1. Introduction

Advances in automation technology over the last century are the basis for additive manufacturing [

1]. The idea of additive manufacturing was originally associated with rapid prototyping in order to test new design strategies in the automotive, aviation, and aerospace industry with a minimum of manufacturing effort. Today, additive manufacturing itself has become a technology that enables the fabrication of geometrically complex construction elements with efficient material usage. Additive manufacturing as a production process is also becoming increasingly interesting for tailored solutions in the construction industry. The beginnings of additive manufacturing in construction started around 10 years ago, mainly focused on extrusion techniques and concrete materials. Pioneering projects were realized by counter crafting [

2], d-shape by Enrico Dini, or 3D concrete printing by Buswell et al. [

3]. Since then, developments in this field have taken place at ever shorter intervals and the number of people involved in AM in the construction industry is constantly increasing [

4,

5].

Additive manufacturing of building components in the building industry is not only limited to processes for cement-bound components. The idea of creating metal components by layers of welded seams was already being considered in the 1930s [

6]. However, additive manufacturing from metals in construction has only recently become the focus of attention and is the subject of research in the construction industry [

7,

8]. Arup [

9] and Joosten with MX3D [

10] demonstrated how steel components can be manufactured by additive manufacturing. Camacho et al., however, showed that the main field of application of metallic AM components currently lies in aircraft construction, automotive engineering, and health technology [

11].

The motivation for additive manufacturing in the construction industry results among other things from the low labor efficiency in comparison to automated machines as well as from aspects, such as occupational safety, accident rate, and low construction quality due to inadequate training of employees [

12,

13]. In addition to these points, increasing material efficiency, minimizing waste, reducing building mass, and, consequently, reducing energy consumption in the construction of the component or building are reasons for additive manufacturing in construction.

The production of components is usually carried out in subsequent steps, which is why the construction industry and the production process can be considered as being very fragmented. For this reason, additive manufacturing should not be regarded as a replacement for previous methods of construction, but as an alternative manufacturing process for components that can only be manufactured by traditional methods at great expense. The manufactured geometries can increase in their complexity without increasing costs and effort in the same measure. The aim is to reduce the sum of all individual parts of a building in order to simplify the construction of the building. By digitalizing the whole design process, the number of necessary steps can be reduced compared to traditional design processes. Design, optimization, and preparation for the additive manufacturing of components is done digitally. Work steps, such as transformation of the three-dimensional digital model into two dimensions for worksite planning, are not necessary. From the planning to the finished component, all information is available digitally and allows the creation of a digital twin, which can be transferred into a building information modelling system (BIM).

For architecture, additive manufacturing changes the limitations of fabrication. It opens up the possibility of adapting the design down to the smallest detail without being subject to the restrictions of today’s common manufacturing methods. Particularly in the field of steel construction, the design based on manufacturing from semi-finished products, such as plates and prefabricated profiles. Therefore, there is a high potential of geometric freedom to be achieved by AM in this area.

Processes for the additive manufacturing of steel structures can be subdivided into powder-based (selective laser melting (SLM), laser metal deposition (LMD), electron beam melting (EBM)) or wire-based (WAAM, electron beam freeform fabrication (EBF

3), laser-engineered net-shaping (LENS)) processes [

14,

15]. In WAAM processes, the wire-shaped additive materials are either supplied to the energy source (gas tungsten arc welding (GTAW), plasma and laser) and are molten, or the wire itself is the electrode, like in gas metal arc welding (GMAW) processes [

16].

The advantages of wire-based technologies in comparison to powder-based processes are the higher deposition rate in combination with a better material utilization and lower material cost, making it suitable for applications in the construction sector. Powder-based technologies are more suitable for complex geometries with high requirements on the geometric precision [

17]. Further, the component size in the SLM process is limited regarding the component size, since the dimensions of the component cannot exceed the powder bed size. The WAAM process utilizes CNC or robot kinematics and the AM element is, hence, theoretically not limited in size.

WAAM as a field of research gains more and more attention. Numerous investigations focusing on the application of WAAM in lightweight constructions using titanium or aluminum alloys as filler material [

18,

19,

20]. The driving forces are the automobile and aerospace industry. Other works focusing on steel as construction material, where the fields of application are pipe couplings and flanges, special machines, and plant construction, mainly driven by the naval and crane industry [

17]. In the construction sector, studies on the WAAM with steel electrodes of nodal joints and beam reinforcements are available. Their focus is mainly on the constructive design potential or on the generation process itself [

7,

21]. Other works identified the processing capabilities of WAAM in general by investigating several materials, power sources, and welding processes, such as GMAW, GTAW, and plasma welding. Studies provide guidelines for the additive process selection, aiming at improved material properties. Advanced process modifications, such as workpiece and wire oscillation, modulated power supplies, and use of shielding gas or different cooling strategies, were applied [

22,

23,

24]. Furthermore, there are publications which investigate the thermal cycles and the reheating of prior layers during the WAAM of wall-like structures using high-strength low-alloy (HSLA) steel [

25] and duplex stainless steel [

26]. According to Rodrigues et al., during reheating, recrystallization may occur, leading to fine-grained microstructure or coarse grains in the case of high peak temperatures. However, the microstructure and thus the mechanical properties are affected by the thermal cycles and the amount of layers being reheated during the welding of subsequent layers.

WAAM makes it possible to increase the geometric complexity of a component without increased manufacturing effort. At present, there is no unified methodology for the design of component geometry [

27]. The most common approaches result either from the manufacturing process or from the optimum use of the material. The first approach is a bottom up process and is based on the path planning of the component to be manufactured [

28]. The second approach is a top down process and is usually based on topology optimization. Questions about the aesthetic qualities of the component have not been discussed yet [

29]. However, it is of essential importance for architecture and the building industry.

Each working step, from the creation of the basic geometry, through topology optimization and adaptation for the manufacturing process, to the verification of the load-bearing capacity and stability, creates its own geometry. Restrictions should already be defined during the design of the initial geometry in order to meet the architectural requirements of the overall structure. Here, traditional design concepts should be abandoned and possibilities of additive production should be decisive. Good design only appears possible if there is a precise knowledge of the effects of each individual design step. One of these design steps must consider and include the process parameters and boundary conditions for the manufacturing of a component by WAAM. Structures to be produced by WAAM can be subdivided into various substructures, such as bars, surface elements, and volume elements.

In this article, the focus is on steel bars not only as a substructure, but also as an independent structural component. The possibility of production and the appearance of surface topography as well as homogenous material properties are of special interest. Problems, such as sufficient space for the welding torch, inclination of bars, number of crossing points, and resulting build-up, and path planning strategies must be taken into account at the design stage.

In addition to using bars as a substructure in a structural component, WAAM manufactured bars can also be used as reinforcement in reinforced concrete.

