1. Introduction

During past three decades, numerous studies have been conducted on the structure and mechanical properties of bulk nanostructured (NS) and ultra-fine-grained (UFG) materials produced by severe plastic deformation (SPD) processing. In these studies, considerable effort has been devoted to high pressure torsion (HPT) [

1,

2] as well as equal channel angular pressing (ECAP) [

3,

4,

5] since these two are the best-known SPD techniques for producing UFG metallic materials. UFG materials with unique combinations of mechanical properties such as high strength and plasticity [

6] have generated intensive interest because the results of some studies have suggested the presence of new strengthening mechanisms.

NS metals, including those processed by HPT, generally exhibit very high strength but limited tensile ductility (with a uniform elongation, only reaching a few percent) with almost no work-hardening [

7]. Low ductility is believed to be an intrinsic “Achilles heel” of NS metals because the conventional deformation mechanisms cease to operate at the nanoscale level such that: (i) the dislocation slip is substantially suppressed by the extremely small grains (which, however, account for the extreme strength values in NS metals); and (ii) grain boundary (GB) sliding or diffusional creep is not active enough to accommodate plastic straining at ambient temperature [

8]. However, some experimental data have hinted to the possibility that the generally observed low plasticity in NS metals might be extrinsic rather than intrinsic to these materials. For instance, dimples have been observed on fracture surfaces of various NS metals, indicating substantial plastic deformation before failure [

7]. In addition, large plastic strains were also obtained when using other deformation schemes such as compression and rolling [

3,

5]. Indeed, limited tensile ductility of NS metals has often been attributed to the absence of work hardening and to their nano-sized grains, so that strain localization and early necking occur immediately after the onset of yielding. On the other hand, intrinsic tensile plasticity of NS metals can be detected by effective suppression of strain localization.

There are several kinds of SPD techniques, which combine extrusion and shear, e.g., twist extrusion [

9], extrusion compression [

10] and cyclic expansion extrusion [

11]. In this study, we used the high pressure torsion extrusion (HPTE) approach, with prevailing shear strain at the periphery of bulk rod samples and extrusion-like deformation near the center of the rods [

12,

13,

14]. The strain conditions at the center and at the edge of the HPTE-processed rods depend on the processing parameters and they can vary by several orders of magnitude. Therefore, HPTE is the one of the SPD methods which is capable of producing rod samples with controlled gradient heterogeneous structures.

During the past decades, comprehensive analyses on the influence of the deformation mode on the structural evolution and the resulting physical properties of initially structurally homogeneous materials have been conducted. For example, refer to the study on the hardness and electrical conductivity of pure copper processed by ECAP and HPT [

15]; the study on the structural evolution in a Siclanic alloy (Cu–Ni–Si) processed by ECAP and HPT [

16]; and the studies on the effect of the SPD deformation mode on the microstructure of pure copper [

17,

18].

Recently, a few studies have been reported on the mechanical properties of structurally heterogeneous materials [

7,

19], consisting of hard and soft domains, which may demonstrate the combination of very attractive properties such as high strength and high tensile ductility values. Knowledge on the effects of fine–ultrafine and nano-grained structures on mechanical properties will make it possible to significantly extend our understanding of the deformation processes from the analysis of homogeneous materials to that of heterogeneous counterparts and, in particular, structurally gradient materials [

20].

One of the clearest structural features of Cu after the HPTE processing is a strong grain refinement in the peripheral area, and a less pronounced grain refinement in the sample’s core [

12]. Such heterogeneous structure was the result of strain gradient along the sample radius. Tensile tests, carried out on the gradient Cu samples after a surface mechanical grinding treatment, have shown that the combination of NS to coarser grained microstructure provide an effective approach for enhancing the “strength–ductility” synergy of materials which offer a potential for using the gradient NS layers as an advanced coating of the bulk materials [

7].

However, since HPTE it is a newly established SPD technique, data on the applicability of this method to produce structurally gradient materials are still not available. Consequently, results on the characterization of their mechanical properties are also limited. This study aims to bridge this gap by conducting a critical analysis of both the structure and the mechanical test results obtained on HPTE-processed Cu rod samples to reveal possible strengthening effects of varying grain refinement steps giving rise to gradient (heterogeneous) structures.

