Development of a High Strength Mg-9Li Alloy via Multi-Pass ECAP and Post-Rolling

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Processing

2.2. Microstructure Characterization

2.3. Tensile Test

3. Results

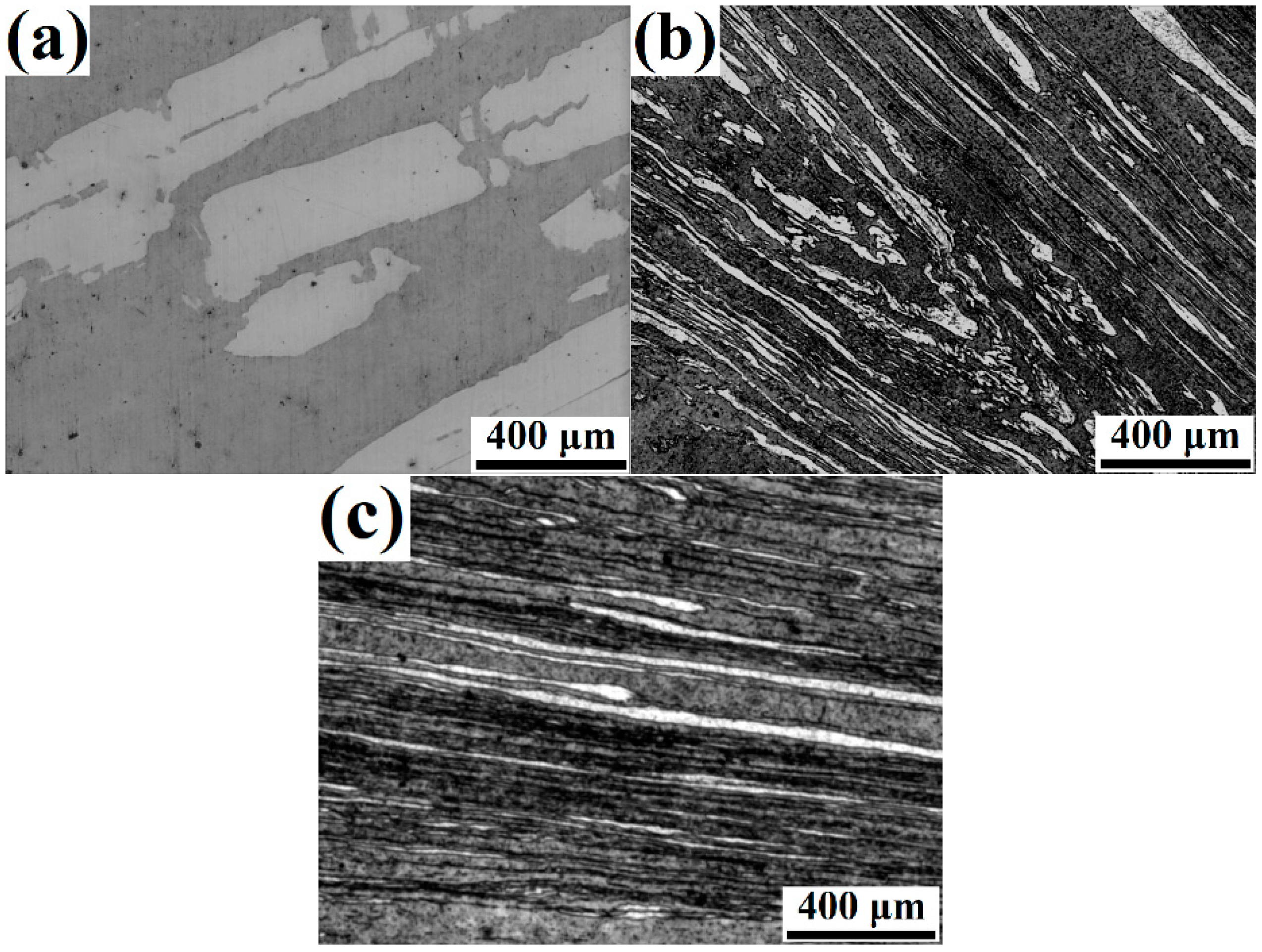

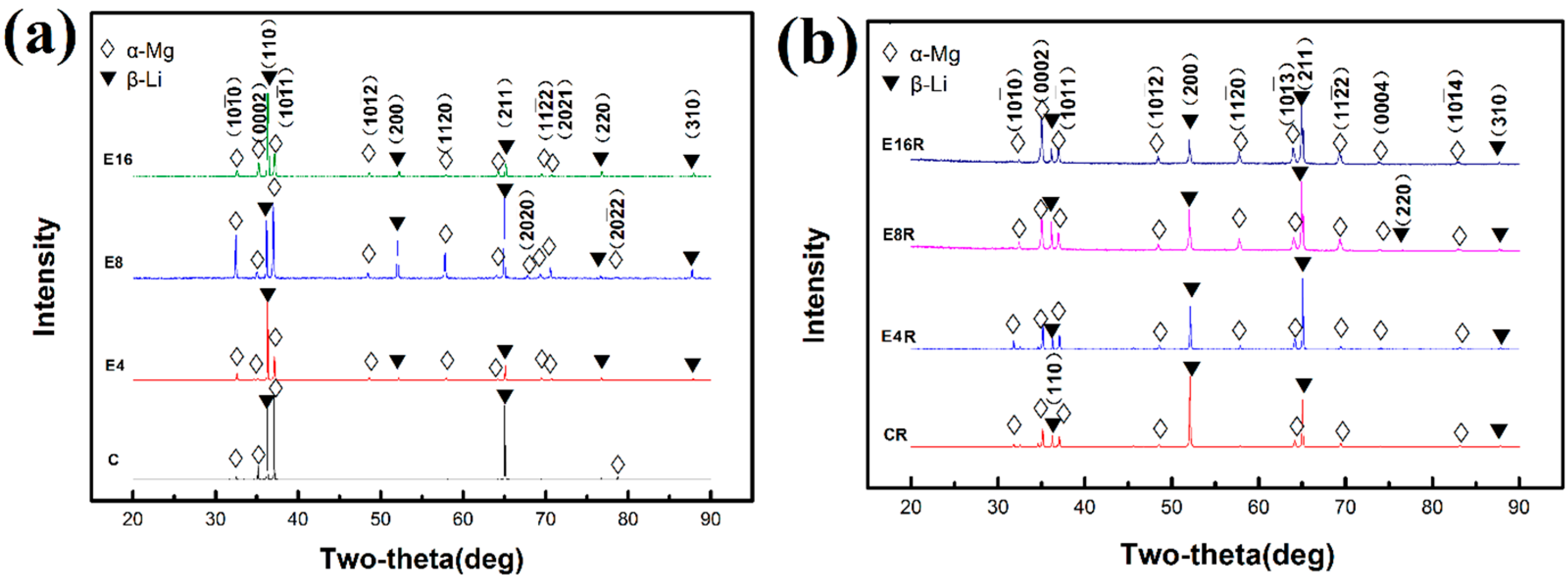

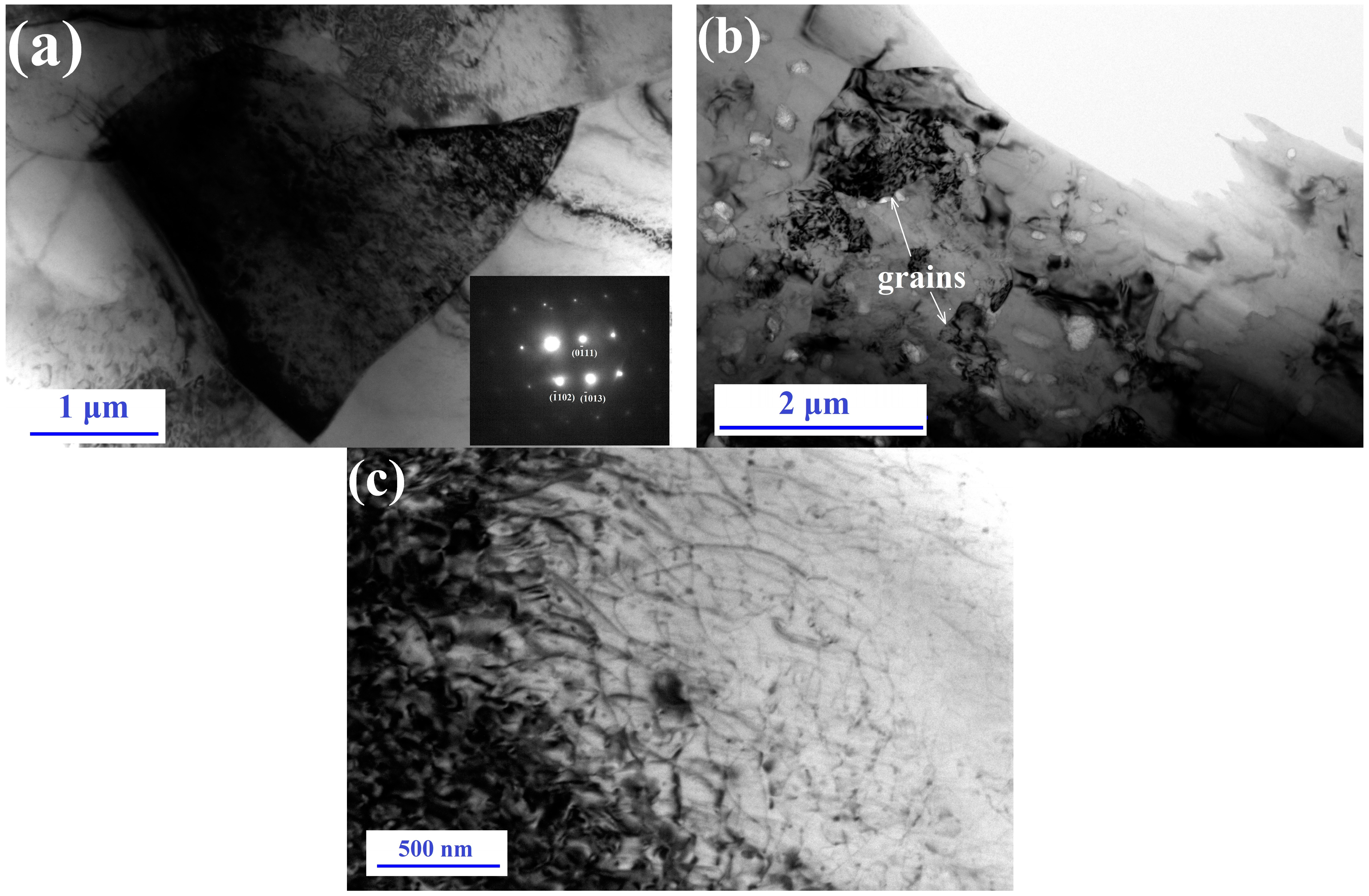

3.1. Microstructure of ECAPed and ECAP-Rolled Alloys

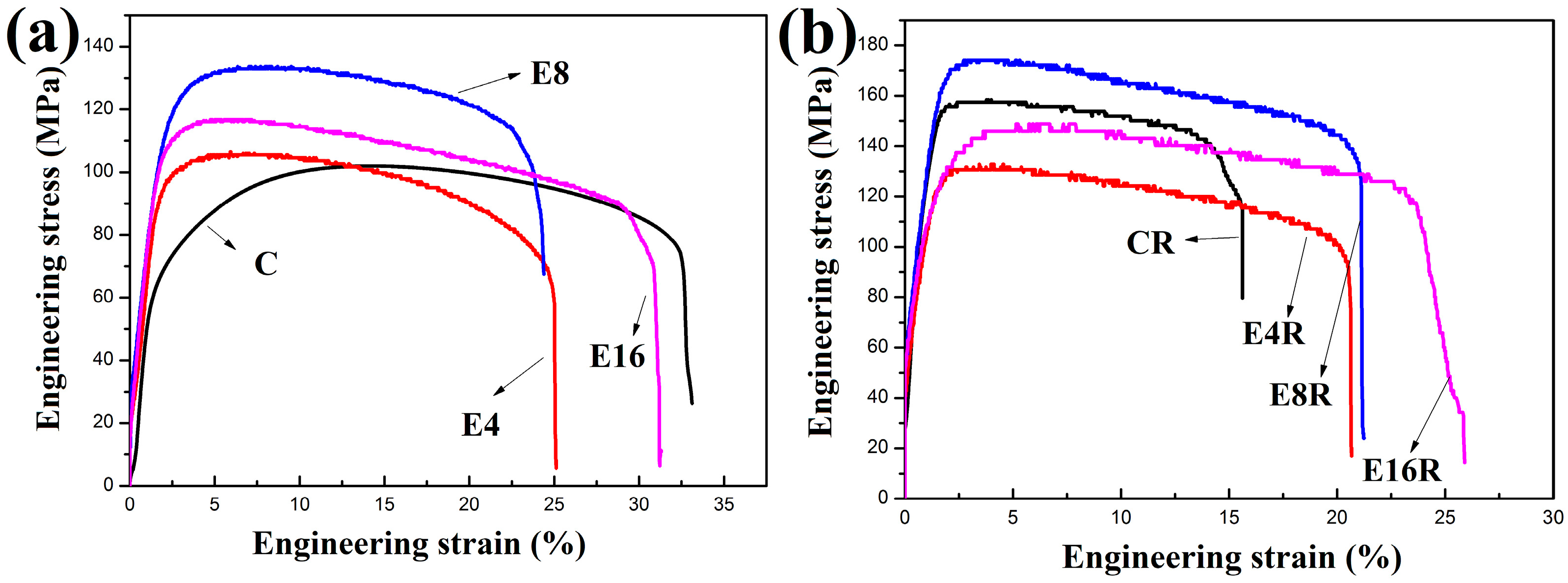

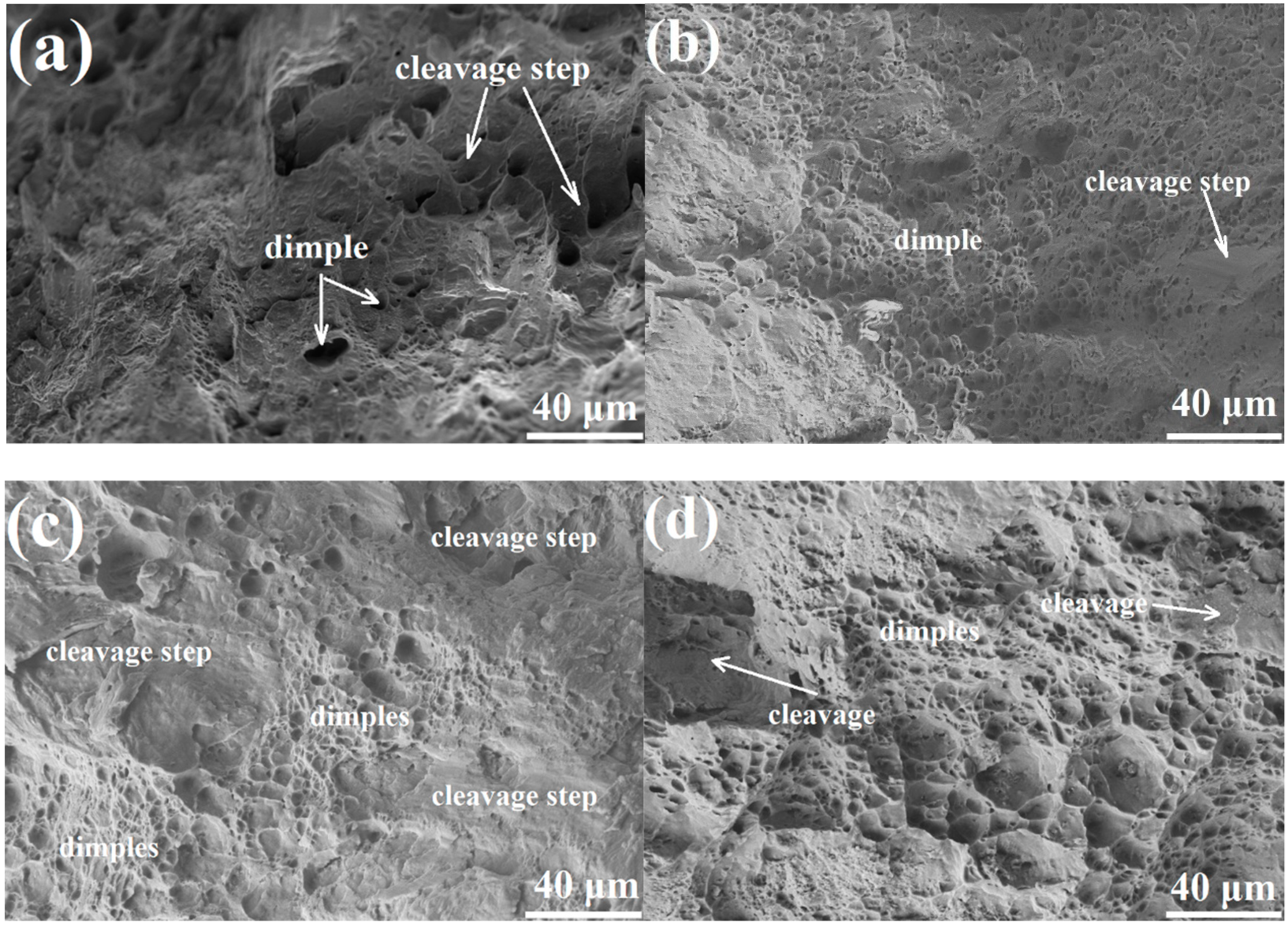

