Abstract

This paper highlights some recent efforts to extend the use of medium-Mn steels for applications other than intercritically batch-annealed steels with exceptional ductility (and strengths in the range of about 1000 MPa). These steels are shown to enable a range of promising properties. In hot-stamping application concepts, elevated Mn concentration helps to stabilize austenite and to provide a range of attractive property combinations, and also reduces the processing temperatures and likely eliminates the need for press quenching. The “double soaking” concept also provides a wide range of attractive mechanical property combinations that may be applicable in cold-forming applications, and could be implemented in continuous annealing and/or continuous galvanizing processes where Zn-coating would typically represent an additional austempering step. Quenching and partitioning of steels with elevated Mn concentrations have exhibited very high strengths, with attractive tensile ductility; and medium-Mn steels have been successfully designed for quenching and partitioning using room temperature as the quench temperature, thereby effectively decoupling the quenching and partitioning steps.

1. Introduction

Medium-manganese steels with Mn concentrations in the range of about 5 to 10 wt. pct. have been explored over the past decade as potential options to provide “3rd Generation” Advanced High Strength Steel (AHSS) sheets for automobile bodies, with excellent combinations of strength and ductility. These steels are most commonly employed in the intercritically batch-annealed condition, where an ultra-fine microstructure is obtained, and extensive Mn partitioning to austenite helps to stabilize substantial amounts of austenite, providing effective transformation-induced plasticity (TRIP) and attractive tensile property combinations. Intercritical annealing may also be employed in the hot-band condition, to obtain the requisite Mn partitioning, while softening the microstructure before cold-rolling. These steels are of particular interest at tensile strength levels of about 1000 MPa, as the levels of Mn alloying are less than those employed in twinning-induced plasticity steels (and yield strengths are higher), and their tensile ductilities are greater than leaner-alloyed AHSS products employing alternative processing approaches. A variety of challenges are also associated with medium-Mn steels, such as very large yield-point elongations in some instances, and sensitivity of mechanical properties to small changes in annealing temperature.

In this overview, some processing routes for medium-Mn steels are considered that are different than intercritical batch-annealing. The applications involve press-hardening of steels subject to hot- stamping, and cold-formable steels at strength levels greater than are commonly achieved in intercritically-annealed medium-Mn steels. Recent work by the authors on these processing variants is highlighted in the sections below.

2. Hot-Forming of Medium-Mn Steels

Press-hardening of low-alloy B-added steels (e.g., 22MnB5) is commonly employed in high strength components, where a martensitic microstructure is obtained by die-quenching after forming. High strengths (above 1500 MPa) are common, beyond the levels typically associated with medium-Mn steels. The ductilities of these high strength components are limited, with values typical of low-carbon martensitic steels, and greater ductilities are of interest to enhance crashworthiness or “toughness” in some applications [1,2]. Medium-Mn steels offer some interesting possibilities to consider in press-hardening steels (PHS) subjected to hot-stamping. The austenite-stabilizing effect of Mn offers the potential to develop and employ retained austenite to enhance ductility, and also reduces the temperatures that would apply to full austenitizing or intercritical annealing prior to hot stamping [3,4,5]. These lower reheating temperatures provide additional benefits related to suppression of liquid-metal embrittlement during forming of Zn-coated PHS, and perhaps reduced oxidation/decarburization during heating [6]. In addition, the increased hardenability associated with an elevated Mn concentration could potentially eliminate the need for in-die heat extraction during forming (press quenching), enabling development of higher-productivity processing concepts.