2. Materials and Methods

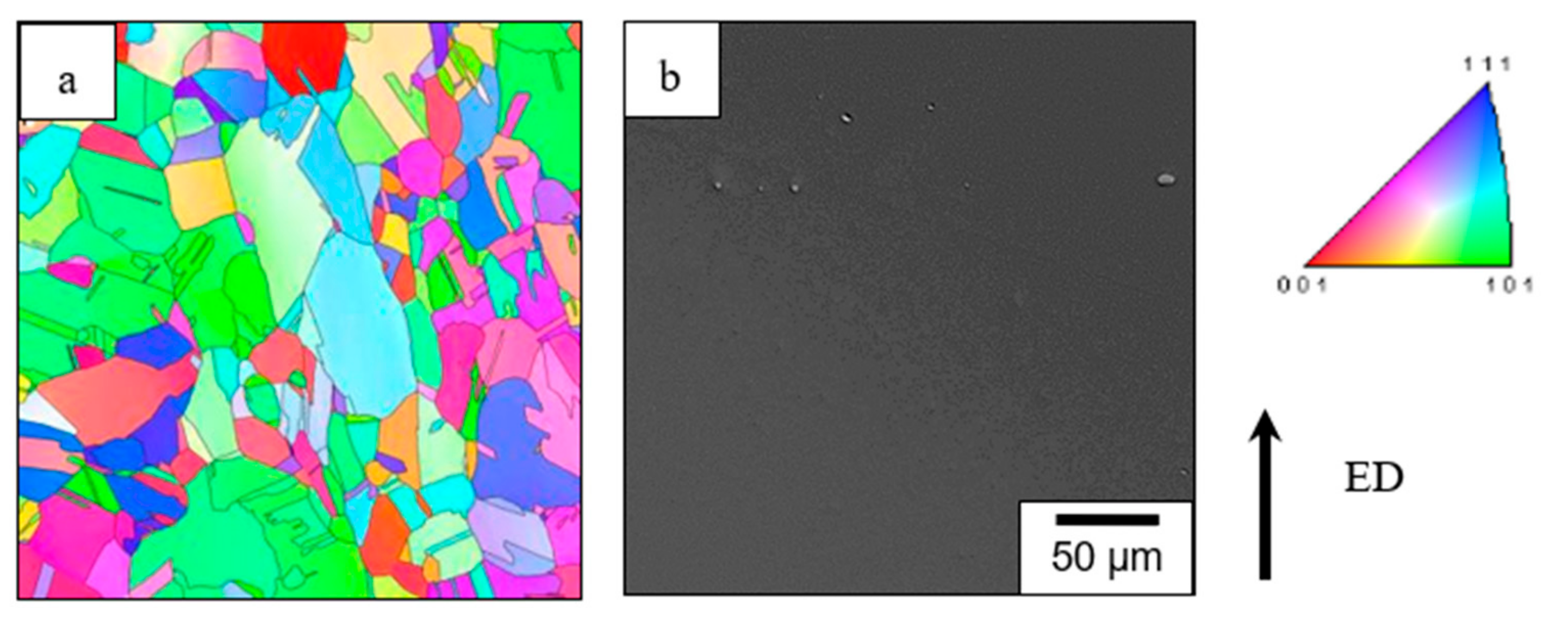

CP copper samples containing 99.0 wt% of Cu and 1.0 wt% of Al were first machined, annealed for two hours at 600 °C, and then water quenched to obtain a coarse-grained (CG) microstructure. A typical orientation imaging microscopy (OIM) map of the initial structure is shown in

Figure 1a. The OIM map was obtained from the electron backscatter diffraction (EBSD) data and it demonstrates, random grain orientations. The initial structure is characterized by near-ellipsoid-shaped grains (the aspect ratio was ~1.3) with numerous annealing twins (

Figure 1a) and an average grain size of ~30 µm. As shown by the back-scattered electron (BSE) image in

Figure 1b, the microstructure also contains second-phase particles. The BSE image shows that the second phases are nearly spherical with an average diameter of ~1–5 µm. Usually, these particles are Cu-rich AlCu

3, Al

4Cu

9 and AlCu

2 intermetallic phases [

21,

22]. According to the technical specifications of CP copper [

22], the particles have a metallurgic origin and they can also include oxides, hydrides, and flux-income impurities.

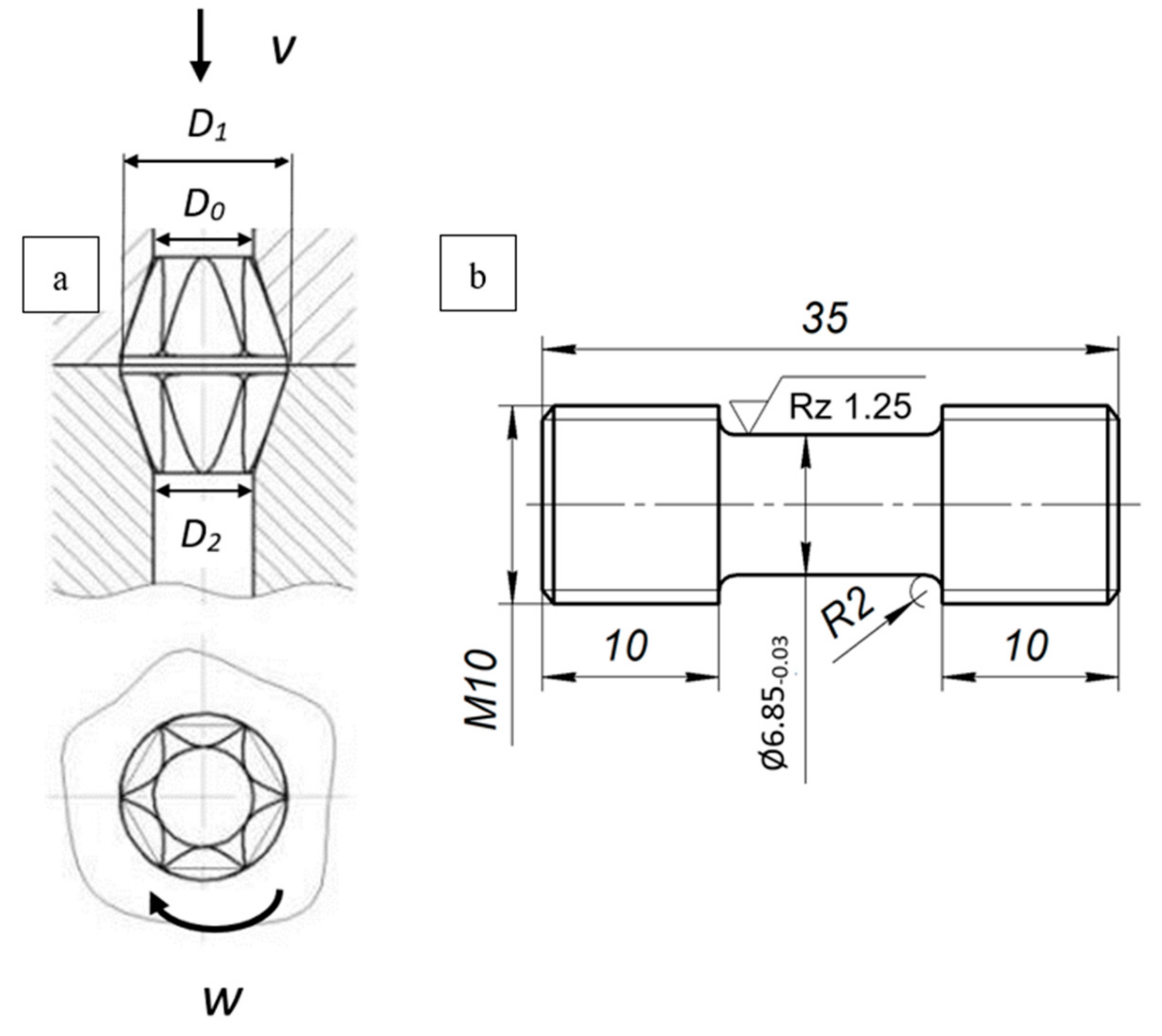

The HPTE apparatus (Karlsruhe Institute of Technology, Institute of Nanotechnology, Eggenstein-Leopoldshafen, Germany), with a specially designed die, is shown in

Figure 2a. The material processing was performed at 100 °C with an extruding velocity (υ) of 1 mm/min and a rotational velocity (ω) of 1 rpm. According to [

12], HPTE-processed copper with v1w1 regime at room temperature led to the formation of a UFG structure. In our study, cylindrical shaped (rod) samples with an initial diameter of 11.8 mm and a length of 35 mm were processed using molybdenum disulfide (MoS

2) as a lubricant to facilitate the extrusion process. The HPTE apparatus was described in detail in [

12]. During the processing, the Cu rod samples were exposed to expansion and extrusion as well as torsion.

