Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder

Abstract

1. Introduction

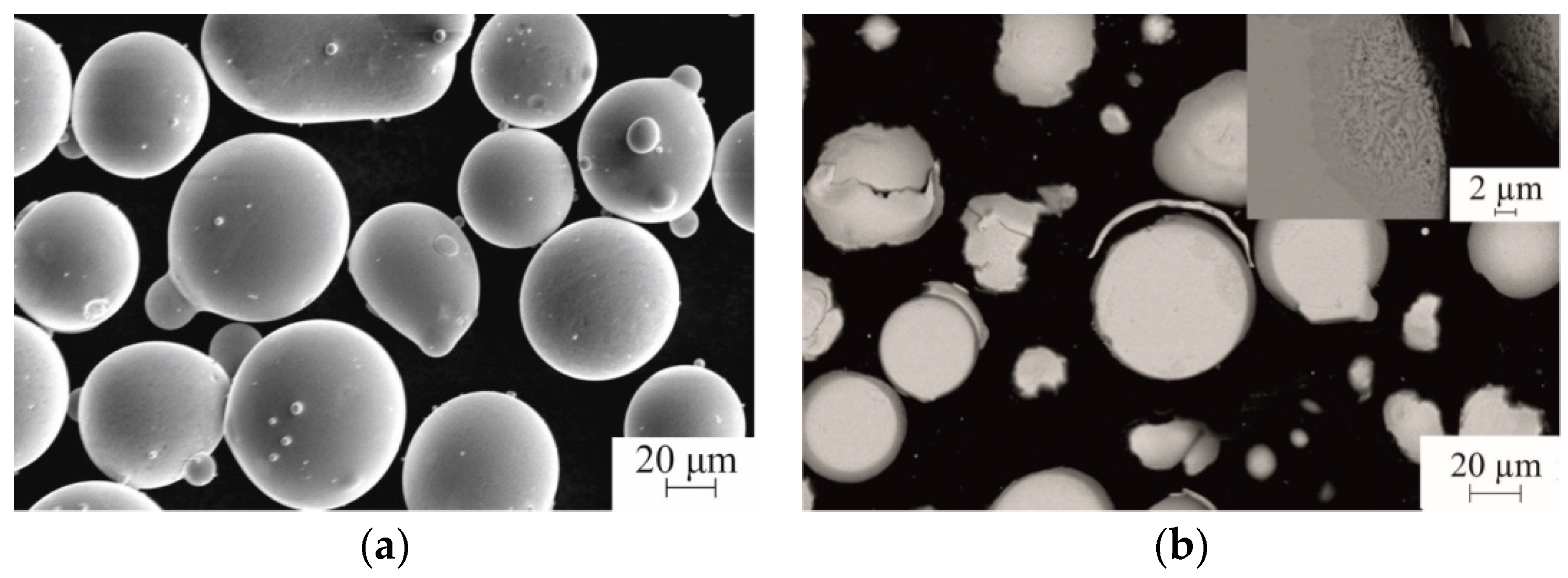

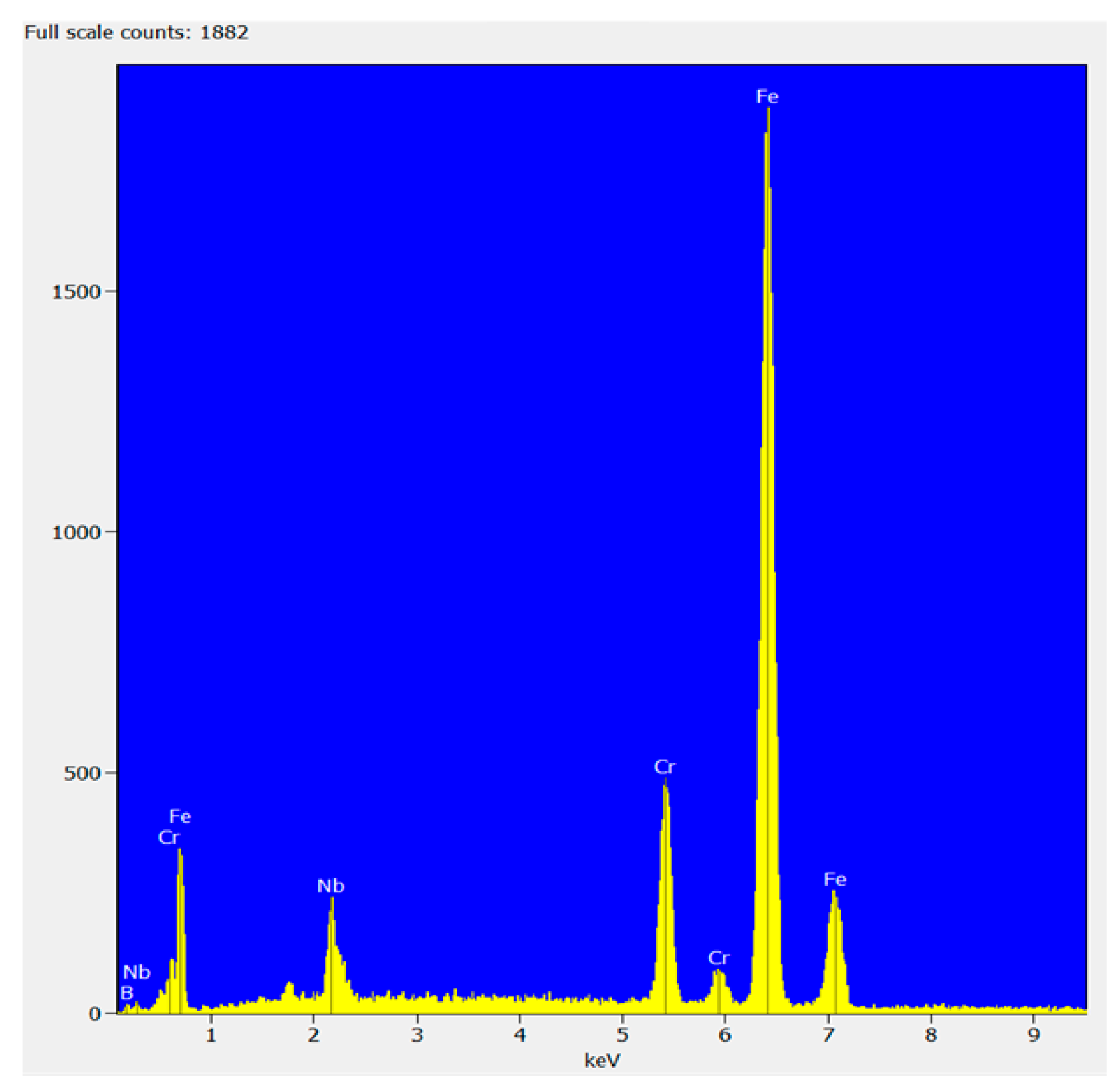

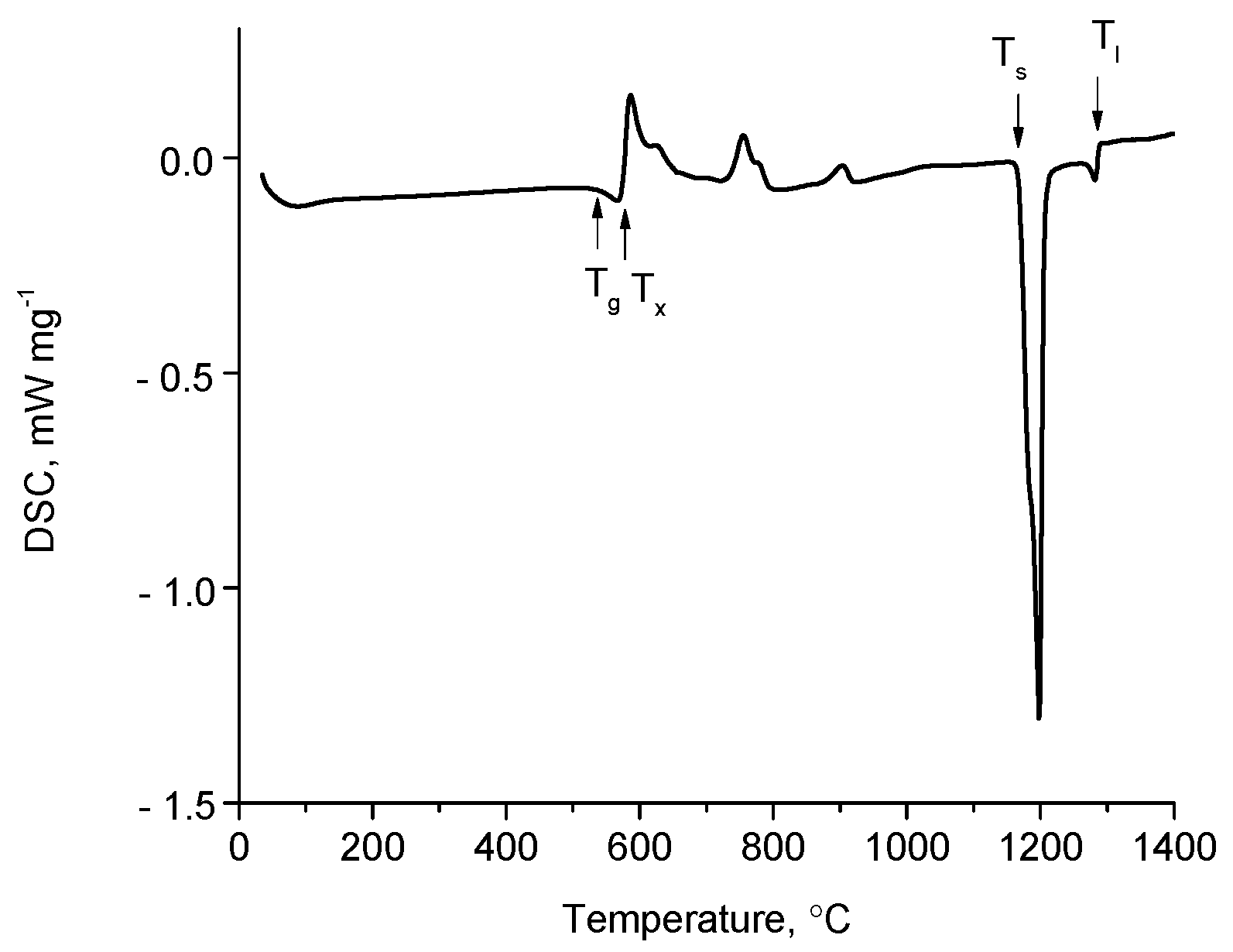

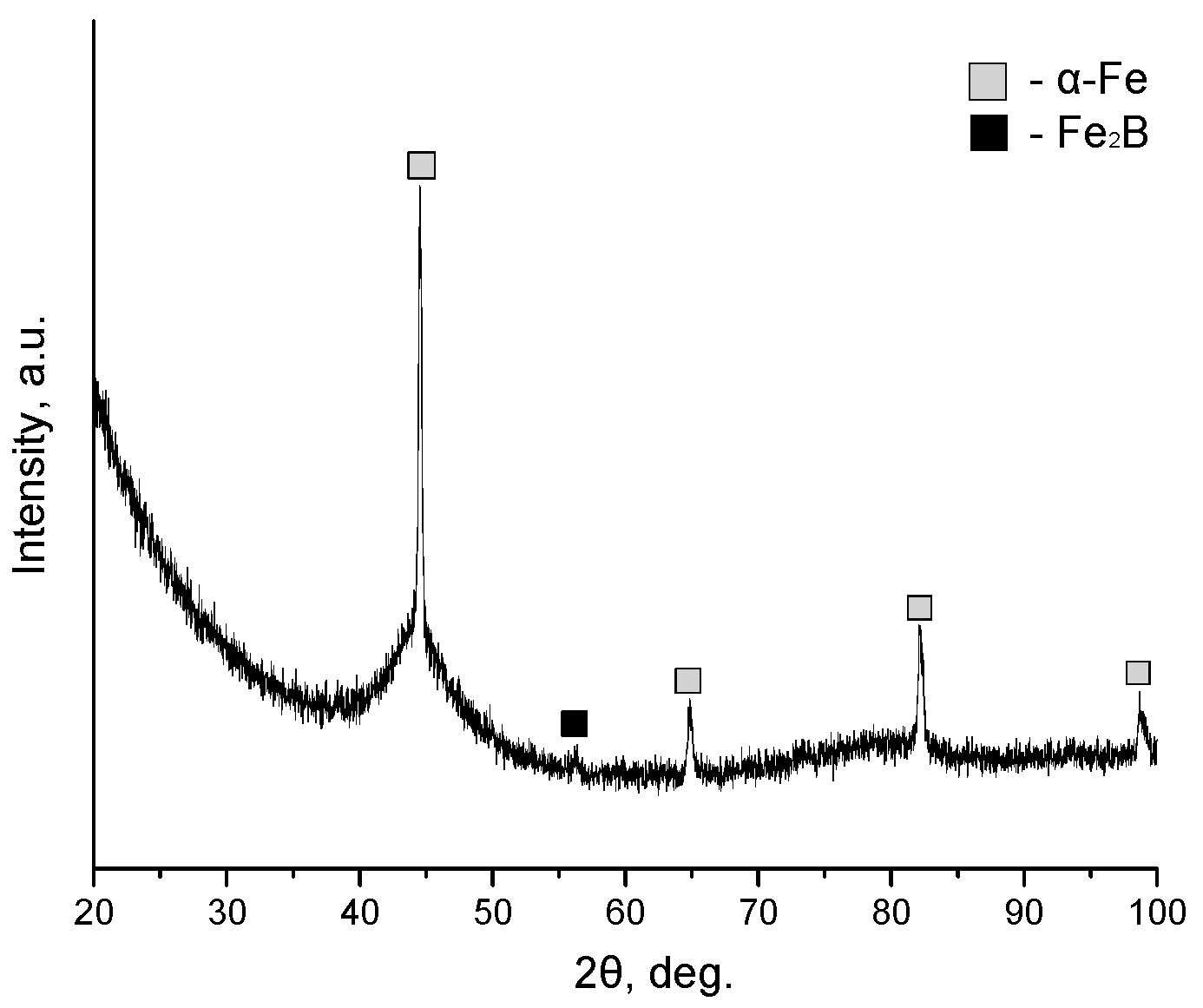

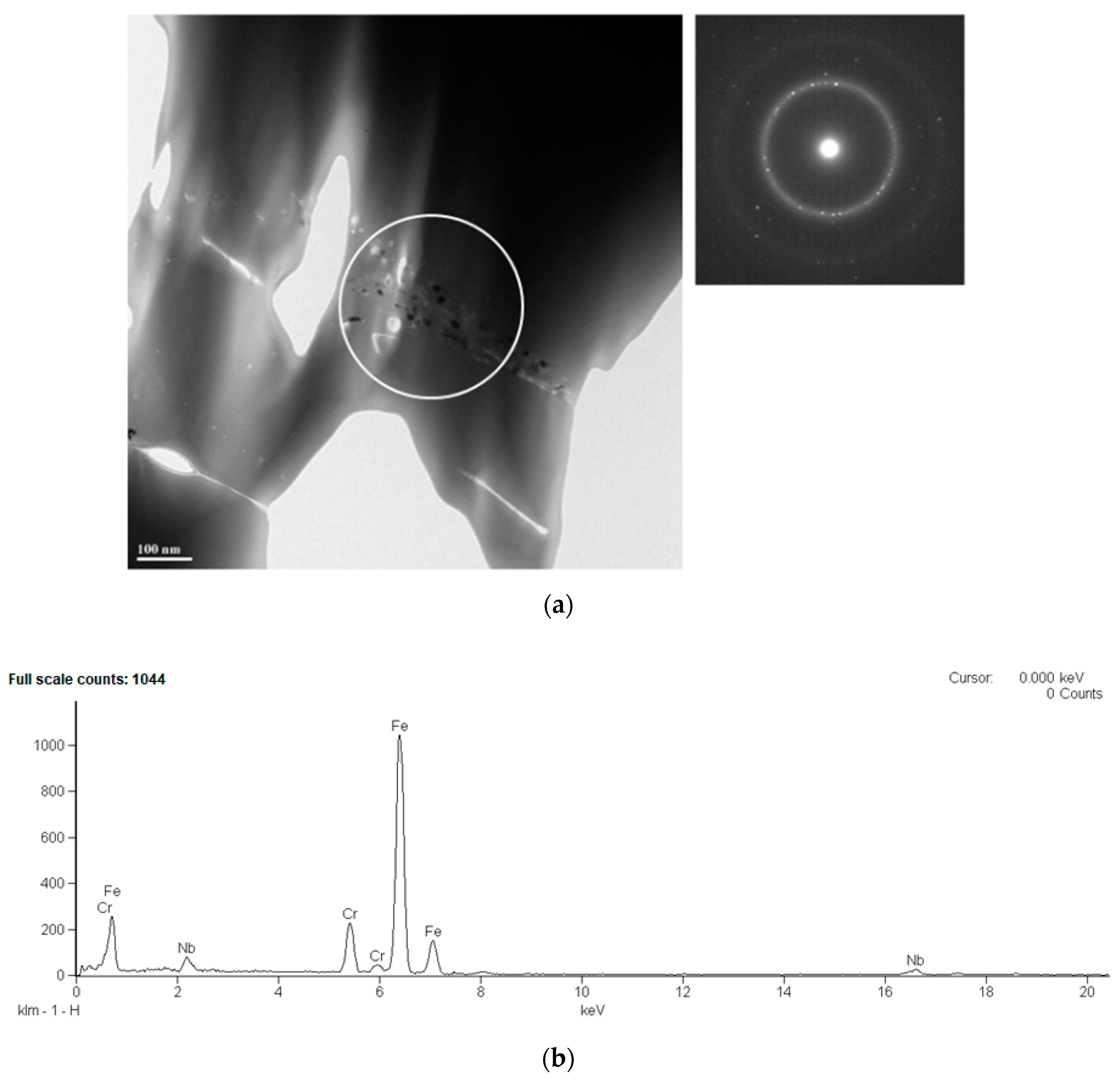

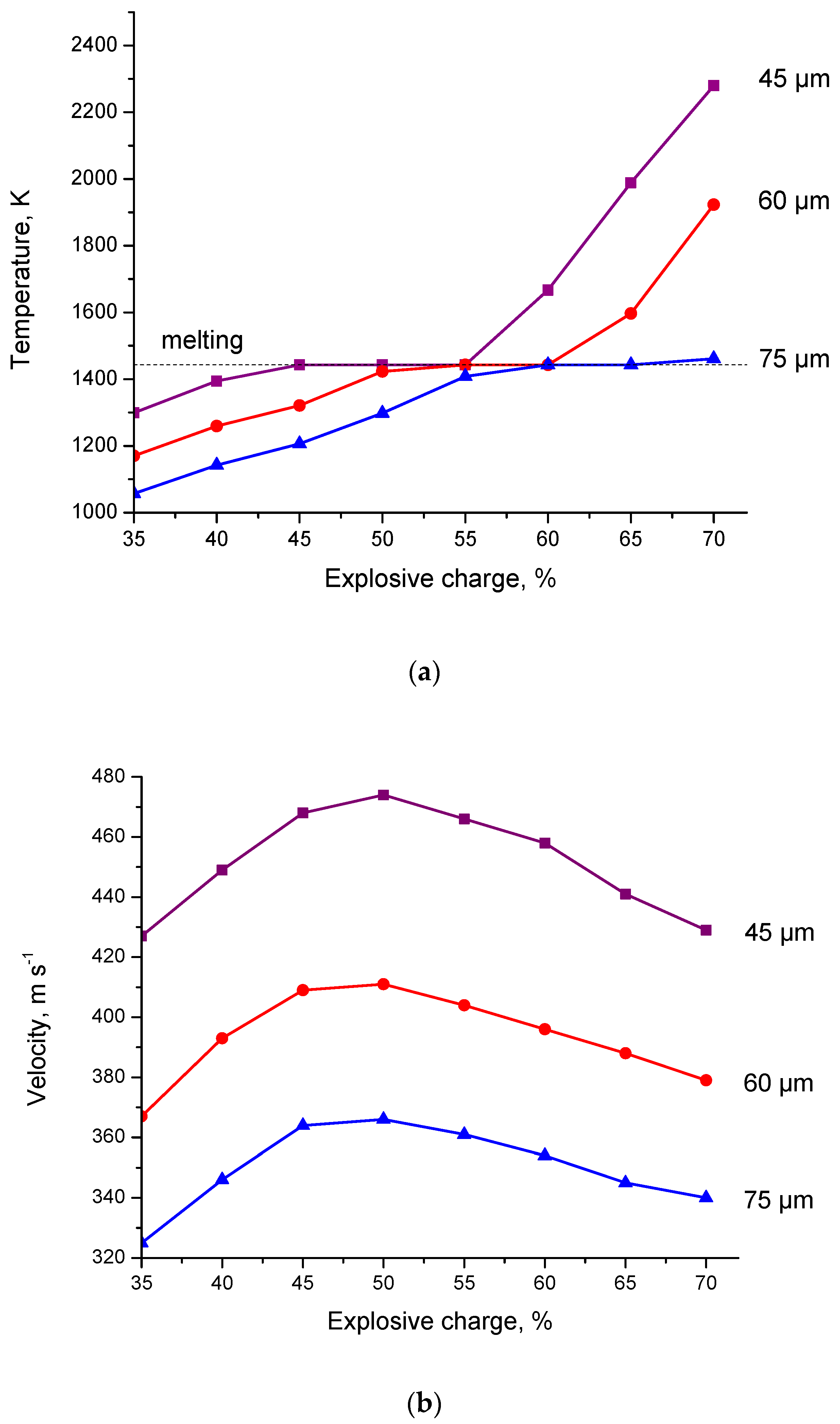

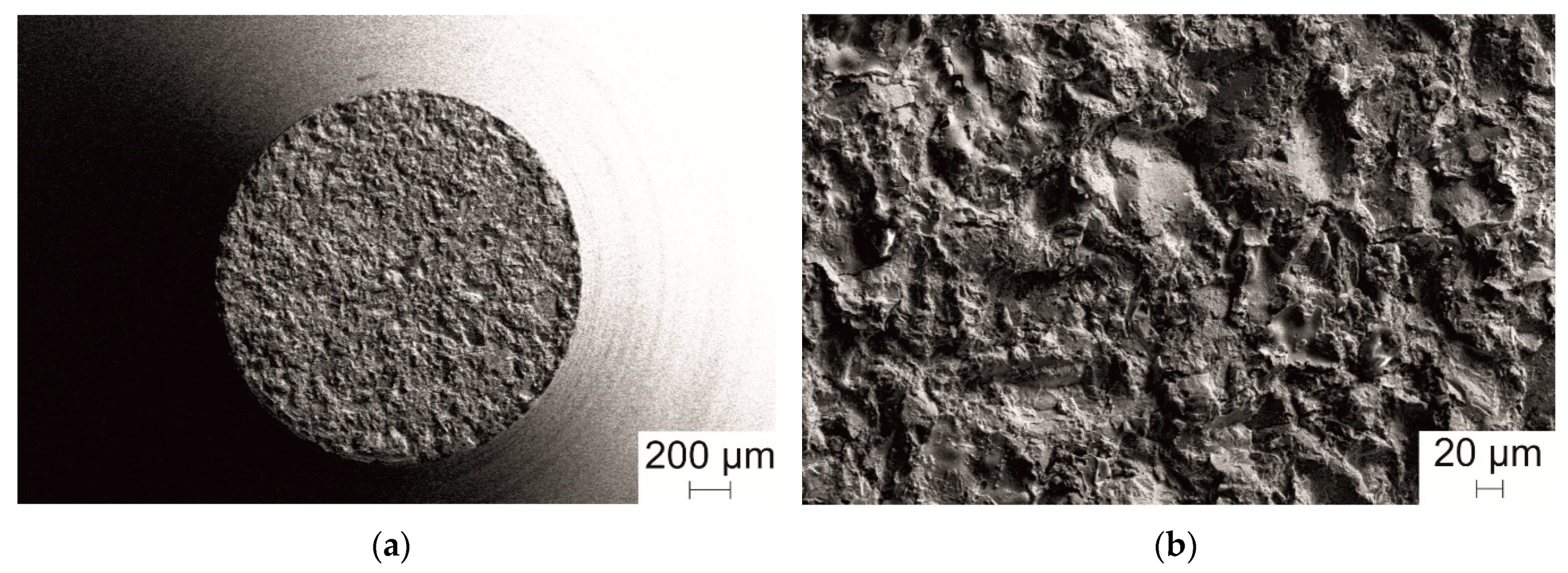

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Greer, A.L. Metallic glasses on the threshold. Mater. Today 2009, 12, 14–22. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent development and application products of bulk glassy alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar] [CrossRef]

- Inoue, A. Bulk glassy alloys: Historical development and current research. Engineering 2015, 1, 185–191. [Google Scholar] [CrossRef]

- Wang, Z.; Scudino, S.; Stoica, M.; Zhang, W.W.; Eckert, J. Al-based matrix composites reinforced with short Fe-based metallic glassy fiber. J. Alloy Compd. 2015, 651, 170–175. [Google Scholar] [CrossRef]

- Wang, Z.; Georgarakis, K.; Nakayama, K.; Li, Y.; Tsarkov, A.; Xie, G.; Dudina, D.; Louzguine, D.; Yavari, A.R. Microstructure and mechanical behavior of metallic glass fiber-reinforced Al alloy matrix composites. Sci. Rep. 2016, 6, 24384. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.W.; Hu, Y.; Wang, Z.; Yang, C.; Zhang, G.Q.; Prashanth, K.G.; Suryanarayana, C. A novel high-strength Al-based nanocomposite reinforced with Ti-based metallic glass nanoparticles produced by powder metallurgy. Mater. Sci. Eng. A 2018, 734, 34–41. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Li, Y.; Aljerf, M.; Braccini, M.; Yavari, A.R.; Inoue, A. Cu-based metallic glass particle additions to significantly improve overall compressive properties of an Al alloy. Compos. Part A 2010, 41, 1551–1557. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, C. Fe-based amorphous coatings: Structures and properties. Thin Solid Film 2014, 561, 70–86. [Google Scholar] [CrossRef]

- Gu, X.J.; Poon, S.J.; Shiflet, G.J. Mechanical properties of iron-based bulk metallic glasses. J. Mater. Res. 2007, 22, 344–351. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Peng, Y.; Yu, Y.; Liu, L. Effects of crystallization on the corrosion resistance of Fe-based amorphous coatings. Corros. Sci. 2012, 59, 10–19. [Google Scholar] [CrossRef]

- Pang, S.J.; Zhang, T.; Asami, K.; Inoue, A. Synthesis of Fe-Cr-Mo-C-B-P bulk metallic glasses with high corrosion resistance. Acta Mater. 2002, 50, 489–497. [Google Scholar] [CrossRef]

- Zhang, H.; Xie, Y.; Huang, L.; Huang, S.; Zheng, X.; Chen, G. Effect of feedstock particle sizes on wear resistance of plasma sprayed Fe-based amorphous coatings. Surf. Coat. Technol. 2014, 258, 495–502. [Google Scholar] [CrossRef]

- Zhou, Y.; Ma, G.; Wang, H.; Li, G.; Chen, S.; Wang, H.; Liu, M. Fabrication and characterization of supersonic plasma sprayed Fe-based amorphous metallic coatings. Mater. Des. 2016, 110, 332–339. [Google Scholar] [CrossRef]

- Xie, L.; Wang, Y.; Xiong, X.; Chen, Z.; Wang, Y. Effects of oxygen fuel rate on microstructure and wear properties of detonation sprayed iron-based amorphous coatings. Mater. Trans. 2018, 59, 1867–1871. [Google Scholar] [CrossRef]