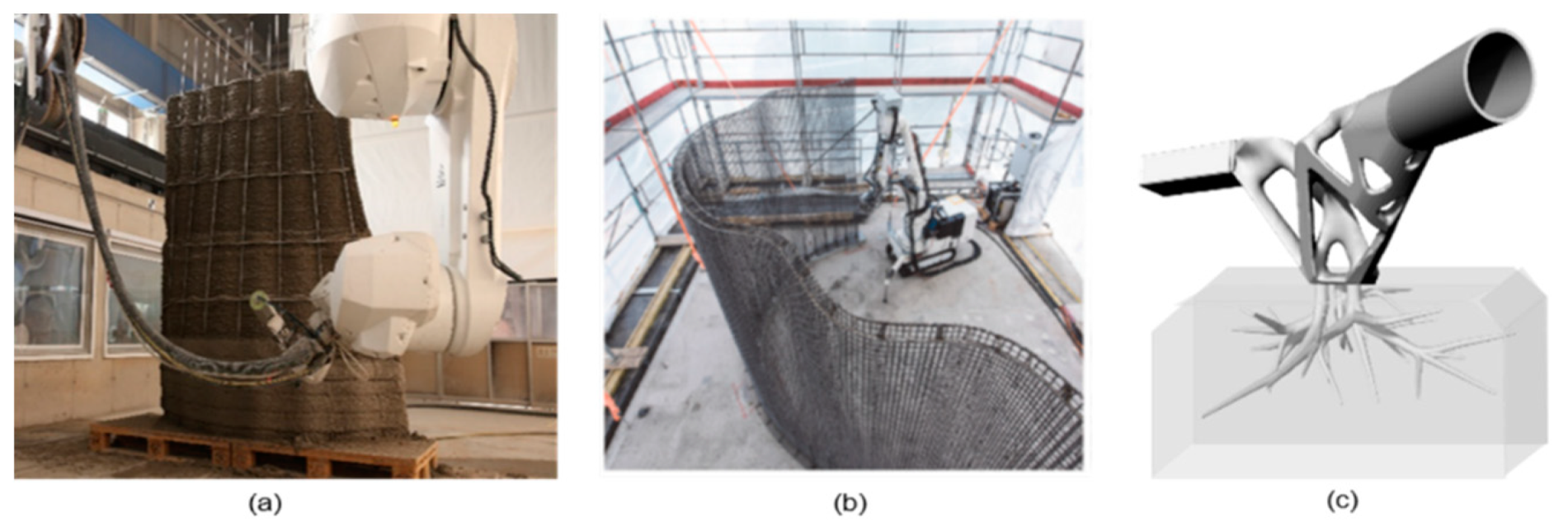

Figure 1 shows reinforcement arrangements for additively manufactured concrete components. The alignment of the reinforcement is still strongly oriented to the geometry of traditional prefabricated reinforcement elements. WAAM allows a more efficient arrangement of the reinforcement and extends the use of additive manufacturing in concrete construction. Due to the higher degree of freedom of WAAM manufactured bars, reinforcement can be arranged according to the tensile stress curve.

An extended application for WAAM-manufactured reinforcement is the anchoring of steel components to reinforced concrete.

Figure 1c schematically shows the possible root-like anchoring of a steel construction node to a concrete foundation. The use of bars as reinforcement requires different surface properties than the nodal joints produced by WAAM. The curvature of the surface is decisive for the bond between the concrete and reinforcement. Control of the surface topology would be advantageous, especially with regard to root-like anchoring, as shown in

Figure 1c.

In order to use components or production types in the European Union, a European Technical Assessment (ETA) is required. The ETA assesses the performance of a construction product with respect to its essential characteristics. ETA provides a way to CE-certification (European Conformity certification) for construction products that are not or are not fully covered by a harmonized standard. This certification process can only be applied to WAAM components with limitations. The evaluation of process and material irregularities and flaws needs to be addressed in future certification concepts for WAAM in construction. Therefore, existing certification concepts need to be extended. A possible solution is the concept of a digital twin, which holds a set of any virtual information that describes the actual physical manufactured product on different scales [

31]. This model is already being used in aircraft production for general components as well as for additive manufactured parts. Currently, this concept will be extended by blockchain technology to ensure the traceability of the process chain steps [

32]. It is necessary to adapt this concept to the particularities of the construction industry. The main challenge for a successful AM technology adoption in the construction sector is the certification of AM components for safe use in the buildings of infrastructure. For this purpose, basic knowledge on the relationship between the manufacturing process and material properties of WAAM components first must be determined.

The determination of the material properties, more specifically, the mechanical properties of additively manufactured bars, differs from conventional material testing due to features, such as topography (notches). Further, different manufacturing irregularities, in terms of WAAM weld irregularities and flaws, need to be addressed by the tests and evaluated. For mechanical testing of AM-parts, like walls or cylinders, the well-established way is to section samples in the form of a standard tension test specimen from the AM-structure, which are prepared and tested according to any ISO or ASTM standard [

33,

34].

Root-like anchoring elements, cast in concrete or reinforcement elements, where an uneven topography or surface irregularities are desired, may show losses in mechanical properties due to notches. Those surface irregularities can be sources for premature failure. So, for applications with cyclic loading, an even surface is more favorable and the bars should be post-processed, i.e., machined. However, those reinforcement elements are not meant to be post-processed, so the influence of the topography on the elastic behavior is essential information when investigating the mechanical properties. So, cutting out standard conform specimen geometries is not an option because the topography information would be lost.

The new approach for the mechanical testing of WAAM-bars, which is introduced here, is to take a standard round tensile test specimen [

35] and replace the cylindrical middle part with an additively manufactured bar.

The aim of this work is to investigate the influence of welding process parameters on the surface topography of steel bars and the local strain distribution as a consequence of mechanical loading. Furthermore, the energy inputs and cooling rates of different welding processes are related with the resulting hardness, microstructure, and the mechanical properties.

2. Materials and Methods

The manufacturing process of the steel bars was carried out on a 10 mm thick S355N (1.0545) substrate plate. The welding material itself was a solid wire electrode of unalloyed steel G4Si1 (1.5130) with a diameter of 1.0 mm. The chemical composition of the materials is given in

Table 1.

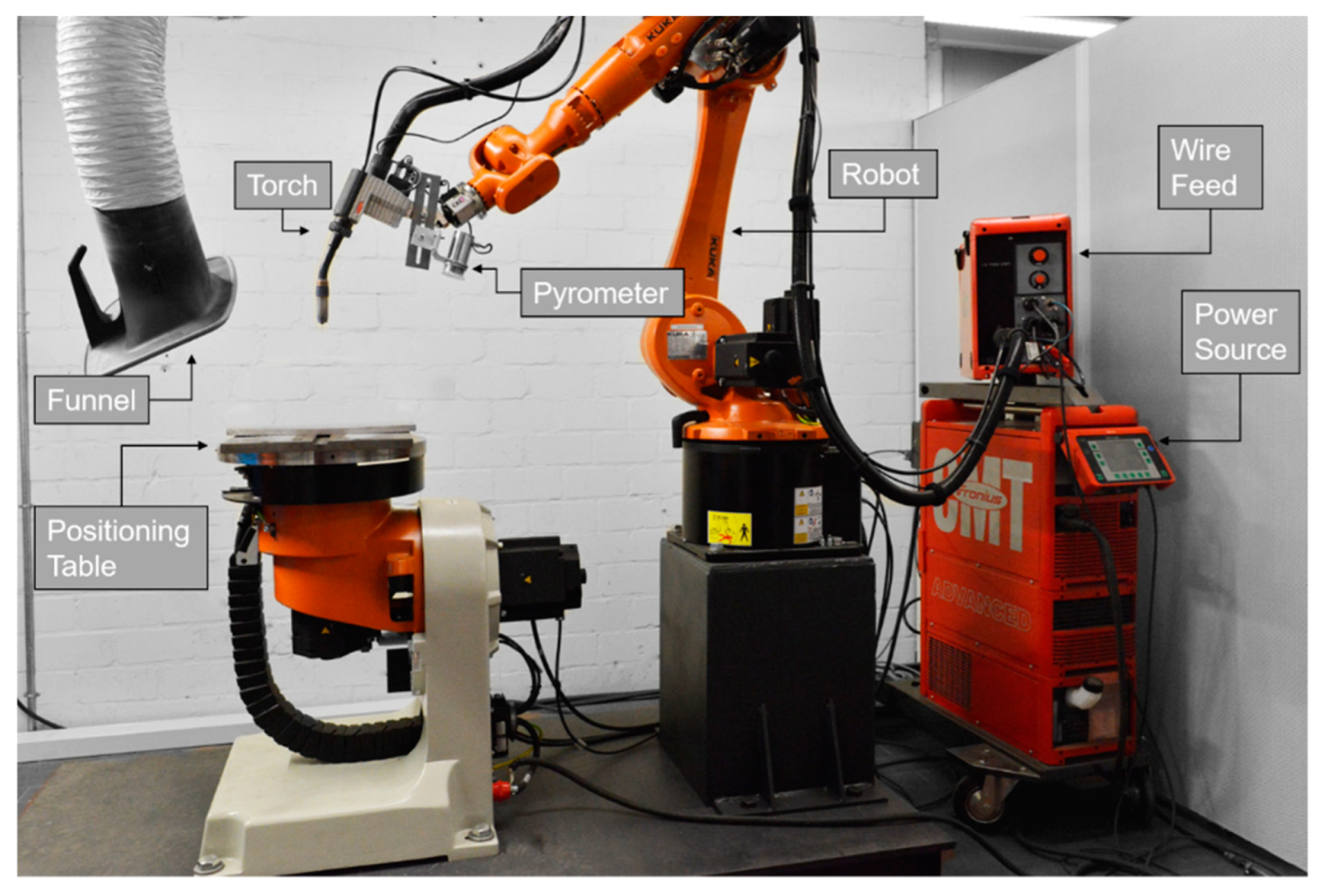

The experimental welding setup was composed of a Fronius Cold Metal Transfer (CMT) Advanced 4000 R power source (Fronius International, Pettenbach, Austria), a handling robot, temperature gauges, and process periphery, as shown in

