3. Results

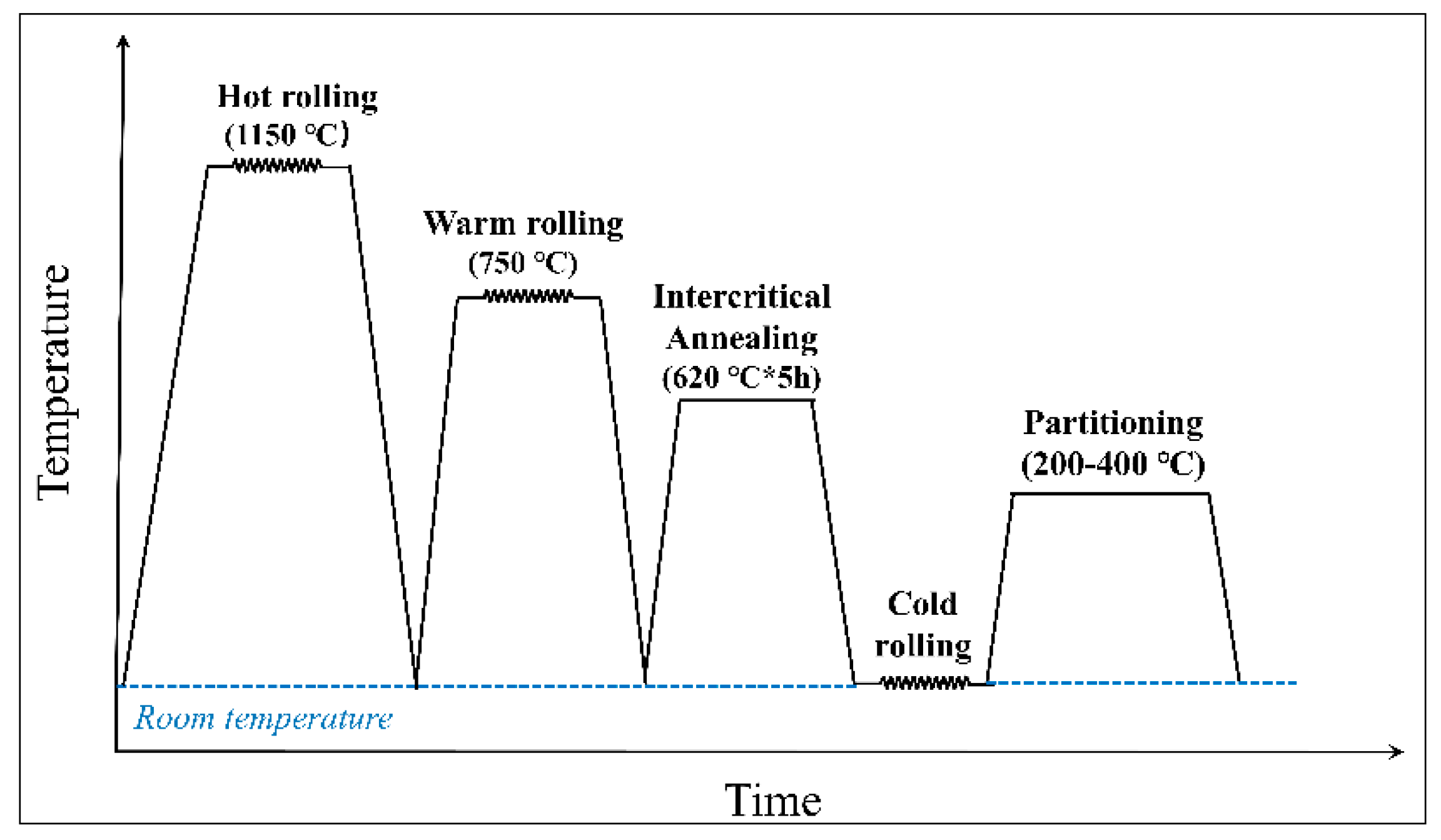

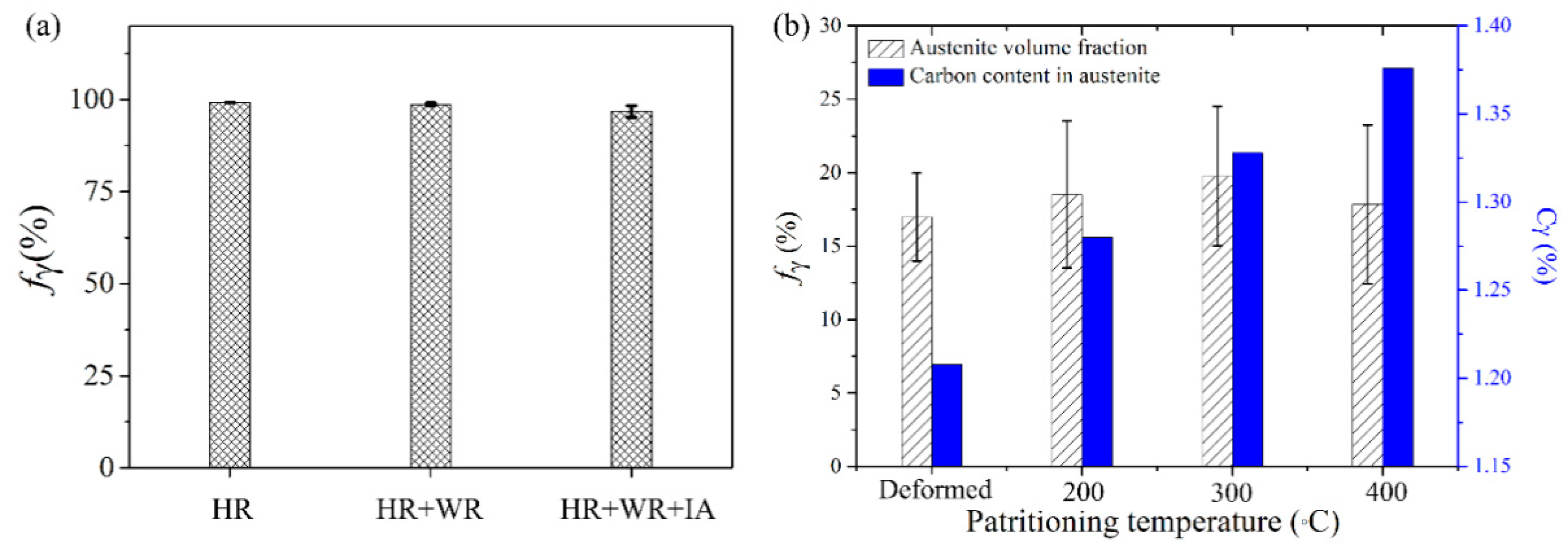

The evolution of phase fraction during thermal-mechanical processing of the D&P steel process is demonstrated in

Figure 2. The specimens had almost fully austenitic microstructure after HR and WR (

Figure 2a). The volume fraction of austenite was slightly decreased after intercritical annealing, indicating that ferrite transformation is negligible during IA. This can be explained by the strong hardenability caused by high Mn content (10%) (

Figure 2a). A large amount of austenite grains transformed to martensite during the subsequent cold rolling process. Around 18% of austenite was retained after cold rolling and it basically remained unchanged during subsequent partitioning process, confirming that almost no phase transformations took place during low-temperature partitioning process (

Figure 2b).

Although the partitioning process had a less-significant effect on the austenite fraction, it influenced the carbon content and, consequently, the stability of austenite. The carbon content of austenite, which can be estimated from the peak shift of XRD profiles [

15,

16], was increased by 0.072, 0.12, and 0.168% after partitioning at 200, 300, and 400 °C, respectively (

Figure 2b).

