Effect of Magnesium Matrix Grain Refinement Induced by Plastic Deformation in a Composite with Short Carbon Fibers

Abstract

:1. Introduction

2. Materials and Methods

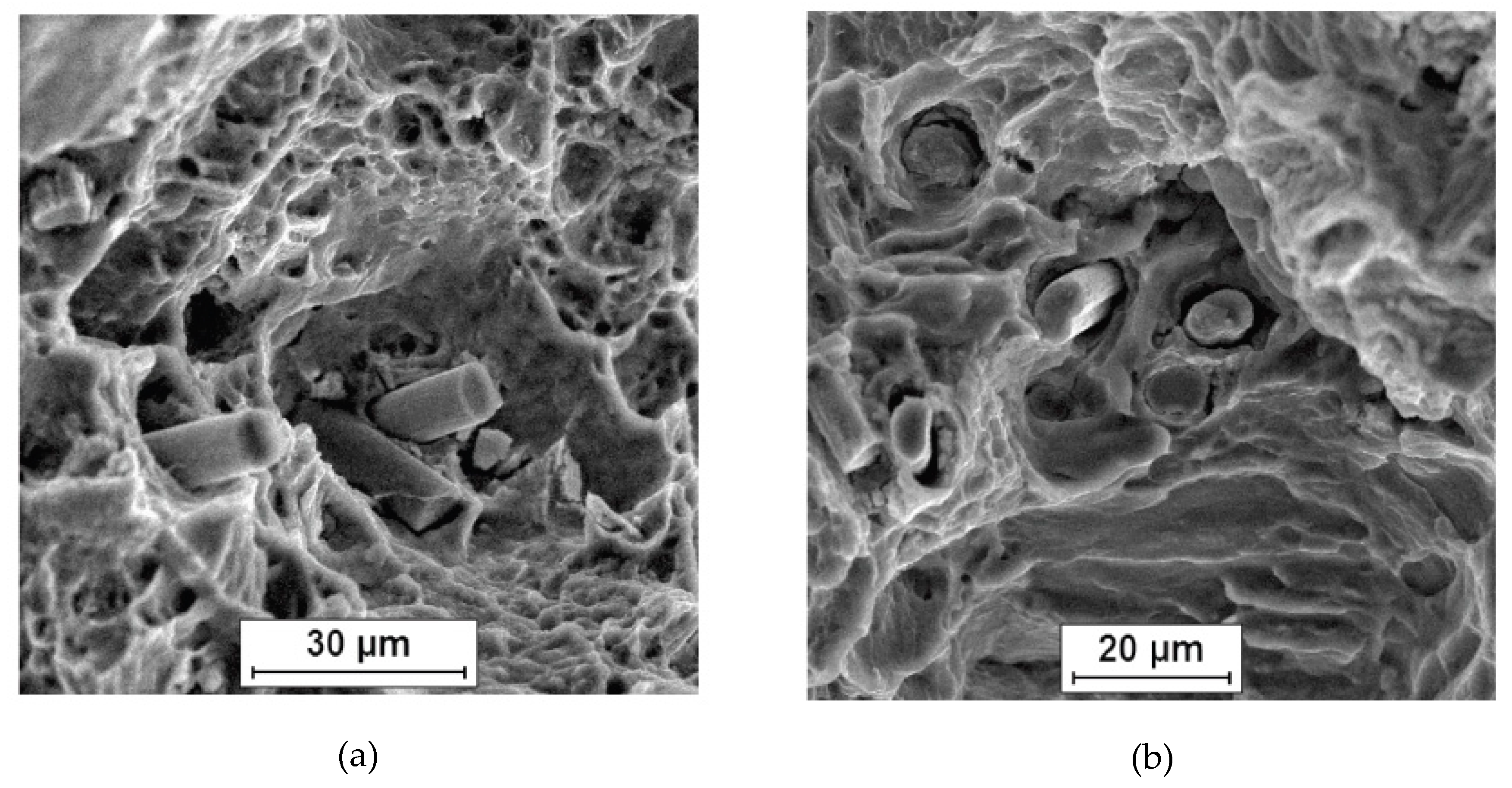