3.2. Tensile Mechanical Properties of the ECAPed and ECAP-Rolled Alloy

4. Discussion

4.1. Grain-Boundary Strengthening and Dislocation Strengthening

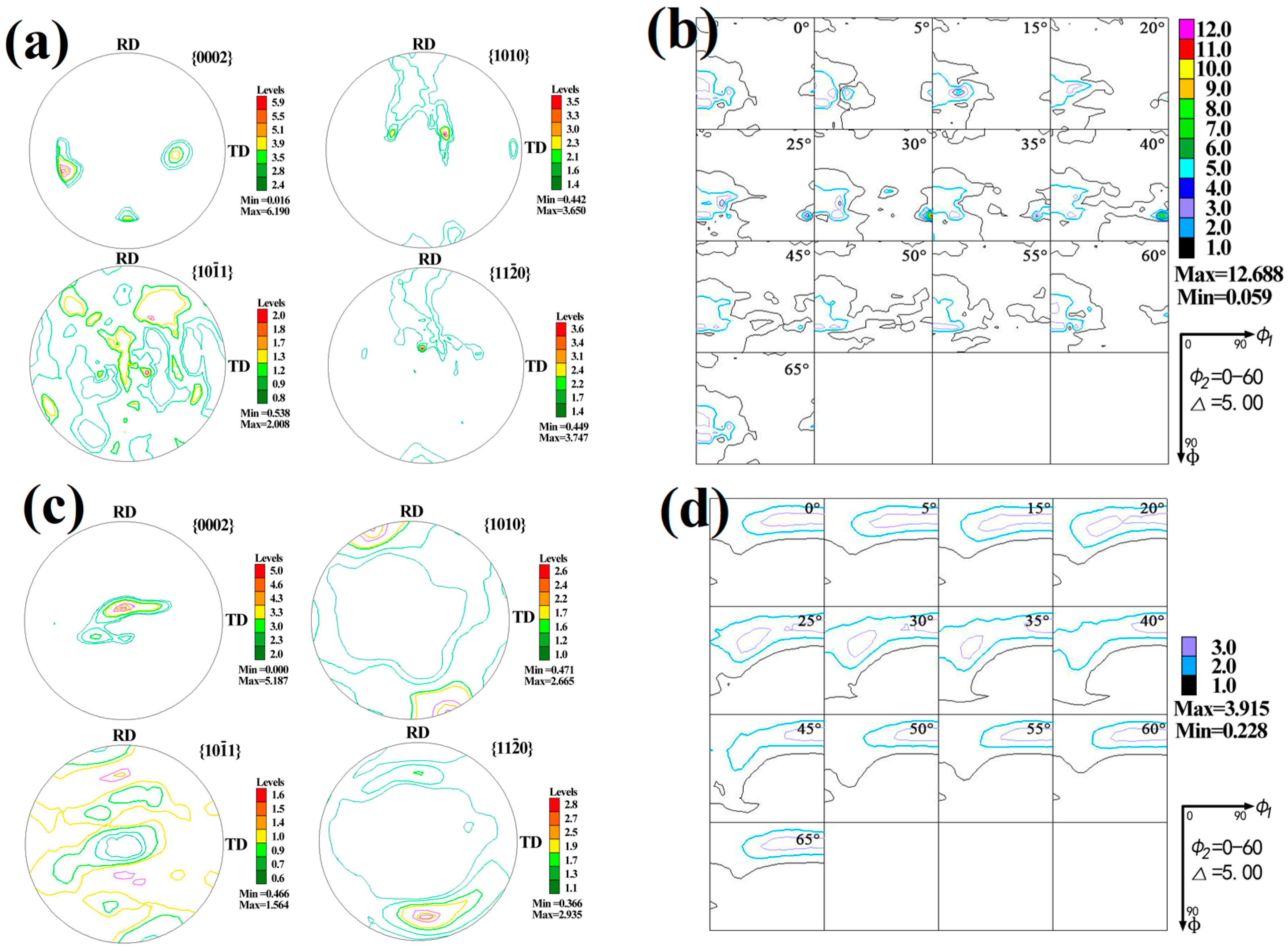

4.2. Texture Strengthening

5. Conclusions

- (1)

- Cast Mg-9Li alloy was firstly processed via multi-pass ECAP at 200 °C for 4, 8, and 16 passes to achieve grain refinement in both α-Mg and β-Li phases of the ECAPed alloys. Post rolling was conducted at room temperature to obtain further strengthening of the alloys. All the