A Study of the Coefficient of Friction in Steel Sheets Forming

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

2.2. Surface Characterisation

2.3. Methods

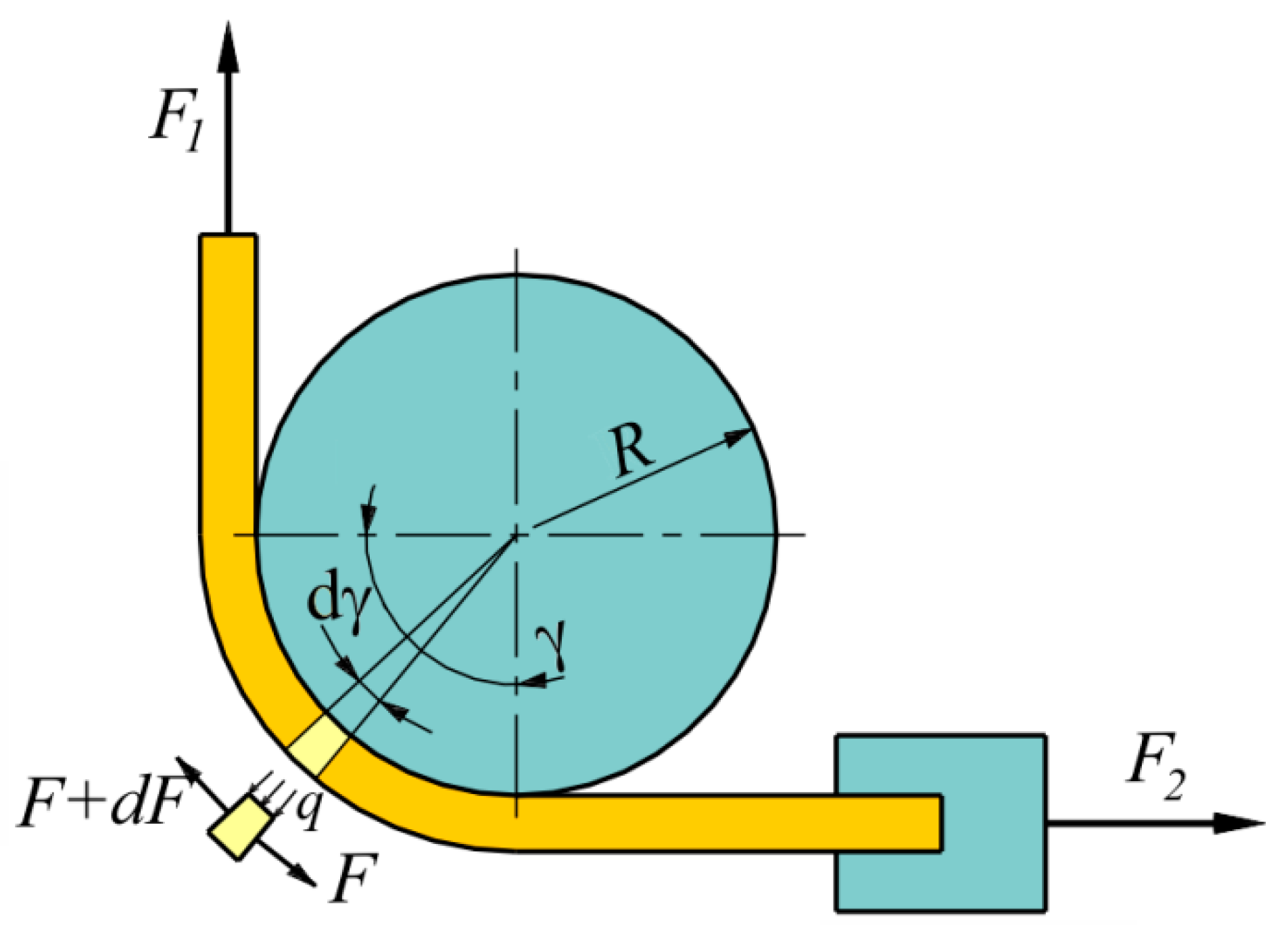

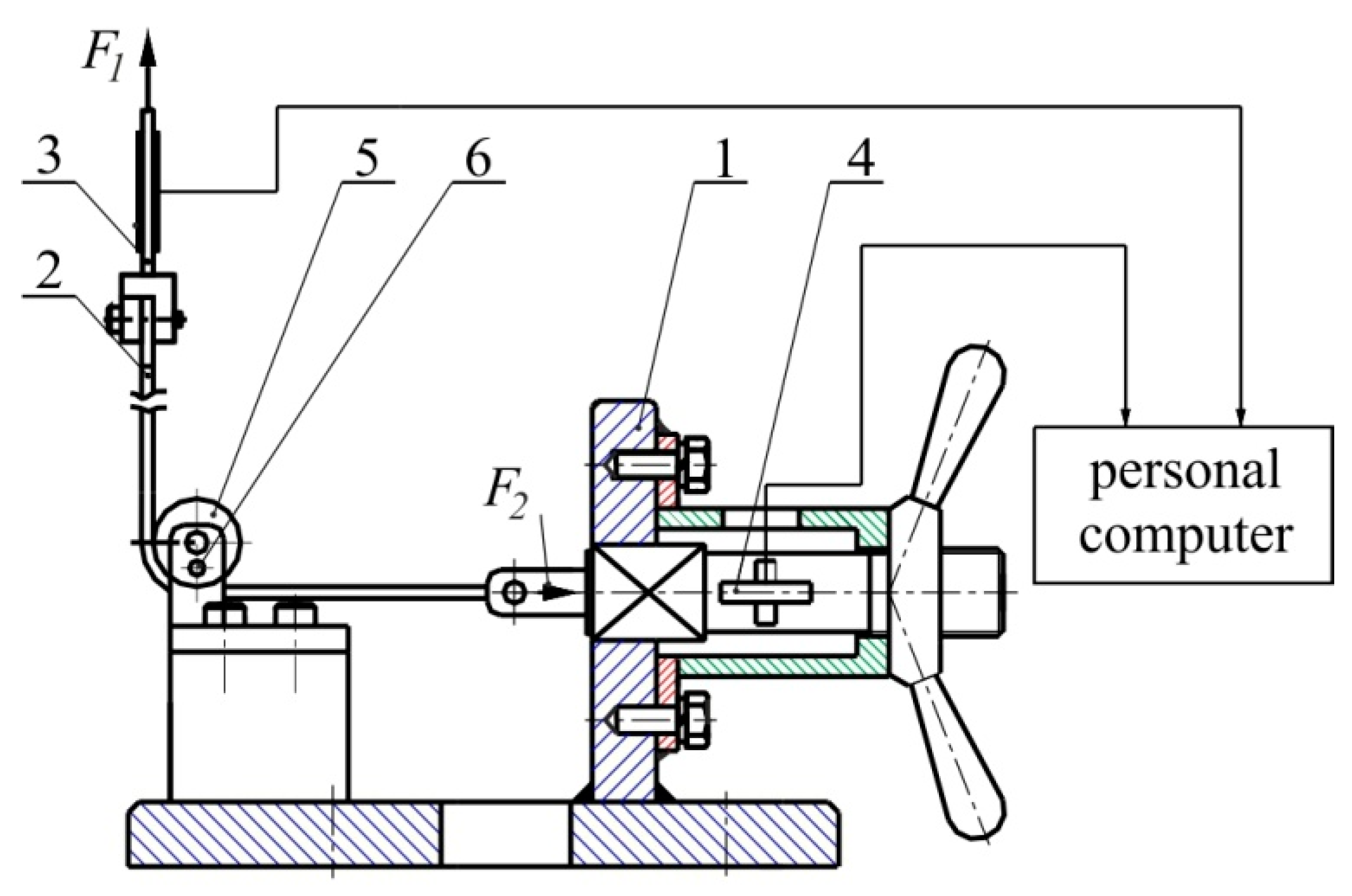

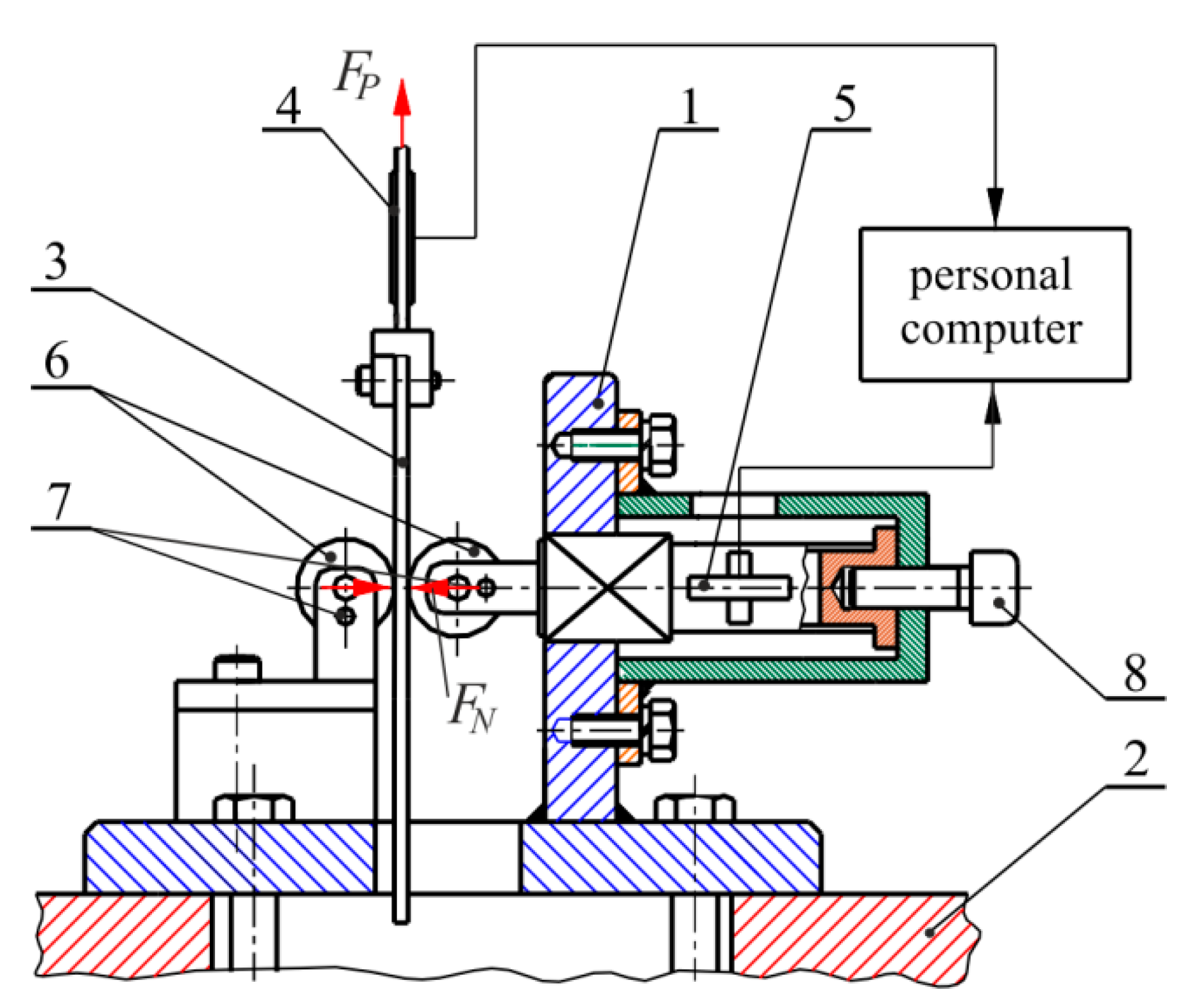

