Sustainable High-Speed Finishing Turning of Haynes 282 Using Carbide Tools in Dry Conditions

Abstract

1. Introduction

2. Experimental Setup

2.1. Material Properties and Cutting Tools.

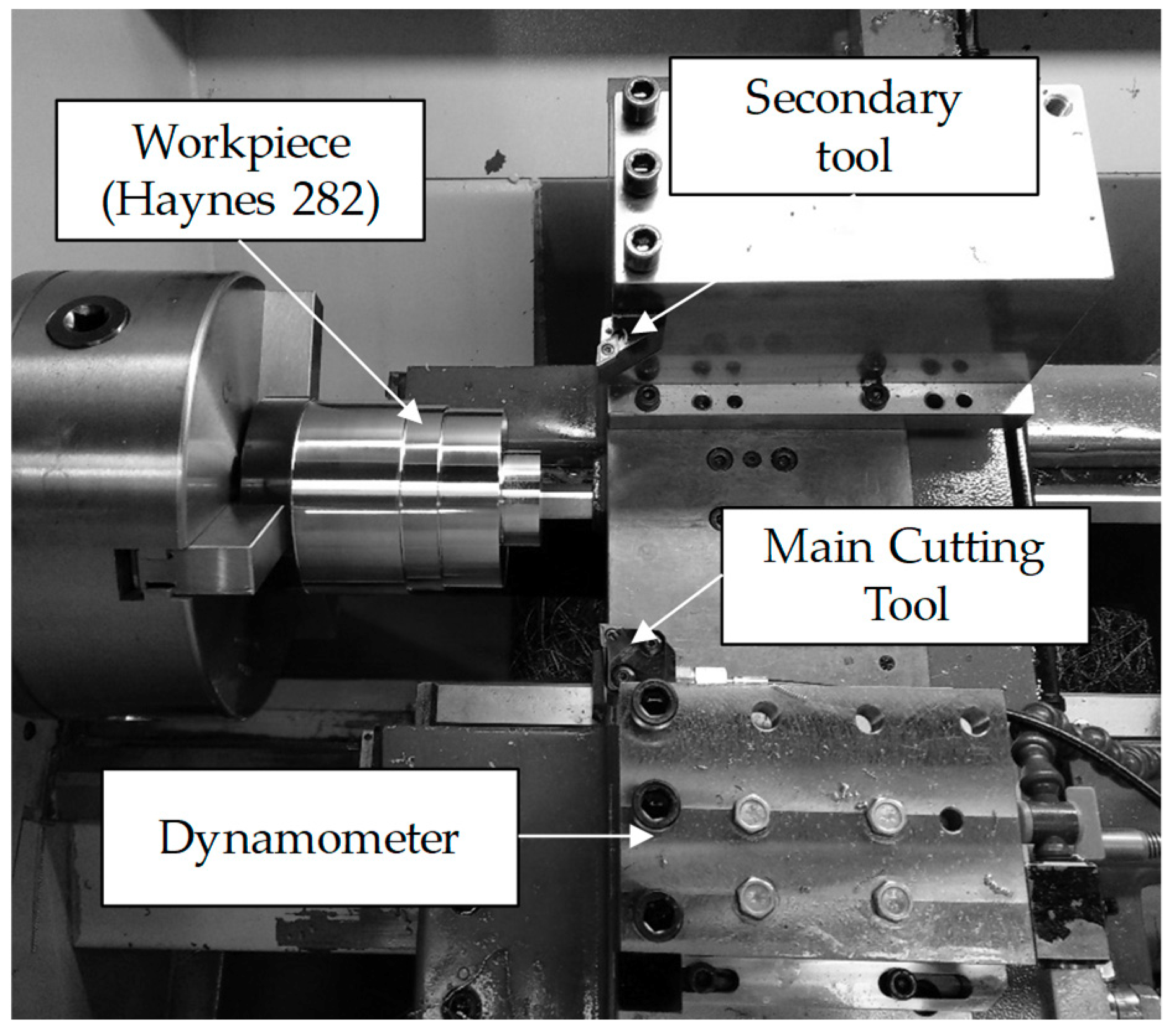

2.2. Experimental Setup and Instrumentation

3. Results and Discussion

3.1. Cutting Forces Analysis

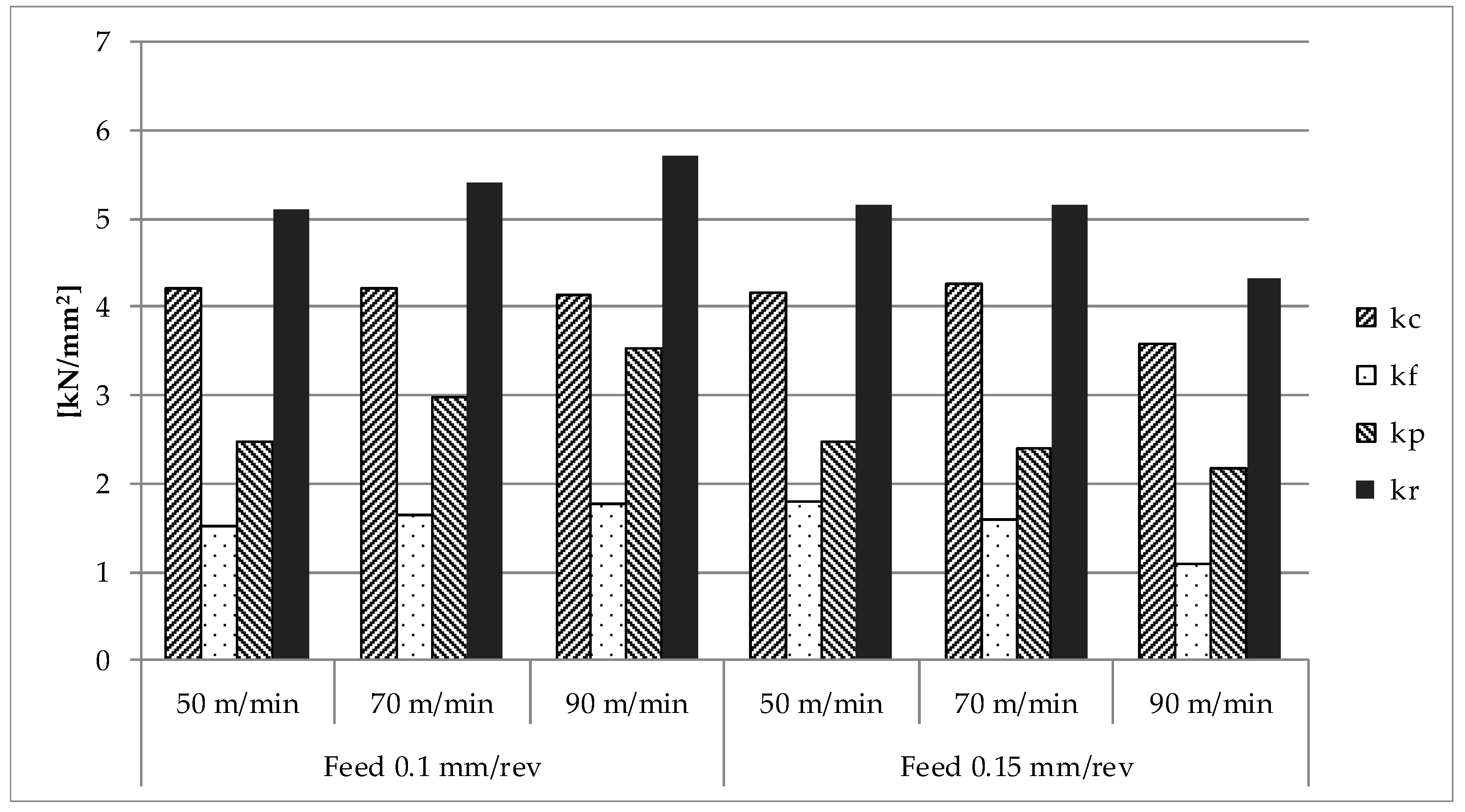

3.1.1. Fresh Tools Results for the Specific Cutting Force

Cutting Speed vs. Specific Cutting Forces

- For the lowest feed (0.1 mm/rev) used, the specific cutting force (kc) was not significantly affected by the cutting speed for the studied range. However, the rest of the components increased by up to 26% for the specific feed force (kf), and up to 100% for the specific back force (kp) when the cutting speed was increased from 50 m/min to 90 m/min. This behavior was not observed for the feed equal to 0.15 mm/rev, whereas the cutting speed was increased from 50 m/min to 90 m/min, the values of the specific cutting forces were decreased by up to 57%, 70%, and 30% for the specific cutting force (kc), the specific feed force (kf), and the specific back force (kp), respectively. By increasing the cutting speed, the temperature of the material to be cut rose, so that it softened, thus requiring lower cutting forces. At the same time, increasing the cutting speed also increased the strain rate by increasing the resistance of the material to be cut. For a feed of 0.1 mm/rev, it was observed that, because of the higher proportion of chip sections with high levels of deformation, when increasing the cutting speed, the specific cutting forces increased because of the strain hardening effect; however, for the feed value of 0.15 mm/rev, the softening effect of the material, because of the increment of the cutting speed, was the predominant effect.

