Improving Strength and Ductility of a Mg-3.7Al-1.8Ca-0.4Mn Alloy with Refined and Dispersed Al2Ca Particles by Industrial-Scale ECAP Processing

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

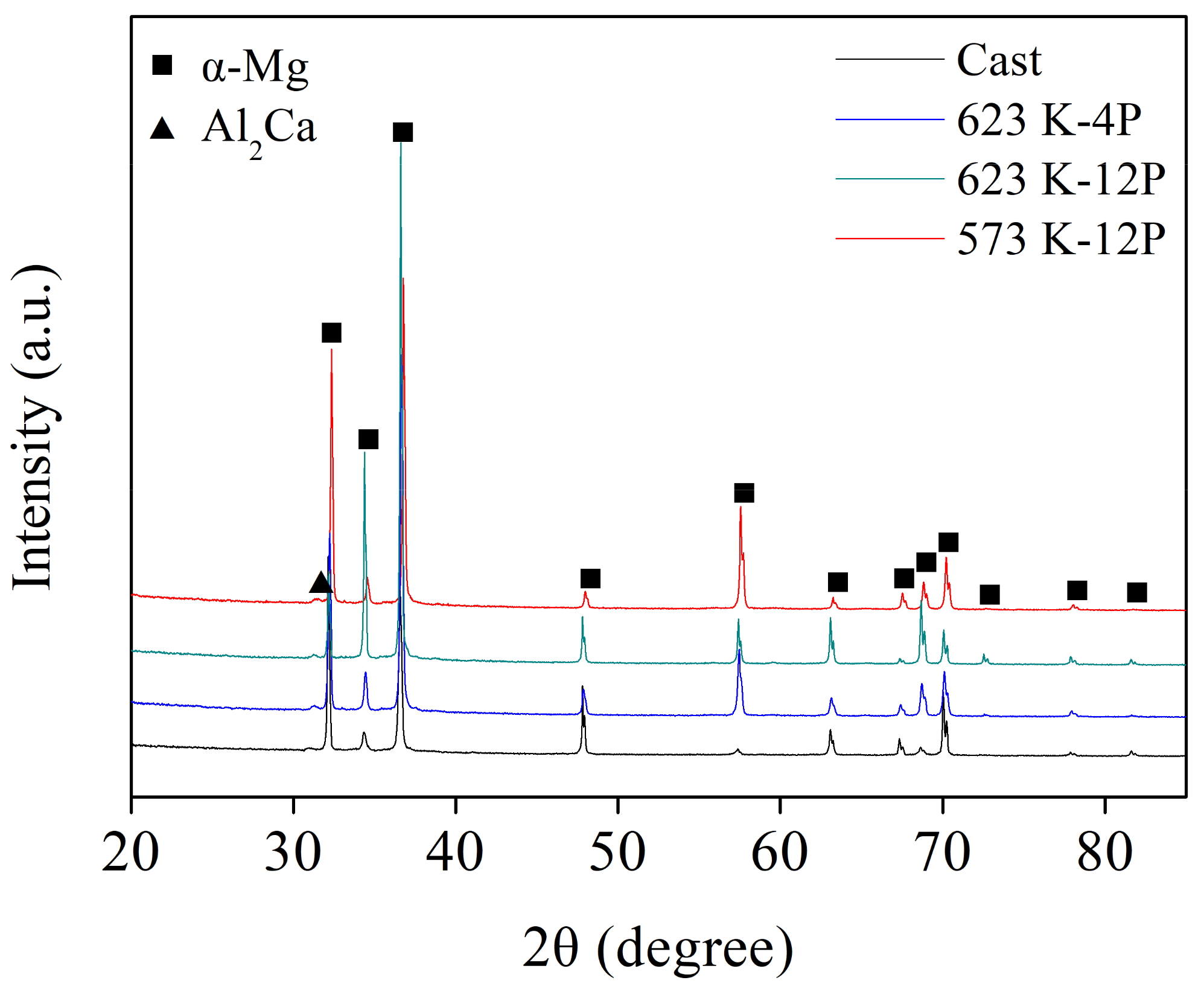

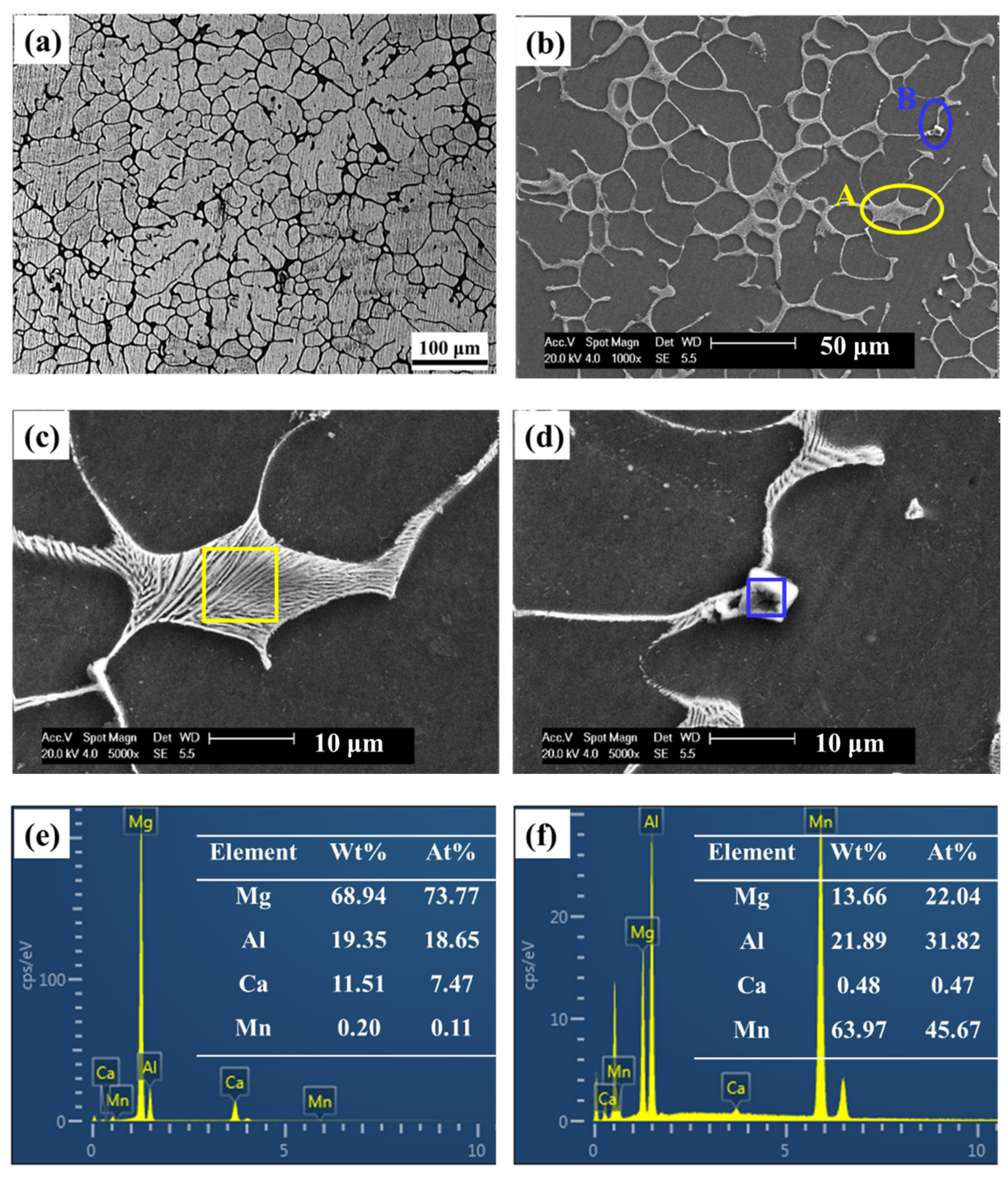

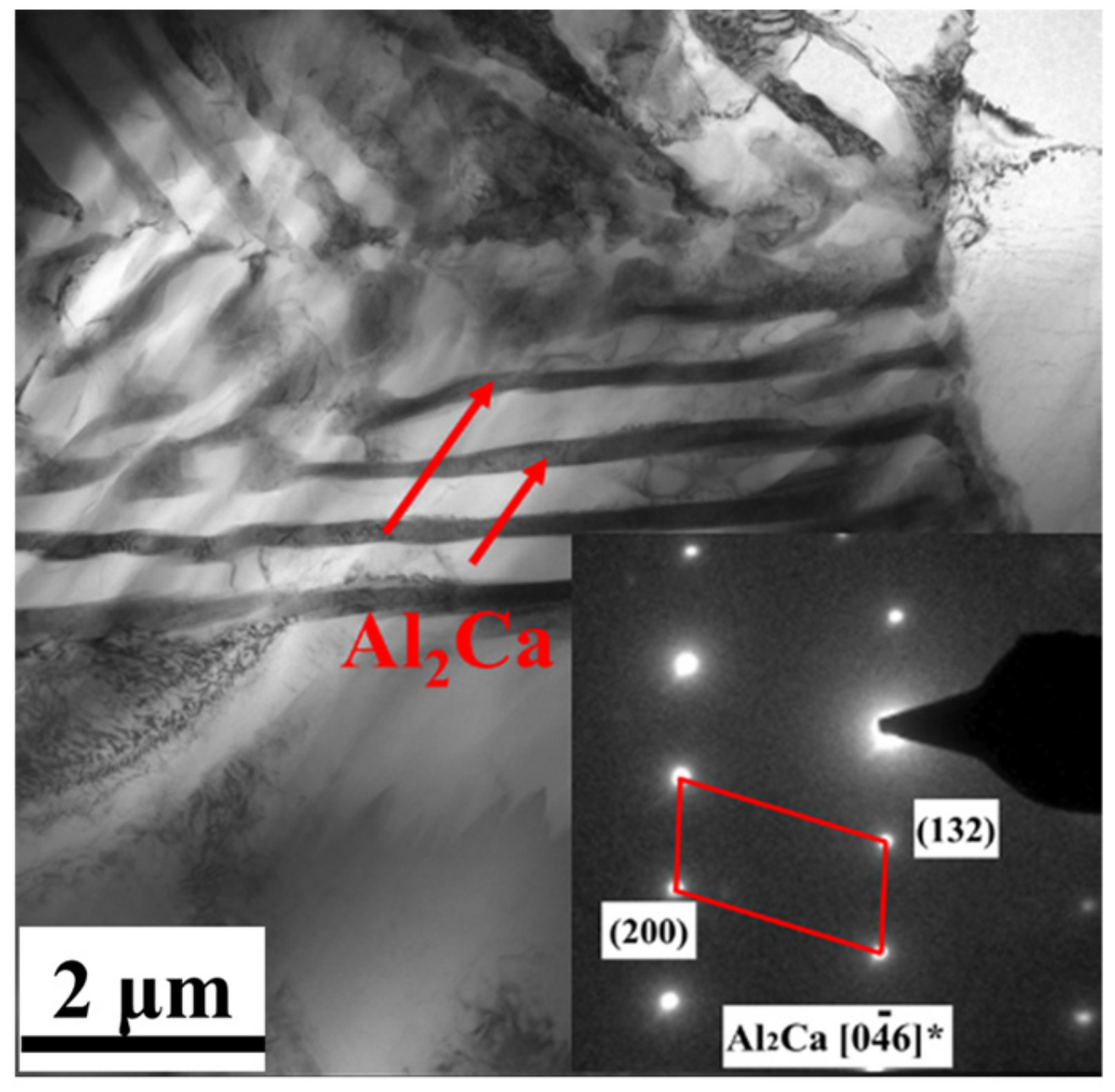

3.1. Microstructure of As-Cast Alloy

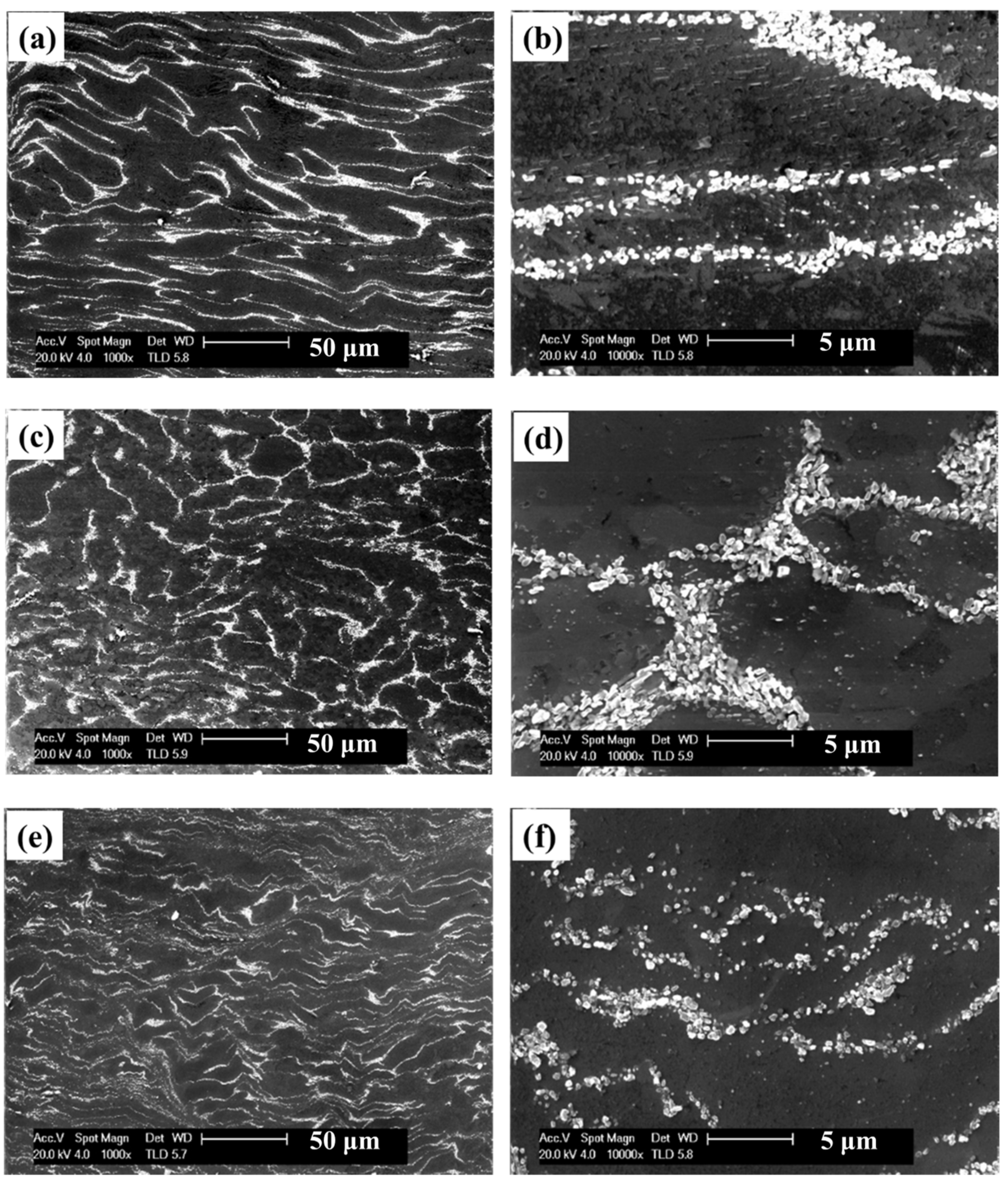

