs Be Measured and Controlled Automatically? J. Constr. Eng. Manag. 2003, 129, 437–445. [Google Scholar] [CrossRef]

- Valero, E.; Sivanathan, A.; Bosché, F.; Abdel-Wahab, M. Analysis of Construction Trade Worker Body Motions Using a Wearable and Wireless Motion Sensor Network. Autom. Constr. 2017, 83, 48–55. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, J.; Ahn, C. Construction Worker’s Awkward Posture Recognition through Supervised Motion Tensor Decomposition. Autom. Constr. 2017, 77, 67–81. [Google Scholar] [CrossRef]

- Tserng, H.P.; Dzeng, R.J.; Lin, Y.C.; Lin, S.T. Mobile Construction Supply Chain Management Using PDA and Bar Codes. Comput. Civ. Infrastruct. Eng. 2005, 20, 242–264. [Google Scholar] [CrossRef]

- Shehab, T.; Moselhi, O.; Nasr, E. Barcode-Assisted System for Document Management of Construction Projects. Int. J. Constr. Educ. Res. 2009, 5, 45–60. [Google Scholar] [CrossRef]

- Chen, J.; Song, X.; Lin, Z. Revealing the “Invisible Gorilla” in Construction: Estimating Construction Safety through Mental Workload Assessment. Autom. Constr. 2016, 63, 173–183. [Google Scholar] [CrossRef]

- Hwang, S.; Seo, J.; Jebelli, H.; Lee, S. Feasibility Analysis of Heart Rate Monitoring of Construction Workers Using a Photoplethysmography (PPG) Sensor Embedded in a Wristband-Type Activity Tracker. Autom. Constr. 2016, 71, 372–381. [Google Scholar] [CrossRef]

- Hwang, S.; Lee, S.H. Wristband-Type Wearable Health Devices to Measure Construction Workers’ Physical Demands. Autom. Constr. 2017, 83, 330–340. [Google Scholar] [CrossRef]

- Lee, W.; Lin, K.Y.; Seto, E.; Migliaccio, G.C. Wearable Sensors for Monitoring On-Duty and Off-Duty Worker Physiological Status and Activities in Construction. Autom. Constr. 2017, 83, 341–353. [Google Scholar] [CrossRef]

- Peterson, B. There’s A New Version of Google Glass, and it’s Been Secretly Used by Hundreds of Factory Workers for the Last Two Years. Available online: http://www.businessinsider.com/theres-a-new-version-of-google-glass-and-its-been-secretly-used-by-hundreds-of-factory-workers-for-the-last-two-years-2017-7 (accessed on 10 November 2019).

- Microsoft. Microsoft HoloLens. Available online: https://www.microsoft.com/en-us/hololens (accessed on 5 October 2018).

- Athos. Available online: https://www.liveathos.com (accessed on 5 October 2018).

- Movit. Motiv Ring. Available online: https://mymotiv.com/motiv-ring (accessed on 5 October 2018).

- Nuada. NUADA. Available online: http://nuada.pt (accessed on 5 October 2018).

- Memarzadeh, M.; Golparvar-Fard, M.; Niebles, J.C. Automated 2D Detection of Construction Equipment and Workers from Site Video Streams Using Histograms of Oriented Gradients and Colors. Autom. Constr. 2013, 32, 24–37. [Google Scholar] [CrossRef]

- Park, M.-W.; Brilakis, I. Construction Worker Detection in Video Frames for Initializing Vision Trackers. Autom. Constr. 2012, 28, 15–25. [Google Scholar] [CrossRef]

- Park, M.-W.; Brilakis, I. Continuous Localization of Construction Workers via Integration of Detection and Tracking. Autom. Constr. 2016, 72, 129–142. [Google Scholar] [CrossRef]

- Yang, J.; Arif, O.; Vela, P.A.; Teizer, J.; Shi, Z. Tracking Multiple Workers on Construction Sites Using Video Cameras. Adv. Eng. Inform. 2010, 24, 428–434. [Google Scholar] [CrossRef]

- Zhu, Z.; Ren, X.; Chen, Z. Visual Tracking of Construction Jobsite Workforce and Equipment with Particle Filtering. J. Comput. Civ. Eng. 2016, 30. [Google Scholar] [CrossRef]

- Zhu, Z.; Ren, X.; Chen, Z. Integrated Detection and Tracking of Workforce and Equipment from Construction Jobsite Videos. Autom. Constr. 2017, 81, 161–171. [Google Scholar] [CrossRef]