alloys after the combined process presented enhanced strength and decreased ductility compared to the cast alloy.

- (2)

- Among all the ECAPed alloys, the E8 alloys presented the best strength, of which the YTS and UTS are 110 MPa and 133 MPa, respectively. Post rolling of the E8 alloy further strengthened the alloy and endowed it with the best strength of all the alloys in this research. The YTS and UTS of the E8R alloys reached 166 MPa and 174 MPa. Approximately 219% and 70% increase in YTS and UTS was achieved compared to the cast alloy, respectively.

- (3)

- Grain-boundary strengthening and dislocation strengthening are the key factors to the greatly improved strength of the Mg-9Li alloys after the combined processing. Significant grain refinement of the α-Mg phase was achieved in the E8 alloy, of which the grain size was about 2 μm. Post rolling further reduced the grain size to between 800 nm and 1.5 μm. With the greatly refined grains, the grain-boundary strengthening of the E8 and E8R alloys was obtained. Profuse intragranular dislocation was accumulated in the deformed matrix of the E8 and E8R alloys, leading to the significant dislocation hardening of the alloy.

- (4)

- Prismatic texture and conical texture were detected with weak texture density in the E8 alloy. The strong basal texture along {0002} plane of the α-Mg phase was formed in the rolled Mg-9Li alloys along the rolling direction, which also contributed to the most improved strength of the E8R alloy.