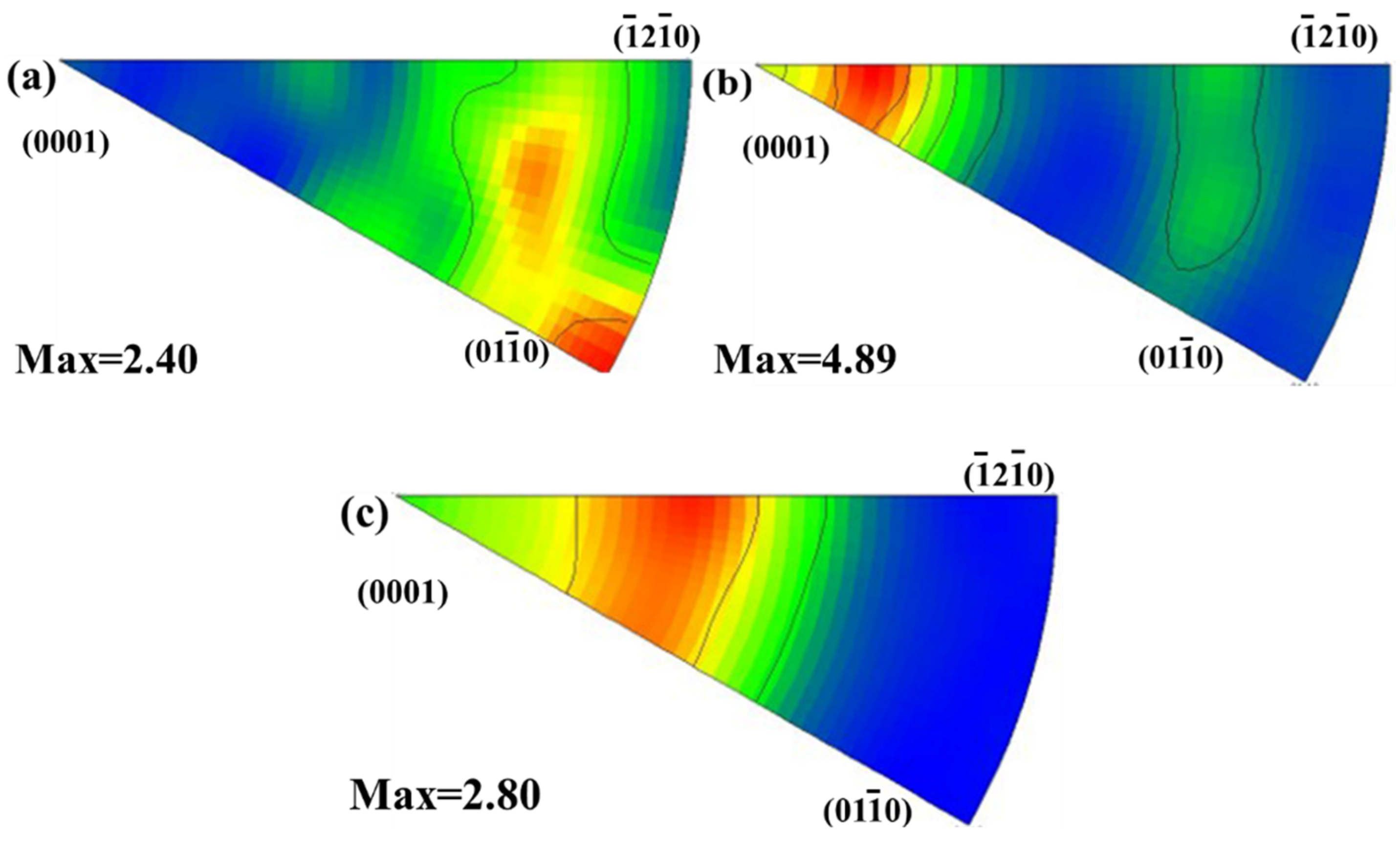

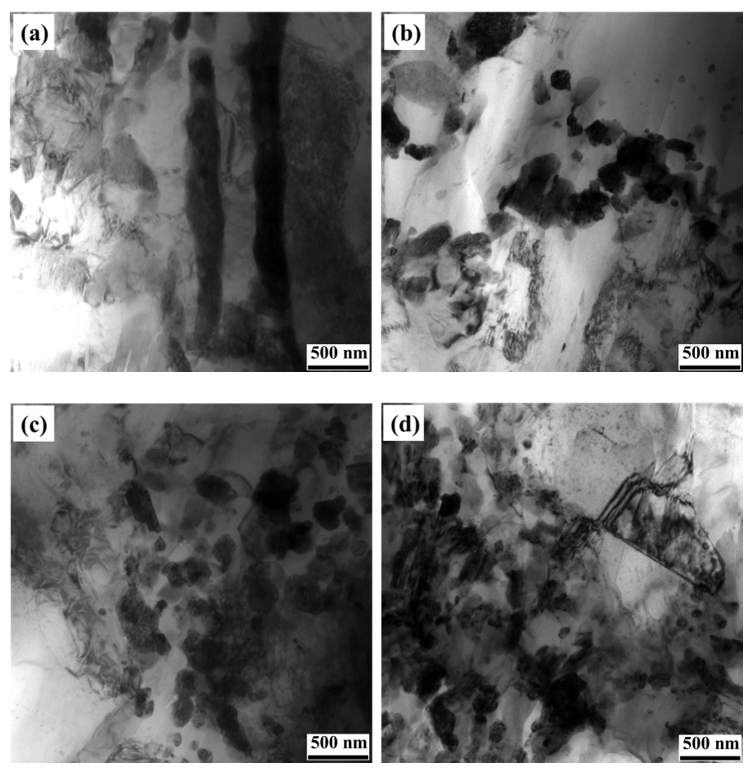

3.2. Microstructure of ECAP Alloys

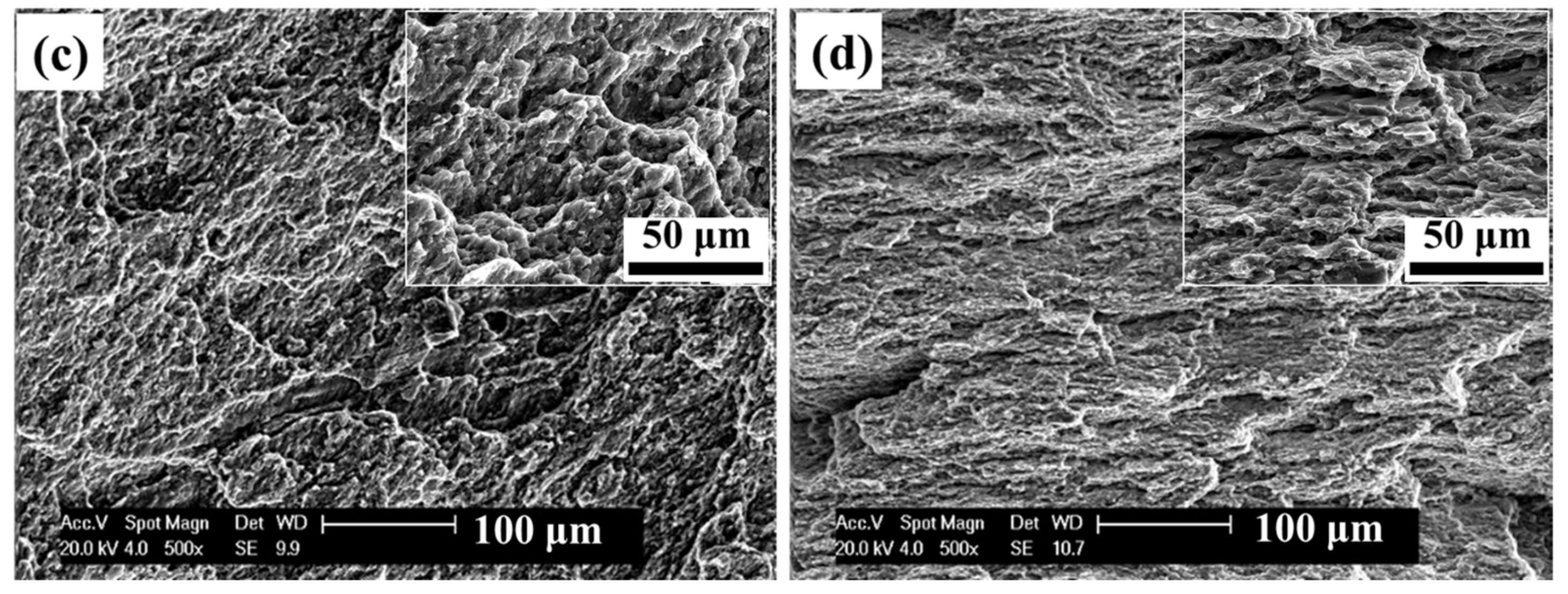

3.3. Microstructure of ECAP Alloys