Figure 2. The torch as well as the pyrometer were mounted on the KUKA KR22 robotic handling system (KUKA AG, Augsburg, Germany). The pyrometer was an optris CTlaser 3MH2 with a measuring range from 200 to 1500 °C. The substrate plate was attached to the positioning table.

One special feature of this power source is the reversing wire electrode controlling short circuit phases and droplet transfer to the weld pool. That leads to a minimal-spatter ignition due to the almost current-free material transition. The current can be kept very low for a longer time, thus significantly reducing the heat input to the piece [

36,

37]. This is what makes such modified short arc processes so suitable for WAAM applications.

In this investigation, two different CMT process variants were used. The first was a CMT standard process and the second was the CMT cycle step, which reaches even higher short-circuit percentages than the CMT standard by controlled switch-offs of the arc, leading to a lower heat input [

37]. The cycle step also convinces with a precise control, which allows the choice of the exact number of droplet transitions per cycle instead of the welding time, like in CMT standard processes [

38]. In addition to the CMT processes, one steel bar was manufactured with an elmatech DV36 L(W) GMAW (denoted in the following as conventional GMAW) power source for comparison. The welding parameters for each process are depicted in

Table 2. As shielding gas M21 (82% argon and 18% CO

2) with a constant flow of 12 L/min was used.

As shown in

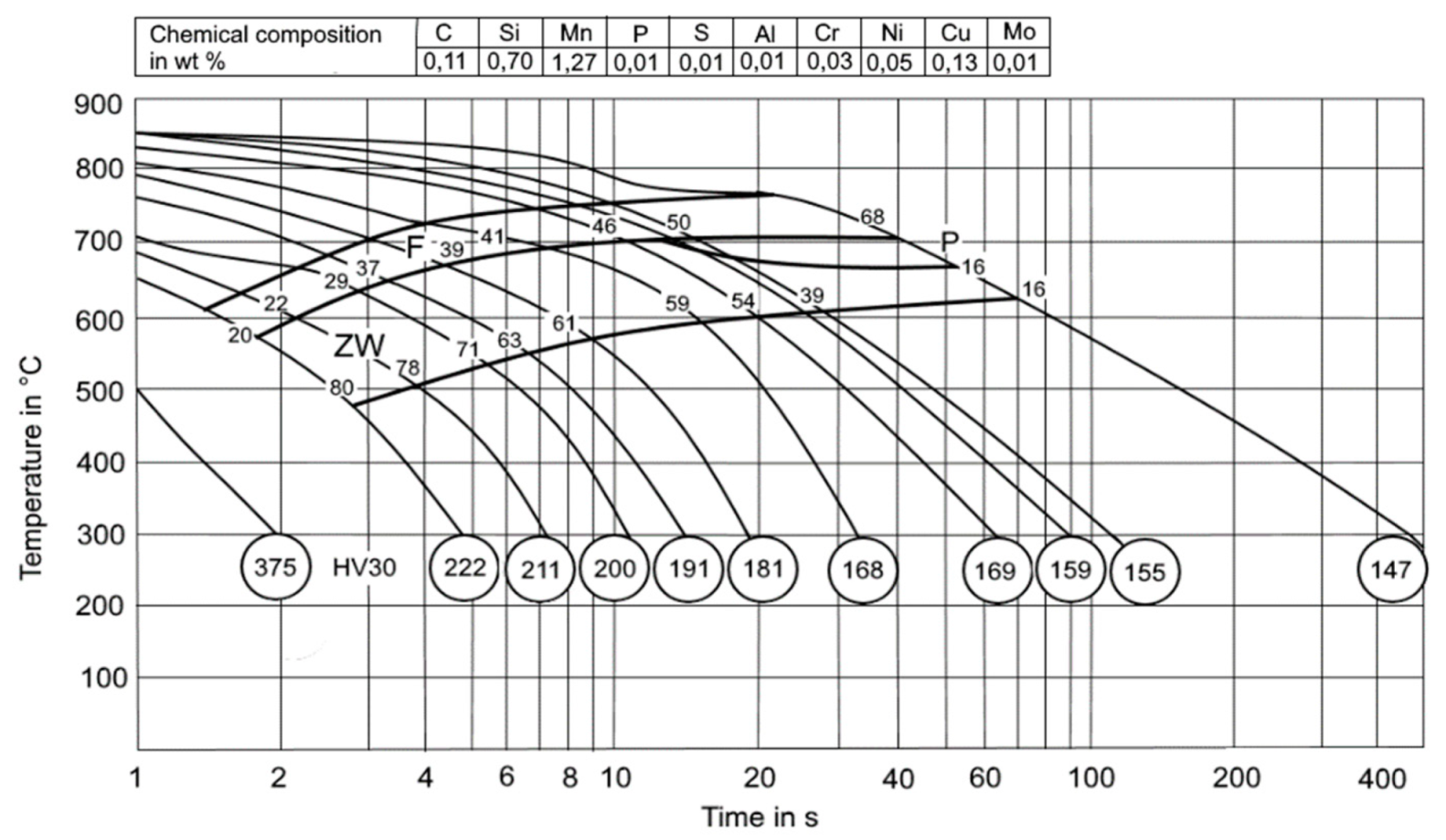

Figure 3a, the bars were welded point by point, while the torch was moved up in the build-up direction. According to the deployed process, one point was welded either for a certain time (conventional GMAW, CMT standard) or for a certain number of droplets (CMT cycle step). Subsequently, the torch was automatically moved up for 2, respectively, 1.6 mm (depending on the resulting layer height) and a waiting period followed, until a constant interpass temperature of 200 °C was reached. Then a new cycle began. The

t8/5-times in the middle layers averaged for both CMT processes was 16 s.