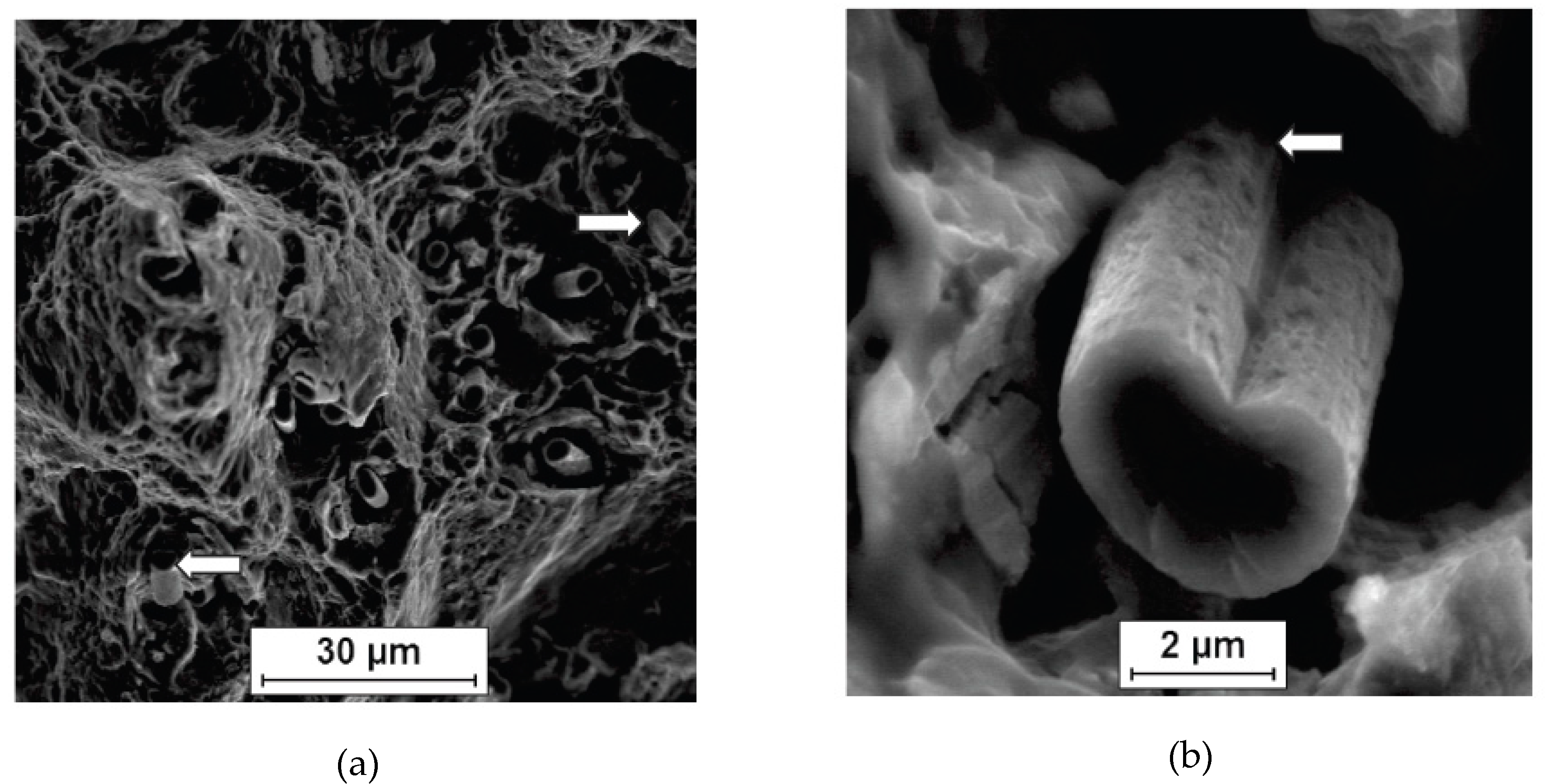

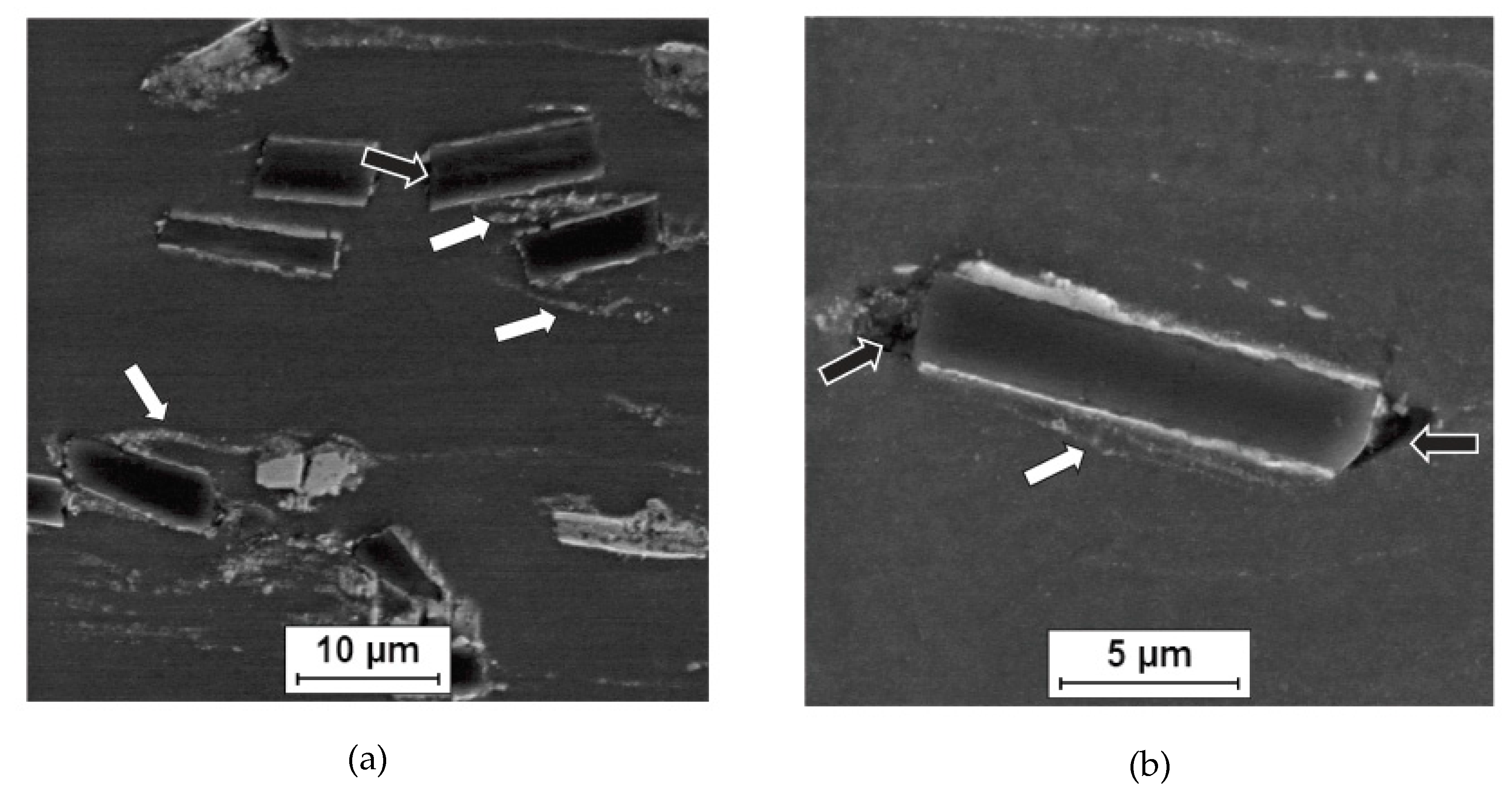

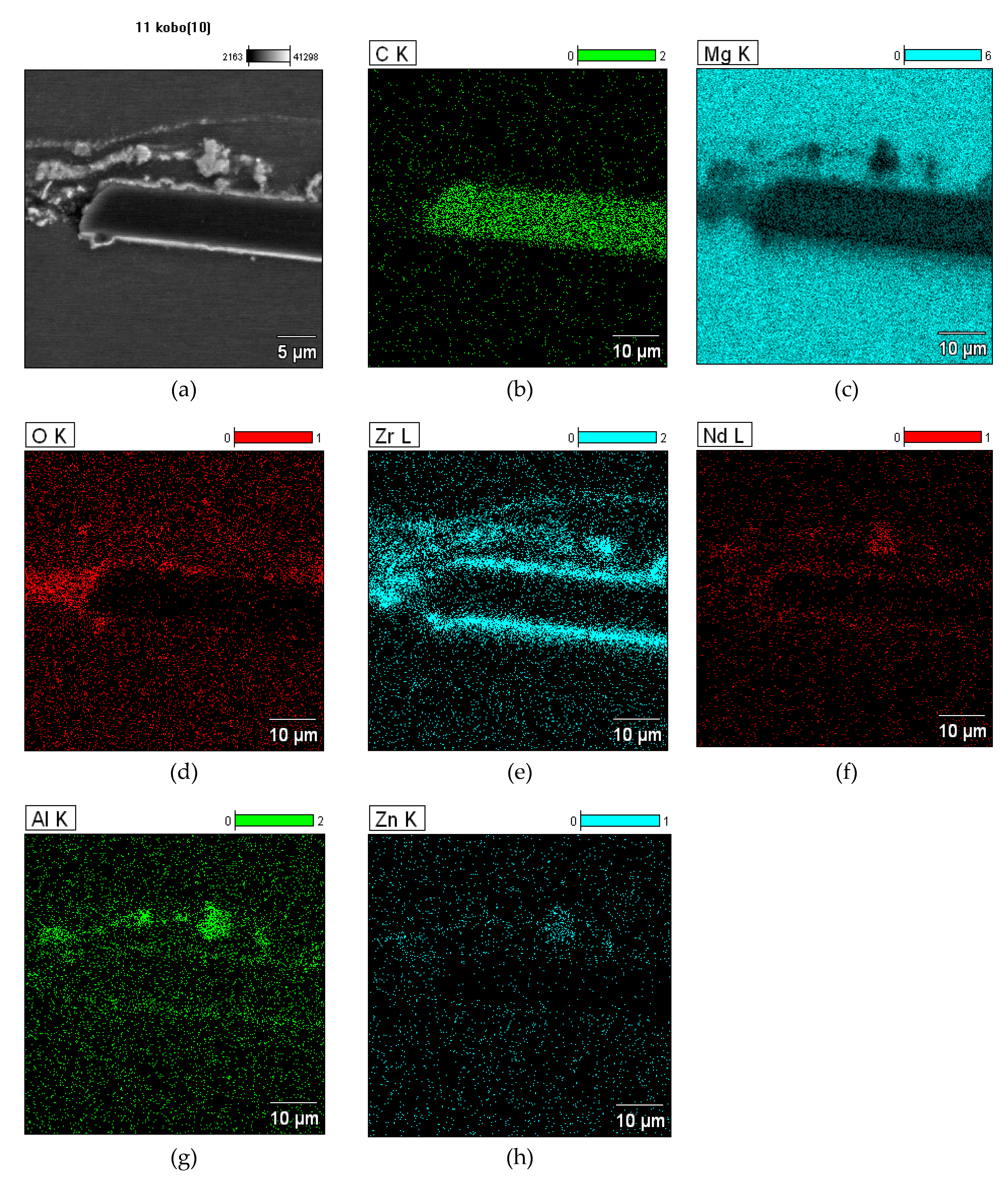

3. Results and Discussion

4. Conclusions

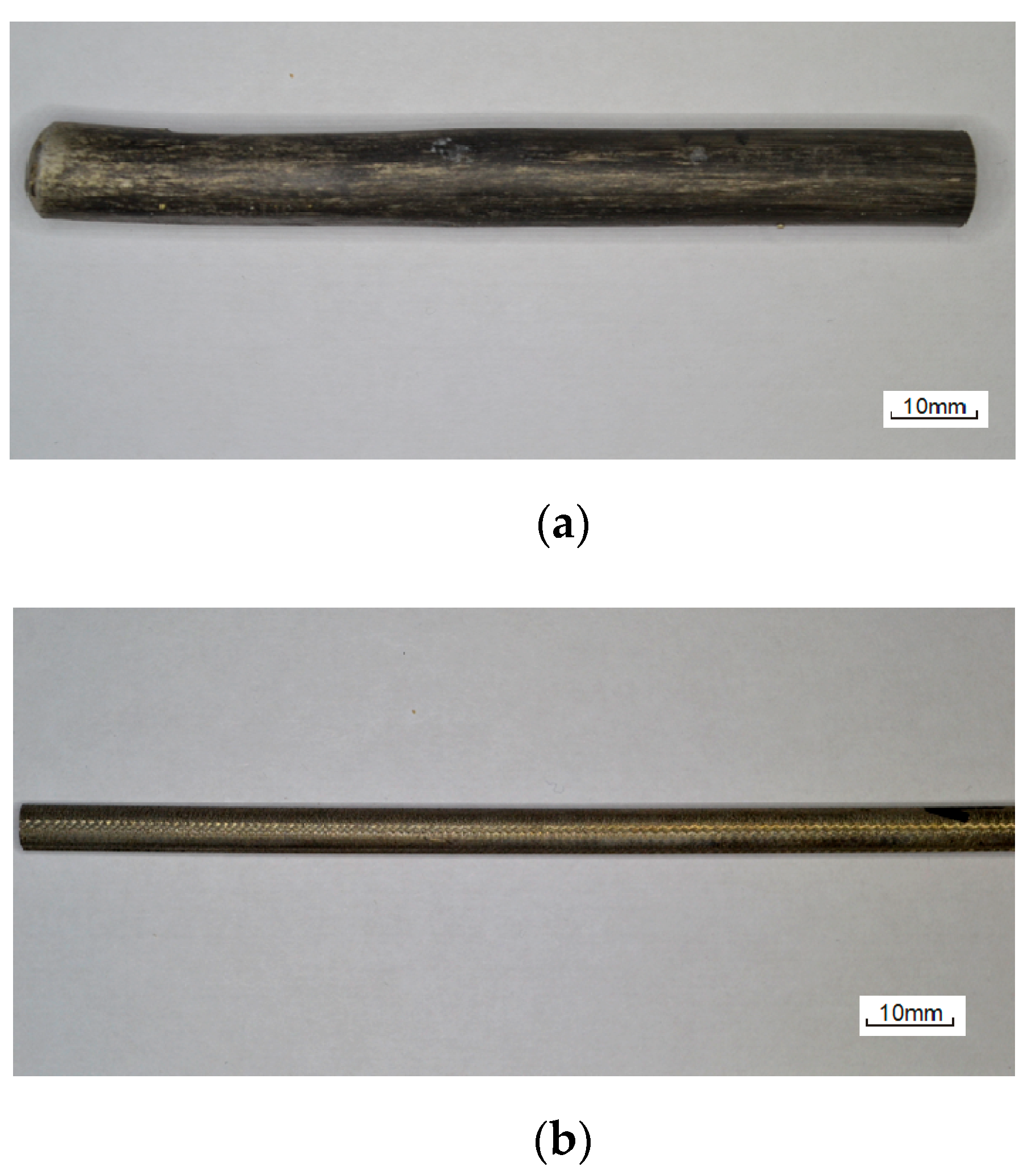

- The degree of composite processing (λ) that is guaranteed to obtain undefective bars was evidently higher for the KoBo method than for plastic working by hot extrusion. The KoBo extrusion led to fabrication from the same initial material, the bars of glossy metallic color with very fine regular relief, while the bars processed by hot extrusion were of dark gray matte color due to intense oxidation effects.

