Review on Advances in Metal Micro-Tube Forming

Abstract

1. Introduction

2. Micro-Tube Fabrication

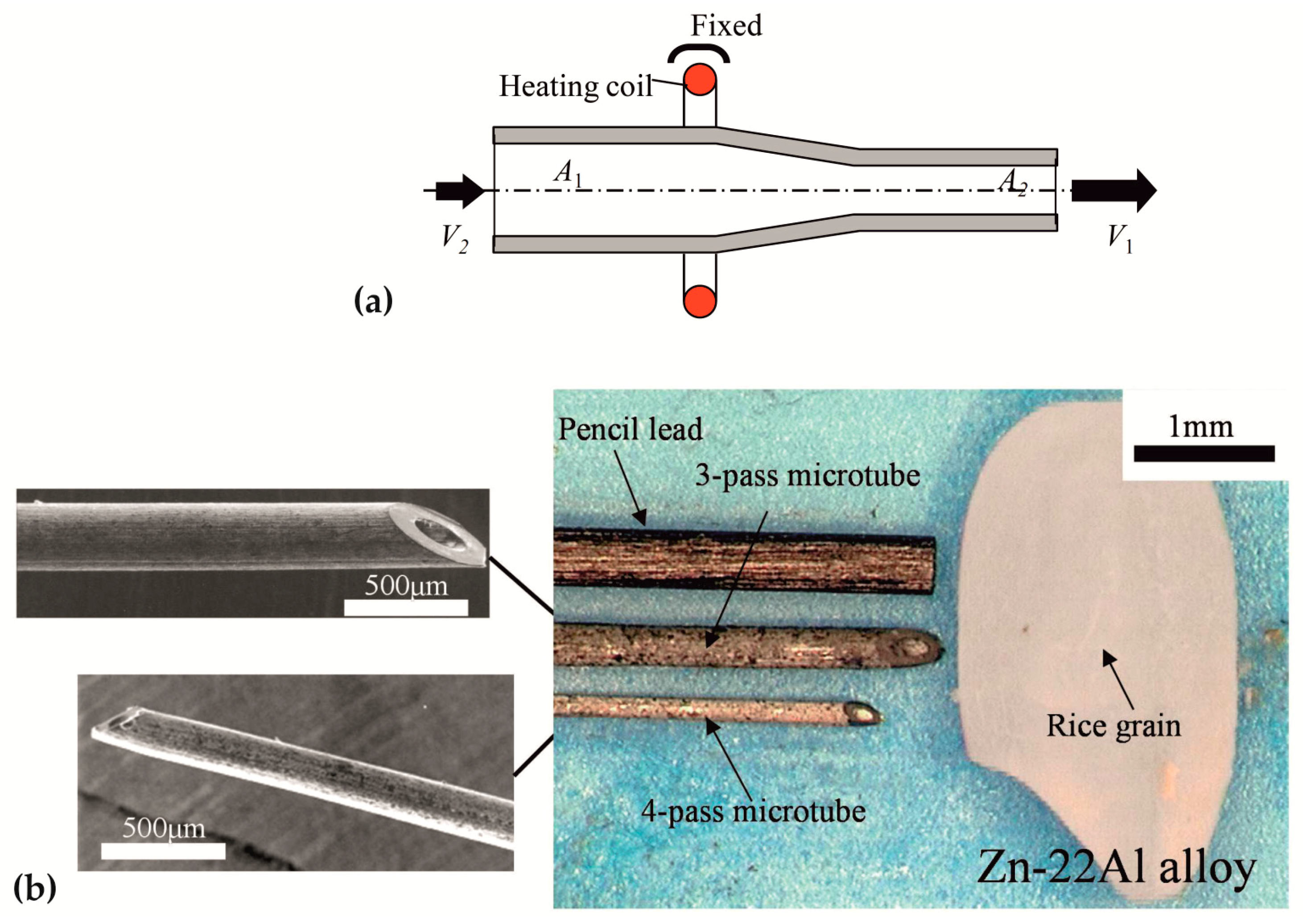

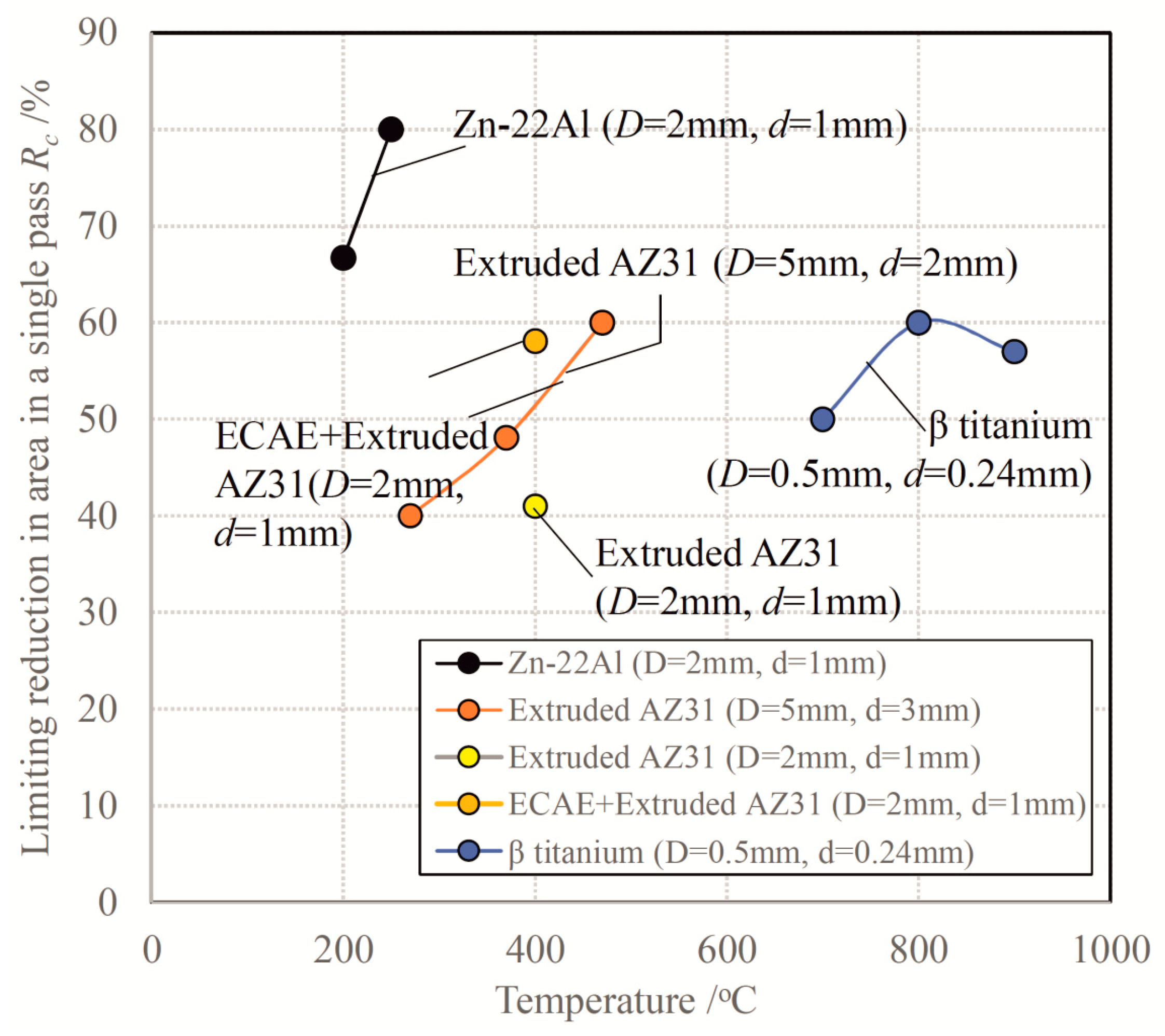

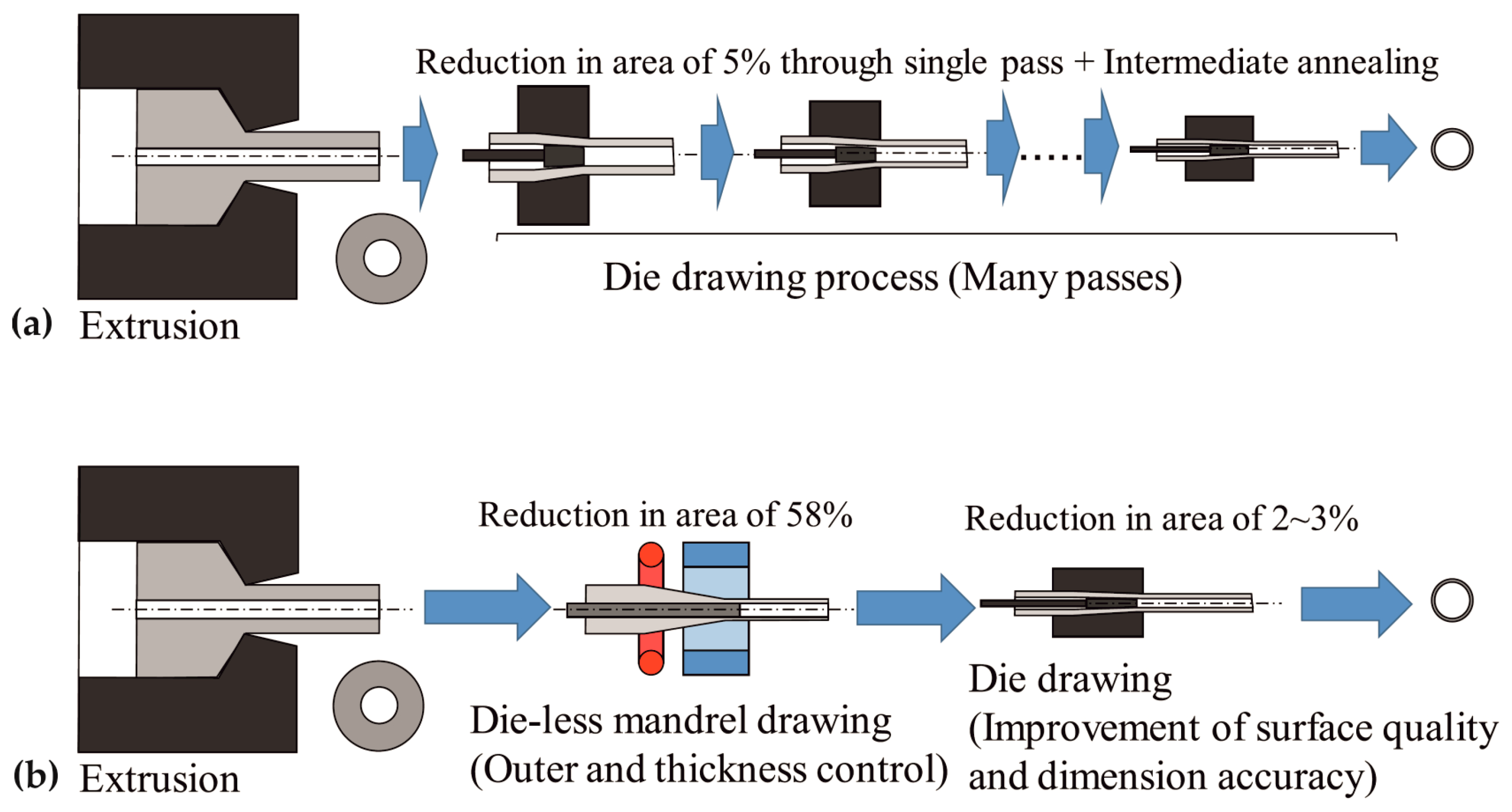

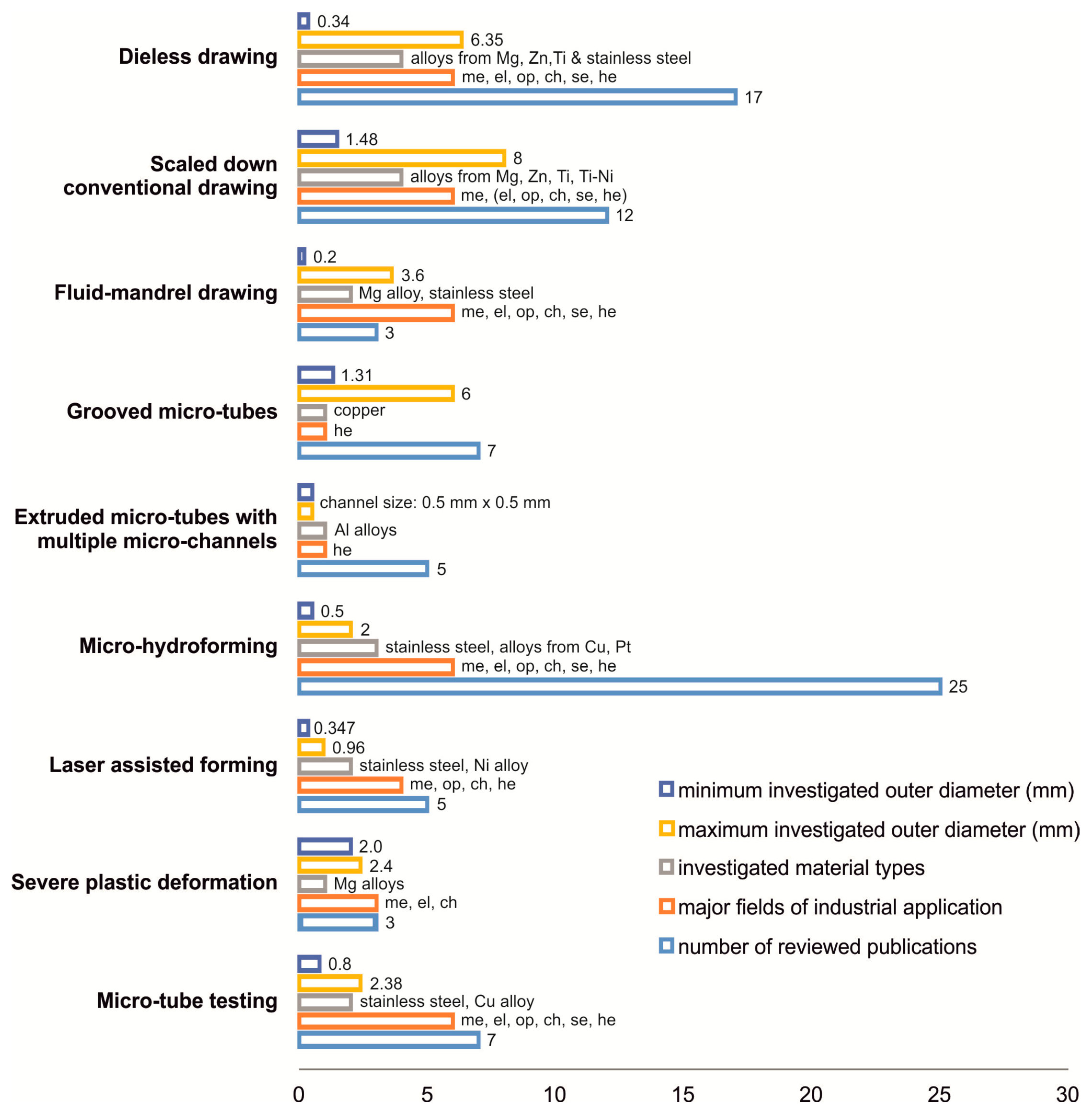

2.1. Dieless Drawing

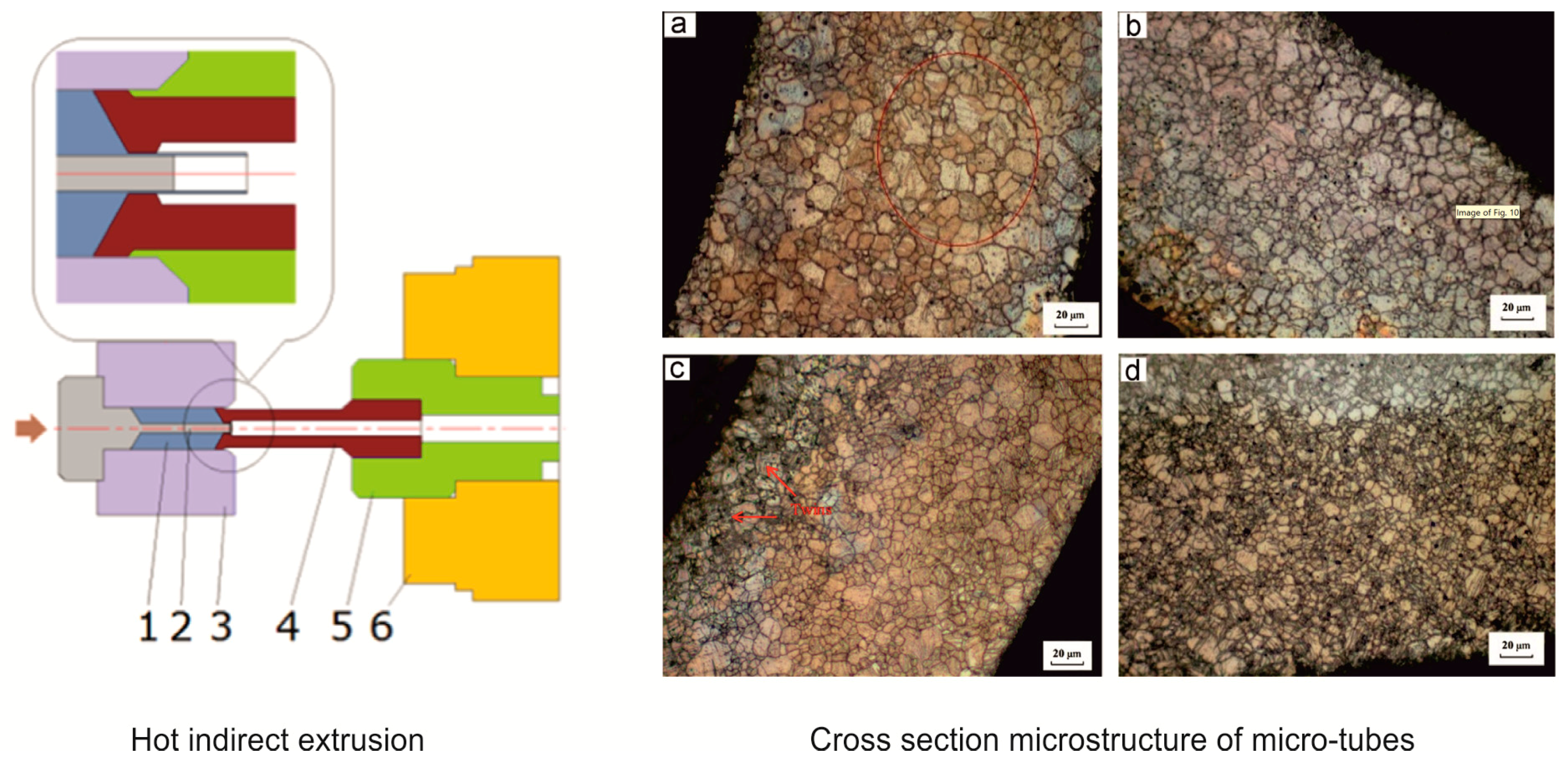

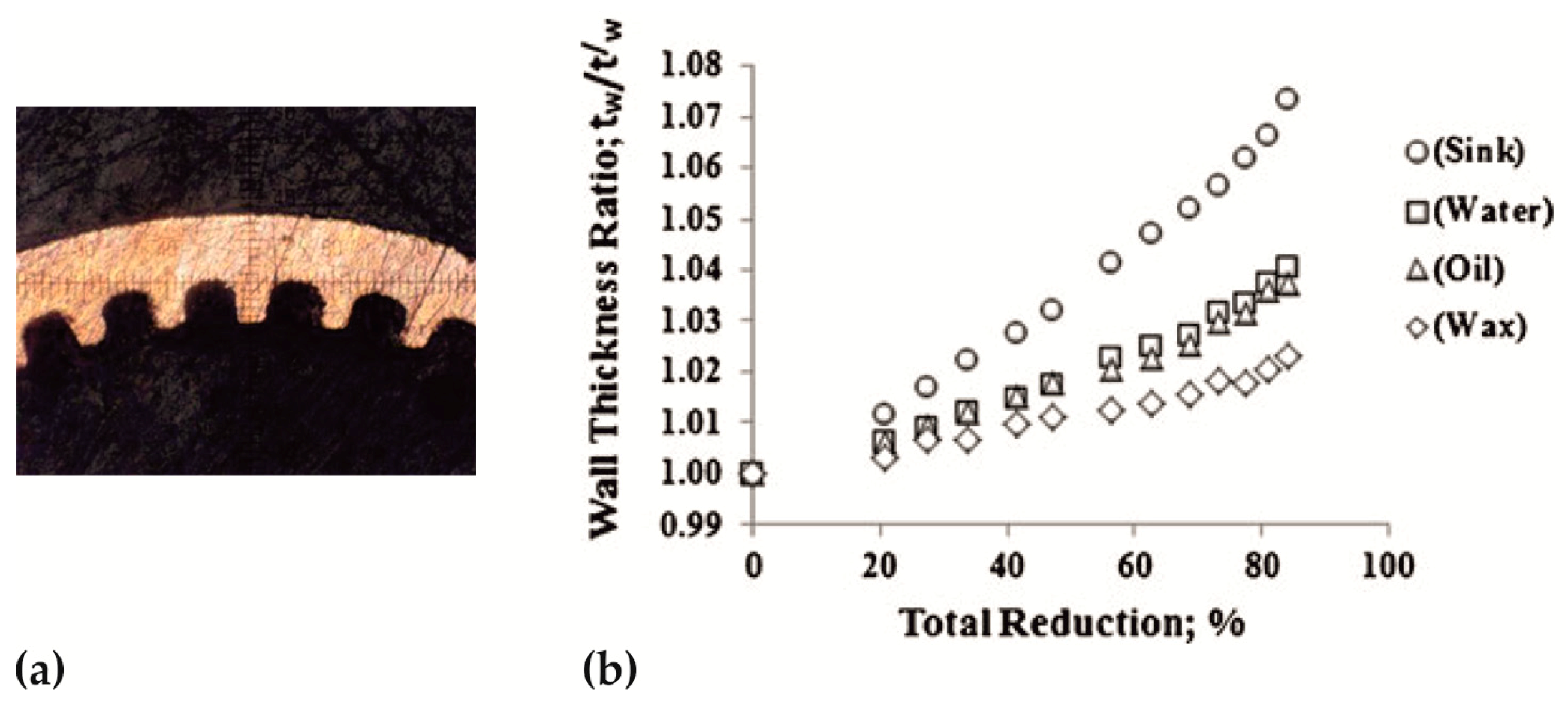

2.2. Scaled-down Tube Drawing and Variants

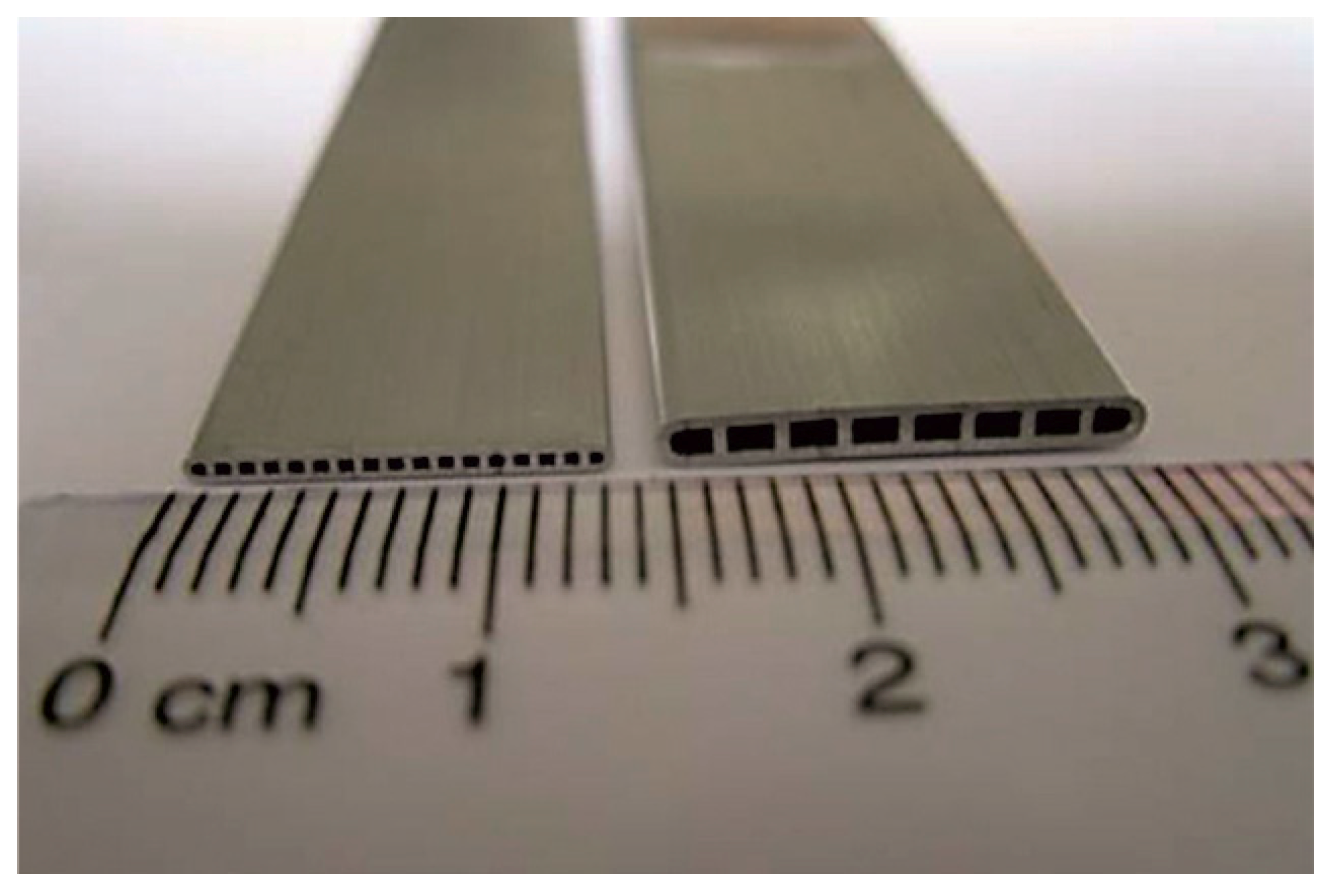

2.3. Grooved Tubes and Non-Circular Tubular Products with Micro-Channels

2.4. Discussion

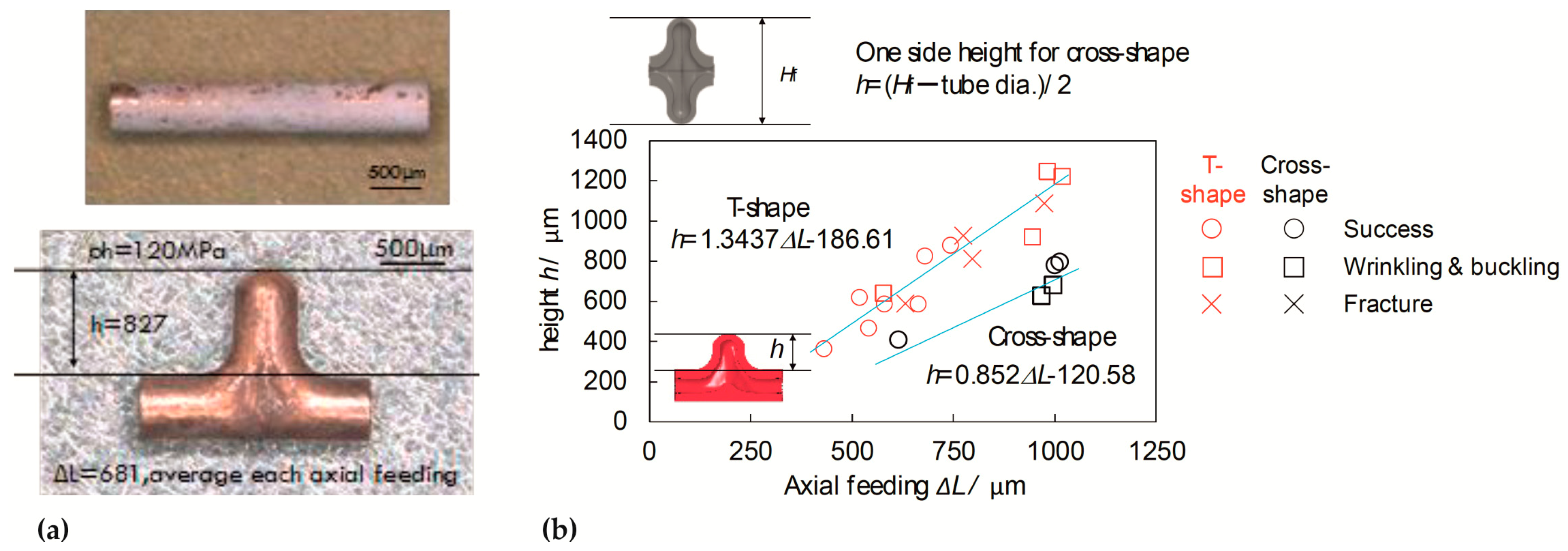

3. Micro-Tube Hydroforming

3.1. Process Development

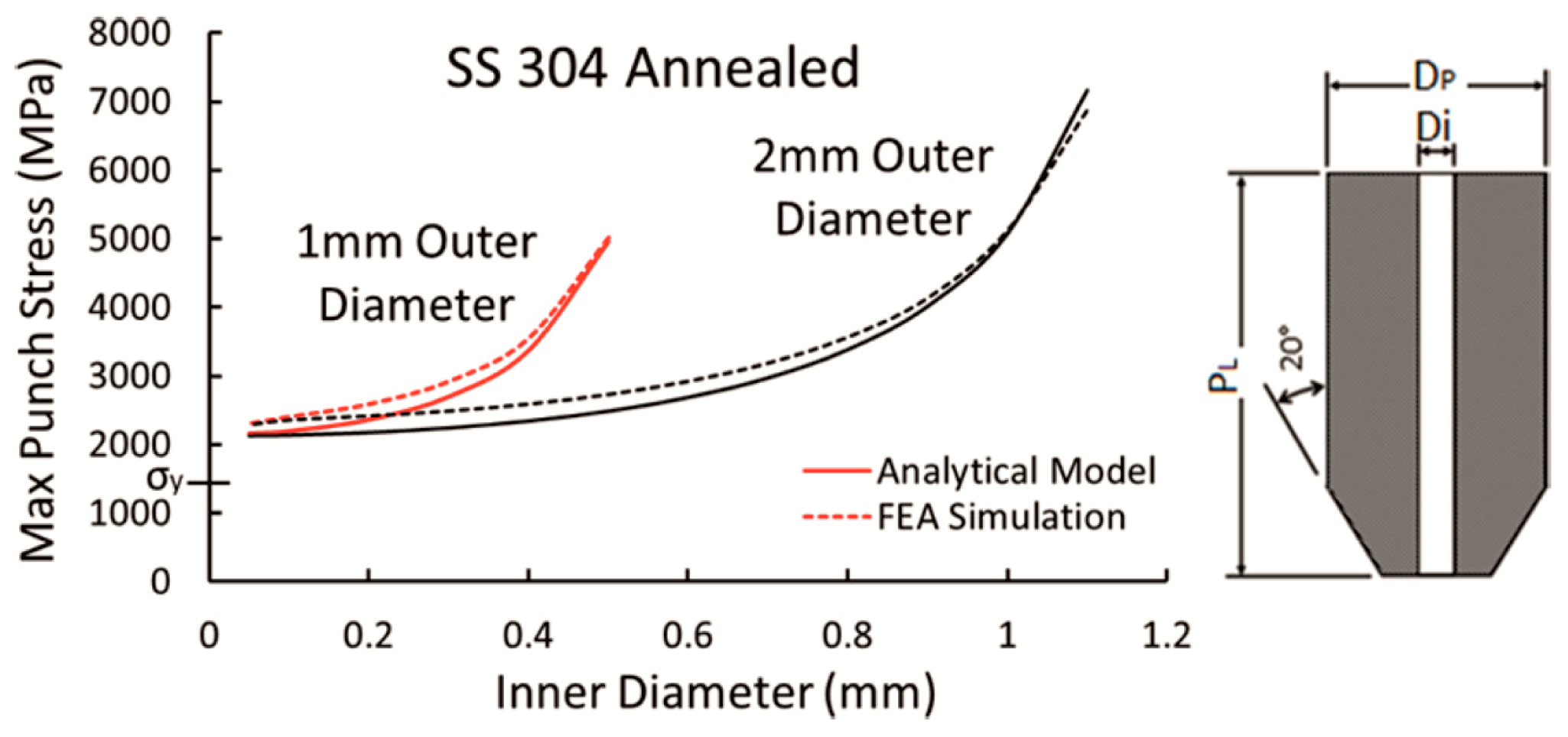

3.2. Tool and Machine Design

3.3. Discussion

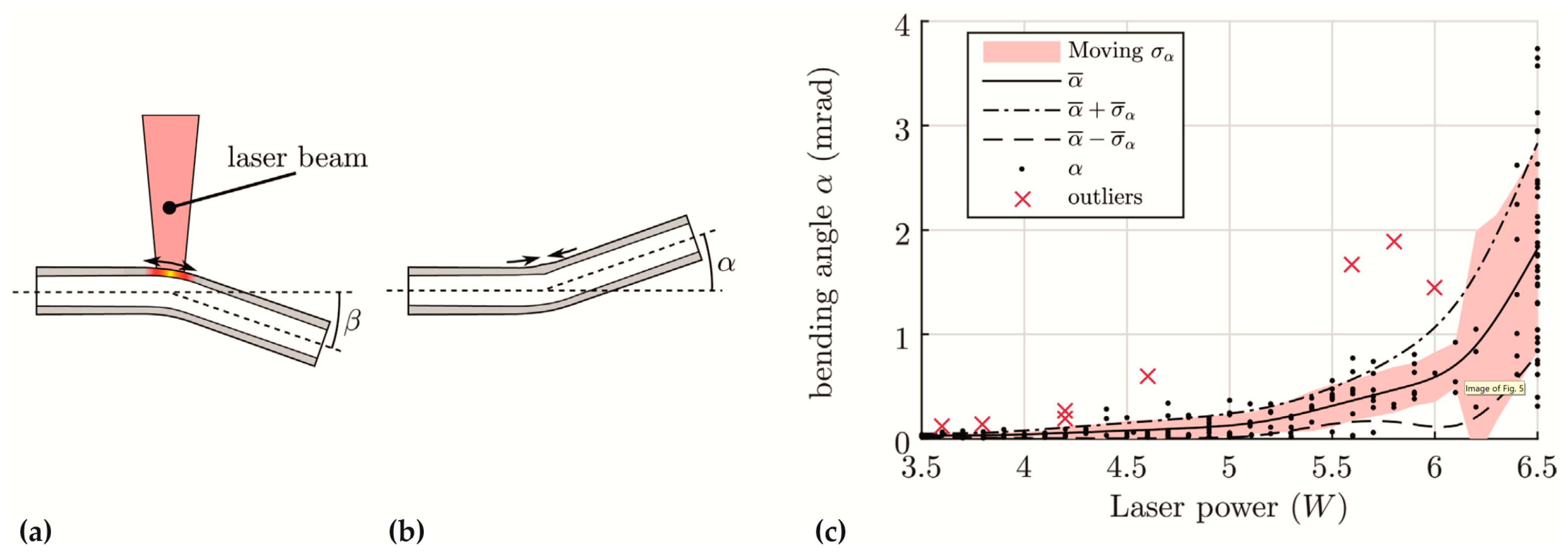

4. Laser-Assisted Forming of Micro-Tubular Components

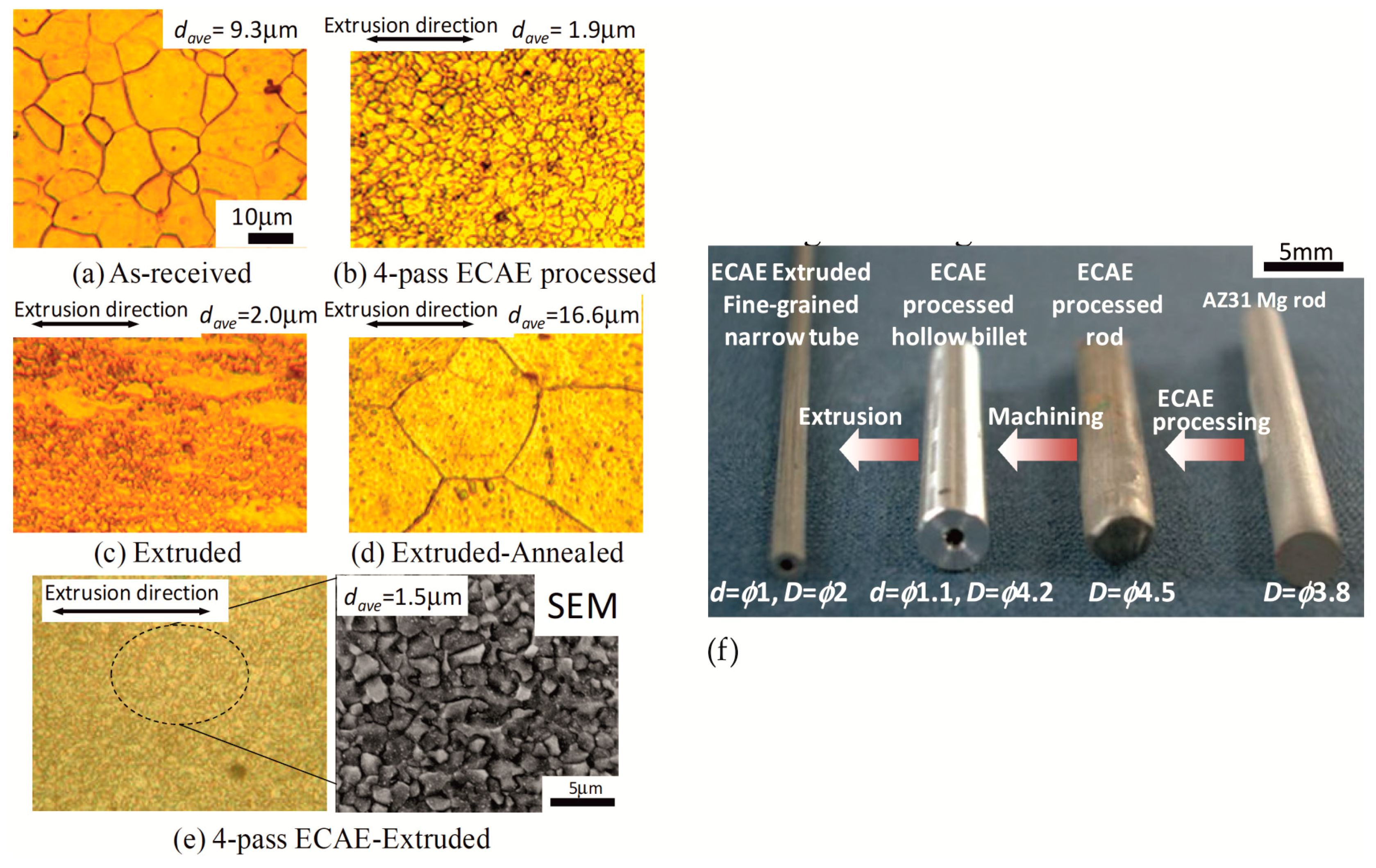

5. Severe Plastic Deformation with a Focus on Micro-Tube Fabrication

6. Testing Micro-Tubes Characteristics

6.1. Flaring Test

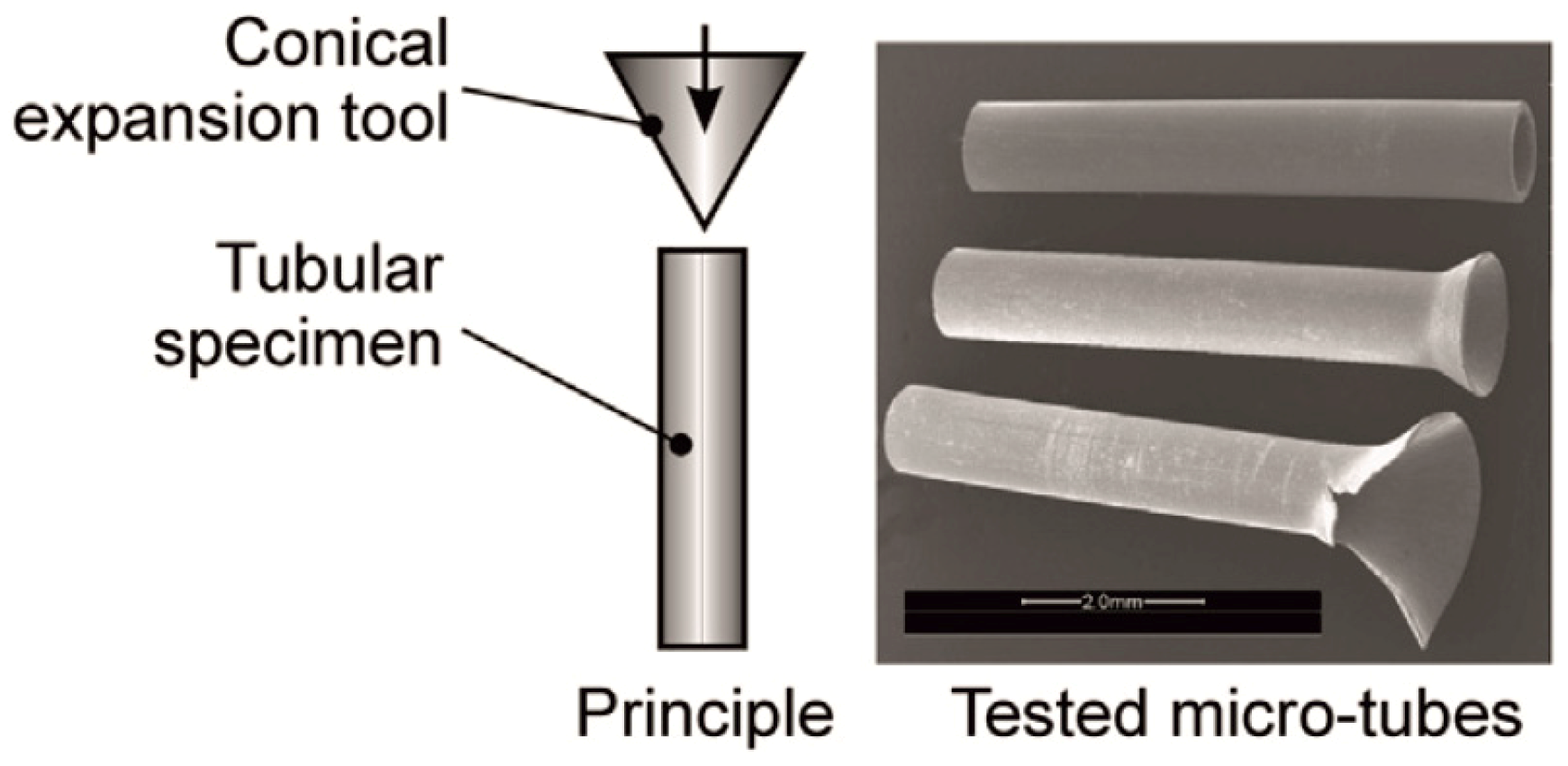

6.2. Expansion Test

6.3. Discussion

7. Summary

Conflicts of Interest

References

- Qin, Y.; Brockett, A.; Ma, Y.; Razali, A.; Zhao, J.; Harrison, C.; Pan, W.; Dai, X.; Loziak, D. Micro-manufacturing: Research, technology outcomes and development issues. Int. J. Adv. Manuf. Technol. 2010, 47, 821–837. [Google Scholar] [CrossRef]

