Effect of Severe Plastic Deformation on the Conductivity and Strength of Copper-Clad Aluminium Conductors

Abstract

1. Introduction

2. Material and Experimental Techniques

3. Results and Discussion

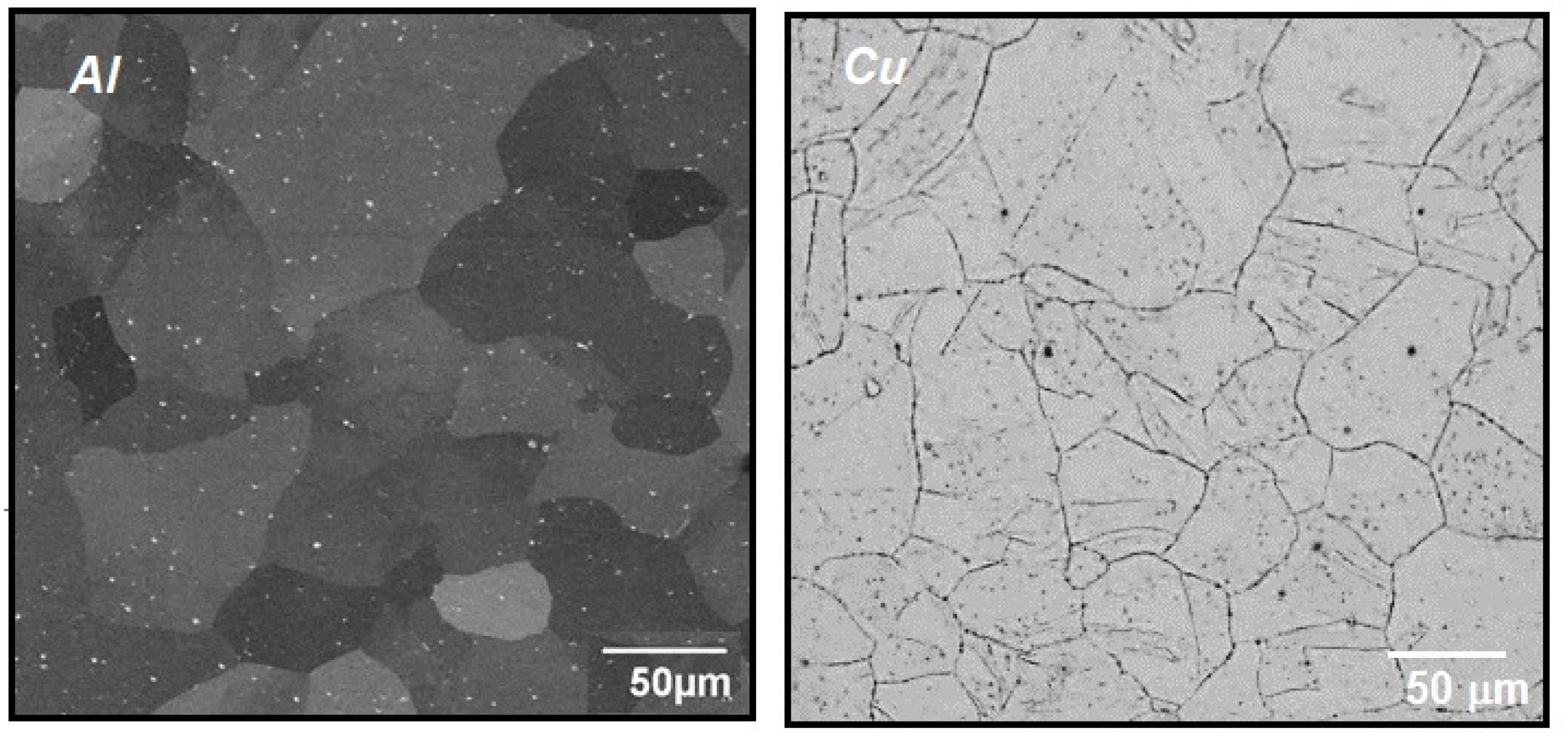

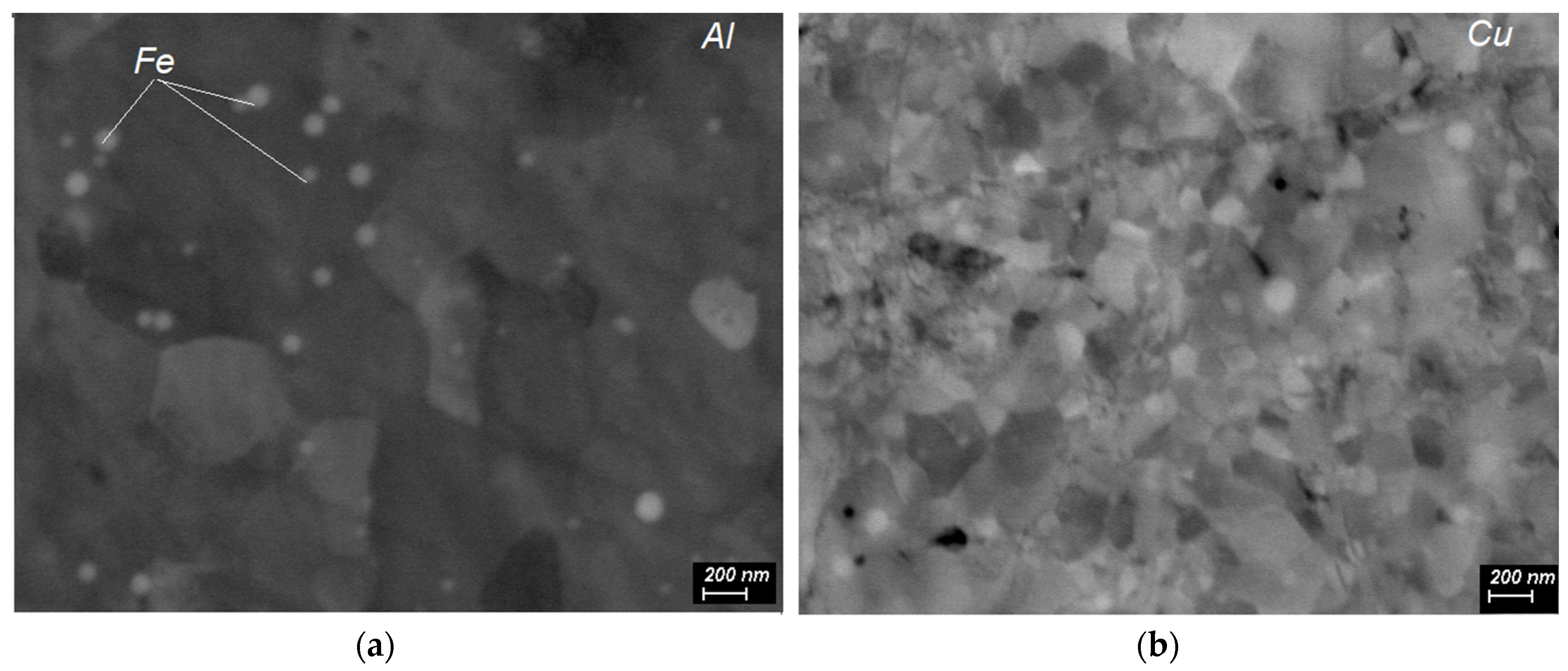

3.1. The Grain Refinement during SPD and Annealing

