1. Introduction

The double-pulsed gas metal arc welding (DP-GMAW) process is a mature arc welding operation technology that is prevalently employed in modern industrial manufacturing occasions. Though this process is designed based on the traditional pulsed-GMAW (P-GMAW), it has some significant merits when compared to the P-GMAW, such as the DP-GMAW process can reduce the porosity incidence [

1] and improve the solidification cracking susceptibility [

2]. Also, the process has better gap bridging ability [

3], and better ability to control the mode of droplet transfer than those of the P-GMAW process [

4]. This new technique is an effective variation of the traditional P-GMAW process, in which the pulsing current aiming to metal transfer control is overlapped by a thermal pulsation [

5], which induces changes of temperature and stress of the welding pool [

6]. Hence, it has been paid more and more attention in academic research and actual industrial production areas in recent years.

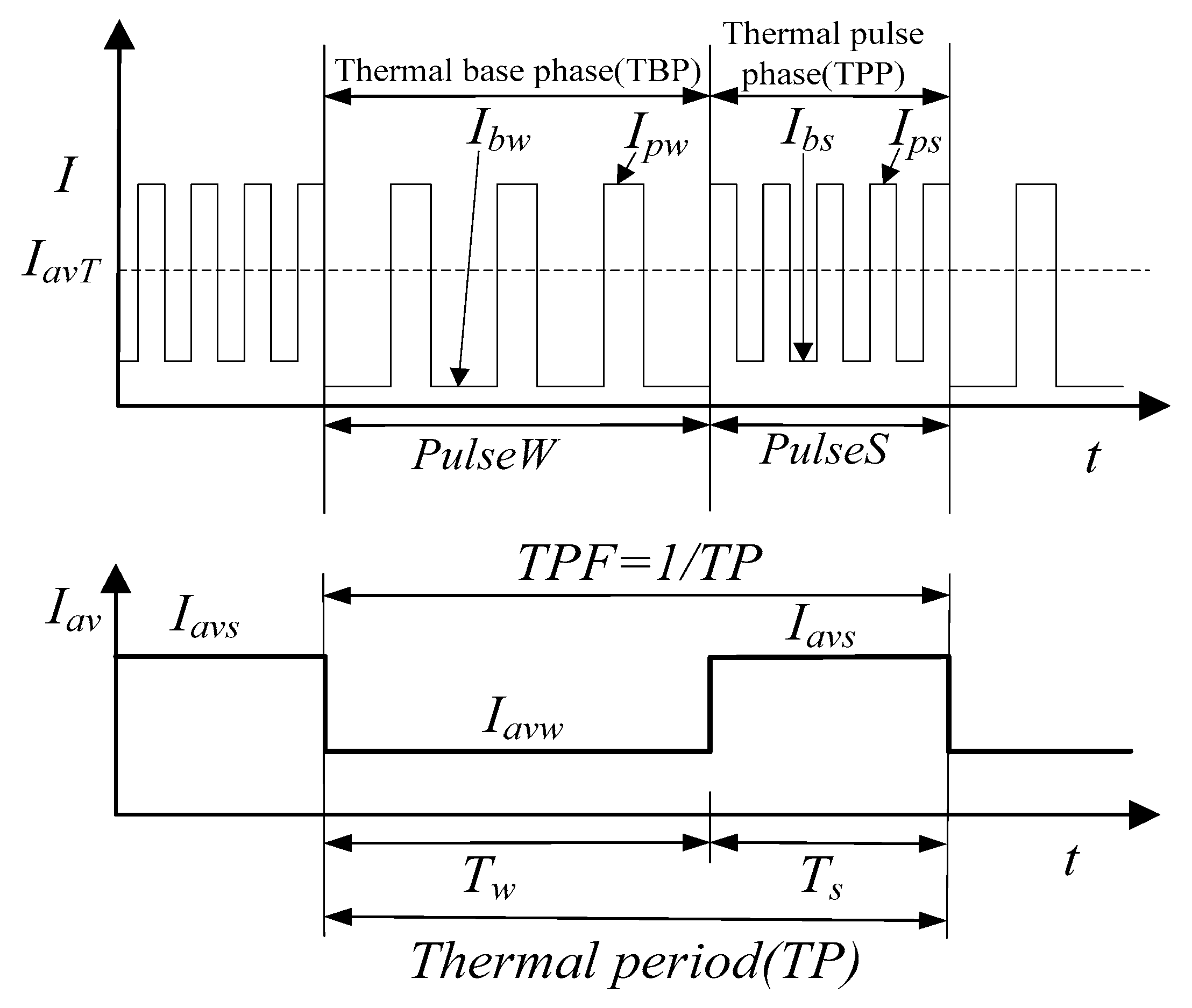

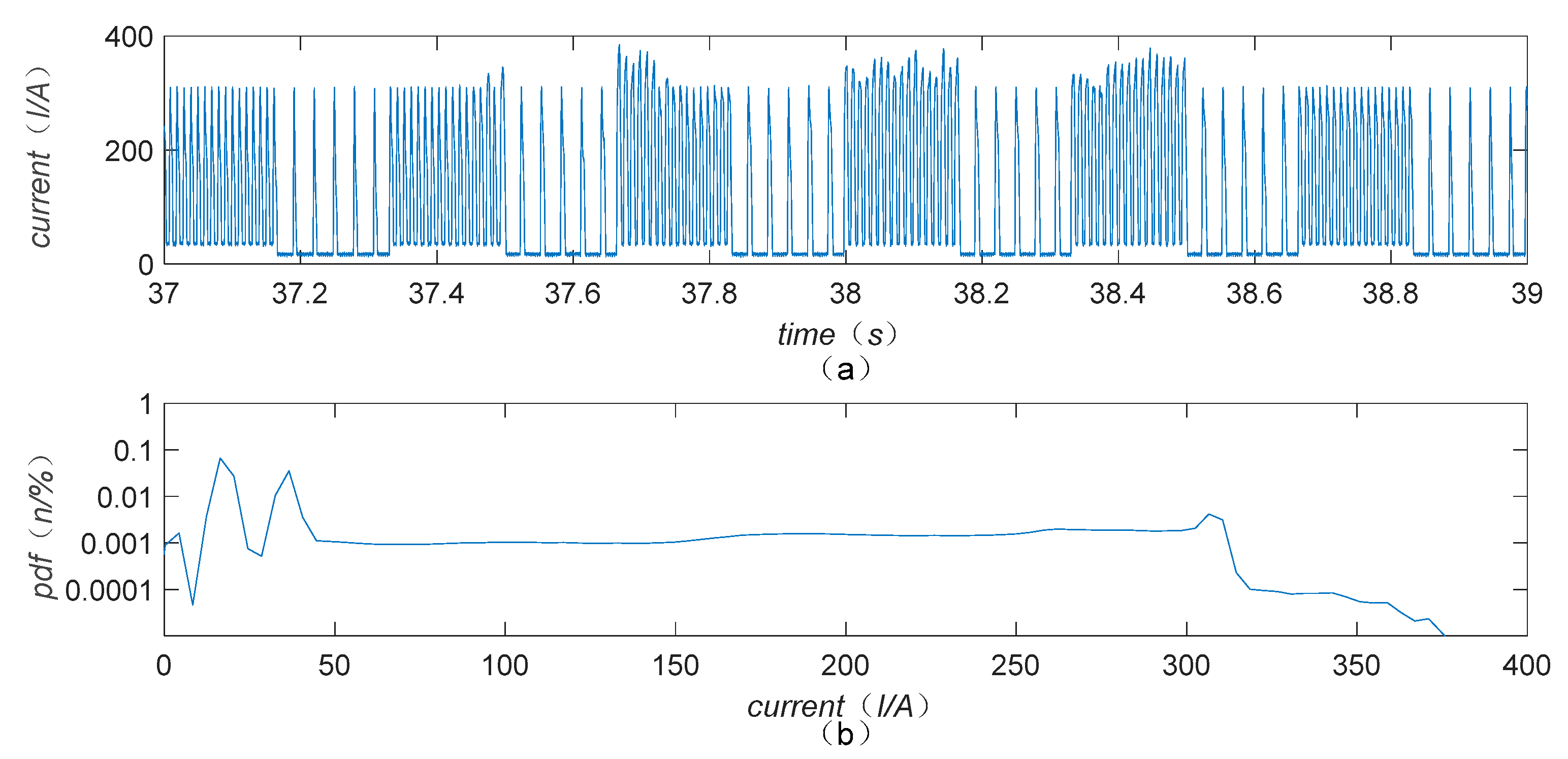

The difference between P-GMAW and DP-GMAW processes is the current waveform. During the DP-GMAW process, the current waveform is composed of a rhythmic thermal pulse phase (TPP) and a thermal base phase (TBP) [

7], which have different frequencies and amplitudes, and the sum of durations of the two phases is equal to a thermal period (TP) [

8]. Because of the existence of double pulses, it was also been named the twin-pulsed GMAW process in some published literature. To assure a stable welding process and obtain weld beads with high quality, researchers and scholars have put a lot of efforts to change the waveforms. The original waveform was a usual types