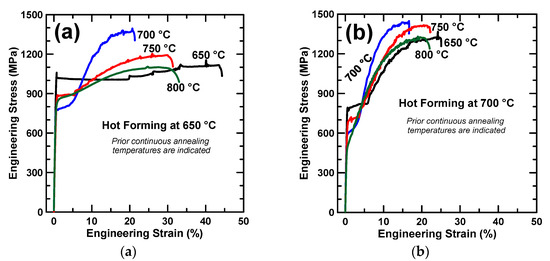

To assess the hot-stamping response, a medium manganese steel containing 9.76 Mn, 0.16 C, 1.37 Al, 0.19 Si, 0.0018 S (wt. pct.), was subjected to thermal treatments simulating hot forming at different temperatures [3]. Prior to reheating for hot stamping, the material was received in the as-cold-rolled condition after hot-band annealing, and was then soaked for 3 min at temperatures between 650 and 800 °C (simulating approximately, for example, the influence of the annealing step in a continuous hot-dip coating process before reheating and hot-stamping). Figure 1a,b illustrate the mechanical property results for samples held 3 min at temperatures of 650 or 700 °C (simulating heating before hot forming), followed by rapid cooling. A variety of strength-ductility combinations resulted, with tensile strengths up to about 1450 MPa and total elongations in the range of about 16 to 43 pct.

Figure 1.

Representative room-temperature engineering stress-strain curves of a 9.76 Mn, 0.16 C, 1.37 Al (wt. pct.) steel subjected to hot-forming thermal simulation (without deformation) using reheating temperatures of (a) 650, or (b) 700 °C, preceded by continuous annealing at 650–800 °C for 3 min [3].

Without the continuous annealing simulation step applicable to the results in Figure 1, even higher strengths are obtainable, with properties after heating for hot stamping exceeding 1600 MPa tensile strength and 16 pct. ductility [3]. Retained austenite fractions exceeded about 20 pct. in the conditions of interest; less than is typical for intercritically batch-annealed medium-Mn steel, but sufficient to provide excellent ductility at high strength levels. The relatively high (10 wt. pct. Mn) concentration associated with the particular steel examined in this work is an exemplar and is not considered to represent an “optimized” steel composition for this processing path.

Other studies on hot-stamped medium-Mn steels have focused more on fully martensitic variants processed by full austenitizing at higher reheating temperatures [4,7], reporting high strength with enhanced ductility. In comparison, the intercritical heating approach as indicated in Figure 1 should provide further increases in ductility and toughness, due to the greater stabilization of austenite through Mn partitioning. The hot stamping process involves deformation before cooling, and aspects relating to that have not been considered in our work, although other authors have provided important information on the effects of warm deformation of the austenite, in terms of elevated temperature strengths as a function of deformation temperature and strain rate, as well as pressure effects on martensite, and the influence of warm deformation of austenite (i.e., thermomechanical treatment) on the final properties at room temperature [6,8]. Overall, research has shown that medium-Mn TRIP steels are promising candidate materials for hot-stamping following a variety of processing paths, not only due to the potential for achieving extraordinary properties, but also due to the additional benefits from enhanced hardenability and lower reheat temperatures.

3. “Double Soaking” of Medium-Mn Steels for Cold Forming Applications

De Moor and Glover have demonstrated concepts for achieving higher strengths in cold-formed medium-Mn steels, by designing “double soaking” (DS) treatments [9,10]. The DS concept aims to achieve substantial Mn-enrichment of austenite in a first soaking that could involve intercritical batch-annealing (typically after cold-rolling), followed by a second soaking step at a higher temperature. The goal of the second soaking step at a higher temperature is to replace some or all of the intercritical ferrite with austenite during heating and holding, and then transform it to martensite during final cooling, thus replacing the typical ferrite + austenite microstructure in medium-Mn steels with a higher strength TRIP microstructure, containing both martensite and austenite. In this concept, the austenitizing time in the second soaking step is envisioned to be relatively short, allowing substantial carbon redistribution but avoiding, as much as possible, redistribution of Mn. In this way, inhomogeneous austenite is obtained at a high temperature, with interlaced ultra-fine regions having higher and lower manganese concentrations, respectively. Retention of the higher-Mn regions should enable much greater austenite fractions to be maintained upon final cooling, while the lower-Mn regions readily transform to martensite (and perhaps ferrite). The second soaking step may be implemented during the annealing portion of a final continuous annealing or continuous galvanizing operation.