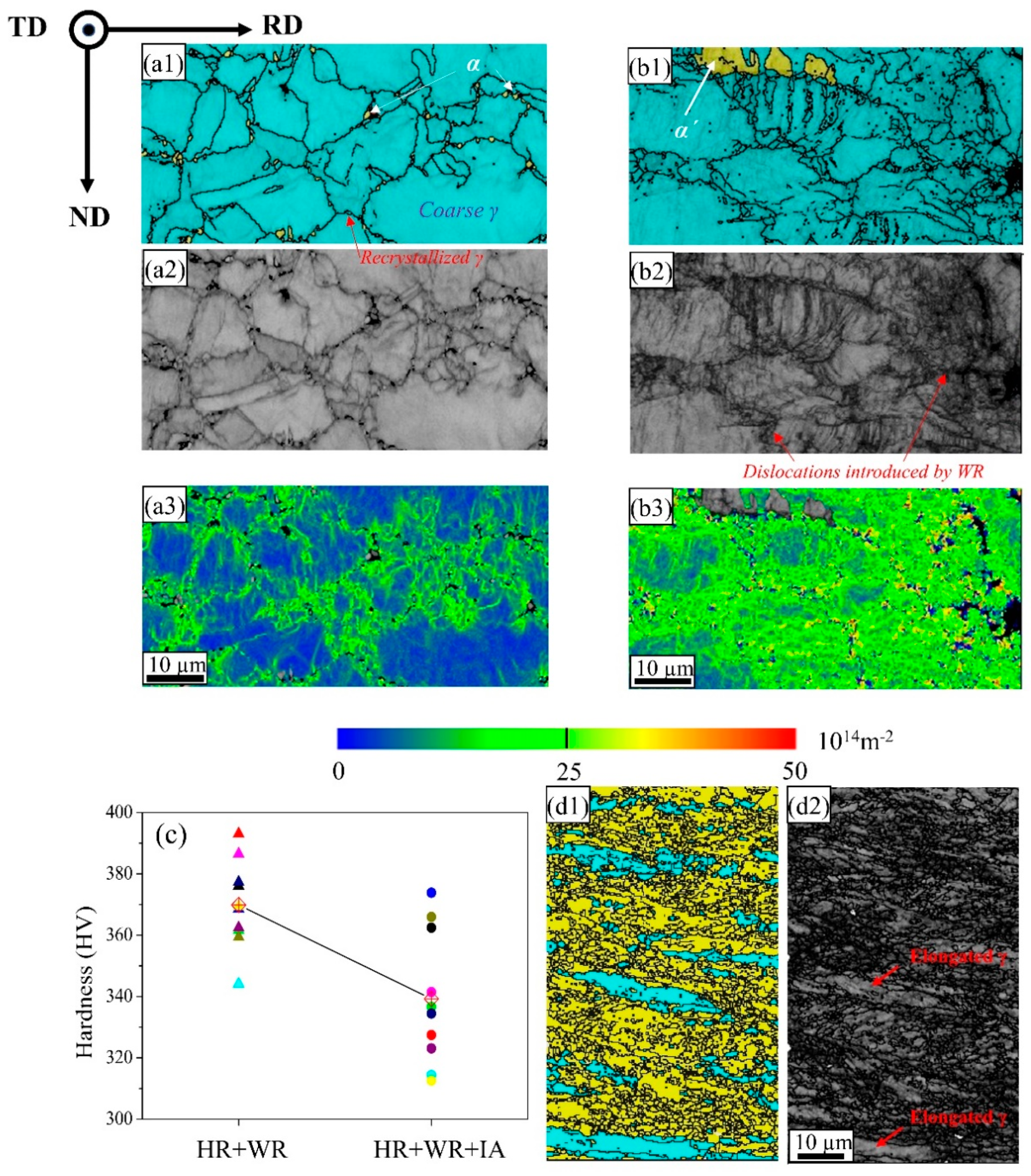

The typical microstructure of HR, HR + WR, and D&P specimens were characterized by EBSD, as shown in

Figure 3. The HR specimen had an austenitic microstructure with prior austenite grain boundaries (PAGBs) decorated with granular submicron ferrite grains (

Figure 3a1,a2). The fraction of austenite obtained from EBSD microstructure was quantitively consistent with the XRD results. The coarse austenite grains (5–30 µm) dominated the microstructure, while some recrystallized austenite grains (~0.5 µm) were found at PAGBs (

Figure 3a1,a2).

The dominated austenitic microstructure was maintained after warm rolling (

Figure 3b1). To distinguish the difference of dislocation density between HR and HR + WR samples, the geometrically necessary dislocation (GND) densities were further estimated based on the kernel average misorientation (KAM), which represents the average misorientation between the measured point and the nearest neighbor points in the EBSD measurement (

Figure 3b3). It was found that intensive dislocations were generated in austenite grains by warm rolling (

Figure 3b3). Moreover, prior austenite grains were substantially elongated along the rolling direction or even fragmented into subgrains, resulting in obvious grain refinement.