of square waveforms where strong current and weak current were alternately appeared during the process. Under the circumstance, arc quenching may appear when actual currents switch between TPP and TBP, because the wire feeding equipment may not be able to catch up with the variation of the current pulse with adequate speed due to the mechanical inertia [

8]. To alleviate the sudden changes of the current amplitude differences in these two phases, corresponding improvements have been revealed, such as trapezoid waveform, or sinusoidal waveform [

8,

9]. By means of the changes, the changes of the currents were replaced by gradual switches, which can improve the stability of the arc to achieve a stable droplet transfer [

10]. Apart from arc quenching, splashes, short-circuit or open-circuit of the electrical system may frequently occur during the process if the parameters setting and matching are improper. All of these phenomena should be carefully considered during system design and operation in order to decrease the cost of production and improve the actual efficiency.

According to the principle of DP-GMAW, there are many parameters requiring proper setting during the process, such as the thermal period and corresponding frequency, twin pulse current change and duty cycles in two phases, and so on. Also, currently the welding robot has been employed more and more in manufacturing, and the robot traveling speed is also an important parameter. Hence, this is a typical multi-parameter system, and how to obtain an optimal operational parameters combination for achieving satisfactory performance is a challenge work for all users. In practical application, testing and justifying each parameter on the welding quality can cost so much and cannot be accepted in the majority of occasions.