Author Contributions

Funding

Conflicts of Interest

References

- Xu, W.; Birbilis, N.; Sha, G.; Wang, Y.; Daniels, J.E.; Xiao, Y.; Ferry, M. A high-specific-strength and corrosion-resistant magnesium alloy. Nat. Mater. 2015, 14, 1229–1235. [Google Scholar] [CrossRef] [PubMed]

- Song, D.; Ma, A.; Jiang, J.; Lin, P.; Yang, D.; Fan, J. Corrosion behavior of equal-channel-angular-pressed pure magnesium in NaCl aqueous solution. Corros. Sci. 2010, 52, 481–490. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Q.; Ye, B.; Guo, W. Hot deformation and processing maps of as-extruded Mg–9.8Gd–2.7Y–0.4Zr Mg alloy. Mater. Sci. Eng. A 2013, 576, 101–107. [Google Scholar] [CrossRef]

- Jiang, B.; Qiu, D.; Zhang, M.X.; Ding, P.; Gao, L. A new approach to grain refinement of an Mg–Li–Al cast alloy. J. Alloys Compd. 2010, 492, 95–98. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Q.D.; Guo, W.; Ye, B.; Jian, W.W.; Xu, W.Z.; Ma, X.L.; Moering, J. Finite element simulation and experimental investigation on homogeneity of Mg-9.8Gd-2.7Y-0.4Zr magnesium alloy processed by repeated-up setting. J. Mater. Process. Technol. 2015, 225, 310–317. [Google Scholar] [CrossRef]

- Wu, R.; Yan, Y.; Wang, G.; Murr, L.E.; Han, W.; Zhang, Z.; Zhang, M. Recent progress in magnesium–lithium alloys. Int. Mater. Rev. 2014, 60, 65–100. [Google Scholar] [CrossRef]

- Haferkamp, H.; Niemeyer, M.; Boehm, R.; Holzkamp, U.; Jaschik, C.; Kaese, V. Development, Processing and Applications Range of Magnesium Lithium Alloys. Mater. Sci. Forum 2000, 350, 31–42. [Google Scholar] [CrossRef]

- Bronfin, B.; Aghion, E. Magnesium Alloys Development towards the 21st Century. Mater. Sci. Forum 2000, 350, 19–30. [Google Scholar]

- Hanwu, D.; Limin, W.; Ke, L.; Lidong, W.; Bin, J.; Fusheng, P. Microstructure and deformation behaviors of two Mg–Li dual-phase alloys with an increasing tensile speed. Mater. Des. 2016, 90, 157–164. [Google Scholar] [CrossRef]

- Valiev, R. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511. [Google Scholar]

- Djavanroodi, F.; Ebrahimi, M. Effect of die channel angle, friction and back pressure in the equal channel angular pressing using 3D finite element simulation. Mater. Sci. Eng. A 2010, 527, 1230–1235. [Google Scholar] [CrossRef]

- Jiang, J.; Yuan, T.; Zhang, W.; Ma, A.; Song, D.; Wu, Y. Effect of equal-channel angular pressing and post-aging on impact toughness of Al-Li alloys. Mater. Sci. Eng. A 2018, 733, 385–392. [Google Scholar] [CrossRef]

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Han, J.; Liu, H.; Song, D.; Jiang, J.; Ma, A. High strength and ductility AZ91 magnesium alloy with multi-heterogenous microstructures prepared by high-temperature ECAP and short-time aging. Mater. Sci. Eng. A 2018, 734, 485–490. [Google Scholar] [CrossRef]

- Ma, A.; Jiang, J.; Saito, N.; Shigematsu, I.; Yuan, Y.; Yang, D.; Nishida, Y. Improving both strength and ductility of a Mg alloy through a large number of ECAP passes. Mater. Sci. Eng. A 2009, 513, 122–127. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Han, J.; Yuan, T.; Song, D.; Wu, Y.; Yuan, Y.; Zhuo, X.; Liu, H.; Ma, A. Enhanced quasi-isotropic ductility in bi-textured AZ91 Mg alloy processed by up-scaled RD-ECAP processing. J. Alloys Compd. 2018, 780, 12. [Google Scholar] [CrossRef]

- Min, X.; Xinying, T.; Chaoping, Y.; Jinyang, Z. Effect of Heat Treatment on Microstructure and Mechanical Properties of Mg 94 Zn 2 Y 4 Alloy. Rare Met. Mater. Eng. 2016, 45, 2804–2808. [Google Scholar] [CrossRef]

- Chang, S.Y.; Lee, S.W.; Kang, K.M.; Kamado, S.; Kojima, Y. Improvement of Mechanical Characteristics in Severely Plastic-deformed Mg Alloys. Mater. Trans. 2004, 45, 488–492. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Wang, Q.; Chen, J.; Ye, B.; Guo, W. Microstructure and mechanical properties of extruded Mg-8.5Gd-2.3Y-0.8Ag-0.4Zr alloy. Trans. Nonferr. Met. Soc. China 2012, 22, 1891–1895. [Google Scholar] [CrossRef]