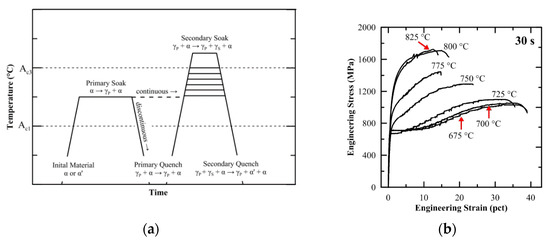

To explore this concept, thermal processing was conducted following the schematic illustration in Figure 2a of “discontinuous” double soaking. An industrially batch-annealed (first soak) 7.14 Mn, 0.14 C (wt. pct.) medium manganese steel was received and subjected to continuous annealing treatments (second soak) between 675 and 825 °C, for holding times between 10 and 120 s. These holding times are shorter than employed in the hot-stamping work discussed above, and resulted in greater levels of austenite retention in most instances (despite the lower Mn concentration), presumably due to reduced homogenization of manganese.

Figure 2.

Schematic illustration of double soaking thermal treatments (a), and tensile properties (b) for a 7.14 Mn, 0.14 C (wt. pct.) steel after a second soak of 30 s at indicated temperatures [10].

Resulting mechanical properties are illustrated in Figure 2b for 30 s holding times during the second soak at temperatures between 675 and 825 °C [10]. This range of “second soak” temperatures creates an interesting and substantial range of properties, with ultimate tensile strengths from about 1000 MPa to 1700 MPa, and corresponding tensile ductilities ranging from about 40 pct. down to about 15 pct. at the highest strength levels. The properties are nearly unchanged from the batch-annealed starting conditions after the second annealing soak for 30 s at 675 °C, while the strength increases substantially as the second soak temperature increases up to 800 °C. Tensile ductility correspondingly decreased as the second soak temperature increased, but the overall combinations of strength and elongation are very good across the full range of results exemplified in Figure 2b. The property changes are related to increasing martensite fractions and decreasing ferrite fractions (and to a lesser extent decreasing austenite fractions) after final cooling, associated with increasing the second soak temperature. These properties might be readily achievable by thermal processing characteristics of industrial continuous annealing or continuous galvanizing facilities.

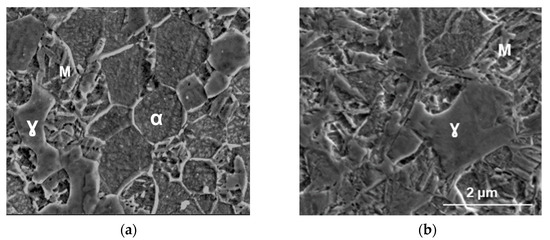

The elevated Mn concentration in the steel, in conjunction with Mn partitioning in a first soak and the limited time for Mn redistribution in the second soak, provide sufficient austenite stabilization and retention, and an effective contribution of transformation-induced plasticity to the property balance. Microstructure evolution associated with double soaking is illustrated by the example in Figure 3. The intercritical batch anneal (first soak) leads to an ultra-fine mixture, as shown in Figure 3a, of equiaxed intercritical ferrite (α) and austenite (γ), along with a small amount of martensite (M). The double soaked condition in Figure 3b shows the microstructure after a 30 s second soak at 800 °C, consisting of a mixture of martensite and austenite. The austenite in the as-received condition largely remained after the second soak, but the equiaxed ferrite was largely replaced by martensite. The phase fractions vary with processing parameters; e.g., longer soaking times at high temperature result in more martensite, while the fractions of both ferrite and retained austenite are correspondingly reduced [10]. While refinement of the austenite was not a primary objective of this processing strategy, the rapid austenitization process was accomplished without substantial coarsening of the microstructure during the second soak at 800 °C [11].

Figure 3.

