Microstructure and Mechanical Properties of Resistance Heat-Assisted High-Power Ultrasonic Dissimilar Welded Cu/Al Joint

Abstract

:1. Introduction

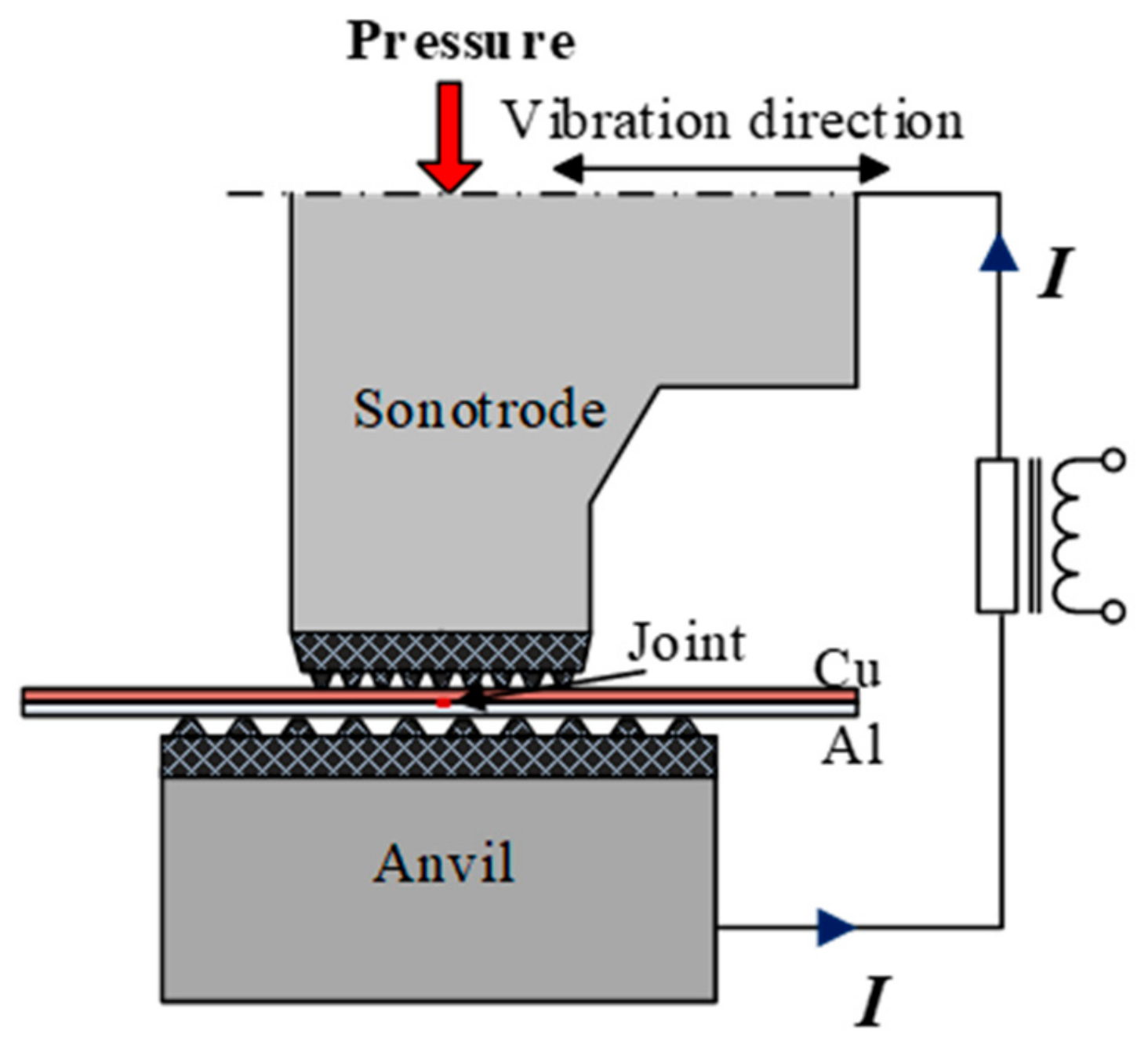

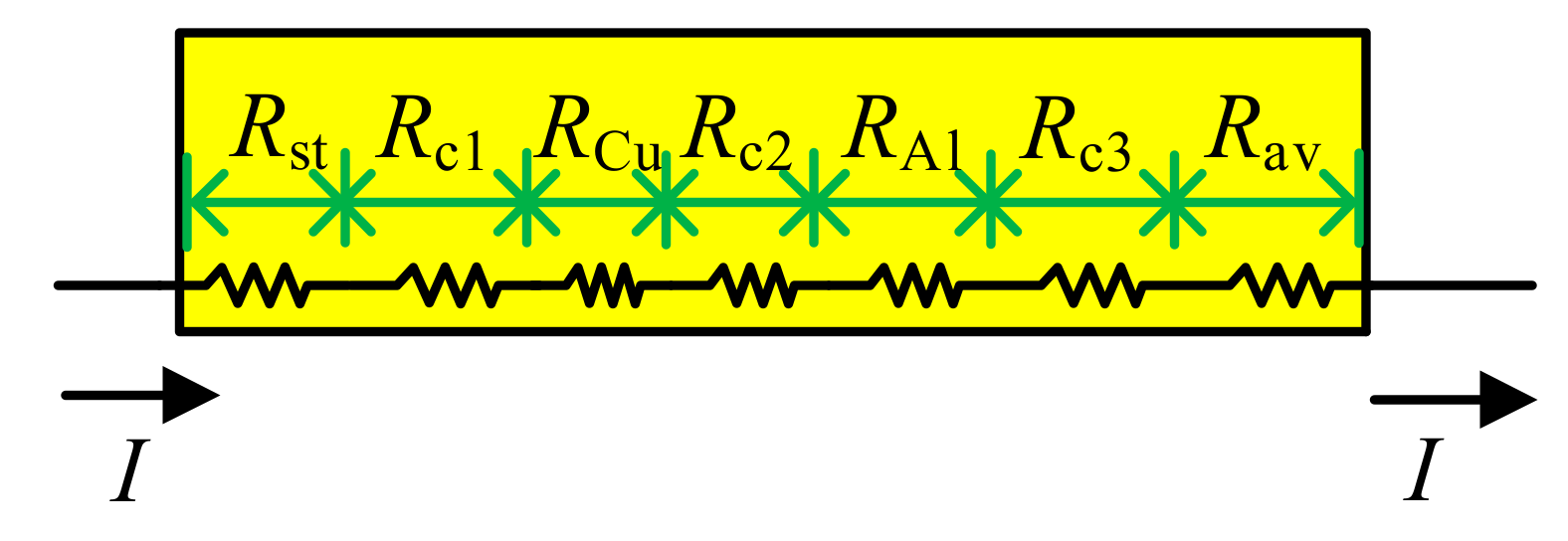

2. The Principle of Hybrid Welding

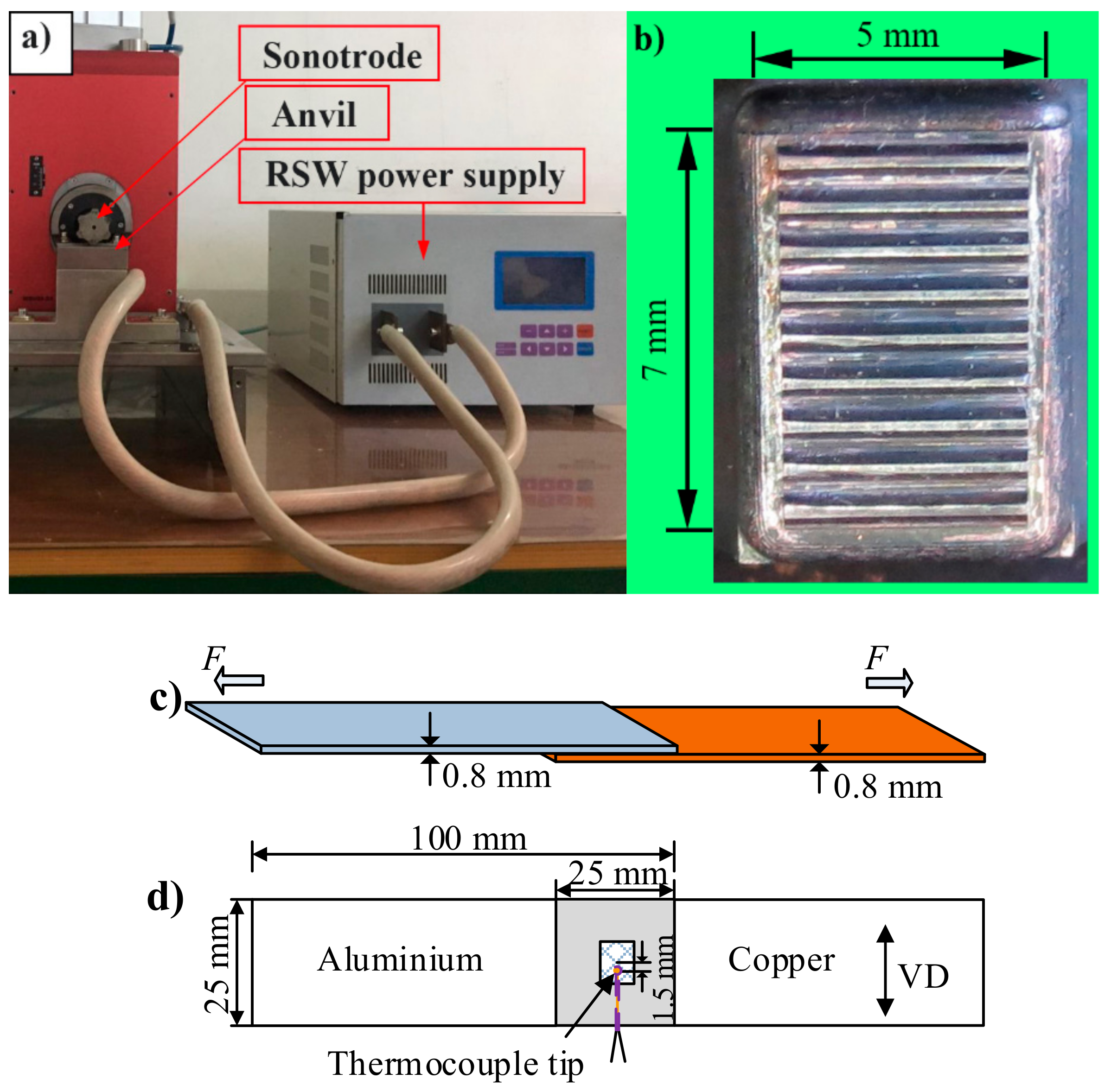

3. Experimental Details

4. Results and Discussion

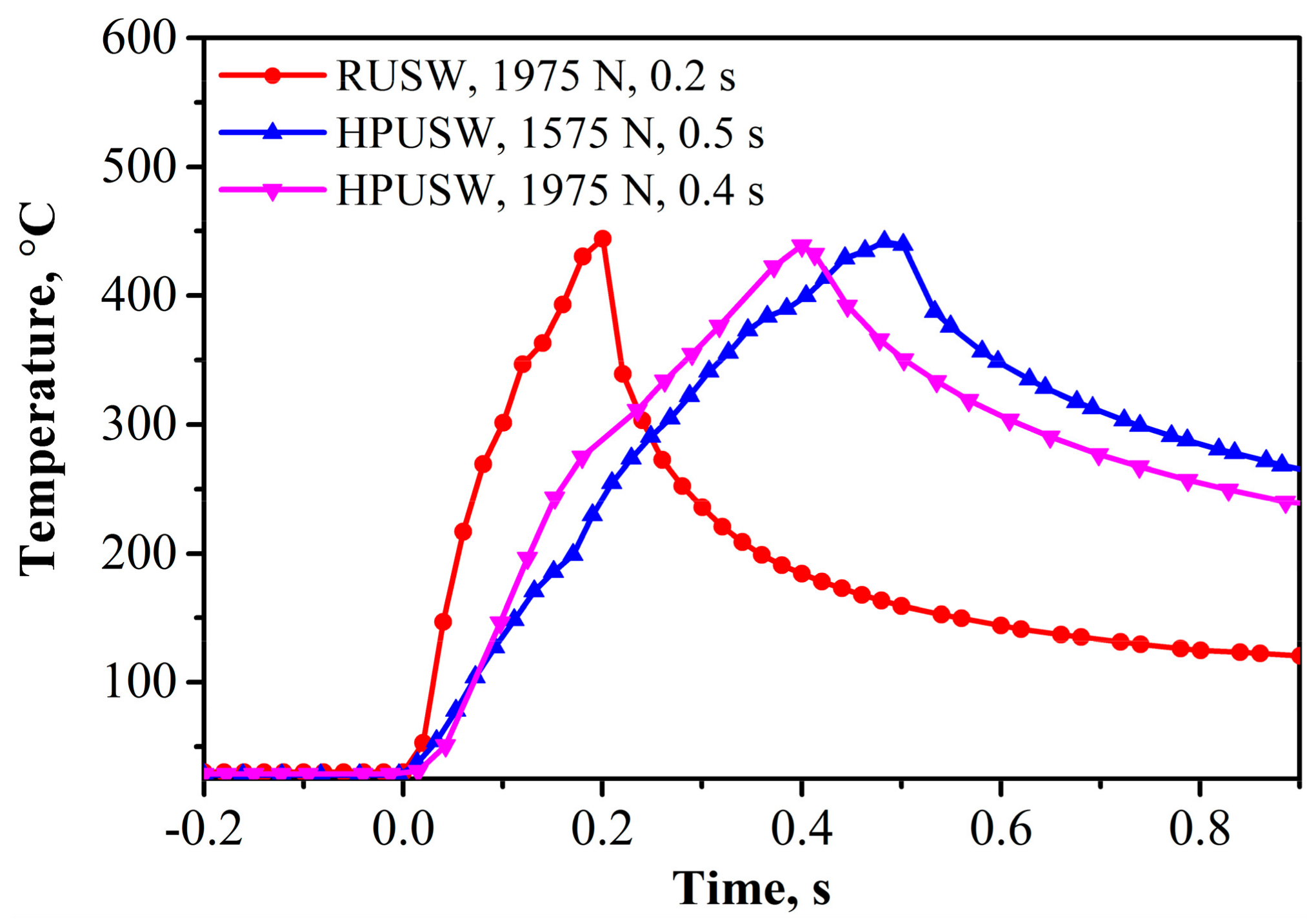

4.1. Interface Temperature

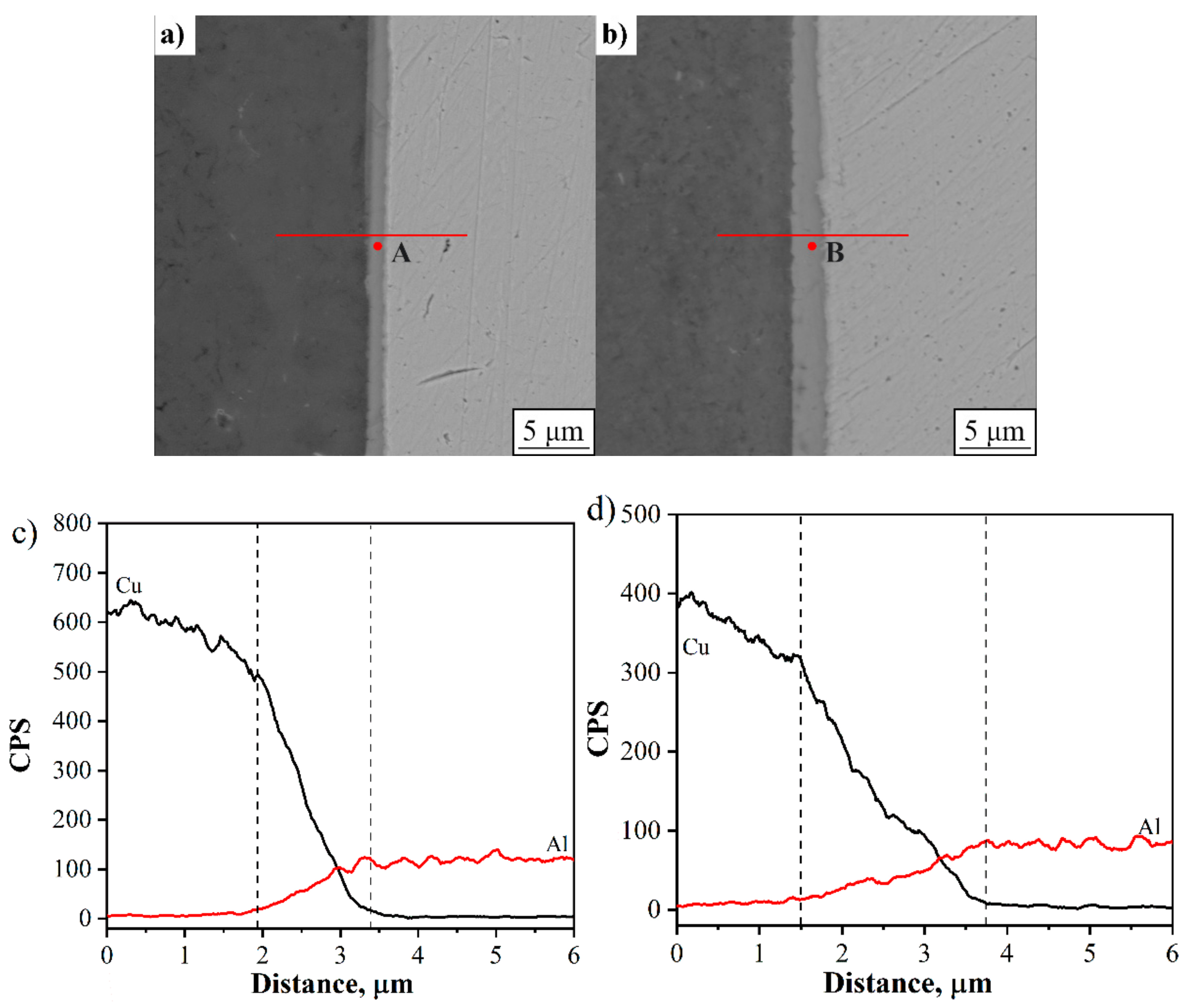