Additional details regarding the development of the die design and the compressive strength the material samples are subjected to during the HPTE processing have been described in an earlier study [

23]. The resulting equivalent strain depends on the ratio of the channel diameters (D1/D0 and D1/D2), the extruding velocity (υ), and the angular velocity of the die (ω), and it can be calculated as follows [

12]:

where D0, D1, and D2 are fixed and equal to 12, 14, and 10.6 mm, respectively, and R is the distance from the center in the sample’s cross section.

Under the above-mentioned parameters,

Table 1 contains the strain values calculated using Equation (1). The equivalent strain is in the range between 5.2 and 22.4, depending on the distance from the center, which ensures the formation of a gradient structure.

The HPTE-processed samples were afterwards sectioned both in the transverse (normal) and longitude directions, thinned to the foil thickness, grinded, and mechanically polished. The polished samples were subsequently examined by EBSD technique, using a ZeissAuriga60 scanning electron microscope (SEM), equipped with an EDAX-TSL EBSD system, and operated at 20 kV. The samples for SEM observations were prepared by conventional electro-polishing procedure with a Tenupol-5 twinjet polisher, using standard Struers solution for copper. Final polishing on GATAN PIPS system was performed to remove the surface oxide layer.

TSL OIM EDAX v.7 (EDAX Inc., Draper, UT, USA) software was used for indexing the EBSD patterns. The dimension of the scan areas was 20 × 20 µm. OIM maps were collected from transverse (shear plane) and longitudinal sections of the samples. They were collected at the sample’s center (~0.5 mm from the sample axis), at the middle-radius (~2.7 mm from the sample axis), and at the sample’s edge (~4.5 mm from the sample axis). Scan step was 0.1 µm for the initial state and at the central area of the deformed samples, and 0.05 µm at the mid-radius and edge of the HPTE samples.

To minimize misindexing error, nine Kikuchi-bands were used for indexing. To ensure reliability of the EBSD data, all grains comprising of three or fewer pixels were automatically removed from the maps using the grain-dilation and neighbor orientation correlation options of the TSL software (minimal grain tolerance angle was 5°). The camera settings and the Hough parameters allowed us to collect data without significant decrease in pattern quality with the angular resolution ~0.5°. For noise reduction, a lower limit boundary misorientation cut-off value of 2° was applied. A 15° criterion was used to differentiate between low—(LABs) and high—(HABs) angle GBs. The grain size (D) was computed using the equal diameter method. Two misorientation threshold values, of 3° and 15°, were used to define the grain area. The respective mean grain sizes are labeled as D3 and D15. Specific grain area (S/Si) distributions by the grain equivalent diameter were plotted for more than 500 grains in each state, where S is the map area and Si is the area of the grains within the i-th interval.

Grain shape was characterized by the N

x/N

y, the aspect ratio parameter corresponding to the ratio between the number of HAB intersections with vertical (N

x) and horizontal (N

y) secant lines in the transverse and longitude sample sections, respectively. The dislocation density was measured by means of two methods, i.e., EBSD and X-ray diffraction (XRD). The EBSD technique allows to define only geometrically necessary dislocation (GND) density [

24], whereas XRD measured total dislocation density, including GNDs and statistically stored dislocations (SSDs). As a first-order estimate, the kernel average misorientation (KAM), which is retrieved directly from EBSD data, was chosen as a measure for the local misorientations. KAM gives the average misorientation around a measurement point with respect to a defined set of nearest and second-nearest neighbor points. The GND density was calculated from the local misorientations, using the option of the OIM software for the angles smaller than 2°. Standard preset for fcc crystal-type slip systems was used in the software set-up. For the calculation of KAM, we considered the slip in (111) crystallographic planes and four possible slip systems along four close-packed <110> directions. We computed the GND density, using the experimental data on the misorientation angle. Additional details regarding GND density calculation can be found elsewhere [

25]. The calculation was done for each map pixel, taking into account the data for five nearest neighbors. Orientation gradient was determined as the misorientation between two points over the corresponding length [

26].

XRD spectra were collected with a Philips X’Pert powder diffractometer (Malvern Panalytical Ltd., Almelo, The Netherlands), operating in the Bragg–Brentano geometry with the Cu-Kα emission line. The background pattern was calculated by the X’pert HighScore software (Malvern Panalytical Ltd., Malvern, UK). The irradiation area had the dimensions of 5 mm in width and 1 mm in length. This made it possible to obtain XRD spectra from three different locations of the sample along the shear direction (SD) in the longitudinal rod section.

Parameters of the XRD peak profiles, i.e., peak intensity and full width at half maximum, were fitted by the Pseudo-Voigt function. The mean diameter of the crystallites (size of coherently scattering domains) and micro-strain have been estimated from the diffraction peak broadening, including reflections up to (420), in a modified Williamson–Hall method [

27]. It is known that in the case of the random distribution of dislocations, the total dislocation density

can be defined as [

28,

29]:

where D

hkl is crystallite size, <

>

1/2 is the mean squared micro-strain value, and

b is the absolute value of the Burgers vector.

SEM Zeiss LEO1530 at the acceleration voltage of 20 kV coupled with energy-dispersion spectrometry (EDS) was used for the elemental analysis of the samples.