The HR + WR specimen was further softened by means of intercritical annealing to facilitate subsequent deformation at room temperature. The Vickers hardness of specimens, before and after intercritical annealing, are summarized in

Figure 3c. The hardness measurements were conducted in different regions through the thickness of the sample. This leads to the dispersion of hardness values due to the edge of the steel sheet which are stronger than the center resulting from warm rolling. The slight decrease of the hardness implies that some dislocations in the HR + WR specimen were annealed after IA.

Cold rolling greatly promoted the deformation-induced martensitic transformation, leading to a dual-phase lamella microstructure with austenite grains embedded in a highly dislocated martensite matrix in D&P steel (

Figure 3d1,d2). The prior austenite grain boundaries (PAGB) exist before the martensitic transformation and can be retained after the formation of martensite. The martensitic matrix possesses a heterogeneous microstructure, consisting of large lenticular grains and small martensite lath. Retained austenite grains also exhibit heterogeneous morphologies and bimodal distribution. The large austenite grains with a length of 30 µm or above were elongated along the rolling direction and constituted most of the austenite phase, while fine granular austenite grains can be observed at PAGB. Abundant dislocations were introduced to the martensitic matrix by cold rolling, as showed by the low image quality of martensite phase in

Figure 3d2. In contrast, it seems that the austenite grains, especially the coarse elongated ones, still contained relatively lower defects than the martensite phase (

Figure 3d2).

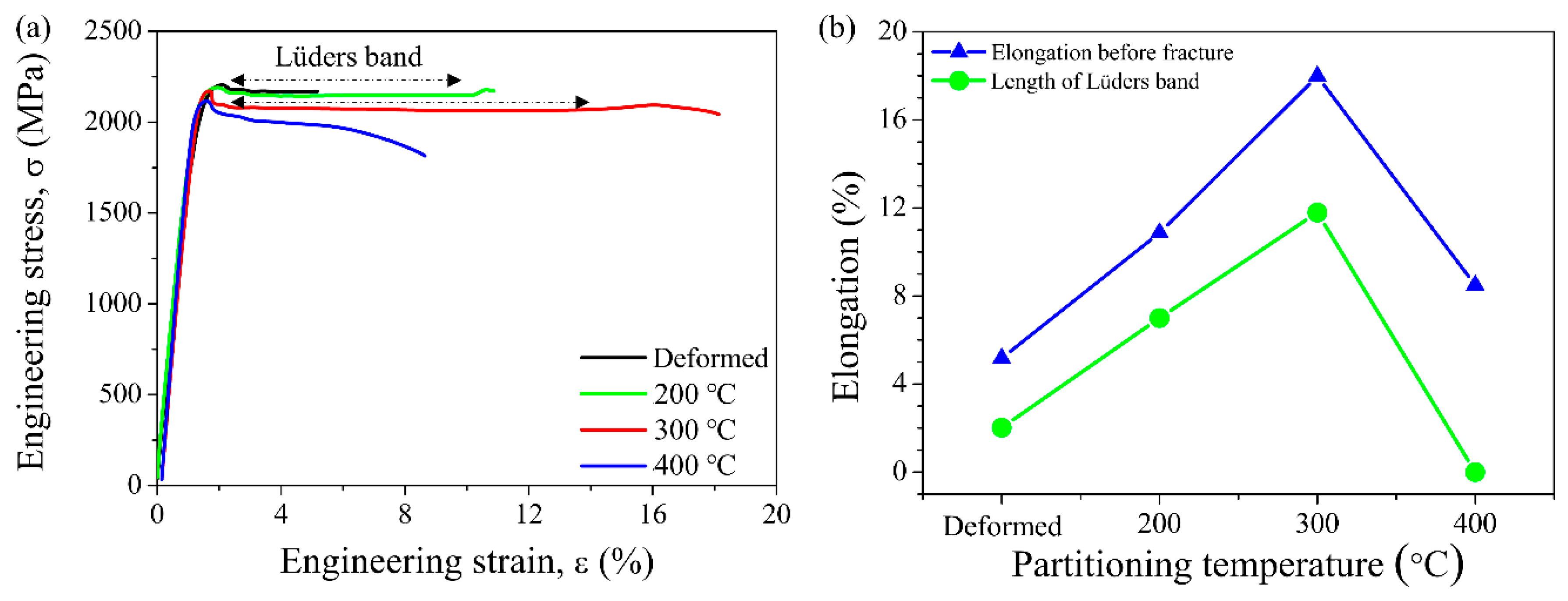

The mechanical properties of the D&P steel processed by varying partitioning temperatures are summarized in