No matter which type of welding technology is employed, quality estimation or evaluation is so important. For example, for resistance spot welding, the tensile-shear strength of the weld can be used for evaluating the welding quality [

11]. For pulsed GMAW products, which is the weld bead, the quality involves more elements, such as crack, appearance, penetration, microstructure, and so on [

12]. In general, these different elements should be properly combined to yield one reliable quality criterion. Nowadays, with developing computer technology, artificial intelligent (AI) technology has demonstrated many achievements. In welding research area, AI technology has been also employed, such as in quality estimation of resistance spot welding [

11], or in optimal parameter prediction in double-wire-pulsed metal inert gas (MIG) arc welding [

13]. As for the quality evaluation of arc welding products, many previous contributions have paid a lot attention to it. Casalino et al. [

14] employed neural networks to establish a relation between process parameters and geometry of the molten zone of the welds, and then used a fuzzy C-means clustering algorithm to evaluate the quality. Wu et al. [

15] used a Kohonen network to monitor the welding process and evaluate the quality in a GMAW process. The inputs were the probability density distribution (PDD) of the welding voltages and the class frequency distribution (CFD) of short circuiting times, and the network can recognize and classify the undisturbed and intentionally disturbed GMAW experiments. It can be noticed that the AI technology can be proper in estimating the quality of weld bead and exert remarkable effects.