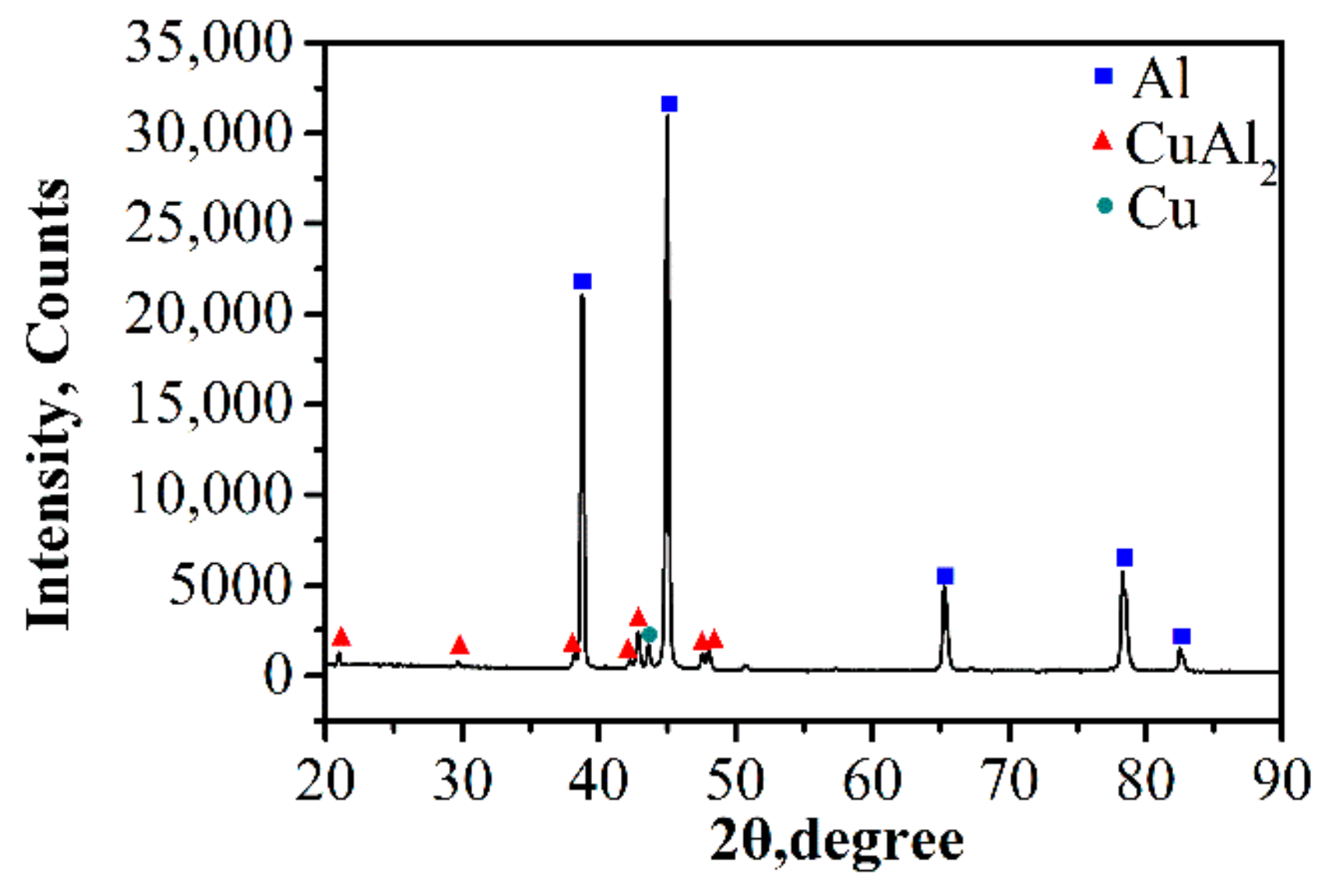

4.2. IMC Layer

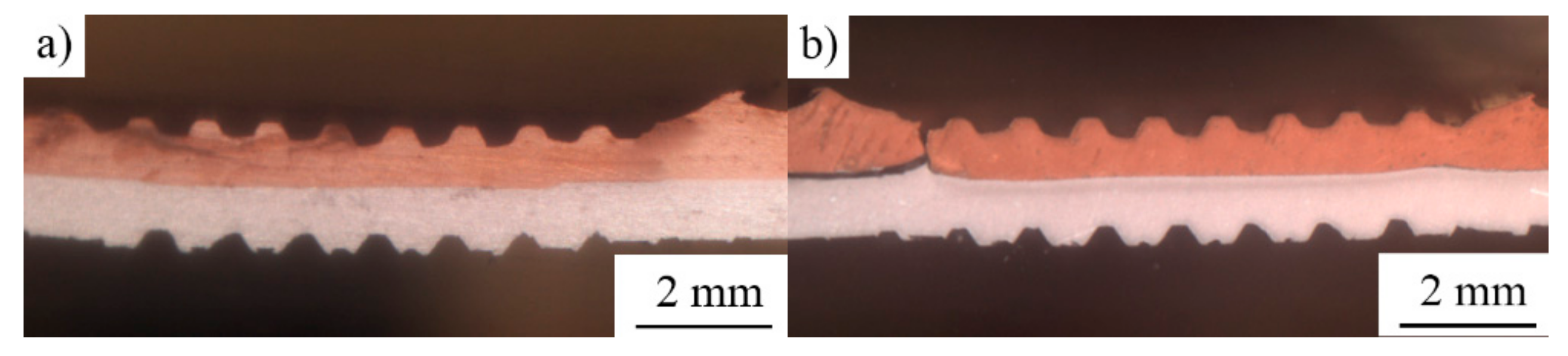

4.3. Weld Cross-Section

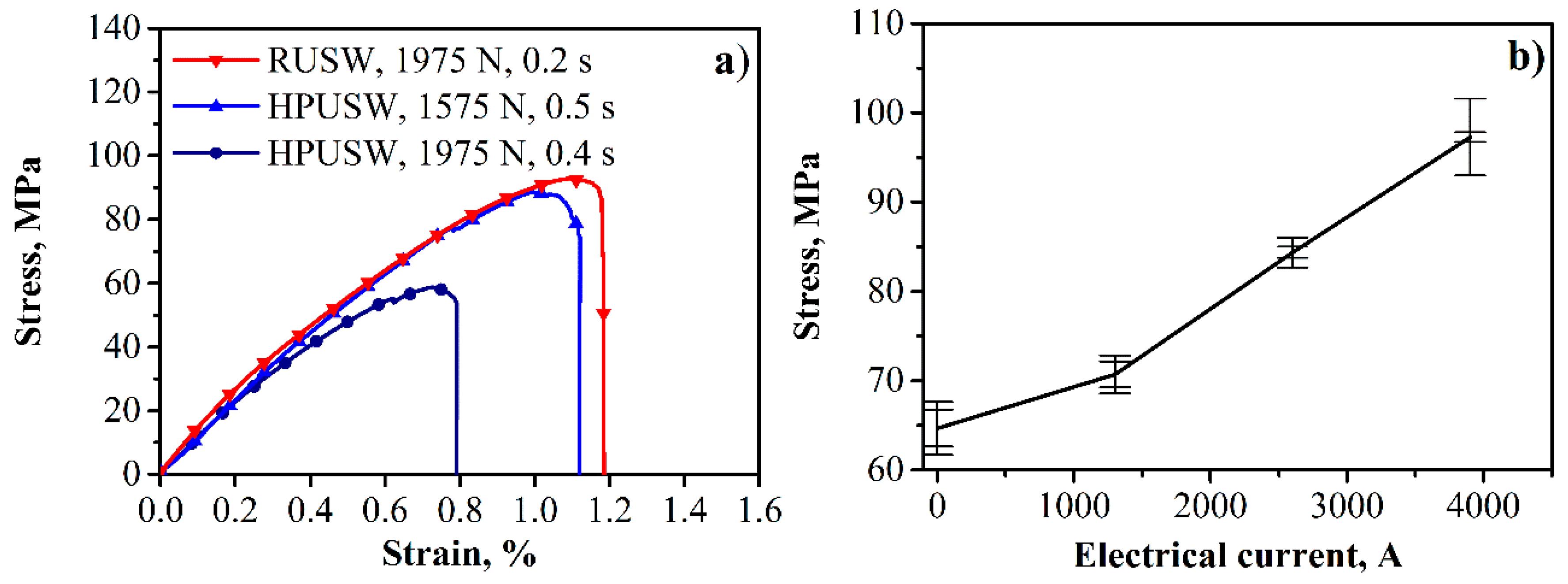

4.4. The Average Shear Stress

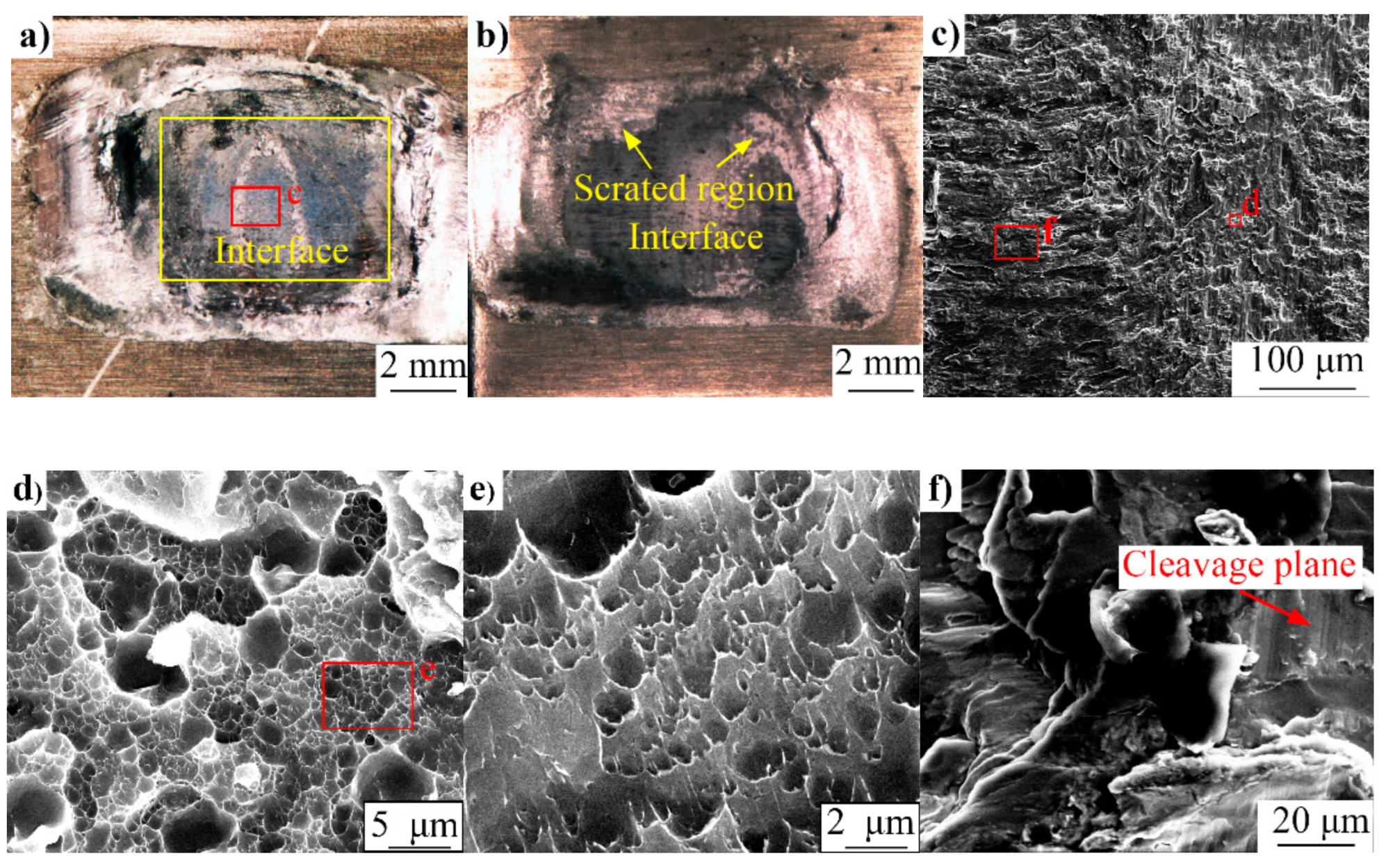

4.5. Fracture Morphology

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peng, H.; Jiang, X.; Bai, X.; Li, D.; Chen, D. Microstructure and mechanical properties of ultrasonic spot welded Mg/Al