Figure 4a. The Deformed specimen is brittle, although it possesses an ultrahigh yield strength of up to 2200 MPa. The ductility of the D&P steel was greatly enhanced after low-temperature partitioning (200 and 300 °C) without a noticeable decrease of the yield strength. However, very different deformation behaviors were obtained after partitioning at a relatively high temperature (400 °C). Necking was found to proceed upon yielding for the D&P400 specimen. A typical yield drop phenomenon, which is induced by the un-locking of dislocations from the interstitial C atoms [

17], was observed in all specimens. It was interesting to find that Lüders deformation is also tailored by the partitioning conditions (

Figure 4b). Lüders deformation dominated in D&P300 specimen and accounted for 65.5% of the total elongation. The highest ductility was obtained in D&P300 specimen, which possessed the largest Lüders strain, followed by work hardening at large plastic deformation regime (

Figure 4a).

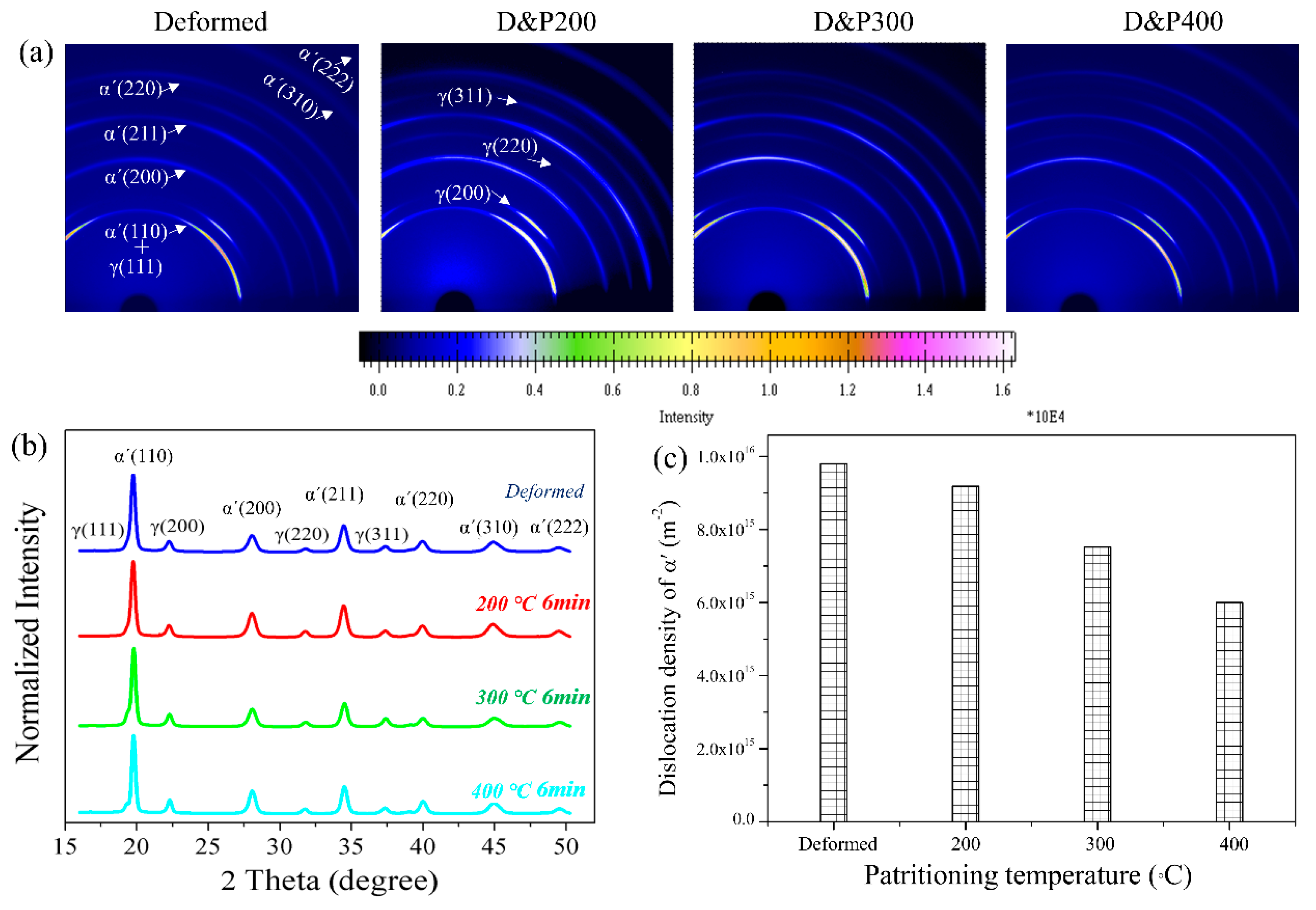

To understand the difference in the mechanical behaviors of various D&P specimens, 2D synchrotron X-ray diffraction measurements were carried out and the modified Williamson–Hall method was employed to study the evolution of dislocation density during the partitioning process. 2D synchrotron X-ray diffraction can provide better intensity and statistics for quantitative analysis and phase identification, especially for samples with texture, large grain size, and small quantity [

18]. The broadening of diffraction peaks depends on the dislocation density (

ρ), the average crystallite size (

d’), and the faulting probability (β) by the following equation [

14]:

where ∆

K = cosθ

B(∆2θ)/λ and

K = 2sinθ

B/λ, θ

B is the diffraction angle at certain Bragg position, ∆2θ is the full width at half-maximum (FWHM) of the diffraction peak at θ

B, and λ is the wavelength of the X-ray.

A is a constant which can be determined by the effective outer cut-off radius of dislocation,

b is the Burgers vector of dislocations and

Whkl is the scale factor representing the peak broadening induced by a fault at exact {hkl} deflection. Here, the faulting probability (β)-induced peak broadening was not considered because twin martensite was barely founded in the present material.

is the average dislocation contrast factor determined by the empirical equations. Six martensite diffraction rings and four austenite diffraction rings were obtained from 2D synchrotron X-ray (