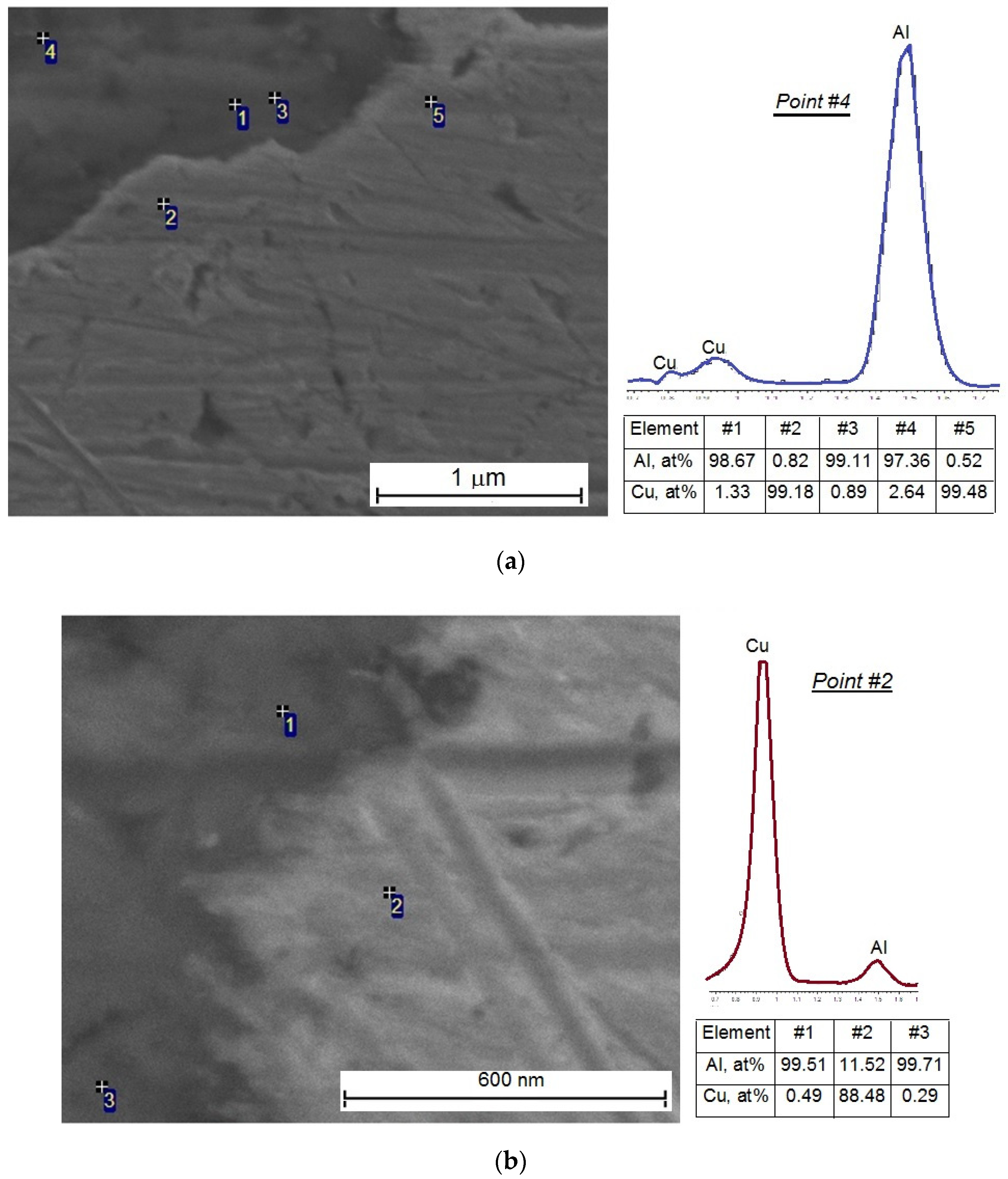

3.2. Interface Formation during Room Temperature Deformation

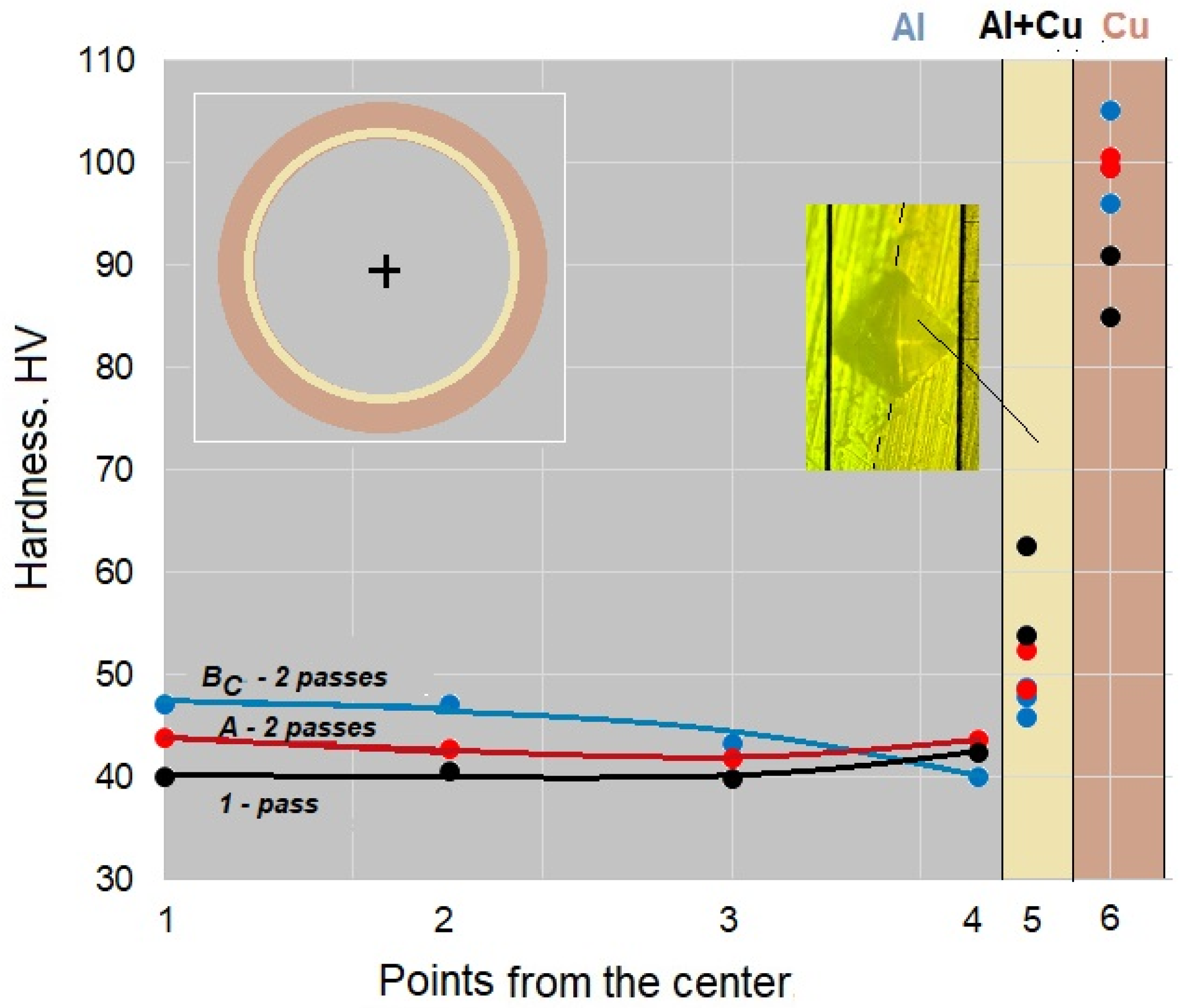

3.3. Hardness

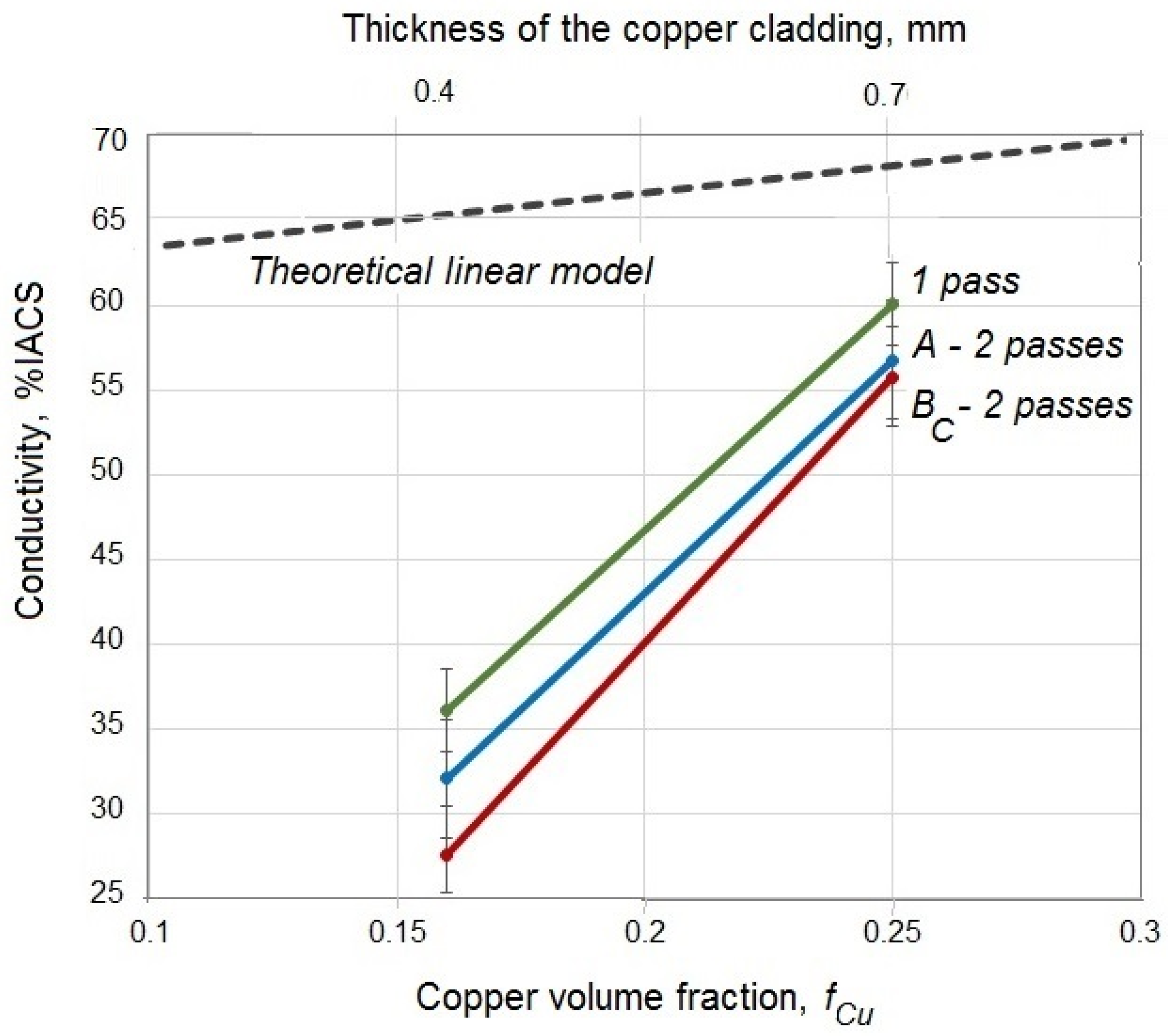

3.4. Electrical Conductivity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Read, D. Copper Clad Aluminum in Electrical Application. SAE Trans. 1968, 77, 1920–1931. [Google Scholar] [CrossRef]

- Miller, J.M. Effective Resistance and Inductance of Iron and Bimetallic Wires; Classic Reprint Series; Forgotten Books Publisher: London, UK, 2019; p. 76. [Google Scholar]

- Hug, E.; Bellido, N. Brittleness study of intermetallic (Cu, Al) layers in copper-clad aluminium thin wires. Mater. Sci. Eng. A 2011, 528, 7103–7106. [Google Scholar] [CrossRef]

- Braunovic, M.; Rodrigue, L.; Gagnon, D. Nanoindentation Study of Intermetallic Phases in Al-Cu Bimetallic System. In Proceedings of the 2008 IEEE 54th Holm Conference on Electrical Contacts, Orlando, FL, USA, 27–29 October 2008. [Google Scholar] [CrossRef]

- Pfeifer, S.; Großmann, S.; Freudenberger, R.; Willing, H.; Kappl, H. Characterization of Intermetallic Compounds in Al-Cu-Bimetallic Interfaces. In Proceedings of the 2012 IEEE 58th Holm Conference on Electrical Contacts, Portland, OR, USA, 23–26 September 2012. [Google Scholar] [CrossRef]