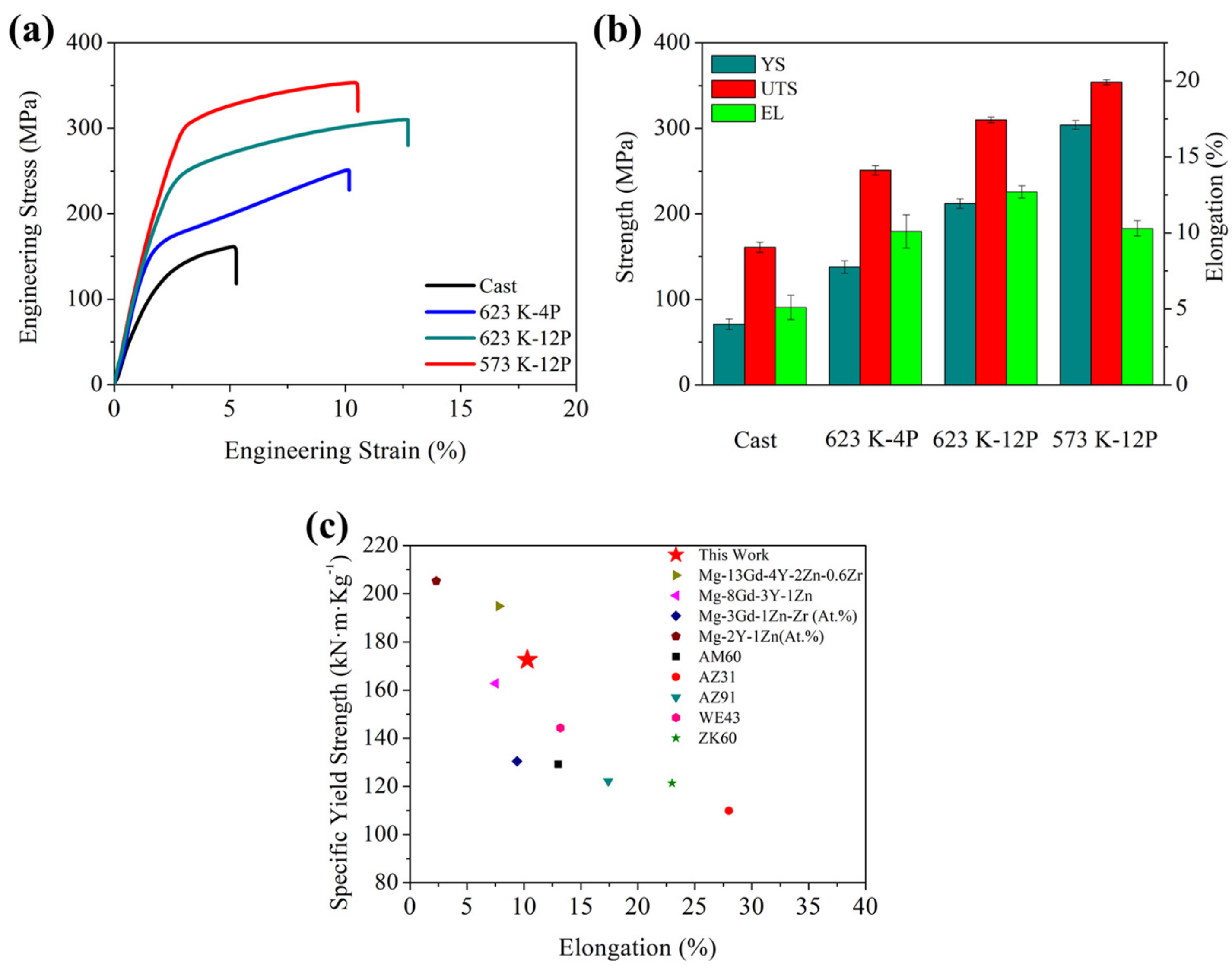

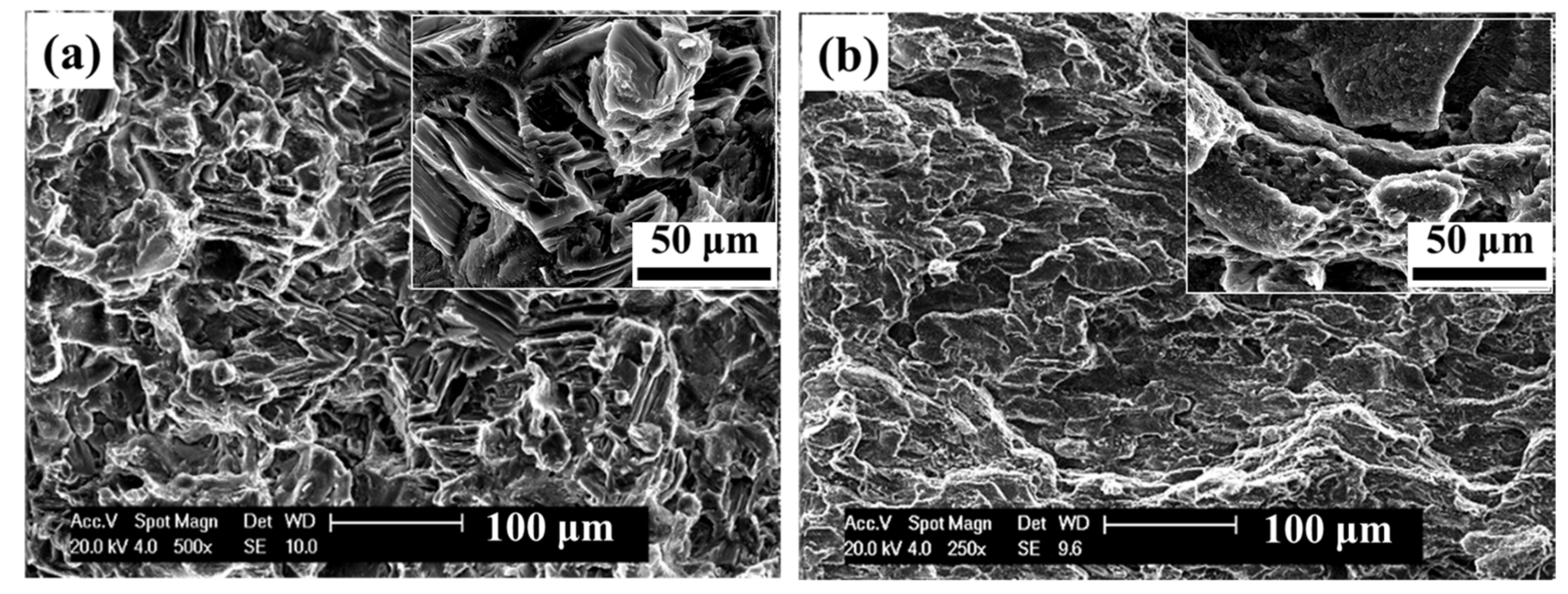

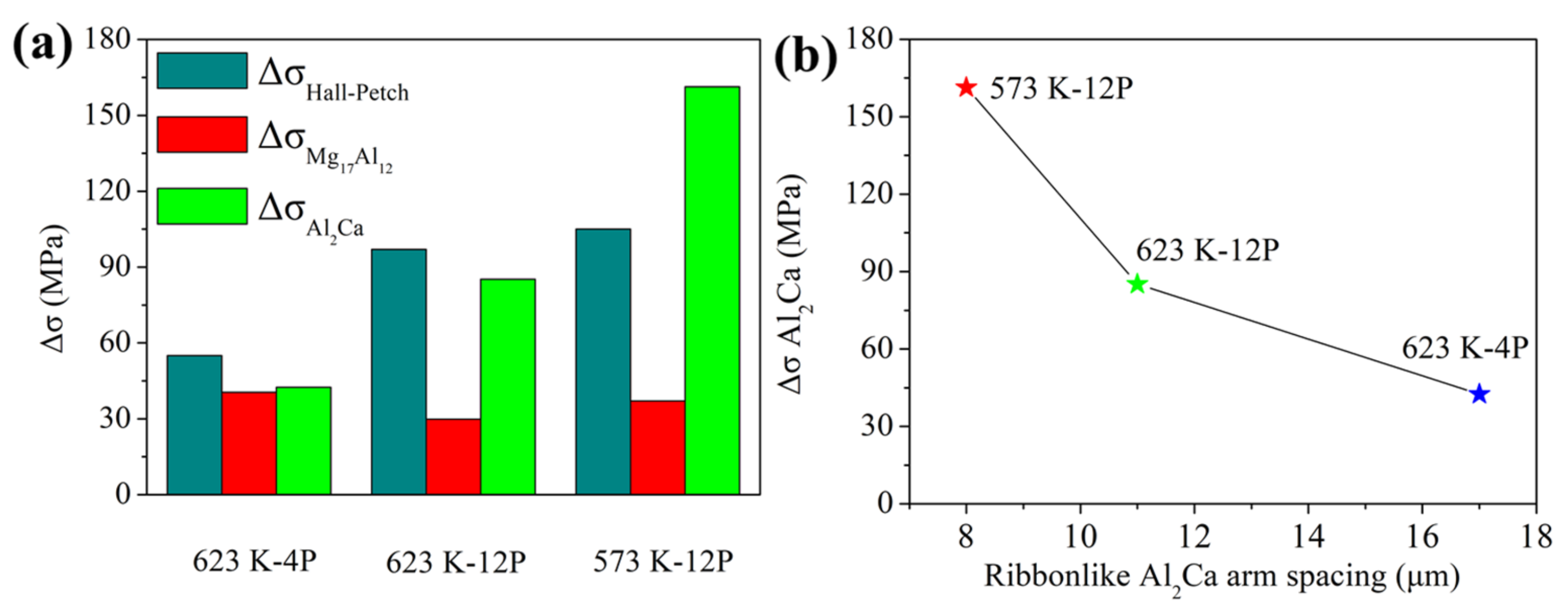

3.4. Influence of Al2Ca Size and Distribution on Mechanical Properties

4. Conclusions

- (1)