Figure 5a). The 2D diffraction patterns are further converted to peak profiles to calculate ∆

K and

K (

Figure 5b). Five martensite peaks, including (110), (200), (211), (220), and (310) were selected to calculate dislocation density of martensitic matrix. Dislocation density (

ρ) and

d’ were subsequently determined by considering the best linear fitting between ∆

K and

.

As shown in

Figure 5c, the dislocation density of martensitic matrix was around 10

16 m

−2 after cold rolling, which is two-orders of magnitude larger than conventional thermally transformed martensite (6 × 10

13 m

−2) and cold-rolled martensite (5.39 × 10

14 m

−2) [

19,

20]. The ultrahigh dislocation density resulted from the deformation (hot rolling, warm rolling, and cold rolling) and displacive shear deformation. The dislocation density decreased with an increase of partitioning temperature and reduced to 6 × 10

15 m

−2 after partitioning at 400 °C for 6 min.

4. Discussion

A heterogeneous microstructure with bimodal grain distribution was firstly developed by hot rolling (

Figure 3a1). The subsequent warm rolling further enhanced the inhomogeneity and introduced intensive dislocations in austenite grains (

Figure 3b1–3b3). These dislocations were slightly recovered during the intercritical annealing, while the majority can be inherited by the martensite formed during cold rolling. Note that the intercritical annealing between warm rolling and cold rolling process plays a key role in relieving the residual internal stress. Sudden cracking may take place before reaching the targeted cold rolling reduction if the HR + WR sheet is not sufficiently annealed. The amount of ferrite transformed during warm rolling and intercritical annealing were very low (

Figure 2a). The sluggish transformation kinetics of ferrite was due to the high alloying contents, especially the high Mn (10%) contents, of the present steel [

21]. Cold rolling enables the occurrence of deformation-induced martensitic transformation. Consequently, substantial amount of dislocations was introduced during the cold rolling process owing to the displacive shear transformation and deformation of early transformed martensite grains (

Figure 3d2). In a word, although the majority of martensite was formed during cold rolling, the previous hot rolling, warm rolling, and intercritical annealing were of great importance in developing heterogeneous and dislocated microstructure in the final martensite matrix.