2.3.1. Bending under Tension Test

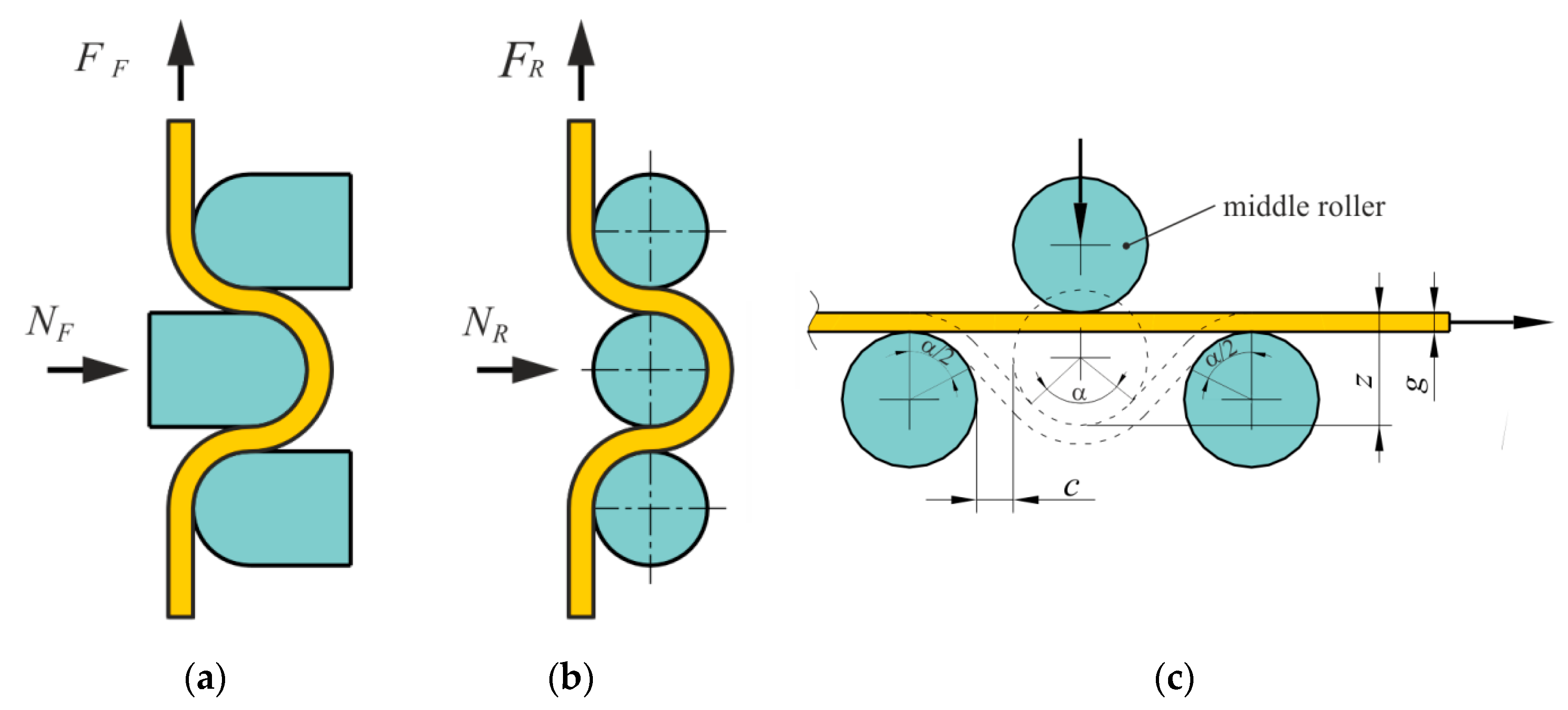

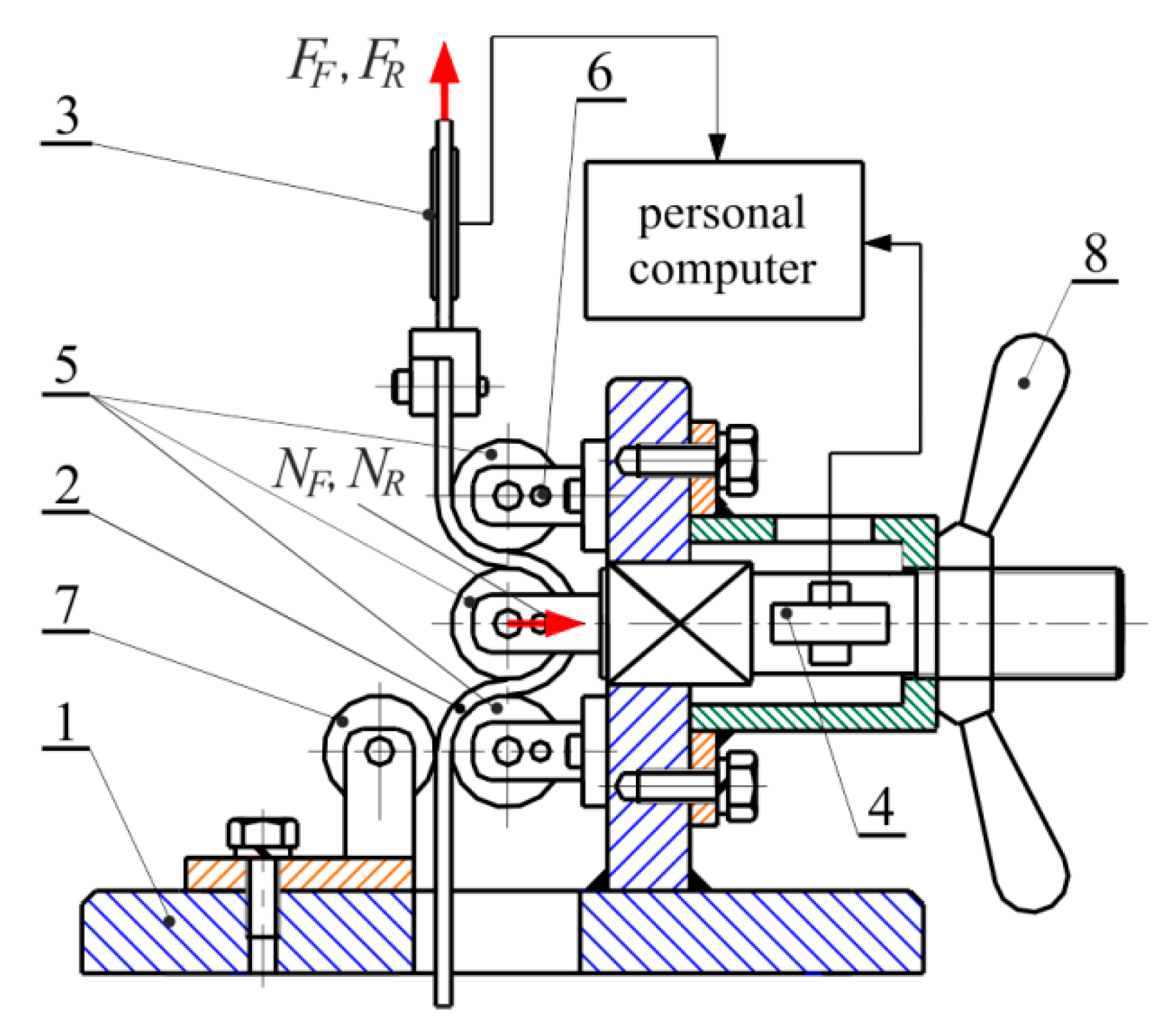

2.3.2. Draw Bead Test

2.3.3. Strip Drawing Test

3. Results and Discussion

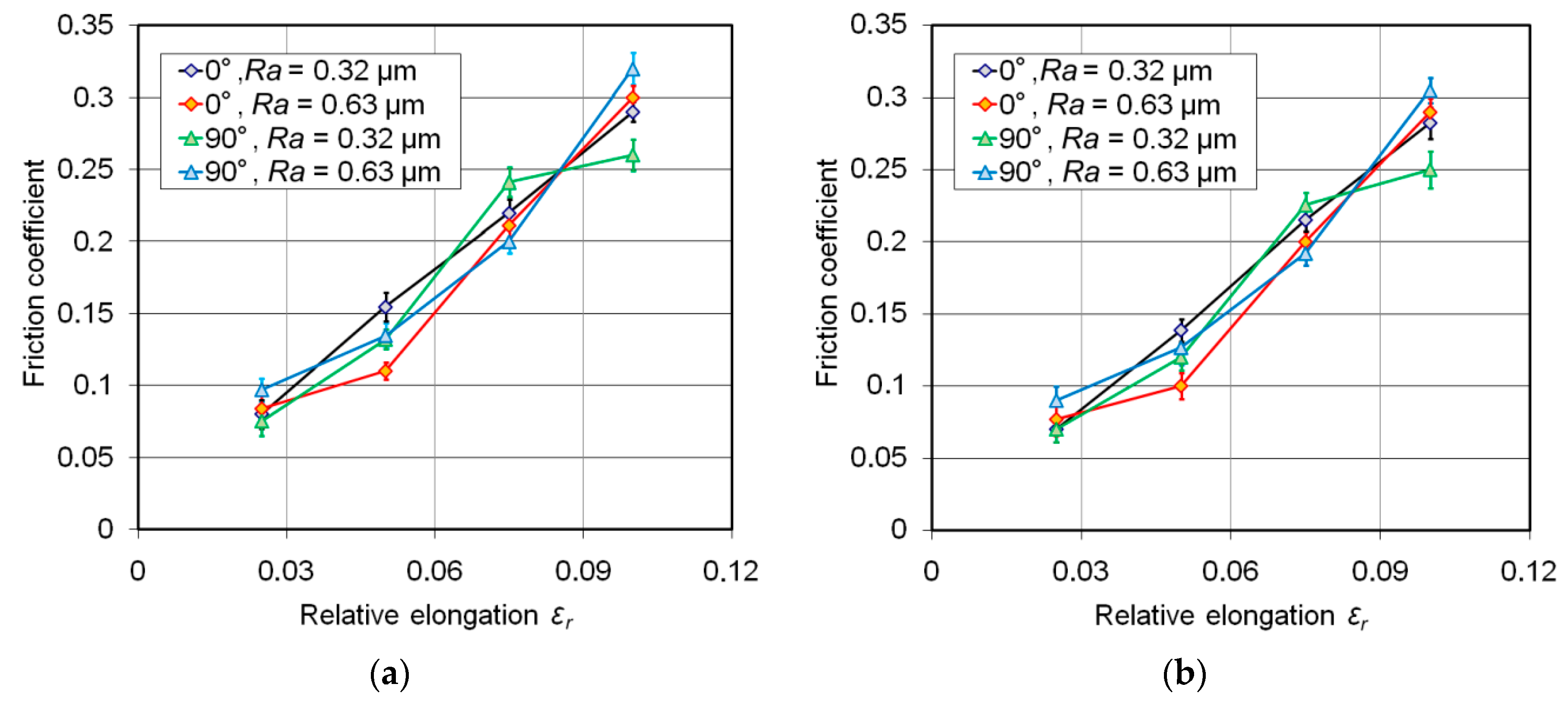

3.1. Bending under Tension Test