- Zhou, H.; Ning, H.; Ma, X.; Yin, D.; Xiao, L.; Sha, X.; Yu, Y.; Wang, Q.; Li, Y. Microstructural evolution and mechanical properties of Mg-9.8Gd-2.7Y-0.4Zr alloy produced by repetitive upsetting. J. Mater. Sci. Technol. 2018, 34, 1067–1075. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, W.Z.; Jian, W.W.; Cheng, G.M.; Ma, X.L.; Guo, W.; Mathaudhu, S.N.; Wang, Q.D.; Zhu, Y.T. A new metastable precipitate phase in Mg-Gd-Y-Zr alloy. Philos. Mag. 2014, 94, 2403–2409. [Google Scholar] [CrossRef]

- Song, D.; Li, C.; Liang, N.; Yang, F.; Jiang, J.; Sun, J.; Wu, G.; Ma, A.; Ma, X. Simultaneously improving corrosion resistance and mechanical properties of a magnesium alloy via equal-channel angular pressing and post water annealing. Mater. Des. 2019, 166, 107621. [Google Scholar] [CrossRef]

- Nishida, Y.; Arima, H.; Kim, J.C.; Ando, T. Rotary-die equal-channel angular pressing of an Al—7 mass% Si—0.35 mass% Mg alloy. Scr. Mater. 2001, 45, 261–266. [Google Scholar] [CrossRef]

- Wei, J.; Huang, G.; Yin, D.; Li, K.; Wang, Q.; Zhou, H. Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy. Metals 2017, 7, 119. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Wei, K.; Xiao, L.; Chen, B.; Long, H.; Yu, Y.; Hu, Z.; Zhou, H. Effect of Micro-Steps on Twinning and Interfacial Segregation in Mg-Ag Alloy. Materials 2019, 12, 1307. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Zhang, L.; Li, Y.; Wang, H.; Liu, J.; Liaw, P.K. Improvement of mechanical behaviors of a superlight Mg–Li base alloy by duplex phases and fine precipitates. J. Alloys Compd. 2017, 735, 2625–2633. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, J.; Liu, H.; Sun, J.; Gu, Y.; Tang, R.; Zhao, X.; Ma, A. Fabrication of an Ultra-Fine Grained Pure Titanium with High Strength and Good Ductility via ECAP plus Cold Rolling. Metals 2017, 7, 563. [Google Scholar] [CrossRef]

- Jiang, B.; Yang, Q.S.; Gao, L.; Pan, F.S. Effect of the Rolling Process on Microstructures and Mechanical Properties of the Extruded LA91 Alloy Sheet. Mater. Sci. Forum 2011, 686, 90–95. [Google Scholar] [CrossRef]

- Chih-Te, C.; Shyong, L.; Chun-lin, C. Rolling route for refining grains of super light Mg–Li alloys containing Sc and Be. Trans. Nonferrous Met. Soc. China 2009, 20, 1374–1379. [Google Scholar]

- Hajizadeh, K.; Eghbali, B. Effect of two-step severe plastic deformation on the microstructure and mechanical properties of commercial purity titanium. Met. Mater. Int. 2014, 20, 343–350. [Google Scholar] [CrossRef]

- Yu, H.L.; Lu, C.; Tieu, A.K.; Li, H.J.; Godbole, A.R. Special rolling techniques for improvement of mechanical properties of ultrafine-grained metal sheets: A review. Adv. Eng. Mater. 2016, 18, 754–769. [Google Scholar] [CrossRef]

- Xiao, L.; Cao, Y.; Li, S.; Zhou, H.; Ma, X.; Mao, L.; Sha, X.; Wang, Q.; Zhu, Y.; Han, X. The formation mechanism of a novel interfacial phase with high thermal stability in a Mg-Gd-Y-Ag-Zr alloy. Acta Mater. 2019, 162, 214–225. [Google Scholar] [CrossRef]

- Han, B.; Dunand, D. Microstructure and mechanical properties of magnesium containing high volume fractions of yttria dispersoids. Mater. Sci. Eng. A 2000, 277, 297–304. [Google Scholar] [CrossRef]

- Xu, C.; Horita, Z.; Furukawa, M.; Langdon, T.G. Using Equal-Channel Angular Pressing for the Production of Superplastic Aluminum and Magnesium Alloys. J. Mater. Eng. Perform. 2004, 13, 683–690. [Google Scholar] [CrossRef]

- Wei, G.B.; Peng, X.D.; Hu, F.P.; Hadadzadeh, A.; Yang, Y.; Xie, W.D.; Wells, M.A. Deformation behavior and constitutive model for dual-phase Mg–Li alloy at elevated temperatures. Trans. Nonferr. Met. Soc. China 2016, 26, 508–518. [Google Scholar] [CrossRef]