alloy dissimilar joints. Metals 2018, 8, 229. [Google Scholar] [CrossRef]

- Pereira, A.B.; Cabrinha, A.; Rocha, F.; Marques, P.; Fernandes, F.A.; Alves de Sousa, R.J. Dissimilar Metals Laser Welding between DP1000 Steel and Aluminum Alloy 1050. Metals 2019, 9, 102. [Google Scholar] [CrossRef]

- Eslami, N.; Hischer, Y.; Harms, A.; Lauterbach, D.; Böhm, S. Influence of Copper-Sided Tin Coating on the Weldability and Formation of Friction Stir Welded Aluminum-Copper-Joints. Metals 2019, 9, 179. [Google Scholar] [CrossRef]

- Eslami, N.; Hischer, Y.; Harms, A.; Lauterbach, D.; Böhm, S. Optimization of process parameters for friction stir welding of aluminum and copper using the taguchi method. Metals 2019, 9, 63. [Google Scholar] [CrossRef]

- Zhou, K.; Yao, P. Overview of recent advances of process analysis and quality control in resistance spot welding. Mech. Syst. Signal Process. 2019, 124, 170–198. [Google Scholar] [CrossRef]

- Liu, G.; Hu, X.; Fu, Y.; Li, Y. Microstructure and mechanical properties of ultrasonic welded joint of 1060 aluminum alloy and T2 pure copper. Metals 2017, 7, 361. [Google Scholar] [CrossRef]

- Liu, J.; Cao, B.; Yang, J. Effects of vibration amplitude on microstructure evolution and mechanical strength of ultrasonic spot welded Cu/Al joints. Metals 2017, 7, 471. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, D.; Luo, A. Joining 5754 automotive aluminum alloy 2-mm-thick sheets using ultrasonic spot welding. Weld. J 2014, 93, 131. [Google Scholar]

- Yang, J.; Cao, B.; He, X.; Luo, H. Microstructure evolution and mechanical properties of Cu–Al joints by ultrasonic welding. Sci. Technol. Weld. Join. 2014, 19, 500–504. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, D.; Zhang, Y. Effect of welding energy on interface zone of Al–Cu ultrasonic welded joint. Sci. Technol. Weld. Join. 2013, 18, 354–360. [Google Scholar] [CrossRef]

- Ni, Z.L.; Ye, F.X. Weldability and mechanical properties of ultrasonic joining of aluminum to copper alloy with an interlayer. Mater. Lett. 2016, 182, 19–22. [Google Scholar] [CrossRef]

- Balasundaram, R.; Patel, V.K.; Bhole, S.D.; Chen, D.L. Effect of zinc interlayer on ultrasonic spot welded aluminum-to-copper joints. Mater. Sci. Eng. A 2014, 607, 277–286. [Google Scholar] [CrossRef]