Feed vs. Specific Cutting Forces

- Regarding the specific cutting force component induced by the feed, reductions of up to 13% for the specific cutting force (kc), up to 39% for the specific feed force (kf), and up to 38% for the specific back force (kp) were recorded with increments on the feed from 0.1 mm/rev to 0.15 mm/rev. The specific cutting force component induced by the feed was as expected. For the lowest feed, as the proportion of material subjected to large deformation (along the cutting edge) was higher, the specific cutting force results were also higher; this tendency can also be verified through the resultant specific cutting force (kr).

3.1.2. Specific Cutting Forces Evolution During Haynes 282 Turning

Cutting Speed vs. Specific Cutting Forces

- Cutting speed 50 m/min: As mentioned in the previous paragraph, a slight linear increase in the cutting forces was recorded in the first region. In the subsequent region, the kp component underwent a drastic increase, contrasting the kf components with a lower increase. These two regions, clearly identifiable during the tests, exhibited a close relationship with the different wear modes observed. Thus, while for the first region of the force evolution a moderate chipping combined with a progressive erosion of the tool flank was observed, for the second region, the kf and kp components of the specific force through the loss of the cutting edge integrity were affected by a more aggressive chipping combined with a rapid progression of the notch. Therefore, a clear trend can be observed, according to which, as the cutting speed increases, both the tool wear rate and consequently the specific forces increase.

- Cutting speed 70 m/min: The evolution of the specific cutting force showed a similar trend to those obtained for the 50 m/min cutting speed. Thus, for kp, it could be clearly seen in the two regions, with a drastic increase in the second one, whereas for the kf component, this increase was not so evident. Therefore, all of the components of the cutting speed exhibited a slight increase during the first region, with the flank wear progression moderated by means of a light chipping. However, the components of force kf and kp suffered suspected growth during the second region because of a great deterioration of the cutting edge through the notch and more intense chipping in this final stage.

- Cutting speed of 90 m/min: As in the previous cases, there were two clearly differentiated regions of specific forces of growth, the main difference between them being the use time of the tool, in which the trend change appeared much smaller than for the lower speeds. These two growth zones were also related by a moderate growth of flank wear together with chipping, until the chipping was dominant, progressing in quick increment of the specific force components kf and kp.

Feed vs. Specific Cutting Forces

- For all of the conditions analyzed, a remarkable influence of the feed on the evolution of the components of the specific cutting force were not found during the turning tests.