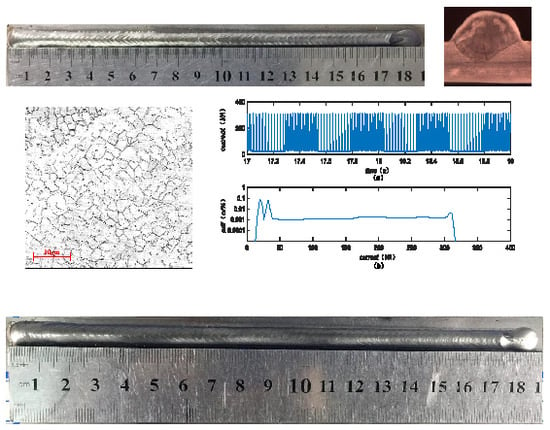

This work aimed to explore how to obtain an optimal parameters matching in order to obtain the weld bead with satisfactory quality, while researching the influential levels of the key operational parameters on the different performances of the weld beads. The DP-GMAW process involves various input parameters, and the quality of weld bead also includes a lot of evaluation criteria. To achieve preliminary goals, two main contents have been included in this work. The first was the optimal parameters machining. Among various operational parameters, few key operational parameters were selected to do experiments. To achieve the desired effects and decrease experimental complexity, orthogonal experimental design, which is an important experimental design method to explore the system effects typically involving multiple factors and multiple levels [

16], was employed. This experimental design method can reduce the workload and involves corresponding methods of analyzing the experimental results, so to yield more reliable conclusions [

17].

After employing orthogonal experimental design to obtain weld beads using different operational parameter combinations, an appropriate quality evaluation method can be used to estimate the experimental results. Because the quality of weld bead involves various elements, the quality evaluation method should also be a multi-input system. In addition, to clearly reflect the evaluation results, the output is better when quantitatively presented. In this work, considering the characteristics of weld beads and application of current AI technology, fuzzy comprehensive evaluation (FCE), which was an effective evaluation method based on the fuzzy sets and fuzzy mathematics, was chosen to conduct the quality evaluation for the weld beads. FCE was introduced in the 1960s, and has become an effective multi-factor decision-making tool for comprehensive evaluations so far. During the actual application, combining with the expert experiences, this method can make a full and comprehensive refection on the evaluation criteria and the influence factors of fuzziness, and produces evaluation results closer to the actual situation [

18]. It has been used in a lot of different areas, such as in power policy making [

19], teaching and education performance evaluation [

20], motion performance evaluation of autonomous underwater vehicle [

21], water resources carrying capacity [

22], distinct heating system evaluation [

23], real estate investment risk research [

24], quality assessment for compressed remote sensing images [

25], and other relative areas.