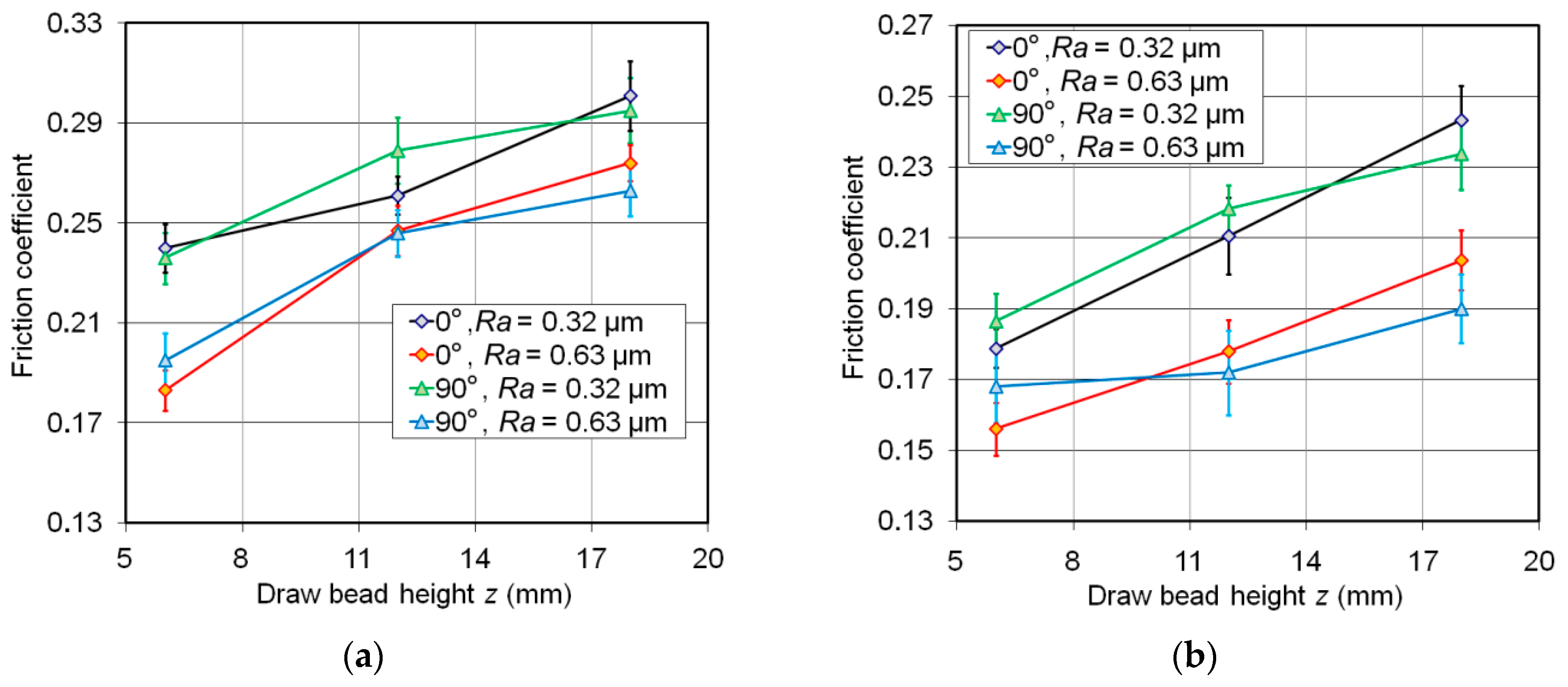

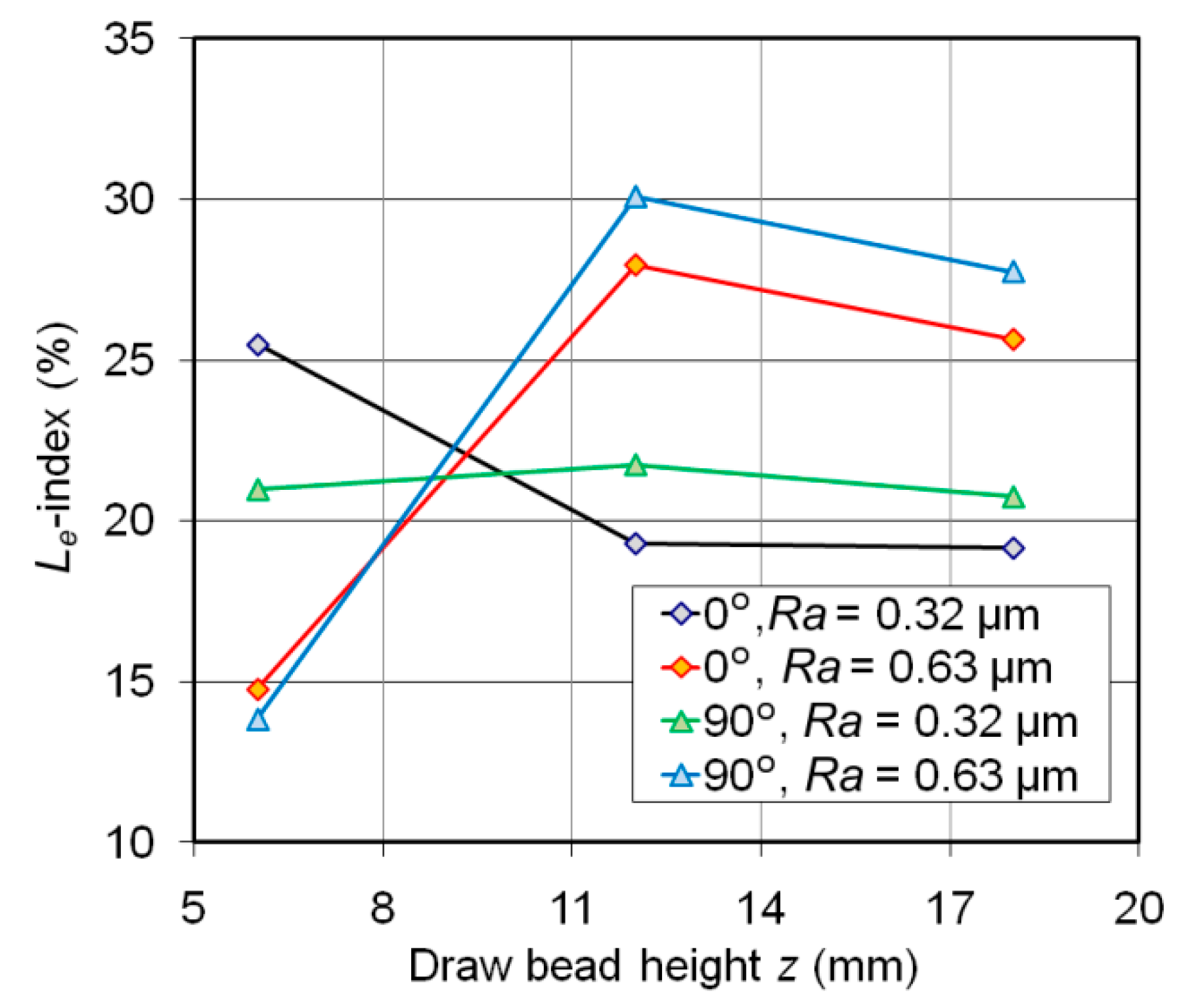

3.2. Draw Bead Test

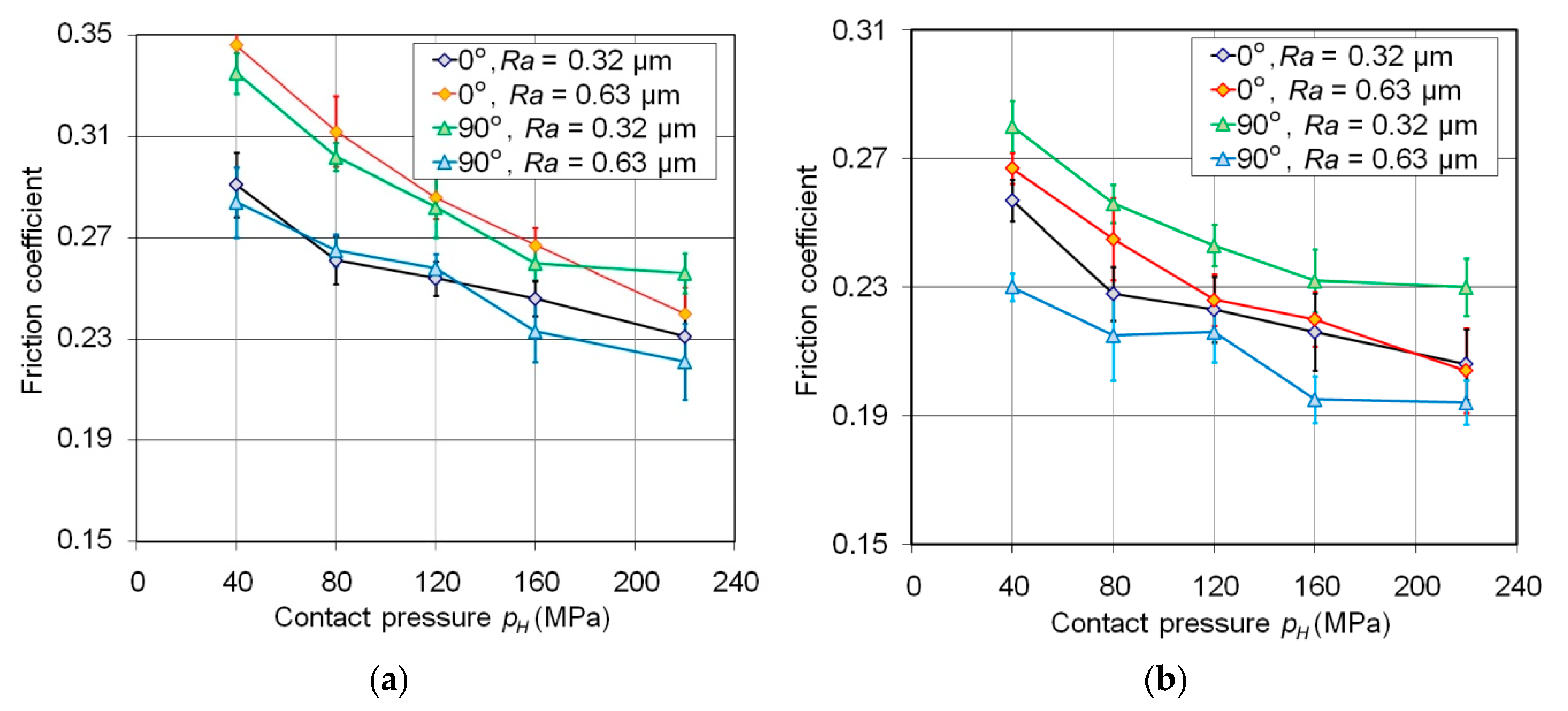

3.3. Strip Drawing Test

4. Conclusions

- −

- the specimens tested in the BUT test exhibit a tendency to an increase in the value of the coefficient of friction with the increasing relative elongation; this relationship is observed for both the specimen orientations and contact conditions analysed; the lubricant reduced the coefficient of friction, but the intensity of its action in the test results analysed depends on the specimen orientation and the value of the surface roughness of the counter-samples; for both sample orientations, the greatest efficiency of lubrication is observed for the small values of sheet deformation,

- −

- in the DBT, the most pronounced differences in friction were due to the surface roughness, while the orientation showed to have only a minor influence; moreover, an increase in the draw bead height leads to an increase in the value of the coefficient of friction,

- −

- in the SDT, the value of the coefficient of friction decreases as the contact pressure increases for both dry and lubricated conditions; the effectiveness of the reduction of the coefficient of friction by the lubricant clearly depended on the specimen orientation and surface roughness of the counter-samples.