- Xie, L.; Wang, Y.; Xiong, X.; Chen, Z. Comparison of microstructure and tribological properties of plasma, high velocity oxy-fuel and detonation sprayed coatings from an iron-based powder. Mater. Trans. 2018, 59, 1591–1595. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, L.; Wang, F.; Liu, Y. Formation and corrosion behavior of Fe-based amorphous metallic coatings prepared by detonation gun spraying. Trans. Nonferr. Met. Soc. China 2009, 19, s634–s638. [Google Scholar] [CrossRef]

- Guo, Y.; Koga, G.Y.; Moreira Jorge, A., Jr.; Savoie, S.; Schulz, R.; Kiminami, C.S.; Bolfarini, C.; Botta, W.J. Microstructural investigation of Fe-Cr-Nb-B amorphous/nanocrystalline coating produced by HVOF. Mater. Des. 2016, 111, 608–615. [Google Scholar] [CrossRef]

- Ulianitsky, V.; Shtertser, A.; Zlobin, S.; Smurov, I. Computer-controlled detonation spraying: From process fundamentals toward advanced applications. J. Therm. Spray Technol. 2011, 20, 791–801. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Dudina, D.V.; Batraev, I.S.; Rybin, D.K.; Bulina, N.V.; Ukhina, A.V.; Bokhonov, B.B. The influence of the in-situ formed and added carbon on the formation of metastable Ni-based phases during detonation spraying. Mater. Lett. 2016, 181, 127–131. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Batraev, I.S.; Shtertser, A.A.; Dudina, D.V.; Bulina, N.V.; Smurov, I. Detonation spraying behaviour of refractory metals: Case studies for Mo and Ta-based powders. Adv. Powder Technol. 2018, 29, 1859–1864. [Google Scholar] [CrossRef]

- Batraev, I.S.; Prokhorov, E.S.; Ul’yanitskii, V.Y. Acceleration and heating of powder particle by gas detonation products in channels with a conical passage. Comb. Explos. Shock Waves 2014, 50, 315–322. [Google Scholar] [CrossRef]

- Gavrilenko, T.P.; Nikolaev, Y.A. Calculation of detonation gas spraying. Comb. Explos. Shock Waves 2007, 43, 724–731. [Google Scholar] [CrossRef]

- Dudina, D.V.; Batraev, I.S.; Ulianitsky, V.Y.; Korchagin, M.A. Possibilities of the Computer-Controlled Detonation Spraying method: A chemistry viewpoint. Ceram. Int. 2014, 40, 3253–3260. [Google Scholar] [CrossRef]

- Batraev, I.S.; Ulianitsky, V.Y.; Dudina, D.V. Detonation spraying of copper: Theoretical analysis and experimental studies. Mater. Today Proc. 2017, 4, 11346–11350. [Google Scholar] [CrossRef]

- Golod, V.M.; Sufiiarov, V.S. The evolution of structural and chemical heterogeneity during rapid solidification at gas atomization. IOP Conf. Ser. Mater. Sci. Eng. 2017, 192, 012009. [Google Scholar] [CrossRef]

- Gavrilenko, T.P.; Nikolaev, Y.A.; Prokhorov, E.S.; Ul’yanitskii, V.Y. Mechanisms of coating formation with flame spraying. Comb. Explos. Shock Waves 1990, 26, 228–238. [Google Scholar] [CrossRef]

- Li, H.X.; Lu, Z.C.; Wang, S.L.; Wu, Y.; Lu, Z.P. Fe-based bulk metallic glasses: Glass formation, fabrication, properties and applications. Prog. Mater. Sci. 2019, 103, 235–318. [Google Scholar] [CrossRef]