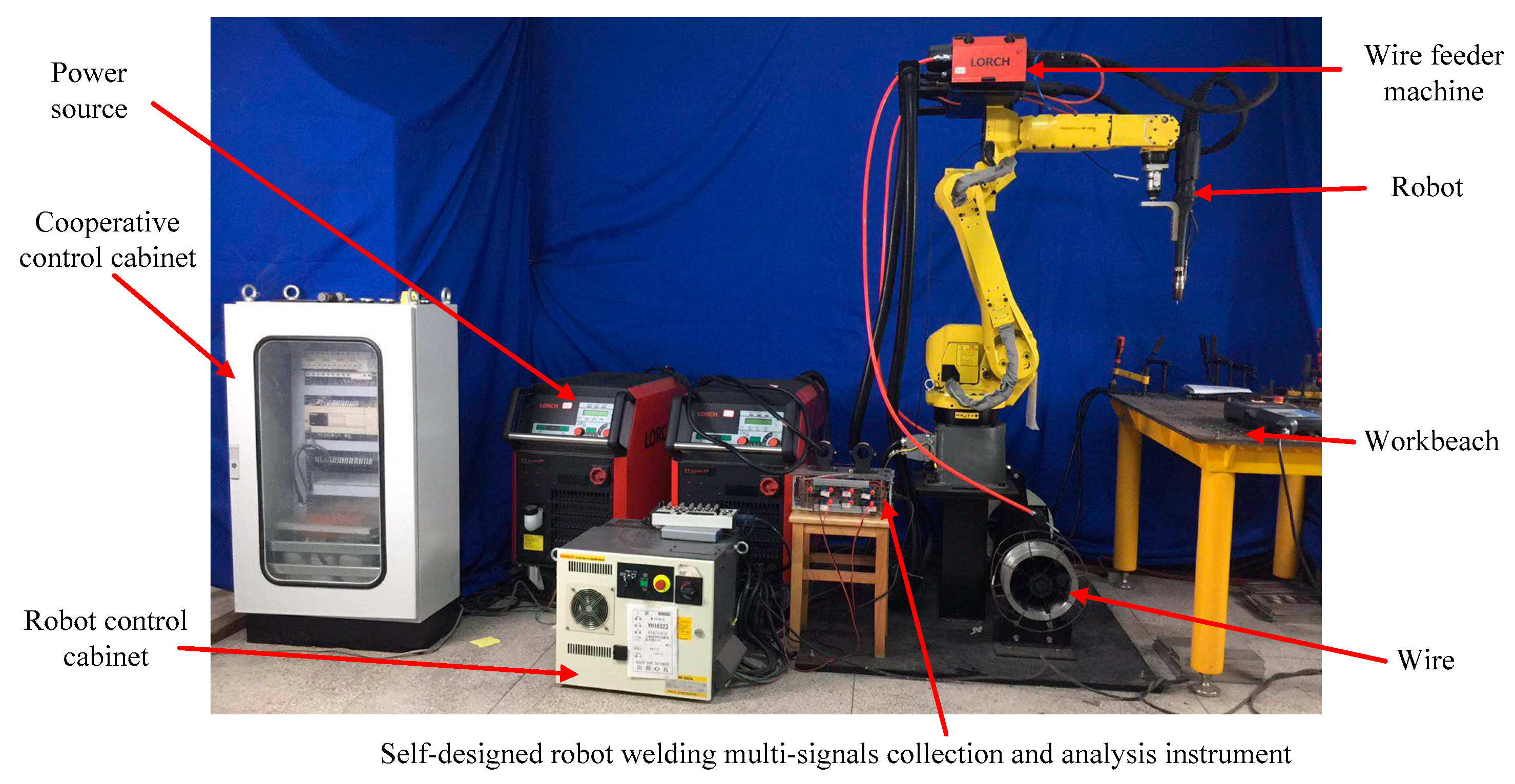

In this work, the DP-GMAW process based on an industrial robot operation was conducted, the objective was seeking optimal operational parameters combination in order to obtain weld bead with satisfactory quality, and obtaining the influential levels of different operational parameters on the performances of the weld bead. During the process, according to principle and operational characteristics of this process, some key operational parameters were selected to design orthogonal experiments, and then the FCE method was employed to do quality evaluation according to relative experimental results and obtained optimal operational parameters combinations. Advanced experimental designing methods and quantitative quality evaluation methods were effectively combined in this work, and the contribution can serve the current DP-GMAW process improvement and parameter optimization.