- Fassi, I.; Shipley, D. Micro-Manufacturing and Their Applications, 1st ed.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Fu, M.W.; Chan, W.L. A review on the state-of-the-art microforming technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 2411–2437. [Google Scholar] [CrossRef]

- Engel, U.; Eckstein, R. Microforming-from basic research to its realization. J. Mater. Process. Technol. 2002, 125, 35–44. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. Superplastic micro-tubes fabricated by dieless drawing processes. In Superplastic Forming of Advanced Metallic Materials, 1st ed.; Giuliano, G., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 327–360. [Google Scholar] [CrossRef]

- Qin, Y. Micromanufacturing Engineering and Technology, 2nd ed.; Elsevier: Oxford, UK, 2015. [Google Scholar] [CrossRef]

- EvaluateMedTech—World Preview 2018, Outlook to 2024; Evaluate: London, UK, 2018; Available online: https://de.statista.com/statistik/daten/studie/313462/umfrage/umsatzentwicklung-der-weltweiten-medizintechnikindustrie/ (accessed on 1 May 2019).

- Koc, M.; Özel, T. Micro-Manufacturing: Design and Manufacturing of Micro-Products, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Jain, V.K.; Sidpara, A.; Balasubramaniam, R.; Lodha, G.S.; Dhamgaye, V.P.; Shukla, R. Micromanufacturing: A review—Part I. J. Eng. Manuf. 2014, 228, 973–994. [Google Scholar] [CrossRef]