Example microstructures of a 7.14 Mn, 0.14 C (wt. pct.) steel (a) after intercritical batch annealing (first soak), and (b) after double soaking with a second soak of 30 s at 800 °C [10,11]. (Nital etch; SEM secondary electron images).

To further enhance the properties of medium-Mn steels processed by double soaking, additional tempering might be considered. The microstructure after cooling following the second soak contains a considerable amount of “fresh” martensite. Martensite tempering could improve tensile ductility, and even more likely, hole expansion performance, since hole expansion has been shown to benefit from reduced variation in the hardness between the various constituents in the microstructure [12]. Tempering might be achieved industrially by an overaging step in a continuous annealing process after quenching from the second soak temperature, or potentially in a continuous galvanizing facility with cooling capability, prior to the coating application. With more conventional hot-dip galvanizing line configuations, the coating application would constitute an austempering step. Tempering was included in the “multi-step partitioning” (MSP) work of Liu et al. [13] and in similar work by Heo et al. [14]; both of these studies also included an austenitizing and quenching step prior to the intercritical treatments, which leads to a more “lamellar” microstructure.

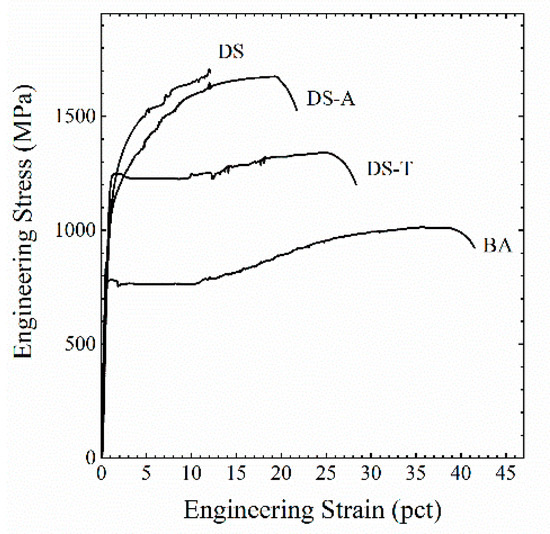

Tempering effects are being explored in ongoing research, following the double soaking thermal path achieved using molten salt baths with heating rates on the order of 80 °C/s [11,15]. Figure 4 illustrates the tensile property changes, showing engineering stress-strain behavior after the primary soak (intercritical batch anneal—BA), then after double-soaking for 30 s at 800 °C (DS), as well as after subsequent cooling to room temperature and then tempering for 300 s at 450 °C (DS-T) or after subsequent austempering (DS-A) for 300 s at 450 °C [11]. The results show that the tempering step decreases the work hardening rate and tensile strength while increasing ductility; austempering decreases the strength to a lesser degree while also enhancing ductility. While the tempering and austempering conditions were identical, the DS-T conditions involved tempering of martensite that was formed during the cooling step after the second soak (and potentially some carbon partitioning [13]), while the austempering step of the DS-A process was completed in advance of martensite formation, with dilation results indicating replacement of some austenite by ferrite.

Figure 4.

Tensile properties of a 7.14 Mn, 0.14 C (wt. pct.) steel after intercritical batch annealing (BA) first soak, after double soaking (DS) with a second soak of 30 s at 800 °C, and after double soaking, cooling to room temperature and tempering for 300 s at 450 °C (DS-T), and after double soaking followed by austempering for 300 s at 450 °C (DS-A) [11].

The double soaking approach is just one of the possible multistep thermal treatments that has been considered to control the fractions of martensite, ferrite and austenite, as well as the phase compositions, particularly the austenite where austenite stability during cooling or during deformation in service is sensitively related to its Mn and C concentrations. In this regard, some studies have suggested that multiple intercritical annealing steps may enhance the Mn and C partitioning response and properties, where a lower intercritical temperature is employed later, to enhance the final austenite stability [16,17].