- The KoBo cold extrusion induced a spectacular increase in the strength and plasticity of the Mg-Csf composite in comparison with the as-cast and hot-extruded material.

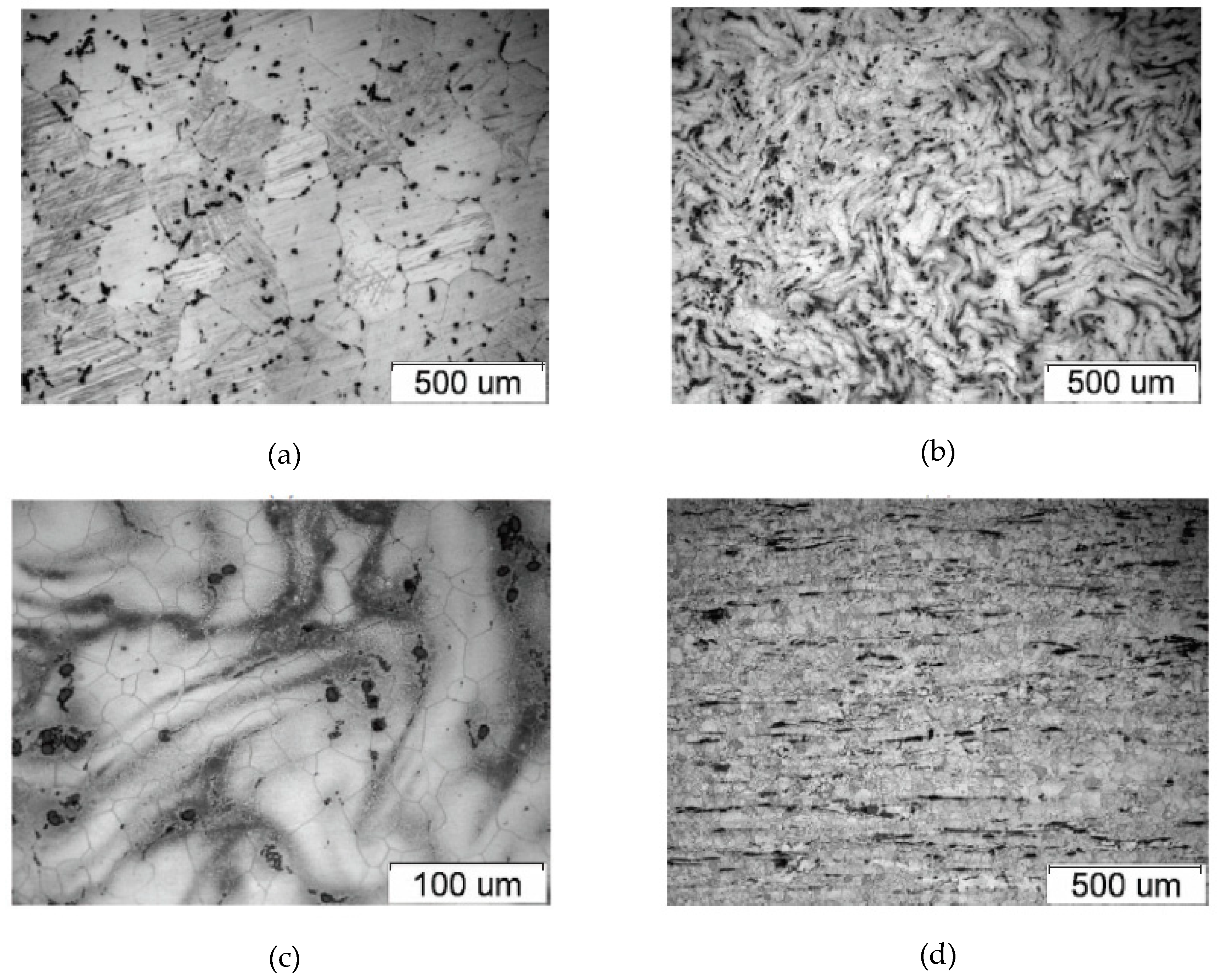

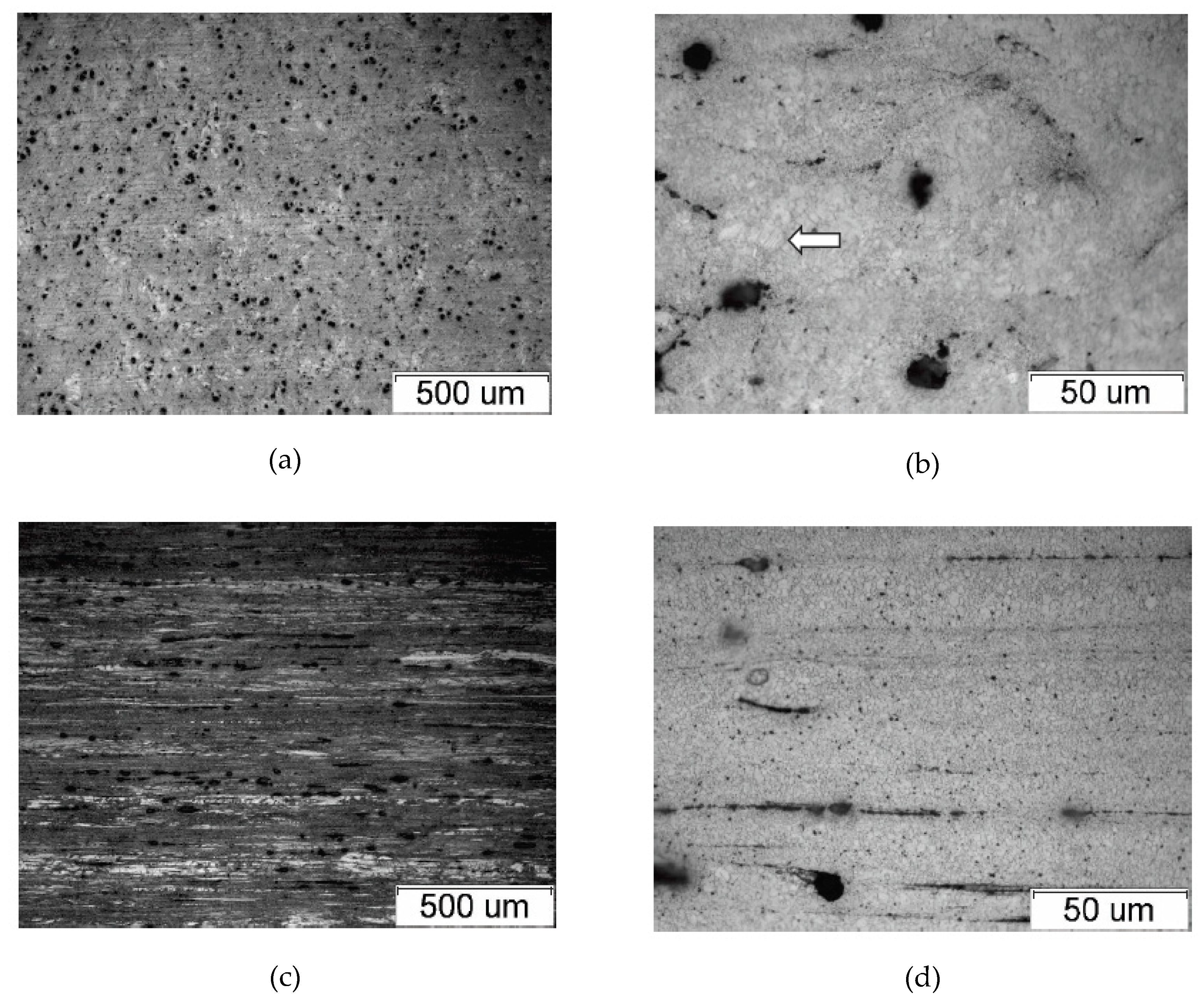

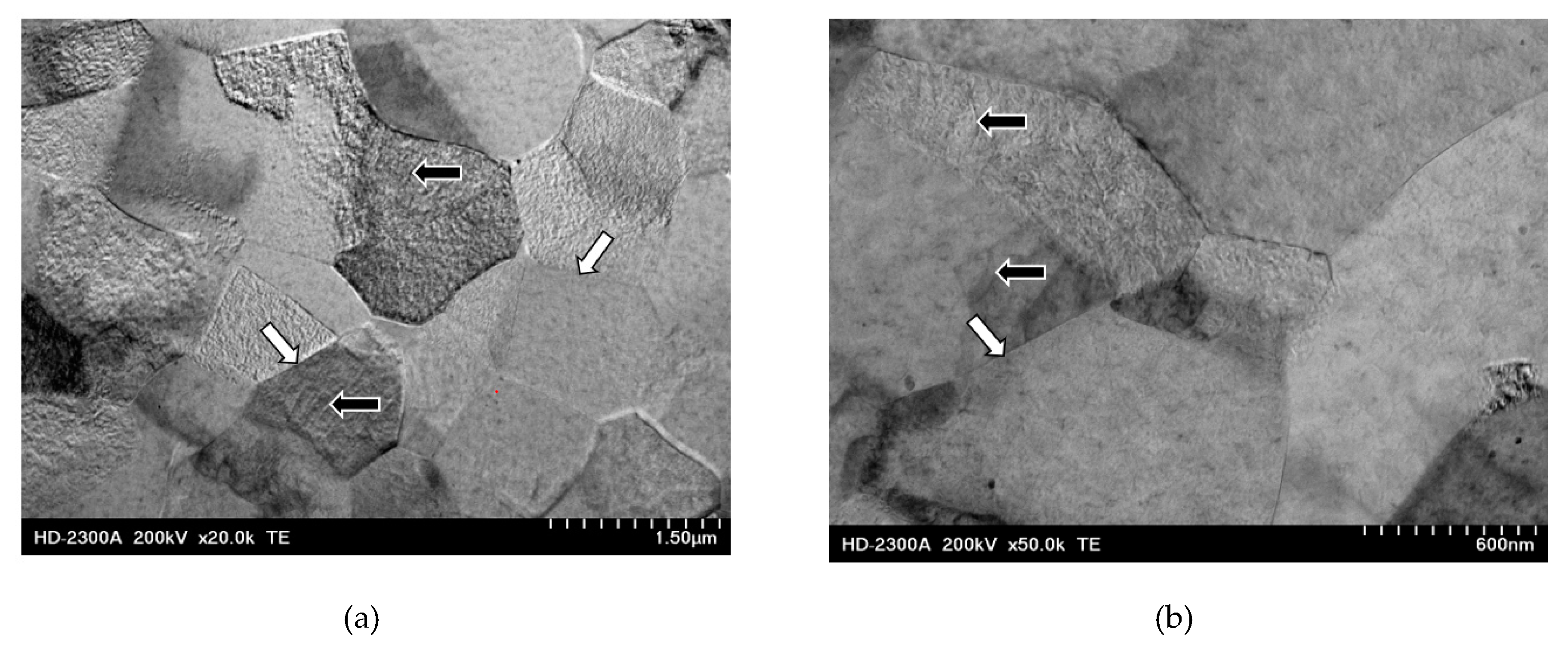

- Independent of the applied extrusion method, the Mg(α) grains were equiaxed and well-refined. After the hot extrusion of the Mg-Csf composite at 400 °C, the matrix grain size was reduced by one order of magnitude in comparison to those in the as-cast composite. The KoBo cold extrusion caused the formation of ultrafine matrix grains, which were two orders of magnitude smaller than those in the as-cast composite and one order smaller than those of the hot-extruded composite. Both types of extrusion induced an orientation of composite microstructure similar to the extrusion direction that contained fibers, as well as finer phases, insoluble in Mg(α) as intermetallics, oxides and zirconium, which formed bands.