- Jain, V.K.; Dixit, U.S.; Paul, C.P.; Kumar, A. Micromanufacturing: A review—Part II. J. Eng. Manuf. 2014, 228, 995–1014. [Google Scholar] [CrossRef]

- Razali, A.K.; Qin, Y. A review on micro-manufacturing, micro-forming and their key issues. Procedia Eng. 2013, 53, 665–672. [Google Scholar] [CrossRef]

- Vollertsen, F.; Schulze Niehoff, H.; Hu, Z. State of the art in micro forming. Int. J. Mach. Tools Manuf. 2006, 46, 1172–1179. [Google Scholar] [CrossRef]

- Lai, X.M.; Fu, M.W.; Peng, L.F. Sheet Metal Meso- and Microforming and Their Industrial Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- Fu, M.W.; Zheng, J.Y.; Meng, B. A Review of Progressive and Compound Forming of Bulk Microparts by Using Sheet Metals. MATEC Web Conf. 2018, 190, 1–10. [Google Scholar] [CrossRef]

- Vollertsen, F.; Biermann, D.; Hansen, H.N.; Jawahir, I.S.; Kuzman, K. Size effects in manufacturing of metallic components. CIRP Ann. Manuf. Technol. 2009, 58, 566–587. [Google Scholar] [CrossRef]

- Fu, M.W.; Wang, J.L.; Korsunsky, A.M. A review of geometrical and microstructural size effects in micro-scale deformation processing of metallic alloy components. Int. J. Mach. Tools Manuf. 2016, 109, 94–125. [Google Scholar] [CrossRef]