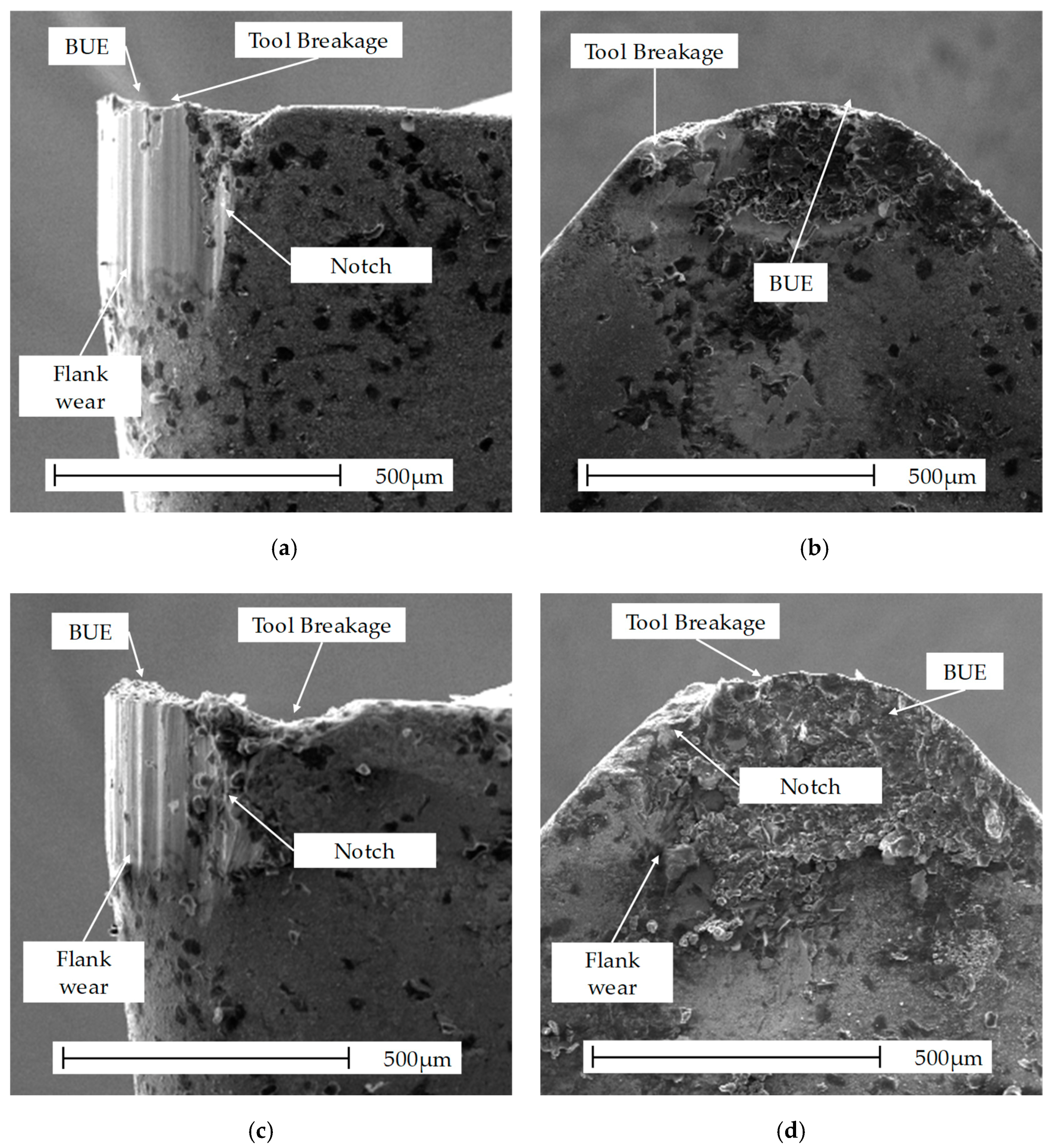

3.2. Analysis of Wear and Tool Life

3.3. Analysis of Surface Quality

4. Conclusions

- The less aggressive conditions for the tool when working on dry conditions are low cutting speeds, 50 m/min in this study. The effect of the feed is not so significant in terms of the mechanized surface, whereas, on the contrary, it is significant in terms of the tool life, with shorter lives having the greatest feed. This effect must be taken into account for productivity purposes.

- It should be noted that life values similar to those obtained in other studies, with lubricant under similar conditions, have been obtained for the most favorable conditions in dry conditions. This is a significant result, demonstrating the suitability of implementing dry turning in an industrial environment.

- The great influence of the cutting speed in the tool life was demonstrated by decreasing it by 85% when going from 50 to 70 m/min for a feed of 0.1 mm/rev and 90% for a feed of 0.15 mm/rev.

- Great increases in cutting forces have been appreciated for all of the tested conditions, obtaining values for the specific back force at the end of tool life, of 10 times the value obtained when the tool was fresh. It has been possible to observe a clear relationship between this force and the tool life.

- Regarding the wear, since the beginning of the trials, chipping, built up edge (BUE), and notch wear were found. The catastrophic failure of the cutting edge has been found at the end of tool life in all of the cutting conditions tested because of the chipping progression.

- For all of the tests, the Ra values were low, regardless of the time of use of the tool (between 0.7 and 2.5 µm). However, the homogeneity in terms of Ra for the test with a 50 cutting speed and 0.1 mm/rev of feed stands out, which gives one an idea of the stability of this condition in relation to the other cutting parameters, where large variations in this value were found.