- An intensive carbon fiber fragmentation perpendicular to the main fiber axis occurred in the KoBo extrusion. That process generates, in carbon reinforcement, a new clean area weakly connected with the matrix and entails a decrease of fibers reinforcing effect on composite properties.

- A very high mechanical properties increase of the Mg-Csf composite bars processed by KoBo, in comparison with the cast material, can be explained by the refining of the matrix grains. That effect indicates plastic working without preheating as a very efficient technology both with respect to the fabrication of different-sized composite profiles as well as the significant improvement of properties, which is unavailable by casting methods.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ataya, S.; El-Magd, E. Quasi-satic behavior of Mg–alloys with and without short-fiber reinforcement. Theor. Appl. Fract. Mech. 2007, 47, 102–112. [Google Scholar] [CrossRef]

- Deng, K.K.; Wang, X.J.; Wu, Y.W.; Hu, X.S.; Wu, K.; Gan, W.M. Effect of particle size on microstructure and mechanical properties of SiCp/AZ91 magnesium matrix composite. Mater. Sci. Eng. A 2012, 543, 158–163. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.-Y.; Xiu, K.; Wang, H.-Y.; Jiang, Q.-C. Fabrication of TiB2 particulate reinforced magnesium matrix composites by two-step processing method. Mater. Lett. 2006, 60, 1533–1537. [Google Scholar] [CrossRef]