- Wang, C.; Guo, B.; Shan, D. Friction related size-effect in microforming—A review. Manuf. Rev. 2014, 1, 1–18. [Google Scholar] [CrossRef]

- Chatzipirpiridis, G.; Ergeneman, O.; Pokki, J.; Ullrich, F.; Fusco, S.; Ortega, J.A.; Sivaraman, K.M.; Nelson, B.J.; Pané, S. Electroforming of Implantable Tubular Magnetic Microrobots for Wireless Ophthalmologic Applications. Adv. Healthc. Mater. 2015, 4, 209–214. [Google Scholar] [CrossRef] [PubMed]

- Chatzipirpiridis, G.; Avilla, E.; Ergeneman, O.; Ullrich, F.; Nelson, B.J.; Pané, S. Electroforming of Magnetic Microtubes for Microrobotic Applications. IEEE Trans. Magn. 2014, 50, 1–3. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Morishima, A.; Takamata, A.; Uetsuji, Y.; Nakamachi, E. Development of valve-less tube type micropump with PZT actuator. In Proceedings of the SPIE Conference Smart Materials Nano- and Micro Smart Systems, Melbourne, Australia, 9–12 December 2008. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. Large reduction die-less mandrel drawing of magnesium alloy micro-tubes. CIRP Ann. Manuf. Technol. 2018, 67, 309–312. [Google Scholar] [CrossRef]