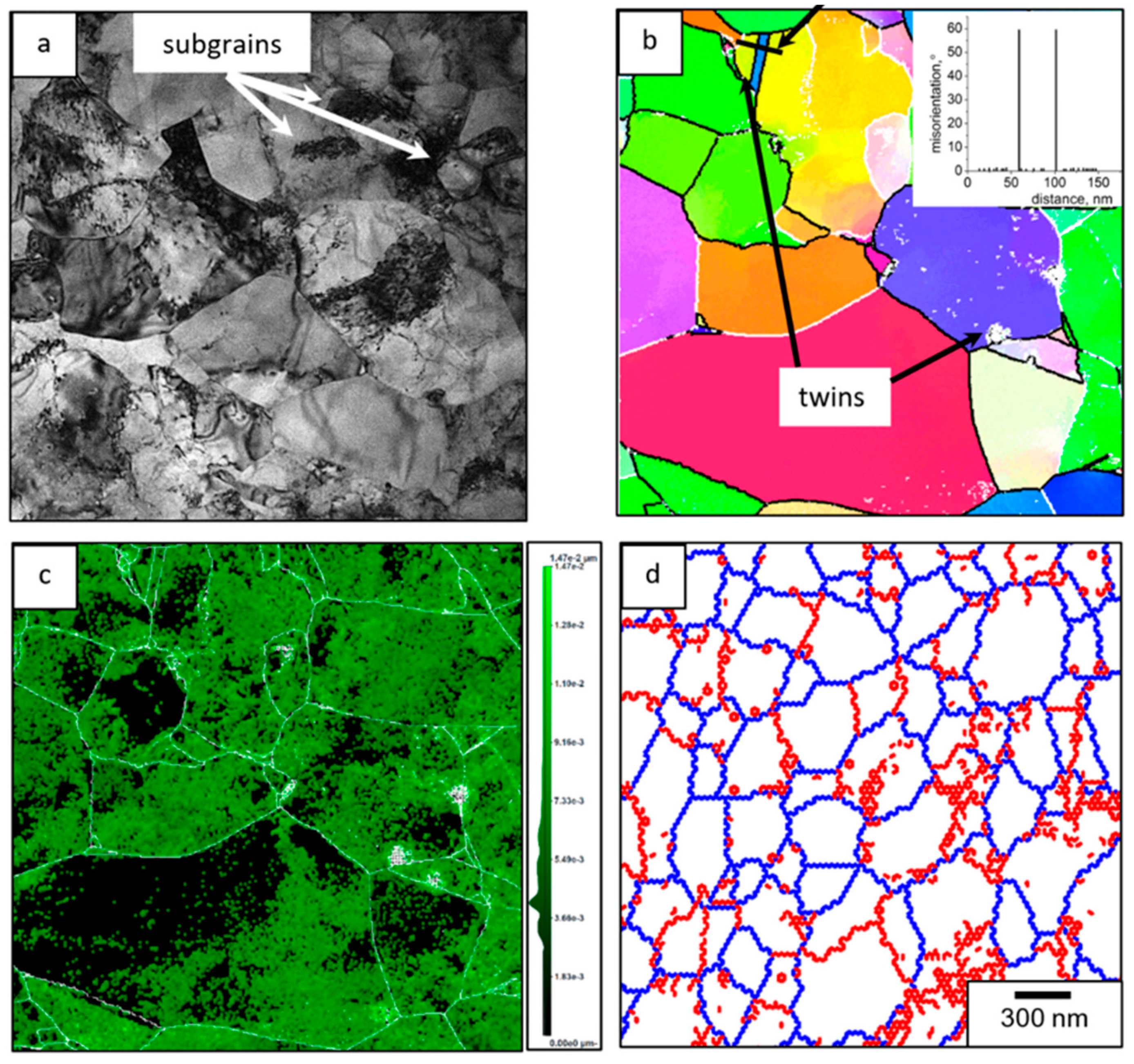

To enhance the spatial and angular resolution of the OIM analysis we carried out the investigations using the FEI Tecnai F20 transmission electron microscope (200 kV) with field emission gun, equipped with the system for automated crystal orientation mapping in the TEM (ACOM-TEM) [

30]. For the mapping we used the µ-probe set-up with a beam diameter of ~1–1.5 nm and step size of 5 nm.

A Buehler Micromet-5104 tester was used for the Vickers hardness measurements. A load of 0.2 kg with a dwell time of 15 s was applied to all samples during the hardness measurements. Five indentations spaced 1 mm apart were made along two mutually perpendicular diameters of the specimens. The average value of each measurement was computed from 10 indentations.

Tensile tests were carried out at ambient temperature at a strain rate of 1 × 10

−3 s

−1, using a Zwick Z100 screw-driven testing machine on cylinder-shaped samples with twist holders (

Figure 2b). The tensile samples were machined from the three HPTE-processed billets along the extrusion direction in accordance with ASTM E 8/E 8M-08 requirements.