- Olszówka-Myalska, A.; Myalski, J. Magnesium alloy AZ31—Short carbon fiber composite obtained by pressure die casting. Solid State Phenom. 2015, 229, 115–122. [Google Scholar] [CrossRef]

- Wang, X.J.; Nie, K.B.; Hu, X.S.; Wang, Y.Q.; Sa, X.J.; Wu, K. Effect of extrusion temperatures on microstructure and mechanical properties of SiCp/Mg–Zn-Ca composite. J. Alloy Compd. 2012, 532, 78–85. [Google Scholar] [CrossRef]

- Han, G.; Wang, Z.; Liu, K.; Li, S.; Du, X.; Du, W. Synthesis of CNT reinforced AZ31 magnesium alloy composites with uniformly distributed CNTs. Mater. Sci. Eng. A 2015, 628, 350–357. [Google Scholar] [CrossRef]

- Khoshzaban Khosroshahi, K.; Fereshteh Saniee, F.; Abedi, H.R. Mechanical properties improvement of cast AZ80 Mg alloy/nano-particles composite via thermomechanical processing. Mater. Sci. Eng. A 2014, 595, 284–290. [Google Scholar] [CrossRef]

- Topolski, K.; Pachla, W.; Garbacz, H. Progress in hydrostatic extrusion of titanium. J. Mater. Sci. 2013, 48, 4543–4548. [Google Scholar] [CrossRef]