2. Operational Characteristics of the DP-GMAW Process

The DP-GMAW process involves a lot of typical operational parameters. The current pulses in TPP and TBP have different frequencies. The thermal period (TP) denotes the duration of two phases. Another important operational parameter, twin pulse frequency (TPF), which is a reciprocal of the TP, can describe the speed of current waveform adjustment between the two double pulses. Also, the TPF can determine the number of fish scale ripples. It can be noticed that this process is a low frequency modulation based on high frequency phases (TPP and TBP), in other words, the low frequency current pulsation or the thermal pulse is superimposed on a pulsed current for active metal transfer control and weld pool stirring [

26]. During the process, TPF can reflect the varying speed of the strong set and weak pulses set, and each set may include up to 10–20 high frequency pulses, the maximum frequencies of the pulses may achieve is 100 Hz. Hence, in a general case, the value of TPF is below 5 Hz. The welding currents were switched between two high frequencies with TPF of the switch frequency. The frequency in TPP is higher than that in TBP, and the pulse set in TPP is called a strong pulse set, which is signed as

PulseS, and the pulse currents are switched between base current

Ibs and peak current

Ips while the pulse set in TBP is called as weak pulse set, which is signed as

PulseW, the corresponding base current and peak current are respectively

Ibw and

Ipw. The durations of TPP and TBP were, respectively,

Ts and

Tw. In addition, the proportion of the time of thermal pulse phase, which is

Ts, in one thermal period TP, is called twin pulse relation, which can be mathematically described in Equation (1):

where this parameter is denoted as

DT in this work.

The strong pulse set is to control the droplet transfer for obtaining enough welding penetration, in a general case, one pulse corresponds to one droplet, while the function of the weak pulse set is obtaining a series of regular pulses to stir the weld pool [

27], and one TBP corresponds to one weld pool. In addition, the average current in TPP is

Iavs, while the average current in TBP is

Iavw, and the average current in one thermal period is marked as

Iav. In general, the

Iav is a preliminary arc welding setting value during the process. Under this circumstance, the regular fish scale grain can form if all the parameters are properly set.