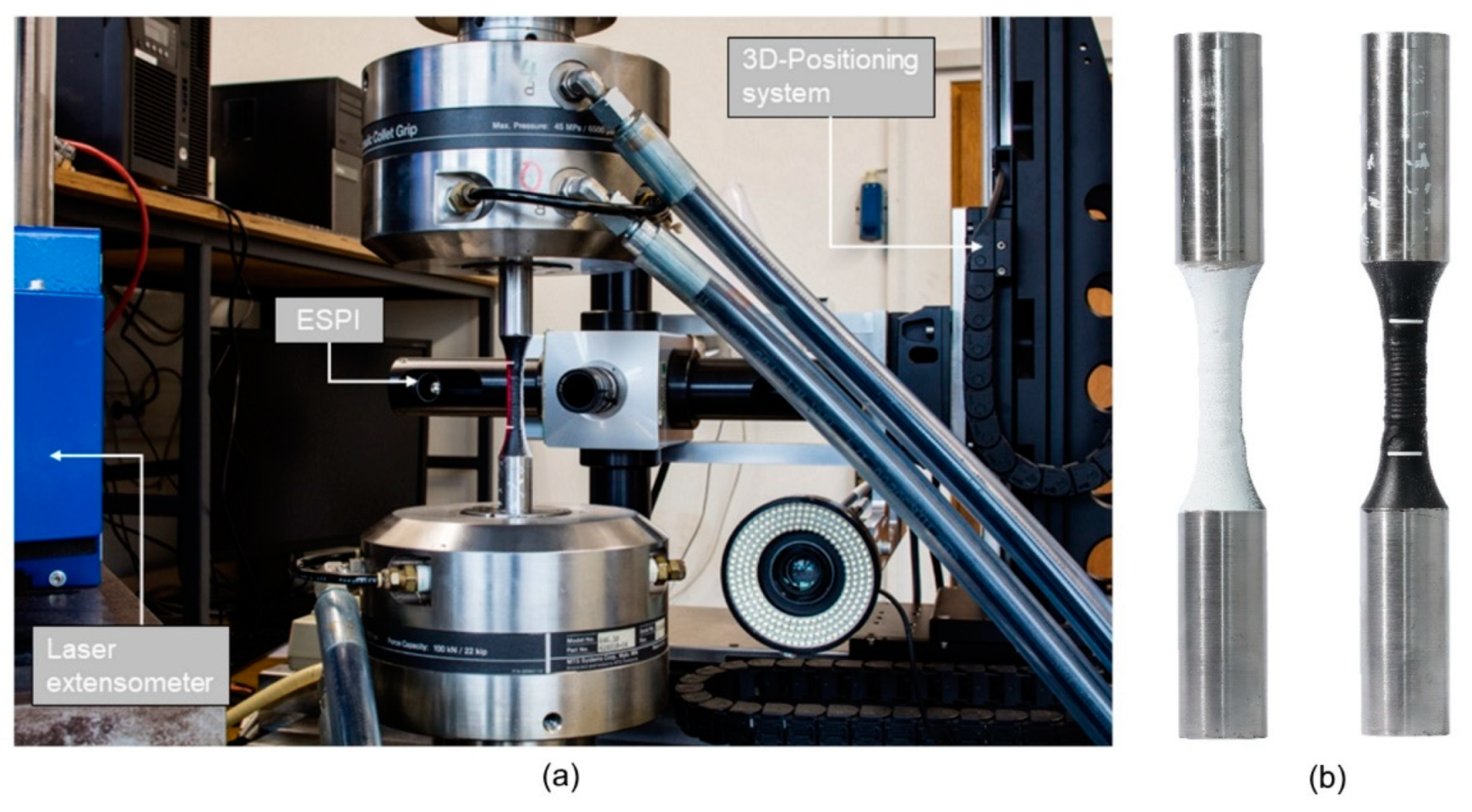

For characterization of the bars regarding their mechanical properties, the bars had to be in a proper shape for execution of the tensile tests. Especially concerning the clamping cylinder in the tensile test machine, the specimens had to be an even shape to not initiate bending moments into the bar itself or into the machine.

The most obvious specimen shape is a round tensile test specimen in dependence on DIN 50125. Therefore, a piece with a length of 30 mm was cut out of the bar and then welded between two cylindrical ends of standard round tensile test specimens, which were turned to a diameter of 11 mm at one side for better accessibility during the welding of the fillet, as shown in

Figure 3b. The joint was welded with a TIG-process using 110 A and no filler material. For all samples, computer tomography scans with a “GE v|tome|×240s Research with micro focus tube” were made. Subsequently, the tensile tests followed. Additionally, for all three samples, the surface was characterized using a laser scanner (optoNCDT 1800, micro-optronic, Langenbrück, Germany), micrographs were prepared, and hardness tests were executed.

The experimental setup for the tensile testing is shown in

Figure 4. The specimens were mounted on a tensile testing machine (MTS 810 Servo Hydraulic Testing System, MTS Systems GmbH, Berlin, Germany) and two optical measurement systems were used for the tensile tests. In order to take sufficient account of surface influences and the anisotropic inhomogeneous material behavior, full field strain measurements were taken with the Electronic Speckle Pattern Interferometry (ESPI; Q-300, Dantec Dynamics GmbH, Ulm, Germany). Because the ESPI requires a high positional accuracy relative to the specimen, it is mounted on a 3D-positioning system, which allows the positioning with an accuracy of 1 μm. Additionally, a laser extensometer (P-50, Fiedler Optoelektronik GmbH, Lützen, Germany) was used to verify the measured strain maps during the test. This second measurement was done over the whole length of the welded part of the bars.

ESPI employs a coherent laser that illuminates the specimen from different positions and monitors the change in the intensity of the produced interference due to the displacements with a CCD camera. The setup used here can measure displacements of the surface in all three spatial directions. The measured displacement fields are then numerically differentiated in order to obtain strain maps. One advantage of the ESPI for the measurements on the material scale is its high displacement measurement resolution (up to 10

−6 m) [

39]. Due to this high resolution, ESPI is often used for measurements of displacement and strain due to thermal loading on small parts in the sectors of aerospace technology or electrical engineering. ESPI measurements on aluminide layers on a MAR 247 nickel alloy were also shown to be able to identify localized areas of deformation concentration as a starting point of damage under cyclic loading [

40].