- Korbel, A.; Bochniak, W. Refinement and control of metal structure elements by plastic deformation. Scripta Mater. 2004, 51, 755–759. [Google Scholar] [CrossRef]

- Korbel, A.; Bochniak, W.; Borowski, J.; Błaż, L.; Ostachowski, P.; Łagoda, M. Anomalies in precipitation hardening process of 7075 aluminum alloy extruded by KOBO method. J. Mater. Process. Tech. 2015, 216, 160–168. [Google Scholar] [CrossRef]

- Mrugała, A.; Kuc, D. Forming construction elements for aviation from light alloys with the use of cold extrusion in complex state of strain. Solid State Phenom. 2016, 246, 240–243. [Google Scholar] [CrossRef]

- Bednarczyk, I.; Mrugała, A.; Tomaszewska, A. Influence of plastic deformation process on the structure and properties of alloy WE43. Arch. Metall. Mater. 2016, 61, 389–392. [Google Scholar] [CrossRef]

- Woźniak, J.; Kostecki, M.; Bochniak, W.; Olszyna, A. AlSiC composites produced by direct extrusion using the KOBO method, composites produced by direct extrusion using the KOBO method. Inżynieria Materiałowa (Mater. Eng.) 2010, 31, 453–456. [Google Scholar]

- Wieczorek, J.; Oleksiak, B.; Łabaj, J.; Węcki, B.; Mańka, M. Silver matrix composites—Structure and properties. Arch. Metall. Mater. 2016, 61, 323–328. [Google Scholar] [CrossRef]

- Olszówka-Myalska, A. Some Physicochemical Phenomena Observed During Fabrication of Mg–C Cast Composites. J. Mater. Eng. Perform. 2016, 25, 3091–3097. [Google Scholar] [CrossRef]

- Szczotok, A.; Szala, J.; Cwajna, J.; Hetmańczyk, M. Selection of etching methods of primary carbides in MAR-M247 nickel–base superalloy for computer-aided quantitative metallography. Mater. Charact. 2006, 56, 348–354. [Google Scholar] [CrossRef]

- Caliman, R. Friction and wearing behaviour of sintered composites made from copper mixed with carbon fibers. Key Eng. Mater. 2015, 660, 81–85. [Google Scholar] [CrossRef]

- Chen, L.W.X.; Tu, J.P.; Wang, L.Y.; Gan, H.Y.; Xu, Z.D.; Zhang, X.B. Tribological application of carbon nanotubes in metal-based composite coating and composites. Carbon 2003, 41, 215–222. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Murdymov, R.V.; Korsun, I.V.; Yakovlev, G.A.; Smirnov, S.V. Novel aluminum-graphene and aluminum-graphite metallic composite materials: Synthesis and properties. J. Alloy Compd. 2016, 663, 449–459. [Google Scholar] [CrossRef]

- Xiao, Y.; Shi, X.; Zhai, W.; Yao, J.; Xu, Z.; Chen, L.; Zhu, Q. Tribological Performance of NiAl Self-lubricating Matrix Composite with Addition of Graphene at Different Loads. J. Mater. Eng. Perform. 2015, 24, 2866–2874. [Google Scholar] [CrossRef]

| Technology | HV0.2 | R0.2, MPa | Rm, MPa | A, % | d2, µm |

|---|---|---|---|---|---|

| Gravity casting | 47 ± 2 | 50 ± 8 | 70 ± 11 | 1.4 ± 0.3 | 219 ± 76 |

| Hot extrusion | ┴56 ± 1, ║52 ± 2 | 160 ± 6 | 230 ± 9 | 10 ± 1.5 | 24 ± 10 |

| KoBo extrusion | ┴78 ± 4, ║71 ± 2 | 270 ± 12 | 301 ± 11 | 14 ± 2 | 0.89 ± 0.35 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olszówka-Myalska, A.; Kuc, D.; Myalski, J.; Chrapoński, J. Effect of Magnesium Matrix Grain Refinement Induced by Plastic Deformation in a Composite with Short Carbon Fibers. Metals 2019, 9, 724. https://doi.org/10.3390/met9070724

Olszówka-Myalska A, Kuc D, Myalski J, Chrapoński J. Effect of Magnesium Matrix Grain Refinement Induced by Plastic Deformation in a Composite with Short Carbon Fibers. Metals. 2019; 9(7):724. https://doi.org/10.3390/met9070724

Chicago/Turabian StyleOlszówka-Myalska, Anita, Dariusz Kuc, Jerzy Myalski, and Jacek Chrapoński. 2019. "Effect of Magnesium Matrix Grain Refinement Induced by Plastic Deformation in a Composite with Short Carbon Fibers" Metals 9, no. 7: 724. https://doi.org/10.3390/met9070724

APA StyleOlszówka-Myalska, A., Kuc, D., Myalski, J., & Chrapoński, J. (2019). Effect of Magnesium Matrix Grain Refinement Induced by Plastic Deformation in a Composite with Short Carbon Fibers. Metals, 9(7), 724. https://doi.org/10.3390/met9070724