- D’Heurle, F.; Alliota, C.; Angilello, J.; Brusic, V.; Dempsey, J.; Irmischer, D. The deposition by evaporation of Cu-Al alloy films. Vacuum 1997, 27, 321–327. [Google Scholar] [CrossRef]

- Murray, J.L. The Aluminium-Copper System. Int. Met. Rev. 1985, 30, 211–233. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation: Ten Years Later. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Qi, Y.; Lapovok, R.; Estrin, Y. Microstructure and electrical conductivity of aluminium/steel bimetallic rods processed by severe plastic deformation. J. Mater. Sci. 2016, 51, 6860–6875. [Google Scholar] [CrossRef]

- Lapovok, R.; Ng, H.P.; Thomus, D.; Estrin, Y. Bimetallic Copper-Aluminium Tube by Severe Plastic Deformation. Scr. Mater. 2012, 66, 1081–1084. [Google Scholar] [CrossRef]

- Lapovok, R.; Qi, Y.; Ng, H.P.; Toth, L.S.; Estrin, Y. Gradient structures in thin-walled metallic tubes produced by continuous high pressure tube shearing process. Adv. Eng. Mater. 2017, 19, 1700345. [Google Scholar] [CrossRef]

- Wang, Y.L.; Lapovok, R.; Wang, J.T.; Qi, Y.S.; Estrin, Y. Thermal behavior of copper processed by ECAP with and without back pressure. Mater. Sci. Eng. A 2015, 628, 21–29. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Lapovok, R.; Koch, E.; Höppel, H.W.; Göken, M. Optimisation of Interface Formation by Shear Inclination: Example of Aluminium-Cooper Hybrid Produced by ECAP with Back-Pressure. Mater. Des. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Mendes, A.; Timokhina, I.; Molotnikov, A.; Hodgson, P.; Lapovok, R. Role of Shear in Interface Formation of Aluminium-Steel Multilayered Composite Sheets. Mater. Sci. Eng. A 2017, 705, 142–152. [Google Scholar] [CrossRef]

- Renk, O.; Hohenwarter, A.; Schuh, B.; Li, J.H.; Pippan, R. Hardening by annealing: Insights from different alloys. In Proceedings of the 36th Risø International Symposium on Materials Science, Risø, Denmark, 7–11 September 2015; IOP Publishing: Bristol, UK, 2015; Volume 89. [Google Scholar] [CrossRef]

- Cengeri, P.; Kerber, M.B.; Schafler, E.; Zehetbauer, M.J.; Setman, D. Strengthening during heat treatment of HPT processed copper and nickel. Mater. Sci. Eng. A 2019, 742, 124–131. [Google Scholar] [CrossRef]

- Medvedev, A.; Murashkin, M.; Enikeev, N.; Valiev, R.Z.; Hodgson, P.D.; Lapovok, R. Optimization of strength-electrical conductivity properties in Al-2Fe alloy by severe plastic deformation and heat treatment. Adv. Eng. Mater. 2018, 20, 1700867. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lapovok, R.; Dubrovsky, M.; Kosinova, A.; Raab, G. Effect of Severe Plastic Deformation on the Conductivity and Strength of Copper-Clad Aluminium Conductors. Metals 2019, 9, 960. https://doi.org/10.3390/met9090960

Lapovok R, Dubrovsky M, Kosinova A, Raab G. Effect of Severe Plastic Deformation on the Conductivity and Strength of Copper-Clad Aluminium Conductors. Metals. 2019; 9(9):960. https://doi.org/10.3390/met9090960

Chicago/Turabian StyleLapovok, Rimma, Michael Dubrovsky, Anna Kosinova, and Georgy Raab. 2019. "Effect of Severe Plastic Deformation on the Conductivity and Strength of Copper-Clad Aluminium Conductors" Metals 9, no. 9: 960. https://doi.org/10.3390/met9090960

APA StyleLapovok, R., Dubrovsky, M., Kosinova, A., & Raab, G. (2019). Effect of Severe Plastic Deformation on the Conductivity and Strength of Copper-Clad Aluminium Conductors. Metals, 9(9), 960. https://doi.org/10.3390/met9090960