4. Quenching and Partitioning of Steels Containing Elevated Manganese Additions

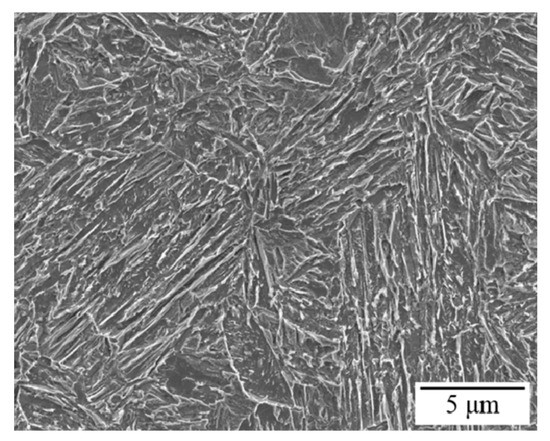

Quenching and partitioning (Q&P) is a heat treatment to stabilize austenite by carbon partitioning from martensite, formed during interrupted quenching after austenitizing or intercritical annealing, into untransformed austenite, leading to martensite-austenite mixtures with attractive combinations of strength and formability (e.g., [18,19,20,21,22]. Compositions similar to bainitic TRIP steels are often employed, with small Mn additions, typically on the order of 1.5 wt. pct., made to help avoid diffusional transformations during the quenching step. Even higher levels of Mn can be considered to enhance austenite retention, employing the austenite stabilizing effects of Mn to adjust the relative fractions of martensite and austenite [18,19]. The use of elevated Mn additions in Q&P steels has been successful in developing very high strength cold-formable sheet steels with tensile strengths in excess of 1500 MPa, in combination with total elongations exceeding 20 pct. [18], and numerous subsequent studies on Q&P processing of medium-Mn steels have also been reported by others. An example of a high strength Q&P microstructure developed through this approach is shown in Figure 5, for a 0.2C, 3Mn, 1.6Si (wt. pct.) steel quenched and partitioned after full austenitizing. The microstructure consists of martensite with a substantial quantity of interlath retained austenite.

Figure 5.

SEM micrograph of a 0.2 C, 3 Mn, 1.6 Si (wt. pct.) steel processed by quenching and partitioning after full austenitization [18]. (Nital etch; secondary electron image).

The quenching temperature employed in the Q&P process is normally well in excess of room temperature, requiring careful process control in the interrupted quenching step. Higher Mn concentrations have also been utilized to suppress the Ms temperature, and reduce the quench temperature in Q&P processing all the way down to room temperature. Use of an ambient “interrupted” quench temperature in these alloy designs allows decoupling of the quenching and partitioning steps. Such alloys were initially designed for fundamental studies of partitioning mechanisms [20,21], but later studies reported that attractive mechanical properties can also be obtained using this approach [22,23]. Ambient temperature quenching also provides additional process flexibility, and could be readily implemented, for example, in hot-rolled products or in a continuous annealing line with water quenching. Enhanced hardenability associated with elevated Mn concentrations can likely mitigate concerns related to cooling rates in thicker sections. In the context of hot stamping, Q&P can be achieved without the need for careful control of the quench temperature after hot forming [24].