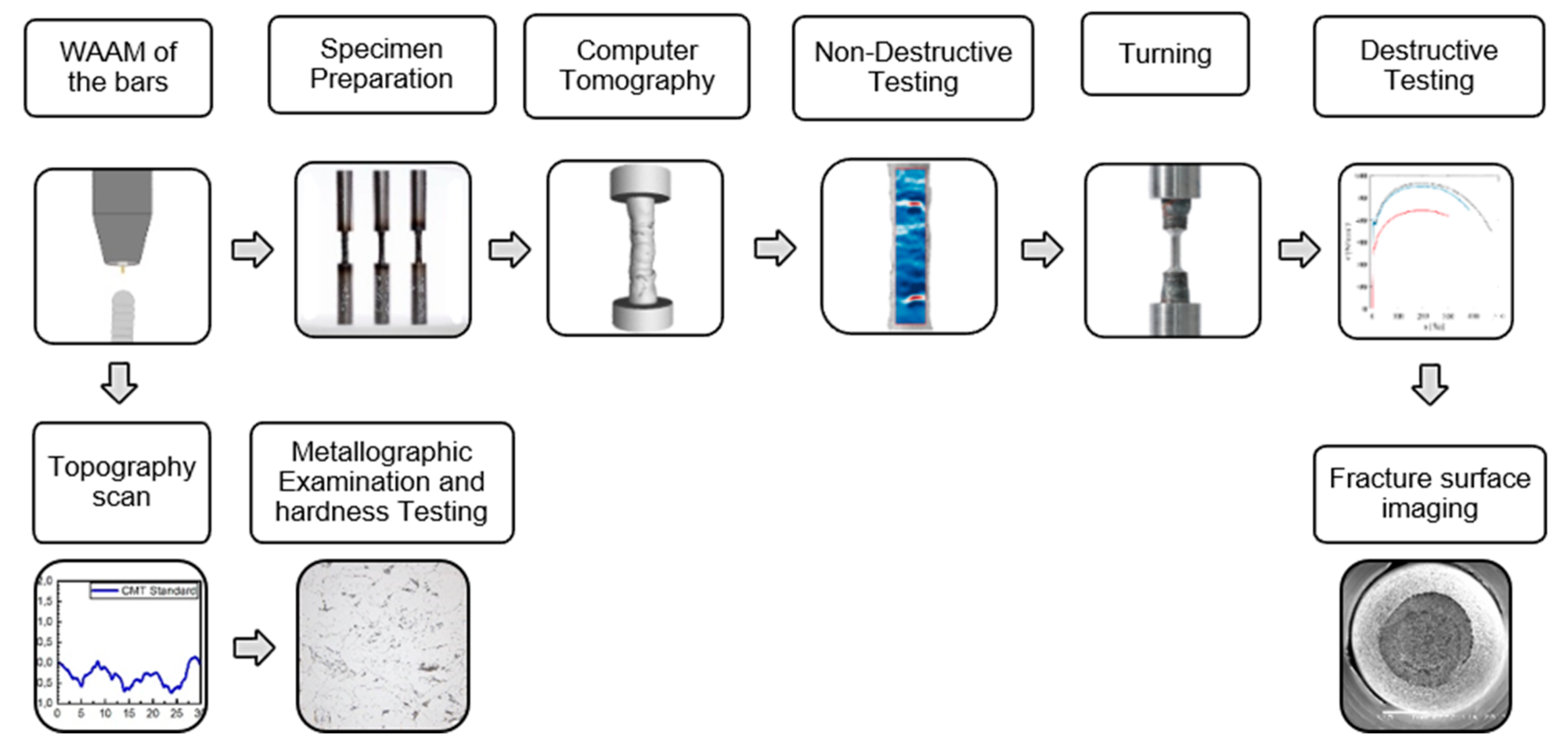

The use of standard tensile test specimens for the determination of mechanical parameters was not directly feasible here. Conducting tensile tests until failure with the topography “as-welded” would not allow the calculation of definitive material parameters, except the component’s bearing load, as the cross section is not well-defined. Turning the whole specimen leads to a loss in information as the surface would be removed to create a defined measuring section. Therefore, an advanced testing strategy was applied here, which was divided in two stages of tensile tests with an additional metallographic examination parallel to the tensile tests, as shown in

Figure 5.

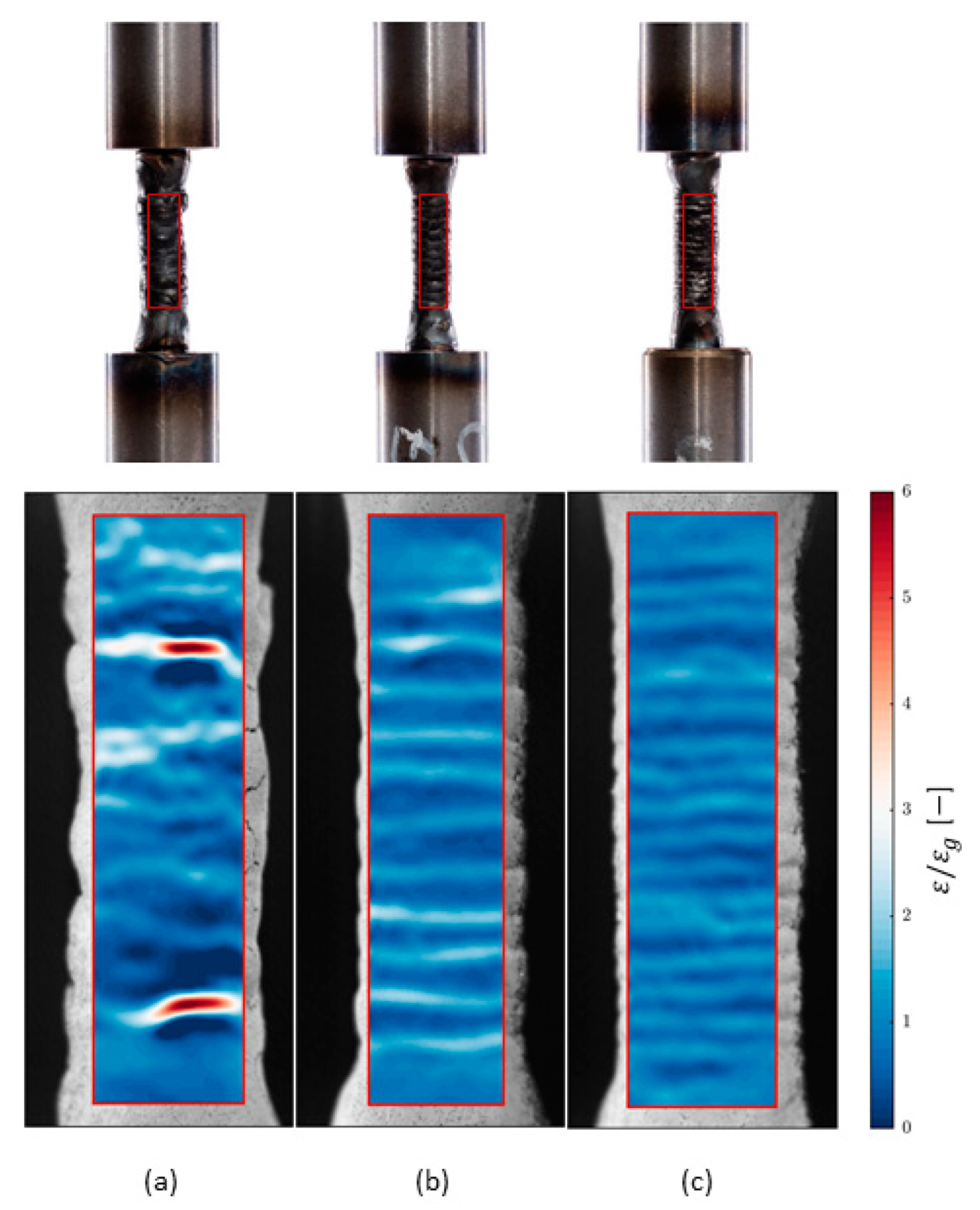

The non-destructive first stage of testing was applied to the sample with the topography “as-welded” as shown in

Figure 5. The aim of the first tests was to analyze the influence of the weld process-dependent surface topography and the inhomogeneous material behavior in the elastic state. The load had to be limited in order to avoid plastic deformations and was identified in preliminary tests to a maximum force of 5 kN. Due to the high sensitivity of the ESPI, the measurements had to be conducted after load step increments of 0.5 kN with holding times of 5 s each. Afterwards, the measured deformations and strains of each load step were summed up. Simultaneously to the ESPI measurement, the laser extensometer measured the strains over the whole length of the welded specimen (30 mm) to verify the strains measured with the ESPI.

Both optical measurements required a different surface preparation. For the ESPI measurement, an optically rough and reflective surface is required. This was achieved by spraying on a layer of lime powder. On the other side of the specimen, a primer with a matt black lacquer was applied to serve as a non-reflective background that could be distinguished from the white measuring marks, which is displayed in

Figure 4b.

In order to obtain the material parameters, a second stage of destructive tensile tests was carried out. For these tests, a well-defined transversal section was needed to calculate the resulting stress and to derive the stress–strain diagram with all needed design parameters. For this reason, the middle part of the bars was turned to an even transversal section with a length of 10 mm. To ensure that the failure of the specimen occurred in the desired section and not in the fillet weld, a diameter of 4 mm was chosen for the transversal section. The strains during the test were measured with the laser extensometer. For this, the measurement markers were placed on the outer edge of the transversal section at a distance of ca. 10 mm.