- Bang, S.; Kim, H.; Kim, H. UAV-Based Automatic Generation of High-Resolution Panorama at a Construction Site with a Focus on Preprocessing for Image Stitching. Autom. Constr. 2017, 84, 70–80. [Google Scholar] [CrossRef]

- Melo, R.R.S.; de Costa, D.B.; Álvares, J.S.; Irizarry, J. Applicability of Unmanned Aerial System (UAS) for Safety Inspection on Construction Sites. Saf. Sci. 2017, 98, 174–185. [Google Scholar] [CrossRef]

- Torque Sensor—Power Tool Measurement. Available online: https://www.futek.com/applications/Power-Tool-Measurement (accessed on 29 July 2020).

- Bestard, G.A.; Sampaio, R.C.; Vargas, J.A.R.; Alfaro, S.C.A. Sensor Fusion to Estimate the Depth and Width of the Weld Bead in Real Time in GMAW Processes. Sensors 2018, 18, 962. [Google Scholar] [CrossRef] [Green Version]

- Sensors for Construction Machinery—TM Automation Instruments Co., Ltd. Available online: https://www.tmvenus.com/Sensors-For-Construction-Machinery-id3842075.html (accessed on 29 July 2020).

- Temperature Sensor, China Temperature Sensor, Temperature Sensorr manufacturer—TM. Available online: https://www.tmvenus.com/Temperature-Sensor-pl3362865.html (accessed on 29 July 2020).

- Gatti, U.C.; Schneider, S.; Migliaccio, G.C. Physiological Condition Monitoring of Construction Workers. Autom. Constr. 2014, 44, 227–233. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Chen, J. A Framework for Real-Time pro-Active Safety Assistance for Mobile Crane Lifting Operations. Autom. Constr. 2016, 72, 367–379. [Google Scholar] [CrossRef] [Green Version]

- Sztyler, T.; Stuckenschmidt, H. On-Body Localization of Wearable Devices: An Investigation of Position-Aware Activity Recognition. In Proceedings of the 2016 IEEE International Conference on Pervasive Computing and Communications, PerCom 2016, Sydney, NSW, Australia, 14–19 March 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Attal, F.; Mohammed, S.; Dedabrishvili, M.; Chamroukhi, F.; Oukhellou, L.; Amirat, Y. Physical Human Activity Recognition Using Wearable Sensors. Sensors 2015, 15, 31314–31338. [Google Scholar] [CrossRef] [Green Version]

- Bao, L.; Intille, S.S. Activity Recognition from User-Annotated Acceleration Data. In Second International Conference, PERVASIVE 2004; Springer: Berlin/Heidelberg, Germany; New York, NY, USA,, 2004; pp. 1–17. [Google Scholar] [CrossRef]

- Yang, K.; Jebelli, H.; Ahn, C.R.; Vuran, M.C. Threshold-Based Approach to Detect Near-Miss Falls of Iron-Workers Using Inertial Measurement Units. In Proceedings of the 2015 International Workshop on Computing in Civil Engineering, Austin, TX, USA, 21–23 June 2015; ASCE: Austin, TX, USA, 2015; pp. 148–155. [Google Scholar] [CrossRef]

- Yang, K.; Ahn, C.R.; Vuran, M.C.; Aria, S.S. Semi-Supervised near-Miss Fall Detection for Ironworkers with a Wearable Inertial Measurement Unit. Autom. Constr. 2016, 68, 194–202. [Google Scholar] [CrossRef] [Green Version]

- Yi, W.; Chan, A.P.C. Critical Review of Labor Productivity Research in Construction Journals. J. Manag. Eng. 2014, 30, 214–225. [Google Scholar] [CrossRef] [Green Version]

- El-Gohary, K.M.; Aziz, R.F.; Abdel-Khalek, H.A. Engineering Approach Using ANN to Improve and Predict Construction Labor Productivity under Different Influences. J. Constr. Eng. Manag. 2017, 143. [Google Scholar] [CrossRef]

- Gilbreth, F.B. Motion Study: A Method for Increasing the Efficiency of the Workman; D. Van Nostrand Company: New York, NY, USA, 1911. [Google Scholar]