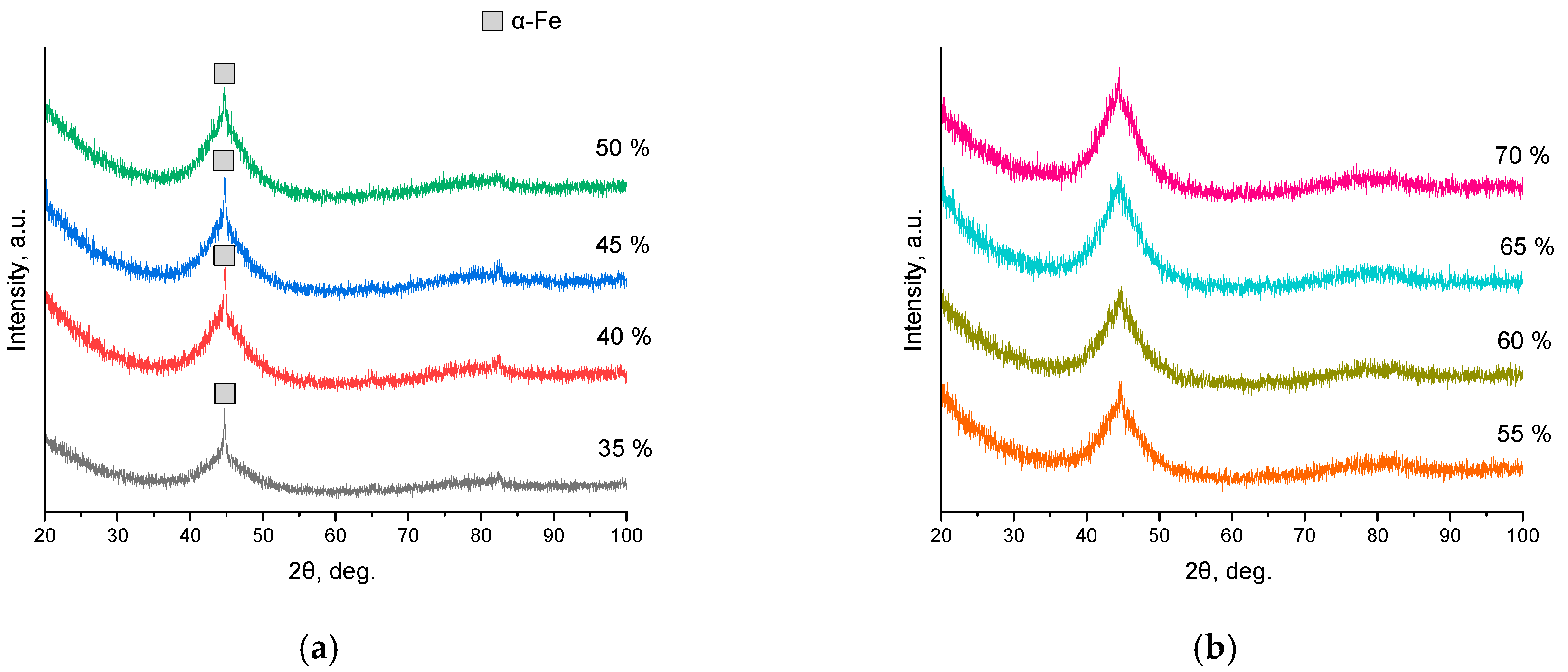

| Explosive Charge, % | Content of the Crystalline Phase, wt.% | Porosity, % | Vickers Microhardness, HV100 |

|---|---|---|---|

| 35 | 5 ± 0.2 | 4.0 ± 1.0 | 540 ± 210 |

| 40 | 4 ± 0.2 | 3.0 ± 0.8 | 750 ± 55 |

| 45 | 3 ± 0.2 | 2.5 ± 1.0 | 780 ± 145 |

| 50 | 2 ± 0.2 | 2.5 ± 0.5 | 875 ± 130 |

| 55 | 1 ± 0.2 | 1.0 ± 0.5 | 920 ± 95 |

| 60 | 1 ± 0.2 | 2.0 ± 0.5 | 870 ± 155 |

| 65 | 1 ± 0.2 | 1.2 ± 0.5 | 770 ± 100 |

| 70 | 1 ± 0.2 | 2.5 ± 0.5 | 770 ± 75 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuchumova, I.D.; Batraev, I.S.; Ulianitsky, V.Y.; Shtertser, A.A.; Gerasimov, K.B.; Ukhina, A.V.; Bulina, N.V.; Bataev, I.A.; Koga, G.Y.; Guo, Y.; et al. Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder. Metals 2019, 9, 846. https://doi.org/10.3390/met9080846

Kuchumova ID, Batraev IS, Ulianitsky VY, Shtertser AA, Gerasimov KB, Ukhina AV, Bulina NV, Bataev IA, Koga GY, Guo Y, et al. Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder. Metals. 2019; 9(8):846. https://doi.org/10.3390/met9080846

Chicago/Turabian StyleKuchumova, Ivanna D., Igor S. Batraev, Vladimir Yu. Ulianitsky, Alexandr A. Shtertser, Konstantin B. Gerasimov, Arina V. Ukhina, Natalia V. Bulina, Ivan A. Bataev, Guilherme Yuuki Koga, Yaofeng Guo, and et al. 2019. "Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder" Metals 9, no. 8: 846. https://doi.org/10.3390/met9080846

APA StyleKuchumova, I. D., Batraev, I. S., Ulianitsky, V. Y., Shtertser, A. A., Gerasimov, K. B., Ukhina, A. V., Bulina, N. V., Bataev, I. A., Koga, G. Y., Guo, Y., Botta, W. J., Kato, H., Wada, T., Bokhonov, B. B., Dudina, D. V., & Moreira Jorge, A., Jr. (2019). Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder. Metals, 9(8), 846. https://doi.org/10.3390/met9080846