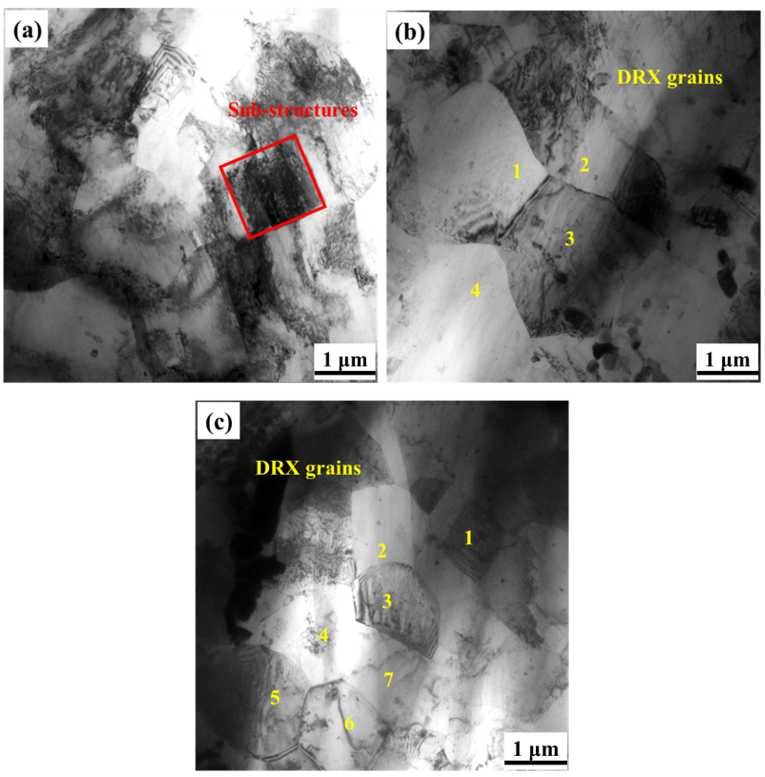

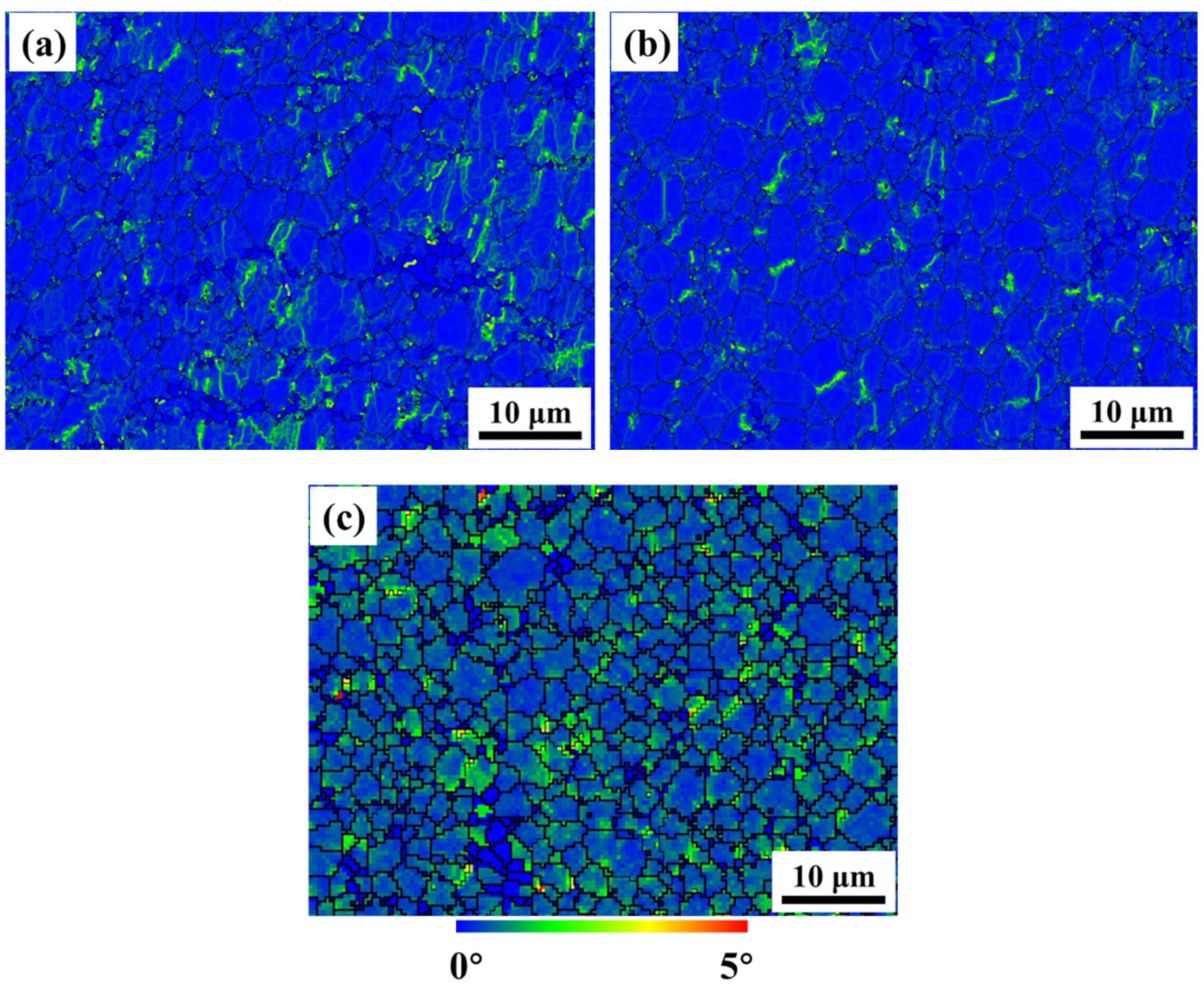

- The microstructure of as-cast Mg-3.5Al-1.7Ca-0.4Mn (wt %) alloy was composed of interdendritic α-Mg grains, network Al2Ca phase and a few Al8Mn5 particles. During multi-pass ECAP, the Al2Ca network phase was gradually broken into ultrafine particles. More ECAP passes and lower processing temperature resulted in finer sizes and a more dispersed distribution of Al2Ca particles, as well as finer α-Mg grains.

- (2)

- Multi-pass ECAP simultaneously enhanced the tensile strength and ductility of Mg-3.5Al-1.8Ca-0.4Mn alloy. The 573 K-12p processed alloy exhibited superior mechanical properties with a tensile yield strength of 304 MPa, ultimate tensile strength of 354 MPa and elongation of 10.3%. The improved comprehensive mechanical performance could be attributed to refined DRX grains, nano-sized Mg17Al12 precipitates and dispersed Al2Ca particles. Moreover, quantitative contribution analysis suggested that the refined and dispersedly distributed Al2Ca particles played a dominant role in strengthening the Al2Ca containing alloys.

Author Contributions

Funding

Data Availability

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Magnesium: Properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Yamashita, A.; Horita, Z.; Langdon, T.G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater. Sci. Eng. A 2001, 300, 142–147. [Google Scholar] [CrossRef]

- Song, M.S.; Zeng, R.C.; Ding, Y.F.; Li, R.W.; Easton, M.; Cole, I.; Birbilis, N.; Chen, X.B. Recent advances in biodegradation controls over Mg alloys for bone fracture management: A review. J. Mater. Sci. Technol. 2019, 35, 535–544. [Google Scholar] [CrossRef]

- Wang, B.J.; Wang, S.D.; Xu, D.K.; Han, E.H. Recent progress in the research about fatigue behavior of Mg alloys in air and aqueous medium: A review. J. Mater. Sci. Technol. 2017, 33, 1075–1086. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Sun, J.P.; Wang, C.; Bai, J.; Ma, A.B.; Chen, X.H. Microstructure and mechanical properties of Mg-RE-TM cast alloys containing long period stacking ordered phases: A review. Acta. Metall. Sin. Engl. 2019, 32, 269–285. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Wang, C.; Ju, J.; Sun, J.; Wu, Y.; Jiang, J.; Ma, A. Comparative study of two aging treatments on microstructure and mechanical properties of an ultra-fine grained Mg-10Y-6Gd-1.5Zn-0.5Zr alloy. Metals 2018, 8, 658. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Wang, C.; Sun, J.; Bai, J.; Xue, F.; Ma, A.; Chen, X.B. Recent advances in LPSO-containing wrought magnesium alloys: Relationships between processing, microstructure, and mechanical properties. JOM 2019, 1–14. [Google Scholar] [CrossRef]