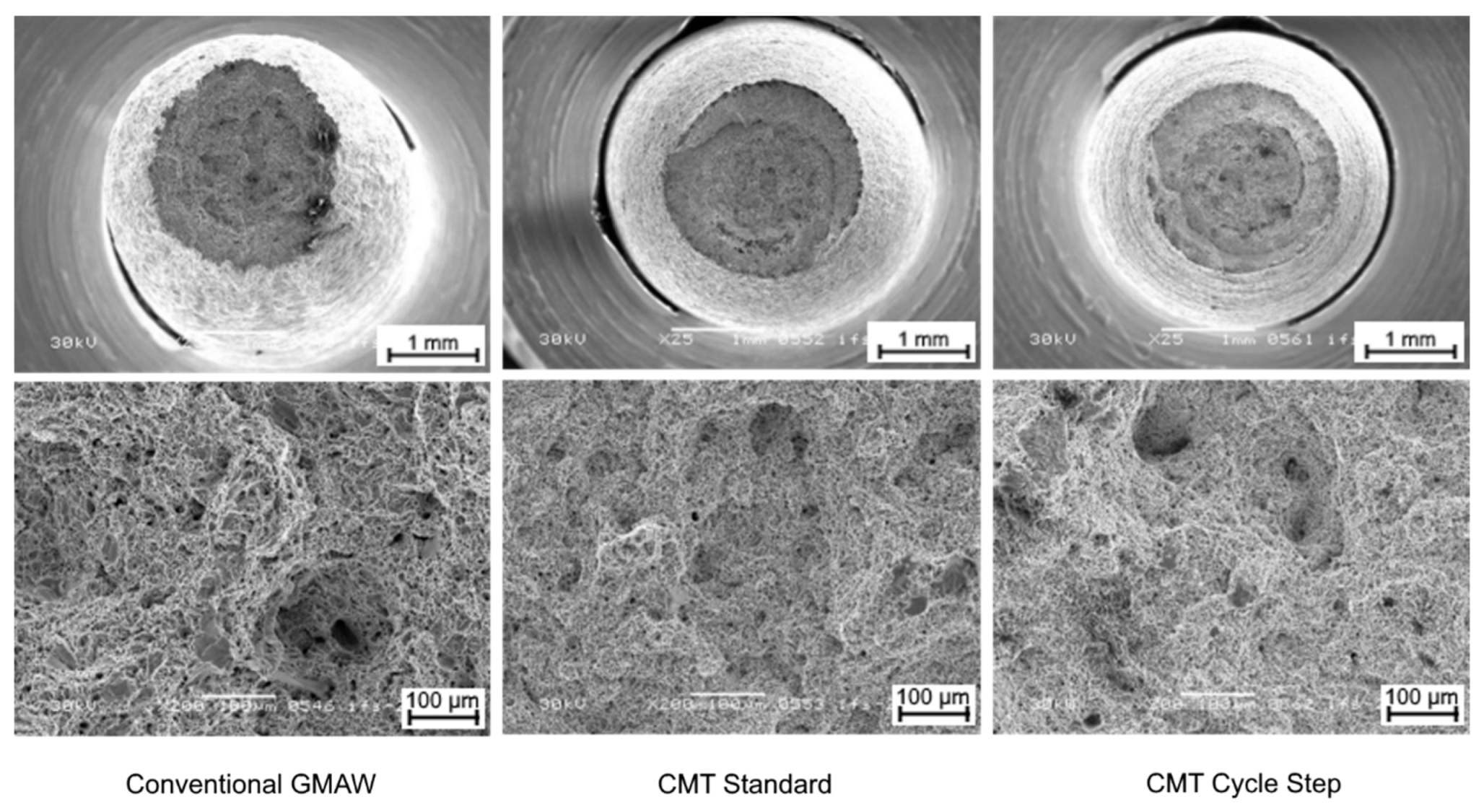

After the destructive testing, the fracture surface was examined using a scanning electron microscope (JEOL JSM 6480, Japan Electron Optics Laboratory, Akishima, Japan) to obtain information about the fracture mechanism.