- Milenina, A.; Kustra, P.; Byrska-Wójcik, D.; Furushima, T. Physical and numerical modelling of laser dieless drawing process of tubes from magnesium alloy. Procedia Eng. 2017, 207, 2352–2357. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. Heat assisted dieless drawing process of superplastic metal microtubes – from Zn22Al to β titanium alloys. Mater. Sci. Forum 2016, 838–839, 459–467. [Google Scholar] [CrossRef]

- Furushima, T.; Imagawa, Y.; Manabe, K.; Sakai, T. Effects of oxidation and surface roughening on drawing limit indieless drawing process of SUS304 stainless steel microtubes. J. Mater. Process. Technol. 2015, 223, 186–192. [Google Scholar] [CrossRef]

- Furushima, T.; Imagawa, Y.; Furusawa, S.; Manabe, K. Development of Rotary Laser Dieless Drawing Apparatus for Metal Microtubes. Key Eng. Mater. 2015, 626, 372–376. [Google Scholar] [CrossRef]

- Hwang, Y.-M.; Li, Z.-S.; Lin, T.-Y. Formability Discussion in Dieless Drawing of Stainless Steel Tubes. Key Eng. Mater. 2015, 626, 10–15. [Google Scholar] [CrossRef]

- Furushima, T.; Imagawa, Y.; Furusawa, S.; Manabe, K. Deformation profile in rotary laser dieless drawing process for metal microtubes. Procedia Eng. 2014, 81, 700–705. [Google Scholar] [CrossRef][Green Version]

- Furushima, T.; Shirasaki, A.; Manabe, K. Fabrication of noncircular multicore microtubes by superplastic dieless drawing process. J. Mater. Process. Technol. 2014, 214, 29–35. [Google Scholar] [CrossRef]