- Zhang, J.H.; Liu, S.J.; Wu, R.Z.; Hou, L.G.; Zhang, M.L. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magnes. Alloy 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Pan, H.C.; Qin, G.W.; Huang, Y.M.; Ren, Y.P.; Sha, X.C.; Han, X.D.; Liu, Z.Q.; Li, C.F.; Wu, X.L.; Chen, H.W.; et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Fu, L.; Le, Q.C.; Tang, Y.; Sun, J.Y.; Jia, Y.H.; Song, Z.T. Effect of Ca and RE additions on microstructures and tensile properties of AZ31 alloys. Mater. Res. Express 2018, 5, 056521. [Google Scholar] [CrossRef]

- Cheng, C.; Lan, Q.; Wang, A.; Le, Q.; Yang, F.; Li, X. Effect of Ca additions on ignition temperature and multi-Stage oxidation behavior of AZ80. Metals 2018, 8, 766. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, J.U.; Kim, Y.J.; Moon, B.G.; You, B.S.; Kim, H.S.; Parka, S.H. Improvement in extrudability and mechanical properties of AZ91 alloy through extrusion with artificial cooling. Mater. Sci. Eng. A 2017, 703, 1–8. [Google Scholar] [CrossRef]

- Kang, J.W.; Sun, X.F.; Deng, K.K.; Xu, F.J.; Zhang, X.; Bai, Y. High strength Mg-9Al serial alloy processed by slow extrusion. Mater. Sci. Eng. A 2017, 697, 211–216. [Google Scholar] [CrossRef]

- Han, L.; Hu, H.; Northwood, D.O. Effect of Ca additions on microstructure and microhardness of an as-cast Mg–5.0 wt. % Al alloy. Mater. Lett. 2008, 62, 381–384. [Google Scholar] [CrossRef]

- Kondori, B.; Mahmudi, R. Effect of Ca additions on the microstructure and creep properties of a cast Mg-Al-Mn magnesium alloy. Mater. Sci. Eng. A 2017, 700, 438–447. [Google Scholar] [CrossRef]

- Xu, S.W.; Oh-ishi, K.; Kamado, S.; Uchida, F.; Homma, T.; Hono, K. High-strength extruded Mg-Al-Ca-Mn alloy. Scr. Mater. 2011, 65, 269–272. [Google Scholar] [CrossRef]

- Li, Z.T.; Zhang, X.D.; Zheng, M.Y.; Qiao, X.G.; Wu, K.; Xu, C.; Kamado, S. Effect of Ca/Al ratio on microstructure and mechanical properties of Mg-Al-Ca-Mn alloys. Mater. Sci. Eng. A 2017, 682, 423–432. [Google Scholar] [CrossRef]

- Li, Z.T.; Qiao, X.G.; Xu, C.; Kamado, S.; Zheng, M.Y.; Luo, A.A. Ultrahigh strength Mg-Al-Ca-Mn extrusion alloys with various aluminum contents. J. Alloys Compd. 2019, 792, 130–141. [Google Scholar] [CrossRef]

- Khorasani, F.; Emamy, M.; Malekan, M.; Mirzadeh, H.; Pourbahari, B.; Krajnák, T.; Minárik, P. Enhancement of the microstructure and elevated temperature mechanical properties of as-cast Mg-Al2Ca-Mg2Ca in-situ composite by hot extrusion. Mater. Charact. 2019, 147, 155–164. [Google Scholar] [CrossRef]

- Wang, C.; Ma, A.; Sun, J.; Liu, H.; Huang, H.; Yang, Z.; Jiang, J. Effect of ECAP process on as-cast and as-homogenized Mg-Al-Ca-Mn alloys with different Mg2Ca morphologies. J. Alloys Compd. 2019, 793, 259–270. [Google Scholar] [CrossRef]

- Watanabe, H.; Yamaguchi, M.; Takigawa, Y.; Higashi, K. Mechanical properties of Mg-Al-Ca alloy processed by hot extrusion. Mater. Sci. Eng. A 2007, 454, 384–388. [Google Scholar] [CrossRef]

- Zhou, D.W.; Liu, J.S.; Peng, P.; Chen, L.; Hu, Y.J. A first-principles study on the structural stability of Al2Ca Al4Ca and Mg2Ca phases. Mater. Lett. 2008, 62, 206–210. [Google Scholar] [CrossRef]