4. Discussion

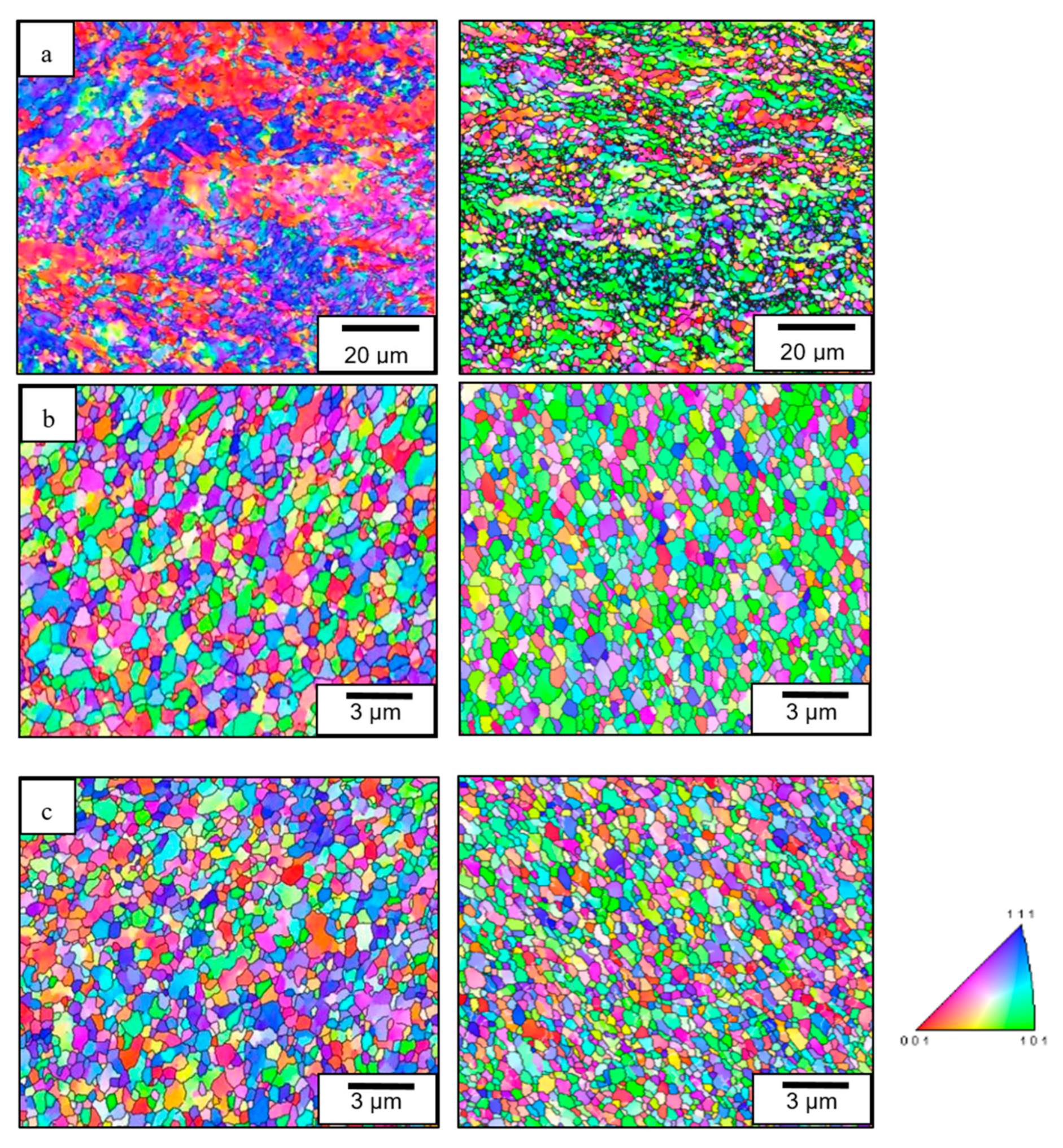

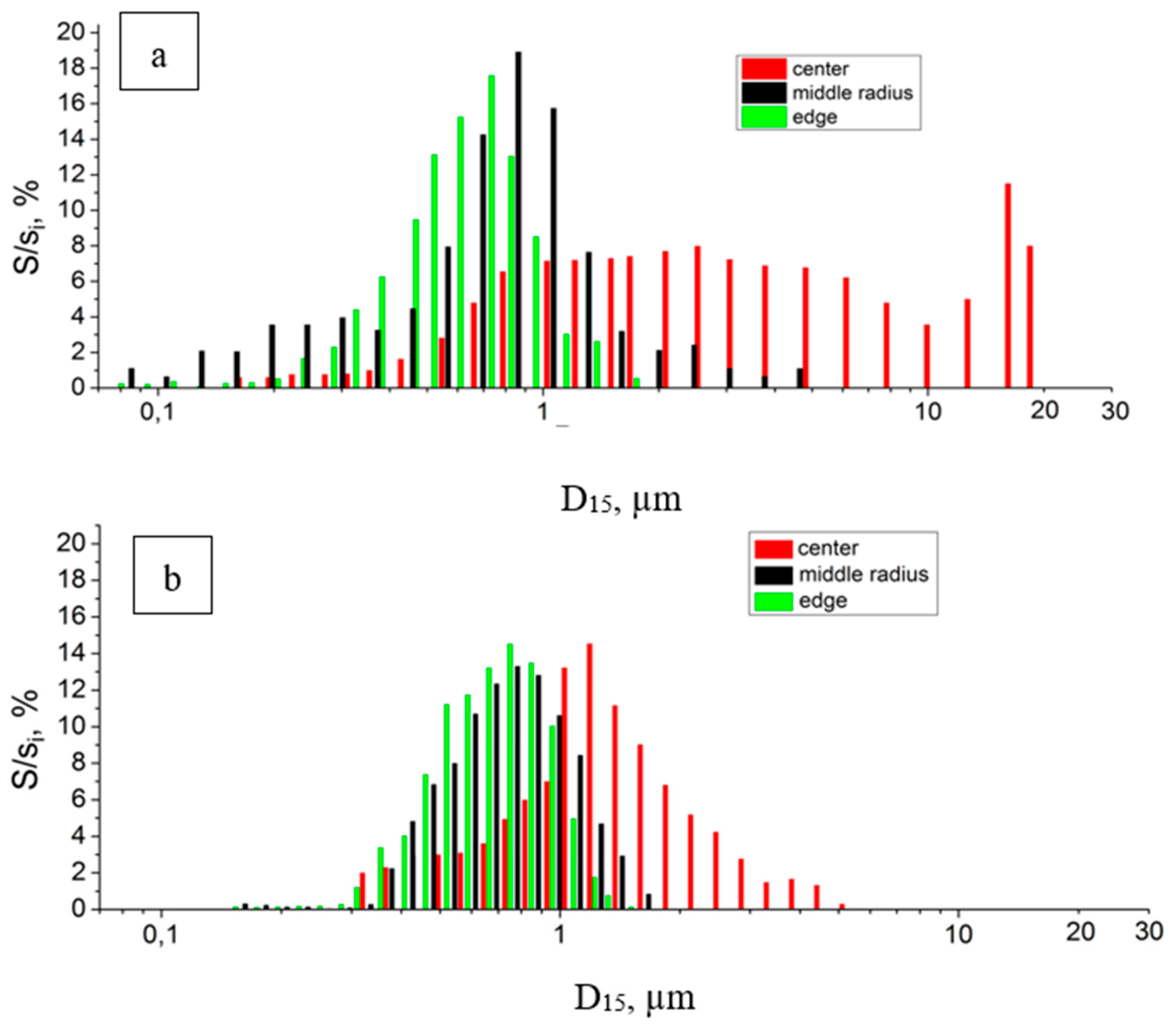

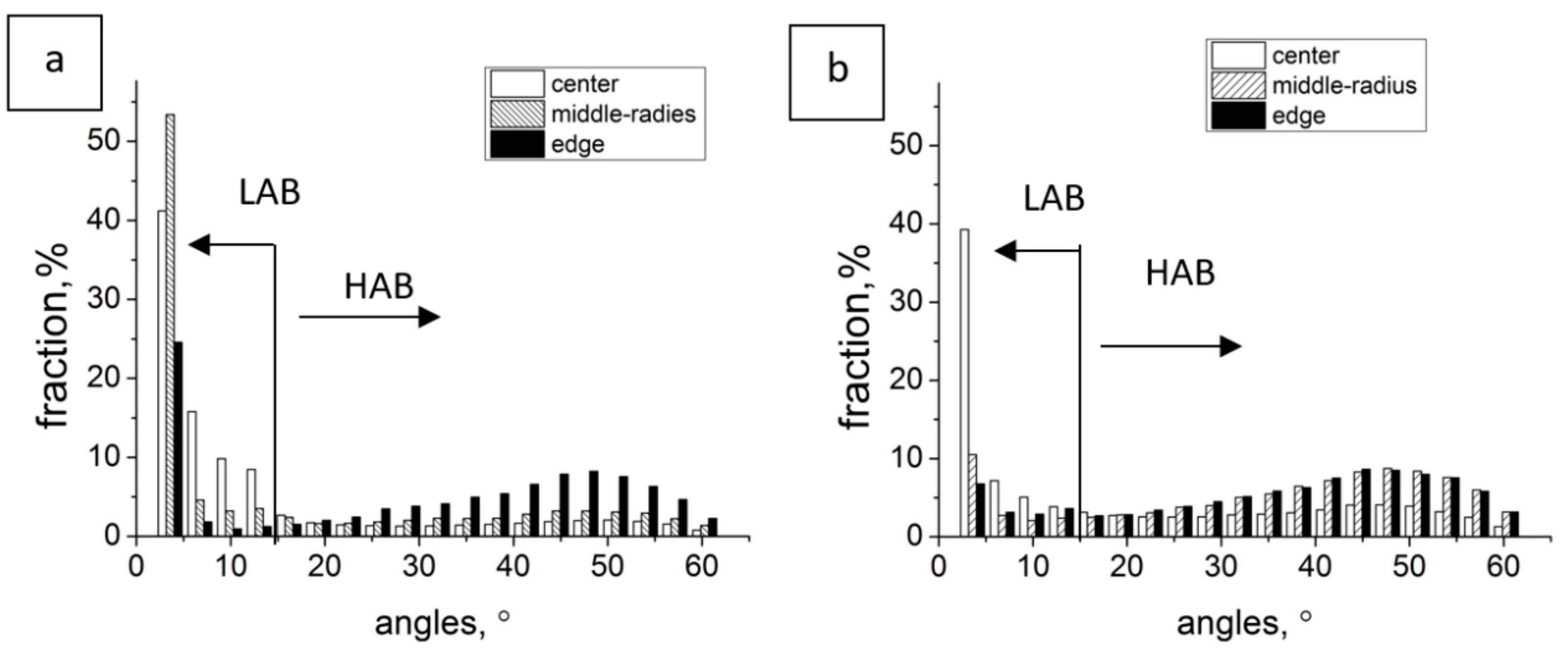

The microstructure study demonstrated that the v1w1 regime of the HPTE deformation, carried out at 100 °C, resulted in the formation of a gradient microstructure in CP copper. This is not surprising since HPTE combines both extrusion and shear deformation modes. The shearing mode gradually increases from the sample´s center to the edge (Equation (1)). Consequently, the central area of the HPTE-processed rod is characterized by the presence of a fine-grained structure, whereas in the mid-radius and edge areas are characterized by an ultrafine-grained structure. Apparently, large grains were gradually refined with an increasing strain, resulting in an increased fraction of the fine grains, as shown in

Figure 4a. Even in the central area of the HPTE rod the majority of grains (about 80–85%) are the newly refined grains with the sizes in the range of ~2–5 µm (

Figure 3a). In this area, new dislocation boundaries were actively formed and the difference between D

15 and D

3 is significant (

Table 1).

At a larger distance from the center, the applied strain increased, and the formation rate of new GBs became slower since both grain sizes, D

3 and D

15, were practically the same at the mid-radius and at the edge, indicative of no further grain refinement. This indicates that the saturation of the grain size refinement was reached, which is typical for other SPD methods [

32]. Following grain refinement saturation, the misorientations at the already-formed interfaces were growing resulting in an increase of the HABs fraction (

Figure 5). Note that this increase occurred at different rates at different grain facets and the difference between D

15 and D

3 still persisted up to the highest strain reached in our experiment. GB distribution maps like one shown in