- Macwan, A.; Kumar, A.; Chen, D. Ultrasonic spot welded 6111-T4 aluminum alloy to galvanized high-strength low-alloy steel: Microstructure and mechanical properties. Mater. Des. 2017, 113, 284–296. [Google Scholar] [CrossRef]

- Ni, Z.; Zhao, H.; Mi, P.; Ye, F. Microstructure and mechanical performances of ultrasonic spot welded Al/Cu joints with Al 2219 alloy particle interlayer. Mater. Des. 2016, 92, 779–786. [Google Scholar] [CrossRef]

- Dehelean, D.; Oanca, O.; Toma, C.; Dorohoi, C.; Budau, V.; Craciunescu, C. Advanced materials joining using a hybrid ultrasonic-electric resistance technique. J. Optoelectron. Adv. Mater. 2010, 12, 1935–1941. [Google Scholar]

- Yang, J.; Cao, B. Investigation of resistance heat assisted ultrasonic welding of 6061 aluminum alloys to pure copper. Mater. Des. 2015, 74, 19–24. [Google Scholar] [CrossRef]

- Li, H.; Cao, B.; Yang, J.; Liu, J. Modeling of resistance heat assisted ultrasonic welding of Cu-Al joint. J. Mater. Process. Technol. 2018, 256, 121–130. [Google Scholar] [CrossRef]

- Li, H.; Cao, B.; Liu, J.; Yang, J. Modeling of high-power ultrasonic welding of Cu/Al joint. Int. J. Adv. Manuf. Technol. 2018, 97, 833–844. [Google Scholar] [CrossRef]

- Lee, D.; Cai, W. The effect of horn knurl geometry on battery tab ultrasonic welding quality: 2D finite element simulations. J. Manuf. Process. 2017, 28, 428–441. [Google Scholar] [CrossRef]

- Samanta, A.; Xiao, S.; Shen, N.; Li, J.; Ding, H. Atomistic simulation of diffusion bonding of dissimilar materials undergoing ultrasonic welding. The International Journal of Advanced Manufacturing Technology; Springer: London, UK, 2019; pp. 1–12. [Google Scholar]

- Das, A.; Masters, I.; Williams, D. Process robustness and strength analysis of multi-layered dissimilar joints using ultrasonic metal welding. The International Journal of Advanced Manufacturing Technology; Springer: London, UK, 2019; Volume 101, pp. 881–900. [Google Scholar]

- Zhao, J.; Li, H.; Choi, H.; Cai, W.; Abell, J.A.; Li, X. Insertable thin film thermocouples for in situ transient temperature monitoring in ultrasonic metal welding of battery tabs. J. Manuf. Process. 2013, 15, 136–140. [Google Scholar] [CrossRef]

- Hu, T.; Zhalehpour, S.; Gouldstone, A.; Muftu, S.; Ando, T. A method for the estimation of the interface temperature in ultrasonic joining. Metall. Mater. Trans. A 2014, 45, 2545–2552. [Google Scholar] [CrossRef]

- Tan, C.; Jiang, Z.; Li, L.; Chen, Y.; Chen, X. Microstructural evolution and mechanical properties of dissimilar Al–Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Badamian, A.; Iwamoto, C.; Sato, S.; Tashiro, S. Interface Characterization of Ultrasonic Spot-Welded Mg Alloy Interlayered with Cu Coating. Metals 2019, 9, 532. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Moat, R.; Threadgill, P.; Addison, A. Linear friction welding of aluminium to magnesium. Sci. Technol. Weld. Join. 2012, 17, 368–374. [Google Scholar] [CrossRef]

- Carboni, M.; Annoni, M. Ultrasonic metal welding of AA 6022-T4 lap joints: Part II–Fatigue behaviour, failure analysis and modelling. Sci. Technol. Weld. Join. 2011, 16, 116–125. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Cao, B. Microstructure and Mechanical Properties of Resistance Heat-Assisted High-Power Ultrasonic Dissimilar Welded Cu/Al Joint. Metals 2019, 9, 873. https://doi.org/10.3390/met9080873

Li H, Cao B. Microstructure and Mechanical Properties of Resistance Heat-Assisted High-Power Ultrasonic Dissimilar Welded Cu/Al Joint. Metals. 2019; 9(8):873. https://doi.org/10.3390/met9080873

Chicago/Turabian StyleLi, Huan, and Biao Cao. 2019. "Microstructure and Mechanical Properties of Resistance Heat-Assisted High-Power Ultrasonic Dissimilar Welded Cu/Al Joint" Metals 9, no. 8: 873. https://doi.org/10.3390/met9080873

APA StyleLi, H., & Cao, B. (2019). Microstructure and Mechanical Properties of Resistance Heat-Assisted High-Power Ultrasonic Dissimilar Welded Cu/Al Joint. Metals, 9(8), 873. https://doi.org/10.3390/met9080873