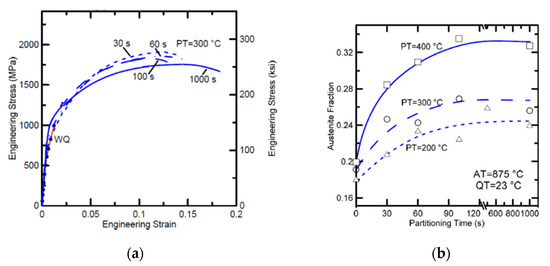

As an example of properties obtained in a steel alloy designed for quenching to room temperature followed by partitioning (at a higher temperature), Figure 6a presents engineering tensile stress-strain curves for a steel containing 0.25 C, 8.23 Mn, 1.87 Si, 0.05 Ni, 0.24 Mo (wt. pct.). After quenching to room temperature, the steel was partitioned at different times at temperatures from 200 to 400 °C; the results in Figure 6a apply to 300 °C partitioning, and tensile strengths exceeding 1800 MPa were obtained with total elongations of about 15 pct. Even higher strengths with good tensile ductility were obtained at a partitioning temperature of 200 °C, and a similar approach was employed more recently to generate interesting properties for hot-stamping of a medium-Mn steel with 3% aluminum added to reduce density (0.3 C, 8 Mn, 3 Al, 0.2 V, in wt. pct.), and using a paint baking thermal treatment at 150 or 170 °C as the partitioning step after cooling to room temperature [25].

Figure 6.

Quenching and partitioning (Q&P) response of 0.25 C, 8.23 Mn, 1.87 Si, 0.05 Ni, 0.24 Mo (wt. pct.) steel. (a) Tensile stress-strain results after quenching to room temperature and partitioning at 300 °C for times indicated. (b) Evolution of austenite fraction during partitioning at temperatures indicated [21].

While the tensile ductility of the 0.25 C, 8.23 Mn (wt. pct.) steel in Figure 6a is outstanding for a steel with 1800 MPa tensile strength [26], some fascinating aspects of microstructure development were also observed in this work [22]. Specifically, the austenite fraction was found to increase with partitioning time and temperature in this steel, following quenching to room temperature, consuming martensite also, due to growth associated with migration of martensite-austenite interfaces. In contrast, the austenite fraction did not increase during partitioning of a high-Ni steel (0.3 C, 14 Ni, 1.5 Si, 0.25 Mo, in wt. pct.) similarly designed for room temperature quenching [22]. A clear understanding of the effects of Mn and/or Ni on partitioning response is still lacking, but the differences in evolution of the austenite fraction were hypothesized to relate potentially to variations in interface mobilities resulting from alloy-dependent interfacial structures associated with different γ/α’ orientation relationships observed in the two steels [27].

5. Summary

Some atypical and potentially novel processing scenarios for medium-Mn steels were discussed, including (1) use of medium-Mn steels for hot-stamping, (2) “double soaked” medium-Mn steels for cold-formable applications at strength levels greater than are commonly achieved via intercritical annealing, and (3) medium-Mn steels processed by quenching and partitioning. For all processing histories emphasized here, increased strength levels are achieved by employing appreciable martensite fractions, with ductility enhancements resulting from TRIP behavior associated with Mn-enriched austenite. An apparent influence of Mn on austenite evolution during partitioning was also highlighted. The austenite stabilizing effects of Mn facilitate a variety of industrially important processing pathways, including room-temperature quenching temperatures. These processing opportunities and associated mechanisms of microstructure evolution remain fruitful areas for further research.

Author Contributions

Authors contributed to conceptualization (J.S., E.D.M., D.M., R.R., G.T., A.G.), methodology (J.S., E.D.M., D.M., R.R., G.T., A.G.), investigation (E.D.M., R.R., G.T., A.G.), formal analysis (J.S., E.D.M., D.M., R.R., G.T., A.G.), data curation (E.D.M., R.R., G.T., A.G.), original draft preparation (J.S.), review and editing (J.S., E.D.M., D.M., R.R., G.T., A.G.), supervision (J.S., E.D.M., D.M., R.R.), project administration (J.S., D.M.), and funding acquisition (J.S., E.D.M., D.M.).

Funding

The sponsors of the Advanced Steel Processing and Products Research Center (ASPPRC) at the Colorado School of Mines are gratefully acknowledged.