Author Contributions

Funding

Conflicts of Interest

References

- Hu, D.; Wang, T.; Ma, Q.; Liu, X.; Shang, L.; Li, D.; Pan, J.; Wang, R. Effect of inclusions on low cycle fatigue lifetime in a powder metallurgy nickel-based superalloy FGH96. Int. J. Fatigue 2019, 118, 237–248. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, X.; Ding, H. Tool wear characteristics in machining of nickel-based superalloys. Int. J. Mach. Tools Manuf. 2013, 64, 60–77. [Google Scholar] [CrossRef]

- Cantero, J.L.; Díaz-Álvarez, J.; Miguélez, M.H.; Marín, N.C. Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 2013, 297, 885–894. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, X.; Liu, Y.; Yang, X.; Meng, F. Micromilling Simulation for the Hard-to-cut Material. Procedia Eng. 2017, 174, 693–699. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Kruger, K.L. HAYNES 282 Alloy; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; ISBN 9780081005583. [Google Scholar]

- Donachie, M.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: New York, NY, USA, 2002; pp. 1–409. [Google Scholar]

- Shin, K.Y.; Kim, J.H.; Terner, M.; Kong, B.O.; Hong, H.U. Effects of heat treatment on the microstructure evolution and the high-temperature tensile properties of Haynes 282 superalloy. Mater. Sci. Eng. A 2019, 751, 311–322. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Díaz-Álvarez, J.; Bernier, R.; Cantero, J.; Rusinek, A.; Miguelez, M. Thermo-Viscoplastic Behavior of Ni-Based Superalloy Haynes 282 and Its Application to Machining Simulation. Metals 2017, 7, 561. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Díaz-Álvarez, A.; Miguélez, H.; Cantero, J. Finishing Turning of Ni Superalloy Haynes 282. Metals 2018, 8, 843. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Tapetado, A.; Vázquez, C.; Miguélez, H. Temperature measurement and numerical prediction in machining inconel 718. Sensors 2017, 17, 1531. [Google Scholar] [CrossRef]

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Choudhury, I.; El-Baradie, M. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Muñoz-Sánchez, A.; Canteli, J.A.; Cantero, J.L.; Miguélez, M.H. Numerical analysis of the tool wear effect in the machining induced residual stresses. Simul. Model. Pract. Theory 2011, 19, 872–886. [Google Scholar] [CrossRef]

- Urbikain, G.; de Lacalle, L.N.L. Modelling of surface roughness in inclined milling operations with circle-segment end mills. Simul. Model. Pract. Theory 2018, 84, 161–176. [Google Scholar] [CrossRef]

- Hoier, P.; Malakizadi, A.; Stuppa, P.; Cedergren, S.; Klement, U. Microstructural characteristics of Alloy 718 and Waspaloy and their influence on flank wear during turning. Wear 2018, 400–401, 184–193. [Google Scholar] [CrossRef]

- Thellaputta, G.R.; Chandra, P.S.; Rao, C.S.P. Machinability of Nickel Based Superalloys: A Review. Mater. Today Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Grzesik, W.; Niesłony, P.; Habrat, W.; Sieniawski, J.; Laskowski, P. Investigation of tool wear in the turning of Inconel 718 superalloy in terms of process performance and productivity enhancement. Tribol. Int. 2018, 118, 337–346. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Study on the machinability characteristics of superalloy Inconel 718 during high speed turning. Mater. Des. 2009, 30, 1718–1725. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. Manuf. Technol. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Olovsjö, S.; Nyborg, L. Influence of microstructure on wear behaviour of uncoated WC tools in turning of Alloy 718 and Waspaloy. Wear 2012, 282–283, 12–21. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining—Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Devillez, A.; Schneider, F.; Dominiak, S.; Dudzinski, D.; Larrouquere, D. Cutting forces and wear in dry machining of Inconel 718 with coated carbide tools. Wear 2007, 262, 931–942. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Sankar, M.R. Hard machining performance of indigenously developed green cutting fluid using flood cooling and minimum quantity cutting fluid. J. Clean. Prod. 2019, 206, 108–123. [Google Scholar] [CrossRef]

- Amiril, S.A.S.; Rahim, E.A.; Syahrullail, S. A review on ionic liquids as sustainable lubricants in manufacturing and engineering: Recent research, performance, and applications. J. Clean. Prod. 2017, 168, 1571–1589. [Google Scholar] [CrossRef]