- Chang, L.; Wang, Y.; Zhao, X.; Huang, J. Microstructure and mechanical properties in an AZ31 magnesium alloy sheet fabricated by asymmetric hot extrusion. Mater. Sci. Eng. A 2008, 496, 512–516. [Google Scholar] [CrossRef]

- Hsiang, S.; Lin, Y. Investigation of the influence of process parameters on hot extrusion of magnesium alloy tubes. J. Mater. Process. Technol. 2007, 192, 292–299. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, M.; Chen, X.; Cao, Y.; Roven, H.J.; Murashkin, M.; Valiev, R.Z.; Zhou, H. Effect of Mg on microstructure and mechanical properties of Al-Mg alloys produced by high pressure torsion. Scr. Mater. 2019, 159, 137–141. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, C.H.; Sha, X.C.; Xiao, L.R.; Ma, X.L.; Höppel, H.W.; Göken, M.; Wu, X.L.; Ameyama, K.; Han, X.D.; et al. In-situ observation of dislocation dynamics near hterostructured interface. Mater. Res. Lett. 2019, 7, 376–382. [Google Scholar] [CrossRef]

- Hu, H.; Zhen, L.; Zhang, B.; Yang, L.; Chen, J. Microstructure characterization of 7050 aluminum alloy during dynamic recrystallization and dynamic recovery. Mater. Charact. 2008, 59, 1185–1189. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, L.; Wang, H.; Tong, X.; Zhang, M.; Zhang, Z. Texture evolution and their effects on the mechanical properties of duplex Mg–Li alloy. J. Alloys Compd. 2016, 669, 72–78. [Google Scholar] [CrossRef]

- Zeng, Y.; Jiang, B.; Li, R.; Yin, H.; Al-Ezzi, S. Grain Refinement Mechanism of the As-Cast and As-Extruded Mg–14Li Alloys with Al or Sn Addition. Metals 2017, 7, 172. [Google Scholar] [CrossRef]

- Kugler, G.; Turk, R. Modeling the dynamic recrystallization under multi-stage hot deformation. Acta Mater. 2004, 52, 4659–4668. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Roodposhti, P.S.; Farahbakhsh, N.; Sarkar, A.; Murty, K.L. Microstructural approach to equal channel angular processing of commercially pure titanium—A review. Trans. Nonferr. Met. Soc. China 2015, 25, 1353–1366. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R: Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Lentz, M.; Klaus, M.; Beyerlein, I.J.; Zecevic, M.; Reimers, W.; Knezevic, M. In situ X-ray diffraction and crystal plasticity modeling of the deformation behavior of extruded Mg–Li–(Al) alloys: An uncommon tension–compression asymmetry. Acta Mater. 2015, 86, 254–268. [Google Scholar] [CrossRef]

| Mg | Li | Fe | Mn | Zn | Cd |

|---|---|---|---|---|---|

| 91.052 | 8.809 | 0.010 | 0.024 | 0.014 | 0.030 |

| Mechanical Properties | C | E4P | E8P | E16P | CR | E4R | E8R | E16R |

|---|---|---|---|---|---|---|---|---|

| UTS (MPa) | 102 | 106 | 133 | 116 | 158 | 133 | 174 | 149 |

| YTS (MPa) | 52 | 88 | 110 | 100 | 152 | 126 | 166 | 120 |

| Eu (%) | 15 | 5 | 7 | 5 | 3 | 3 | 2 | 7 |

| Ef (%) | 33 | 25 | 24 | 31 | 16 | 21 | 22 | 26 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klu, E.E.; Song, D.; Li, C.; Wang, G.; Zhou, Z.; Gao, B.; Sun, J.; Ma, A.; Jiang, J. Development of a High Strength Mg-9Li Alloy via Multi-Pass ECAP and Post-Rolling. Metals 2019, 9, 1008. https://doi.org/10.3390/met9091008

Klu EE, Song D, Li C, Wang G, Zhou Z, Gao B, Sun J, Ma A, Jiang J. Development of a High Strength Mg-9Li Alloy via Multi-Pass ECAP and Post-Rolling. Metals. 2019; 9(9):1008. https://doi.org/10.3390/met9091008

Chicago/Turabian StyleKlu, Edwin Eyram, Dan Song, Chen Li, Guowei Wang, Zhikai Zhou, Bo Gao, Jiapeng Sun, Aibin Ma, and Jinghua Jiang. 2019. "Development of a High Strength Mg-9Li Alloy via Multi-Pass ECAP and Post-Rolling" Metals 9, no. 9: 1008. https://doi.org/10.3390/met9091008

APA StyleKlu, E. E., Song, D., Li, C., Wang, G., Zhou, Z., Gao, B., Sun, J., Ma, A., & Jiang, J. (2019). Development of a High Strength Mg-9Li Alloy via Multi-Pass ECAP and Post-Rolling. Metals, 9(9), 1008. https://doi.org/10.3390/met9091008