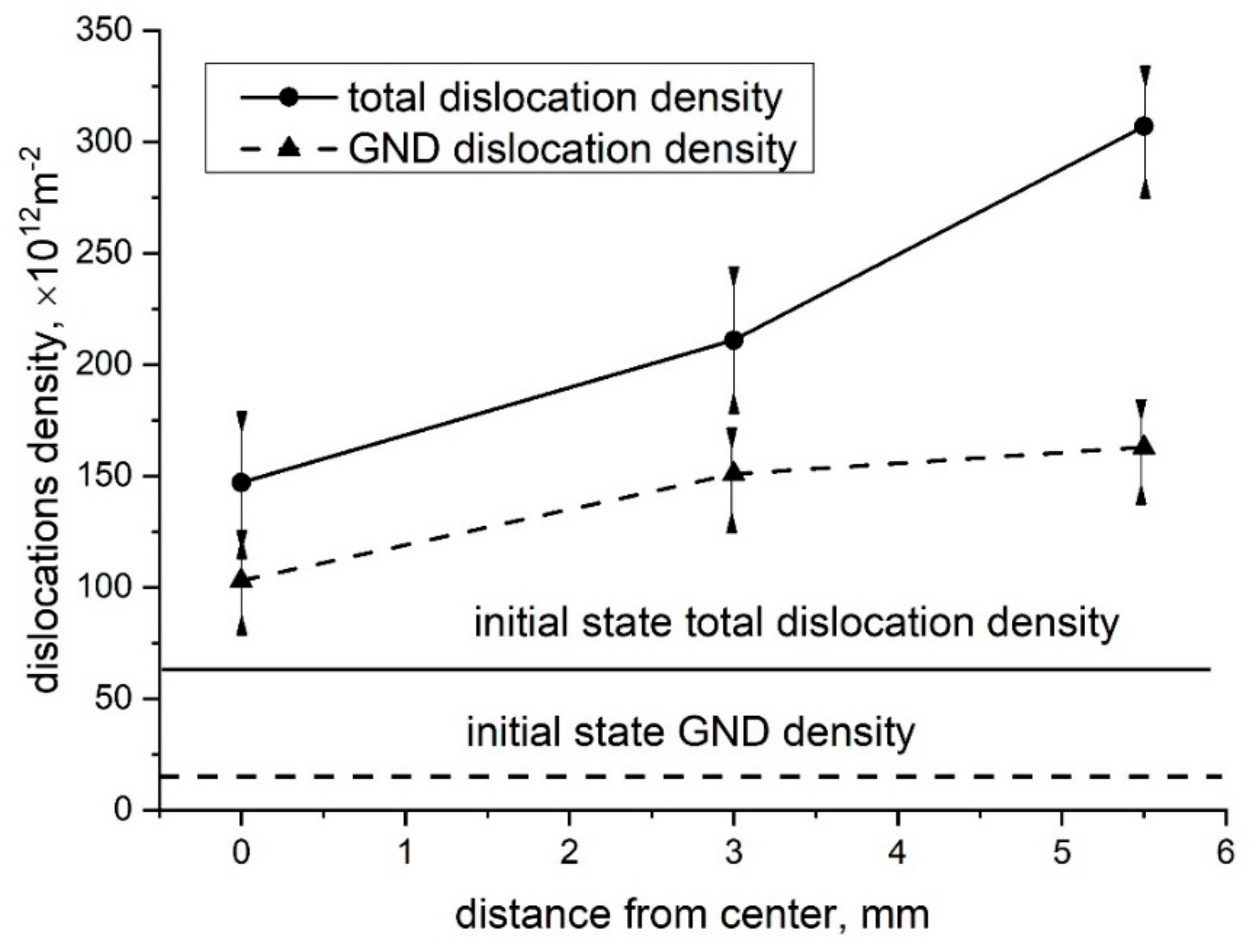

Figure 6d clearly demonstrate that in all sample areas, the microstructure is complex, i.e., the LABs and HABs represent an interpenetrated network. In other words, a crystallite (grain or subgrain) can be simultaneously bounded by high angle and low angle boundaries. Interestingly, the density of SSD showed an enhanced increase at the edge of the HPTE-processed sample in comparison with that of GND (

Figure 6c). This fact suggests that the multiplication rate of SSD was higher than their recovery/annihilation rate at the edge (also in the mid-radius) area, compared to the kinetics of the same processes in the central area. The difference in density for both kinds of dislocations (GND and SSD) is consistent with the published data [

33], showing that: (i) in well-annealed metallic materials the GND density is 20%–30% lower than the total dislocation density; and (ii) that both values are strongly correlated.

The microstructure resulting from HPTE processing has similar features with the gradient microstructure of CP Cu after free-end torsion [

31,

34]. Nevertheless, several distinctions should be mentioned here. HPTE provided a more efficient grain refinement compared to that achievable with free-end torsion. Furthermore, instead of a coarse-grained structure in the center and a fine-grained structure at the periphery, we observed an FG structure at the center and a UFG structure at the periphery after HPTE. After HPTE, we observed a more homogeneous grain structure in the entire sample with no grain elongation, as it was observed after the free-end torsion.

CP Cu samples deformed via the HPTE under the v1w1 regime demonstrated a yield strength and an ultimate strength close to the corresponding values obtained after the free-end torsion with strain 1.3 [

31]. The elongation to failure of Cu was reduced for more than 1.5 times compared to the elongation after free end torsion. By contrast, the ductility after HPTE remained at the level of the annealed state.

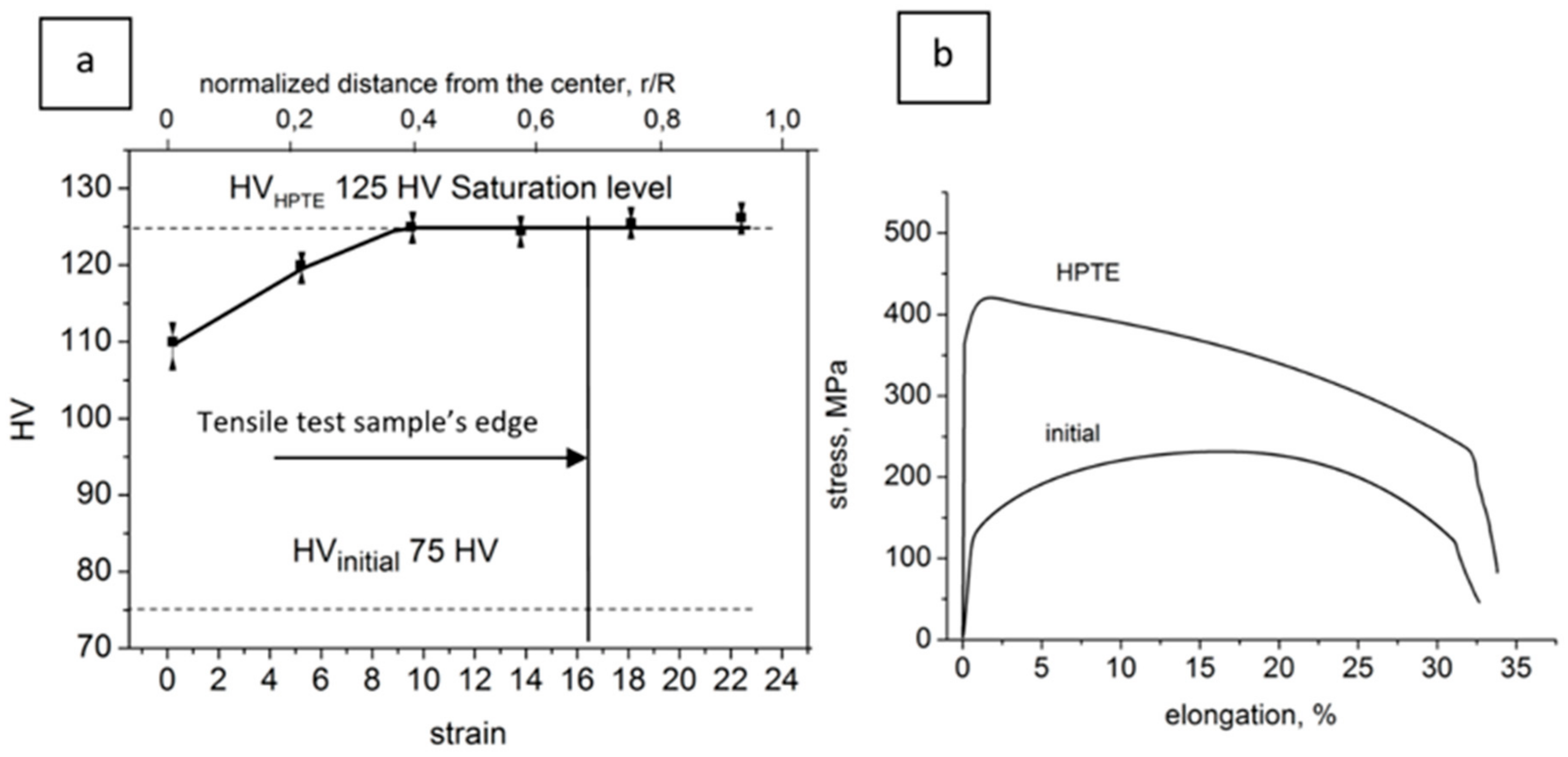

The microhardness saturation value of 125 HV is very close to the microhardness of oxygen-free (OF) copper deformed by HPTE under the v1w1 regime at room temperature [

12], and also close to OF copper microhardness after HPT [

8,

15] (

Table 2). The strength of the HPTE-processed copper is comparable with that of copper after ECAP, and it is not as high as that after HPT [

8].