- Jiang, Z.T.; Jiang, B.; Yang, H.; Yang, Q.S.; Dai, J.H.; Pan, F.S. Influence of the Al2Ca phase on microstructure and mechanical properties of Mg-Al-Ca alloys. J. Alloys Compd. 2015, 647, 357–363. [Google Scholar] [CrossRef]

- Su, K.; Deng, K.K.; Xu, F.J.; Nie, K.B.; Zhang, L.; Zhang, X.; Li, W.J. Effect of extrusion temperature on the microstructure and mechanical properties of Mg-5Al-2Ca alloy. Acta. Metall. Sin. Engl. 2015, 28, 1015–1023. [Google Scholar] [CrossRef]

- Homma, T.; Hirawatari, S.; Sunohara, H.; Kamado, S. Room and elevated temperature mechanical properties in the as-extruded Mg-Al-Ca-Mn alloys. Mater. Sci. Eng. A 2012, 539, 163–169. [Google Scholar] [CrossRef]

- Jin, L.; Lin, D.L.; Mao, D.L.; Zeng, X.Q.; Ding, W.J. Mechanical properties and microstructure of AZ31 Mg alloy processed by two-step equal channel angular extrusion. Mater. Lett. 2005, 59, 2267–2270. [Google Scholar] [CrossRef]

- Sun, J.P.; Yang, Z.Q.; Han, J.; Liu, H.; Song, D.; Jiang, J.H.; Ma, A.B. High strength and ductility AZ91 magnesium alloy with multi-heterogenous microstructures prepared by high-temperature ECAP and short-time aging. Mater. Sci. Eng. A 2018, 734, 485–490. [Google Scholar] [CrossRef]

- Garces, G.; Pérez, P.; Barea, R.; Medina, J.; Stark, A.; Schell, N.; Adeva, P. Increase in the mechanical strength of Mg-8Gd-3Y-1Zn alloy containing long-period stacking ordered phases using equal channel angular pressing processing. Metals 2019, 9, 221. [Google Scholar] [CrossRef]

- Chen, B.; Lin, D.L.; Zeng, X.Q.; Lu, C. Microstructure and mechanical properties of ultrafine grained Mg97Y2Zn1 alloy processed by equal channel angular pressing. J. Alloys Compd. 2007, 440, 94–100. [Google Scholar] [CrossRef]

- Zhang, J.S.; Zhang, W.B.; Bian, L.P.; Cheng, W.L.; Niu, X.F.; Xu, C.X.; Wu, S.J. Study of Mg-Gd-Zn-Zr alloys with long period stacking ordered structures. Mater. Sci. Eng. A 2013, 585, 268–276. [Google Scholar] [CrossRef]

- Martynenko, N.S.; Lukyanova, E.A.; Serebryany, V.N.; Gorshenkov, M.V.; Shchetinin, I.V.; Raab, G.I.; Dobatkin, S.V.; Estrin, Y. Increasing strength and ductility of magnesium alloy WE43 by equal-channel angular pressing. Mater. Sci. Eng. A 2018, 712, 625–629. [Google Scholar] [CrossRef]

- Ma, A.B.; Nishida, Y.; Suzuki, K.; Shigematsu, I.; Saito, N. Characteristics of plastic deformation by rotary-die equal-channel angular pressing. Scr. Mater. 2005, 52, 433–437. [Google Scholar] [CrossRef]

- Jin, L.; Lin, D.L.; Mao, D.L.; Zeng, X.Q.; Ding, W.J. An electron back-scattered diffraction study on the microstructure evolution of AZ31 Mg alloy during equal channel angular extrusion. J. Alloys Compd. 2006, 426, 148–154. [Google Scholar] [CrossRef]

- Rong, W.; Zhang, Y.; Wu, Y.J.; Chen, Y.L.; Sun, M.; Chen, J.; Peng, L.M. The role of bimodal-grained structure in strengthening tensile strength and decreasing yield asymmetry of Mg-Gd-Zn-Zr alloys. Mater. Sci. Eng. A 2019, 740, 262–273. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, A.; Liu, H.; Sun, J.; Song, D.; Wang, C.; Yuan, Y.; Jiang, J. Multimodal microstructure and mechanical properties of AZ91 Mg alloy prepared by equal channel angular pressing plus aging. Metals 2018, 8, 763. [Google Scholar] [CrossRef]

- Li, B.; Teng, B.G.; Chen, G.X. Microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy during equal channel angular pressing. Mater. Sci. Eng. A 2019, 744, 396–405. [Google Scholar] [CrossRef]

- Akbaripanah, F.; Saniee, F.F.; Mahmudi, R.; Kim, H.K. Microstructural homogeneity, texture, tensile and shear behavior of AM60 magnesium alloy produced by extrusion and equal channel angular pressing. Mater. Des. 2013, 43, 31–39. [Google Scholar] [CrossRef]

- Dumitru, F.D.; Cobos, O.F.H.; Cabrera, J.M. ZK60 alloy processed by ECAP: Microstructural, physical and mechanical characterization. Mater. Sci. Eng. A 2014, 594, 32–39. [Google Scholar] [CrossRef]

- Yu, H.H.; Xin, Y.C.; Wang, M.Y.; Liu, Q. Hall-petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar] [CrossRef]

- Sun, X.F.; Wang, C.J.; Deng, K.K.; Nie, K.B.; Zhang, X.C.; Xiao, X.Y. High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg17Al12 phase. J. Alloys Compd. 2018, 732, 328–335. [Google Scholar] [CrossRef]

- Yamasaki, M.; Hashimoto, K.; Hagihara, K.; Kawamura, Y. Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy. Acta Mater. 2011, 59, 3646–3658. [Google Scholar] [CrossRef]