Acknowledgments

The advice and feedback of ASPPRC sponsors is acknowledged. AK Steel, POSCO, US Steel and Baosteel are acknowledged for provision of experimental materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, J.; Liu, Y.; Lu, Q.; Pang, J.; Wang, Z.; Enloe, C.M.; Singh, J.P.; Horvath, C.D. Effect of microstructure on impact toughness of press hardening steels with tensile strength above 1.8 GPa. In Proceedings of the 6th CHS2 Conference, Atlanta, GA, USA, 4–7 June 2017; AIST: Warrendale, PA, USA, 2017; pp. 717–727. [Google Scholar]

- Lu, Q.; Wang, J.; Liu, Y.; Wang, Z. Impact toughness of a medium-Mn steel after hot stamping. In Proceedings of the 6th CHS2 Conference, Atlanta, GA, USA, 4–7 June 2017; AIST: Warrendale, PA, USA, 2017; pp. 737–746. [Google Scholar]

- Rana, R.; Carson, C.H.; Speer, J.G. Hot forming response of medium manganese transformation induced plasticity steels. In Proceedings of the 5th CHS2 Conference, Toronto, ON, Canada, 31 May–3 June 2015; AIST: Warrendale, PA, USA, 2015; pp. 391–399. [Google Scholar]

- Han, Q.; Bi, W.; Jin, X.; Xu, W.; Wang, L.; Xiong, X.; Wang, J.; Belanger, P. Low temperature hot forming of medium-Mn steel. In Proceedings of the 5th CHS2 Conference, Toronto, ON, Canada, 31 May–3 June 2015; AIST: Warrendale, PA, USA, 2015; pp. 381–390. [Google Scholar]

- Speer, J.; Matlock, D.K.; De Moor, E.; Thomas, G.A. Highlights of recent progress in automotive sheet development. In Proceedings of the Fifth Baosteel Biennial Academic Conference, Shanghai, China, 4–6 June 2013; pp. E59–E65. [Google Scholar]

- Li, X.; Chang, Y.; Wang, C.; Hu, P.; Dong, H. Comparison of the hot-stamped boron-alloyed steel and the warm-stamped medium-Mn steel on microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 679, 240–248. [Google Scholar] [CrossRef]

- Hanamura, T.; Torizuka, S.; Sunahara, A.; Imagumba, M.; Takechi, H. Excellent total mechanical-properties-balance of 5% Mn, 30000 MPa% steel. ISIJ Int. 2011, 51, 685–697. [Google Scholar] [CrossRef]

- Chang, Y.; Wang, C.Y.; Zhao, K.M.; Dong, H.; Yan, J.W. An introduction to medium-Mn steel: Metallurgy, mechanical properties and warm stamping process. Mater. Des. 2016, 94, 424–432. [Google Scholar] [CrossRef]

- De Moor, E.; Speer, J.G.; Matlock, D.K. Heat treating opportunities for medium manganese steels. In Proceedings of the ICAS 2016 & HMnS 2016, Jeju, Korea, 5–10 September 2016; pp. 182–185. [Google Scholar]

- Glover, A.; Speer, J.G.; De Moor, E. Double soaking of a 0.14C-7.14Mn steel. In Proceedings of the International Symposium on New Developments in Advanced High-Strength Sheet Steels, Keystone, CO, USA, 30 May–2 June 2017; AIST: Warrendale, PA, USA, 2017; pp. 189–197. [Google Scholar]

- Glover, A. Private Communication; Colorado School of Mines: Golden, IL, USA, 2018. [Google Scholar]

- Taylor, M.D.; Choi, K.S.; Sun, X.; Matlock, D.K.; Packard, C.E.; Xu, L.; Barlat, F. Correlations between nanoindentation hardness and macroscopic mechanical properties in DP980 steels. Mater. Sci. Eng. A 2014, 597, 431–439. [Google Scholar] [CrossRef]

- Liu, S.; Xiong, Z.; Guo, H.; Shang, C.; Misra, R.D.K. The significance of multi-step partitioning: Processing-structure-property relationship in governing high strength-high ductility combination in medium-manganese steel. Acta Mater. 2017, 124, 159–172. [Google Scholar] [CrossRef]

- Heo, Y.U.; Suh, D.W.; Lee, H.C. Fabrication of an ultrafine-grained structure by a compositional pinning. Acta Mater. 2014, 77, 236–247. [Google Scholar] [CrossRef]