- Furushima, T.; Noda, Y.; Manabe, K. Laser Dieless Drawing Process for Metal Micro-tubes. Key Eng. Mater. 2010, 443, 699–704. [Google Scholar] [CrossRef]

- Furushima, T.; Noda, Y.; Manabe, K. Laser Dieless Drawing Process for Metal Microtubes. In Proceedings of the International Conference on Materials Processing Technology 2010, Bangkok, Thailand, 5–6 January 2010; pp. 64–67. [Google Scholar]

- Furushima, T.; Shimizu, T.; Manabe, K. Grain Refinement by Combined ECAE/Extrusion and Dieless Drawing Processes for AZ31 Magnesium Alloy Tubes. Mater. Sci. Forum 2010, 654–656, 735–738. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K.; Sakai, T. Fabrication of Superplastic Microtubes Using Dieless Drawing Process. Mater. Trans. 2008, 49, 1365–1371. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. FE analysis of size effect on deformation and heat transfer behavior in microtube dieless drawing. J. Mater. Process. Technol. 2008, 201, 123–127. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. Experimental and numerical study on deformation behavior in dieless drawing process of superplastic microtubes. J. Mater. Process. Technol. 2007, 191, 59–63. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. Experimental study on multi-pass dieless drawing process of superplastic Zn-22%Al alloy microtubes. J. Mater. Process. Technol. 2007, 187–188, 236–240. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Y.; Yang, Z.; Zhu, S.; Wang, L.; Guan, S. Processing and properties of magnesium alloy micro-tubes for biodegradable vascular stents. Mater. Sci. Eng. C 2018, 90, 504–513. [Google Scholar] [CrossRef]

- Kim, Y.N.; Hwang, S.K.; Joo, H.S.; Im, Y.T. Effect of heat treatment and mandrel material on precision tube drawing of Ni-Ti shape memory alloy. Procedia Eng. 2017, 207, 1517–1522. [Google Scholar] [CrossRef]

- Wang, C.; Yu, Z.; Cui, Y.; Zhang, Y.; Yu, S.; Qu, G.; Gong, H. Processing of a Novel Zn Alloy Micro-Tube for Biodegradable Vascular Stent Application. J. Mater. Sci. Technol. 2016, 32, 925–929. [Google Scholar] [CrossRef]

- Liu, F.; Chen, C.; Niu, J.; Pei, J.; Zhang, H.; Huang, H.; Yuan, G. The processing of Mg alloy micro-tubes for biodegradable vascular stents. Mater. Sci. Eng. C 2015, 48, 400–407. [Google Scholar] [CrossRef]

- Wang, L.; Fang, G.; Qian, L.; Leeflang, S.; Duszczyk, J.; Zhou, J. Forming of magnesium alloy microtubes in the fabrication of biodegradable stents. Prog. Nat. Sci. Mater. Int. 2014, 24, 500–506. [Google Scholar] [CrossRef]

- Zhang, Y.; Kent, D.; Wang, G.; StJohn, D.; Dargusch, M.S. The cold-rolling behaviour of AZ31 tubes for fabrication of biodegradable stents. J. Mech. Behav. Biomed. Mater. 2014, 39, 292–303. [Google Scholar] [CrossRef]

- Hong, S.-K.; Kang, J.J.; Kim, J.-D.; Kim, H.-K.; Lee, S.-Y.; Park, C.H. Finite Element Analysis for the Tube Sinking Process of the Micro Ti-0.2Pd Tube. Appl. Mech. Mater. 2014, 465–466, 693–698. [Google Scholar] [CrossRef]

- Yoshida, K.; Yokomizo, D.T.; Komatsu, T. Production of special tubes with a variety cross-sectional shapes by bunch drawing and fluid-mandrel drawing. Key Eng. Mater. 2014, 622–623, 731–738. [Google Scholar] [CrossRef]

- Fang, G.; Ai, W.; Leeflang, S.; Duszczyk, J.; Zhou, J. Multipass cold drawing of magnesium alloy minitubes for biodegradable vascular stents. Mater. Sci. Eng. C 2013, 33, 3481–3488. [Google Scholar] [CrossRef]

- Yoshida, K.; Koiwa, K. Cold Drawing of Magnesium Alloy Tubes for Medical. J. Solid Mech. Mater. Eng. 2011, 5, 1071–1078. [Google Scholar] [CrossRef]

- Yoshida, K.; Furuya, H. Mandrel drawing and plug drawing of shape-memory-alloy fine tubes used in catheters and stents. J. Mater. Process. Technol. 2004, 153–154, 145–150. [Google Scholar] [CrossRef]

- Yoshida, K.; Watanabe, M.; Ishikawa, H. Drawing of Ni-Ti shape-memory-alloy fine tubes used in medical tests. J. Mater. Proces. Technol. 2001, 118, 251–255. [Google Scholar] [CrossRef]

- Tangsri, T.; Norasethasopon, S. 3D FEM validation of ultra-small inner spiral ribbed copper tube using the tube sinking method. Int. J. Adv. Manuf. Technol. 2015, 81, 1949–1959. [Google Scholar] [CrossRef]

- Tangsri, T.; Norasethasopon, S.; Yoshida, K. Fabrication of small size inner spiral ribbed copper tube by fluid mandrel drawing. Int. J. Adv. Manuf. Technol. 2014, 70, 1923–1930. [Google Scholar] [CrossRef]

- Ou, D.S.; Tang, Y.; Wan, Z.P.; Lu, L.S.; Lian, B. Effect of drawing parameters on elongation of micro copper tube with straight grooves. Key Eng. Mater. 2012, 499, 62–67. [Google Scholar] [CrossRef]

- Tang, Y.; OU, D.S.; Wan, Z.P.; Lu, L.; Lian, B. Influence of drawing process parameters on forming of micro copper tube with straight grooves. Trans. Nonferrous Met. Soc. China 2011, 21, 2264–2269. [Google Scholar] [CrossRef]

- Wan, Z.P.; Li, Y.C. Forming Process and Mechanism of Microcapillary Grooves of Miniature Cylindrical Heat Pipe. Adv. Mater. Res. 2011, 328–330, 22–26. [Google Scholar] [CrossRef]

- Tang, Y.; Long-sheng Lu, L.; Yuan, D.; Wang, Q.; Zhaoa, X. Experimental and FEM study on sinking of miniature inner grooved copper tube. J. Mater. Process. Technol. 2009, 209, 5333–5340. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, H.; Bin, L.; Tang, Y.; Zeng, Z. Forming method of axial micro grooves inside copper heat pipe. Trans. Nonferrous Met. Soc. China 2008, 18, 1229–1233. [Google Scholar] [CrossRef]

- Tang, D.; Fang, W.; Fan, X.; Zou, T.; Li, Z.; Wang, H.; Li, D.; Peng, Y.; Wu, P. Evolution of the Material Microstructures and Mechanical Properties of AA1100 Aluminum Alloy within a Complex Porthole Die during Extrusion. Materials 2019, 12, 16. [Google Scholar] [CrossRef]

- Tang, D.; Fan, X.; Fang, W.; Li, D.; Peng, Y.; Wang, H. Microstructure and mechanical properties development of micro channel tubes in extrusion, rolling and brazing. Mater. Charact. 2018, 142, 449–457. [Google Scholar] [CrossRef]

- Tang, D.; Fang, W.; Fan, X.; Li, D.; Peng, Y. Effect of die design in microchannel tube extrusion. Procedia Eng. 2014, 81, 628–633. [Google Scholar] [CrossRef]

- Tang, D.; Zhang, Q.; Li, D.; Peng, Y. A physical simulation of longitudinal seam welding in micro channel tube extrusion. J. Mater. Process. Technol. 2014, 214, 2777–2783. [Google Scholar] [CrossRef]

- Cho, H.; Hwang, D.-Y.; Lee, B.-S.; Jo, H.-H. Fabrication of micro condenser tube through direct extrusion. J. Mater. Process. Technol. 2007, 187–188, 645–648. [Google Scholar] [CrossRef]

- Furushima, T.; Ikeda, T.; Manabe, K. Deformation and Heat Transfer Analysis for High Speed Dieless Drawing of AZ31 Magnesium Alloy Tubes. Adv. Mater. Res. 2012, 418–420, 1036–1039. [Google Scholar] [CrossRef]

- Palm, B. Heat transfer in microchannels. Nanoscale Microscale Thermophys. Eng. 2001, 5, 155–175. [Google Scholar] [CrossRef]

- Hartl, C. Deformation mechanism and fundamentals of hydroforming. In Hydroforming for Advanced Manufacturing, 1st ed.; Koc, M., Ed.; Woodhead Publishing: Cambridge, UK, 2008; pp. 52–76. [Google Scholar] [CrossRef]

- Koc, M.; Cora, O.N. Introduction and state of the art of hydroforming. In Hydroforming for Advanced Manufacturing, 1st ed.; Koc, M., Ed.; Woodhead Publishing: Cambridge, UK, 2008; pp. 1–29. [Google Scholar] [CrossRef]

- Lee, M.-G.; Korkolis, Y.P.; Kim, J.H. Recent developments in hydroforming technology. J. Eng. Manuf. 2015, 229, 572–596. [Google Scholar] [CrossRef]

- Yuan, S.J.; Liu, G. Tube Hydroforming. In Comprehensive Materials Processing, 1st ed.; Hashmi, M.S.J., Ed.; Elsevier: Amsterdam, The Netherland, 2014; Volume 3, pp. 55–80. [Google Scholar]

- Lihui, L.; Kangning, L.; Cai, G.; Yang, X.; Guo, C.; Bu, G. A critical review on special forming processes and associated research for lightweight components based on sheet and tube materials. Manuf. Rev. 2014, 1, 1–20. [Google Scholar] [CrossRef]

- Hartl, C. Research and advances in fundamentals and industrial application of hydroforming. J. Mater. Process. Technol. 2005, 167, 383–392. [Google Scholar] [CrossRef]