- Guo, S.-J.; Tucker, R.L. Automation Needs Determination Using AHP Approach. Autom. Robot. Constr. X 1993, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Everett, J.G.; Slocum, A.H. Automation and Robotic Opportunities: Construction versus Manufacture. J. Constr. Eng. Manag. 1994, 120, 443–452. [Google Scholar] [CrossRef]

- Ahmadt, A.N.B.; Scott, J.N.; Bradley, D.A. Task Decomposition in Support of Automation and Robotics in Construction. Autom. Robot. Constr. XII 1995, 407–414. [Google Scholar] [CrossRef] [Green Version]

- Kisi, K.P.; Mani, N.; Rojas, E.M.; Foster, E.T. Optimal Productivity in Labor-Intensive Construction Operations: Pilot Study. J. Constr. Eng. Manag. 2017, 143. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Ong, J.J.M.; Krishnankutty, P. Mechanization in Building Construction Projects: Assessment and Views from the Practitioners. Prod. Plan. Control 2019, 31, 613–628. [Google Scholar] [CrossRef]

- McKinsey. Reinventing Construction: A Route To Higher Productivity; McKinsey & Company: Houston, TX, USA, 2017. [Google Scholar]

- Bröchner, J.; Olofsson, T. Construction Productivity Measures for Innovation Projects. J. Constr. Eng. Manag. 2012, 138, 670–677. [Google Scholar] [CrossRef]

- Park, H.-S.; Thomas Stephen, R.; Tucker Richard, L. Benchmarking of Construction Productivity. J. Constr. Eng. Manag. 2005, 131, 772–778. [Google Scholar] [CrossRef]

- Nweke, H.F.; Teh, Y.W.; Al-garadi, M.A.; Alo, U.R. Deep Learning Algorithms for Human Activity Recognition Using Mobile and Wearable Sensor Networks: State of the Art and Research Challenges. Expert Syst. Appl. 2018, 105, 233–261. [Google Scholar] [CrossRef]

- Nath, N.D.; Chaspari, T.; Behzadan, A.H. Automated Ergonomic Risk Monitoring Using Body-Mounted Sensors and Machine Learning. Adv. Eng. Inform. 2018, 38, 514–526. [Google Scholar] [CrossRef]

- Meyers, F.E.; Stewart, J.R. Motion and Time Study for Lean Manufacturing, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Adrian, J.J. Construction Productivity: Measurement and Improvement; Stipes Publishing: Champaign, IL, USA, 2004. [Google Scholar]

- CYPE. Generator of Prices for Construction. Available online: http://www.geradordeprecos.info/ (accessed on 10 October 2019).

- Calvetti, D.; Magalhães, P.N.M.; Sujan, S.F.; Gonçalves, M.C.; Campos de Sousa, H.J. Challenges of Upgrading Craft Workforce into Construction 4.0—Framework and Agreements. Proc. Inst. Civ. Eng. Manag. Procure. Law 2020, 1–7. [Google Scholar] [CrossRef]

| Characteristic | Number of Papers | References | |

|---|---|---|---|

| Sensors | Accelerometer | 4 | [24,27,28,30,93] |

| Accelerometer and gyroscope | 5 | [18,19,20,21,23] | |

| Accelerometer, gyroscope and magnetometer | 3 | [25,26,91] | |

| Movement of | Arm | 5 | [18,19,20,21,25] |

| Arms and waist | 2 | [29,30] | |

| All body | 4 | [24,26,91,93] | |

| Spine | 2 | [94,95] | |

| Wrist | 2 | [27,28] | |

| Wrist and leg | 1 | [23] | |

| Reference | Year | Classified Activity |

|---|---|---|

| [18] | 2016 | (1) Cut lumber; (2) transport (3) installation |

| [21] | 2018 | Category 1 ((1) sawing against (2) idling); Category 2 ((3) hammer and (4) turn a wrench against idling); Category 3 ((5) load sections into a wheelbarrow, (6) push a loaded wheelbarrow, (7) dump sections from a wheelbarrow and (8) return an empty wheelbarrow against idling) |

| [23] | 2018 | (1) Stand, (2) walk, (3) squat, (4) clean up the template, (5) fetch and place rebar, (6) locate the rebar, (7) bind rebar,(8) place concrete pads |

| [25] | 2018 | (1) Grab tool/part, (2) hammer nail, (3) use power screwdriver, (4) rest arm, (5) turn screwdriver and (6) use wrench |