The change of the microhardness along the radius of the Cu rod cross-section allows to analyze the contribution of various hardening mechanisms after HPTE in different sample areas (

Figure 8a). In fact, after HPTE treatment the variation of hardness is determined by the distribution of strain in the sample affecting the dislocation density values and the degree of grain refinement which gives rise to Hall–Petch hardening [

35]. The inhomogeneity of the strain distribution in the HPTE-processed rod (Equation (1)) leads to the formation of the gradient structure. The tensile sample geometry (

Figure 2b) made it possible to conduct mechanical testing on the sample with gradient structure.

We assume that experimentally obtained strength in CP copper samples after HPTE results from the following hardening mechanisms: accumulation of dislocations (σρ), Hall–Petch strengthening and subgrains (σH-P), solid solution strengthening (σSSS), and second-phase particle strengthening (σSPPS).

The contribution of stored dislocations to the yield strength can be estimated using the Taylor Equation:

where M is Taylor factor, α is a constant, G is the shear modulus, b is the absolute value of the average Burgers vector, and

ρ is the total dislocation density. We can estimate strengthening due to the grain refinement using the Hall–Petch relation:

where σ

0 is the friction stress, k is a constant, and d is the mean grain size in the corresponding sample area. The sample contained material from central and mid-radius areas. The microstructure in both areas is complex because the grains are bounded by both HABs and LABs. Therefore, it is not clear which GB misorientation threshold and grain size should be used in Equation (3). Prior in-situ TEM study [

36] had shown that in FCC metals with low and middle stacking fault energy, the LABs with Θ > 3° and special GBs provide effective barriers for the dislocation slip. Therefore, we can assume that the effective grain size, d, in the Hall–Petch equation is equal to D

3. In Hall–Petch strengthening it is also necessary to account for the input from nanotwins. Twin boundaries are the obstacles for dislocations slip. The volume fraction of twin boundaries was 15.4% and the effective grain size d for the Hall–Petch strengthening calculation is D

3 with twins = 0.25 µm, estimated from several ACOM TEM maps. This value is smaller than D

3 obtained from EBSD maps (0.4 µm,

Table 1) due to higher angular resolution of ACOM TEM technique as previously discussed.

Solid solution strengthening is complex since the solute atoms can interact with dislocations by the elastic, electrical, short-range and long-range interactions [

37]. For the Cu-Al substitutional solid solution, the elastic interaction is most important. This elastic interaction can be associated with local short-range mean normal stress. In the linear approximation, the elastic interaction is assessed as Paierls-Nabarro forces taking into account the atomic radius misfits and alloying element concentrations [

37]. As a result, solid solution strengthening leads to an increase in the friction stress σ

0. Solid solution strengthening for the Cu–Al single crystal was measured experimentally and, depending on the concentration of Al in solid solution, a linear dependence of the σ

sss was obtained [

38]:

where c is the concentration of Al in the Cu–Al solid solution.

Second-phase particle strengthening was provided by the large (about 1 micrometer in diameter) particles and it can be calculated using the Orovan’s formula for the non-coherent particles:

The parameters (σ

0, k, α, G, b) used for computing the various strengthening mechanisms described above were taken from [

22,

39,

40], whereas the structure parameters D

3, ρ,

dp,

f are given in

Table 1 and

Table 3.

As can be seen in

Table 4, the calculated contributions from the solid solution and the precipitation strengthening are small and they provide less than 10% to the YS

calc value, while the dislocation strengthening is 3–4 times higher, which provides ~50% to the YS

calc in the initial state and only 20% of the YS

calc in HPTE-processed copper. The low contribution of dislocation strengthening to YS

calc in the HPTE-processed copper is likely related to the elevated temperature of the HPTE processing of 100 °C, which promoted recovery of dislocation density. Therefore, the main contribution (~60%) to the strength of HPTE-processed Cu is due to the GB strengthening via the Hall–Petch mechanism.

In order to compare the calculated (YS

calc) and the experimentally measured (YS

M) yield strengths of the entire HPTE-processed sample we can use the rule of mixture:

where YS

C and YS

MR are the calculated values of the yield strength of the material from the center and mid-radius area, respectively (

Table 4), and V

C and V

MR are the volume fractions in these same areas. According to the microhardness distribution along the radius of the HPTE-processed sample (

Figure 8a), the hardness is low in a narrow area with the radius of 1.2 mm around the rod axis. Therefore, the volume fraction of this part of the tensile specimen is only 0.12. Consequently, the majority of the volume fraction is contributed by mid-radius area. The calculated value of YS

M = 374.6 MPa is in a good agreement with experimentally measured yield strength of 370 MPa. A part of the HPTE-processed rod with high hardness and strength values was removed upon machining of the tensile specimen (

Figure 8b). A rapid strengthening and a short uniform elongation range characterized the stress–elongation curve of copper after HPTE. A decrease of uniform elongation from ~16% in the annealed state to ~2% after the HPTE deformation is a typical behavior for the materials produced by SPD methods. However, as the deformation is localized, the elongation to fracture reaches 30%, which is two times higher than post-necking elongation of the annealed copper (

Figure 8b). Such a behavior is typical for materials with ultrafine-grained microstructure [

41,

42,

43] and most likely related to the increased strain rate sensitivity of such materials. Otherwise, the strength of the entire specimen would be even higher. Therefore, HPTE processing of CP copper provides large elongation to failure and high strengthening mostly due to the Hall–Petch mechanism. The uniform elongation (~2%) had not been improved despite the presence of gradient microstructure as proposed in [

7]. Most likely, this approach could not be realized in the HPTE-processed copper because both central and outer layers were sufficiently strengthened, and the material demonstrated tensile behavior similar to that of the homogeneous UFG materials.