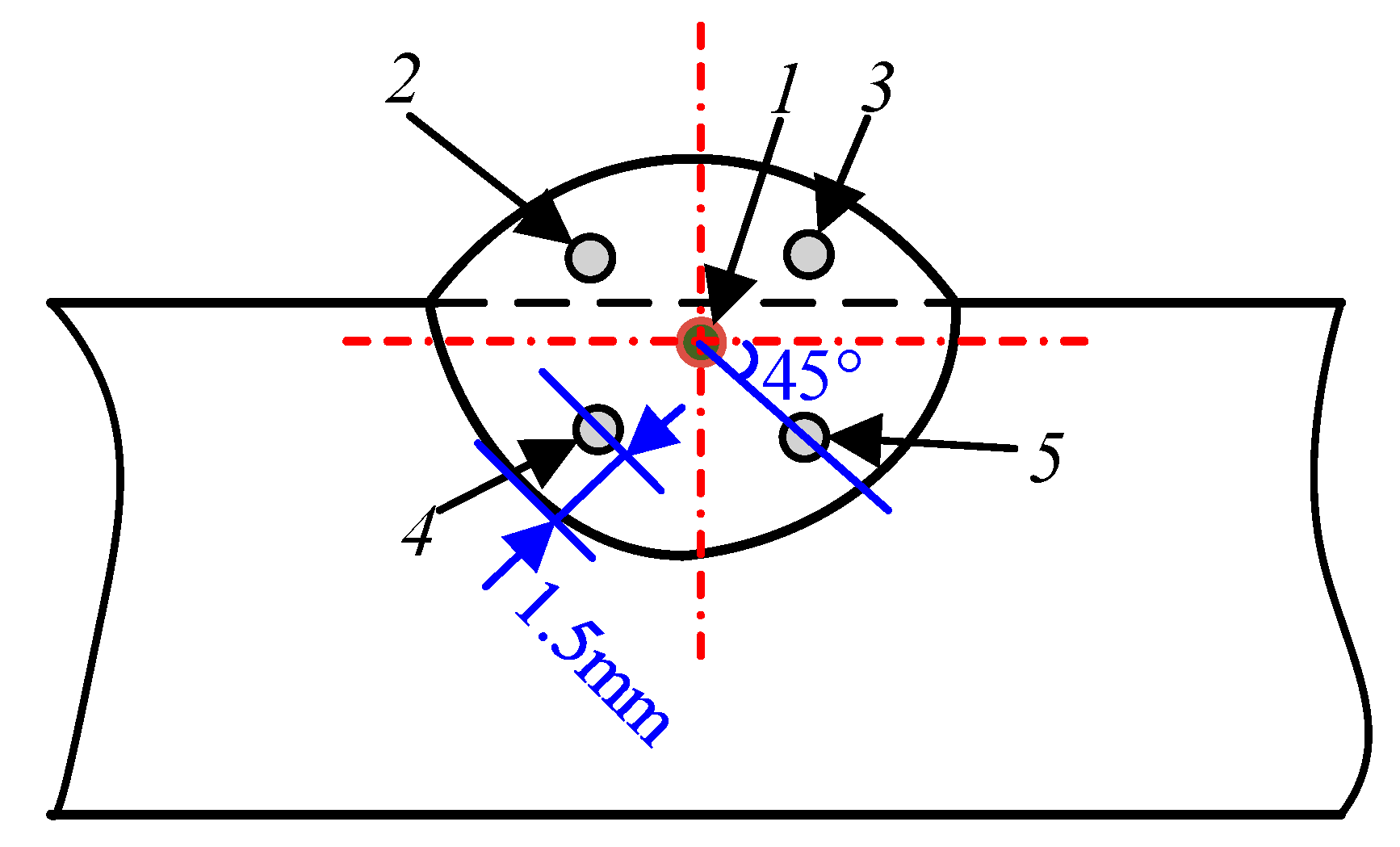

Figure 1 shows the schematic and main operational parameters of the DP-GMAW process.

In this figure, TP is the sum of

Tw and

Ts. Apart from the relations shown in the

Figure 1, twin pulse current change, whose value is half of the subtraction between mean value of currents in TPP and TBP, is also an important parameter during the process because it can reflect the current variation in between two phases. In this work, to clearly reflect the current adjustment, this parameter can be described combining the

Iav and in percent format as in the following equation:

where

IΔ is called twin pulse current change in percent. Moreover, the relations between

IΔ, and

Iavs as well as

Iavw, can be also be derived as follows:

During the welding process, proper combination of the operational parameters of the pulse sets in TPP and TBP, and other process parameters, are the utmost important for improving the welding quality and obtaining weld bead with satisfactory fish scale ripples. During the traditional DP-GMAW operation process, various relative operational parameters cannot be accurately adjusted and matched one by one. In this work, the latest twinpulse XT DP control technology developed by the LORCH Company was employed. This process has two significant features:

The pulse frequency in TPP is so high, which can achieve 100 Hz, on the other hand, the pulse frequency in TPB can also achieve 30 Hz, and both of these two pulse frequencies were higher than those of traditional DP- GMAW process.

The peak current and base current in TPP and TPB are unchanged when the average current Iav in one thermal period is unchanged. The process control can be conducted through only adjusting average current Iav and the twin pulse relation DT, then the parameters about PulseW and PulseS can correspondingly vary and need not to be adjusted, so that the number of operational parameters during the process which are required to be adjusted can be significantly decreased. Using this new control technology, the operational parameters of the arc welding process can be more effectively set and matched.

According to the above introduction about the DP-GMAW process, it can be noticed that there are various operational parameters included in the DP-GMAW process, and to obtain the weld bead with satisfactory quality, all the operational parameters should be carefully and seriously considered. Employing twinpulse XT DP control technology can decrease the setting complexity and improve the control performance, because this new control technology can use a few key operational parameters to control two waveforms, some important process parameters, such as peak current, base current, frequency, duty cycle, peak current, base current, peak time, base time, did not individually set. Therefore, realizing the proper control of energy delivery into the base plate was so convenient. Then in the next section, corresponding experiments can be conducted to produce weld beads with different qualities, and then the influential levels of different operational parameters on the selected performance of weld bead can be seriously explored after combining selected quality evaluation method.