The partitioning process was applied to tailor the austenite stability, dislocation density, and consequently, mechanical behaviors of the D&P steel. The carbon content of austenite only increased slightly after partitioning (

Figure 2b), which could be because of the formation of abundant Cottrell atmosphere, leading to a retarded carbon diffusion from martensite to austenite. These results suggest that the stability of retained austenite is not the key factor controlling the mechanical behaviors of D&P steel.

The high yield strength of D&P steels is mainly contributed by the presence of high dislocation density (

Figure 4a). The contribution of the dislocation density to the yield strength can be estimated by the Taylor hardening law [

11]:

where

M represents the Taylor factor and is taken as 2.9, α = 0.23 is an empirical constant for martensite with dislocation cell structure, µ = 85 GPa is shear modulus, and

b = 0.25 nm is Burgers vector [

10,

11]. Therefore, the contribution of the dislocation density was estimated to be 1400, 1360, 1230, and 1100 MPa for Deformed, D&P200, D&P300, and D&P400 specimens, respectively. Therefore, the decreased yield strength of D&P400 should be around 300 MPa owing to the dislocation recovery. However, the upper yield stress of deformed sample was decreased slightly from 2204 to 2115 MPa after partitioning at 400 °C for 6 min. Therefore, other strengthening mechanisms may take place to compensate the reduction of strength caused by dislocation recovery. The reduction of dislocation density without obviously sacrificing the strength may be ascribed to the bake hardening. The carbon atoms tend to diffuse into adjacent dislocations in martensitic matrix to minimize the strain energy during the partitioning process, resulting in the formation of “Cottrell atmosphere” [

17]. Dislocations surrounded by atmosphere were immobilized, leading to an increase of the upper yield stress. The increase of yield stress realized by the combination of pre-strain and strain-aging is known as bake hardening [

22]. Therefore, bake hardening to some extent compensates the loss of dislocation hardening, beneficial to the high yield strength of the D&P steel. However, dislocations can break away the Contrell atmosphere and become mobile when a sufficiently large stress is applied. This causes the occurrence of yield drop as observed in some D&P specimens (

Figure 4a) [

17].

The propagation of Lüders band after a yield drop depends on the work hardening ability of the specimen [

23,

24]. The tangled dislocation structure makes the slip of dislocation very difficult to proceed. Hence, the deformed specimen has low work hardening rate and very limited ductility (

Figure 4). After low-temperature partitioning (200 °C), D&P steel was recovered but not yet sufficiently. The D&P200 sample had improved ductility but still fractured during Lüders deformation (

Figure 4). Further increasing the partitioning temperature greatly improved the ductility of samples. The D&P300 specimen showed a completed propagation of Lüders band, followed by work hardening which could be provided by the TRIP effect [

10]. Although some reports on austenitic steels suggest that the TRIP effect is the reason for the propagation of Lüders band [

25], it was found that the Lüders band is still present in medium Mn steels during relatively high temperature tensile deformation where the TRIP effect is completely suppressed [

26]. Therefore, the TRIP-induced Lüders band mechanism is not favorable in explaining the deformation behaviors of the D&P steels with both of high dislocation density and high carbon content. The discontinuous yielding in D&P400 sample results in localized necking which is not able to propagate owing to the low work hardening ability, leading to the disappearance of Lüders deformation. This can be explained in two aspects. The annihilation of dislocation was promoted at high temperature, which greatly reduces the mobile dislocation density in the specimen. Moreover, the diffusion of interstitial carbon atoms to dislocations was energetically favored at high temperature. Namely, dislocations were more likely to be locked by carbon atoms, leading to a further reduction of the mobile dislocations. Consequently, necking proceeded quickly after the yield drop in D&P400 specimen (

Figure 4).