- Hartl, C.; Anyasodor, G. Experimental and Numerical Investigations into Micro-Hydroforming Processes and Machine Design. In Proceedings of the 13th International Conference on Metal Forming, Toyohashi, Japan, 19–22 September 2010; pp. 1193–1196. [Google Scholar]

- Wagner, S.W.; Ng, K.; Emblom, W.J.; Camelio, J.A. Influence of continuous direct current on the microtube hydroforming process. J. Manuf. Sci. Eng. 2017, 139, 034502. [Google Scholar] [CrossRef]

- Manabe, K.; Sato, H.; Itai, K.; Vilotic, M.; Tada, K. Factors influencing the forming characteristics in micro tube hydroforming by ultra high-forming pressure. Procedia Eng. 2017, 207, 2334–2339. [Google Scholar] [CrossRef]

- Manabe, K.; Itai, K.; Sato, H.; Vilotic, M.; Takahashi, S. FE analysis of micro tube hydroforming process for cross- and T-shaped components. In Proceedings of the 7th International Conference on Tube Hydroforming (TUBEHYDRO 2017), Bangkok, Thailand, 14–17 November 2017; pp. 37–42. [Google Scholar]

- Manabe, K.; Itai, K.; Tada, K. Fabrication of micro T-shaped tubular components by hydroforming process. In Proceedings of the 20th International ESAFORM Conference on Material Forming, Dublin, Ireland, 26–28 April 2017; p. 050017. [Google Scholar]

- Manabe, K.; Vilotic, M.; Itai, K.; Tada, K. Failures in micro cross-shaped tube hydroforming process. In Proceedings of the 14th International Conference on Fracture (ICF 14), Rhodes, Greece, 18–23 June 2017; pp. 1–2. [Google Scholar]

- Ngaile, G.; Lowrie, J. Micro-Tube Hydroforming System Based on Floating Die Assembly. In 60 Excellent Inventions in Metal Forming, 1st ed.; Tekkaya, A.E., Homberg, W., Brosius, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 427–432. [Google Scholar]

- Ngaile, G.; Lowrie, J. New Micro Tube Hydroforming System Based on Floating Die Assembly Concept. J. Micro Nano-Manuf. 2014, 2, 041004. [Google Scholar] [CrossRef]

- Hartl, C.; Chlynin, A.; Radetzky, M. Investigations into Forming Limits and Process Control of Micro-Hydroforming. In Proceedings of the 7th International Conference on Tube Hydroforming (TUBEHYDRO 2015), Xi’an, China, 9–11 September 2015; pp. 3–16. [Google Scholar]

- Hartl, C. Micro-hydroforming. In Micromanufacturing Engineering and Technology, 2nd ed.; Qin, Y., Ed.; Elsevier: Oxford, UK, 2015; pp. 323–345. [Google Scholar] [CrossRef]

- Hartl, C.; Chlynin, A.; Radetzky, M. The influence of axial compressive stresses on the formability and scattering of process parameters in micro-hydroforming processes of tubes. In Proceedings of the 4th International Conference on New Forming Technology (ICNFT 2015), Glasgow, UK, 6–9 August 2015; p. 06001. [Google Scholar] [CrossRef]

- Hartl, C.; Schiefer, H.; Chlynin, A. Evaluation of experimental and numerical investigations into micro-hydroforming of platinum tubes for industrial application. Manuf. Rev. 2014, 1, 1–7. [Google Scholar] [CrossRef]

- Zhuang, W.; Wang, S.; Lin, J.; Balint, D.; Hartl, C. Experimental and numerical investigation of localized thinning in hydroforming of micro-tubes. Eur. J. Mech. A/Solids 2012, 31, 67–76. [Google Scholar] [CrossRef]

- Wagner, S.W.; Ng, K.; Emblom, W.J.; Camelio, J.A. Effect of continuous direct current on the yield stress of stainless steel 304 micro tubes during hydroforming operations. In Proceedings of the ASME 2012 International Manufacturing Science and Engineering Conference (MSEC2012), Notre Dame, IN, USA, 4–8 June 2012; pp. 1–8. [Google Scholar]

- Wagner, S.W.; Ng, K.; Emblom, W.J.; Camelio, J.A. Influence of continuous direct current on the micro tube hydroforming process. In Proceedings of the ASME 2011 International Manufacturing Science and Engineering Conference (MSEC2011), Corvallis, OR, USA, 13–17 June 2011; pp. 1–6. [Google Scholar]

- Hartl, C.; Anyasodor, G.; Lungershausen, J. Formability of Micro-Tubes in Hydroforming. In Proceedings of the 14th International ESAFORM Conference on Metal Forming, Belfast, Ireland, 27–29 April 2011; pp. 529–534. [Google Scholar] [CrossRef]

- Zhuang, W.; Wang, S.; Cao, J.; Lin, J.; Hartl, C. Modelling of localised thinning features in hydroforming of micro-tubes using crystal plasticity FE method. Int. J. Adv. Manuf. Technol. 2010, 47, 859–865. [Google Scholar] [CrossRef]

- Ngaile, G.; Lowrie, J. Punch design for floating based micro-tube hydroforming die assembly. J. Mater. Process. Technol. 2018, 253, 168–177. [Google Scholar] [CrossRef]

- Lowrie, J.; Ngaile, G. Scalability of conventional tube hydroforming processes from macro to micro/meso. J. Eng. Manuf. 2018, 232, 2164–2177. [Google Scholar] [CrossRef]

- Sato, H.; Kobayashi, D.; Manabe, K. Numerical and experimental investigations of cross shaped micro tube forming. In Proceedings of the 7th International Conference on Tube Hydroforming (TUBEHYDRO 2015), Xi’an, China, 9–11 September 2015; pp. 64–69. [Google Scholar]

- Wagner, S.W.; Ng, K.; Emblom, W.J.; Camelio, J.A. Novel high pressure sealing system for tube hydroforming. In Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference (MSEC2013), Madison, WI, USA, 10–14 June 2013; pp. 1–10. [Google Scholar]

- Hartl, C.; Anyasodor, G.; Ptaschlik, T.; Lungershausen, J.; Lippert, S. Investigation into reduction of die-cavity deflection in micro-hydroforming processes using FEA. Int. J. Adv. Manuf. Technol. 2010, 47, 853–858. [Google Scholar] [CrossRef]

- Hartl, C.; Anyasodor, G. Design and development of a new machine system for the mass manufacture of complex shaped tubular components by micro-hydroforming. In Proceedings of the 9th International Conference on Exhibition on Laser Metrology, Machine Tool, CMM & Robotic Performance (Lamdamap 2009), London, UK, 29 June–2 July 2009; pp. 206–214. [Google Scholar]

- Hartl, C.; Lungershausen, J.; Anyasodor, G.; Ptaschlik, T. Development of tools and machines for micro-hydroforming with improved accuracy. Zeszyty Naukowe Instytutu Pojazdów 2008, 5, 157–164. [Google Scholar]

- Vollertsen, F. Laserstrahlumformen—Lasergestützte Formgebung: Verfahren Mechanismen, Modellierung; Meisenbach Verlag: Bamberg, Germany, 1996. [Google Scholar]

- Wielage, H.; Vollertsen, F. Increase of Acting Pressure by Adjusted Tool Geometry in Laser Shock Forming. In Proceedings of the International Conference on Advances in Materials and Processing Technologies (AMPT 2010), Paris, France, 24–27 October 2010; pp. 763–768. [Google Scholar]

- Furushima, T. Development of Rotary Laser Dieless Forming Apparatus for Micro Metal Bellows. In Proceedings of the 7th International Conference on Tube Hydroforming (TUBEHYDRO 2017), Bangkok, Thailand, 14–17 November 2017; pp. 48–51. [Google Scholar]

- Cheng, C.-M.; Tu, M.-Z.; Teng, T.-P.; Yu, S.-P.; Yu, C.-Y.; Chang, Y.-T. Development of inner-grooved tubes by dieless micro-forming with laser-assisted air pressure. MATEC Web Conf. 2017, 95, 1–4. [Google Scholar] [CrossRef]

- Folkersma, G.; Brouwer, D.; Römer, G.-W. Microtube Laser Forming for Precision Component Alignment. J. Manuf. Sci. Eng. 2016, 138, 081012. [Google Scholar] [CrossRef]

- Folkersma, K.G.P.; Brouwer, D.M.; Römer, G.R.B.E.; Herder, J.L. Robust precision alignment algorithm for micro tube laser forming. Precis. Eng. 2016, 46, 301–308. [Google Scholar] [CrossRef]

- Che Jamil, M.S.; Imam Fauzi, E.R.; Juinn, C.S.; Sheikh, M.A. Laser bending of pre-stressed thin-walled nickel micro-tubes. Opt. Laser Technol. 2015, 73, 105–117. [Google Scholar] [CrossRef]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Ebrahimi, R. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2019, 100, 1647–1694. [Google Scholar] [CrossRef]

- Bruder, E. Formability of Ultrafine Grained Metals Produced by Severe Plastic Deformation – An Overview. Adv. Eng. Mater. 2019, 21, 1800316. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Segal, V. Review: Modes and Processes of Severe Plastic Deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef]

- Faraji, G.; Kim, H.S. Review of principles and methods of severe plastic deformation for producing ultrafine-grained tubes. Mater. Sci. Technol. 2016, 1–20. [Google Scholar] [CrossRef]

- Amani, S.; Faraji, G.; Mehrabadi, H.K.; Baghani, M. Manufacturing and mechanical characterization of Mg-4Y-2Nd-0.4Zr-0.25La magnesium microtubes by combined severe plastic deformation process for biodegradable vascular stents. J. Eng. Manuf. 2018, 233, 1–10. [Google Scholar] [CrossRef]

- Ge, Q.; Dellasega, D.; Demir, A.G.; Vedani, M. The processing of ultrafine-grained Mg tubes for biodegradable stents. Acta Biomat. 2013, 9, 8604–8610. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Studies of the interactive effect of specimen and grain sizes on the plastic deformation behavior in microforming. Int. J. Adv. Manuf. Technol. 2012, 62, 989–1000. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W.; Lu, J. The size effect on micro deformation behaviour in micro-scale plastic deformation. Mater. Des. 2011, 32, 198–206. [Google Scholar] [CrossRef]