- Gutnichenko, O.; Bushlya, V.; Bihagen, S.; Ståhl, J.-E. Influence of GnP additive to vegetable oil on machining performance when MQL-assisted turning Alloy 718. Procedia Manuf. 2018, 25, 330–337. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Ram, D.; Ravi Sankar, M. Biodegradation and hard machining performance comparison of eco-friendly cutting fluid and mineral oil using flood cooling and minimum quantity cutting fluid techniques. J. Clean. Prod. 2017, 165, 1420–1435. [Google Scholar] [CrossRef]

- Cantero, J.; Díaz-Álvarez, J.; Infante-García, D.; Rodríguez, M.; Criado, V. High Speed Finish Turning of Inconel 718 Using PCBN Tools under Dry Conditions. Metals 2018, 8, 192. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; de Lacalle, L.N.L.; Polvorosa, R.; Wretland, A. An investigation of cutting forces and tool wear in turning of Haynes 282. J. Manuf. Process. 2019, 37, 529–540. [Google Scholar] [CrossRef]

- Pike, L.M.; Weatherhill, A.E. HAYNES® 282TM Alloy: A New Wrought Superalloy Designed for Improved Creep Strength and Fabrication Ability; ASME: New York, NY, USA, 2006; pp. 1031–1039. [Google Scholar]

- Díaz-Álvarez, J.; Criado, V.; Miguélez, H.; Cantero, J. PCBN Performance in High Speed Finishing Turning of Inconel 718. Metals 2018, 8, 582. [Google Scholar] [CrossRef]

- Asiltürk, I.; Çunkas, M. Expert Systems with Applications Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Syst. Appl. 2011, 38, 5826–5832. [Google Scholar] [CrossRef]

| Element (%) | Ni | Cr | Fe | Nb | Mo | Ti | Al | Co | Si | Cu | Mn | C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Haynes 282 | 57 | 19.42 | 0.87 | ˂0.01 | 8.52 | 2.22 | 1.41 | 10.2 | ˂0.05 | ˂0.01 | 0.06 | 0.062 |

| Cutting Speed (m/min) | Feed (rev/min) | Pass Depth (mm) |

|---|---|---|

| 50 | 0.1 | 0.25 |

| 0.15 | ||

| 70 | 0.1 | |

| 0.15 | ||

| 90 | 0.1 | |

| 0.15 |

| Tool | Cutting Speed (m/min) | Feed (mm/rev) | Depth (mm) | Life (min) | Machined Surface per Unit Time (mm2/s) | Machined Surface per Cutting Edge (mm2) |

|---|---|---|---|---|---|---|

| Carbide (TS2000, Seco) | 50 | 0.1 | 0.25 | 30.1 | 83.3 | 150,520 |

| 0.15 | 21.0 | 125.0 | 157,629 | |||

| 70 | 0.1 | 0.25 | 4.5 | 117 | 31,196 | |

| 0.15 | 2.1 | 175.0 | 22,266 | |||

| 90 | 0.1 | 0.25 | 2.3 | 150.0 | 20,263 | |

| 0.15 | 1.9 | 225.0 | 25,525 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Álvarez, A.; Díaz-Álvarez, J.; Cantero, J.L.; Miguélez, H. Sustainable High-Speed Finishing Turning of Haynes 282 Using Carbide Tools in Dry Conditions. Metals 2019, 9, 989. https://doi.org/10.3390/met9090989

Díaz-Álvarez A, Díaz-Álvarez J, Cantero JL, Miguélez H. Sustainable High-Speed Finishing Turning of Haynes 282 Using Carbide Tools in Dry Conditions. Metals. 2019; 9(9):989. https://doi.org/10.3390/met9090989

Chicago/Turabian StyleDíaz-Álvarez, Antonio, José Díaz-Álvarez, José Luis Cantero, and Henar Miguélez. 2019. "Sustainable High-Speed Finishing Turning of Haynes 282 Using Carbide Tools in Dry Conditions" Metals 9, no. 9: 989. https://doi.org/10.3390/met9090989

APA StyleDíaz-Álvarez, A., Díaz-Álvarez, J., Cantero, J. L., & Miguélez, H. (2019). Sustainable High-Speed Finishing Turning of Haynes 282 Using Carbide Tools in Dry Conditions. Metals, 9(9), 989. https://doi.org/10.3390/met9090989