4. Discussion

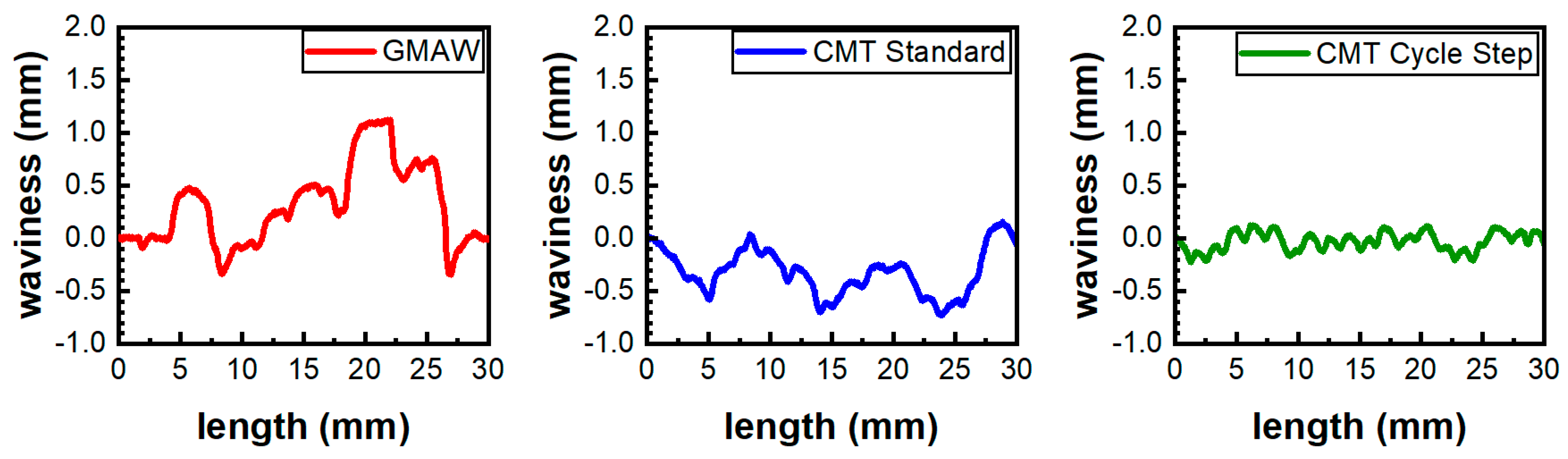

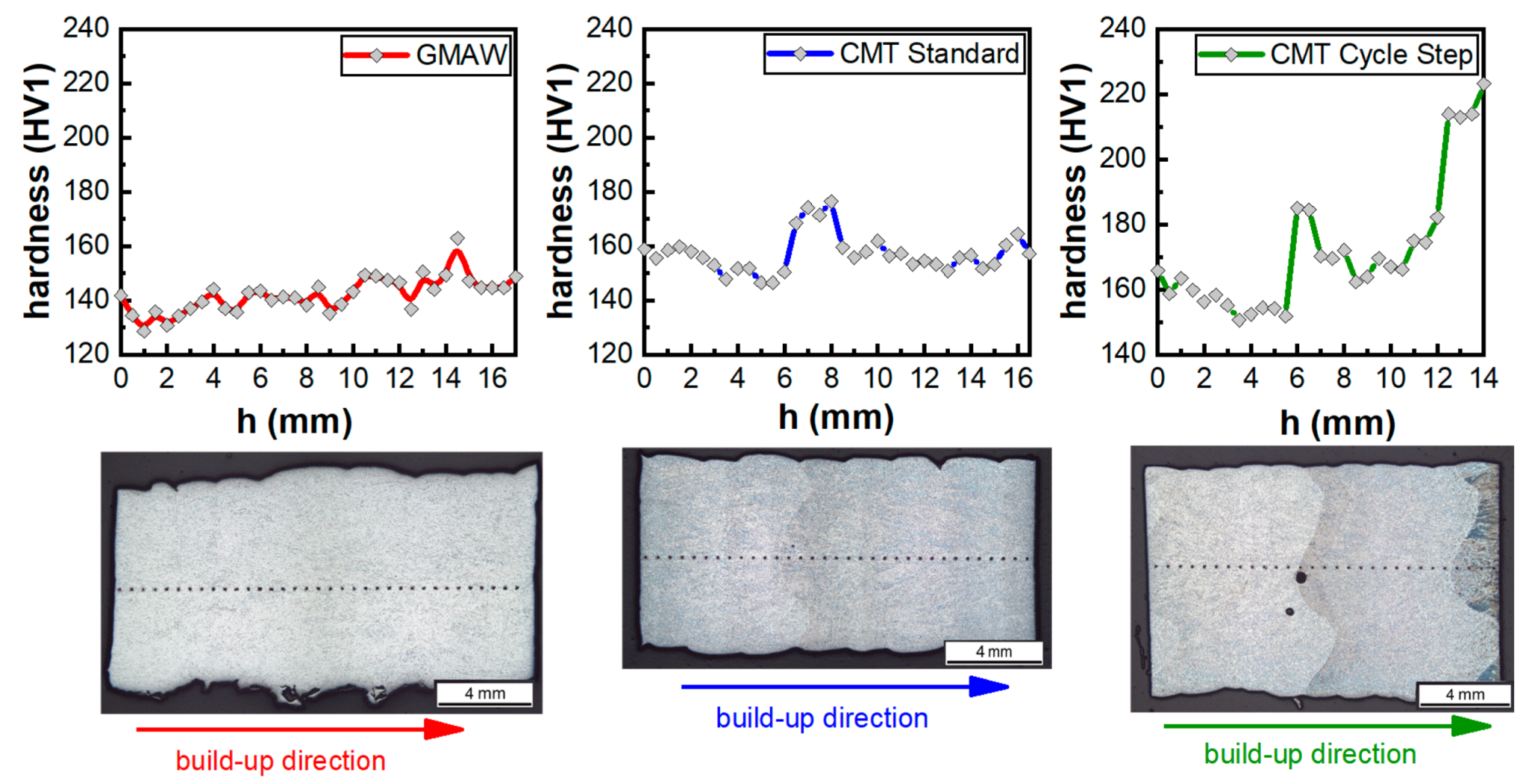

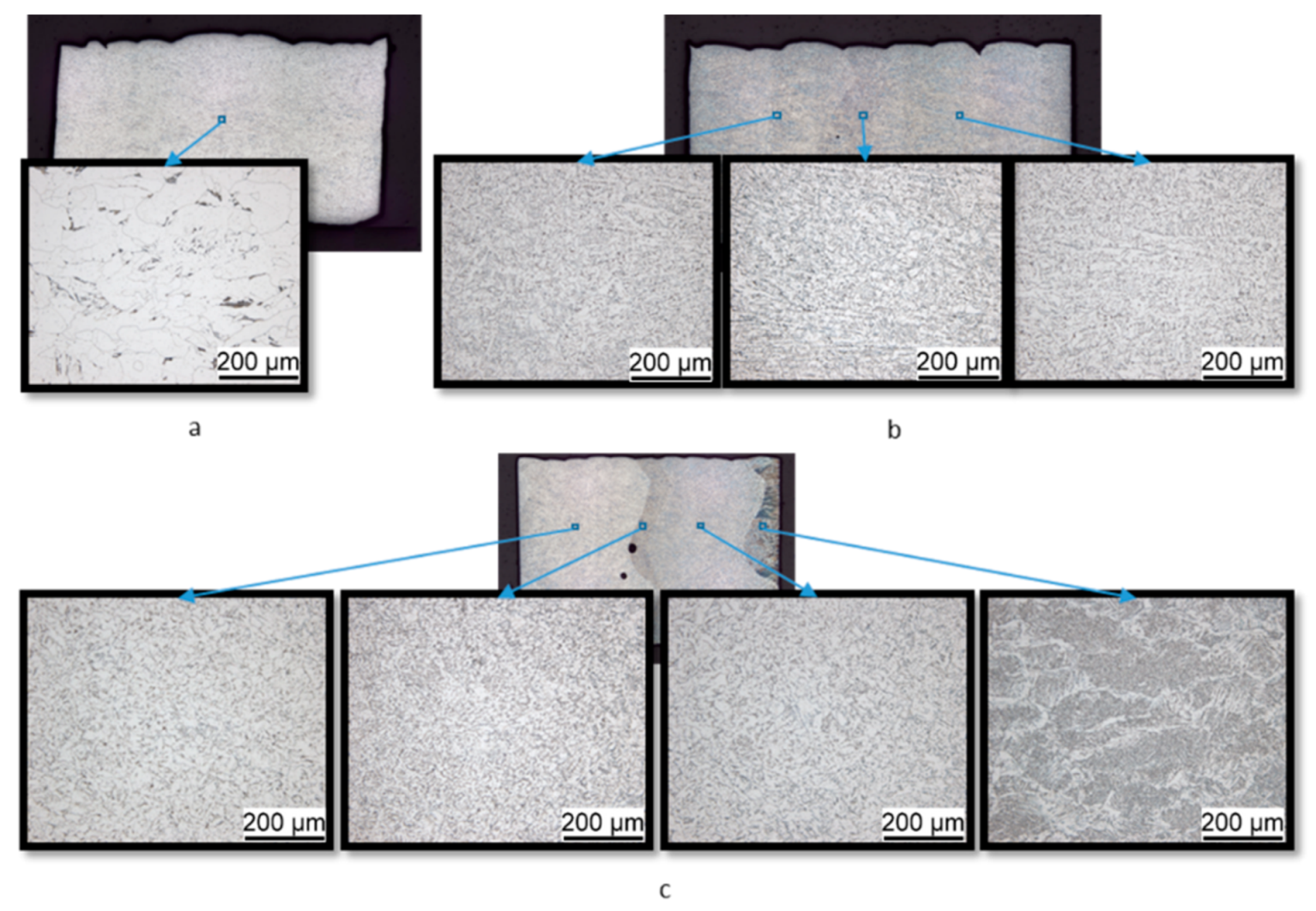

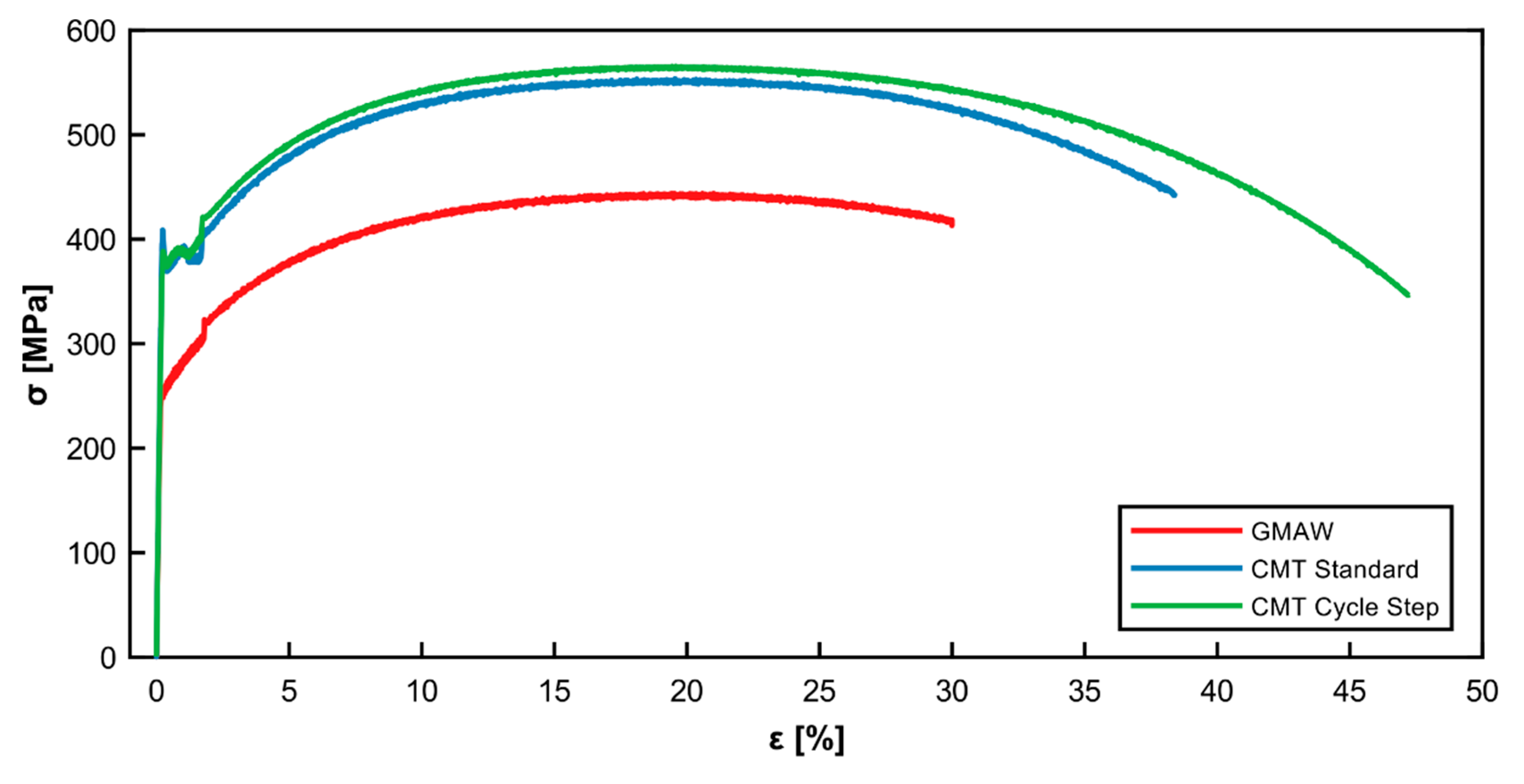

Steel bars manufactured by the WAAM process demonstrate the use of AM in construction. For this study, several samples were manufactured with each process to identify the influence of welding parameters. However, only one sample of each process was tested until fracture. The overall objective was the identification of an advanced test routine, which can be applied to further WAAM components as well. The steel bars, as manufactured and tested here, could represent reinforcement elements in concrete applications or standalone, respectively, parts of complex larger steel components structural members. Further, it is demonstrated that the use of manufacturing parameters, such as the welding process and the energy input, may result in a severe influence on the component and material properties. The energy reduced short arc welding processes led to a heterogeneous microstructure with hardness peaks at the layer interfaces, probably resulting from low annealing temperatures between A1 and A3. This is usually not favorable as mechanical properties become heterogeneous as well. Higher interpass temperatures could solve this issue also for welding processes with low heat input. However, the resulting lower weld pool viscosity may affect the resulting surface topography as well. The results from the microstructure and hardness testing of WAAM bars as well as the surface fracture images correspond well with theoretical findings from the literature (e.g., TTT-diagrams), weld parameters, and results from tensile tests. The conventional GMAW bar with lower, but homogeneous, hardness showed lower ultimate strength and higher areas of reduction at the fracture compared to the CMT-welded bars. However, the peak temperatures and annealing times should be controlled more intensively in future research as they control the grain size.