- Barbier, C.; Thibaud, S.; Richard, F.; Picart, P. Size effects on material behavior in microforming. Int. J. Mater. Form. 2009, 2, 625–628. [Google Scholar] [CrossRef]

- Chen, F.-K.; Tsai, J.-W. A study of size effect in micro-forming with micro-hardness tests. J. Mater. Process Technol. 2006, 177, 146–149. [Google Scholar] [CrossRef]

- Raulea, L.V.; Goijaerts, A.M.; Govaert, L.E.; Baaijens, F.P.T. Size effects in the processing of thin metal sheets. J. Mater. Process. Technol. 2001, 115, 44–48. [Google Scholar] [CrossRef]

- Geiger, M.; Messner, A.; Engel, U. Production of micro parts—Size effects in bulk metal forming, similarity theory. Prod. Eng. 1997, 4, 55–58. [Google Scholar]

- Jiang, C.-P.; Chen, C.-C.; Wu, Y.-S.; Tsai, C.-H. Effect of annealing on grain size and flaring limit of seamless SUS 304 stainless microtubes. J. Chin. Inst. Eng. 2012, 35, 37–43. [Google Scholar] [CrossRef]

- Mirzai, M.A.; Manabe, K. Tribological behavior and surface characteristics of metal microtube in flaring test. J. Solid Mech. Mater. Eng. 2009, 3, 375–386. [Google Scholar] [CrossRef]

- Mirzai, M.A.; Manabe, K. Effect of tool surface topography on interfacial deformation behaviour of metal microtubes in flaring test. Int. J. Surf. Sci. Eng. 2009, 3, 391–406. [Google Scholar] [CrossRef]

- Mirzai, M.A.; Manabe, K. FE Analysis of Size Effect on Deformation Behavior of Metal Microtube Considering Surface Roughness in Flaring Test. Mater. Sci. Forum 2009, 623, 79–87. [Google Scholar] [CrossRef]

- Mirzai, M.A.; Manabe, K.; Mabuchi, T. Deformation characteristics of microtubes in flaring test. J. Mater. Process. Technol. 2008, 201, 214–219. [Google Scholar] [CrossRef]

- Korkolis, Y.P.; Ripley, P.W.; Knysh, P. Failure of an austenitic stainless steel under linear and non-linear loading paths. In Proceedings of the 24th International Congress of Theoretical and Applied Mechanics (ICTAM 2016), Montreal, QC, Canada, 22–26 August 2016; pp. 2102–2103. [Google Scholar]

| Industries | Examples of Products | Typical Materials |

|---|---|---|

| Medical engineering | Painless injection needles Catheters Stents Needles for cosmetic surgery Implants | Stainless steel Titanium/titanium alloys Magnesium/magnesium alloys |

| Electronic and electrical engineering | Contact probes Electrode tubes for EDM | Nickel/nickel alloys Copper/copper alloys |

| Optoelectronics | Optical fibers Laser accelerators | Nickel/nickel alloys Kovar |

| Chemical technology | Micro-reactors Micro-nozzles | Stainless steel Titanium/titanium alloys |

| Sensing technology | Differential gas pressure detector Micro-quantitative analysis device | Platinum/platinum alloys Tungsten/tungsten alloys |

| Heat transfer technology | Micro-heat exchanger | Titanium/titanium alloys Aluminum/aluminum alloys |

| Tube Dimensions | |||||

|---|---|---|---|---|---|

| Listed Shaping Techniques | Material | do (mm) | t (µm) | Designated Application | Reference |

| Machining, hot extrusion, dieless drawing (IH) | Superplastic alloy (Zn-22Al) | 0.19 | 49.5 | - | [35] |

| Machining, hot extrusion, multi-pass dieless drawing (IH) | Superplastic alloy (Zn-22Al) | 0.343 | 91 | MN, SP | [32] |

| Rotary laser multi-pass dieless drawing | β Titanium alloy (Ti-22V-4Al) | <0.5 | <130 | CA, ME, ST | [23] |

| Rotary laser dieless drawing | Stainless steel (SUS304) | <0.5 | <130 | - | [25,27] |

| Dieless drawing (IH) | Stainless steel (SUS304) | <0.5 | <130 | - | [24] |

| Laser dieless drawing | Stainless steel (SUS304) | <0.52 | <100 | MN, IN, MH | [29,30] |

| ECAP, hot extrusion, dieless drawing (IH) | Magnesium alloy (AZ31) | <2.0 | <500 | BI | [31] |

| Extrusion, multi-pass dieless mandrel drawing (IH) | Magnesium alloy (AZ31) | 3.35 | 690 | ME, SA, CH | [21] |

| Extrusion, rotary laser dieless drawing | Magnesium alloy (AZ31) | <5.0 | <500 | – | [22] |

| Dieless drawing (IH) | Stainless steel (SUS304) | <6.35 | <1000 | – | [26] |

| Hot extrusion, multi-pass dieless drawing (IH) | Superplastic alloy (Zn-22Al) | a | – | MH, CO, FC, ET | [28] |

| Tube Dimensions | |||||

|---|---|---|---|---|---|

| Listed Shaping Techniques | Material | do (mm) | t (µm) | Designated Application | Reference |

| Multi-pass fluid mandrel cold drawing | Stainless steel (SUS304) | 0.2 | 42 | ME, IN | [43] |

| Multi-pass cold drawing (FP, MD) | Shape memory alloy (Ti (51 at. %)-Ni) | 1.48 | 210 | CA, ST | [46] |

| Hot extrusion, multi-pass mandrel cold drawing | Magnesium alloy (Mg-Zn-Y-Nd) | 2.0 | 150 | BS | [36] |

| Multi-pass cold tube sinking | Titanium alloy (Ti-0.2Pd) | 2.4 | 400 | ME | [42] |

| Extrusion, drilling, cold-rolling, cold drawing (SI, MD) | Zinc alloy (Zn-5Mg-1Fe) (wt. %) | 2.5 | 130 | BS | [38] |

| Extrusion, machining, hot indirect extrusion, mandrel cold drawing | Magnesium alloy (ZM21) | 2.9 2.9 | 200 220 | BS | [40,44] |

| Hot extrusion, multi-pass cold-rolling, multi-pass mandrel cold drawing | Magnesium alloys (Mg-Nd-Zn-Zr, AZ31, WE43) | 3.0 | 180 | BS | [39] |

| Multi-pass fluid mandrel cold drawing | Magnesium alloy (AZ31) | 3.6 | 610 | ME | [45] |

| Single-pass mandrel cold drawing | Shape memory alloy (Ni(56 wt %)-Ti) | 4.0 | 400 | - | [37] |

| Hot extrusion, cold-rolling | Magnesium alloy (AZ31) | <7.71 | <900 | BS | [41] |

| Multi-pass cold drawing (SI, FP) | Shape memory alloy (Ti (49.3%)-Ni) | <8.0 | - | ME | [47] |

| Tube Dimensions | |||||

|---|---|---|---|---|---|

| Listed Shaping Techniques a | Material | do (mm) | t (µm) | Number of Grooves | Reference |

| Tube spinning, multi-pass sinking | Copper | 3.0 | >223 | 18 | [50,51] |

| Multi-pass fluid mandrel drawing | Copper | <5.0 | >364 | 45 | [49] |

| Multi-pass fluid mandrel drawing | Copper | 5.1 | 300 | 55 | [43] |

| Tube spinning, multi-pass sinking | Copper | <6.0 | <480 | 12, 18 | [53] |

| Tube spinning | Copper | 6.0 | 300 | 60 | [54] |

| Tube spinning | Copper | 6.0 | - | 60 | [52] |

| Cross-Section Dimensions a | |||||

|---|---|---|---|---|---|

| Material | w (mm) | h (mm) | t (µm) | Number of Channels | Reference |

| Aluminum alloy (AA3003) | 16.0 | 1.8 | 250 | 10 | [57] |

| Aluminum alloy (AA1100) | 16.0 | 2.0 | 300 | 10 | [55,56] |

| Aluminum alloy (AA3003) | – | – | 250 | 17 | [58] |

| Aluminum alloys (A1100, A3003) | – | – | >200 | 12 | [59] |

| Tube Dimensions | |||||

|---|---|---|---|---|---|

| Hydroforming Process Type | Material | do (mm) | t (µm) | Designated Application | Reference |

| T-shape forming (AF) | Copper (1220-H) | 0.5 | 100 | – | [71,72] |

| T-shape forming (AF) | Stainless steel (SUS304) | 0.5 | 100 | – | [70] |

| Cross-shape forming (AF) | Copper (1220-H) | 0.5 | 100 | – | [70,71] |

| Non-axisymmetric expansion | Stainless steel (AISI 304) | 0.8 | 40 | MF | [68,89] |

| Rotationally symmetrical expansion | Stainless steel (AISI 304) | 0.8 | 40 | MS | [89,91] |

| Rotationally symmetrical expansion. (AF) | Stainless steel (SS 304) | 1.0 | 100 | – | [75] |

| Rotationally symmetrical expansion (AF) | Platinum (PtIr10) | 1.65 | 76 | ME | [78,79] |

| Rotationally symmetrical expansion (AF) Axisymmetric expansion (AF) T-shape forming (AF) Y-shape forming (AF) | Stainless steel (SS 304) | 2.0 | 160 | – | [75] |

| Rotationally symmetrical expansion (AF) Axisymmetric expansion (AF) T-shape forming (AF) Y-shape forming (AF) | Stainless steel (SS 304) | 2.0 | 200 | – | [85] |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hartl, C. Review on Advances in Metal Micro-Tube Forming. Metals 2019, 9, 542. https://doi.org/10.3390/met9050542

Hartl C. Review on Advances in Metal Micro-Tube Forming. Metals. 2019; 9(5):542. https://doi.org/10.3390/met9050542

Chicago/Turabian StyleHartl, Christoph. 2019. "Review on Advances in Metal Micro-Tube Forming" Metals 9, no. 5: 542. https://doi.org/10.3390/met9050542

APA StyleHartl, C. (2019). Review on Advances in Metal Micro-Tube Forming. Metals, 9(5), 542. https://doi.org/10.3390/met9050542