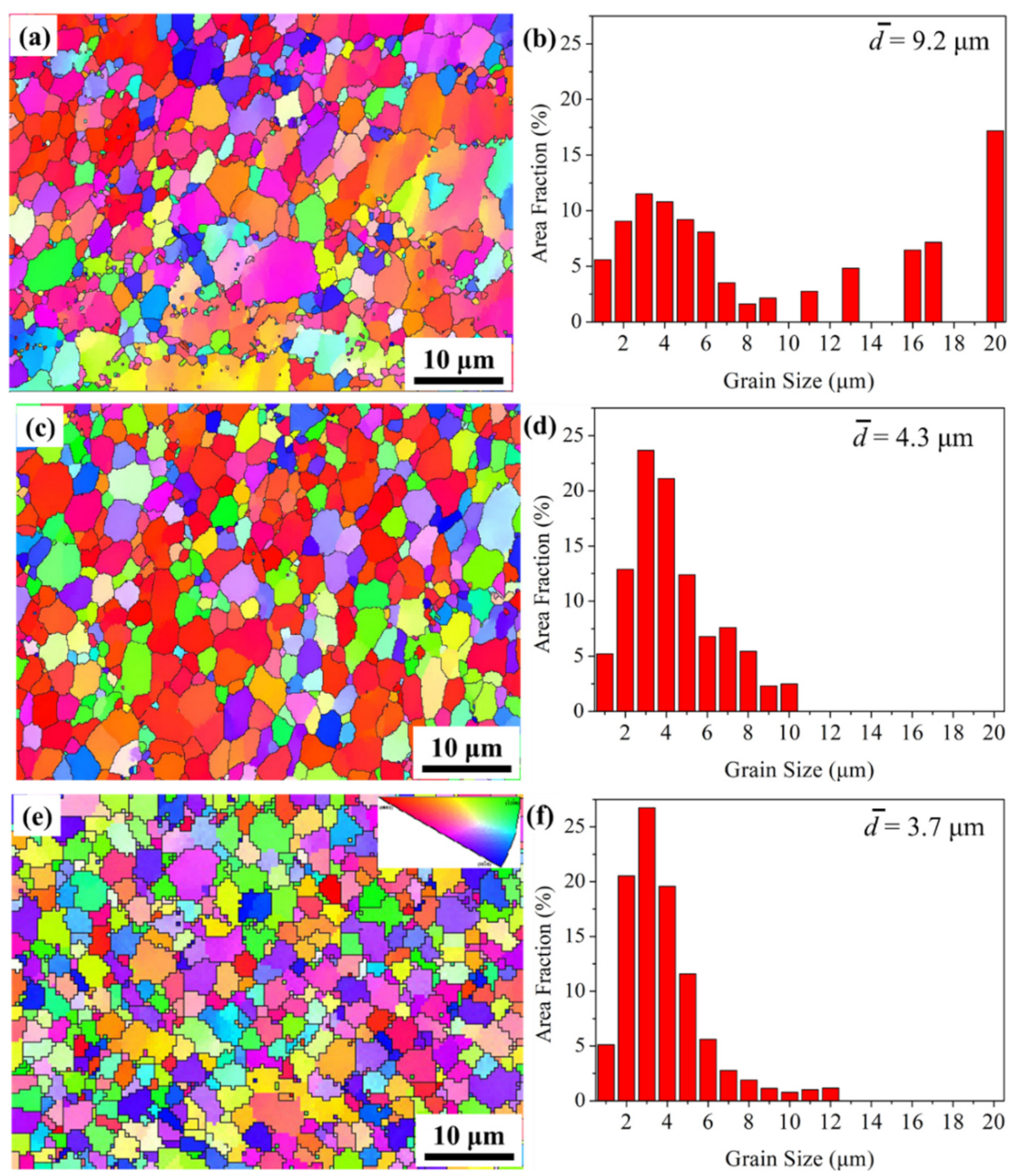

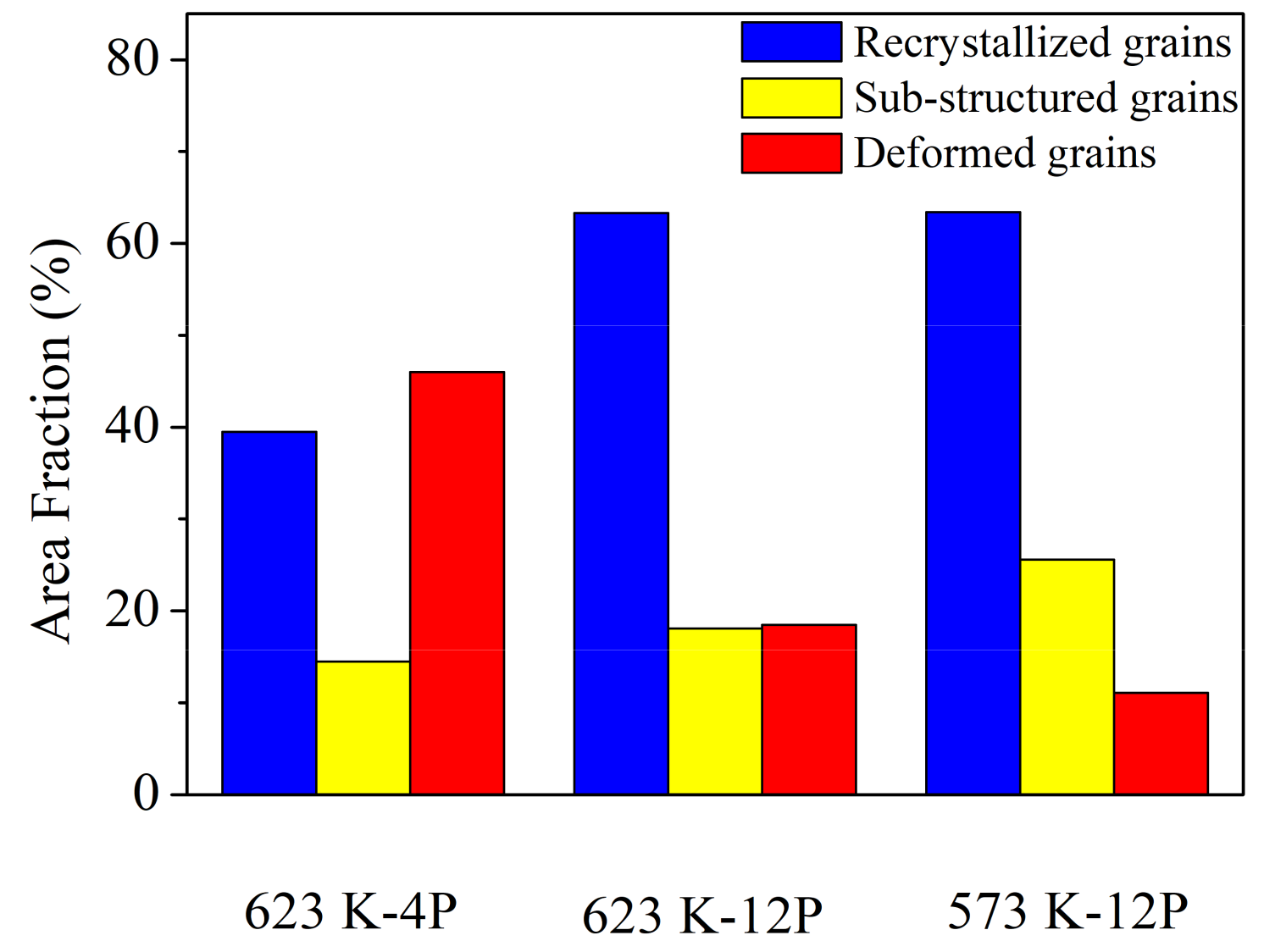

| Microstructural Characteristics | 623 K-4P | 623 K-12P | 573 K-12P |

|---|---|---|---|

| Grain (μm) | 9.2 ± 1.9 | 4.3 ± 1.5 | 3.7 ± 1.2 |

| Al2Ca (μm) | 0.6 ± 0.2 | 0.5 ± 0.2 | 0.3 ± 0.1 |

| Ribbonlike Al2Ca arm spacing (μm) | 17 ± 4 | 11 ± 2 | 8 ± 2 |

| Mg17Al12 (nm) | 12 ± 4 | 22 ± 7 | 14 ± 6 |

| Mg17Al12 volume fraction (%) | 2.5% | 6.7% | 6.1% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Ma, A.; Sun, J.; Zhuo, X.; Huang, H.; Liu, H.; Yang, Z.; Jiang, J. Improving Strength and Ductility of a Mg-3.7Al-1.8Ca-0.4Mn Alloy with Refined and Dispersed Al2Ca Particles by Industrial-Scale ECAP Processing. Metals 2019, 9, 767. https://doi.org/10.3390/met9070767

Wang C, Ma A, Sun J, Zhuo X, Huang H, Liu H, Yang Z, Jiang J. Improving Strength and Ductility of a Mg-3.7Al-1.8Ca-0.4Mn Alloy with Refined and Dispersed Al2Ca Particles by Industrial-Scale ECAP Processing. Metals. 2019; 9(7):767. https://doi.org/10.3390/met9070767

Chicago/Turabian StyleWang, Ce, Aibin Ma, Jiapeng Sun, Xiaoru Zhuo, He Huang, Huan Liu, Zhenquan Yang, and Jinghua Jiang. 2019. "Improving Strength and Ductility of a Mg-3.7Al-1.8Ca-0.4Mn Alloy with Refined and Dispersed Al2Ca Particles by Industrial-Scale ECAP Processing" Metals 9, no. 7: 767. https://doi.org/10.3390/met9070767

APA StyleWang, C., Ma, A., Sun, J., Zhuo, X., Huang, H., Liu, H., Yang, Z., & Jiang, J. (2019). Improving Strength and Ductility of a Mg-3.7Al-1.8Ca-0.4Mn Alloy with Refined and Dispersed Al2Ca Particles by Industrial-Scale ECAP Processing. Metals, 9(7), 767. https://doi.org/10.3390/met9070767