The surface topography and the geometric dimensions, here the bar diameter, depend on the process characteristics. A homogeneous diameter is preferable in terms of mechanical material utilization. However, in concrete applications, rougher surfaces may be beneficial due to better load transfer from concrete to reinforcement bars. Cyclically loaded components would benefit from smoother surfaces as observed in the case of CMT-welding. Next, the layer volume increases with increasing energy input, which is beneficial for economical manufacturing times.

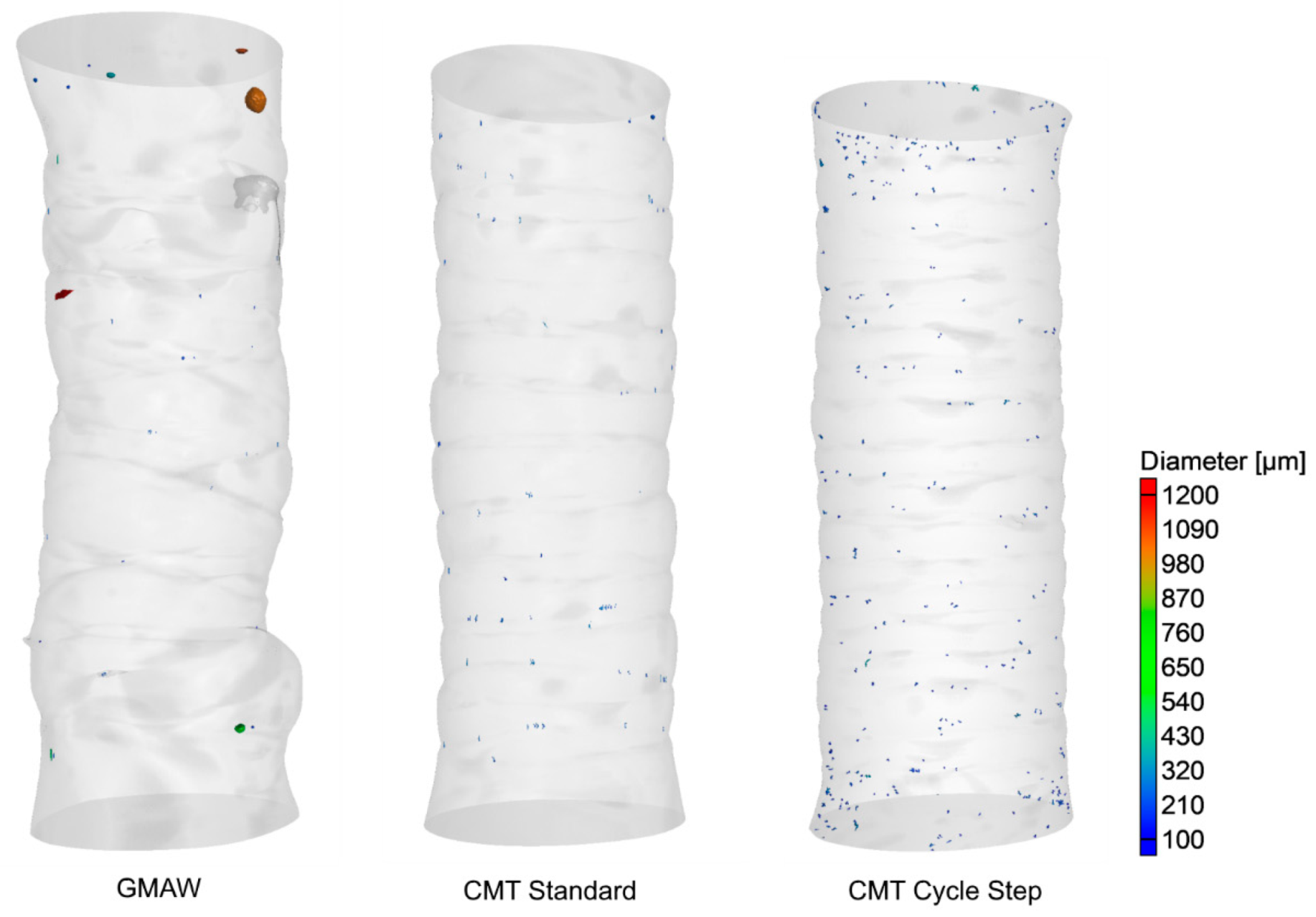

CT scans did not show severe inner defects or irregularities in the manufactured steel bars, except a low number of single pores with a diameter of ~1000 µm. The differences in pore size and magnitude are explained by the welding time and weld pool size. However, this must be examined statistically in future research with higher numbers of specimens.

The applied test methodology captured both local elastic component behavior and integral material parameters. The full field strain measurements can identify the inhomogeneous material behavior. Most likely, the heterogeneous strain distribution results from geometric variations, i.e., the change of diameter and local notches at layer interfaces. However, future work will address the material properties of deposited weld metal depending on the applied weld process in more detail. The detected stress concentration is of large importance for plasticity-induced phenomena, such as crack initiation and fatigue.

Various parameter identification methods could be used to quantify the deviations of the material in further research, for example the virtual fields method [

43]. The measurements on the material scale presented here are not sufficient to evaluate the behavior of more complex WAAM-components in its entirety and 360° digital image correlation systems could be utilized for the purpose of analyzing the deformation behavior of the entire component during a test, even in regions of large deformations where the ESPI system reaches its limits. When analyzing the component behavior, it is also necessary to evaluate the behavior under compressive loads in regards to buckling as the WAAM components are generally slender components.