| [28] | 2019 | (1) Spread mortar; (2) bring and lay blocks; (3) adjust blocks; and (4) remove remaining mortar |

| [30] | 2014 | (1) Effective work, (2) contributory work and (3) ineffective work |

| [31] | 2011 | (1) Fetch and spread mortar, (2) fetch and lay brick and (3) fill joints |

| Worker 4.0 Motion Productivity | Group of Movements and Performance | Example |

|---|---|---|

| Free-hand performing | One or both hands during the tasks, handling materials or products | putting a brick, etc. |

| Auxiliary tools | One or both hands during the tasks handling auxiliary tools | using a spirit-level, etc. |

| Manual tools | One or both hands during the tasks handling manual tools | using a trowel, etc. |

| Electric/electronic tools | One or both hands during the tasks, handling electric/electronic tools | using a drill, etc. |

| Machines operation | One or both hands during the tasks, dealing with machines/workstations or dealing with equipment | using a bench circular saw, using a backhoe, etc. |

| Robotic automation | Automated work based on robotic equipment | robotic bricklaying arm, etc. |

| Do not operate value | Doing any productive work. That does not advance the progress of the tasks. Furthermore, identified as “ineffective Therbligs” or “not productive” | planning, searching, chatting, resting, human needs, etc. |

| Walking | Walking without carrying anything on hands | going to the WC, idleness, etc. |

| Carrying | Walking carrying something on hands | products, equipment, tools, etc. |

| Worker 4.0 Motion Productivity | Acronym | Element Level of the Tasks | Process | Productive State | Monitoring | |

|---|---|---|---|---|---|---|

| Indication | Symbol | |||||

| Free-hand Performing | FHP | work element | Operation | O | Productive or Direct work | BM |

| Auxiliary tools | AUT | work element | Inspection | ☐ | Contributory orSupport work | BM |

| Manual tools | MNT | work element | Operation | O | Productive or Direct work | BM |

| Electric/electronic tools | EET | work element | Operation | O | Productive or Direct work | BM + So |

| Machines operation | MOP | work element | Operation | O | Productive or Direct work | BM + Loc + So |

| Robotic automation | RBA | autonomous | Operation | O | Autonomous Production | BM + Loc + So |

| Do not operate value | IDL | basic motion element | Delay | D | Nonproduction work | BM + Loc |

| Walking | WLK | basic motion element | Delay | D | Nonproduction work | BM + Loc |

| Carrying | CAR | basic motion element | Transportation/ Storage | Δ➔ | Contributory orSupport work | BM + Loc |

| Worker 4.0 Motion Productivity | First Analysis Indications on How to Boost Efficiency and Mechanization Levels |

|---|---|

| Free-hand performing | Does the activity justify the use of any tool, mechanized or automated robotic equipment? |

| Auxiliary tools | Can it be eliminated? Can it be used as an electric/electronic tool? |

| Manual tools | Does the activity justify the use of an electric/electronic tool or mechanized or automated robotic equipment? |

| Electric/electronic tools | Does the activity justify mechanized or automated robotic equipment? |

| Machines operation | Does the activity justify automated robotic equipment? |

| Robotic automation | If that robotic solution demand for workforce auxiliary work, can it be avoided or shortened? |

| Do not operate value | Can it be avoided or shortened? |

| Walking | Can it be avoided or shortened? Can the worker carry something? |

| Carrying | Can it be avoided or shortened? Does the activity justify automated equipment? |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calvetti, D.; Mêda, P.; Chichorro Gonçalves, M.; Sousa, H. Worker 4.0: The Future of Sensored Construction Sites. Buildings 2020, 10, 169. https://doi.org/10.3390/buildings10100169

Calvetti D, Mêda P, Chichorro Gonçalves M, Sousa H. Worker 4.0: The Future of Sensored Construction Sites. Buildings. 2020; 10(10):169. https://doi.org/10.3390/buildings10100169

Chicago/Turabian StyleCalvetti, Diego, Pedro Mêda, Miguel Chichorro Gonçalves, and Hipólito Sousa. 2020. "Worker 4.0: The Future of Sensored Construction Sites" Buildings 10, no. 10: 169. https://doi.org/10.3390/buildings10100169

APA StyleCalvetti, D., Mêda, P., Chichorro Gonçalves, M., & Sousa, H. (2020). Worker 4.0: The Future of Sensored Construction Sites. Buildings, 10(10), 169. https://doi.org/10.3390/buildings10100169