- Glover, A.; Gibbs, P.J.; Liu, C.; Brown, D.W.; Clausen, B.; Speer, J.G.; De Moor, E. Deformation behavior of a double soaked medium manganese steel with varied martensite strength. Metals 2019, 7, 761. [Google Scholar] [CrossRef]

- Xie, Z.J.; Yuan, S.F.; Zhou, W.H.; Yang, J.R.; Guo, H.; Shang, C.J. Stabilization of retained austenite by the two-step intercritical heat treatment and its effect on the toughness of a low alloyed steel. Mater. Des. 2014, 59, 193–198. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, Z.; Zou, Y.; Tan, X.; Han, D.; Chen, S. Effect of two-step intercritical annealing on microstructure and mechanical properties of hot-rolled medium manganese TRIP steel containing δ-ferrite. Mater. Sci. Eng. A 2017, 688, 40–55. [Google Scholar] [CrossRef]

- De Moor, E.; Kähkönen, J.; Speer, J.G.; Matlock, D.K. Quenching and partitioning of a 5 wt pct manganese steel. In Proceedings of the Ninth Pacific Rim International Conference Advanced Materials and Processing (PRICM9), Kyoto, Japan, 1–5 August 2016; Furuhara, T., Nishida, M., Miura, S., Eds.; Japan Institute of Metals and Materials: Sendai, Japan, 2016; pp. 167–170. [Google Scholar]

- De Moor, E.; Speer, J.G.; Matlock, D.K.; Kwak, J.H.; Lee, S.B. Quenching and partitioning of CMnSi steels containing elevated manganese levels. Steel Res. Int. 2012, 83, 322–327. [Google Scholar] [CrossRef]

- Thomas, G.; Speer, J.G.; Matlock, D.K.; De Moor, E.; Garza, L. Alloy design for fundamental study of quenched and partitioned steels. In Proceedings of the Materials Science & Technology (MS&T) 2011, Columbus, OH, USA, 16–20 October 2011; TMS: Plano, TX, USA, 2011; pp. 552–567. [Google Scholar]

- Bigg, T.D.; Matlock, D.K.; Speer, J.G.; Edmonds, D.V. Dynamics of the quenching and partitioning (Q&P) process. Solid State Phenom. 2011, 172–174, 827–832. [Google Scholar]

- Thomas, G.A.; De Moor, E.; Speer, J.G. Tensile properties obtained by Q&P processing of Mn-Ni steels with room temperature quench temperatures. In Proceedings of the International Symposium on New Developments in Advanced High-Strength Sheet Steels, Vail, CO, USA, 23–27 June 2013; AIST: Warrendale, PA, USA, 2013; pp. 153–165. [Google Scholar]

- Hou, Z.R.; Zhao, X.M.; Zhang, W.; Liu, H.L.; Yi, H.L. A medium manganese steel designed for water quenching and partitioning. Mater. Sci. Technol. 2018, 34, 1168–1175. [Google Scholar] [CrossRef]

- Yi, H.L.; Du, P.J.; Wang, B.G. A new invention of press-hardened steel achieving 1880 MPa tensile strength combined with 16% elongation in hot-stamped parts. In Proceedings of the 5th CHS2 Conference, Toronto, ON, Canada, 31 May–3 June 2015; AIST: Warrendale, PA, USA, 2015; pp. 725–734. [Google Scholar]

- Pang, J.; Lu, Q.; Wang, J.; Enloe, C.; Wang, G.; Yi, H. A new low density press hardening steel with superior performance. In Proceedings of the 7th CHS2 Conference, Luleå, Sweden, 2–5 June 2019; AIST: Warrendale, PA, USA, 2019; pp. 123–130. [Google Scholar]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Thomas, G.; Speer, J.G. Interface migration during partitioning of Q&P steel. Mater. Sci. Technol. 2014, 30, 998–1007. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).