Funding

Conflicts of Interest

References

- Altan, T.; Tekkaya, A.E. Sheet Metal Forming Processes and Applications; ASM International: Materials Park, OH, USA, 2012. [Google Scholar]

- Nielsen, C.V.; Bay, N. Overview of friction modelling in metal forming processes. Procedia Eng. 2017, 207, 2257–2262. [Google Scholar] [CrossRef] [Green Version]

- Trzepieciński, T.; Bazan, A.; Lemu, H.G. Frictional characteristics of steel sheets used in automotive industry. Int. J. Automot. Technol. 2015, 16, 849–863. [Google Scholar] [CrossRef]

- Masters, L.G.; Williams, D.K.; Roy, R. Friction behaviour in strip draw test of pre-stretched high strength automotive aluminium alloys. Int. J. Mach. Tools Manuf. 2013, 73, 17–24. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Lemu, H.G. Effect of computational parameters on springback prediction by numerical simulation. Metals 2017, 7, 380. [Google Scholar] [CrossRef]

- Trzepieciński, T. 3D elasto-plastic FEM analysis of the sheet drawing of anisotropic steel sheet. Arch. Civ. Mech. Eng. 2010, 10, 95–106. [Google Scholar] [CrossRef]

- Bay, N.; Olsson, D.D.; Andreasen, J.L. Lubricant test methods for sheet metal forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kumar, K.; Kishore; Kailas, S.V. Influence of friction during forming processes—A study using a numerical simulation technique. Int. J. Adv. Manuf. Technol. 2009, 40, 1067–1076. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M.; Výrostek, M. Verification the numerical simulation of the strip drawing test by its physical model. Acta Mech. Slovaca 2016, 20, 14–21. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Lemu, H.G. Proposal for an experimental-numerical method for friction description in sheet metal forming. Stroj. Vestn. J. Mech. Eng. 2015, 61, 383–391. [Google Scholar] [CrossRef]

- Üstünyagiz, E.; Nielsen, C.V.; Christiansen, P.; Martins, P.A.F.; Bay, N. Continuous strip reduction test simulating tribological conditions in ironing. Procedia Eng. 2017, 207, 2286–2291. [Google Scholar] [CrossRef]

- Littlewood, M.; Wallace, J.F. The effect of surface finish and lubrication on the fictional variation involved in the sheet-metal-forming process. Sheet Met. Ind. 1964, 41, 925–1930. [Google Scholar]

- Zhang, S.; Hodgson, P.D.; Duncan, J.L.; Cardew-Hall, M.J.; Kalyanasundaram, S. Effect of membrane stress on surface roughness changes in sheet forming. Wear 2002, 253, 610–617. [Google Scholar] [CrossRef]

- Nine, H.D. Drawbead forces in sheet metal forming. In Mechanics of Sheet Metal Forming, 1st ed.; Koistinen, D.P., Wang, N.M., Eds.; Springer: Boston, MA, USA, 1978; pp. 179–211. [Google Scholar]

- Nanayakkara, N.K.B.M.P.; Kelly, G.L.; Hodgson, P.D. Determination of the coefficient of friction in partially penetrated draw beads. Steel Grips 2004, 2, 677–680. [Google Scholar]

- Ter Haar, R. Friction in Sheet Metal Forming, the Influence of (Local) Contact Conditions and Deformation. Ph.D. Thesis, Universiteit Twente, Enschede, Holland, 1996. [Google Scholar]

| Orientation | Rp0.2, MPa | Rm, MPa | K, MPa | n |

|---|---|---|---|---|

| 0° | 162 | 310 | 554 | 0.217 |

| 90° | 163 | 312 | 530 | 0.210 |

| Sa (μm) | Sq (μm) | Sz (μm) | Sp (μm) | Sv (μm) | St (μm) |

|---|---|---|---|---|---|

| 1.31 | 1.53 | 9.41 | 4.41 | 6.98 | 11.39 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzepiecinski, T. A Study of the Coefficient of Friction in Steel Sheets Forming. Metals 2019, 9, 988. https://doi.org/10.3390/met9090988

Trzepiecinski T. A Study of the Coefficient of Friction in Steel Sheets Forming. Metals. 2019; 9(9):988. https://doi.org/10.3390/met9090988

Chicago/Turabian StyleTrzepiecinski, Tomasz. 2019. "A Study of the Coefficient of Friction in Steel Sheets Forming" Metals 9, no. 9: 988. https://doi.org/10.3390/met9090988

APA StyleTrzepiecinski, T. (2019). A Study of the Coefficient of Friction in Steel Sheets Forming. Metals, 9(9), 988. https://doi.org/10.3390/met9090988